Effect of Shell Growth on the Morphology of Polyvinyl Acetate/Polystyrene Inverted Core-Shell Latex Fabricated by Acrylonitrile Grafting

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Latex Preparation

2.2.1. Synthesis of Seed Latex

2.2.2. Synthesis of Core-Shell Structure Emulsion

2.3. Characterization

3. Results and Discussion

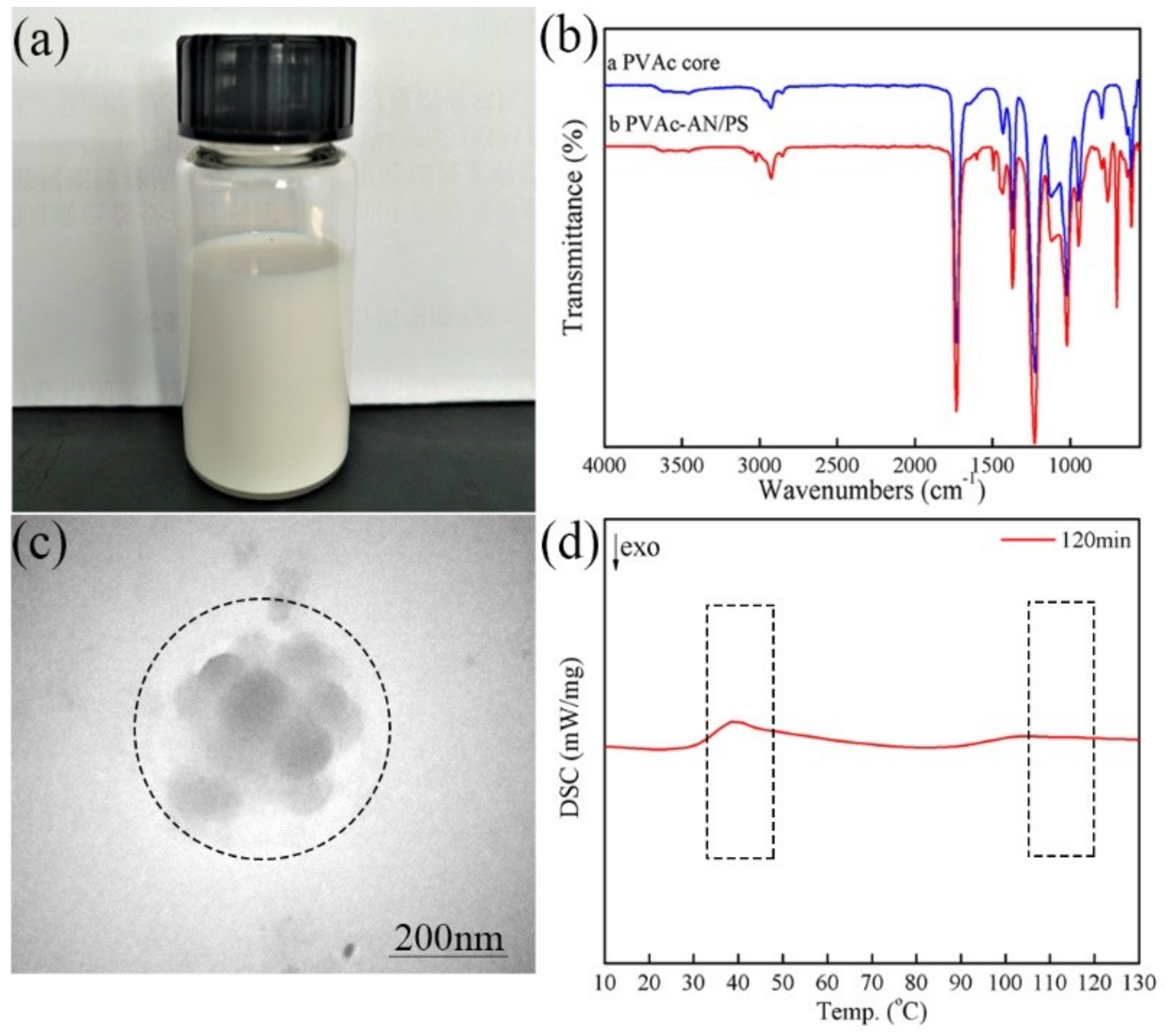

3.1. Characterization of Structured Latexes

3.2. Morphological Evolution of PVAc-AN/PS Latex Particle

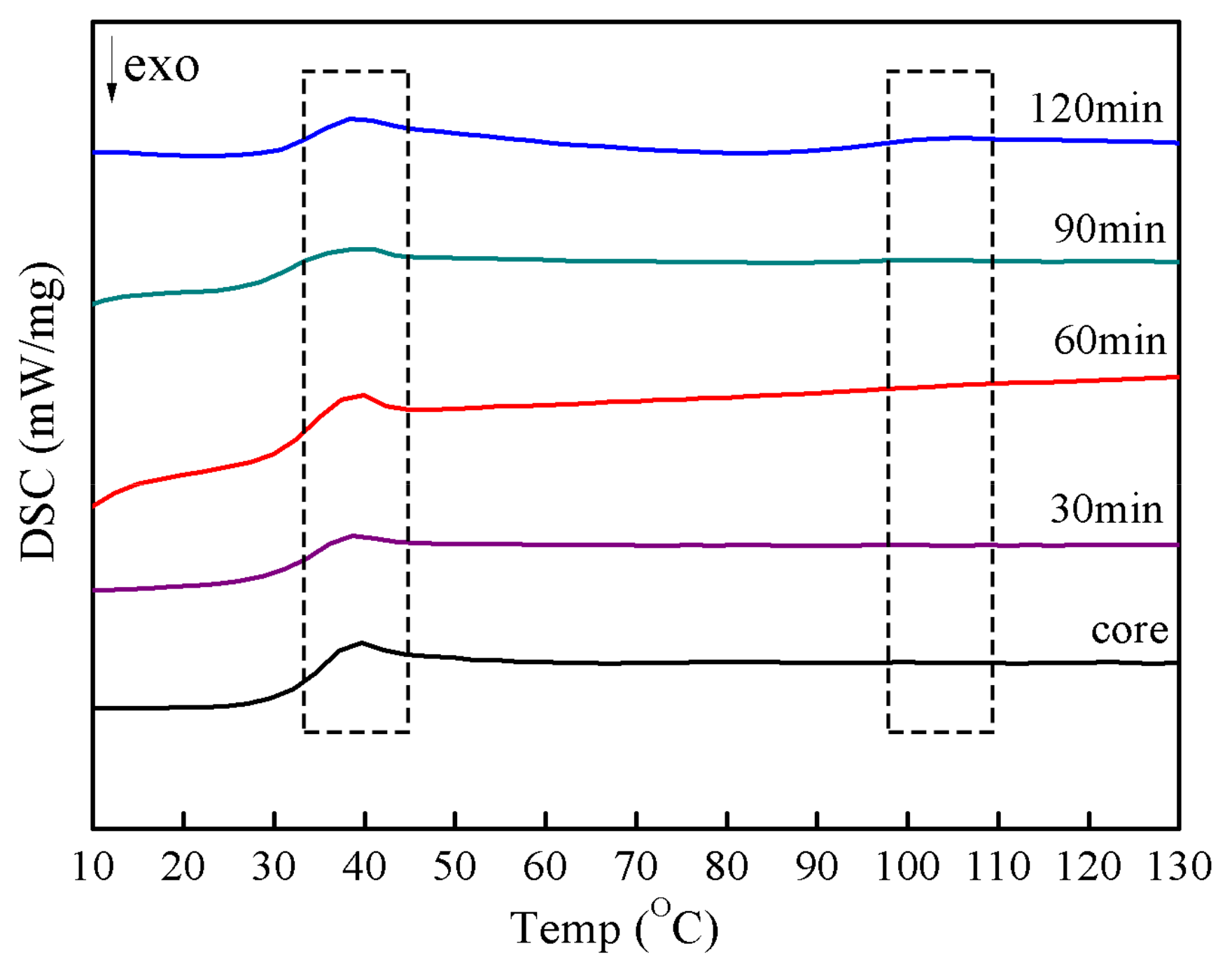

