Evolution of Secondary α Phase during Aging Treatment in Novel near β Ti-6Mo-5V-3Al-2Fe Alloy

Abstract

:1. Introduction

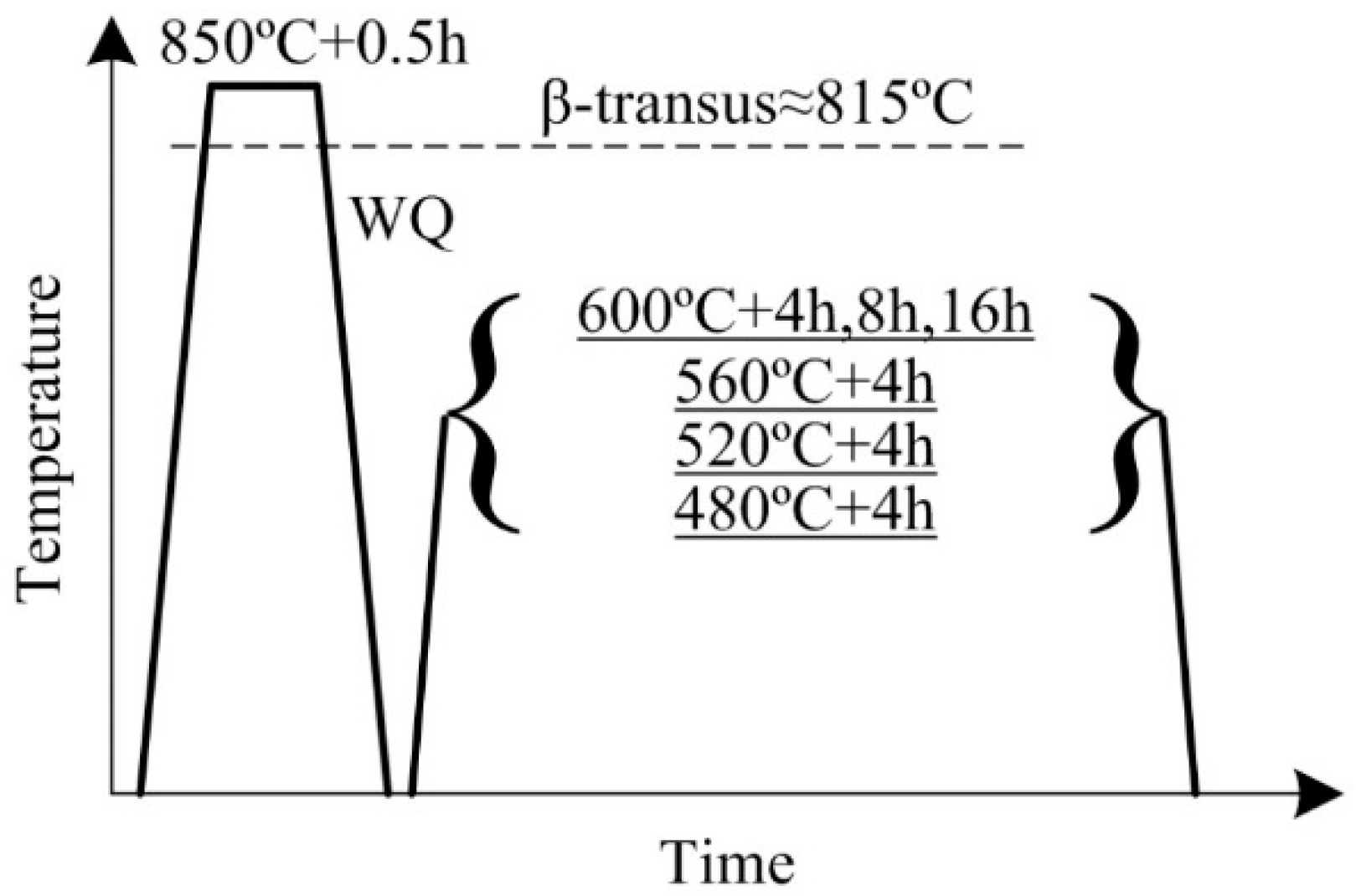

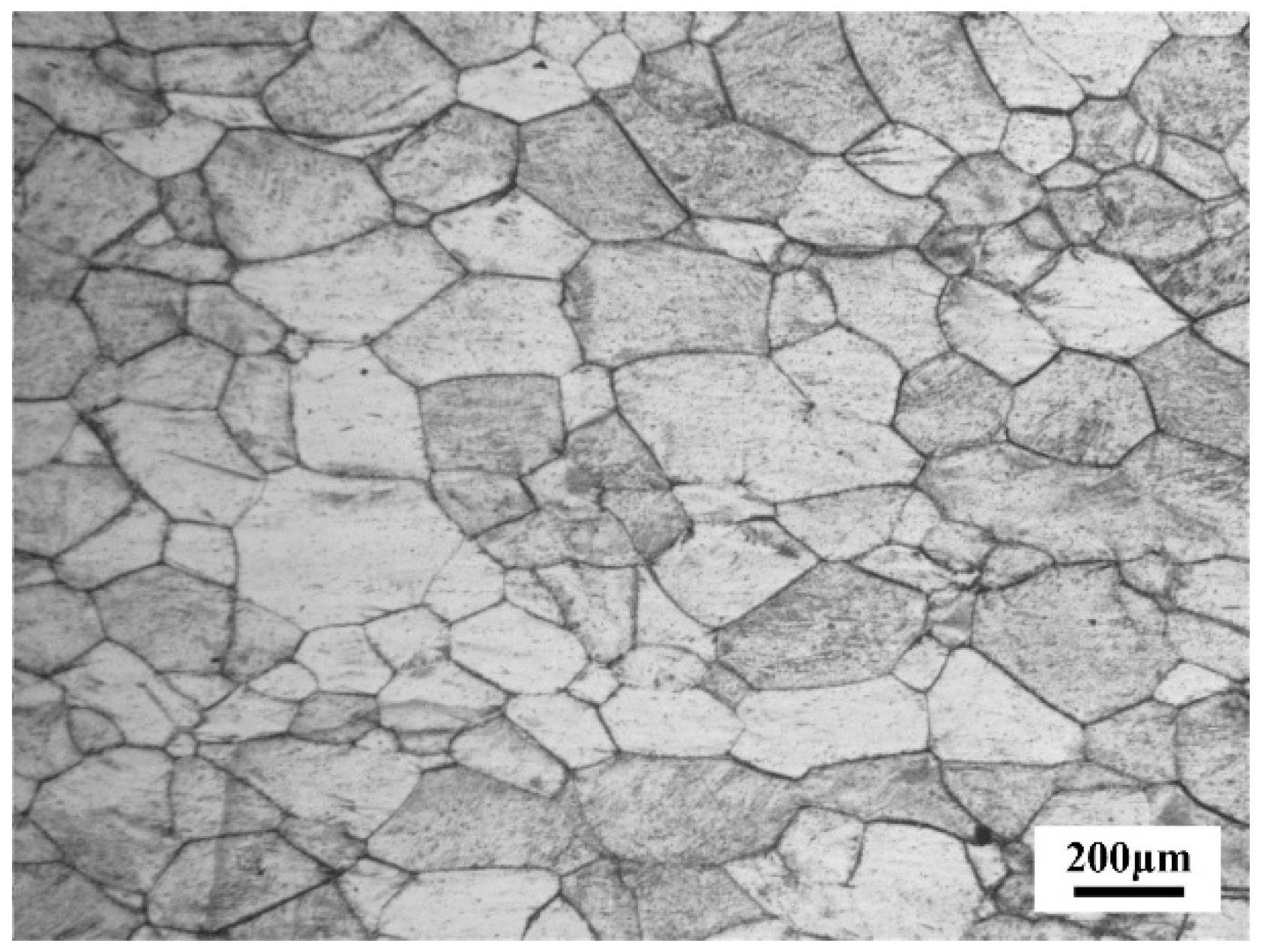

