Studies of the Influence of Beam Profile and Cooling Conditions on the Laser Deposition of a Directionally-Solidified Superalloy

Abstract

:1. Introduction

2. Research Approaches

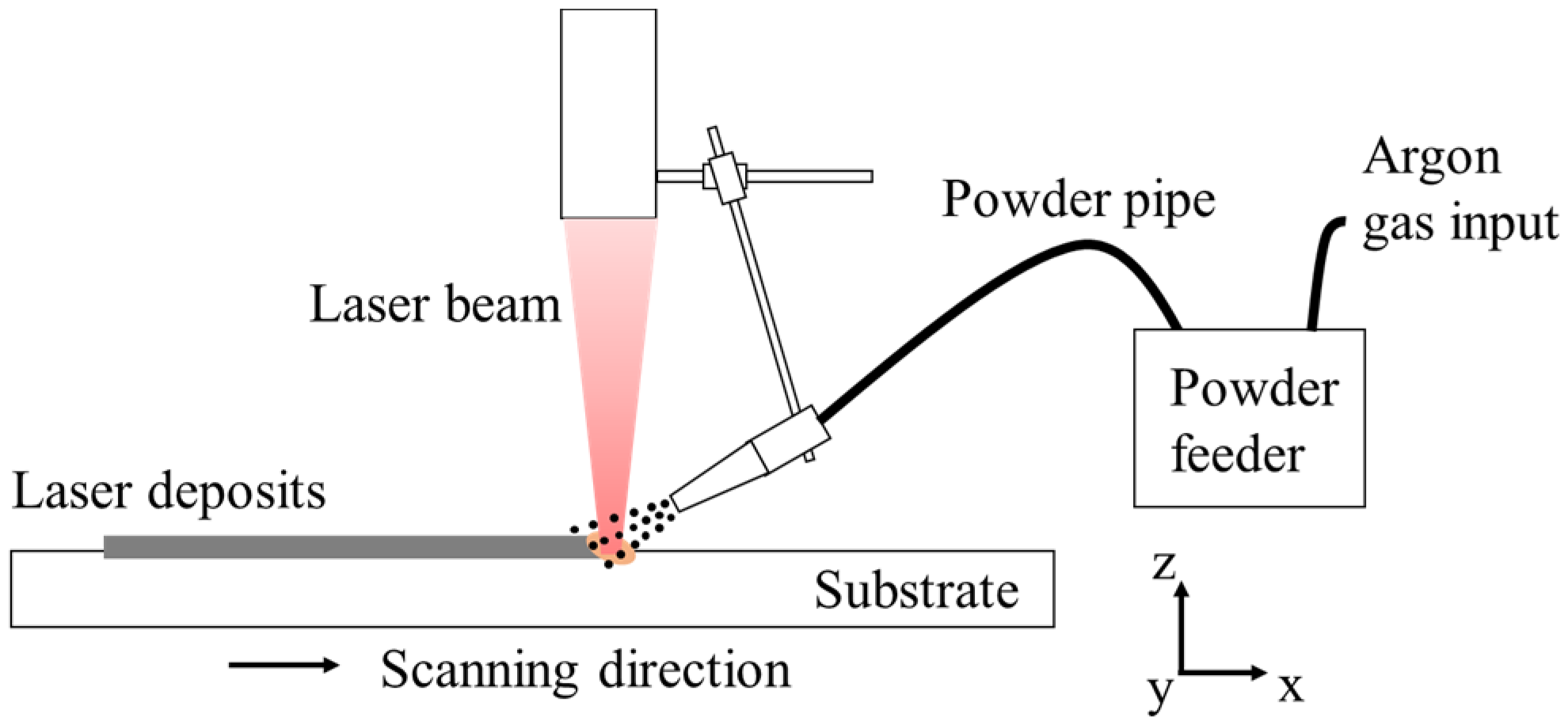

2.1. Experimental Research

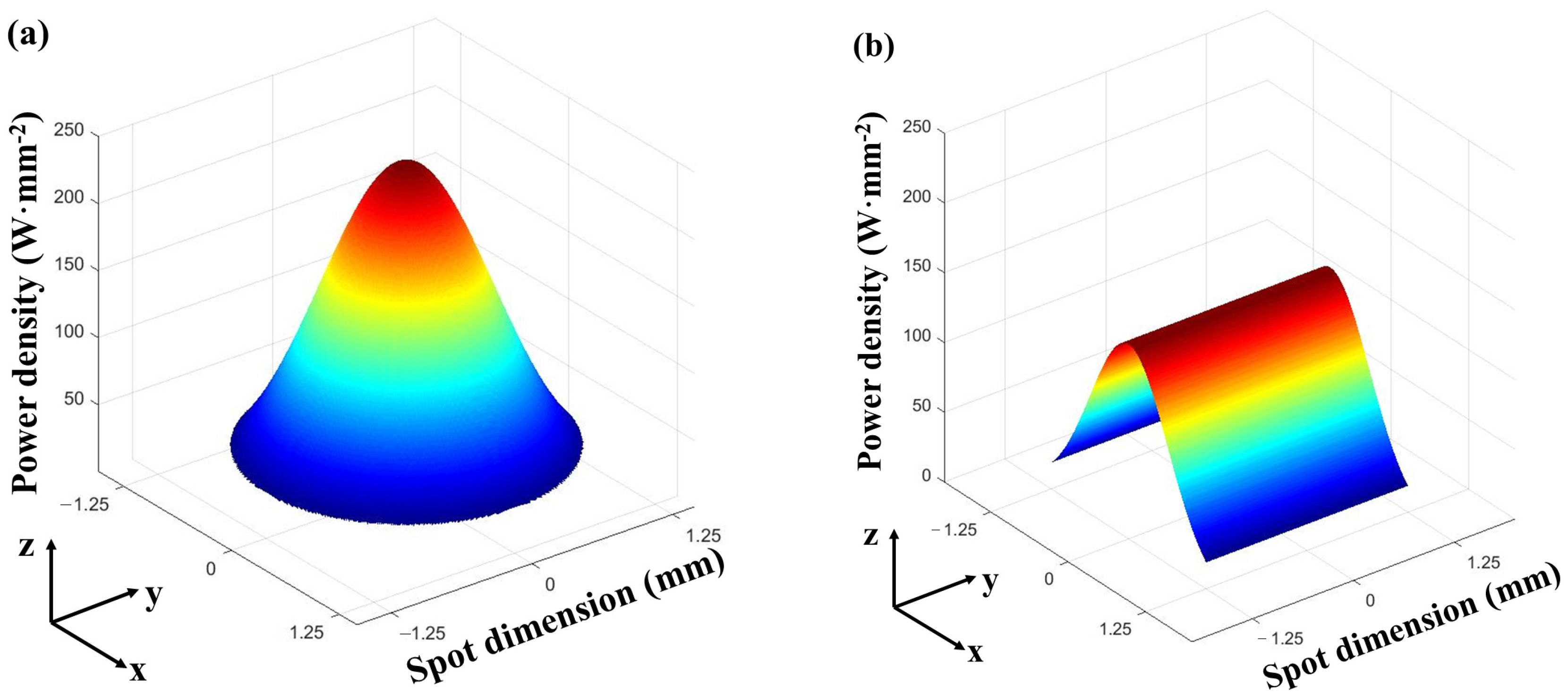

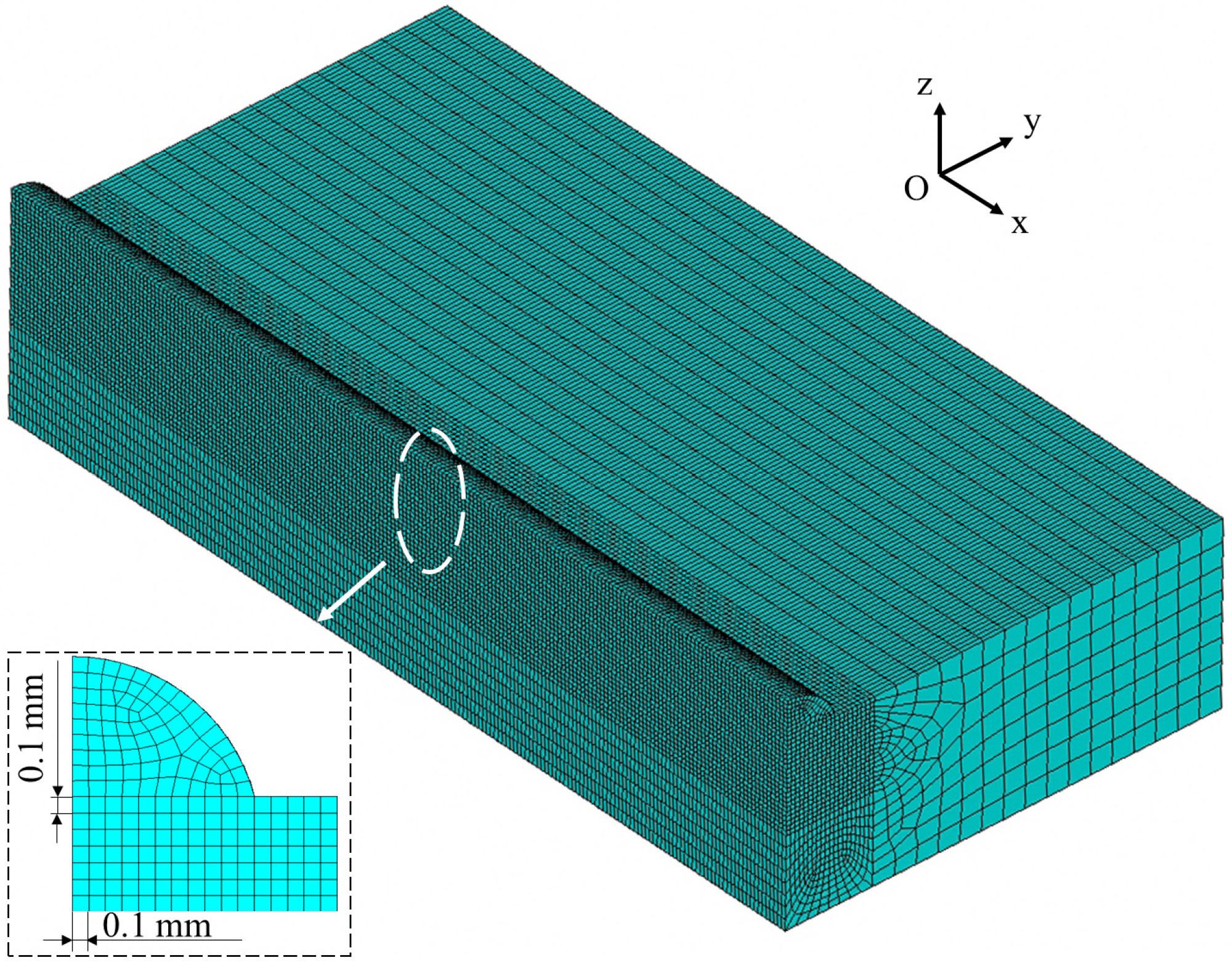

