Optimization of Process Parameters, Microstructure, and Properties of Laser Cladding Fe-Based Alloy on 42CrMo Steel Roller

Abstract

:1. Introduction

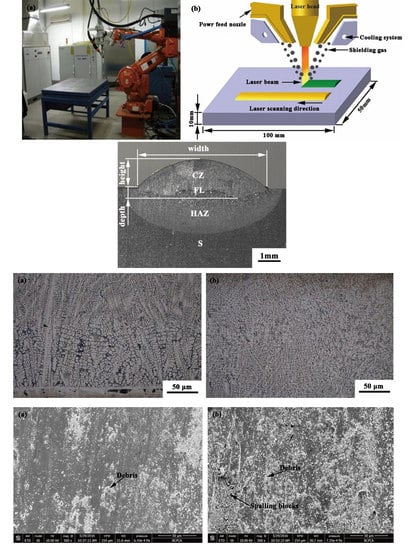

2. Experimental Materials and Methods

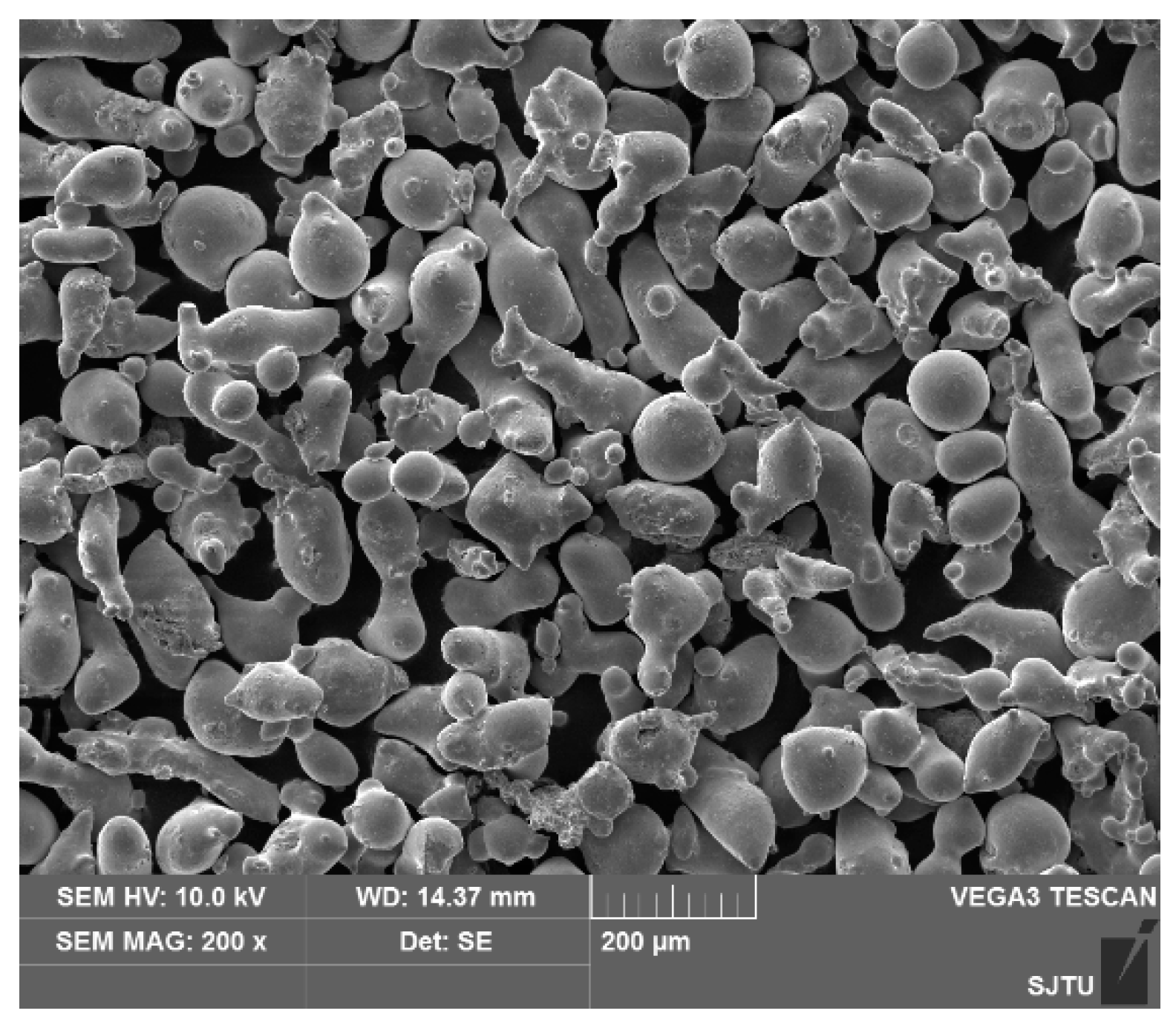

2.1. Material Preparation

2.2. Microstructure Observation

2.3. Hardness and Wear Resistance Tests

2.4. Salt Spray Corrosion Test

3. Results and Discussion

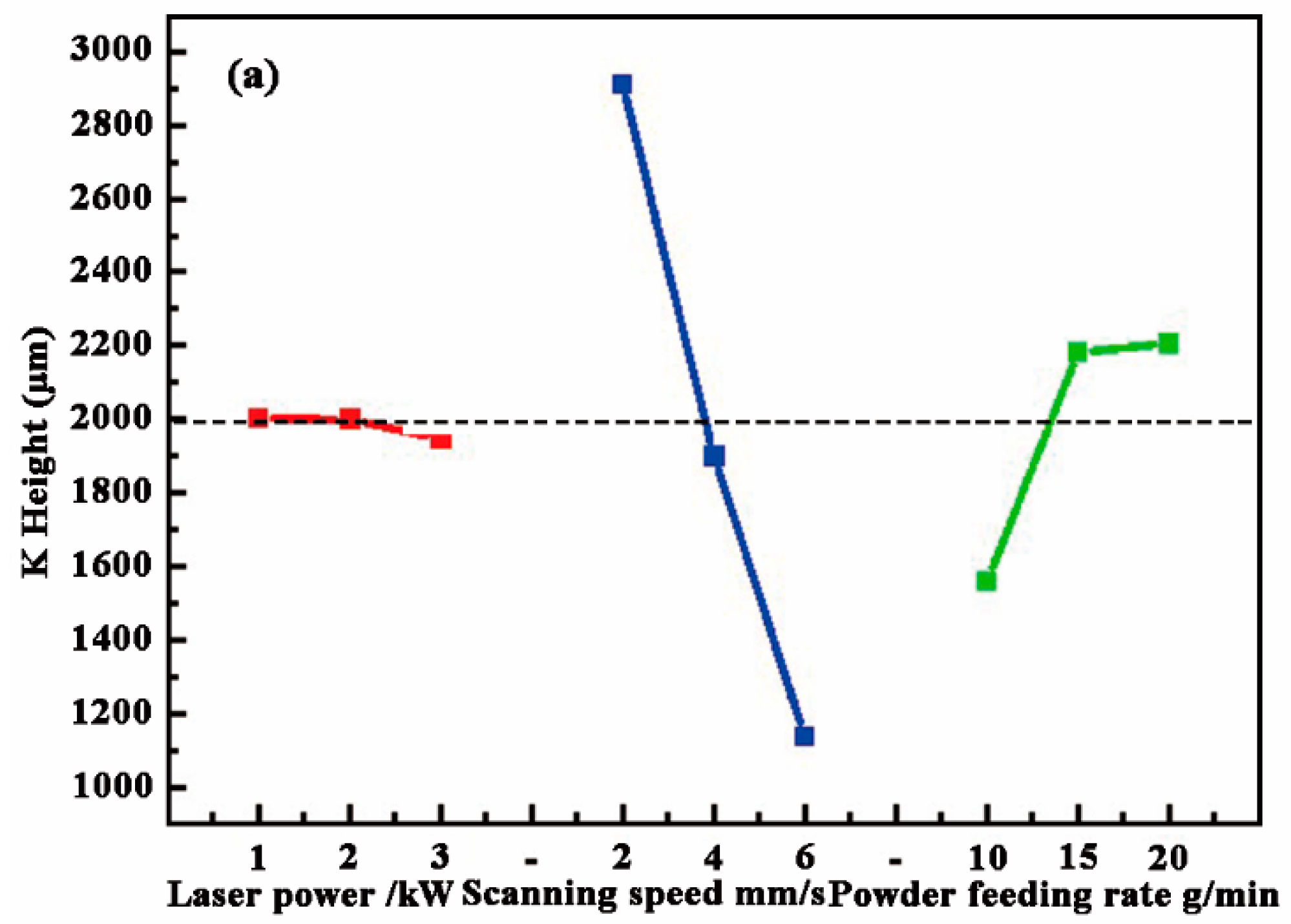

3.1. Optimization of Process Parameters

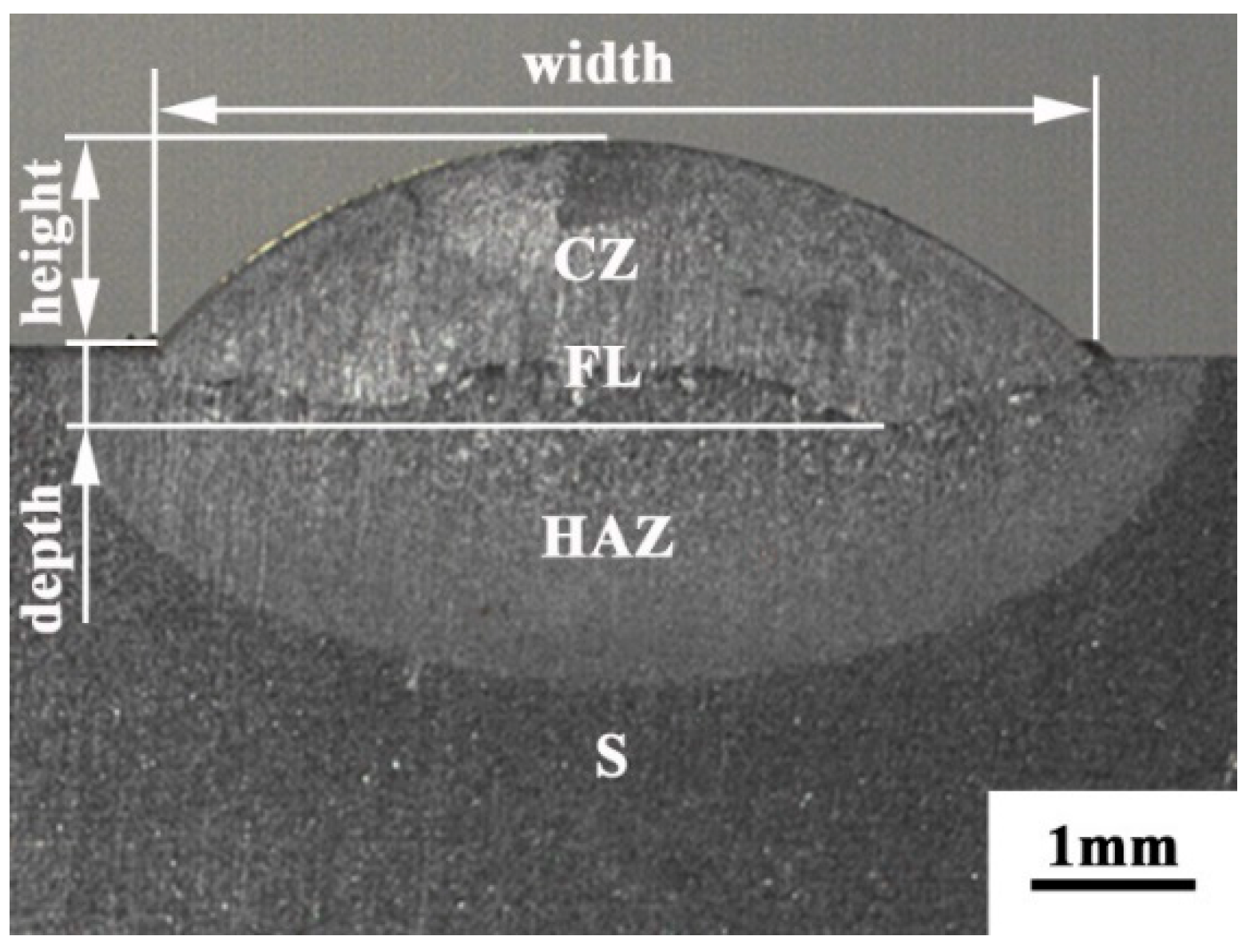

3.1.1. The Macro Appearance of Laser Cladding Layer

3.1.2. The Analysis of Orthogonal Experiment Results