2. Materials and Methods

2.1. Alloy Design

2.2. Alloy Preparation

3. Results

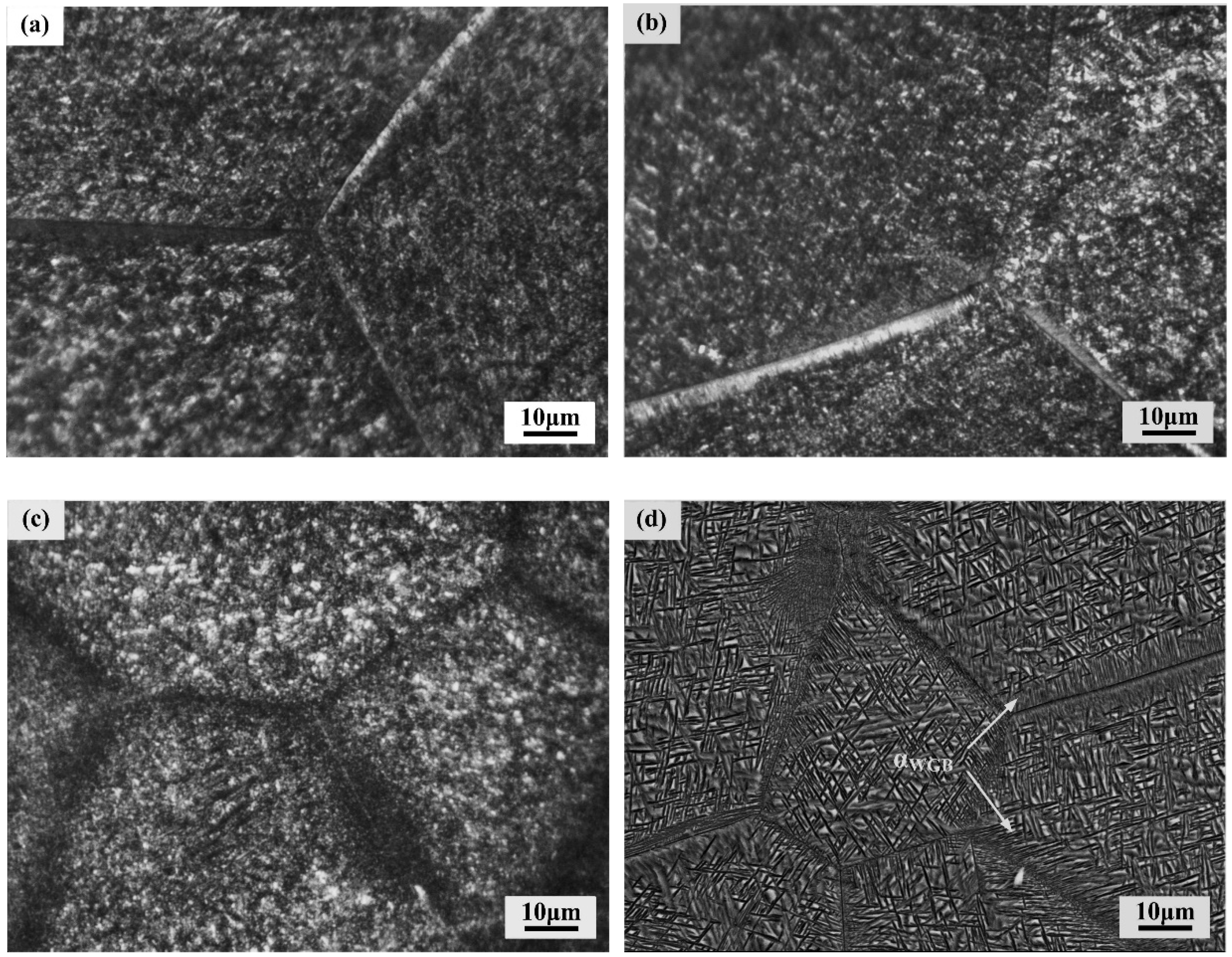

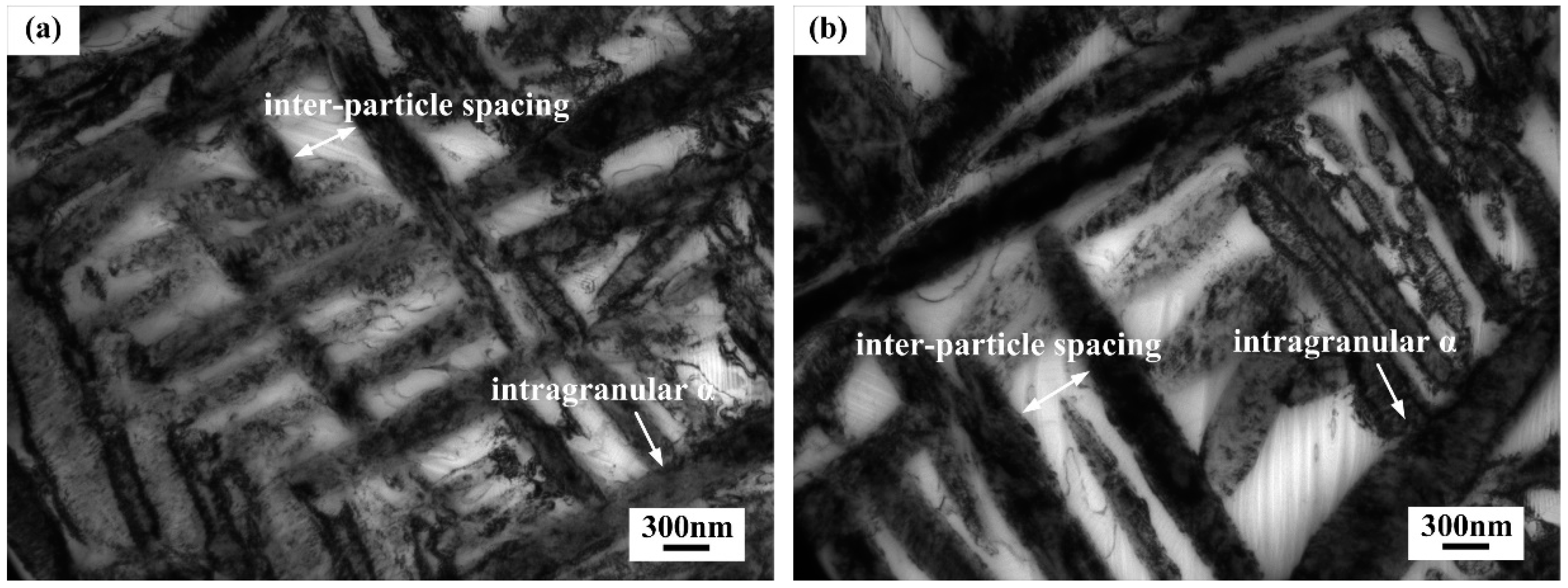