2.2. Numerical Analysis

3. Experimental Results

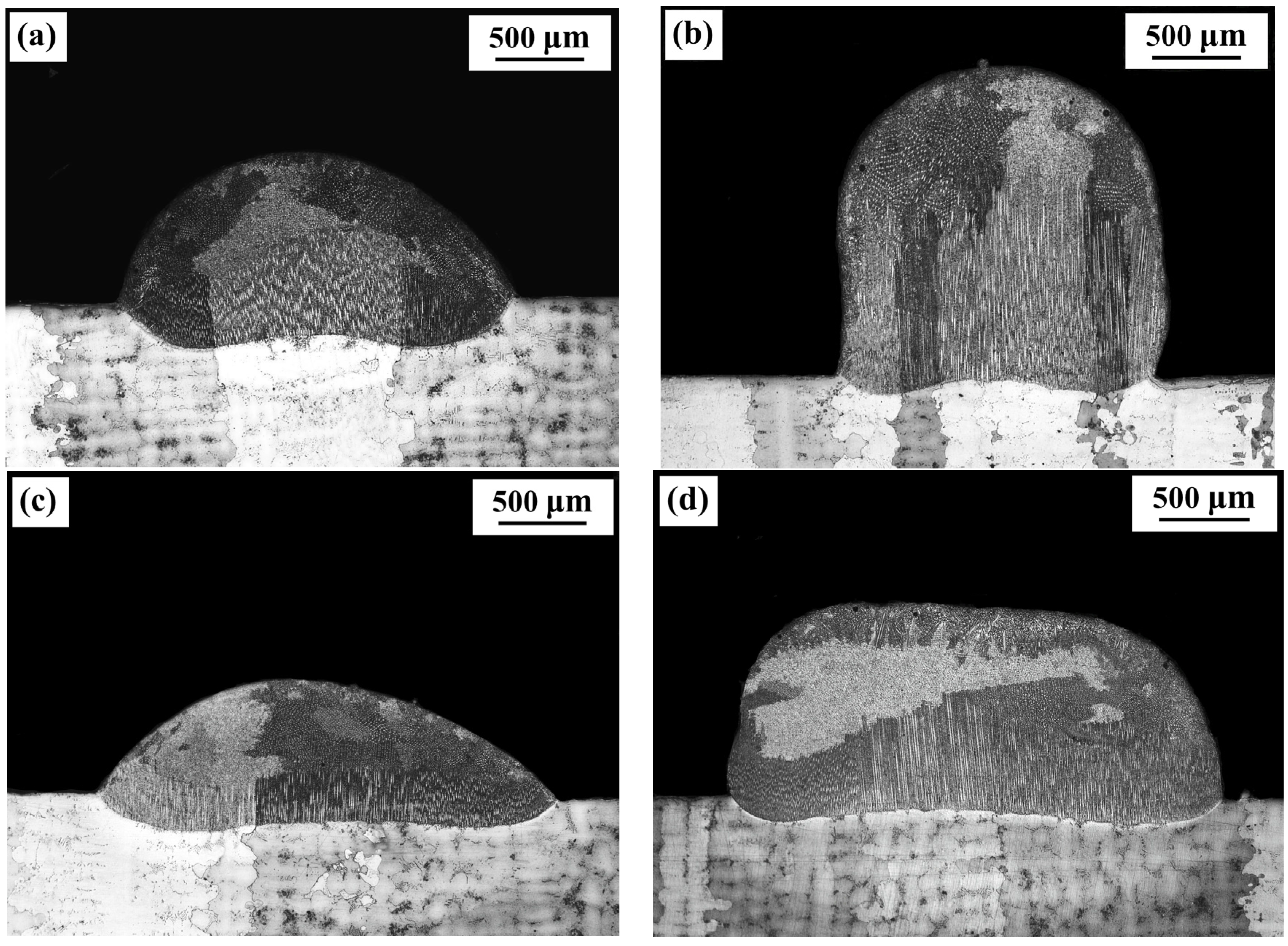

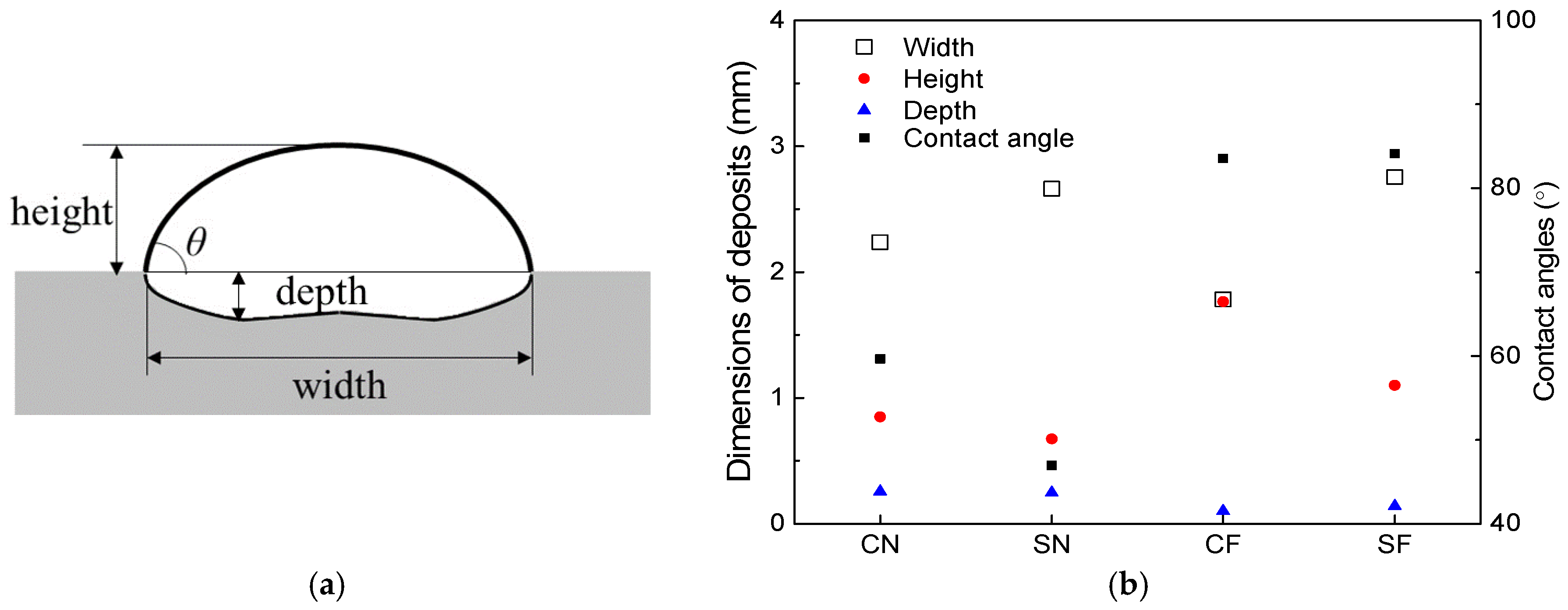

3.1. Geometric Morphology of Deposits

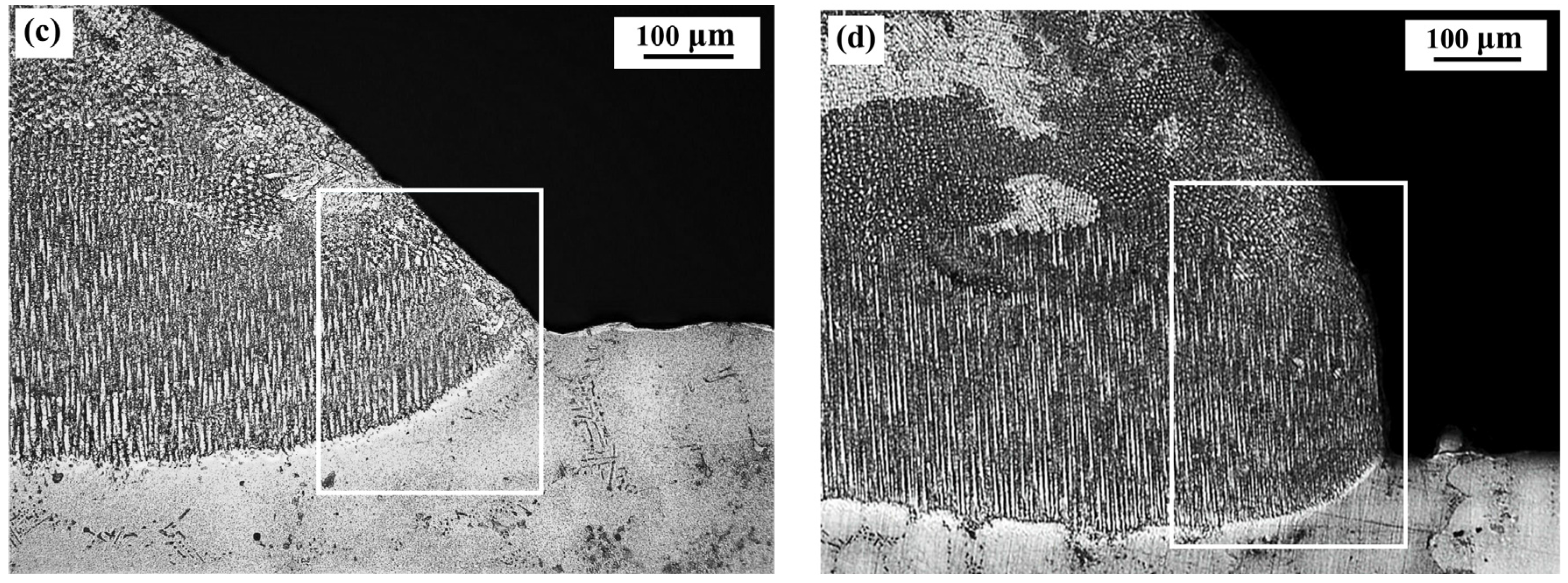

3.2. Characteristics of Columnar Grains

4. Discussion

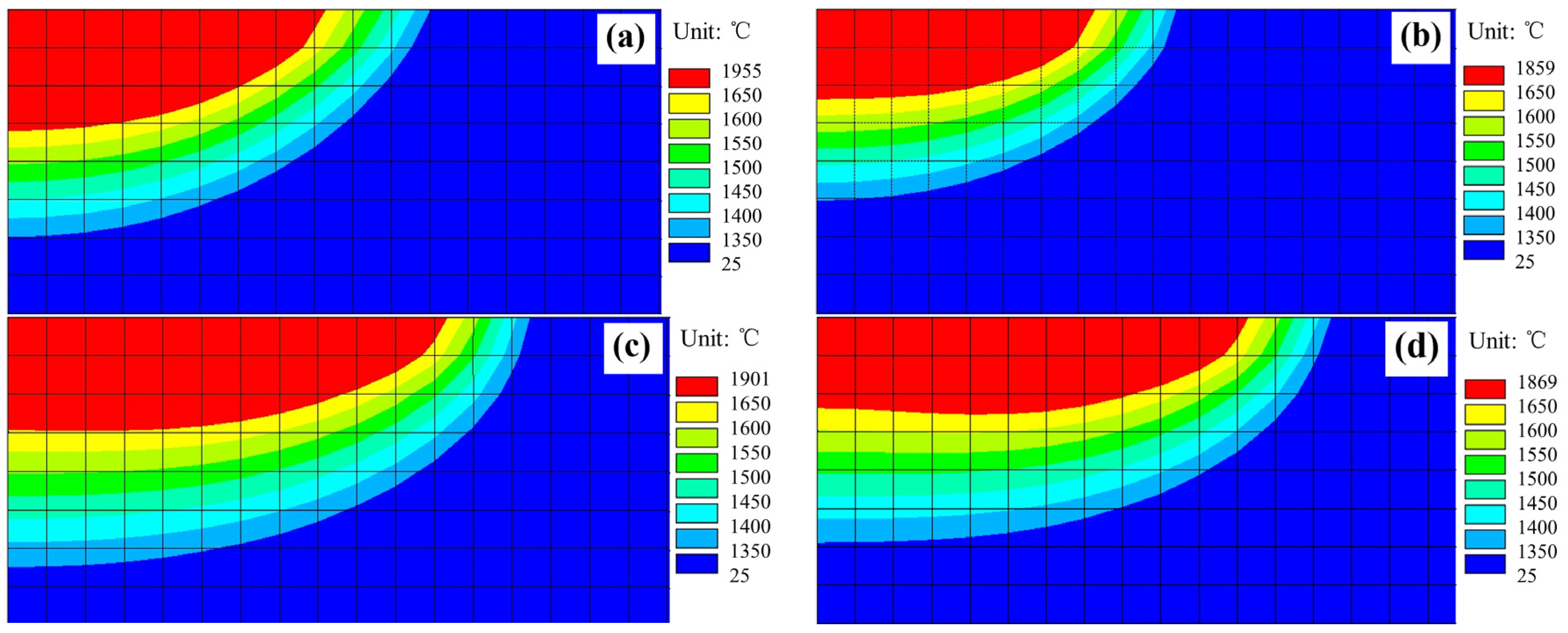

4.1. Relationships between the Thermal Process and Geometric Morphology of Deposits

