Mechanism-Based FE Simulation of Tool Wear in Diamond Drilling of SiCp/Al Composites

Abstract

:1. Introduction

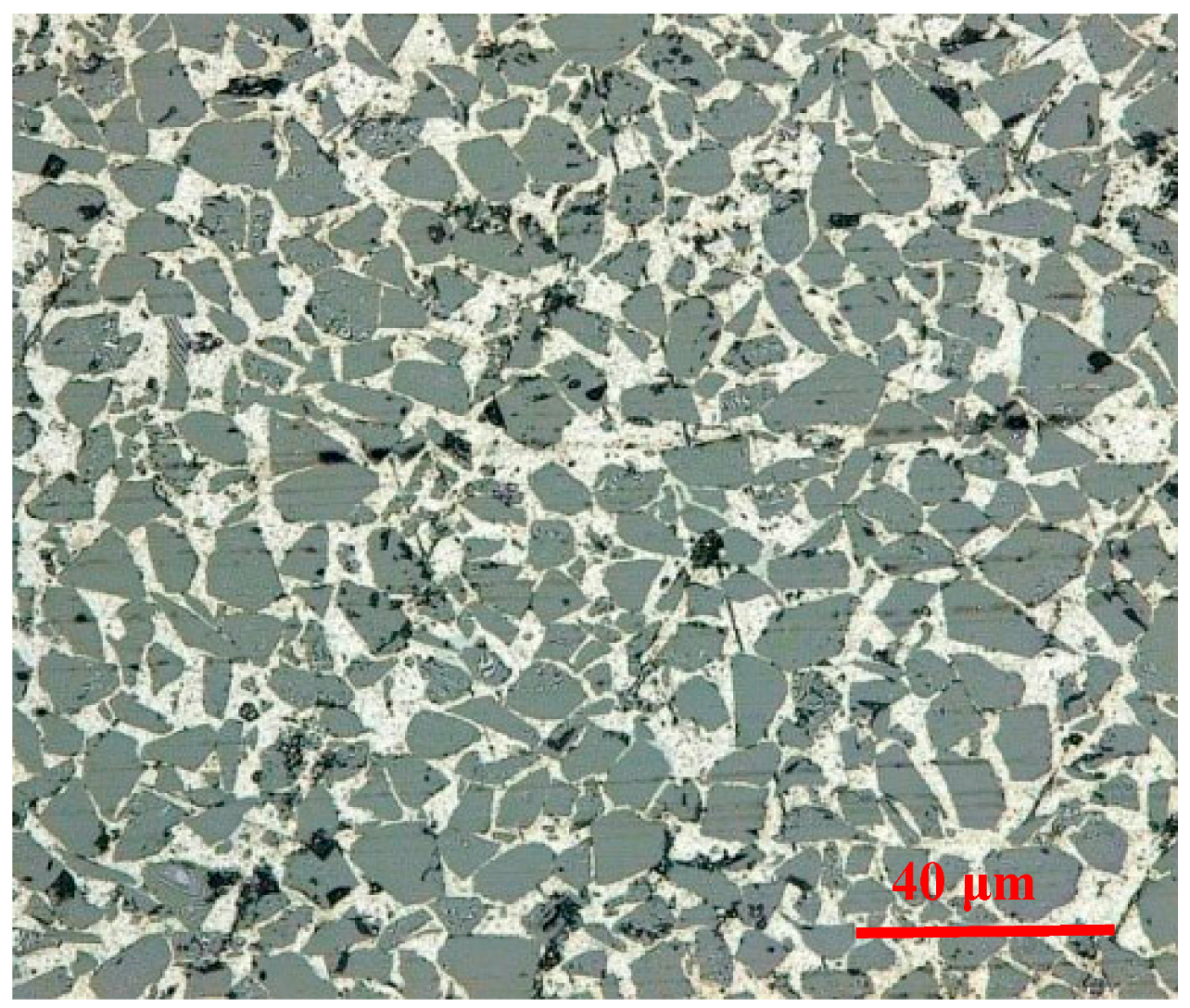

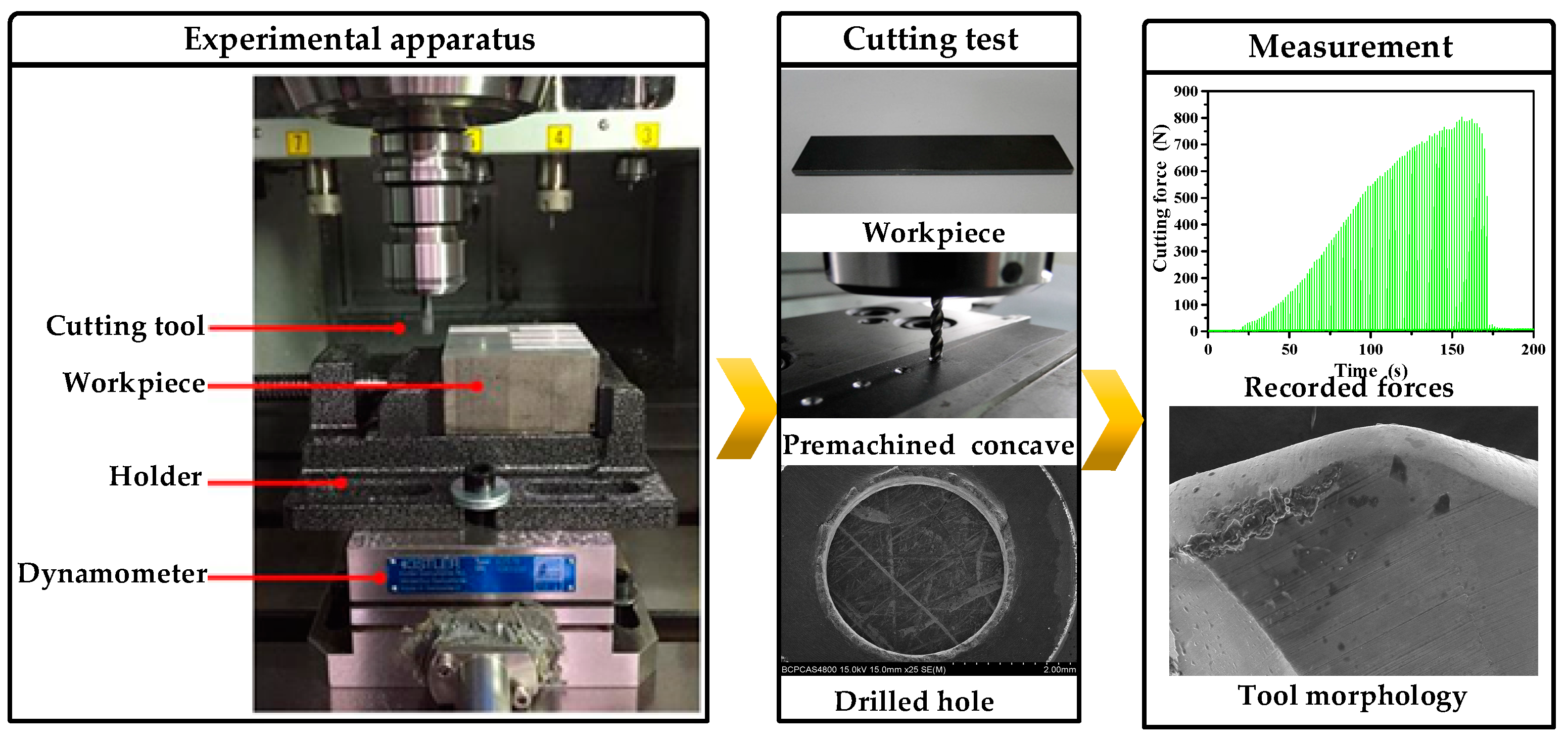

2. Experimental Work

2.1. Experimental Setup

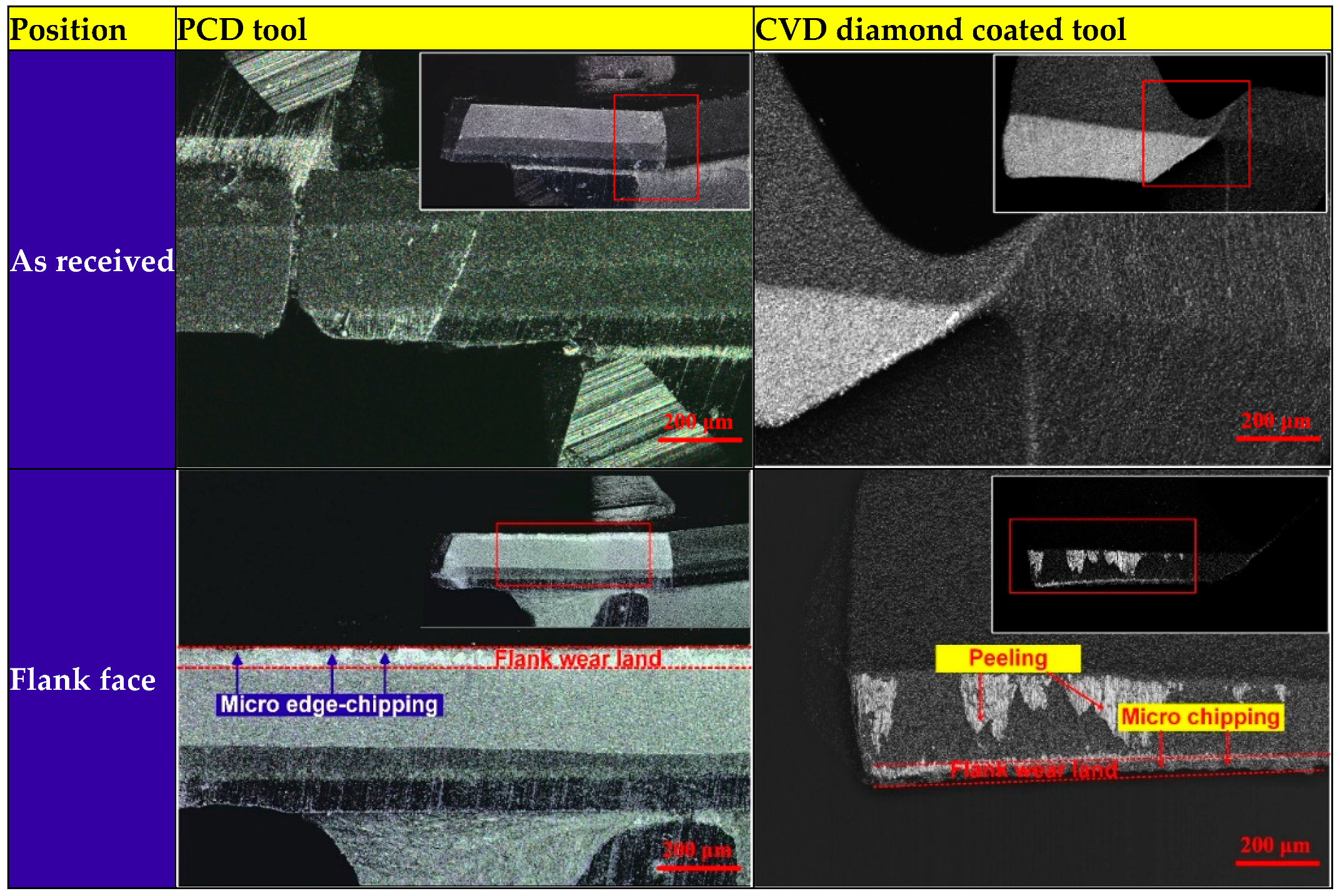

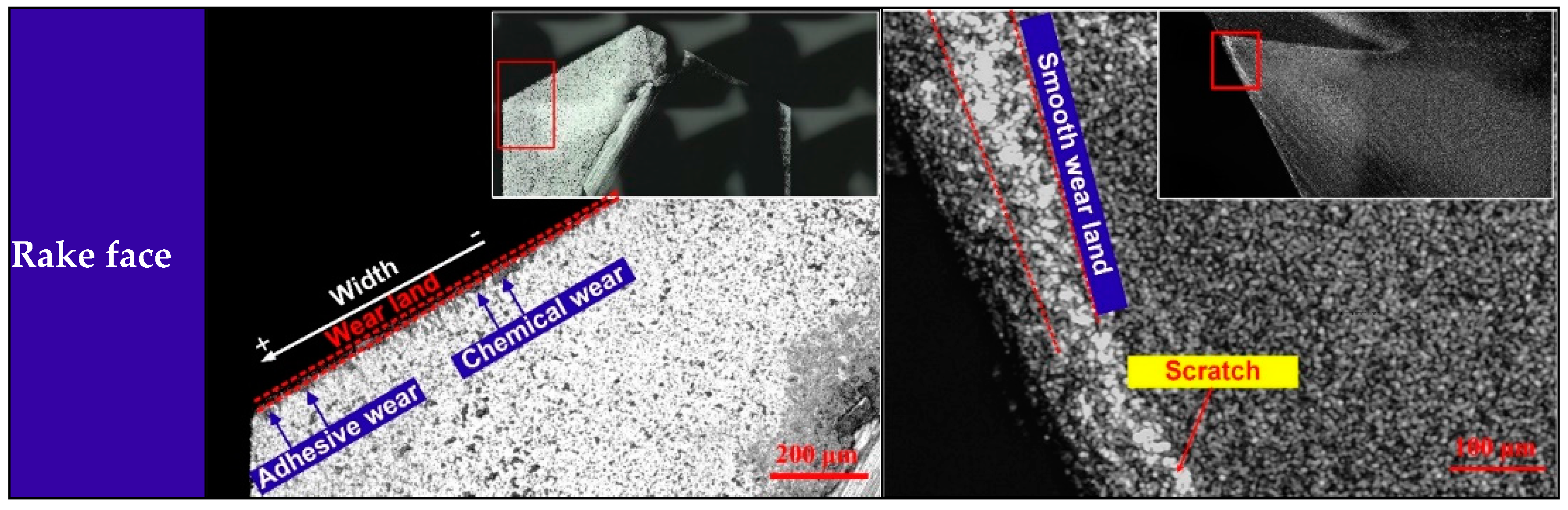

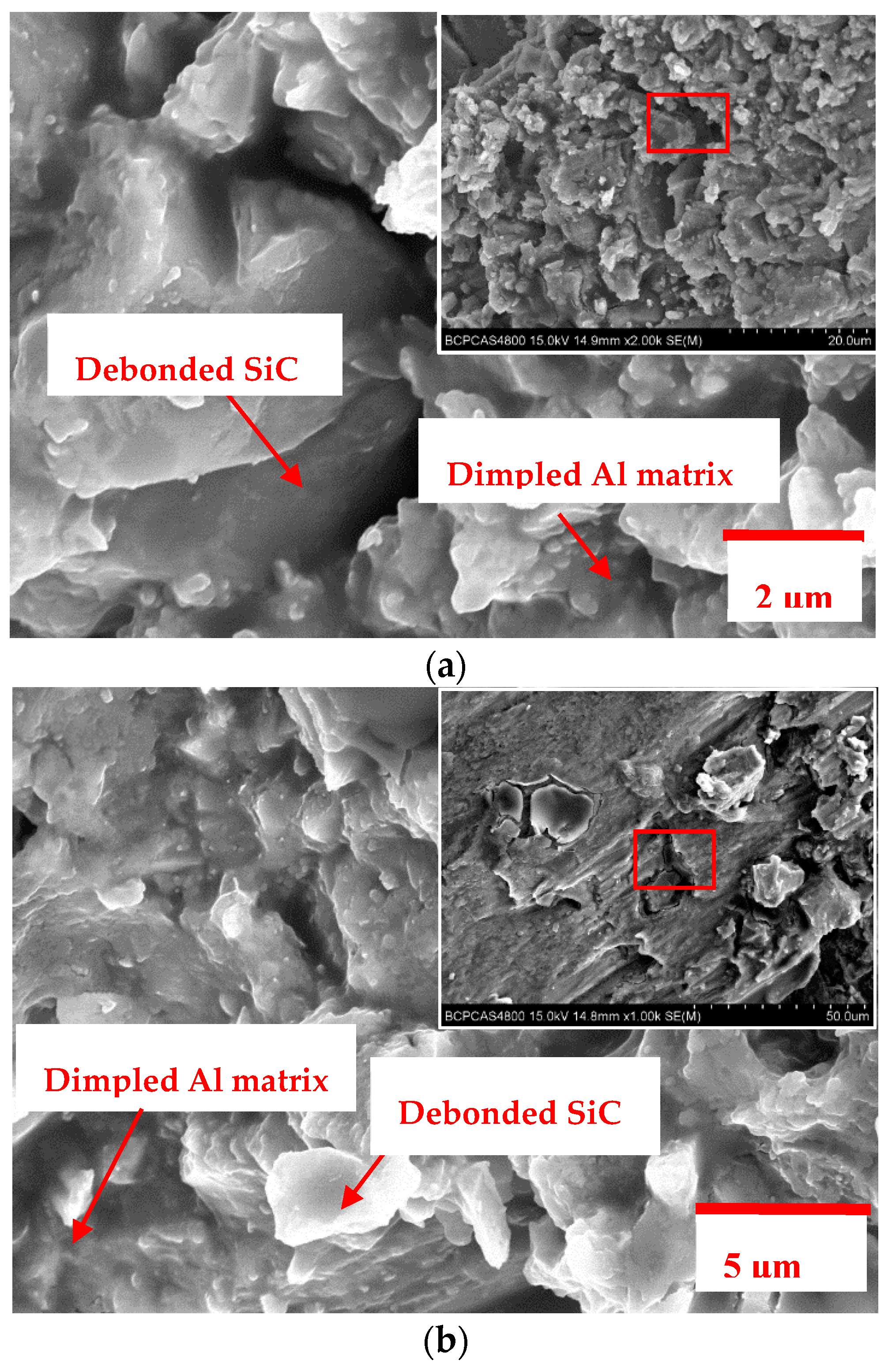

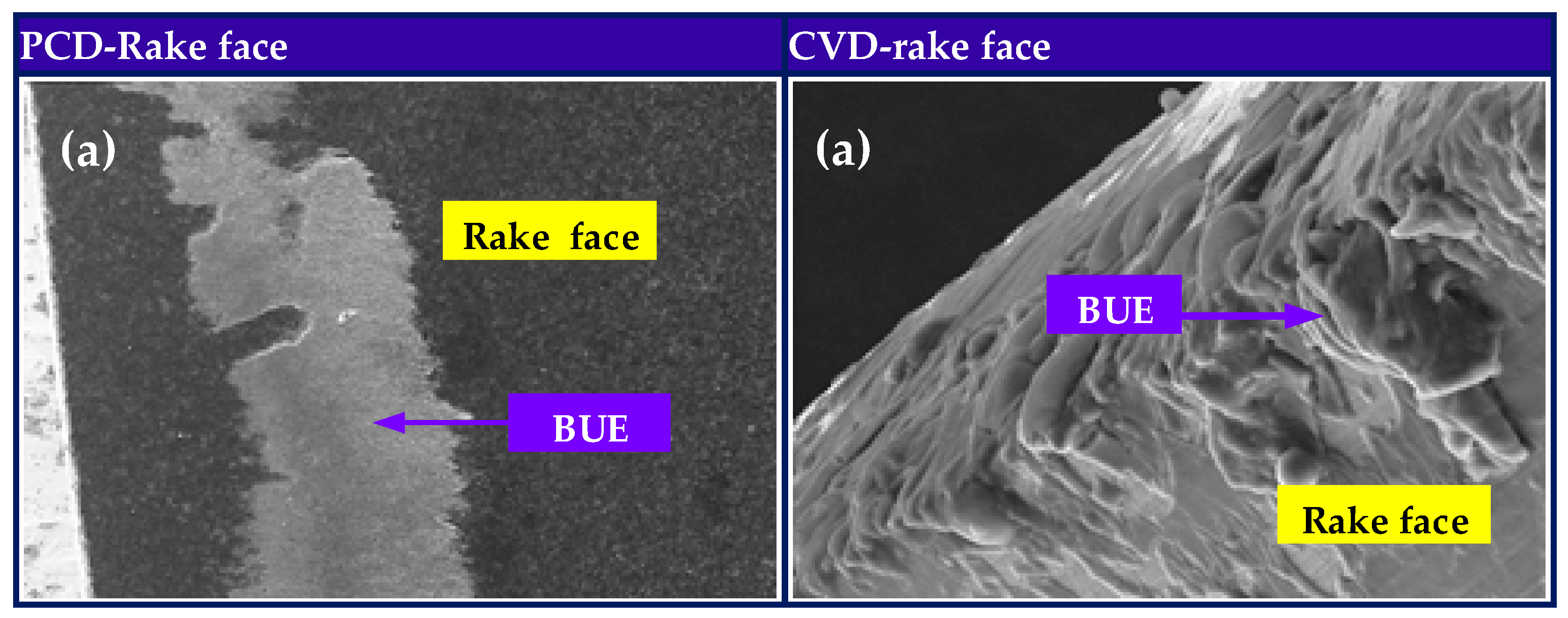

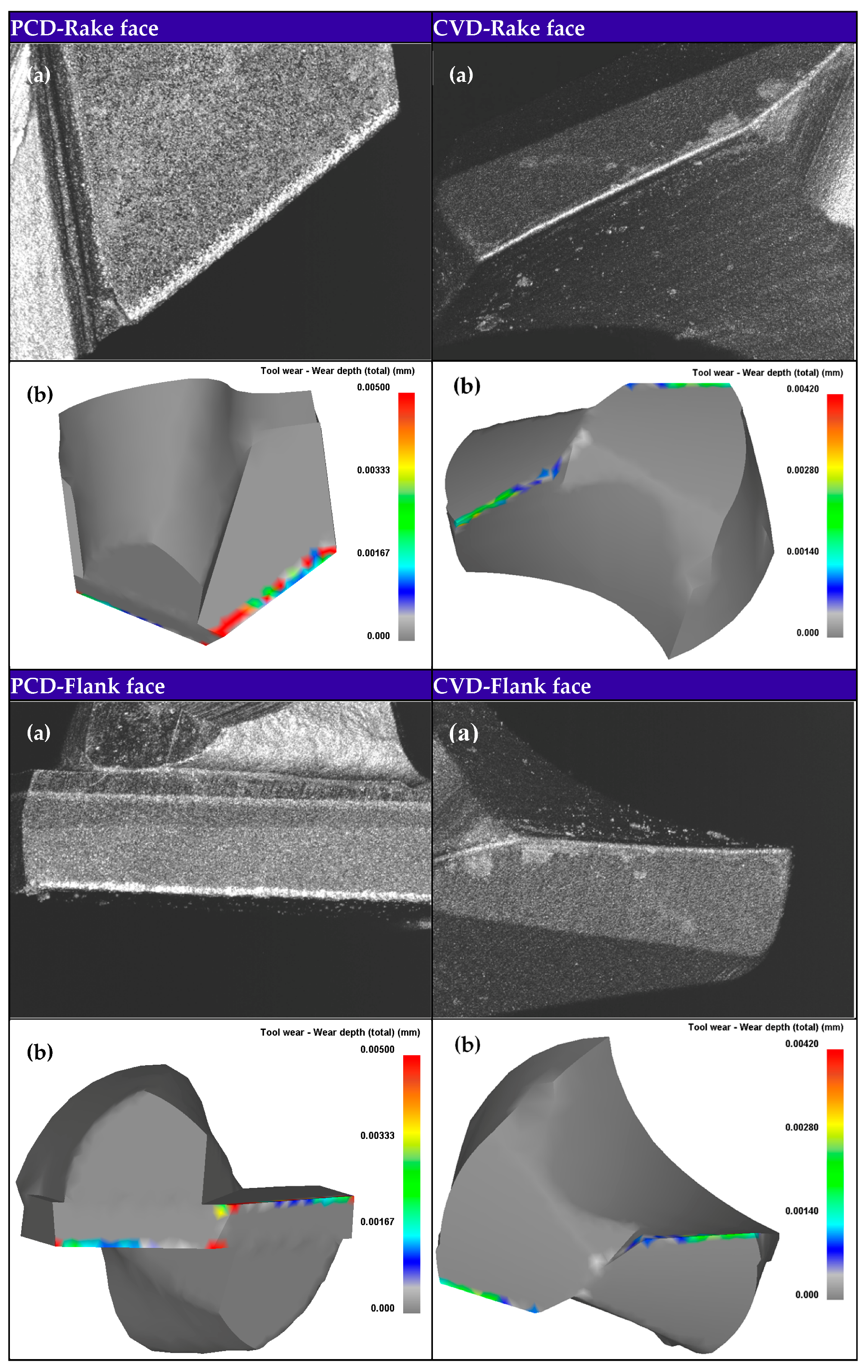

2.2. Wear Mechanisms

3. Results

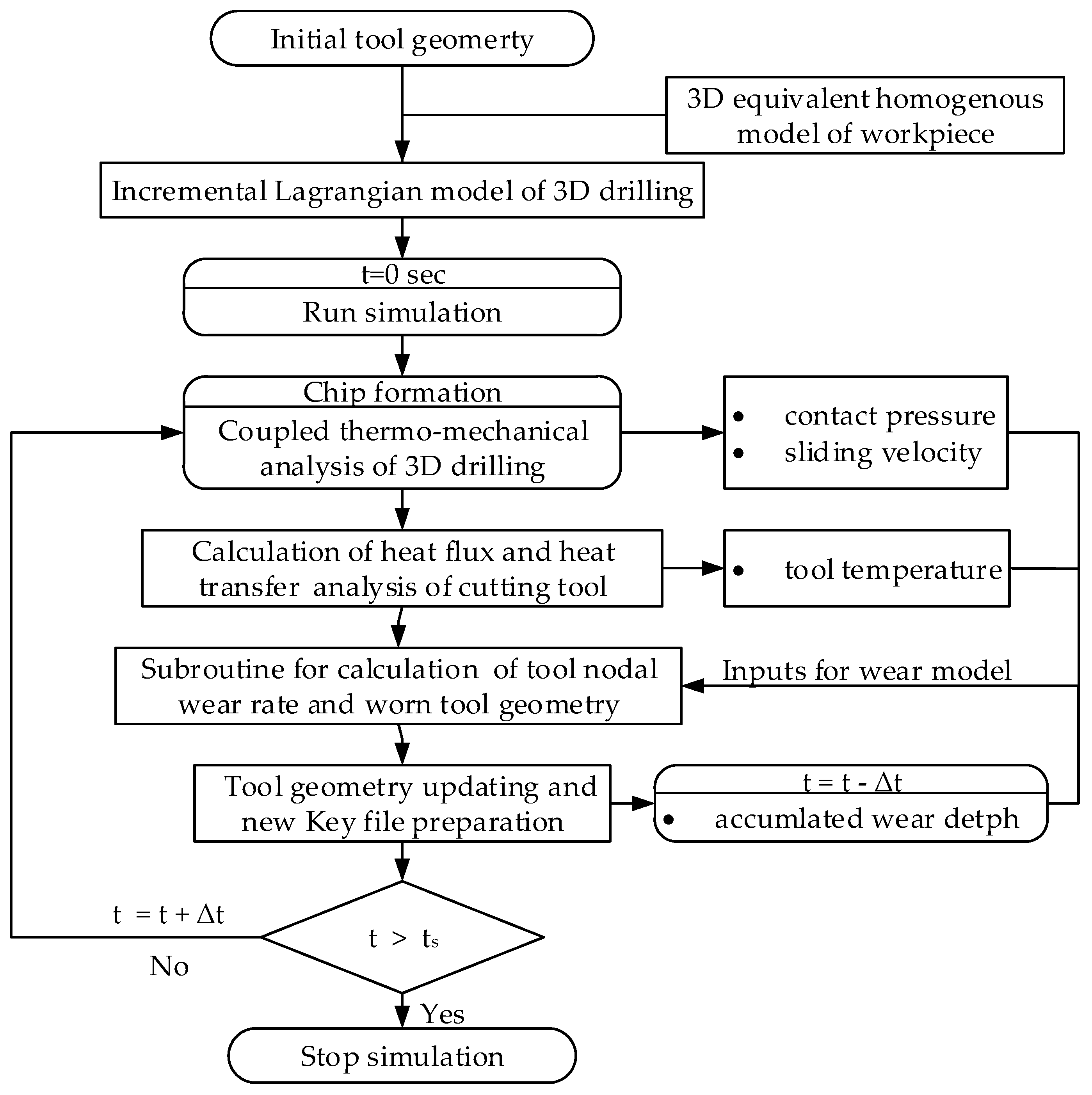

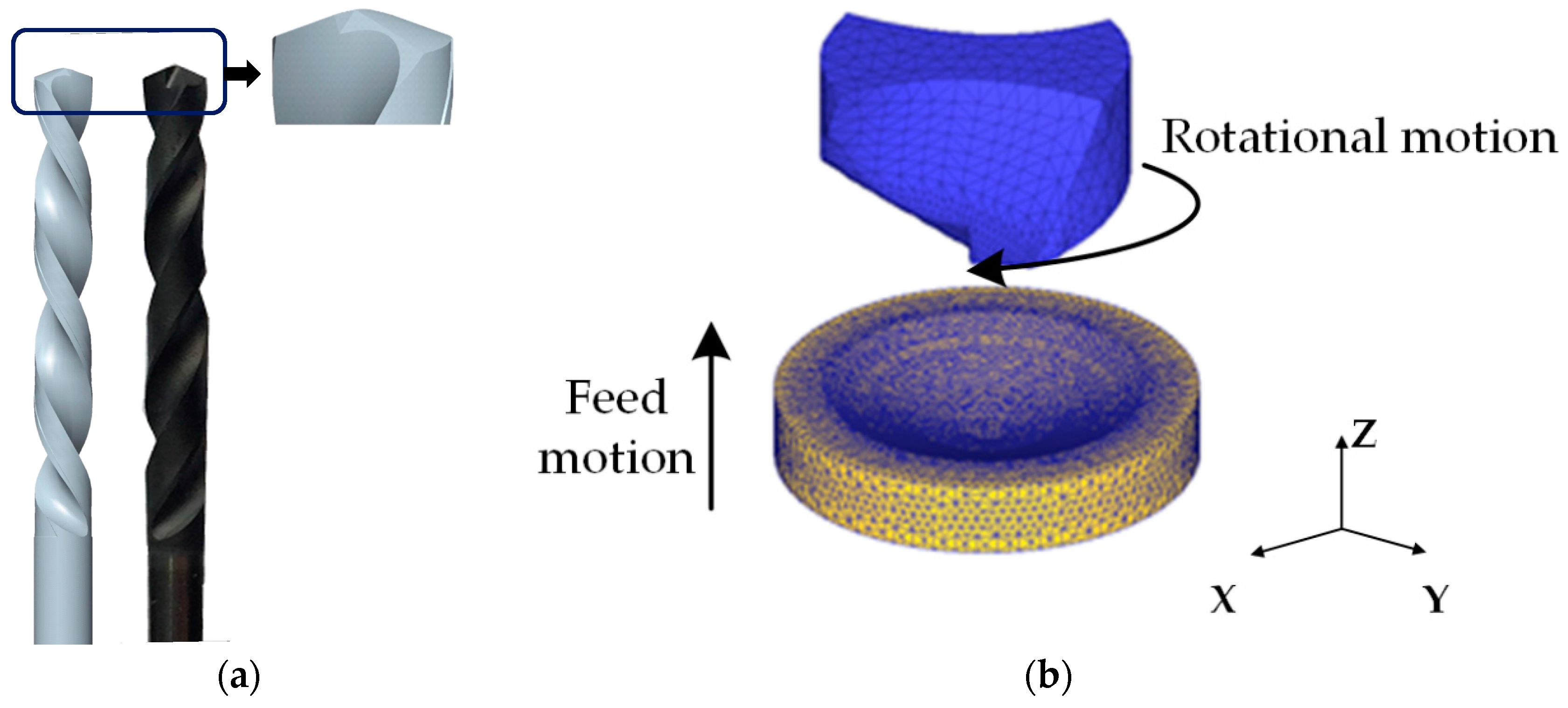

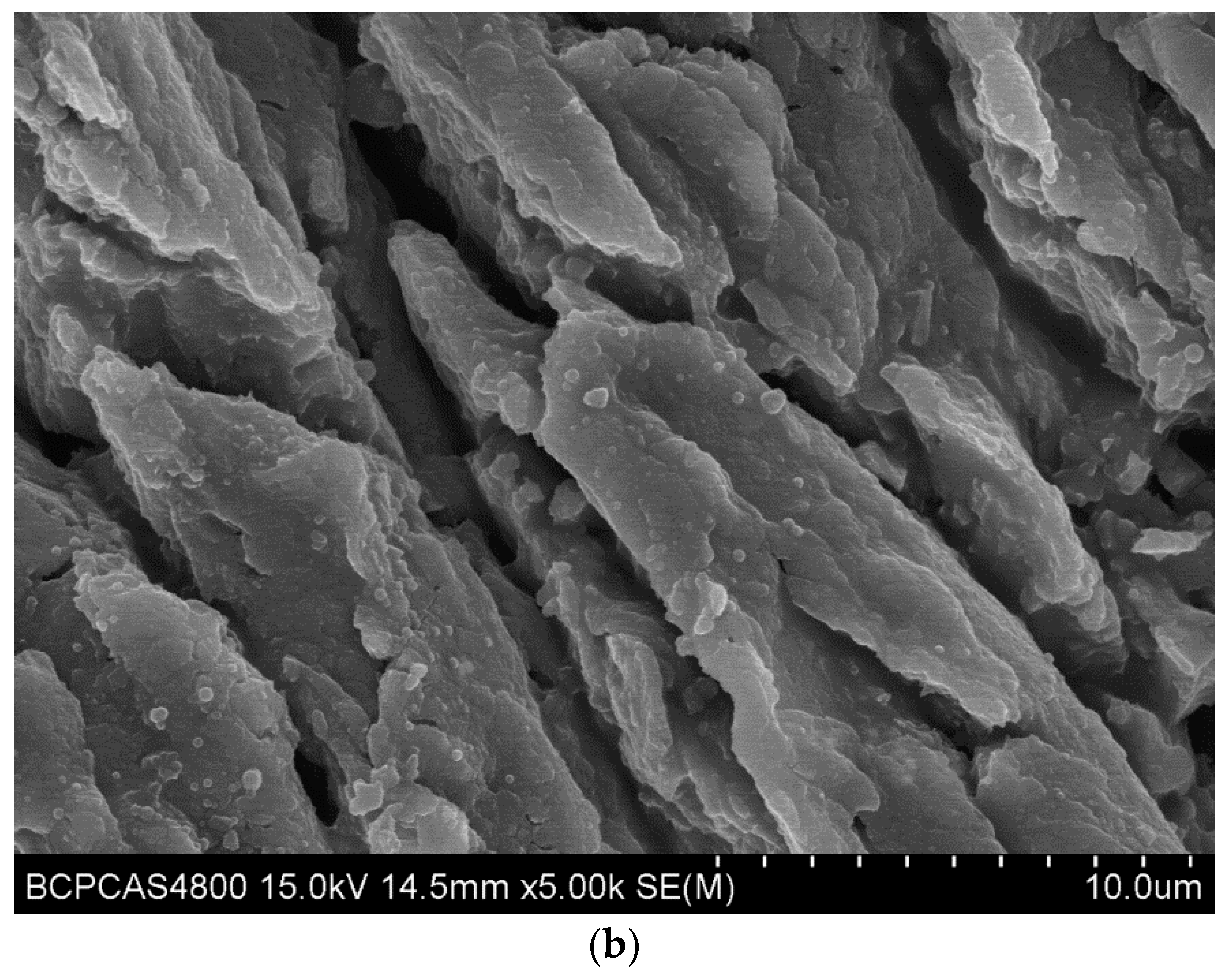

3.1. Chip Formation

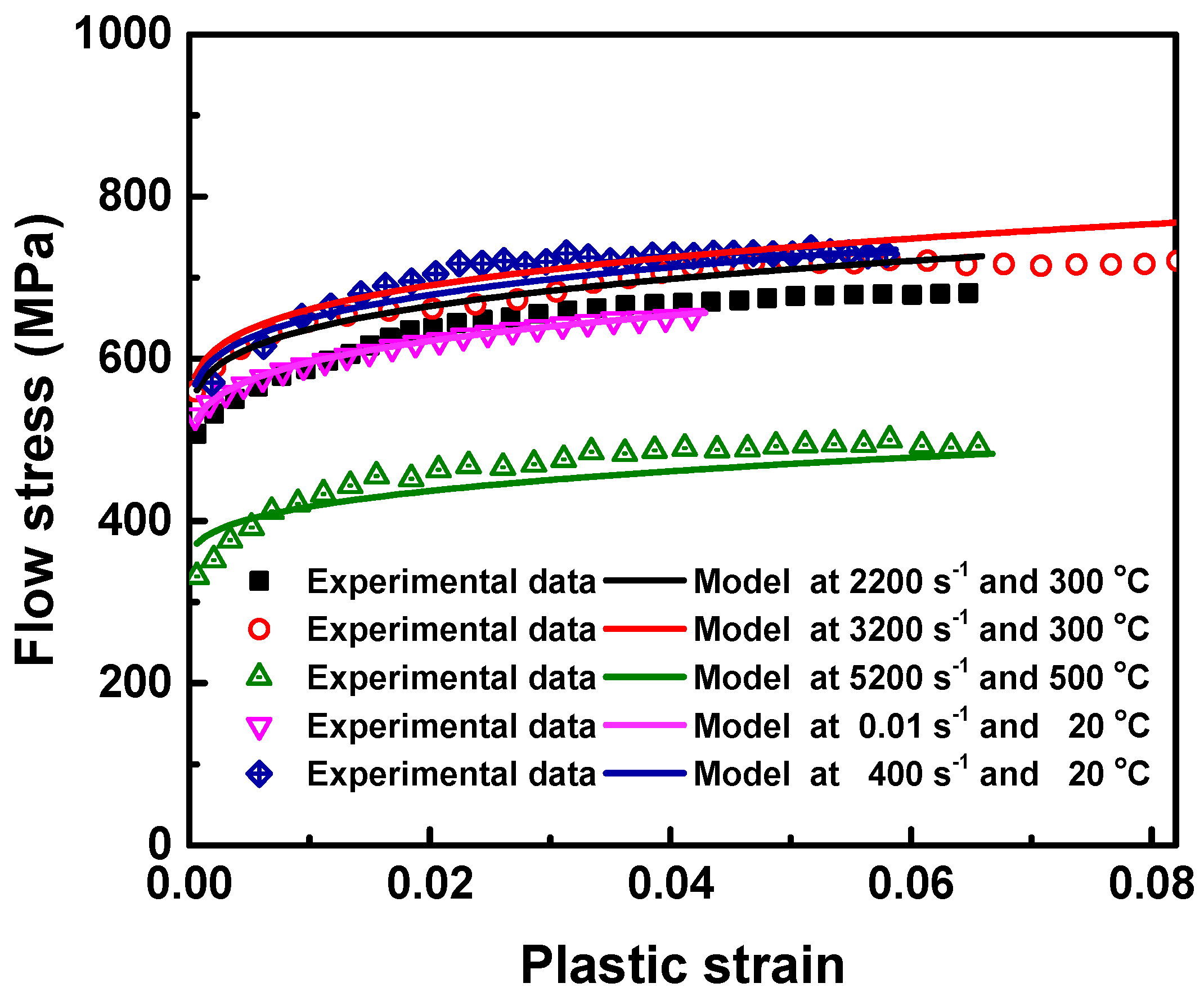