3.2. Microstructure and Hardness of the Cladding Layer

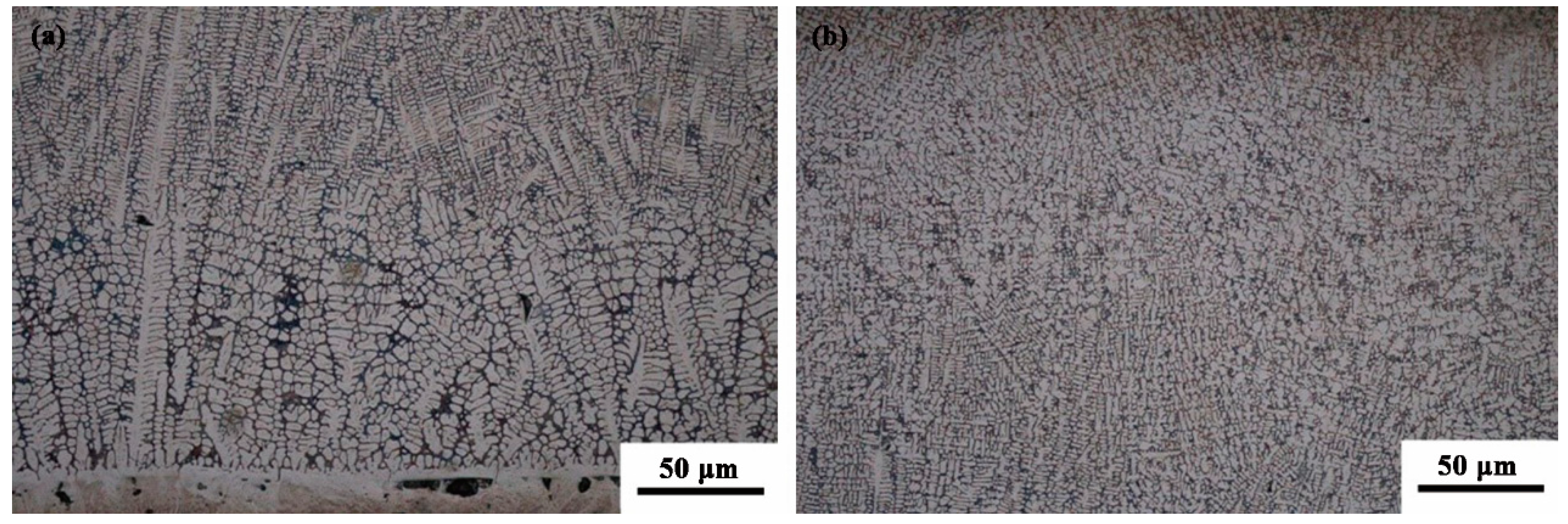

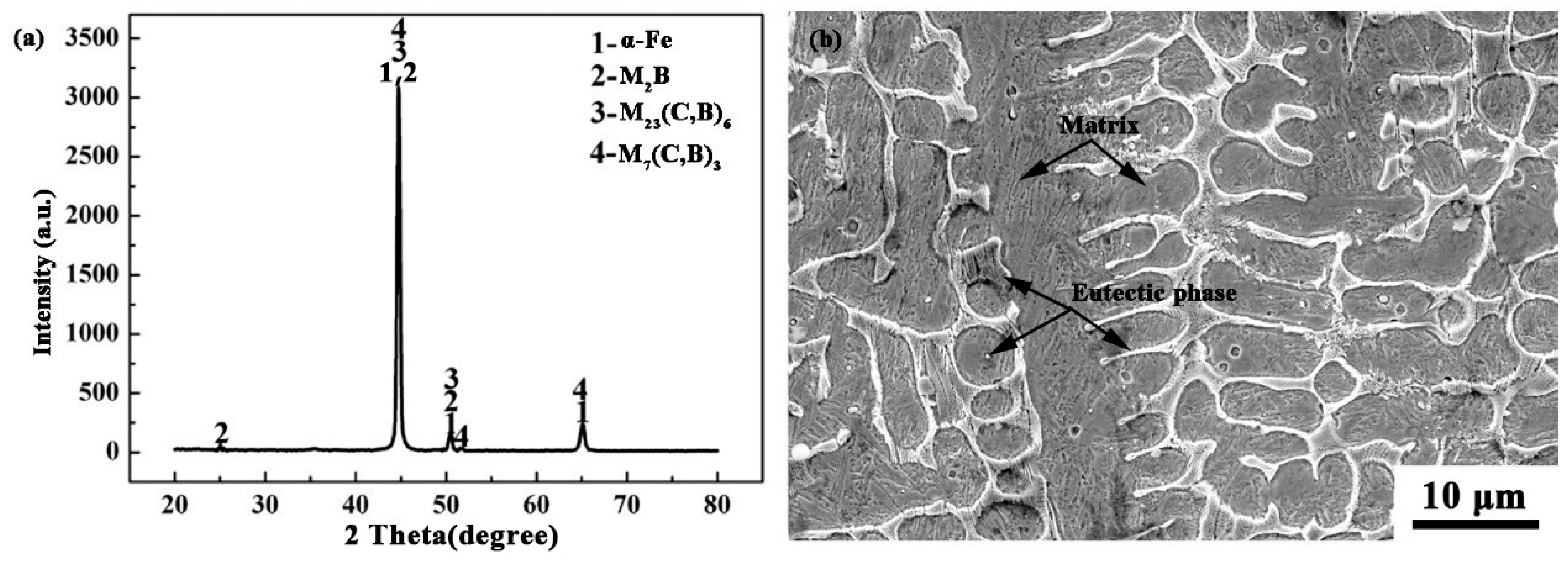

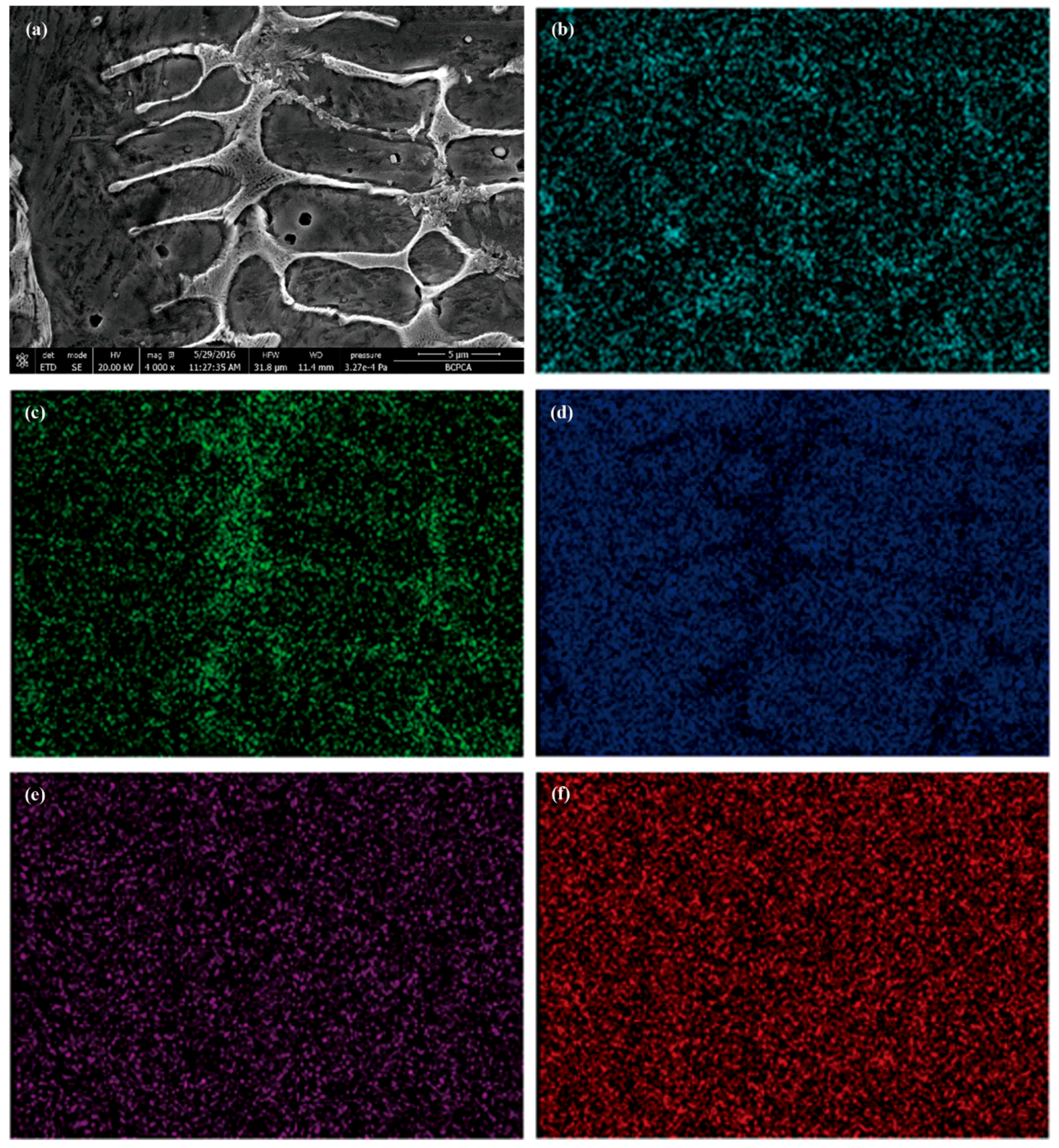

3.2.1. Microstructure and Phase Analysis

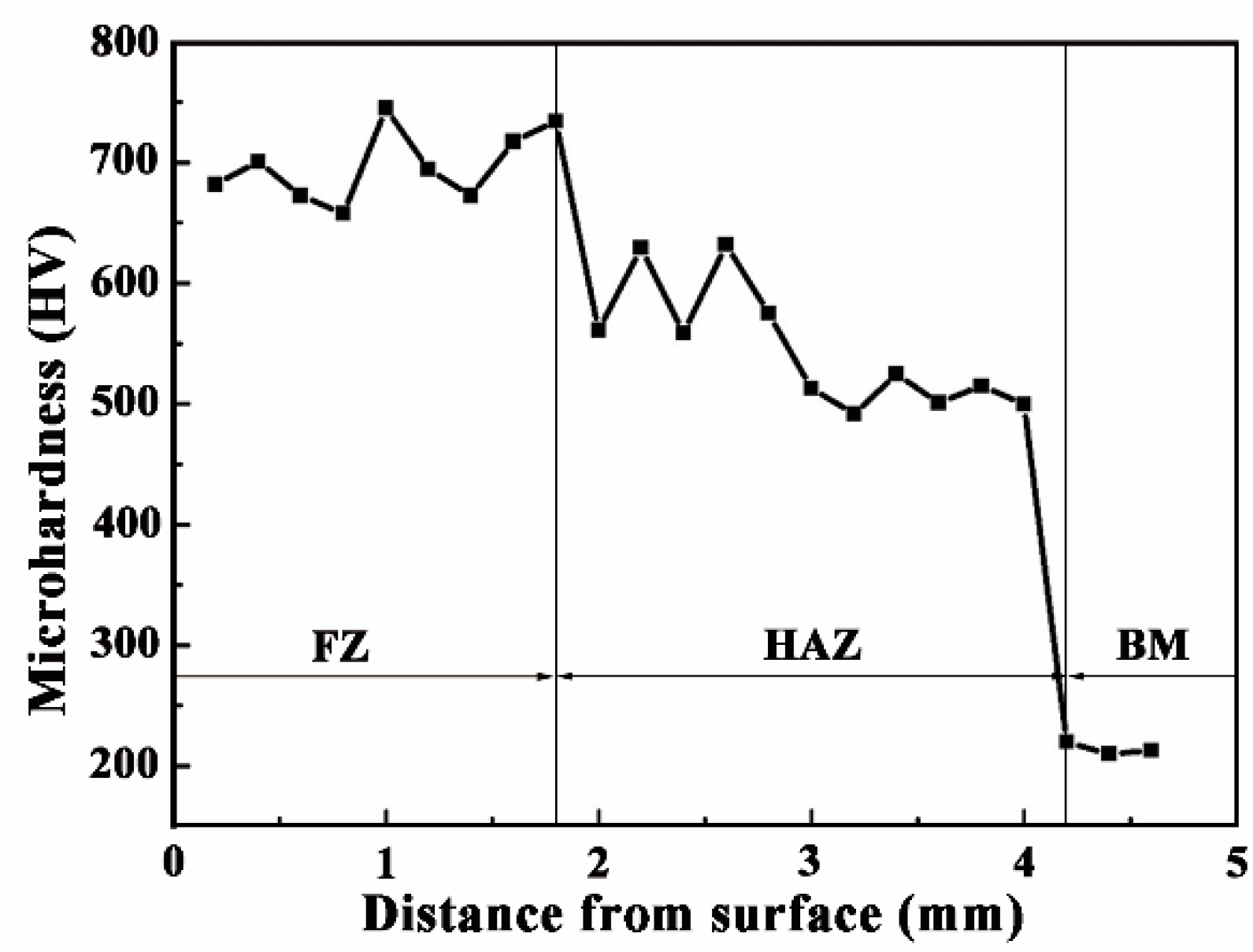

3.2.2. Hardness

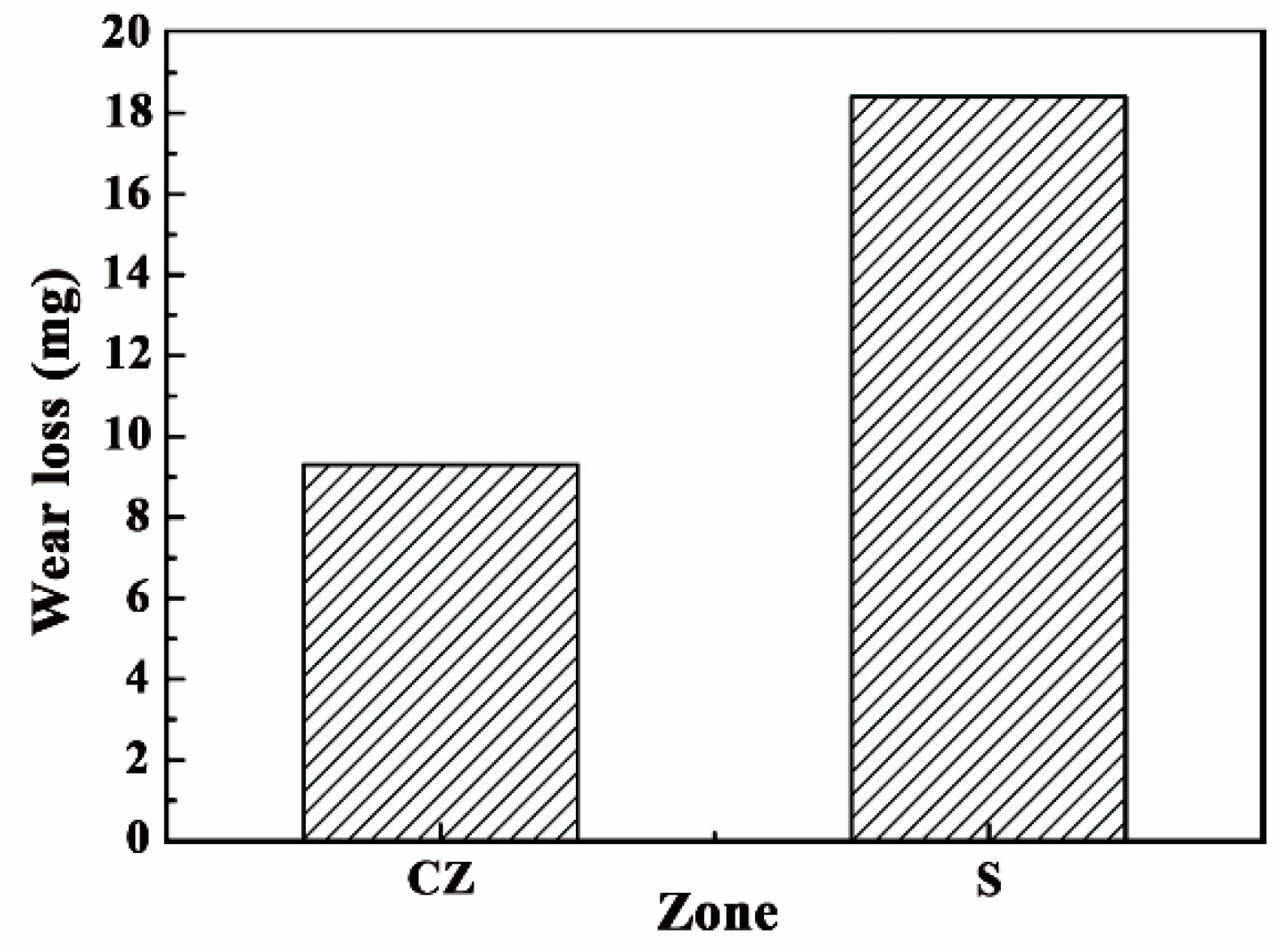

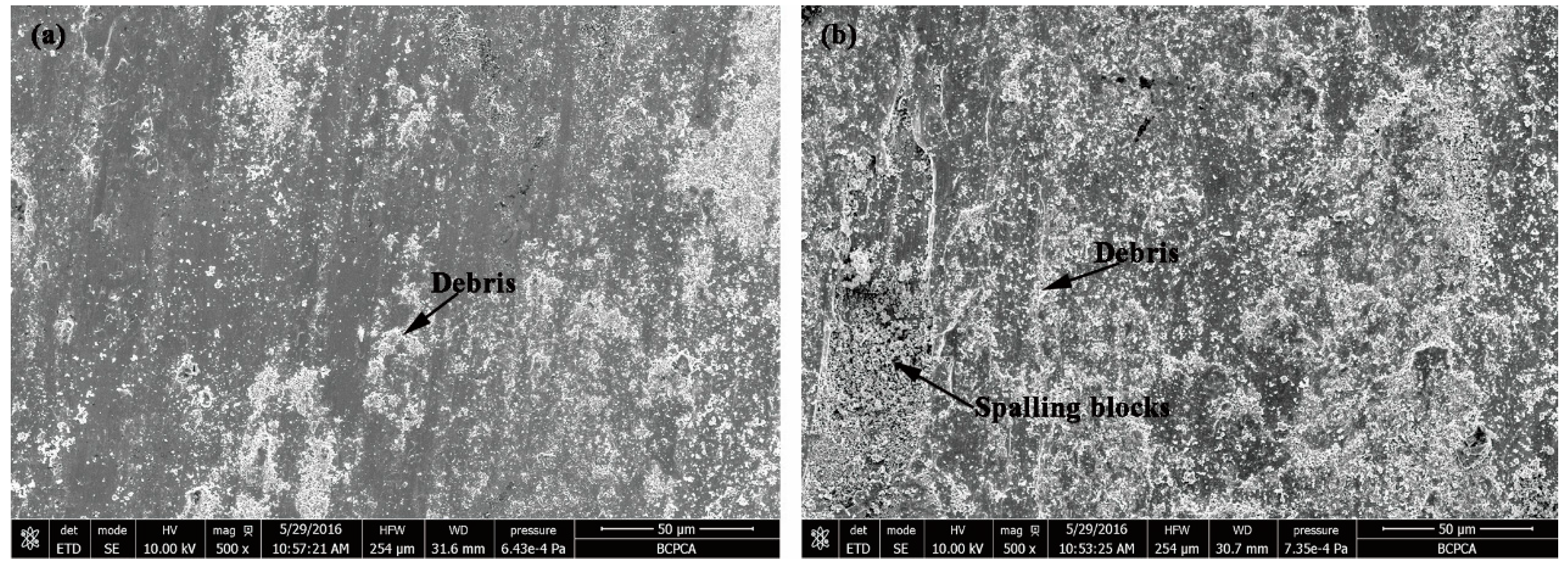

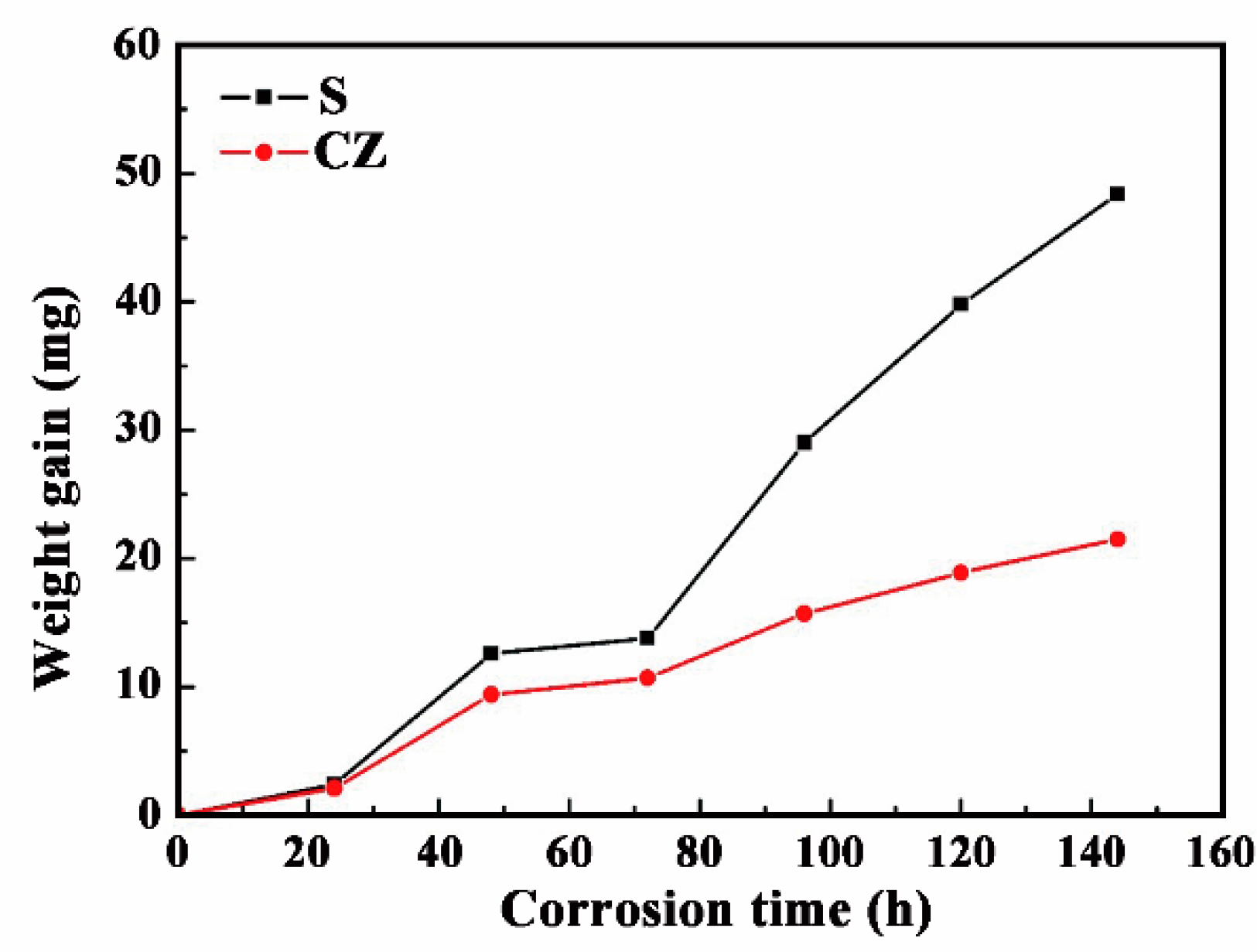

3.3. Wear Resistance and Corrosion Resistance

3.4. Discussion

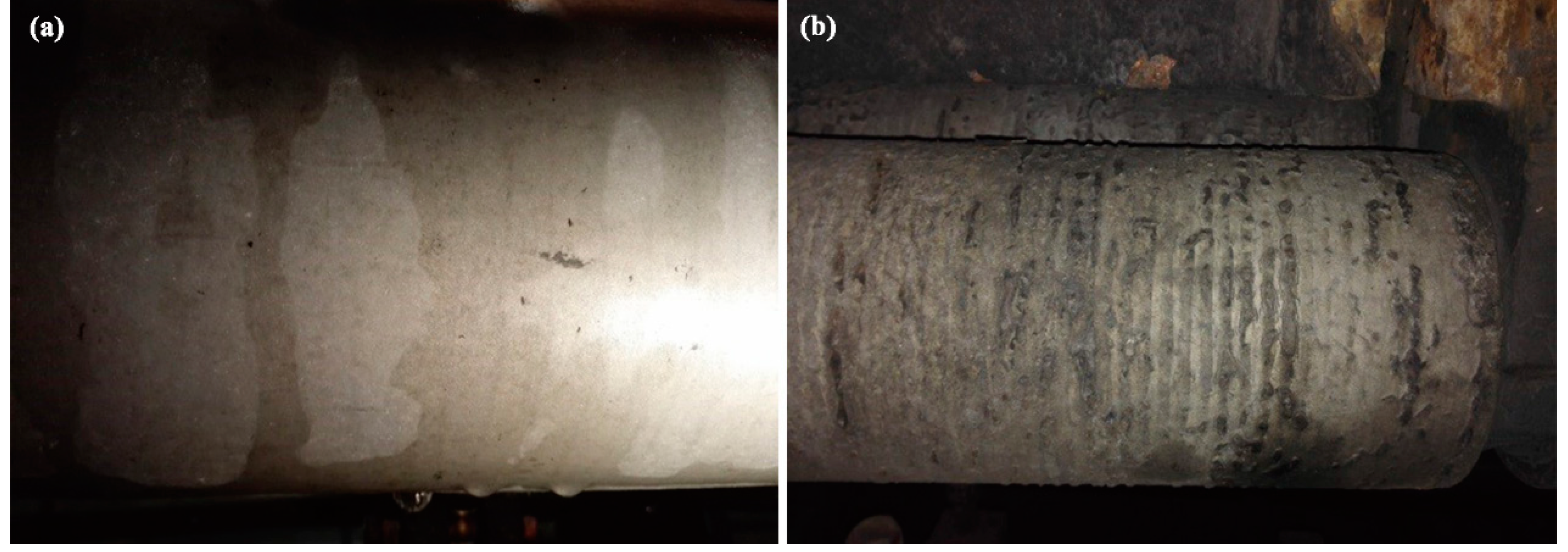

3.5. Comparison under Service Condition

4. Conclusions

- (1)

- The laser power has the primary effect on the width and depth of the cladding layer. The scanning speed has a significant