Applying Low-Frequency Vibration for the Experimental Investigation of Clutch Hub Forming

Abstract

:1. Introduction

2. Materials and Methods

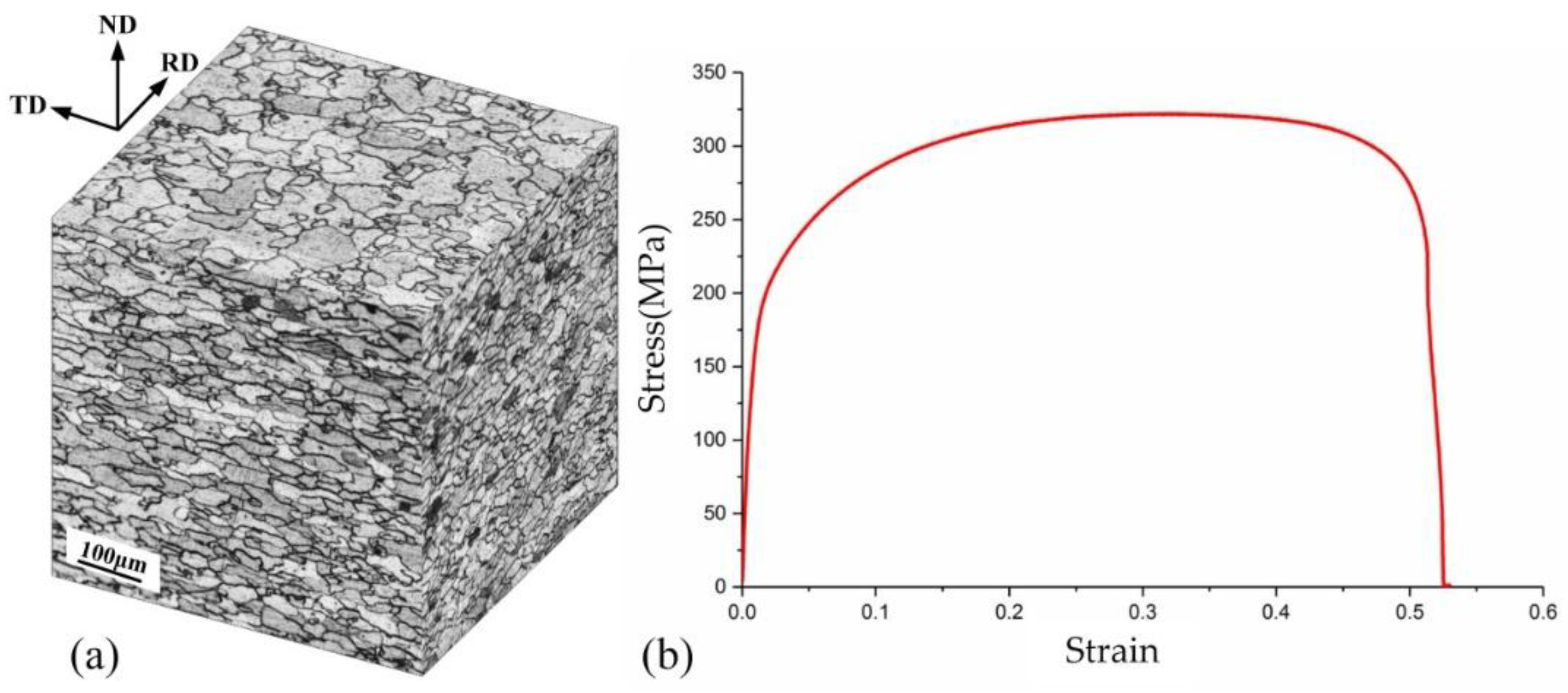

2.1. Material Properties

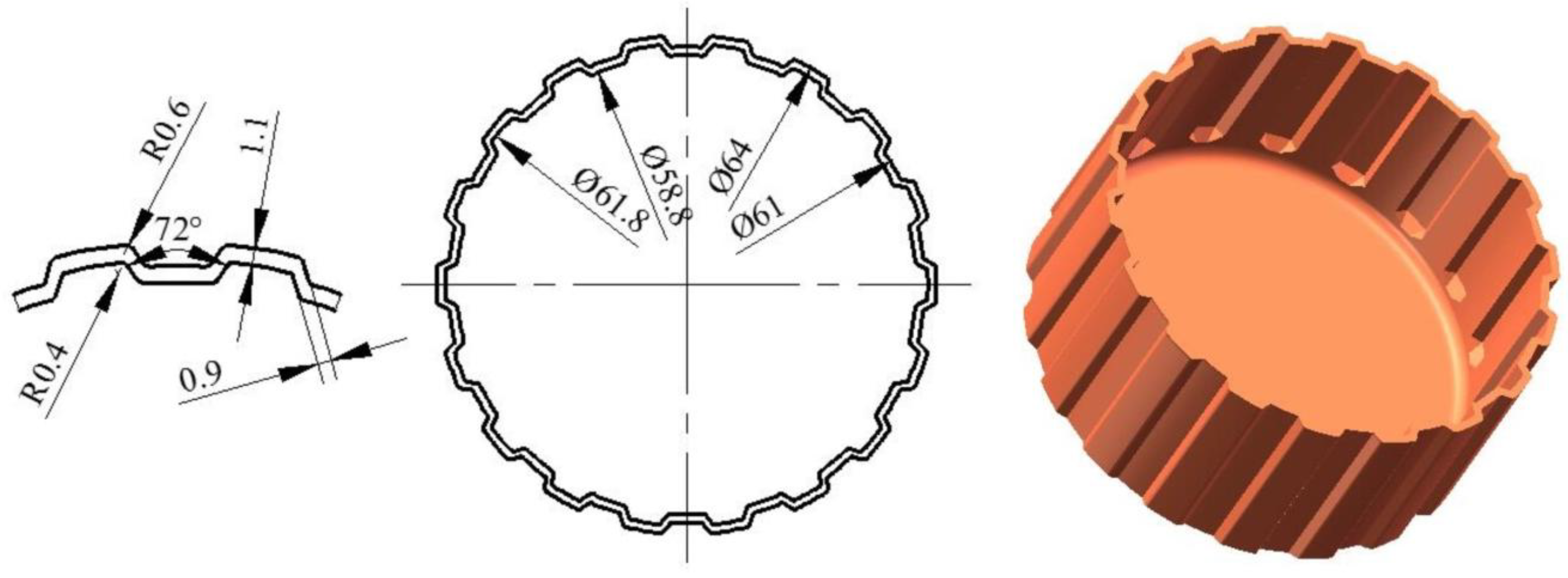

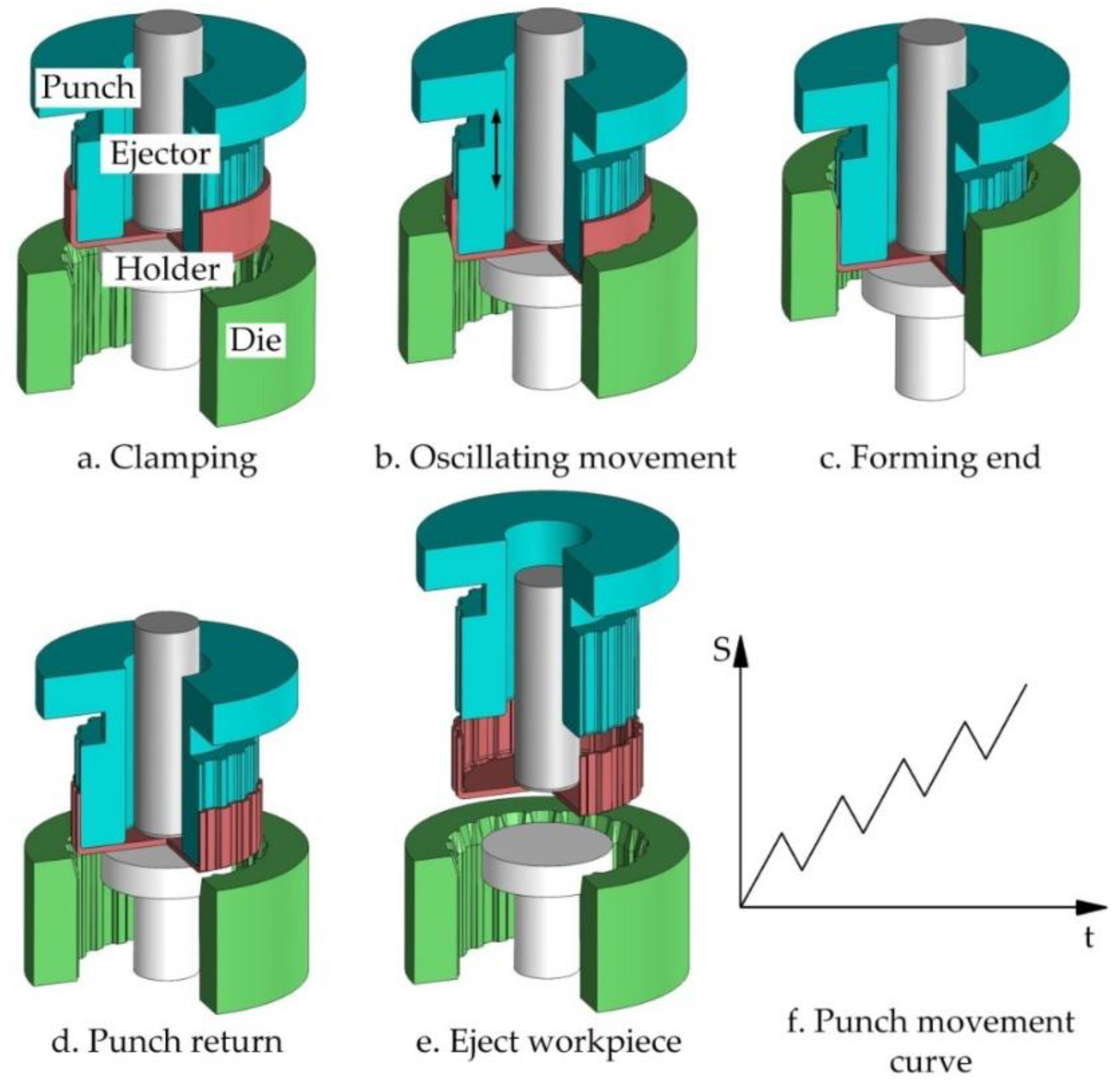

2.2. Process of Vibration-Assisted Clutch Hub Forming

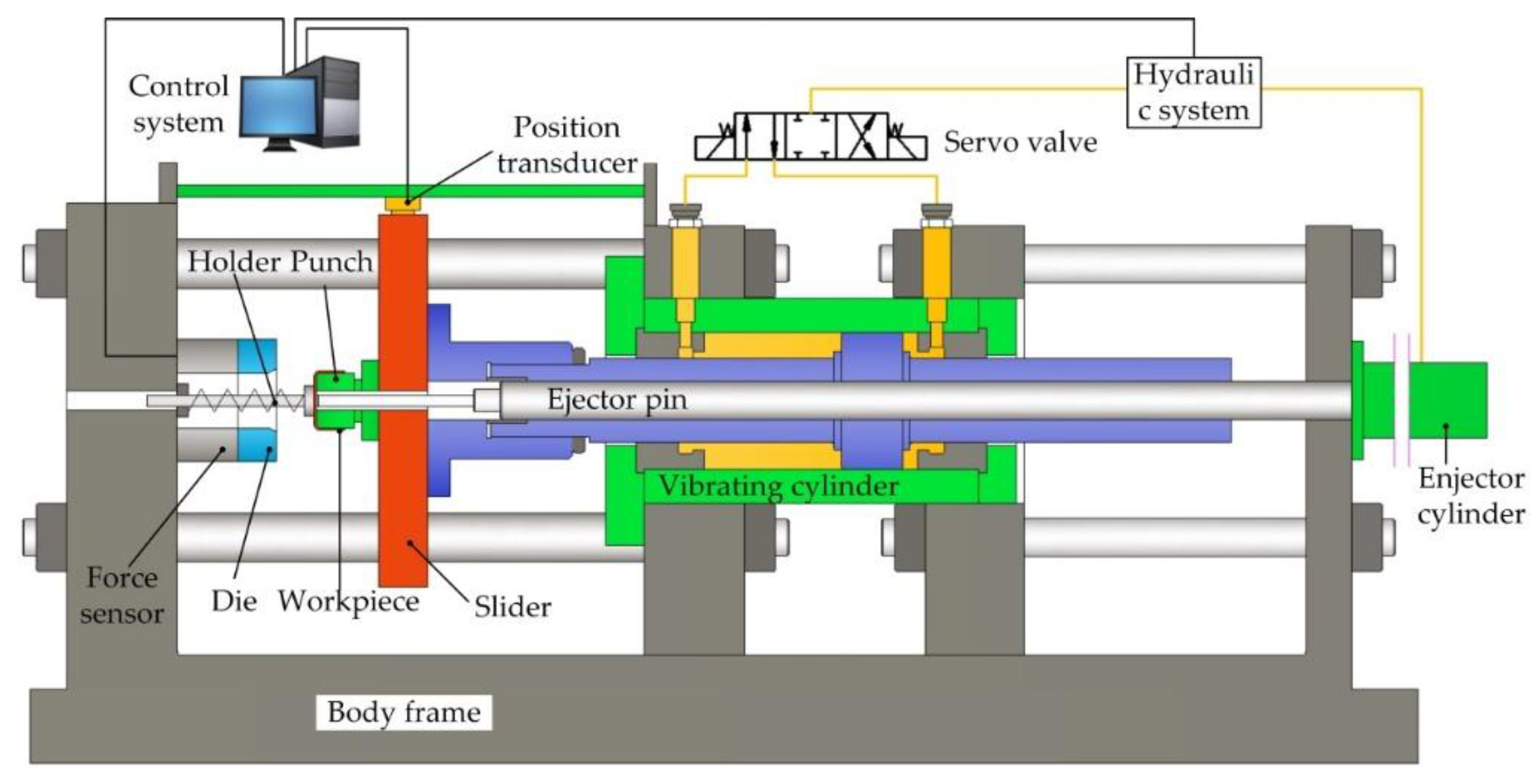

2.3. Experiments

3. Results

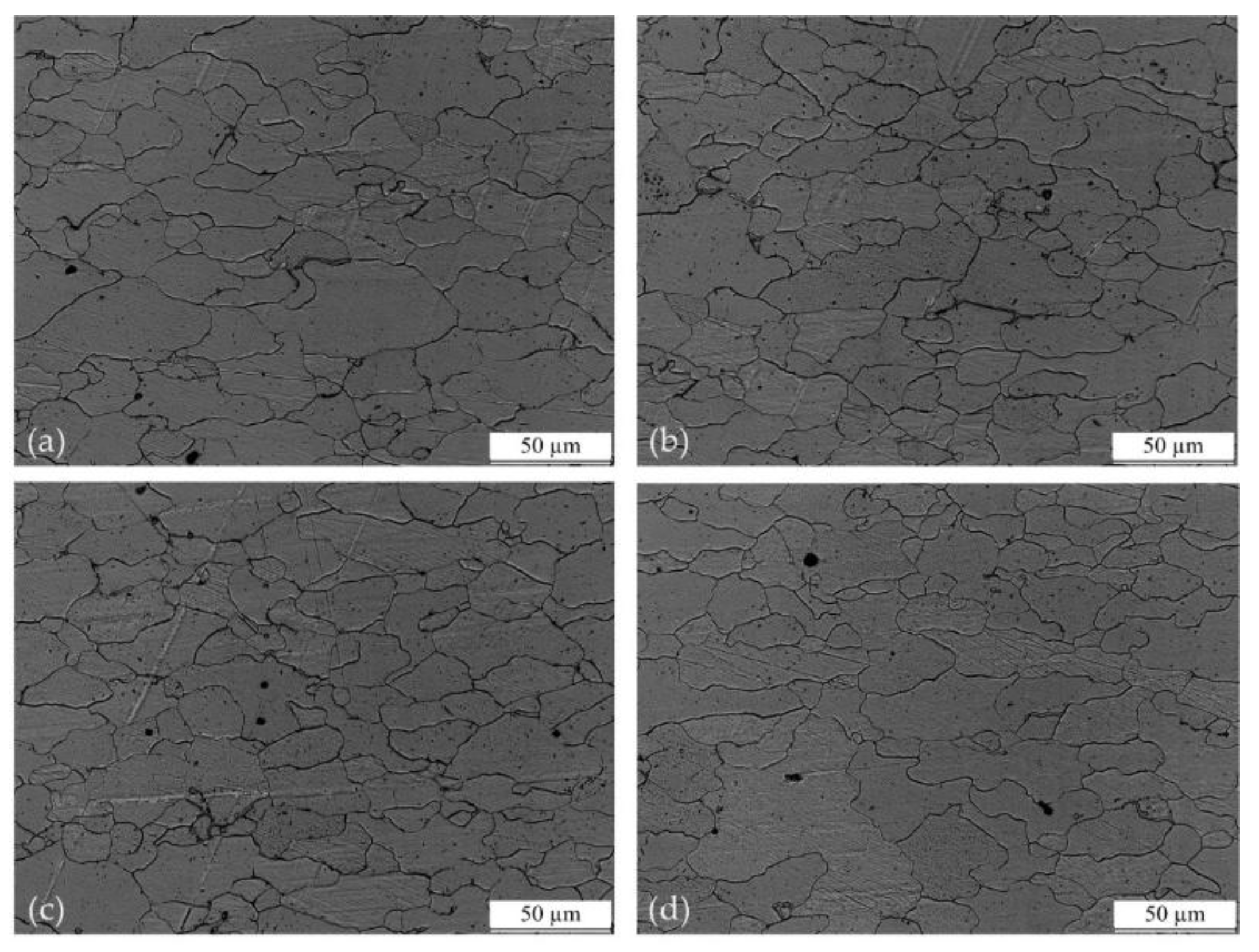

3.1. Microstructure

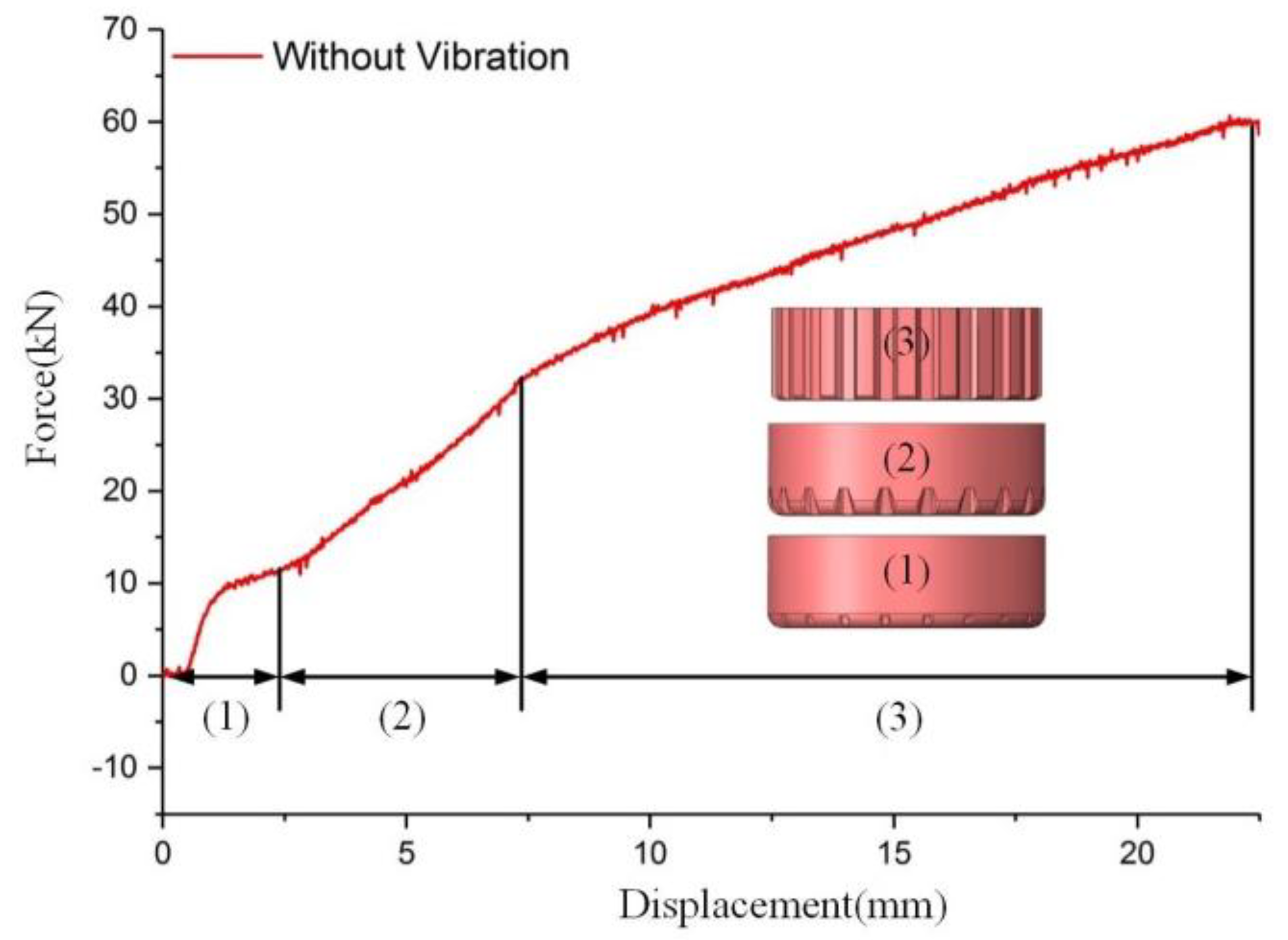

3.2. Forming Force along with Punch Displacement