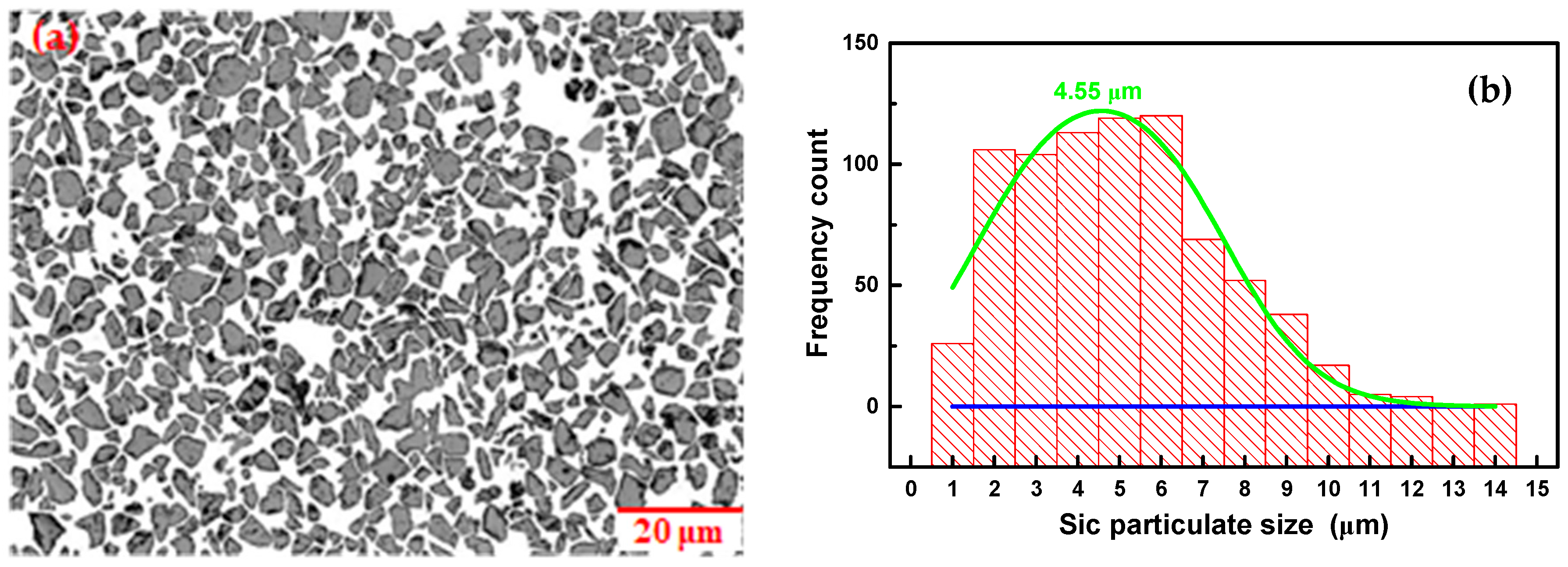

3.1.1. Material Model

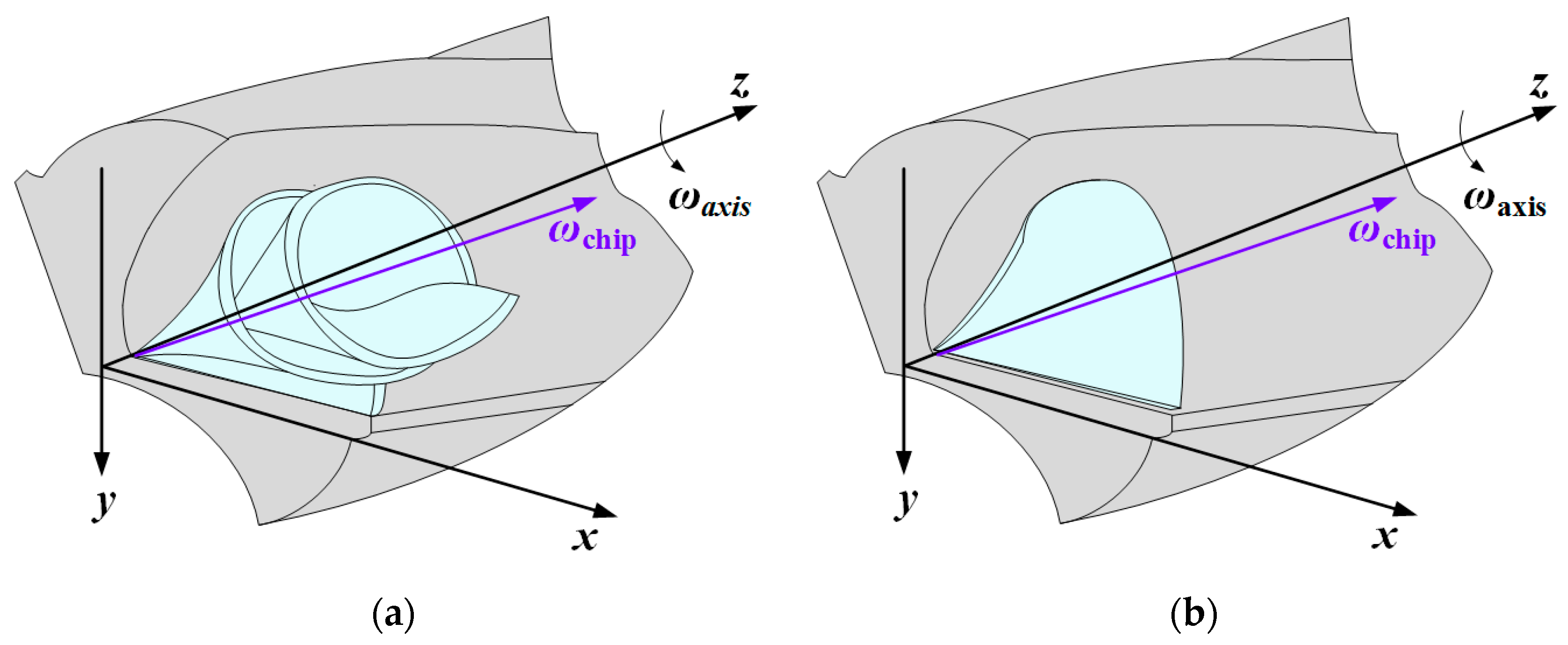

3.1.2. Chip Separation

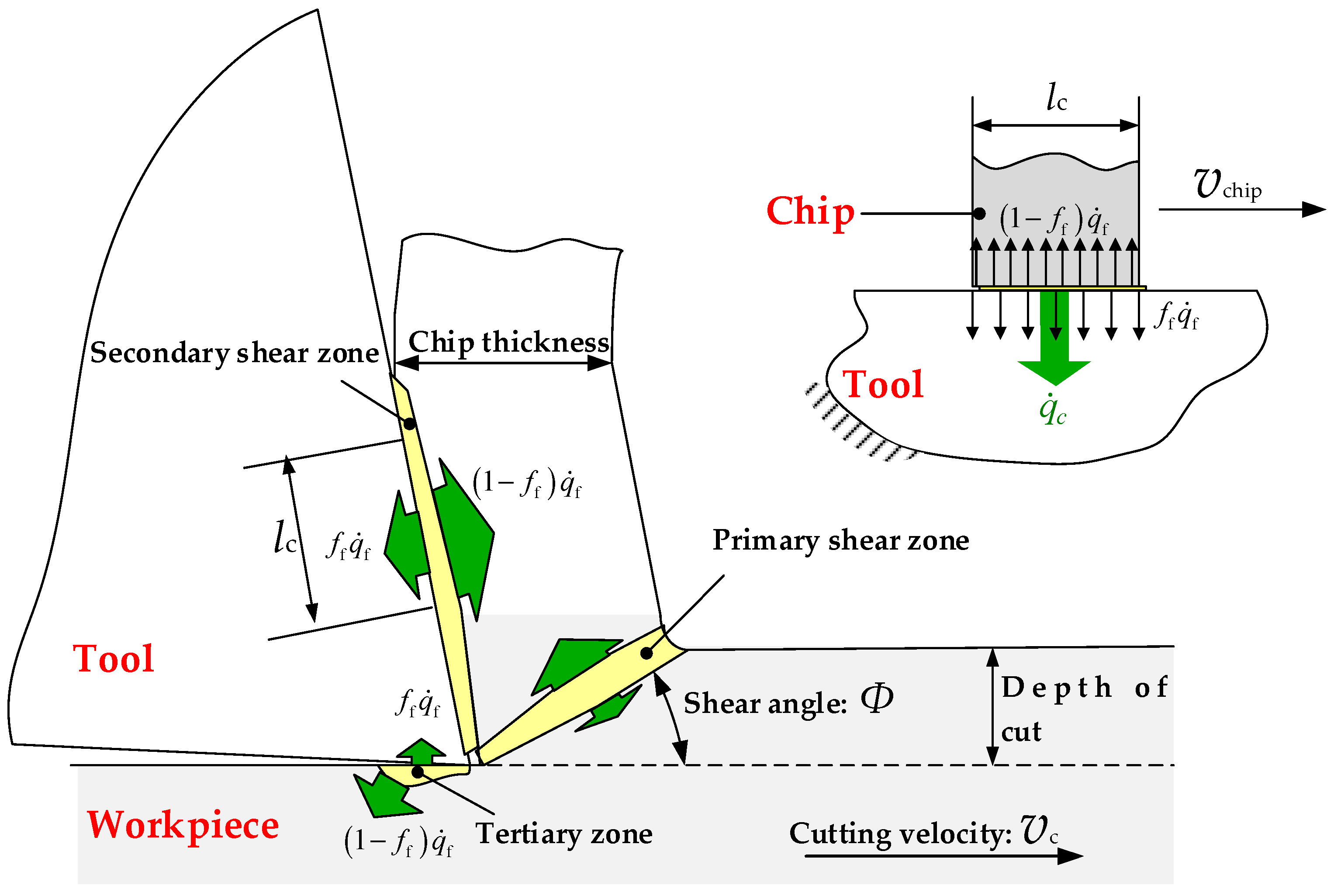

3.2. Heat Generation

3.3. Diamond Wear Modelling

4. Results and Discussions

4.1. Cutting Forces

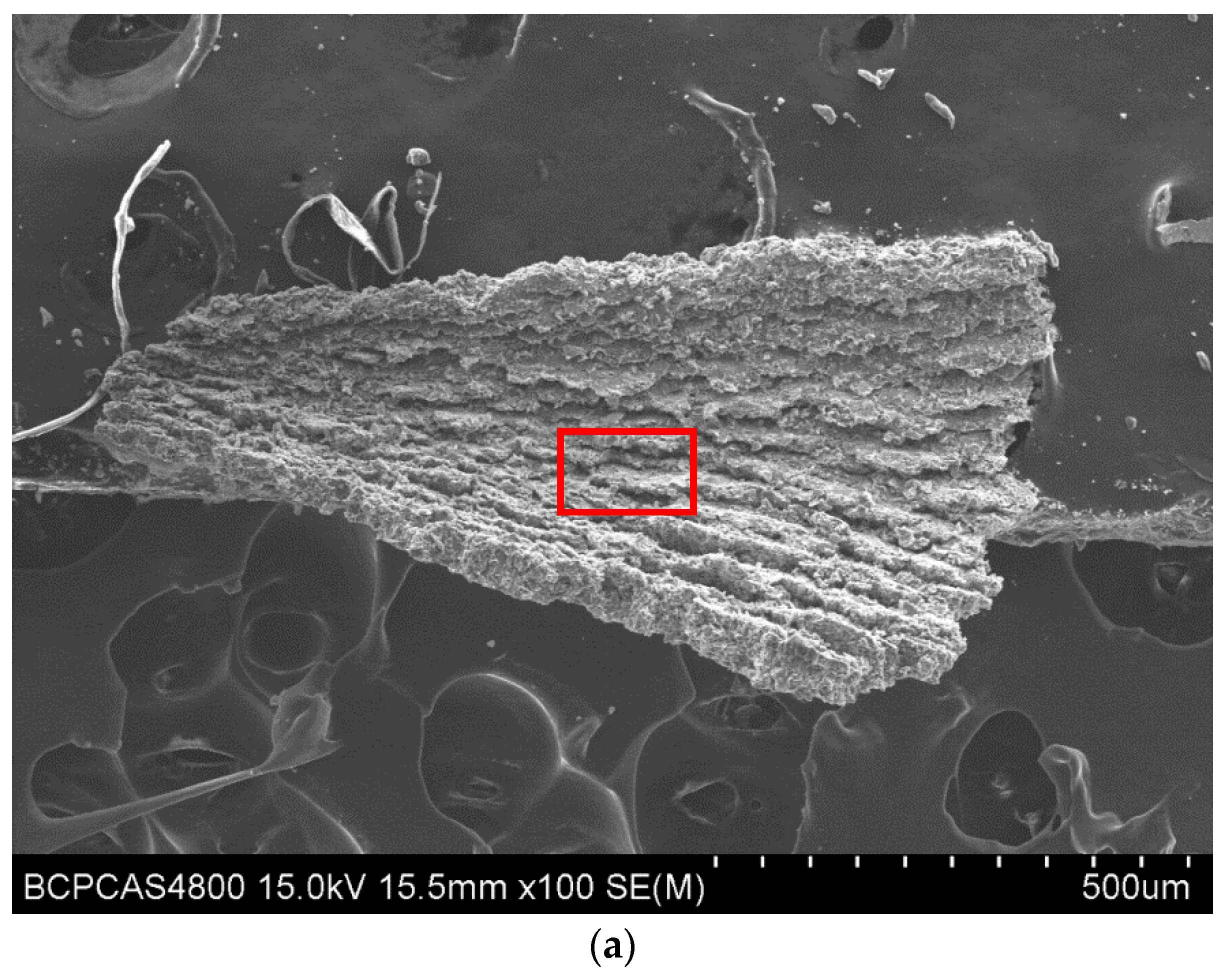

4.2. Chip Morphology

4.3. Tool Temperature

4.4. Tool Wear

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Dong, Z.; Zheng, F.; Zhu, X.; Kang, R.; Zhang, B. Characterization of material removal in ultrasonically assisted grinding of SiCp/Al with high volume fraction. Int. J. Adv. Manuf. Technol. 2017, 93, 2827–2839. [Google Scholar] [CrossRef]