3.1. Secondary α Phase after Being Aged at Various Temperatures

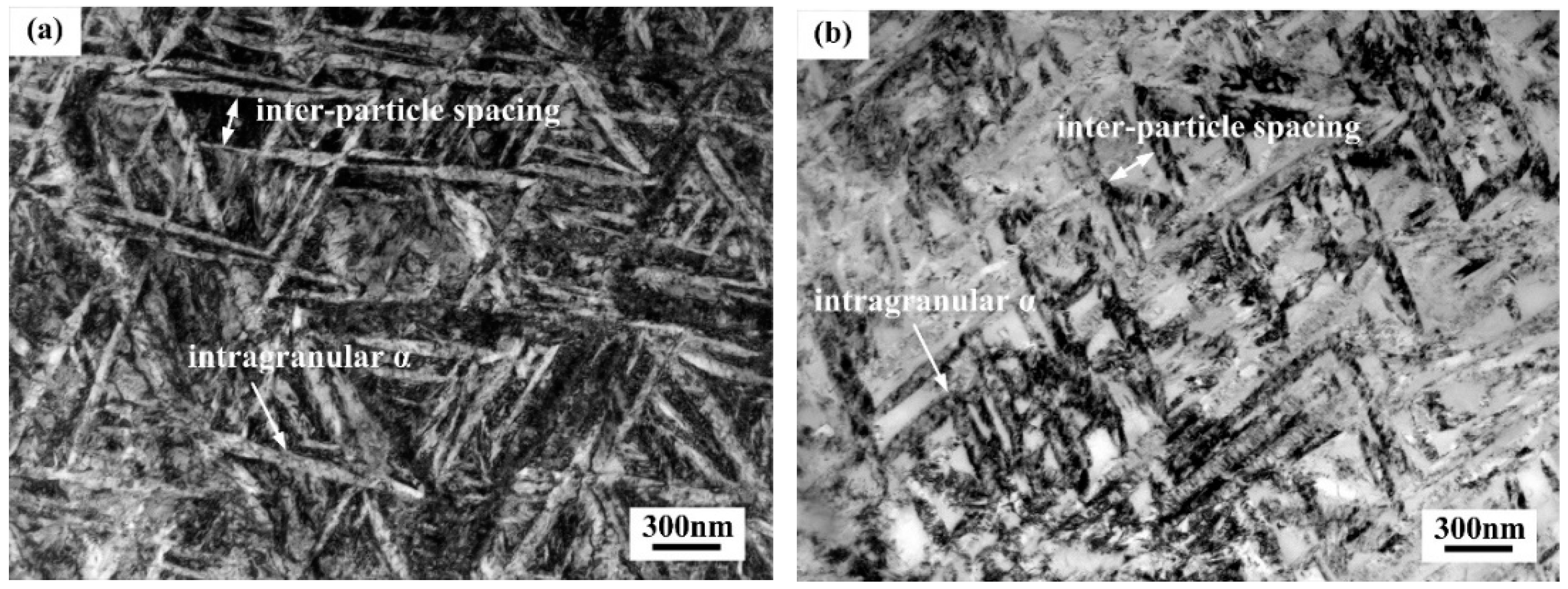

3.2. Secondary α Phase after Being Aged for Different Time

4. Discussion

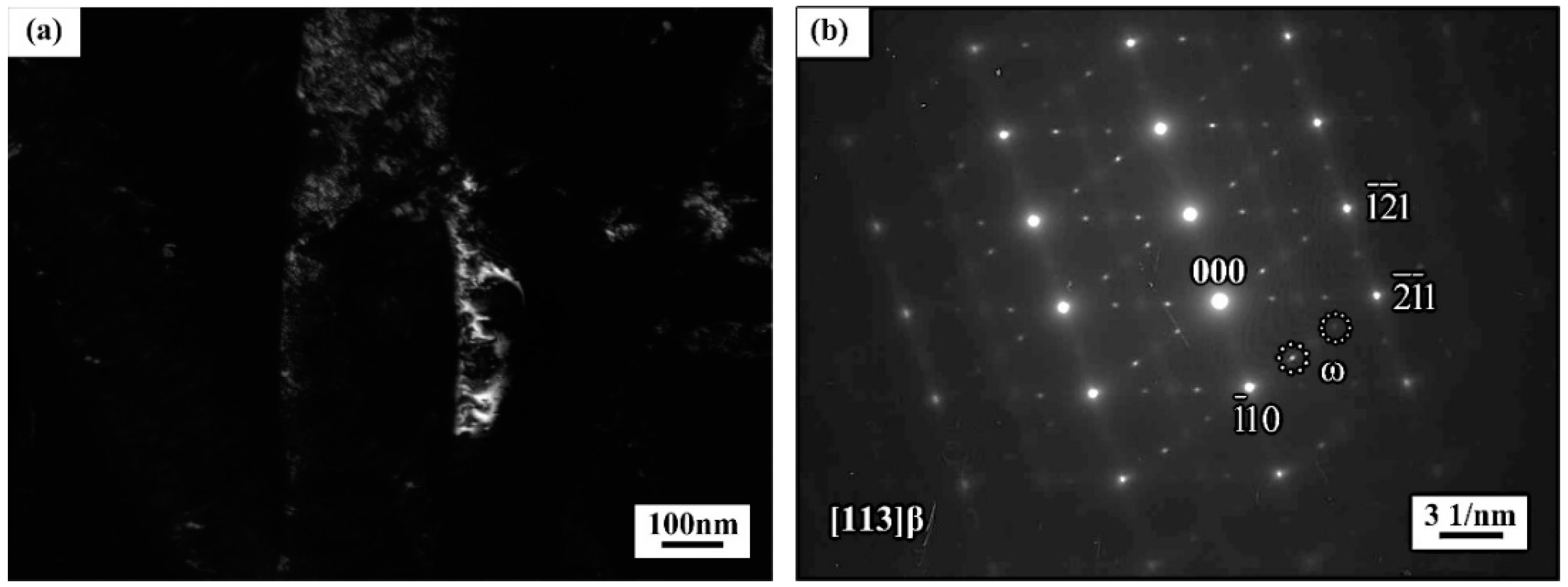