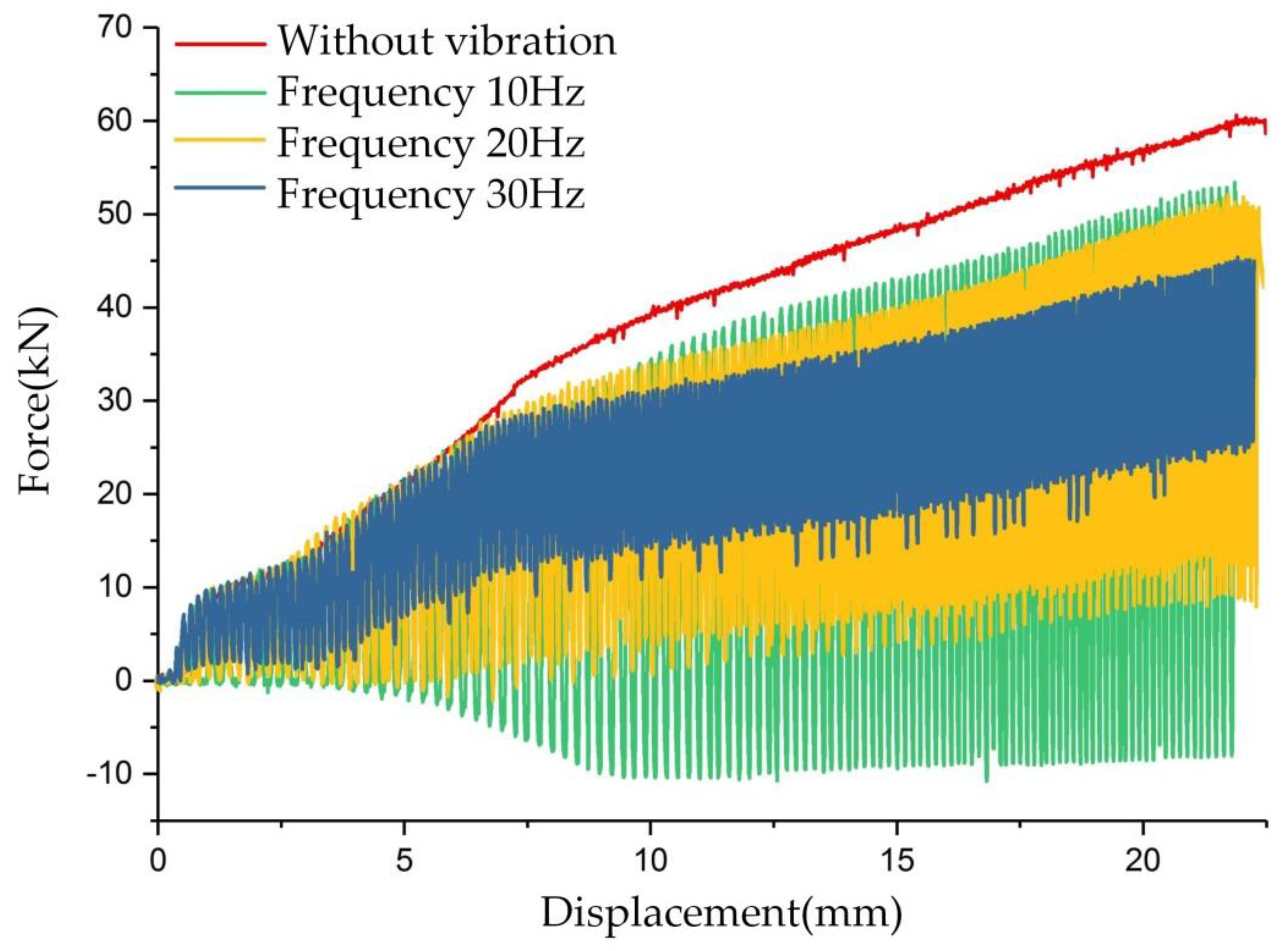

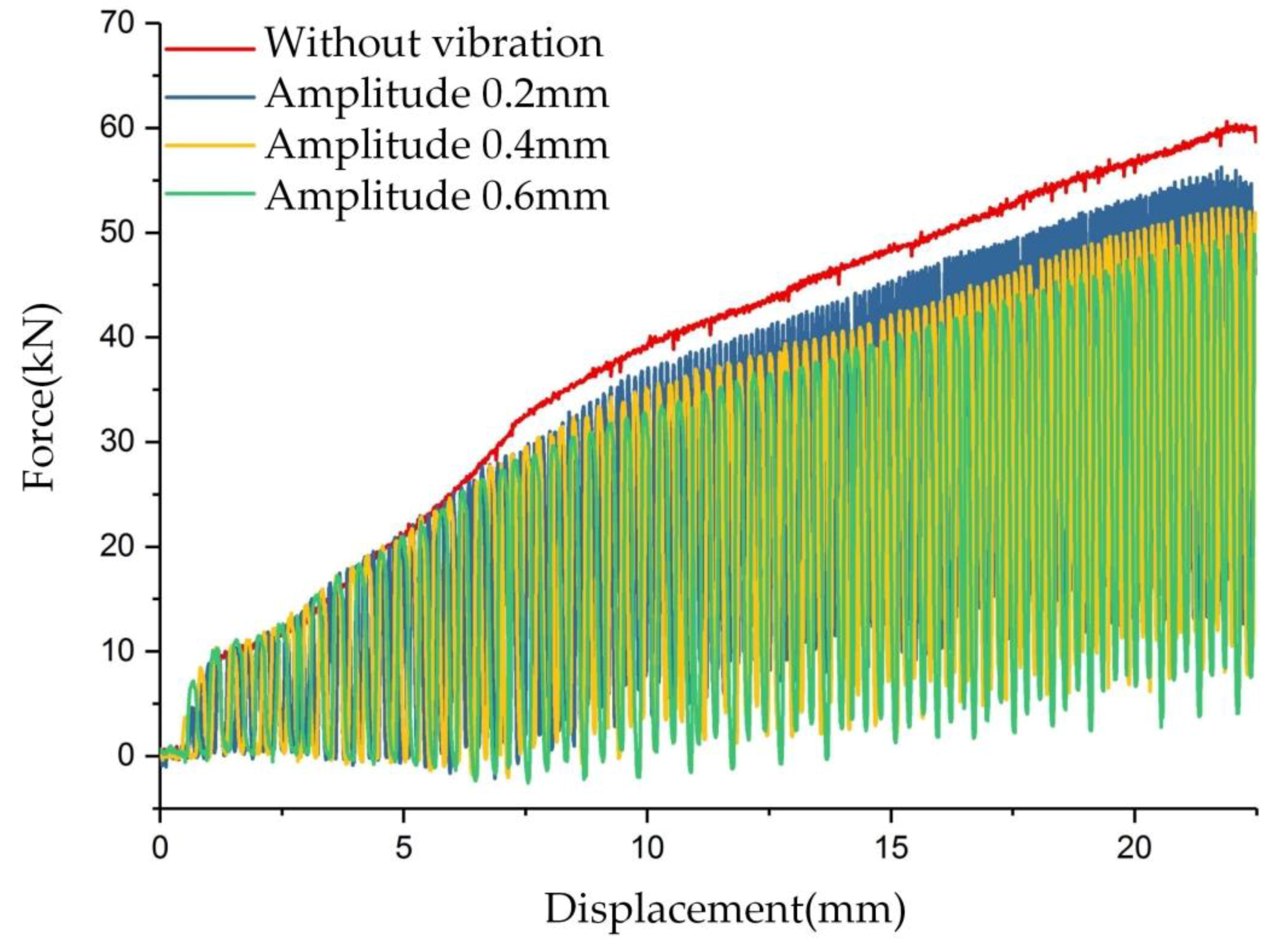

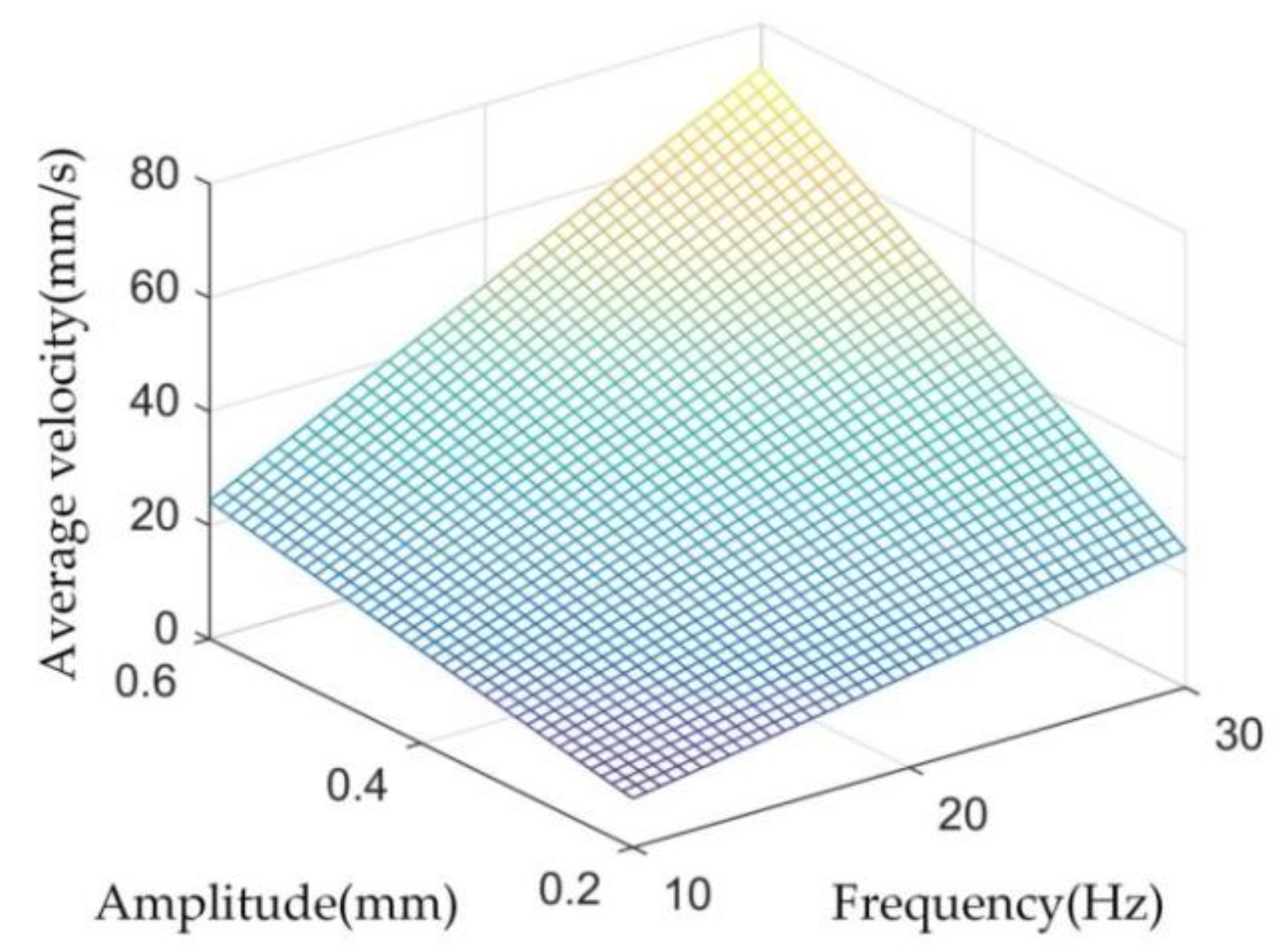

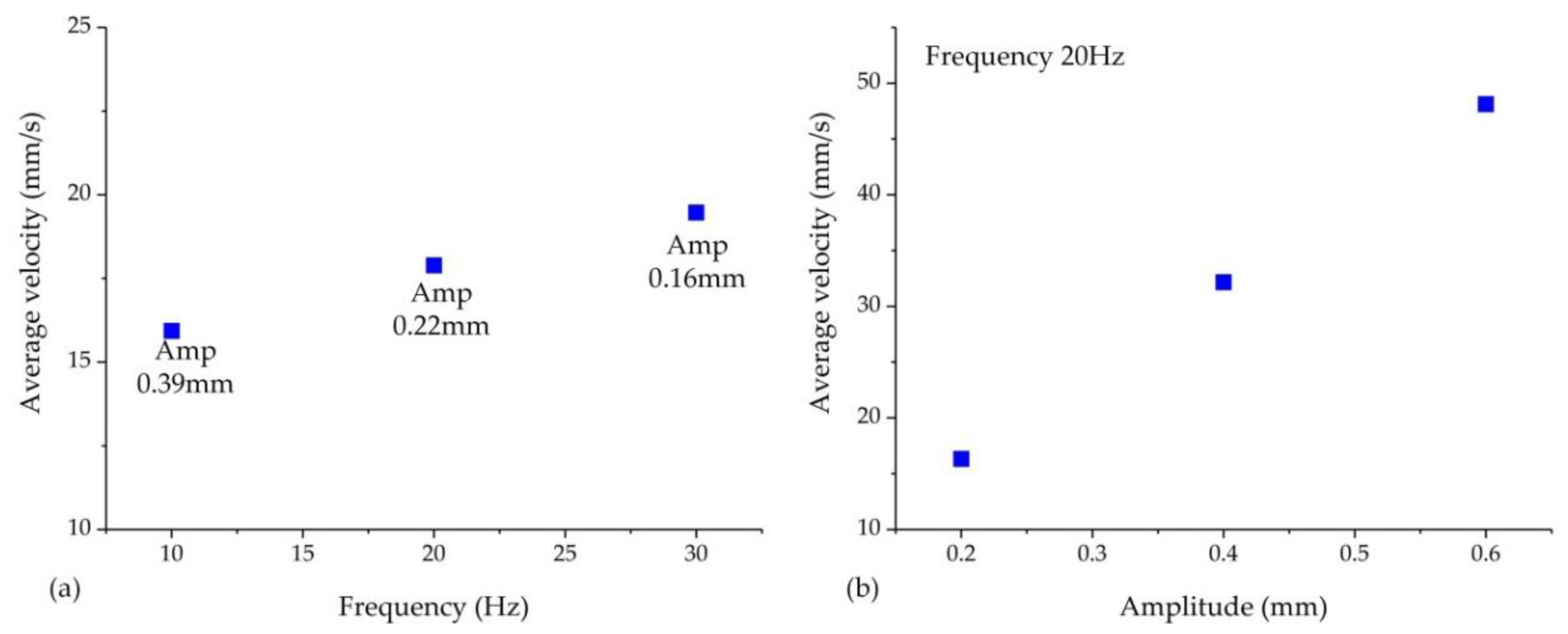

3.3. Influence of Vibration Frequency and Amplitude on Forming Force

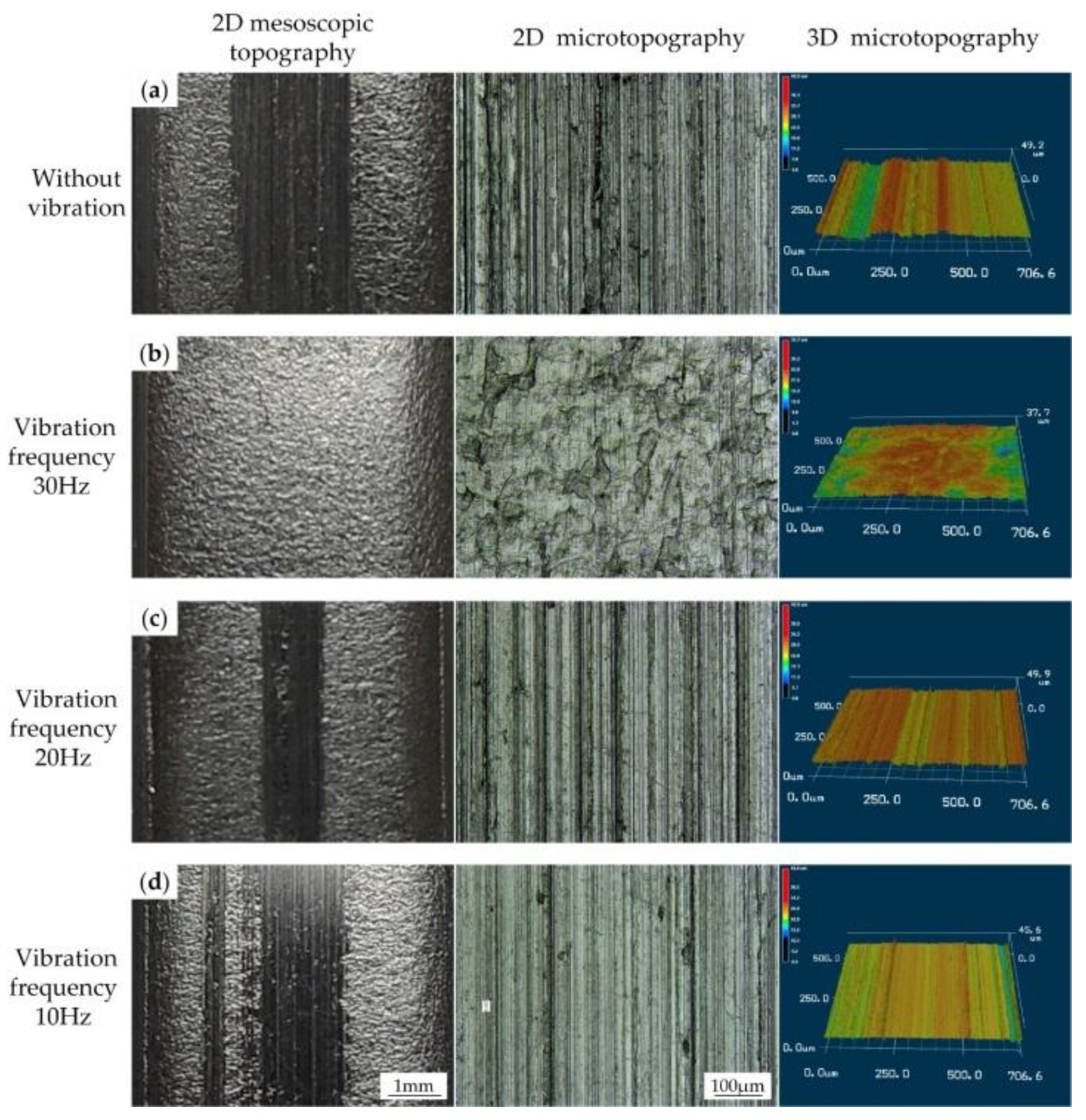

3.4. Influence of Vibration Frequency and Amplitude on Surface Quality

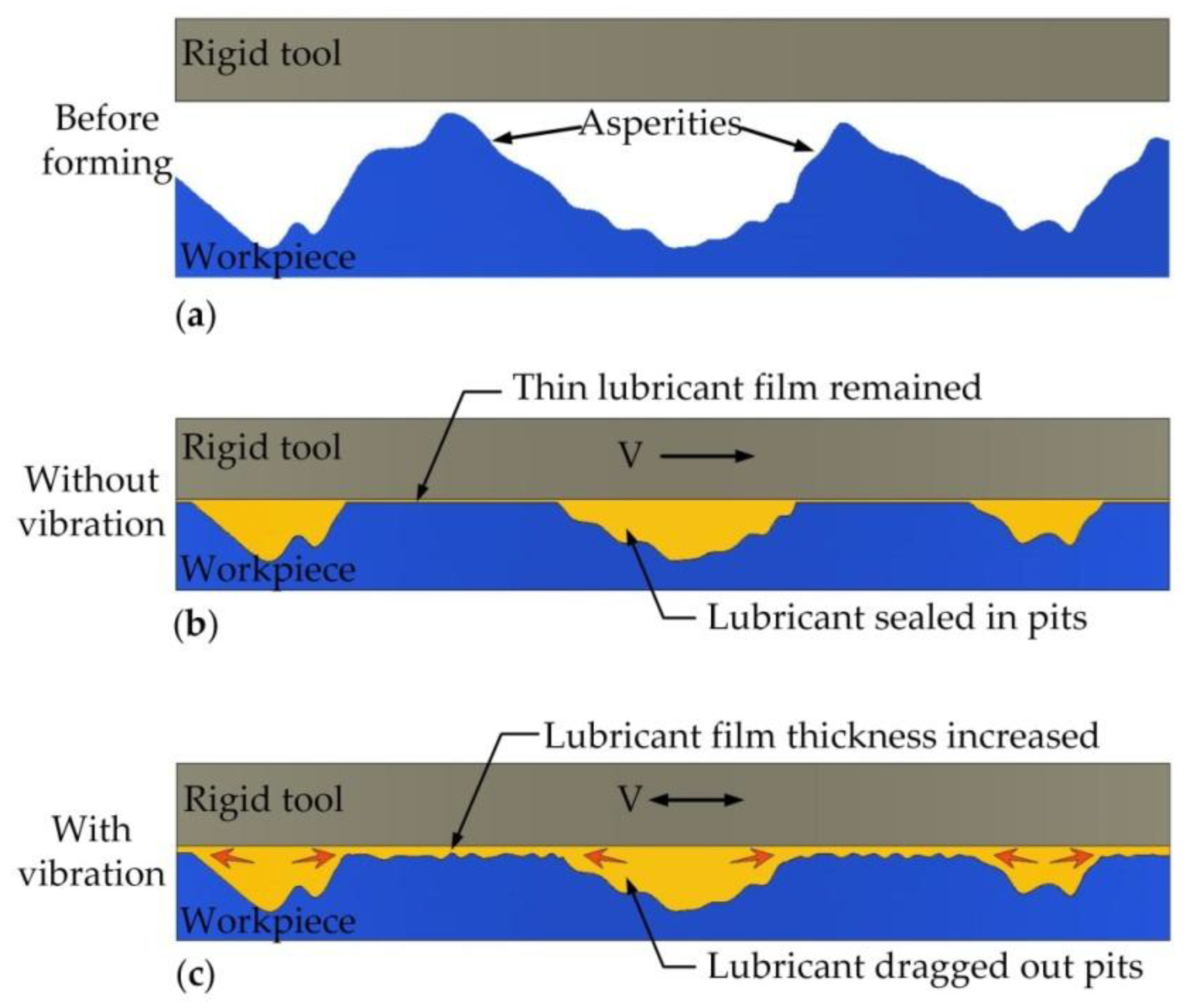

4. Discussion

5. Conclusions

- (1)

- Increases in vibration frequency and amplitude positively affect forming load reduction.

- (2)

- The effect of vibration frequency on the load drop was greater than that of the vibration amplitude.