- Ozben, T.; Kilickap, E.; Çakır, O. Investigation of mechanical and machinability properties of SiC particle reinforced Al-MMC. J. Mater. Process. Technol. 2008, 198, 220–225. [Google Scholar] [CrossRef]

- Wang, B.; Zhao, S.; Ojima, F.; Yang, J.; Ishizaki, K. Pulse electric current sintering of 3D interpenetrating SiC/Al composite. Ceram. Int. 2017, 43, 2867–2870. [Google Scholar] [CrossRef]

- Chen, X.; Xie, L.; Xue, X.; Wang, X. Research on 3D milling simulation of SiCp/Al composite based on a phenomenological model. Int. J. Adv. Manuf. Technol. 2017, 92, 2715–2723. [Google Scholar] [CrossRef]

- Palanikumar, K.; Muniaraj, A. Experimental investigation and analysis of thrust force in drilling cast hybrid metal matrix (Al–15% SiC–4% graphite) composites. Measurement 2014, 53, 240–250. [Google Scholar] [CrossRef]

- Das, S.; Behera, R.; Majumdar, G.; Oraon, B.; Sutradhar, G. An experimental investigation on the machinability of powder formed silicon carbide particle reinforced aluminium metal matrix composites. Int. J. Heat Mass Transf. 2007, 50, 5054–5064. [Google Scholar]

- Muthukrishnan, N.; Murugan, M.; Rao, K.P. An investigation on the machinability of Al-SiC metal matrix composites using PCD inserts. Int. J. Adv. Manuf. Technol. 2008, 5–6, 447–454. [Google Scholar] [CrossRef]