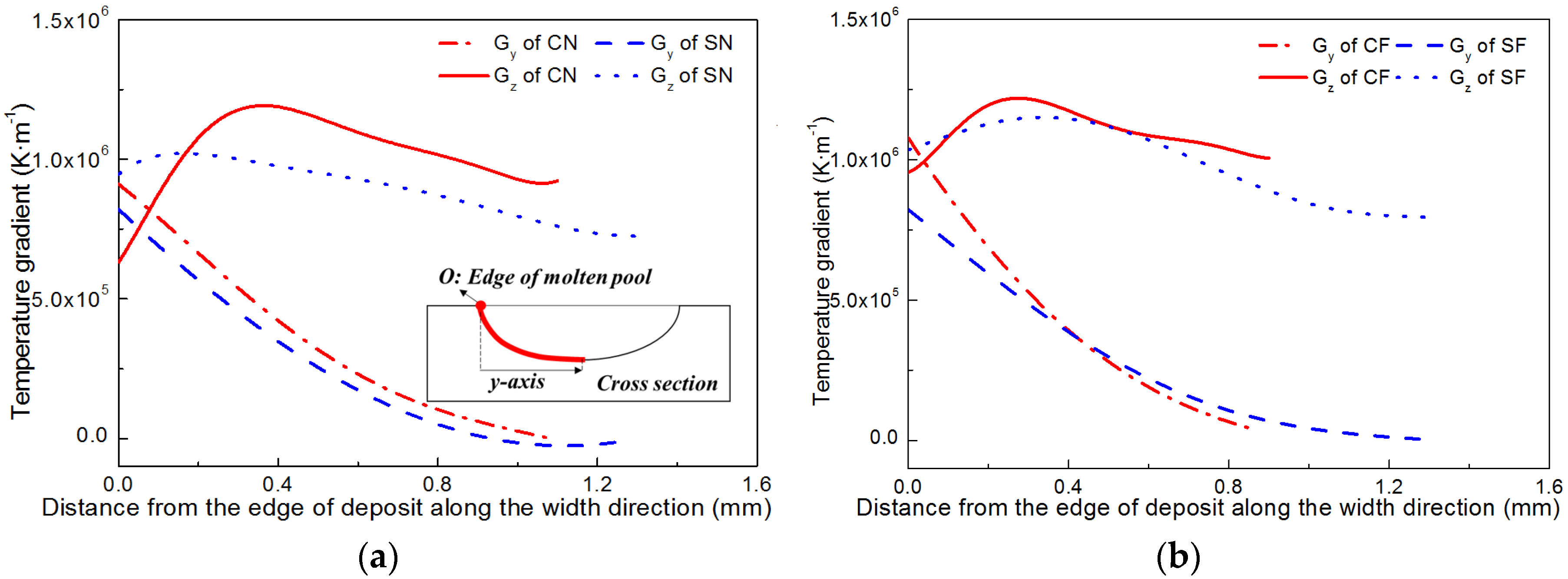

4.2. Relationships between the Thermal Process and the Growth Direction of Columnar Grains

4.3. Relationships between the Thermal Process and the Heights of Columnar Grains

5. Conclusions

- (1)

- Wider and thinner deposits were obtained with the square laser beam than those with the circular laser beam, no matter whether natural or forced cooling conditions were used. The heights and contact angles of the deposits were notably increased by the application of forced cooling.

- (2)

- Under the natural cooling conditions, the epitaxial columnar grains formed at the edge of the deposits with the square laser beam, but not with the circular laser beam; a higher volume fraction of columnar grains was therefore obtained by using the square beam profile.

- (3)

- Under forced cooling conditions, columnar grains formed at both the center and the edges of the deposits, regardless the laser beam profiles. The volume fractions of columnar grains were increased by applying forced cooling, and the increase was more significant for the circular beam than for the square beam.

- (4)

- Low substrate temperatures and short solidification times of molten metals under forced cooling are beneficial to forming deposits with increased heights and contact angles between deposits and substrates.

- (5)