4.1. Evolution of Secondary α Phase within β Grains

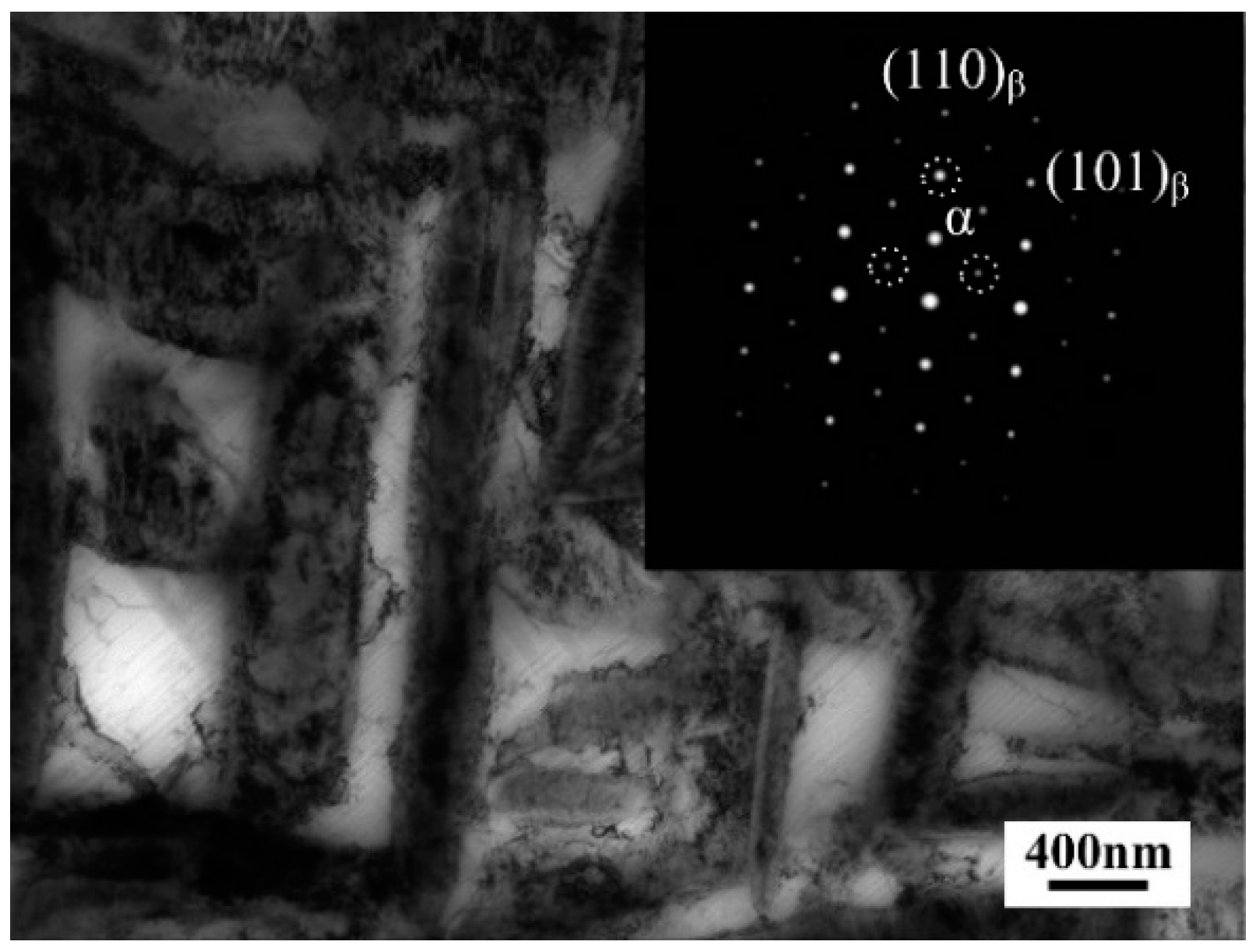

4.2. Evolution of Secondary α Phase near β Grain Boundary

4.3. Effect of Secondary α Phase on Tensile Properties

5. Conclusions

- (1)

- The athermal ω phase formed after water quenching and disappeared after aged at 600 °C. The ω phase assisted the nucleation of intragranular α phase during aging treatment.

