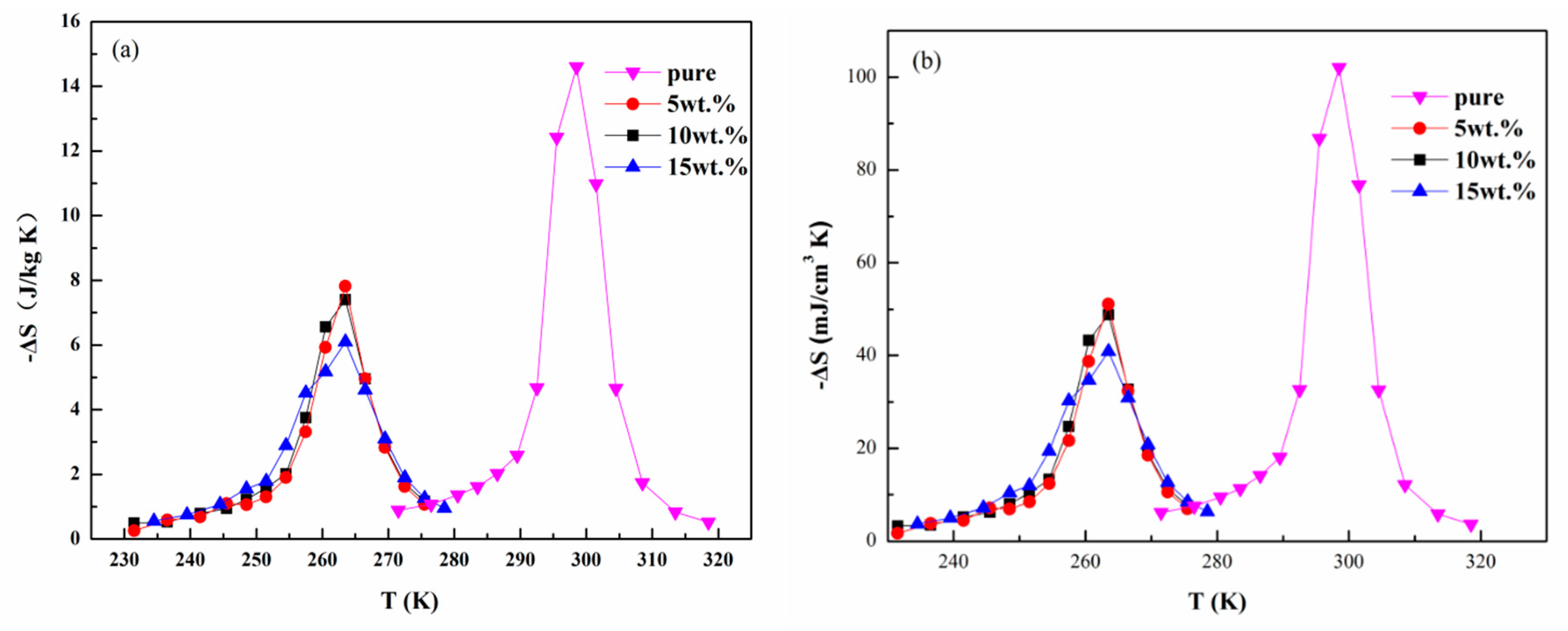

Study of the Microstructure, Mechanical, and Magnetic Properties of LaFe11.6Si1.4Hy/Bi Magnetocaloric Composites

