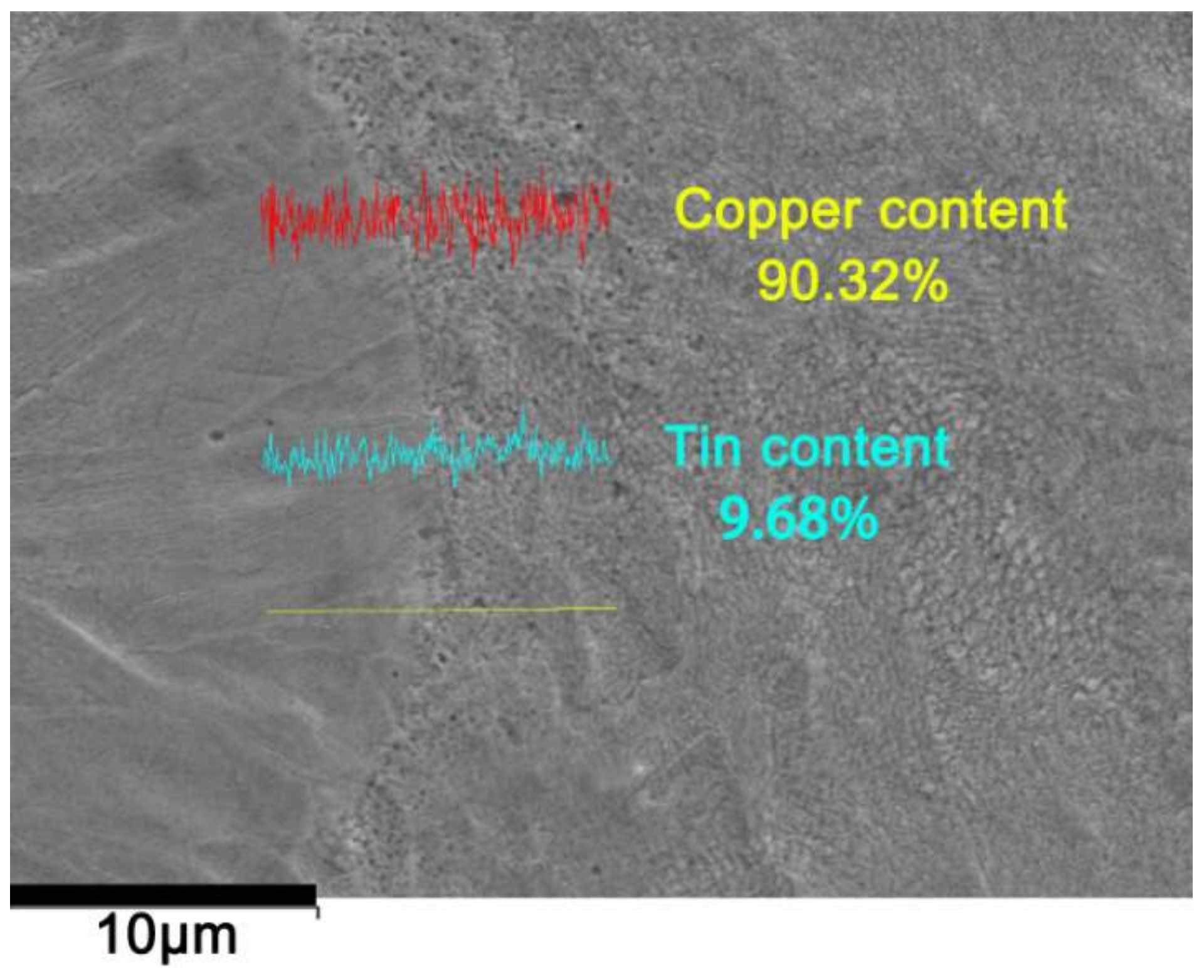

Study on the Selective Laser Melting of CuSn10 Powder

Abstract

:1. Introduction

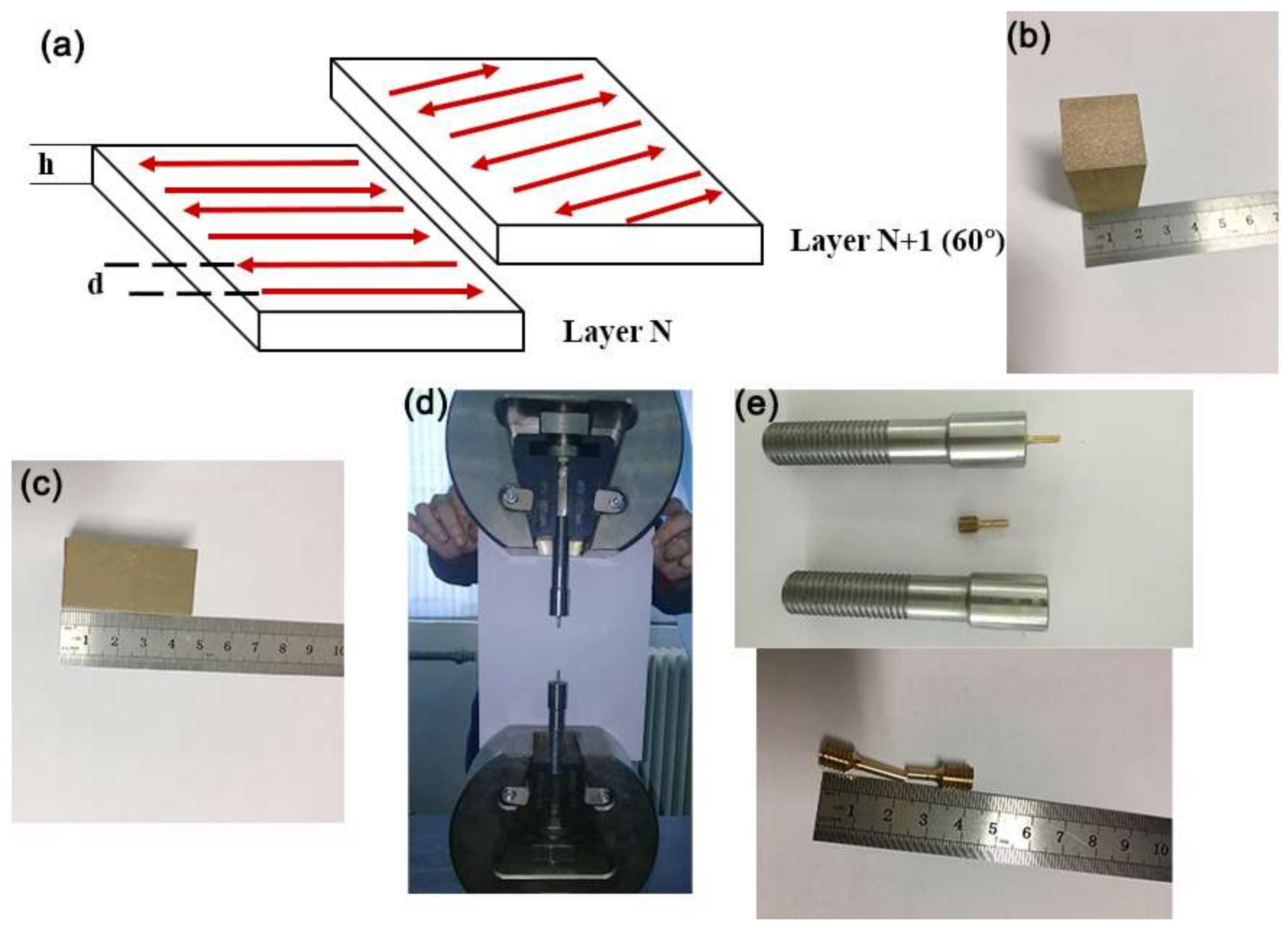

2. Experimental

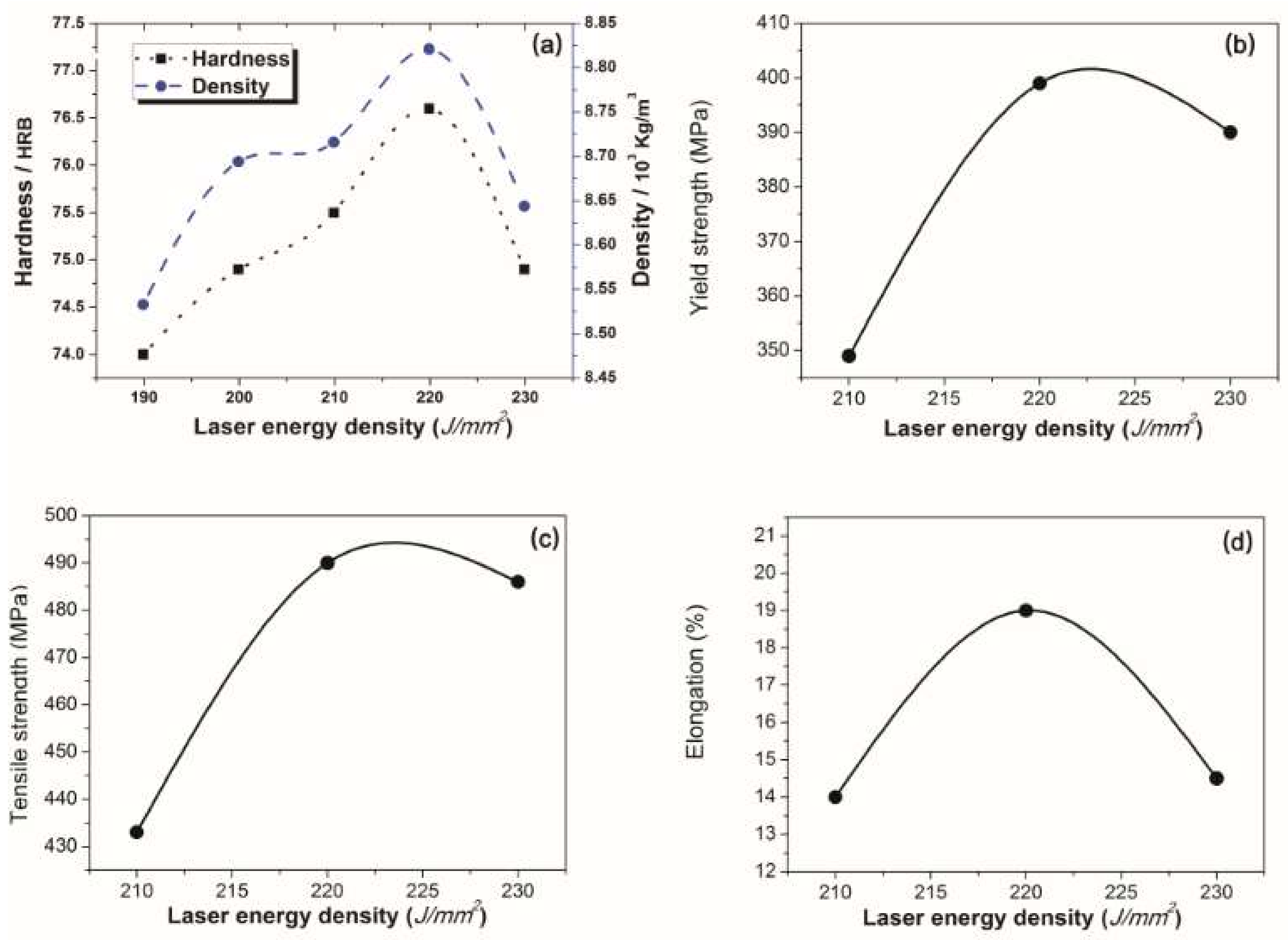

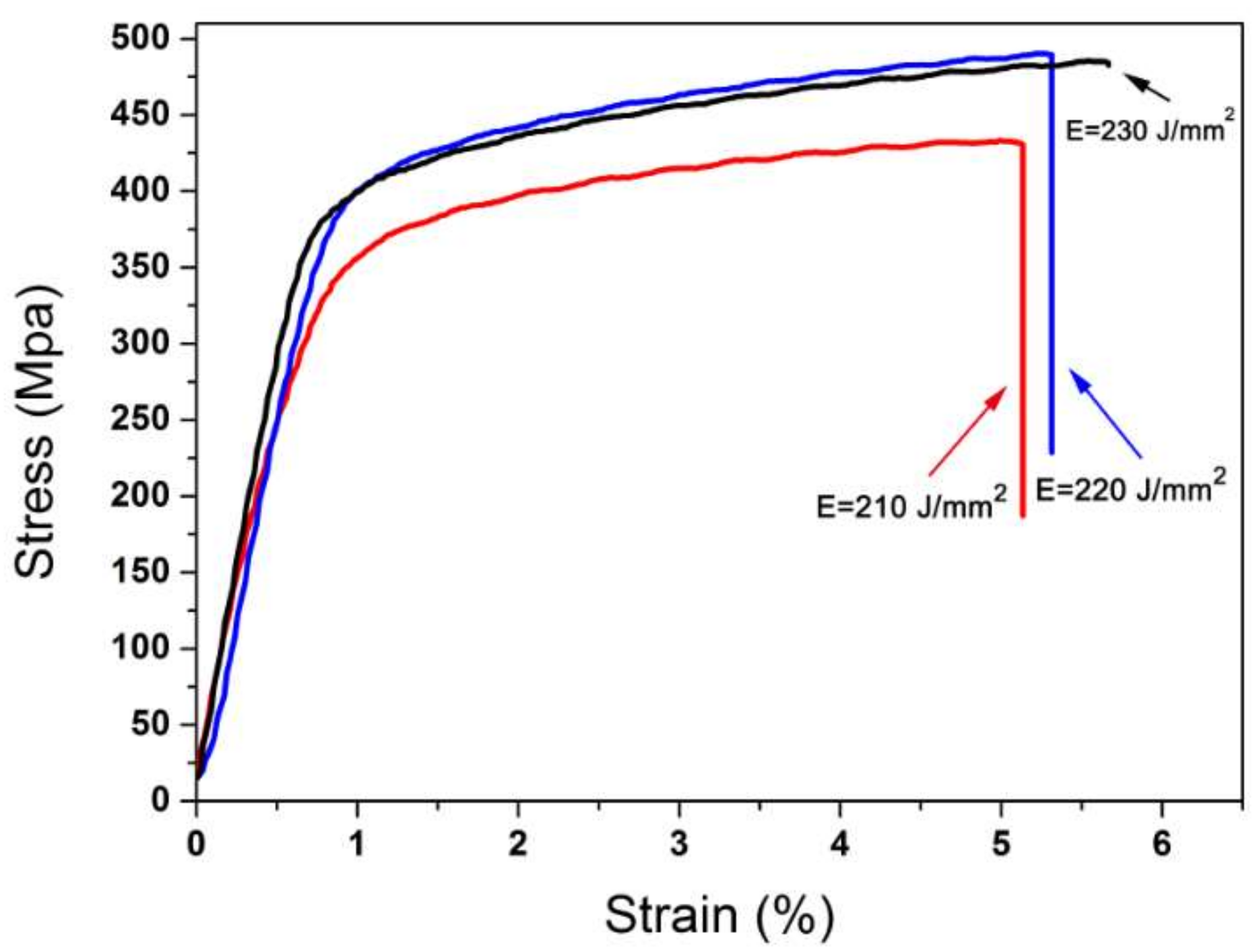

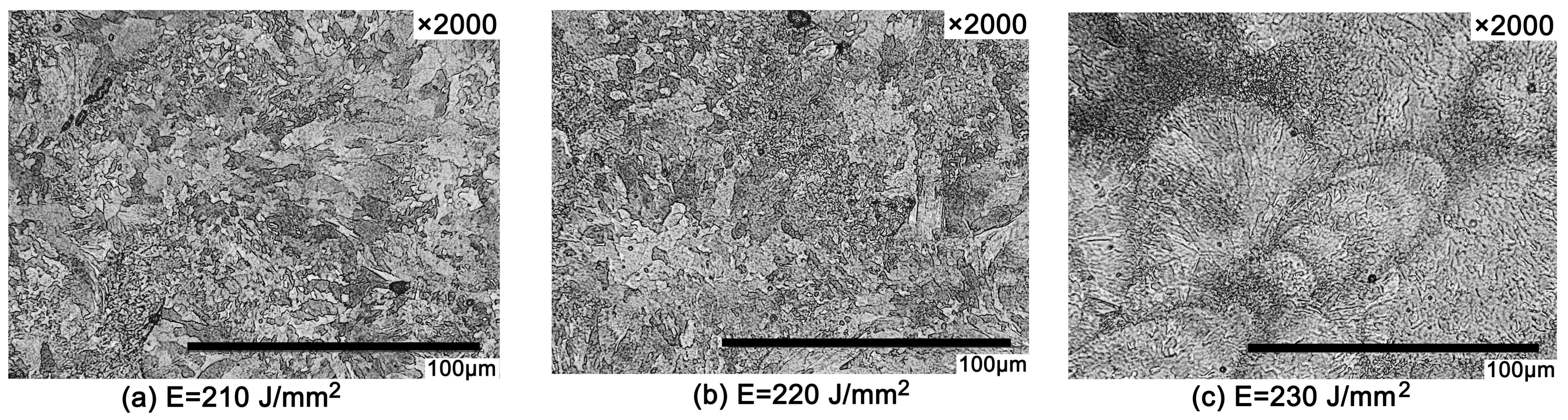

3. Results and Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Afshari, E.; Ghambari, M.; Abdolmalek, H. Production of CuSn10 bronze powder from machining chips using jet milling. Int. J. Adv. Manuf. Technol. 2017, 92, 663–672. [Google Scholar] [CrossRef]