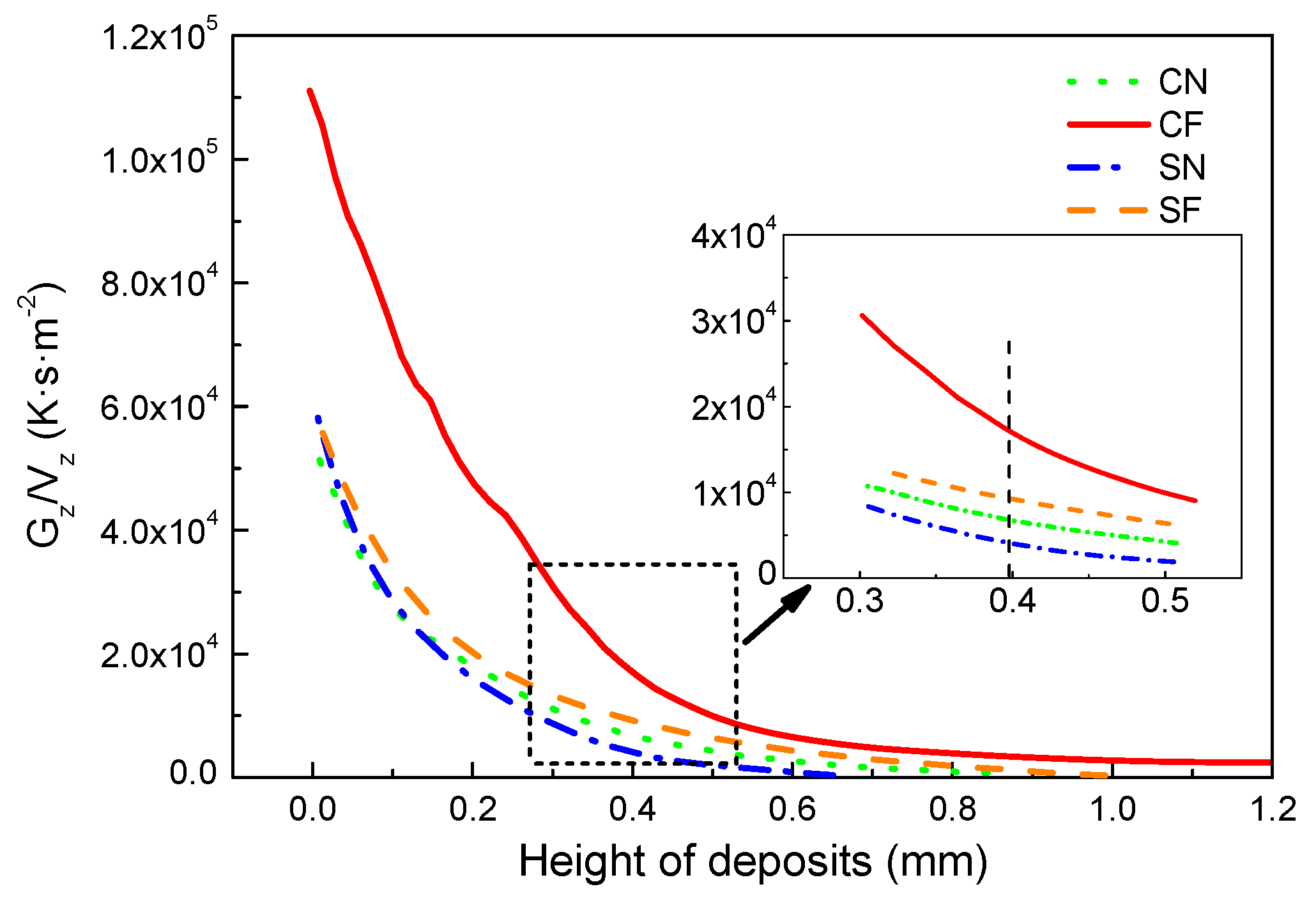

- High thermal gradients and large ratios of G/V in the height direction can be obtained by adjusting the laser beam profiles and cooling conditions, which are preferable for forming deposits with higher volume fractions of directionally-grown columnar grains.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Caron, P.; Khan, T. Evolution of Ni-based superalloys for single crystal gas turbine blade applications. Aerosp. Sci. Technol. 1999, 3, 513–523. [Google Scholar] [CrossRef]

- Li, H.; Cheng, T.; Zhang, J. Analysis of transient temperature distribution. Aircr. Eng. Aerosp. Technol. 2004, 76, 607–611. [Google Scholar] [CrossRef]

- Versnyde, F.L.; Shank, M.E. Development of columnar grain and single crystal high temperature materials through directional solidification. Mater. Sci. Eng. 1970, 6, 213–247. [Google Scholar] [CrossRef]

- Hunt, J.D. Steady state columnar and equiaxed growth of dendrites and eutectic. Mater. Sci. Eng. 1984, 65, 75–83. [Google Scholar] [CrossRef]

- Gaumann, M.; Trivedi, R.; Kurz, W. Nucleation ahead of the advancing interface in directional solidification. Mater. Sci. Eng. A 1997, 226, 763–769. [Google Scholar] [CrossRef]

- Gaumann, M.; Henry, S.; Cleton, F.; Wagniere, J.D.; Kurz, W. Epitaxial laser metal forming: Analysis of microstructure formation. Mater. Sci. Eng. A 1999, 271, 232–241. [Google Scholar] [CrossRef]

- Gaumann, M.; Bezencom, C.; Canalis, P.; Kurz, W. Single-crystal laser deposition of superalloys: Processing-microstructure maps. Acta Mater. 2001, 49, 1051–1062. [Google Scholar] [CrossRef]

- Liu, W.P.; Dupont, J.N. Direct laser deposition of a single-crystal Ni3Al-based IC221W alloy. Metall. Mater. Trans. 2005, 36, 3397–3406. [Google Scholar] [CrossRef]

- Basak, A.; Das, S. Additive manufacturing of Nickel-base superalloy Rene N5 through scanning laser epitaxy (SLE)—Material processing, microstructures, and microhardness properties. Adv. Eng. Mater. 2017, 19, 1600690. [Google Scholar] [CrossRef]

- Basak, A.; Acharya, R.; Das, S. Additive manufacturing of single-crystal superalloy CMSX-4 through scanning laser epitaxy: Computational modeling, experimental process development, and process parameter optimization. Metall. Mater. Trans. A 2016, 47A, 3845–3859. [Google Scholar] [CrossRef]

- Liu, Z.Y.; Qi, H. Mathematical modeling of crystal growth and microstructure formation in multi-layer and multi-track laser powder deposition of single-crystal superally. Phys. Procedia 2014, 56, 411–420. [Google Scholar] [CrossRef]

- Liu, Z.Y.; Qi, H. Effects of processing parameters on crystal growth and microstructure formation in laser powder deposition of single-crystal superalloy. J. Mater. Process. Technol. 2015, 216, 19–27. [Google Scholar] [CrossRef]