Abstract

:1. Introduction

2. Materials and Methods

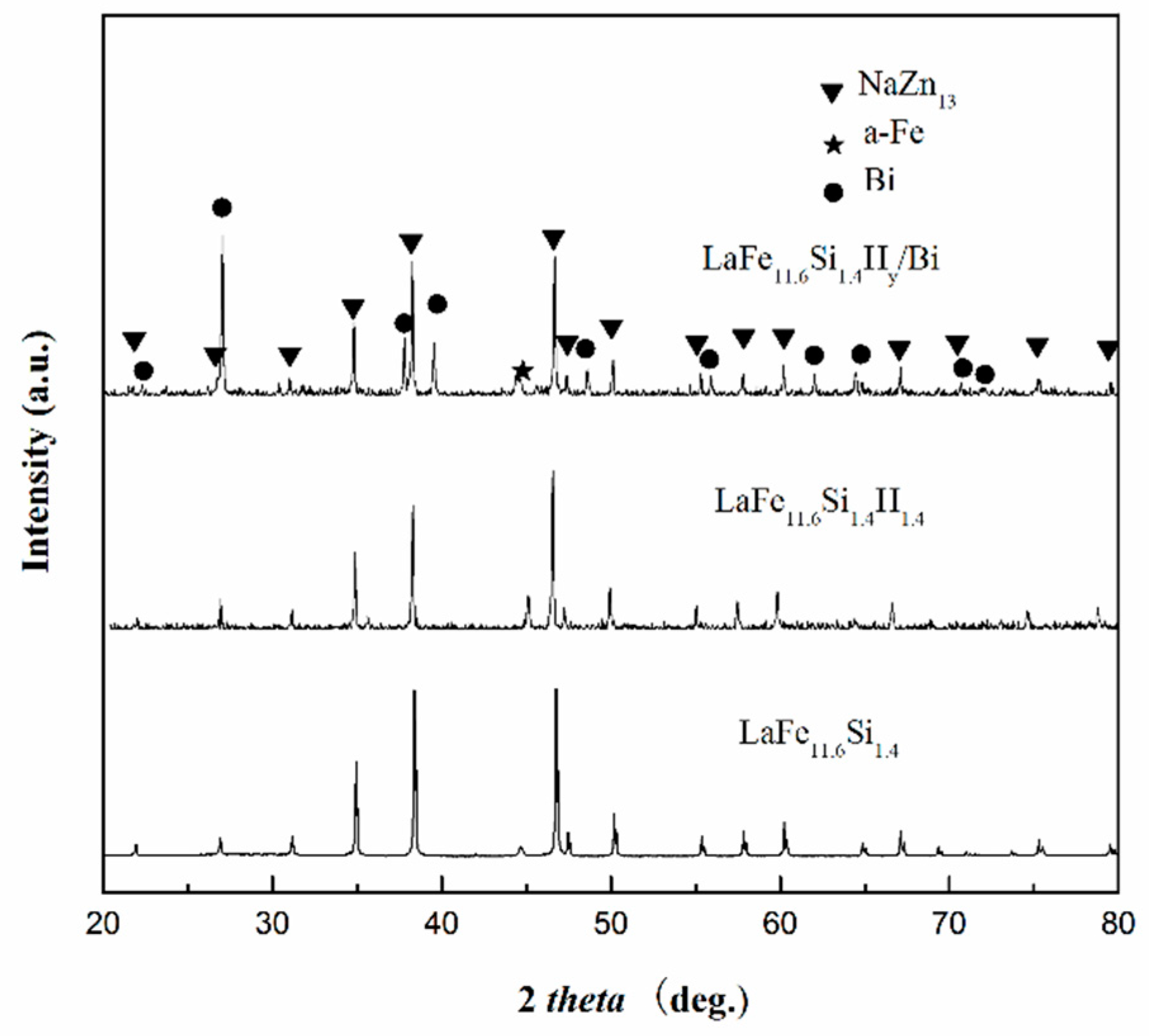

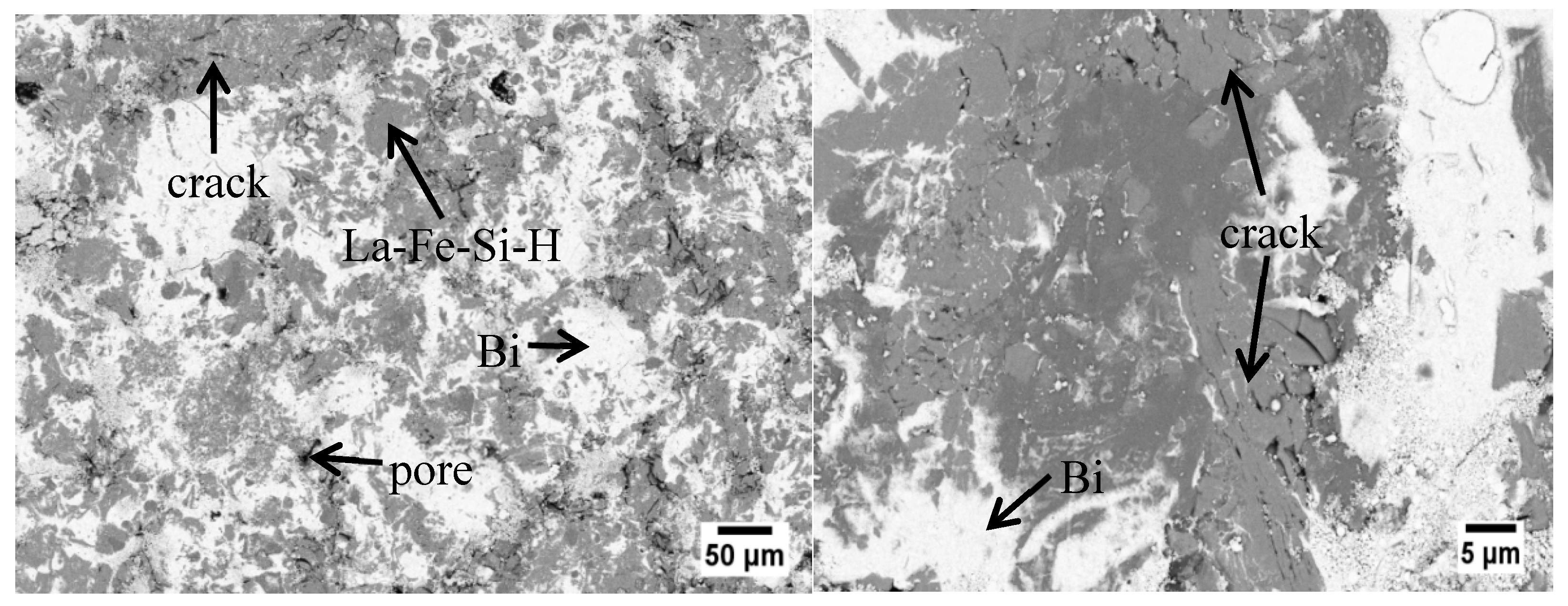

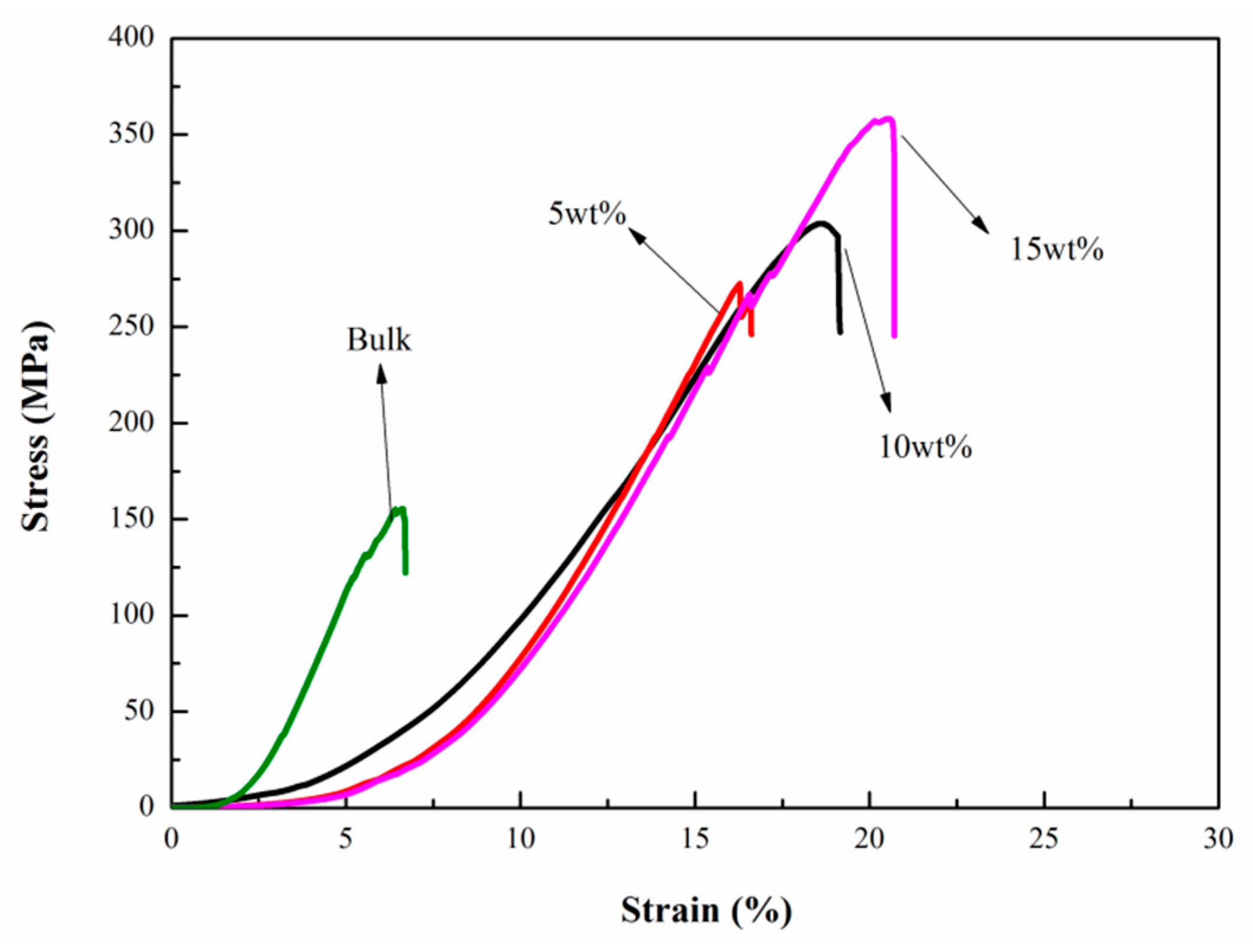

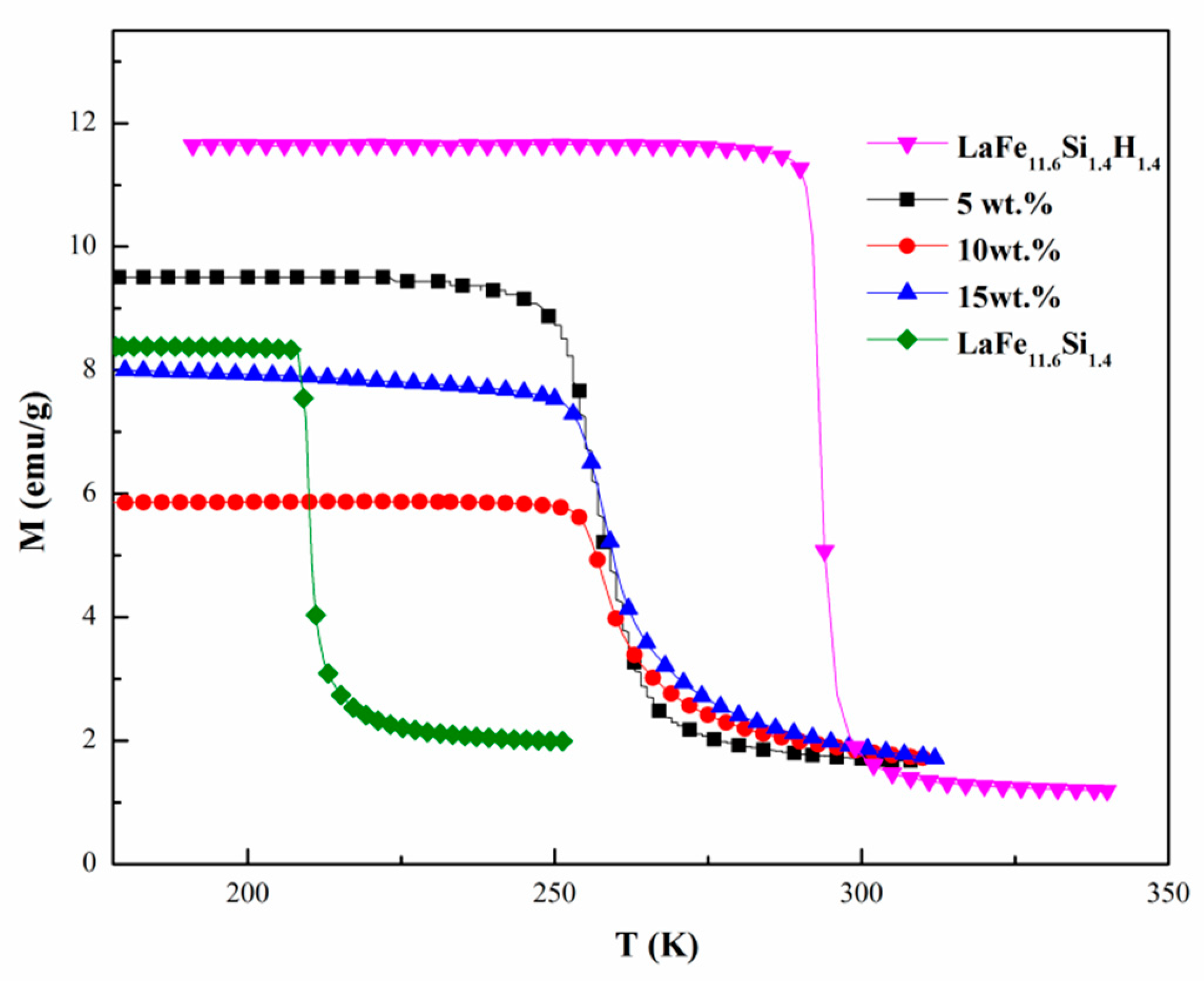

3. Results and Discussion

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Yu, B.F.; Gao, Q.; Zhang, B.; Meng, X.Z.; Chen, Z. Review on research of room temperature magnetic refrigeration. Int. J. Refrig. 2003, 26, 622–636. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, H.D.; Wang, J.; Li, X.; Ren, Z.; Wilde, G. Structure and cryogenic magnetic properties in Ho2BaCuO5 cuprate. Ceram. Int. 2018, 44, 1991–1994. [Google Scholar] [CrossRef]