- Canakci, A.; Varol, T.; Cuvalci, H.; Erdemir, F. Synthesis of novel CuSn10-graphite nanocomposite powders by mechanical alloying. Micro Nano Lett. 2014, 9, 109–112. [Google Scholar] [CrossRef]

- Widyastuti; Vicko, G.A.; Ardhyananta, H.; Rochman, R. Study of Frangible Cu-Sn Composite by Powder Metallurgy Method. Adv. Mater. Res. 2015, 1112, 497–501. [Google Scholar]

- Li, T.; Yi, D.; Hu, J.; Xu, J.; Liu, J.; Wang, B. Surface modification of h-BN and its influence on the mechanical properties of CuSn 10/h-BN composites. J. Alloys Compd. 2017, 723, 345–353. [Google Scholar] [CrossRef]

- Dong, X.J.; Wang, L.M.; Zhang, J.H.; Liu, Y.H.; Wang, L.S. Influence of morphology of different partially alloyed CuSn10 powders on the sintering character self-lubricated bearings. Powder Metall. 2010, 20, 28–32. [Google Scholar]

- Hui, L.I.; Wang, L.; Wan, X.; Zhan, L.I.; Bai. Study on preparation of partially alloyed CuSn10 powders by diffusion treatment. Powder Metall. Ind. 2003, 13, 13–17. [Google Scholar]

- Simchi, A.; Petzoldt, F.; Pohl, H. On the development of direct metal laser sintering for rapid tooling. J. Mater. Process. Technol. 2003, 141, 319–328. [Google Scholar] [CrossRef]