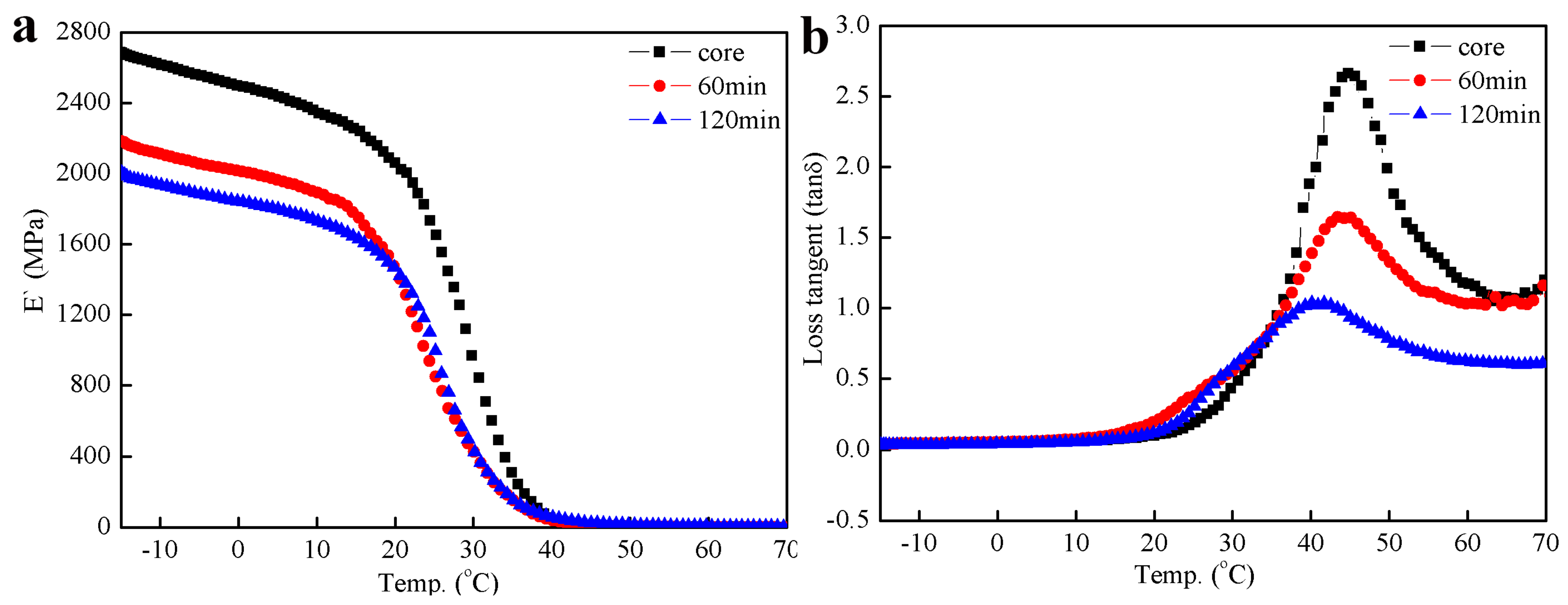

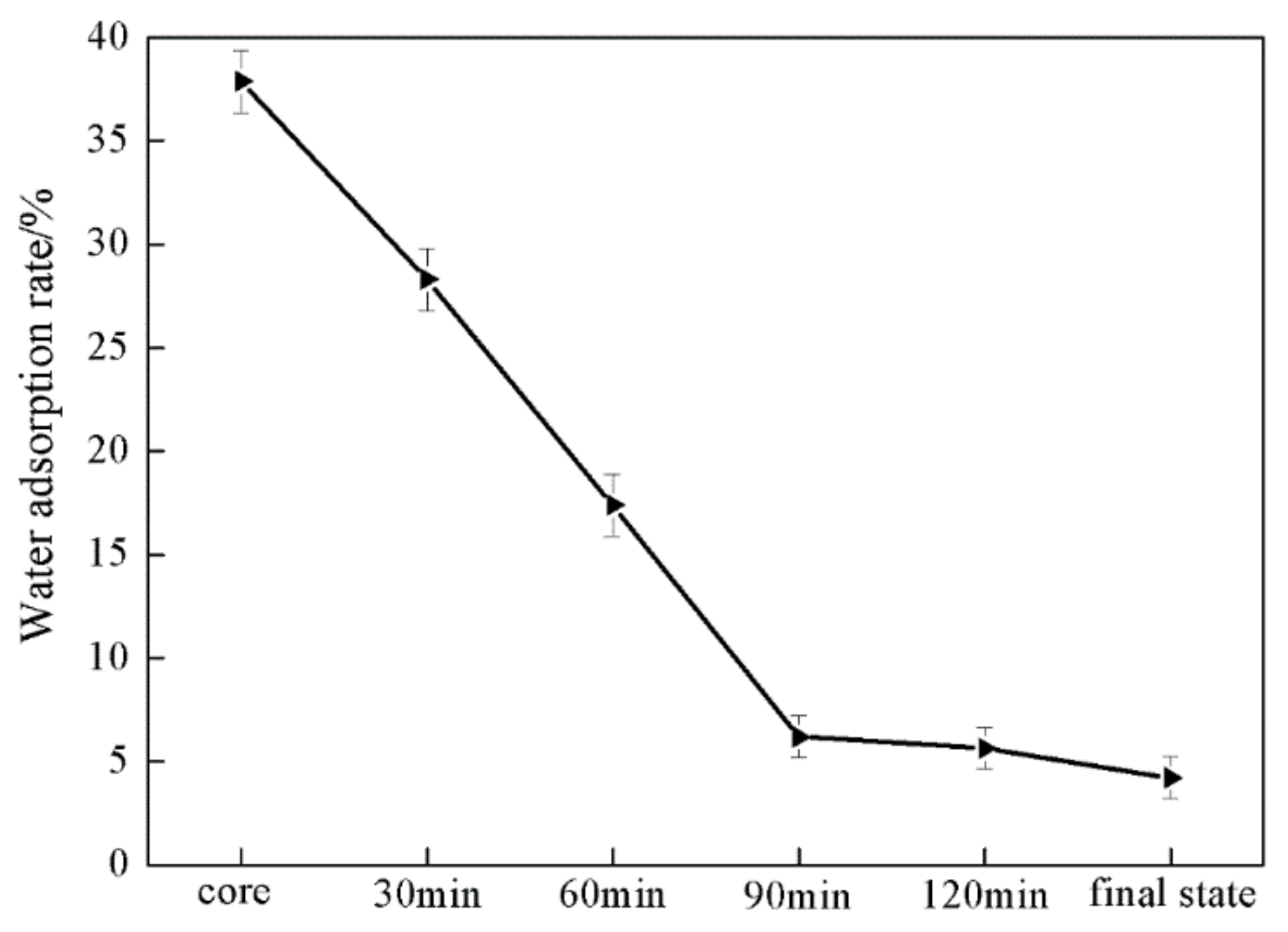

3.3. Effect of Shell Growth on the Latex Particle Structure

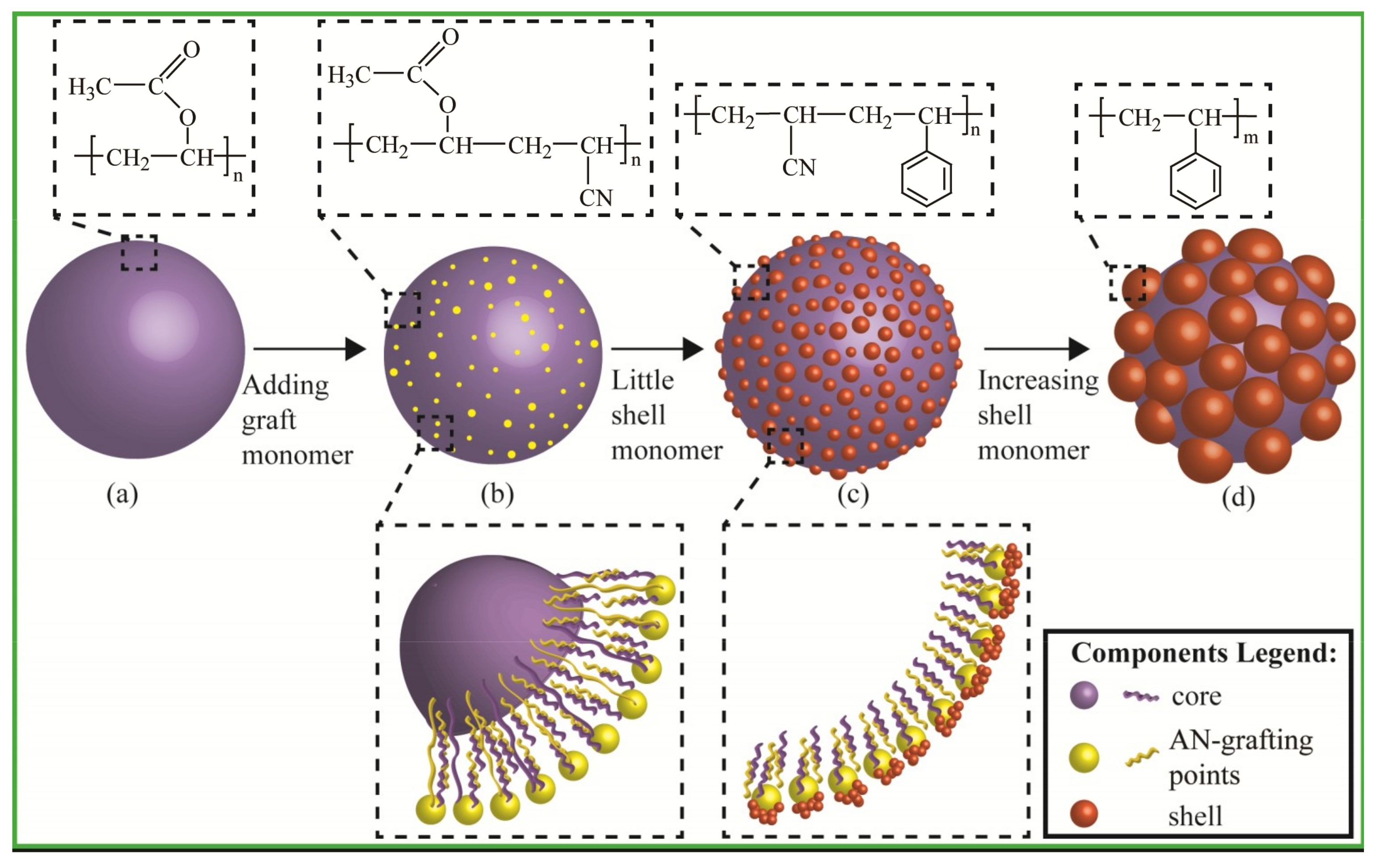

4. Formation Mechanism

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ma, J.Z.; Liu, Y.H.; Bao, Y.; Liu, J.L.; Zhang, J. Research advances in polymer emulsion based on “core-shell” structure particle design. Adv. Colloid Interface Sci. 2013, 197–198, 118–131. [Google Scholar] [CrossRef]