- Li, L.W. Review of magnetic properties and magnetocaloric effect in the intermetallic compounds of rare earth with low boiling point metals. Chin. Phys. B 2016, 25, 037502. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.K.; Guo, D.; Li, H.; Geng, S.; Wang, J.; Li, X.; Ren, Z.M.; Wilde, G. Low field induced large magnetic entropy change in the amorphousized Tm60Co20Ni20 ribbon. J. Alloys Compd. 2018, 733, 40–44. [Google Scholar] [CrossRef]

- Li, L.; Su, K.; Huo, D. Large reversible normal and inverse magneto-caloric effects in the RE2BaCuO5 (RE = Dy and Er) compounds. J. Alloys Compd. 2018, 735, 773–776. [Google Scholar] [CrossRef]

- Zhang, Y.K.; Yang, Y.; Hou, C.J.; Guo, D.; Wang, J.; Geng, S.H.; Li, X.; Ren, Z.M.; Wilde, G. Metamagnetic transition and magnetocaloric properties in antiferromagnetic Ho2Ni2Ga and Tm2Ni2Ga compounds. Intermetallics 2018, 94, 17–21. [Google Scholar] [CrossRef]

- Li, L.W.; Yuan, Y.; Qi, Y.; Wang, Q.; Zhou, S. Achievement of a table-like magnetocaloric effect in the dual-phase ErZn2/ErZn composite. Mater. Res. Lett. 2018, 6, 67–71. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, Y.; Xu, X.; Geng, S.; Hou, L.; Li, X.; Ren, Z.; Wilde, G. Magnetic and magnetocaloric properties of the ternary cadmium based intermetallic compounds of Gd2Cu2Cd and Er2Cu2Cd. J. Alloys Compd. 2017, 692, 665–669. [Google Scholar] [CrossRef]

- Wang, G.F.; Mu, L.J.; Zhang, X.F.; Zhao, Z.R.; Huang, J.H. Hydriding and dehydriding kinetics in magnetocaloric La(Fe,Si)13 compounds. J. Appl. Phys. 2014, 115, 143903. [Google Scholar] [CrossRef]

- Lyubina, J.; Schäfer, R.; Martin, N.; Schultz, L.; Gutfleisch, O. Novel Design of La(Fe,Si)13 Alloys Towards High Magnetic Refrigeration Performance. Adv. Mater. 2010, 22, 3735–3739. [Google Scholar] [CrossRef] [PubMed]