- Feng, P.; Liang, G.; Zhang, J. Ultrasonic vibration-assisted scratch characteristics of silicon carbide-reinforced aluminum matrix composites. Ceram. Int. 2014, 40, 10817–10823. [Google Scholar] [CrossRef]

- Ding, X.; Liew, W.Y.H.; Liu, X.D. Evaluation of machining performance of MMC with PCBN and PCD tools. Wear 2005, 259, 1225–1234. [Google Scholar] [CrossRef]

- Han, J.; Hao, X.; Li, L.; Wu, Q.; He, N. Milling of high volume fraction SiCp/Al composites using PCD tools with different structures of tool edges and grain sizes. Int. J. Adv. Manuf. Technol. 2017, 92, 1875–1882. [Google Scholar] [CrossRef]

- Bushlya, V.; Lenrick, F.; Gutnichenko, O.; Petrusha, I.; Osipov, O.; Kristiansson, S.; Stahl, J.E. Performance and wear mechanisms of novel superhard diamond and boron nitride based tools in machining Al-SiCp metal matrix composite. Wear 2017, 376–377, 152–164. [Google Scholar] [CrossRef]

- Schmauder, S.; Schäfer, I. Multiscale materials modeling. Mater. Today 2016, 19, 130–131. [Google Scholar] [CrossRef]

- Li, B. A review of tool wear estimation using theoretical analysis and numerical simulation technologies. Int. J. Refract. Met. Hard Mater. 2012, 35, 143–151. [Google Scholar] [CrossRef]

- Zhang, S.J.; To, S.; Zhang, G.Q. Diamond tool wear in ultra-precision machining. Int. J. Adv. Manuf. Technol. 2016, 88, 613–641. [Google Scholar] [CrossRef]

- Colding, B.N. Machinability of metals and machining costs. Int. J. Mach. Tool Des. Res. 1961, 1, 220–248. [Google Scholar] [CrossRef]

- Choudhury, S.K.; Rao, I.V.K.A. Optimization of cutting parameters for maximizing tool life. Int. J. Mach. Tools Manuf. 1999, 39, 343–353. [Google Scholar] [CrossRef]

- Marksberry, P.W.; Jawahir, I.S. A comprehensive tool-wear/tool-life performance model in the evaluation of NDM (near dry machining) for sustainable manufacturing. Int. J. Mach. Tools Manuf. 2008, 48, 878–886. [Google Scholar] [CrossRef]

- Tool Life Testing in Milling; International Standard 8688-2-1989; International Organization for Standardization: Geneva, Switzerland, 1989.