- Ferguson, C.J.; Russell, G.T.; Gilbert, R.G. Modelling secondary particle formation in emulsion polymerisation: Application to making core-shell morphologies. Polymer 2002, 43, 4557–4570. [Google Scholar] [CrossRef]

- Pérez-Carrillo, L.A.; Puca, M.; Rabelero, M.; Meza, K.E.; Puig, J.E.; Mendizábal, E.; López-Serrano, F.; López, R.G. Effect of particle size on the mechanical properties of polystyrene and poly(butyl acrylate) core/shell polymers. Polymer 2007, 48, 1212–1218. [Google Scholar] [CrossRef]

- Sahiner, N.; Butun, S.; Ilgin, P. Hydrogel particles with core shell morphology for versatile applications: Environmental, biomedical and catalysis. Colloids Surf. A Physicochem. Eng. Asp. 2011, 386, 16–24. [Google Scholar] [CrossRef]

- Schroffenegger, M.; Reimhult, E. Thermoresponsive Core-Shell Nanoparticles: Does Core Size Matter? Materials 2018, 11, 1654. [Google Scholar] [CrossRef]

- Xu, M.; Liu, J.; Xu, X.; Liu, S.; Peterka, F.; Ren, Y.; Zhu, X. Synthesis and Comparative Biological Properties of Ag-PEG Nanoparticles with Tunable Morphologies from Janus to Multi-Core Shell Structure. Materials 2018, 11, 1787. [Google Scholar] [CrossRef]

- Pei, X.; Zhai, K.; Tan, Y.; Xu, K.; Lu, C.; Wang, P.; Wang, T.; Chen, C.; Tao, Y.; Dai, L.; et al. Synthesis of monodisperse starch-polystyrene core-shell nanoparticles via seeded emulsion polymerization without stabilizer. Polymer 2017, 108, 78–86. [Google Scholar] [CrossRef]

- Lee, C.F. Effects of surfactants on the morphology of composite polymer particles produced by two-stage seeded emulsion polymerization. J. Polym. Sci. Part A Polym. Chem. 2005, 43, 2224–2236. [Google Scholar] [CrossRef]