- Smith, A.; Bahl, C.R.H.; Bjørk, R.; Engelbrecht, K.; Nielsen, K.K.; Pryds, N. Materials Challenges for High Performance Magnetocaloric Refrigeration Devices. Adv. Energy Mater. 2012, 2, 1288–1318. [Google Scholar] [CrossRef]

- Yu, B.F.; Liu, M.; Egolf, P.W.; Kitanovski, A. A review of magnetic refrigerator and heat pump prototypes built before the year 2010. Int. J. Refrig. 2010, 33, 1029–1060. [Google Scholar] [CrossRef]

- Wada, H.; Tanabe, Y. Giant magnetocaloric effect of MnAs1−xSbx. Appl. Phys. Lett. 2001, 79, 3302–3304. [Google Scholar] [CrossRef]

- Hu, F.X.; Shen, B.G.; Sun, J.R. Magnetic entropy change in Ni51.5Mn22.7Ga25.8 alloy. Appl. Phys. Lett. 2000, 76, 3460–3462. [Google Scholar] [CrossRef]

- Krenke, T.; Duman, E.; Acet, M.; Wassermann, E.F.; Moya, X.; Mañosa, L.; Planes, A. Inverse magnetocaloric effect in ferromagnetic Ni–Mn–Sn alloys. Nat. Mater. 2005, 4, 450–454. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lei, T.; Nielsen, K.K.; Engelbrecht, K.; Bahl, C.R.H.; Bez, H.N.; Veje, C.T. Sensitivity study of multi-layer active magnetic regenerators using first order magnetocaloric material La(Fe,Mn,Si)13Hy. J. Appl. Phys. 2015, 118, 014903. [Google Scholar] [CrossRef] [Green Version]

- Fujita, A.; Fujieda, S.; Hasegawa, Y.; Fukamichi, K. Itinerant-electron metamagnetic transition and large magnetocaloric effects in La (FexSi1−x)13 compounds and their hydrides. Phys. Rev. B 2003, 67, 104416. [Google Scholar] [CrossRef]

- Skokov, K.P.; Karpenkov, D.Y.; Kuzmin, M.D.; Radulov, I.A.; Gottschall, T.; Kaeswurm, B.; Fries, M.; Gutfleisch, O. Heat exchangers made of polymer-bonded La(Fe,Si)13. J. Appl. Phys. 2014, 115, 17A941. [Google Scholar] [CrossRef]

- Zhang, H.; Sun, Y.J.; Li, Y.W.; Wu, Y.Y.; Long, Y.; Shen, J.; Hu, F.X.; Sun, J.R.; Shen, B.G. Mechanical properties and magnetocaloric effects in La(Fe, Si)13 hydrides bonded with different epoxy resins. J. Appl. Phys. 2015, 117, 063902. [Google Scholar] [CrossRef]

- Pulko, B.; Tušek, J.; Moore, J.D.; Weise, B.; Skokov, K.; Mityashkin, O.; Kitanovski, A.; Favero, C.; Fajfar, P.; Gutfleisch, O.; et al. Epoxy-bonded La–Fe–Co–Si magnetocaloric plates. J. Magn. Magn. Mater. 2015, 375, 65–73. [Google Scholar] [CrossRef]

- Imamura, W.; Coelho, A.A.; Kupfer, V.L.; Carvalho, A.M.G.; Zago, J.G.; Rinaldi, A.W.; Favaro, S.L.; Alves, C.S. A new type of magnetocaloric composite based on conductive polymer and magnetocaloric compound. J. Magn. Magn. Mater. 2017, 425, 65–71. [Google Scholar] [CrossRef]

- You, C.; Wang, S.; Zhang, J.; Yang, N.; Tian, N. Improvement of magnetic hysteresis loss, corrosion resistance and compressive strength through spark plasma sintering magnetocaloric LaFe11.65Si1.35/Cu core-shell powders. AIP Adv. 2016, 6, 055321. [Google Scholar] [CrossRef]