- (2)

- When aged at 480 °C, fine intragranular α precipitated because of the synergetic contribution of ω-assisted nucleation, high nucleation rate and slow growth rate. The width and inter-particle spacing of intragranular α increased slightly as the aging temperature increased from 480 °C to 560 °C, but increased considerably when the aging temperature reached as high as 600 °C.

- (3)

- When aged at 600 °C, the size and quantity of intragranular α were not sensitive to the aging time ranging from 4 h to 16 h. After aged at 600 °C, the mutually parallel formed on grain boundary α and grew into the internal areas of β grains.

- (3)

- The alloy aged at 480 °C exhibited high strength but poor ductility, with the UTS and EL are 1510 MPa and 4.2%, respectively. As the aging temperature increased to 560 °C, the minor variation of intragranular α led to slight decrease of strength and minor improvement of ductility. When aging temperature reached 600 °C, the strength decreased seriously but ductility improved dramatically, resulting from boarder inter-particle spacing of intragranular α and the formation of .

Author Contributions

Funding

Conflicts of Interest

References

- Zhao, J.; Zhong, J.; Yan, F.; Chai, F.; Dargusch, M. Deformation Behaviour and Mechanisms during Hot Compression at Supertransus Temperatures in Ti-10V-2Fe-3Al. J. Alloys Compd. 2017, 710, 616–627. [Google Scholar] [CrossRef]

- Fan, X.G.; Zhang, Y.; Gao, P.F.; Lei, Z.N.; Zhan, M. Deformation Behavior and Microstructure Evolution during Hot Working of A Coarse-grained Ti-5Al-5Mo-5V-3Cr-1Zr Titanium Alloy in Beta Phase Field. Mater. Sci. Eng. A 2017, 694, 24–32. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, Y.; Zhang, B.; Huang, H.J.; Chen, J.H.; Wang, P. Strain Rate Sensitivity of Tensile Properties in Ti-6.6Al-3.3Mo-1.8Zr-0.29Si Alloy: Experiments and Constitutive Modeling. Materials 2018, 11, 1591. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Yu, D.H.; Fan, Q.B.; Shi, R. Influence of Hot Rolling and Heat Treatment on the Microstructural Evolution of β20C Titanium Alloy. Materials 2017, 10, 1071. [Google Scholar] [CrossRef] [PubMed]

- Lhadi, S.; Chini, M.R.; Richeton, T.; Gey, N.; Germain, L.; Berbenni, S. Micromechanical Modeling of the Elasto-Viscoplastic Behavior and Incompatibility Stresses of β-Ti Alloys. Materials 2018, 11, 1227. [Google Scholar] [CrossRef] [PubMed]

- Shekhar, S.; Sarkar, R.; Kar, S.K.; Bhattacharjee, A. Effect of Solution Treatment and Aging on Microstructure and Tensile Properties of High Strength β Titanium Alloy, Ti–5Al–5V–5Mo–3Cr. Mater. Des. 2015, 66, 596–610. [Google Scholar] [CrossRef]

- Du, Z.X.; Xiao, S.L.; Xu, L.J.; Tian, J.; Kong, F.T.; Chen, Y.Y. Effect of Heat Treatment on Microstructure and Mechanical Properties of a New β High Strength Titanium Alloy. Mater. Des. 2014, 55, 183–190. [Google Scholar] [CrossRef]

- Ivasishin, O.M.; Markovsky, P.E.; Semiatin, S.L.; Ward, C.H. Aging Response of Coarse- and Fine-grained Titanium Alloys. Mater. Sci. Eng. A 2005, 405, 296–305. [Google Scholar] [CrossRef]

- Angelier, C.; Bein, S.; Béchet, J. Building a Continuous Cooling Transformation Diagram of β-CEZ Alloy by Metallography and Electrical Resistivity Measurements. Metall. Mater. Trans. A 1997, 28, 2467–2475. [Google Scholar] [CrossRef]

- Ivasishin, O.M.; Markovsky, P.E.; Matviychuk, Y.V.; Semiatin, S.L.; Ward, C.H.; Fox, S. A Comparative Study of the Mechanical Properties of High-strength β-titanium Alloys. J. Alloys Compd. 2008, 457, 296–309. [Google Scholar] [CrossRef]

- Ma, X.K.; Li, F.G.; Cao, J.; Li, J.H.; Sun, Z.K.; Zhu, G.; Zhou, S.S. Strain Rate Effects on Tensile Deformation Behaviors of Ti-10V-2Fe-3Al Alloy Undergoing Stress-induced Martensitic Transformation. Mater. Sci. Eng. A 2018, 710, 1–9. [Google Scholar] [CrossRef]

- Huang, L.G.; Chen, Y.Y. A Study on the Microstructures and Mechanical Properties of Ti–B20–0.1B Alloys of Direct Rolling in the α + β Phase Region. J. Alloys Compd. 2015, 646, 557–564. [Google Scholar] [CrossRef]

- Li, C.; Chen, J.; Li, W.; Ren, Y.J.; He, J.J.; Song, Z.X. Effect of Heat Treatment Variations on the Microstructure Evolution and Mechanical Properties in a β Metastable Ti Alloy. J. Alloys Compd. 2016, 684, 466–473. [Google Scholar] [CrossRef]