- Klein, M.K.; Klinkenberg, N.; Schuetter, S.; Saenger, N.; Pfleiderer, P.; Zumbusch, A. PMMA/PMMA core-shell particles with ellipsoidal, fluorescent cores: Accessing rotational dynamics. Langmuir 2015, 31, 2655–2661. [Google Scholar] [CrossRef]

- Carrà, S.; Sliepcevich, A.; Canevarolo, A.; Carrà, S. Grafting and adsorption of poly(vinyl) alcohol in vinyl acetate emulsion polymerization. Polymer 2005, 46, 1379–1384. [Google Scholar] [CrossRef]

- Zhang, X.; Bai, L.; Lou, C.; Chen, X.; Jia, Z.; Gu, J.; Li, Z. Fabrication and morphological evolution of inverse core/shell structural latex particles of poly(vinyl acetate)/polystyrene by maleic anhydride grafting. Colloid Polym. Sci. 2016, 294, 1117–1128. [Google Scholar] [CrossRef]

- Bai, L.; Huan, S.; Zhang, X.; Jia, Z.; Gu, J.; Li, Z. Rational design and synthesis of transition layer-mediated structured latex particles with poly(vinyl acetate) cores and poly(styrene) shells. Colloid Polym. Sci. 2017, 295, 353–362. [Google Scholar] [CrossRef]

- Lin, C.L.; Chiu, W.Y.; Lee, C.F. Thermal/pH-sensitive core-shell copolymer latex and its potential for targeting drug carrier application. Polymer 2005, 46, 10092–10101. [Google Scholar] [CrossRef]

- Aguirre, M.; Paulis, M.; Barrado, M.; Iturrondobeitia, M.; Okariz, A.; Guraya, T.; Ibarretxe, J.; Leiza, J.R. Evolution of particle morphology during the synthesis of hybrid acrylic/CeO2 nanocomposites by miniemulsion polymerization. J. Polym. Sci. Part A Polym. Chem. 2014, 53, 792–799. [Google Scholar] [CrossRef]

- Xuan, S.; Wang, Y.J.; Leung, K.C.; Shu, K.; August, R.V.; Re, V.; Recei, M.; October, V. Synthesis of Fe3O4@Polyaniline Core/Shell Microspheres with Well-Defined Blackberry-Like Morphology. J. Phys. Chem. C 2008, 112, 18804–18809. [Google Scholar] [CrossRef]

- Song, T.; Liu, T.; Yang, X.; Bai, F. Raspberry-like particles via the heterocoagulated reaction between reactive epoxy and amino groups. Colloids Surf. A Physicochem. Eng. Asp. 2015, 469, 60–65. [Google Scholar] [CrossRef]

- Bonnefond, A.; Pereira Gomes, C.; de la Cal, J.C.; Leiza, J.R. Surfactant-free poly(methyl methacrylate)/poly(vinylamine) (PMMA/PVAm) amphiphilic core-shell polymer particles. Colloid Polym. Sci. 2017, 295, 135–144. [Google Scholar] [CrossRef]

- McKenzie, A.; Hoskins, R.; Swift, T.; Grant, C.; Rimmer, S. Core (Polystyrene)-Shell [Poly(glycerol monomethacrylate)] Particles. ACS Appl. Mater. Interfaces 2017, 9, 7577–7590. [Google Scholar] [CrossRef] [PubMed]

- Ferguson, C.J.; Russell, G.T.; Gilbert, R.G. Synthesis of latices with hydrophobic cores and poly(vinyl acetate) shells. 2. Use of poly(vinyl acetate) seeds. Polymer 2003, 44, 2607–2619. [Google Scholar] [CrossRef]

- Ferguson, C.J.; Russell, G.T.; Gilbert, R.G. Synthesis of latices with polystyrene cores and poly(vinyl acetate) shells. 1. Use of polystyrene seeds. Polymer 2002, 43, 6371–6382. [Google Scholar] [CrossRef]

- Aizpurua, I.; Amalvy, J.I.; Barandiaran, M.J. Influence of the Polymeric Hidrophobe on the Kinetics of Vinyl Acetate Miniemulsion Polymerization. Colloids Surf. A Physicochem. Eng. Asp. 2000, 166, 59–66. [Google Scholar] [CrossRef]

- Chiozza, F.; Pizzo, B. Innovation in poly(vinyl acetate) water resistant D3 glues used in wood industry. Int. J. Adhes. Adhes. 2016, 70, 102–109. [Google Scholar] [CrossRef]