- Wang, Y.; Shen, Y.; Wang, Z.; Yang, J.; Liu, N.; Huang, W. Development of highly porous titanium scaffolds by selective laser melting. Mater. Lett. 2010, 64, 674–676. [Google Scholar] [CrossRef]

- Attar, H.; Prashanth, K.G.; Chaubey, A.K.; Calin, M.; Zhang, L.C.; Scudino, S.; Eckert, J.L. Comparison of wear properties of commercially pure titanium prepared by selective laser melting and casting processes. Mater. Lett. 2015, 142, 38–41. [Google Scholar] [CrossRef]

- Baraton, M.I.; Merhari, L.; Ferkel, H.; Castagnet, J.F. Comparison of the gas sensing properties of tin, indium and tungsten oxides nanopowders: Carbon monoxide and oxygen detection. Mater. Sci. Eng. C 2002, 19, 315–321. [Google Scholar] [CrossRef]

- Liu, Z.H.; Zhang, D.Q.; Sing, S.L.; Chua, C.K.; Loh, L.E. Interfacial characterization of SLM parts in multi-material processing: Metallurgical diffusion between 316L stainless steel and C18400 copper alloy. Mater. Charact. 2014, 94, 116–125. [Google Scholar] [CrossRef]

- Wang, L.; Wang, S.; Wu, J. Experimental investigation on densification behavior and surface roughness of AlSi10Mg powders produced by selective laser melting. Opt. Laser Technol. 2017, 96, 88–96. [Google Scholar] [CrossRef]