- (3)

- The forming load decreased with increasing vibration amplitude because the increase in vibration amplitude improved the relative speed between the workpiece and the blank and weakened the adhesion in the interface.

- (4)

- The increase in vibration frequency raises the number of attempts for dragging out lubricant oil from the pits and in turn greatly widens the lubricant film thickness. The 3D microscope results confirmed this notion.

Author Contributions

Funding

Conflicts of Interest

References

- Bouzakis, K.D.; Friderikos, O.; Tsiafis, I. Fem-supported simulation of chip formation and flow in gear hobbing of spur and helical gears. CIRP J. Manuf. Sci. Technol. 2009, 1, 18–26. [Google Scholar] [CrossRef]

- Kim, H.-K.; Hong, S.K. Fem-based optimum design of multi-stage deep drawing process of molybdenum sheet. J. Mater. Process. Technol. 2007, 184, 354–362. [Google Scholar] [CrossRef]

- Hussain, P.; Cheon, J.; Kwak, D.; Kim, S.; Im, Y. Simulation of clutch-hub forging process using campform. J. Mater. Process. Technol. 2002, 123, 120–132. [Google Scholar] [CrossRef]

- Fujikawa, S.; Yoshioka, H.; Shimamura, S. Cold-and warm-forging applications in the automotive industry. J. Mater. Process. Technol. 1992, 35, 317–342. [Google Scholar] [CrossRef]

- Merklein, M.; Allwood, J.M.; Behrens, B.A.; Brosius, A.; Hagenah, H.; Kuzman, K.; Mori, K.; Tekkaya, A.E.; Weckenmann, A. Bulk forming of sheet metal. CIRP Ann.-Manuf. Technol. 2012, 61, 725–745. [Google Scholar] [CrossRef]

- Merklein, M.; Koch, J.; Opel, S.; Schneider, T. Fundamental investigations on the material flow at combined sheet and bulk metal forming processes. CIRP Ann.-Manuf. Technol. 2011, 60, 283–286. [Google Scholar] [CrossRef]