effect on the height. The optimum process parameters for repairing the mould foot roller are 2 kW laser power, 4 mm/s scanning speed, and 15 g/min powder feeding rate.

- (2)

- Along the depth directions, the crystal styles of the cladding zone gradually transformed from planar, dendritic, to equiaxed grain. The microstructure of the cladding layer consisted of matrix phase (martensite) and eutectic phase (netlike M2B, particulate M23(C,B)6, and M7(C,B)3).

- (3)

- The microhardness and Rockwell hardness of the cladding layer are about three times that of the substrate. The weight loss of the cladding layer is just half that of the substrate.

- (4)

- The wear resistance and corrosion resistance of the cladding layer are better than those of the substrate. The excellent wear resistance is mainly due to the existence of martensite and eutectic phase with high hardness.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Corbin, S.F.; Toyserkani, E.; Khajepour, A. Cladding of an Fe-aluminide coating on mild steel using pulsed laser assisted powder deposition. Mater. Sci. Eng. A 2003, 354, 48–57. [Google Scholar] [CrossRef]

- Farnia, A.; Ghaini, F.M.; Ocelı’k, V.; De Hosson, J.T.M. Microstructural characterization of Co-based coating deposited by low power pulse laser cladding. J. Mater. Sci. 2013, 48, 2714–2723. [Google Scholar] [CrossRef]