- Mao, Z.; Zhang, D.Z.; Wei, P.; Zhang, K. Manufacturing Feasibility and Forming Properties of Cu-4Sn in Selective Laser Melting. Materials 2017, 10, 333. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Zhu, H.; Qi, T.; Hu, Z.; Zeng, X. Selective laser melting of high strength Al–Cu–Mg alloys: Processing, microstructure and mechanical properties. Mater. Sci. Eng. A 2016, 656, 47–54. [Google Scholar] [CrossRef]

- National Technical Committee for Standardization of Nonferrous Metals. Standard Collection of Copper and Copper Alloy: Method Volume 2008; China Standard Press: Beijing, China, 2008. [Google Scholar]

- Lin, G.B.; Wang, Z.D.; Zhang, W.; Li, W.Q.; Zhang, H. Effects of heat treatment on microstructure and performance of tin bronze alloy. Foundry 2011, 60, 286–287. [Google Scholar]

- Li, Y.Z. Rapid Solidification Technology and Materials; National Defence Industry Press: Beijing, China, 1993; p. 20. [Google Scholar]

- Scudino, S.; Unterdörfer, C.; Prashanth, K.G.; Attar, H.; Ellendt, N.; Uhlenwinkel, V. Additive manufacturing of Cu–10Sn bronze. Mater. Lett. 2015, 156, 202–204. [Google Scholar] [CrossRef]

- Heo, N.H.; Heo, Y.U.; Kwon, S.K.; Kim, N.J.; Kim, S.J.; Lee, H.C. Extended Hall–Petch Relationships for Yield, Cleavage and Intergranular Fracture Strengths of bcc Steel and Its Deformation and Fracture Behaviors. Met. Mater. Int. 2018, 24, 265–281. [Google Scholar] [CrossRef]

| Mark | Laser Energy Density/J/mm2 |

|---|---|

| A1 | 190 |

| A2 | 200 |

| A3 | 210 |

| A4 | 220 |

| A5 | 230 |

| The Standard | Density/g/cm3 | Hardness/HRB | Yield Strength/MPa | Tensile Strength/Mpa | Elongation % | ||||

|---|---|---|---|---|---|---|---|---|---|

| YS/T 545-2006 | 8.6 | 55 | 360 | 170 | 6 | ||||

| Laser Energy Density | Measured Value | Measured Value | Increased by | Measured Value | Increased by | Measured Value | Increased by | Measured Value | Increased by |

| E = 210 J/mm2 | 8.8 ± 0.2 | 75.5 ± 0.3 | 37% | 369 ± 3 | 3% | 433 ± 3 | 155% | 14 ± 0.6 | 133% |

| E = 220 J/mm2 | 8.9 ± 0.1 | 76.6 ± 0.2 | 39% | 399 ± 2 | 11% | 490 ± 4 | 188% | 19 ± 0.8 | 217% |

| E = 230 J/mm2 | 8.7 ± 0.2 | 74.9 ± 0.2 | 36% | 390 ± 2 | 8% | 486 ± 3 | 185% | 15 ± 0.7 | 150% |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Deng, C.; Kang, J.; Feng, T.; Feng, Y.; Wang, X.; Wu, P. Study on the Selective Laser Melting of CuSn10 Powder. Materials 2018, 11, 614. https://doi.org/10.3390/ma11040614

Deng C, Kang J, Feng T, Feng Y, Wang X, Wu P. Study on the Selective Laser Melting of CuSn10 Powder. Materials. 2018; 11(4):614. https://doi.org/10.3390/ma11040614

Chicago/Turabian StyleDeng, Chengyang, Jinwu Kang, Tao Feng, Yunlong Feng, Xiang Wang, and Pengyue Wu. 2018. "Study on the Selective Laser Melting of CuSn10 Powder" Materials 11, no. 4: 614. https://doi.org/10.3390/ma11040614

APA StyleDeng, C., Kang, J., Feng, T., Feng, Y., Wang, X., & Wu, P. (2018). Study on the Selective Laser Melting of CuSn10 Powder. Materials, 11(4), 614. https://doi.org/10.3390/ma11040614