- Radulov, I.A.; Karpenkov, D.Y.; Skokov, K.P.; Karpenkov, A.Y.; Braun, T.; Brabander, V.; Gottschall, T.; Pabst, M.; Stoll, B.; Gutfleisch, O. Production and properties of metal-bonded La(Fe,Mn,Si)13Hx composite material. Acta Mater. 2017, 127, 389–399. [Google Scholar] [CrossRef]

- Krautz, M.; Funk, A.; Skokov, K.P.; Gottschall, T.; Eckert, J.; Gutfleisch, O.; Waske, A. A new type of La (Fe,Si)13-based magnetocaloric composite with amorphous metallic matrix. Scr. Mater. 2015, 95, 50–53. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, J.; Zhang, M.; Shao, Y.; Li, Y.; Yan, A. LaFe11.6Si1.4Hy/Sn magnetocaloric composites by hot pressing. Scr. Mater. 2016, 120, 58–61. [Google Scholar] [CrossRef]

- Raynor, G.V.; Smith, R.W. The transition temperature of the transition between grey and white tin. Proc. R. Soc. Lond. A 1958, 244, 101–109. [Google Scholar] [CrossRef]

- Zhang, M.X.; Liu, J.; Zhang, Y.; Dong, J.D.; Yan, A.; Skokov, K.P.; Gutfleisch, O. Large entropy change, adiabatic temperature change, and small hysteresis in La(Fe,Mn)11.6Si1.4 strip-cast flakes. J. Magn. Magn. Mater. 2015, 377, 90–94. [Google Scholar] [CrossRef]

- Zhang, H.; Sun, Y.J.; Niu, E.; Hu, F.X.; Sun, J.R.; Shen, B.G. Enhanced mechanical properties and large magnetocaloric effects in bonded La(Fe, Si)13-based magnetic refrigeration materials. Appl. Phys. Lett. 2014, 104, 062407. [Google Scholar] [CrossRef]

- Dong, X.T.; Zhong, X.C.; Peng, D.R.; Huang, J.H.; Zhang, H.; Jiao, D.L.; Liu, Z.W.; Ramanujan, R.V. La0.8Ce0.2(Fe0.95Co0.05)11.8Si1.2/Sn42Bi58magnetocaloric composites prepared by low temperature hot pressing. J. Alloys Compd. 2018, 737, 568–574. [Google Scholar] [CrossRef]

- Hu, F.X.; Chen, L.; Wang, J.; Bao, L.F.; Sun, J.R.; Shen, B.G. Particle size dependent hysteresis loss in La0.7Ce0.3Fe11.6Si1.4C0.2 first-order systems. Appl. Phys. Lett. 2012, 100, 072403. [Google Scholar] [CrossRef]

- Radulov, I.A.; Skokov, K.P.; Karpenkov, D.Y.; Gottschall, T.; Gutfleisch, O. On the preparation of La (Fe,Mn,Si)13Hx polymer-composites with optimized magnetocaloric properties. J. Magn. Magn. Mater. 2015, 396, 228–236. [Google Scholar] [CrossRef]

| Metallic Bi Content (wt %) | Theoretical Density ρ (g/cm3) | Apparent Density ρ (g/cm3) | Porosity (%) |

|---|---|---|---|

| 5 | 7.14 | 6.53 | 8.52 |

| 10 | 7.24 | 6.61 | 8.86 |

| 15 | 7.35 | 6.70 | 8.82 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Z.; Wu, Q.; Sun, N.; Ding, Z.; Li, L. Study of the Microstructure, Mechanical, and Magnetic Properties of LaFe11.6Si1.4Hy/Bi Magnetocaloric Composites. Materials 2018, 11, 943. https://doi.org/10.3390/ma11060943

Liu Z, Wu Q, Sun N, Ding Z, Li L. Study of the Microstructure, Mechanical, and Magnetic Properties of LaFe11.6Si1.4Hy/Bi Magnetocaloric Composites. Materials. 2018; 11(6):943. https://doi.org/10.3390/ma11060943

Chicago/Turabian StyleLiu, Zhengang, Qiming Wu, Naikun Sun, Zan Ding, and Lingwei Li. 2018. "Study of the Microstructure, Mechanical, and Magnetic Properties of LaFe11.6Si1.4Hy/Bi Magnetocaloric Composites" Materials 11, no. 6: 943. https://doi.org/10.3390/ma11060943