- Xuantuoi, D.; Li, D.C.; Zhang, A.F.; He, B. Numeriacal experimental investigation on the epitaxial growth of columnar crystal in laser metal direct forming of DZ125L superalloy. Chin. J. Lasers 2013, 40, 1–7. [Google Scholar] [CrossRef]

- Kurz, W.; Bezencon, C.; Gaumann, M. Columnar to equiaxed transition in solidification processing. Sci. Technol. Adv. Mater. 2001, 2, 185–191. [Google Scholar] [CrossRef]

- Wang, L.; Wang, N.; Yao, W.J.; Zheng, Y.P. Effect of substrate orientation on the columnar-to-equiaxed transition in laser surface remelted single crystal superalloys. Acta Meter. 2015, 88, 283–292. [Google Scholar] [CrossRef]

- Shang, S.; Wellburn, D.; Sun, Y.Z.; Wang, S.Y.; Cheng, J.; Liang, J.; Liu, C.S. Laser beam profile modulation for microstructure control in laser cladding of an NiCrBSi alloy. Surf. Coat. Technol. 2014, 248, 46–53. [Google Scholar] [CrossRef]

- Goffin, N.J.; Higginson, R.L.; Tyrer, J.R. The use of holographic optical elements (HOE’s) to investigate the use of a flat irradiance profile in the control of heat absorption in wire-fed laser cladding. J. Mater. Process. Technol. 2015, 220, 191–201. [Google Scholar] [CrossRef] [Green Version]

- Chen, Y.; Lu, F.G.; Zhang, K.; Nie, P.L.; Hosseini, S.R.E.; Feng, K.; Li, Z.G. Dendritic microstructure and hot cracking of laser additive manufactured Inconel 718 under improved base cooling. J. Alloys Compd. 2016, 670, 312–321. [Google Scholar] [CrossRef]

- Zhao, X.H.; Huang, Z.H.; Tan, Y.N.; Zhang, Q.; Yu, Q.; Xu, H.B. New Ni3Al-based directionally-solidified superalloy IC10. J. Aeronaut. Mater. 2006, 26, 20–24. [Google Scholar]

- Xing, B.; Chang, B.H.; Du, D. Effects of process parameters on morphology of laser deposited layer on IC10 directionally solidified superalloy. Trans. China Weld. Inst. 2015, 36, 88–92. [Google Scholar]

- Pellissier, G.E.; Purdy, S.M. Stereology and Quantitative Metallography; ASTM: New York, NY, USA, 1979. [Google Scholar]

- Yu, J.; Lin, X.; Wang, J.J.; Chen, J.; Huang, W.D. Mechanics and energy analysis on molten pool spreading during laser solid forming. Appl. Surf. Sci. 2010, 256, 4612–4620. [Google Scholar] [CrossRef]

- Liu, Z.Y.; Qi, H. Effects of substrate crystallographic orientations on crystal growth and microstructure formation in laser powder deposition of nickel-based superalloy. Acta Mater. 2015, 87, 248–258. [Google Scholar] [CrossRef]

| Elements | C | Co. | Cr | Al | W | Mo | Ta | Hf | B | Ni |

|---|---|---|---|---|---|---|---|---|---|---|

| Content, wt % | 0.1 | 12.0 | 7.0 | 5.9 | 5.0 | 1.5 | 7.0 | 1.5 | 0.015 | Balance |

| Conditions | Forced Cooling (F) | Natural Cooling (N) |

|---|---|---|

| Circular laser beam spot with a Gaussian distribution of power density (C) | Circular beam with forced cooling (CF) | Circular beam with natural cooling (CN) |

| Square laser beam spot with an uniform power density in one direction and a Gaussian distribution in another (S) | Square beam with forced cooling (SF) | Square beam with natural cooling (SN) |

| Property | Values |

|---|---|

| Density (kg/m3) | 8290 |

| Specific heat (J/kg·°C) | 360 + 0.04 × T (°C) |

| Thermal conductivity (W/m·°C) | 8.43 + 0.0178 × T (°C) |

| Solidus temperature (°C) | 1337 |

| Liquidus temperature (°C) | 1370 |

| Latent heat of fusion (J/kg) | 3.0 × 105 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, S.; Du, D.; Chang, B. Studies of the Influence of Beam Profile and Cooling Conditions on the Laser Deposition of a Directionally-Solidified Superalloy. Materials 2018, 11, 240. https://doi.org/10.3390/ma11020240

Yang S, Du D, Chang B. Studies of the Influence of Beam Profile and Cooling Conditions on the Laser Deposition of a Directionally-Solidified Superalloy. Materials. 2018; 11(2):240. https://doi.org/10.3390/ma11020240

Chicago/Turabian StyleYang, Shuo, Dong Du, and Baohua Chang. 2018. "Studies of the Influence of Beam Profile and Cooling Conditions on the Laser Deposition of a Directionally-Solidified Superalloy" Materials 11, no. 2: 240. https://doi.org/10.3390/ma11020240