- Rojek, J.; Onate, E.; Postek, E. Application of explicit fe codes to simulation of sheet and bulk metal forming processes. J. Mater. Process. Technol. 1998, 80, 620–627. [Google Scholar] [CrossRef]

- Vierzigmann, U.; Koch, J.; Merklein, M.; Engel, U. Material flow in sheet-bulk metal forming. Key Eng. Mater. 2012, 504–505, 1035–1040. [Google Scholar] [CrossRef]

- Ko, D.-H.; Lee, S.-K.; Kwon, Y.-N.; Kim, S.-W.; Kim, B.-H.; Kim, B.-M.; Ko, D.-C. Improvement in dimensional accuracy of roll-die-formed clutch hub used in automotive transmission. Int. J. Precis. Eng. Manuf. 2012, 13, 237–243. [Google Scholar] [CrossRef]

- Zhuang, X.; Sun, X.; Xiang, H.; Xia, M.; Zhao, Z. Compound deep drawing and extrusion process for the manufacture of geared drum. Int. J. Adv. Manuf. Technol. 2015, 84, 2331–2345. [Google Scholar] [CrossRef]

- Mori, K.; Maeno, T.; Fukui, Y. Spline forming of ultra-high strength gear drum using resistance heating of side wall of cup. CIRP Ann.-Manuf. Technol. 2011, 60, 299–302. [Google Scholar] [CrossRef]

- Mori, K.; Maeno, T.; Nakamoto, S. Hot spline forming of ultra-high strength steel gear drum using resistance heating. Key Eng. Mater. 2014, 622–623, 201–206. [Google Scholar] [CrossRef]