- Li, K.; Gao, X.L.; Sutherland, J.W. Finite element simulation of the orthogonal metal cutting process for qualitative understanding of the effects of crater wear on the chip formation process. J. Mater. Process. Technol. 2002, 127, 309–324. [Google Scholar] [CrossRef]

- Snr, D.E.D. Sensor signals for tool-wear monitoring in metal cutting operations—A review of methods. Int. J. Mach. Tools Manuf. 2000, 40, 1073–1098. [Google Scholar] [CrossRef]

- Takeyama, H.; Murata, R. Basic investigation of tool wear. J. Eng. Ind. 1963, 85, 33. [Google Scholar] [CrossRef]

- Usui, E.; Shirakashi, T.; Kitagawa, T. Analytical prediction of cutting tool wear. Wear 1984, 100, 129–151. [Google Scholar] [CrossRef]

- Shaw, M.C.; Dirke, S.O. On the wear of cutting tools. Microtecnic 1956, 10, 187. [Google Scholar] [CrossRef]

- Attanasio, A.; Ceretti, E.; Fiorentino, A.; Cappellini, C.; Giardini, C. Investigation and FEM-based simulation of tool wear in turning operations with uncoated carbide tools. Wear 2010, 269, 344–350. [Google Scholar] [CrossRef]

- Jiang, H. A cobalt diffusion based model for predicting crater wear of carbide tools in machining titanium alloys. J. Eng. Mater. Technol. ASME 2005, 127, 136–144. [Google Scholar] [CrossRef]

- López de Lacalle, L.N.; Lamikiz, A. Mechanistic model for drills with double point-angle edges. Int. J. Adv. Manuf. Technol. 2009, 40, 447–457. [Google Scholar] [CrossRef]

- Xie, L.J.; Schmidt, J.; Schmidt, C.; Biesinger, F. 2D FEM estimate of tool wear in turning operation. Wear 2005, 258, 1479–1490. [Google Scholar] [CrossRef]

- Attanasio, A.; Ceretti, E.; Rizzuti, S.; Umbrello, D.; Micari, F. 3D finite element analysis of tool wear in machining. CIRP Ann.-Manuf. Technol. 2008, 57, 61–64. [Google Scholar] [CrossRef]

- Narulkar, R.; Bukkapatnam, S.; Raff, L.M.; Komanduri, R. Graphitization as a precursor to wear of diamond in machining pure iron: A molecular dynamics investigation. Comp. Mater. Sci. 2009, 45, 358–366. [Google Scholar] [CrossRef]

- Bródka, A.; Zerda, T.W.; Burian, A. Graphitization of small diamond cluster—Molecular dynamics simulation. Diam. Relat. Mater. 2006, 15, 1818–1821. [Google Scholar] [CrossRef]

- Xiang, J.; Xie, L.; Gao, F.; Yi, J.; Pang, S.; Wang, X. Diamond tools wear in drilling of SiCp/Al matrix composites containing Copper. Ceram. Int. 2018, 44, 5341–5351. [Google Scholar] [CrossRef]

- Chou, Y.K.; Liu, J. CVD diamond tool performance in metal matrix composite machining. Surf. Coat. Technol. 2005, 200, 1872–1878. [Google Scholar] [CrossRef]

- Rodríguez-Barrero, S.; Fernández-Larrinoa, J.; Azkona, I.; López de Lacalle, L.N.; Polvorosa, R. Enhanced performance of nanostructured coatings for drilling by droplet elimination. Mater. Manuf. Process. 2016, 31, 593–602. [Google Scholar] [CrossRef]

- Xiang, J.; Xie, L.; Gao, F.; Zhang, Y.; Yi, J.; Pang, S.; Wang, X. On multi-objective based constitutive modelling methodology and numerical validation in small-hole drilling of Al6063/SiCp composites. Materials 2018, 11, 97. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Ramesh, K.T.; Chin, E.S.C. Viscoplastic deformations and compressive damage in an A359/SiCp metal–matrix composite. Acta Mater. 2000, 48, 1563–1573. [Google Scholar] [CrossRef]

- Lloyd, D.J. Aspects of fracture in particulate reinforced metal matrix composites. Acta Metall. Mater. 1991, 39, 59–71. [Google Scholar] [CrossRef]

- Wang, T.; Xie, L.; Wang, X. Simulation study on defect formation mechanism of the machined surface in milling of high volume fraction SiCp/Al composite. Int. J. Adv. Manuf. Technol. 2015, 79, 1185–1194. [Google Scholar] [CrossRef]

- Zhang, P.; Li, F. Statistical analysis of reinforcement characterization in SiC particle reinforced Al matrix composites. J. Mater. Sci. Technol. 2009, 25, 807–813. [Google Scholar] [CrossRef]

- Pujana, J.; Rivero, A.; Celaya, A.; López de Lacalle, L.N. Analysis of ultrasonic-assisted drilling of Ti6Al4V. Int. J. Mach. Tools Manuf. 2009, 49, 500–508. [Google Scholar] [CrossRef]

- Gandarias, A.; López de Lacalle, L.N.; Aizpitarte, X.; Lamikiz, A. Study of the performance of the turning and drilling of austenitic stainless steels using two coolant techniques. Int. J. Mach. Mach. Mater. 2008, 3, 1–17. [Google Scholar] [CrossRef]

- Calatoru, V.D.; Balazinski, M.; Mayer, J.R.R.; Paris, H.; L’Espérance, G. Diffusion wear mechanism during high-speed machining of 7475-T7351 aluminum alloy with carbide end mills. Wear 2008, 265, 1793–1800. [Google Scholar] [CrossRef]

- Batzer, S.A.; Haan, D.M.; Rao, P.D.; Olson, W.W.; Sutherland, J.W. Chip morphology and hole surface texture in the drilling of cast Aluminum alloys. J. Mater. Process. Technol. 1998, 79, 72–78. [Google Scholar] [CrossRef]

| Element | Al | Mg | Cu | Si | C | Others |

|---|---|---|---|---|---|---|

| wt % | 38.33 | 0.48 | 1.51 | 51.24 | 8.43 | margin |

| Items | Contents | |

|---|---|---|

| Tooling | ||

| Tool Manufacturer | Zhengzuan Precision Manufacture Co., Ltd. (Zhengzhou, China) | |

| Drill bit material | PCD | CVD diamond |

| Diameter d (mm) | 3 | 3 |

| Point angle (°) | 120 | 140 |

| Rake angle (°) | 0 | |

| Relief angle (°) | 10 | |

| Helix angle (°) | 30 | 30 |

| Workpiece | ||

| Material | Al6063/SiCp/65p composites | |

| Thickness (mm) | 2 | |

| Cutting Conditions | ||

| Operation | Drilling | |

| Rotational speed (rpm) | 2000 | |

| Feed velocity (mm/min) | 100 | |

| Drilling environment | Dry | |

| A/MPa | B/MPa | C | D0 | E | n | m | α | β | k | Tb |

|---|---|---|---|---|---|---|---|---|---|---|

| 501 | 449 | 0.0002 | 0.291 | 0.8995 | 0.2539 | 1.602 | 0.0105 | 0.1675 | 0.4781 | 98.2 |

| Notation | Material Properties | Value |

|---|---|---|

| Density (kg/m3) | 2960 | |

| Specific heat capacity (J/kg) | 750 | |

| α | Coefficient of thermal expansion (10−6) | 7.7 |

| κ | Thermal conductivity (W/m∙) | 175 |

| Elastic modulus (GPa) | 221 | |

| υ | Poisson’s ratio | 0.21 |

| Room temperature | 20 | |

| Melting point | 635 | |

| Reference strain rate | 0.01 | |

| η | Inelastic heat fraction | 0.9 |

| Cutting Tool | Experimental MFWW | Simulated MFWW | Relative Error |

|---|---|---|---|

| PCD | 43.237 μm | 47.544 μm | 9.96% |

| CVD | 38.119 | 37.608 μm | 1.34% |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiang, J.; Pang, S.; Xie, L.; Gao, F.; Hu, X.; Yi, J.; Hu, F. Mechanism-Based FE Simulation of Tool Wear in Diamond Drilling of SiCp/Al Composites. Materials 2018, 11, 252. https://doi.org/10.3390/ma11020252

Xiang J, Pang S, Xie L, Gao F, Hu X, Yi J, Hu F. Mechanism-Based FE Simulation of Tool Wear in Diamond Drilling of SiCp/Al Composites. Materials. 2018; 11(2):252. https://doi.org/10.3390/ma11020252

Chicago/Turabian StyleXiang, Junfeng, Siqin Pang, Lijing Xie, Feinong Gao, Xin Hu, Jie Yi, and Fang Hu. 2018. "Mechanism-Based FE Simulation of Tool Wear in Diamond Drilling of SiCp/Al Composites" Materials 11, no. 2: 252. https://doi.org/10.3390/ma11020252