- Ren, L.; Xiao, W.L.; Chang, H.; Zhao, Y.Q.; Ma, C.L.; Zhou, L. Microstructural Tailoring and Mechanical Properties of a Multi-alloyed Near β Titanium Alloy Ti-5321 with Various Heat Treatment. Mater. Sci. Eng. A 2018, 771, 553–561. [Google Scholar] [CrossRef]

- He, T.; Feng, Y.; Luo, W.Z.; He, Y.S.; Tian, L.; Lai, Y.J. Microstructural Evolution of ω Assisted α Precipitates in β-CEZ Alloy during Ageing Process. Mater. Charact. 2018, 138, 19–25. [Google Scholar] [CrossRef]

- Ahmed, M.; Wexler, D.; Casillas, G.; Ivasishin, O.M.; Pereloma, E.V. The Influence of β Phase Stability on Deformation Mode and Compressive Mechanical Properties of Ti–10V–3Fe–3Al Alloy. Acta. Mater. 2015, 84, 124–135. [Google Scholar] [CrossRef]

- Hua, K.; Zhang, Y.D.; Kou, H.C.; Li, J.S.; Gan, W.M.; Fundenberger, J.J.; Esling, C. Composite Structure of α Phase in Metastable β Ti Alloys Induced by Lattice Strain during β to α Phase Transformation. Acta. Mater. 2017, 132, 307–326. [Google Scholar] [CrossRef]

- Abdel-Hady, M.; Hinoshita, K.; Morinaga, M. General Approach to Phase Stability and Elastic Properties of β-type Ti-alloys Using Electronic Parameters. Scr. Mater. 2006, 55, 477–480. [Google Scholar] [CrossRef]

- Brozek, C.; Sun, F.; Vermaut, P.; Millet, Y.; Lenain, A.; Embury, D.; Jacques, P.J.; Prima, F. A β-titanium Alloy with Extra High Strain-hardening Rate: Design and Mechanical Properties. Scr. Mater. 2016, 114, 60–64. [Google Scholar] [CrossRef]

- Ren, L.; Xiao, W.L.; Ma, C.L.; Zheng, R.X.; Zhou, L. Development of a High Strength and High Ductility Near β-Ti alloy with Twinning Induced Plasticity Effect. Scr. Mater. 2018, 156, 47–50. [Google Scholar] [CrossRef]

- Kuroda, D.; Niinomi, M.; Morinaga, M.; Kato, Y.; Yashiro, T. Design and mechanical properties of new β type titanium alloys for implant materials. Mater. Sci. Eng. A 1998, 243, 244–249. [Google Scholar] [CrossRef]

- Cotton, J.D.; Briggs, R.D.; Boyer, R.R.; Tamirisakandala, S.; Russo, P.; Shchetnikov, N.; Fanning, J.C. State of the Art in Beta Titanium Alloys for Airframe Applications. JOM 2015, 67, 1281–1303. [Google Scholar] [CrossRef] [Green Version]

- Wang, K.; Li, M.Q. Effects of Heat Treatment and Hot Deformation on the Secondary α Phase Evolution of TC8 Titanium Alloy. Mater. Sci. Eng. A 2014, 613, 209–216. [Google Scholar] [CrossRef]

- Nag, S.; Banerjee, R.; Srinivasan, R.; Hwang, J.Y.; Harper, M.; Fraser, H.L. ω-Assisted Nucleation and Growth of α Precipitates in the Ti–5Al–5Mo–5V–3Cr–0.5Fe β Titanium Alloy. Acta Mater. 2009, 57, 2136–2147. [Google Scholar] [CrossRef]

- Li, C.L.; Mi, X.J.; Ye, W.J.; Hui, S.X.; Lee, D.G.; Lee, Y.T. Microstructural Evolution and Age Hardening Behavior of a New Metastable Beta Ti–2Al–9.2Mo–2Fe Alloy. Mater. Sci. Eng. A 2015, 645, 225–231. [Google Scholar] [CrossRef]

- Xu, T.W.; Zhang, S.S.; Zhang, F.S.; Kou, H.C.; Li, J.S. Effect of ω-assisted Precipitation on β→α Transformation and Tensile Properties of Ti–15Mo–2.7Nb–3Al–0.2Si Alloy. Mater. Sci. Eng. A 2016, 654, 249–255. [Google Scholar] [CrossRef]

- Zheng, Y.F.; Williams, R.; Wang, D.; Shi, R.P.; Nag, S.; Kami, P.; Sosa, J.M.; Banerjee, R.; Wang, Y.Z.; Fraser, H.L. Role of ω Phase in the Formation of Extremely Refined Intragranular α Precipitates in Metastable β-titanium Alloys. Acta Mater. 2016, 103, 850–858. [Google Scholar] [CrossRef]

- Prima, F.; Vermaut, P.; Texier, G.; Ansel, D.; Gloriant, T. Evidence of α-nanophase Heterogeneous Nucleation From ω Particles in a β-metastable Ti-based Alloy by Highresolution Electron Microscopy. Scr. Mater. 2006, 54, 645–648. [Google Scholar] [CrossRef]