- Paatsch, W. Energy turnaround—A challenge for surface technology. Trans. IMF 2016, 94, 228–230. [Google Scholar] [CrossRef]

- Gao, Y.L.; Xiong, D.S.; Wang, C.S.; Chen, Y.Z. Influences of laser powers on microstructure and properties of the coatings on the AZ91HP magnesium alloy. Acta Metall. Sin. 2009, 22, 167–173. [Google Scholar] [CrossRef]

- Chen, J.Y.; Wang, S.H.; Xue, L.J. On the development of microstructures and residual stresses during laser cladding and post-heat treatments. J. Mater. Sci. 2012, 47, 779–792. [Google Scholar] [CrossRef]

- Bansal, A.; Zafar, S.; Sharma, A.K. Microstructure and Abrasive Wear Performance of Ni-Wc Composite Microwave Clad. J. Mater. Eng. Perform. 2015, 24, 3708–3716. [Google Scholar] [CrossRef]

- Simunovic, K.; Saric, T.; Simunovic, G. Different Approaches to the Investigation and Testing of the Ni-Based Self-Fluxing Alloy Coatings—A Review. Part 1: General Facts, Wear and Corrosion Investigations. Tribol. Trans. 2014, 57, 955–979. [Google Scholar] [CrossRef]

- Heigel, J.C.; Gouge, M.F.; Michaleris, P.; Palmer, T.A. Selection of powder or wire feedstock material for the laser cladding of Inconel® 625. J. Mater. Process. Technol. 2016, 231, 357–365. [Google Scholar] [CrossRef]

- Lei, Y.W.; Sun, R.L.; Lei, J.B.; Tang, Y.; Niu, W. A new theoretical model for high power laser clad TiC/NiCrBSiC composite coatings on Ti6Al4V alloys. Opt. Laser Technol. 2010, 48, 899–905. [Google Scholar] [CrossRef]

- Radovic, M.; Lar-Curzio, E.; Riester, L. Evaluation of Four Different Experimental Techniques for Determination of Elastic Properties of Solids. Mater. Sci. Eng. A 2004, 368, 56–70. [Google Scholar] [CrossRef]

- Botta, W.J.; Berger, J.E.; Kiminami, C.S.; Roche, V.; Nogueira, R.P.; Bolfarini, C. Corrosion resistance of Fe-based amorphous alloys. J. Alloys Compd. 2014, 586, 105–110. [Google Scholar] [CrossRef]

- Yao, C.W.; Huang, J.; Zhang, P.L.; Li, Z.G.; Wu, Y.X. Toughening of Fe-based laser-clad alloy coating. Appl. Surf. Sci. 2011, 257, 2184–2192. [Google Scholar] [CrossRef]