- Joensson, J.E.L.; Hassander, H.; Jansson, L.H.; Toernell, B. Morphology of two-phase polystyrene/poly(methyl methacrylate) latex particles prepared under different polymerization conditions. Macromolecules 1991, 24, 126–131. [Google Scholar] [CrossRef]

- Ramli, R.A.; Laftah, W.A.; Hashim, S. Core–shell polymers: A review. RSC Adv. 2013, 3, 15543. [Google Scholar] [CrossRef]

- Karlsson, O.J.; Hassander, H.; Colombini, D. The effect of first-stage polymer Tg on the morphology and thermomechanical properties of structured polymer latex particles. C. R. Chim. 2003, 6, 1233–1244. [Google Scholar] [CrossRef]

- Stubbs, J.M.; Sundberg, D.C. Measuring the extent of phase separation during polymerization of composite latex particles using modulated temperature DSC. J. Polym. Sci. Part B Polym. Phys. 2005, 43, 2790–2806. [Google Scholar] [CrossRef]

- Stubbs, J.M.; Sundberg, D.C. Fundamental studies on morphology control for latex systems with application to waterborne coatings: The effect of polymer radical mobility in latex particles during polymerization. J. Coat. Technol. 2003, 75, 59–67. [Google Scholar] [CrossRef]

- Hergeth, W.D.; Bittrich, H.J.; Eichhorn, F.; Schlenker, S.; Schmutzler, K.; Steinau, U.J. Polymerizations in the presence of seeds: 5. Core-shell structure of two-stage emulsion polymers. Polymer 1989, 30, 1913–1917. [Google Scholar] [CrossRef]

| Codes | CS-1 | CS-2 | CS-3 | CS-4 | CS-5 | |

|---|---|---|---|---|---|---|

| Seed latex | Temperature/°C | 60 | 60 | 60 | 60 | 60 |

| m(Water)/g | 70 | 70 | 70 | 70 | 70 | |

| m (VAc)/g | 16 | 16 | 16 | 16 | 16 | |

| m(PCA078)/g | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | |

| m(PCA507)/g | 2.5 | 2.5 | 2.5 | 2.5 | ||

| m(NaHCO3)/g | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | |

| m(APS)/g | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | |

| Core-shell latex | Temperature/°C | 80 | 80 | 80 | 80 | 80 |

| m (VAc)/g | 54 | 54 | 54 | 54 | 54 | |

| m (St)/g | 30 | 30 | 30 | 30 | 30 | |

| m (AN)/g | 2 | 2 | 2 | 2 | 2 | |

| m(APS)/m(water)/(g·g−1) | 0.25/20 | 0.25/20 | 0.25/20 | 0.25/20 | 0.25/20 | |

| The time of shell polymerization/min | 30 | 60 | 90 | 120 | final state | |

| Codes | Tg (Core Polymer) (°C) | Tg (Core Polymer) (°C) | ||

|---|---|---|---|---|

| Designed Tg | Experimental Tg | Designed Tg | Experimental Tg | |

| core | 30 | 38 | / | / |

| 30 min | 30 | 38 | 100 | / |

| 60 min | 30 | 38 | 100 | / |

| 90 min | 30 | 38 | 100 | 106 |

| 120 min | 30 | 38 | 100 | 106 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, J.; Zhang, X.; Bai, L.; Li, Z.; Jia, Z.; Gu, J. Effect of Shell Growth on the Morphology of Polyvinyl Acetate/Polystyrene Inverted Core-Shell Latex Fabricated by Acrylonitrile Grafting. Materials 2018, 11, 2482. https://doi.org/10.3390/ma11122482

Sun J, Zhang X, Bai L, Li Z, Jia Z, Gu J. Effect of Shell Growth on the Morphology of Polyvinyl Acetate/Polystyrene Inverted Core-Shell Latex Fabricated by Acrylonitrile Grafting. Materials. 2018; 11(12):2482. https://doi.org/10.3390/ma11122482

Chicago/Turabian StyleSun, Jiaxing, Xiao Zhang, Long Bai, Zhiguo Li, Zhao Jia, and Jiyou Gu. 2018. "Effect of Shell Growth on the Morphology of Polyvinyl Acetate/Polystyrene Inverted Core-Shell Latex Fabricated by Acrylonitrile Grafting" Materials 11, no. 12: 2482. https://doi.org/10.3390/ma11122482