- Yi, R.W.; Liu, H.Q.; Yi, D.Q.; Wan, W.F.; Wang, B.; Jiang, Y.; Yang, Q.; Wang, D.C.; Gao, Q.; Xu, Y.F.; et al. Precipitation hardening and microstructure evolution of the Ti–7Nb–10Mo alloy during aging. Mater. Sci. Eng. C 2016, 63, 577–586. [Google Scholar] [CrossRef] [PubMed]

- Dong, R.F.; Li, J.S.; Fan, J.K.; Kou, H.C.; Tang, B. Precipitation of α Phase and Its Morphological Evolution during Continuous Heating in a Near β Titanium Alloy Ti-7333. Mater. Charact. 2017, 132, 199–204. [Google Scholar] [CrossRef]

- Zhang, X.; Kou, H.C.; Li, J.S.; Zhang, F.S.; Zhou, L. Evolution of the Secondary a Phase Morphologies during Isothermal Heat Treatment in Ti-7333 Alloy. J. Alloys Compd. 2013, 577, 516–522. [Google Scholar] [CrossRef]

- Xavier, C.C.; Correa, D.R.N.; Grandini, C.R.; Rocha, L.A. Low Temperature Heat Treatments on Ti-15Zr-xMo Alloys. J. Alloys Compd. 2017, 727, 246–253. [Google Scholar] [CrossRef]

- Fan, J.K.; Li, J.S.; Kou, H.C.; Hua, K.; Tang, B.; Zhang, Y.D. Microstructure and mechanical property correlation and property optimization of a near b titanium alloy Ti-7333. J. Alloys Compd. 2016, 682, 517–524. [Google Scholar] [CrossRef]

- Nag, S.; Banerjee, R.; Hwang, J.Y.; Harper, M.; Fraser, H.L. Elemental Partitioning Between α and β Phases in the Ti–5Al–5Mo–5V–3Cr–0.5Fe (Ti-5553) Alloy. Philos. Mag. 2009, 89, 2136–2147. [Google Scholar] [CrossRef]

- Zheng, Y.F.; Choudhuri, D.; Alam, T.; Williams, R.E.A.; Banerjee, R.; Fraser, H.L. The Role of Cuboidal ω Precipitates on α Precipitation in a Ti-20V Alloy. Scr. Mater. 2016, 123, 81–85. [Google Scholar] [CrossRef]

- Guo, S.; Zhang, J.S.; Cheng, X.N.; Zhao, X.Q. A Metastable β-type Ti-Nb Binary Alloy with Low Modulus and High Strength. J. Alloys Compd. 2015, 644, 411–415. [Google Scholar] [CrossRef]

- Devaraj, A.; Joshi, V.V.; Srivastava, A.; Manandhar, S.; Moxson, V.; Duz, V.A.; Lavender, C. A low-cost hierarchical nanostructured beta-titanium alloy with high strength. Nat. Commun. 2016, 7, 11176. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chen, Y.Y.; Du, Z.X.; Xiao, S.L.; Xu, L.J.; Tian, J. Effect of aging heat treatment on microstructure and tensile properties of a new β high strength titanium alloy. J. Alloys Compd. 2014, 586, 588–592. [Google Scholar] [CrossRef]

- Huang, L.G.; Chen, Y.Y. A study on the microstructures and mechanical properties of forged trace-boron-modified Ti–B20 alloy. Mater. Des. 2015, 66, 110–117. [Google Scholar] [CrossRef]

| Aging Treatment | 480 °C/4 h | 520 °C/4 h | 560 °C/4 h | 600 °C/4 h | 600 °C/8 h | 600 °C/16 h |

|---|---|---|---|---|---|---|

| Averaged width (nm) | 67 | 93 | 124 | 231 | 257 | 287 |

| Averaged inter-particle spacing (nm) | 90 | 131 | 142 | 246 | 282 | 290 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, H.; Wang, C.; Zhang, S.; Zhou, G.; Chen, L. Evolution of Secondary α Phase during Aging Treatment in Novel near β Ti-6Mo-5V-3Al-2Fe Alloy. Materials 2018, 11, 2283. https://doi.org/10.3390/ma11112283

Zhang H, Wang C, Zhang S, Zhou G, Chen L. Evolution of Secondary α Phase during Aging Treatment in Novel near β Ti-6Mo-5V-3Al-2Fe Alloy. Materials. 2018; 11(11):2283. https://doi.org/10.3390/ma11112283

Chicago/Turabian StyleZhang, Haoyu, Chuan Wang, Siqian Zhang, Ge Zhou, and Lijia Chen. 2018. "Evolution of Secondary α Phase during Aging Treatment in Novel near β Ti-6Mo-5V-3Al-2Fe Alloy" Materials 11, no. 11: 2283. https://doi.org/10.3390/ma11112283

APA StyleZhang, H., Wang, C., Zhang, S., Zhou, G., & Chen, L. (2018). Evolution of Secondary α Phase during Aging Treatment in Novel near β Ti-6Mo-5V-3Al-2Fe Alloy. Materials, 11(11), 2283. https://doi.org/10.3390/ma11112283