- Sun, X.; Zhu, S.; Zhuang, X.; Zhao, Z. Numerical investigation on tooth filling of clutch drum forming processes. Prod. Eng. 2016, 10, 25–35. [Google Scholar] [CrossRef]

- Wu, H.C.; Altan, T. Process optimization in stamping—A case study for flanging a clutch hub from steel plate. J. Mater. Process. Technol. 2004, 146, 8–19. [Google Scholar] [CrossRef]

- Park, J.H.; Kim, S.G.; Park, Y.C.; Song, X.G. Shape design of the deep-drawing preform for manufacturing of automobile drum clutch hubs. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2011, 226, 1016–1024. [Google Scholar] [CrossRef]

- Lee, J.M.; Kim, B.M.; Kang, C.G. A study on the cold ironing process for the drum clutch with inner gear shapes. Int. J. Mach. Tools Manuf. 2006, 46, 640–650. [Google Scholar] [CrossRef]

- Meng, D.A.; Zhao, S.; Li, L.; Liu, C. A servo-motor driven active blank holder control system for deep drawing process. Int. J. Aav. Manuf. Technol. 2016, 87, 3185–3193. [Google Scholar] [CrossRef]

- Osakada, K.; Mori, K.; Altan, T.; Groche, P. Mechanical servo press technology for metal forming. Cirp Ann.-Manuf. Technol. 2011, 60, 651–672. [Google Scholar] [CrossRef]

- Maeno, T.; Mori, K.; Hori, A. Application of load pulsation using servo press to plate forging of stainless steel parts. J. Mater. Process. Technol. 2014, 214, 1379–1387. [Google Scholar] [CrossRef]

- Kriechenbauer, S.; Mauermann, R.; Muller, P. Deep drawing with superimposed low-frequency vibrations on servo-screw presses. Procedia Eng. 2014, 81, 905–913. [Google Scholar] [CrossRef]

- Matsumoto, R.; Jeon, J.-Y.; Utsunomiya, H. Shape accuracy in the forming of deep holes with retreat and advance pulse ram motion on a servo press. J. Mater. Process. Technol. 2013, 213, 770–778. [Google Scholar] [CrossRef]

- Travieso-Rodríguez, J.A.; Gras, G.G.; Peiró, J.J.; Carrillo, F.; Dessein, G.; Alexis, J.; Rojas, H.G. Experimental study on the mechanical effects of the vibration-assisted ball-burnishing process. Mater. Manuf. Process. 2015, 30, 1490–1497. [Google Scholar] [CrossRef] [Green Version]

- Jerez-Mesa, R.; Travieso-Rodriguez, J.A.; Gomez-Gras, G.; Lluma-Fuentes, J. Development, characterization and test of an ultrasonic vibration-assisted ball burnishing tool. J. Mater. Process. Technol. 2018, 257, 203–212. [Google Scholar] [CrossRef]

- Liu, Y.; Suslov, S.; Han, Q.; Hua, L.; Xu, C. Comparison between ultrasonic vibration-assisted upsetting and conventional upsetting. Metall. Mater. Trans. A 2013, 44, 3232–3244. [Google Scholar] [CrossRef]

- Liu, Y.; Suslov, S.; Han, Q.; Xu, C.; Hua, L. Microstructure of the pure copper produced by upsetting with ultrasonic vibration. Mater. Lett. 2012, 67, 52–55. [Google Scholar] [CrossRef]

- Meng, D.A.; Zhao, X.; Li, J.; Zhao, S.; Han, Q. Mechanical behavior and microstructure of low-carbon steel undergoing low-frequency vibration-assisted tensile deformation. J. Mater. Res. 2017, 32, 3885–3893. [Google Scholar] [CrossRef]

- Siu, K.W.; Ngan, A.H.W.; Jones, I.P. New insight on acoustoplasticity—Ultrasonic irradiation enhances subgrain formation during deformation. Int. J. Plast. 2011, 27, 788–800. [Google Scholar] [CrossRef]

- Kumar, V.; Hutchings, I. Reduction of the sliding friction of metals by the application of longitudinal or transverse ultrasonic vibration. Tribol. Int. 2004, 37, 833–840. [Google Scholar] [CrossRef]

- Ben, N.-Y.; Zhang, Q.; Meng, D.-A.; Lee, M.-G. Analysis of real contact area and re-lubrication in oscillating bulk forming process by corrosion method. J. Mater. Process. Technol. 2018, 253, 178–194. [Google Scholar] [CrossRef]

- Kirchner, H.; Kromp, W.; Prinz, F.; Trimmel, P. Plastic deformation under simultaneous cyclic and unidirectional loading at low and ultrasonic frequencies. Mater. Sci. Eng. 1985, 68, 197–206. [Google Scholar] [CrossRef]

- Lu, X.; Khonsari, M.; Gelinck, E. The stribeck curve: Experimental results and theoretical prediction. J. Tribol. 2006, 128, 789–794. [Google Scholar] [CrossRef]

- Azushima, A.; Uda, M.; Kudo, H. An interpretation of the speed dependence of the coefficient of friction under the micro-phl condition in sheet drawing. CIRP Ann.-Manuf. Technol. 1991, 40, 227–230. [Google Scholar] [CrossRef]

- Mizuno, T.; Okamoto, M. Effects of lubricant viscosity at pressure and sliding velocity on lubricating conditions in the compression-friction test on sheet metals. J. Lubr. Technol. 1982, 104, 53–59. [Google Scholar] [CrossRef]

- Zhang, Q.; Ben, N.-Y.; Yang, K. Effect of variational friction and elastic deformation of die on oscillating cold forging for spline shaft. J. Mater. Process. Technol. 2017, 244, 166–177. [Google Scholar] [CrossRef]

- Wang, P.; Ni, H.; Wang, R.; Liu, W.; Lu, S. Research on the mechanism of in-plane vibration on friction reduction. Materials 2017, 10. [Google Scholar] [CrossRef] [PubMed]

| C% | Mn% | Al% | P% | S% |

|---|---|---|---|---|

| 0.07 | 0.3 | 0.02 | 0.02 | 0.025 |

| Without Vibration | Vibration Frequency 10 Hz | Vibration Frequency 10 Hz | Vibration Frequency 10 Hz |

|---|---|---|---|

| 24.3 μm | 25.2 μm | 24.1 μm | 25.6 μm |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meng, D.; Zhu, C.; Zhao, X.; Zhao, S. Applying Low-Frequency Vibration for the Experimental Investigation of Clutch Hub Forming. Materials 2018, 11, 928. https://doi.org/10.3390/ma11060928

Meng D, Zhu C, Zhao X, Zhao S. Applying Low-Frequency Vibration for the Experimental Investigation of Clutch Hub Forming. Materials. 2018; 11(6):928. https://doi.org/10.3390/ma11060928

Chicago/Turabian StyleMeng, De’an, Chengcheng Zhu, Xuzhe Zhao, and Shengdun Zhao. 2018. "Applying Low-Frequency Vibration for the Experimental Investigation of Clutch Hub Forming" Materials 11, no. 6: 928. https://doi.org/10.3390/ma11060928