- Yang, X.Y.; Peng, X.; Chen, J.; Wang, F.H. Effect of a small increase in the Ni content on the properties of a laser surface clad Fe-based alloy. Appl. Surf. Sci. 2007, 253, 4420–4426. [Google Scholar] [CrossRef]

- Li, S.; Hu, Q.W.; Zeng, X.Y.; Ji, S.Q.; Li, S. Effect of carbon content on the microstructure and the cracking susceptibility of Fe-based laser-clad layer. Appl. Surf. Sci. 2005, 240, 63–70. [Google Scholar] [CrossRef]

- Gao, L.L.; Bian, X.F.; Tian, Y.S.; Fu, C.X. Effect of Co on microstructure and interfacial properties of Fe-based laser cladding. J. Iron Steel Res. Int. 2009, 16, 84–88. [Google Scholar] [CrossRef]

- Zhou, S.F.; Dai, X.Q.; Zheng, H.Z. Microstructure and wear resistance of Fe-based WC coating by multi-track overlapping laser induction hybrid rapid cladding. Opt. Laser Technol. 2012, 44, 190–197. [Google Scholar] [CrossRef]

- Qu, S.Y.; Wang, X.H.; Zhang, M.; Zou, Z.D. Microstructure and wear properties of Fe–TiC surface composite coating by laser cladding. J. Mater. Sci. 2008, 43, 1546–1551. [Google Scholar] [CrossRef]

- Kim, H.J.; Yoon, B.H.; Lee, C.H. Wear performance of the Fe-based alloy coatings produced by plasma transferred arc weld-surfacing process. Wear 2001, 249, 846–852. [Google Scholar] [CrossRef]

- Raya, A.; Arora, K.S.; Lester, S.; Shomea, M. Laser cladding of continuous caster lateral rolls: Microstructure, wearand corrosion characterisation and on-field performance evaluation. J. Mater. Process. Technol. 2014, 214, 1566–1575. [Google Scholar] [CrossRef]

- Ma, C.Q.; Hou, L.G.; Zhang, J.S.; Zhuang, L.Z. Influence of thickness reduction per pass on strain, microstructures and mechanical properties of 7050 Al alloy sheet processed by asymmetric rolling. Mater. Sci. Eng. A 2016, 650, 454–468. [Google Scholar] [CrossRef]

- Yanushkevich, Z.; Belyakov, A.; Haase, C.; Molodov, D.A.; Kaibyshev, R. Structural/textural changes and strengthening of an advanced high-Mn steel subjected to cold rolling. Mater. Sci. Eng. A 2016, 651, 763–773. [Google Scholar] [CrossRef]

- Xie, M.X.; Zhang, L.J.; Zhang, G.F.; Zhang, J.X.; Bi, Z.Y.; Li, P.C. Microstructure and mechanical properties of CP-Ti/X65 bimetallic sheets fabricated by explosive welding and hot rolling. Mater. Des. 2015, 87, 181–197. [Google Scholar] [CrossRef]

- Lewis, S.R.; Lewis, R.; Fletcher, D.I. Assessment of laser cladding as an option for repairing/enhancing rails. Wear 2015, 330, 581–591. [Google Scholar] [CrossRef] [Green Version]

- Cheikh, H.E.; Courant, B.; Hascoët, J.Y.; Guillén, R. Prediction and analytical description of the single laser track geometry in direct laser fabrication from process parameters and energy balance reasoning. J. Mater. Process. Technol. 2012, 212, 1832–1839. [Google Scholar] [CrossRef]

- Tsirkas, S.A.; Papanikas, P.; Kermanidis, T. Numerical simulation of the laser welding process in butt-joint specimens. J. Mater. Process. Technol. 2003, 134, 59–69. [Google Scholar] [CrossRef]

- Sun, Y.W.; Hao, M. Statistical analysis and optimization of process parameters in Ti6Al4V laser cladding using Nd:YAG laser. Opt. Laser Eng. 2012, 50, 985–995. [Google Scholar] [CrossRef]

- Lee, H.K. Effects of the cladding parameters on the deposition efficiency in pulsed Nd:YAG laser cladding. J. Mater. Process. Technol. 2008, 202, 321–327. [Google Scholar] [CrossRef]

- Xiang, L.; Min, X.H.; Ji, X.; Emura, S.; Cheng, C.Q.; Tsuchiya, K. Effect of Pre-cold Rolling-Induced Twins and Subsequent Precipitated x-Phase on Mechanical Properties in a β-Type Ti–Mo Alloy. Acta Metall. Sin. 2018, 31, 1–11. [Google Scholar] [CrossRef]

- Ma, X.L.; Wang, K.M.; Fu, H.G.; Ju, J.; Lei, Y.P.; Yi, D.W. Effect of Mo content on microstructure and properties of laser cladding Fe-based alloy coatings. Surf. Rev. Lett. 2017, 5, 1850077. [Google Scholar]

- Wang, K.M.; Fu, H.G.; Li, Y.L.; Lei, Y.P.; Wei, S.Z.; Su, Z.Q. Effect of power on microstructure and properties of laser cladding NiCrBSi composite coating. Trans. IMF 2017, 95, 328–336. [Google Scholar]

- Pan, Q.Y.; Huang, W.D.; Li, Y.M.; Lin, X.; Zhou, Y.H.; Yan, X.C. Wide-band laser cladding: Wear and corrosion resistance of a Ni-based alloy. Acta Metall. Sin. 1997, 10, 445–452. [Google Scholar]

- Karantzalis, A.E.; Lekatou, A.; Mavros, H. Microstructural Modifications of As-Cast High-Chromium White Iron by Heat Treatment. J. Mater. Eng. Perform. 2009, 18, 174–181. [Google Scholar] [CrossRef]

- Korkut, M.H.; Yilmaz, O.; Buytoz, S. Effect of aging on the microstructure and toughness of the interface zone of a gas tungsten arc (GTA) synthesized Fe–Cr–Si–Mo–C coated low carbon steel. Surf. Coat. Technol. 2002, 157, 5–13. [Google Scholar] [CrossRef]

- Gao, W.Y.; Zhao, S.S.; Liu, F.L.; Wang, Y.B.; Zhou, C.Y.; Lin, X.C. Effect of defocus manner on laser cladding of Fe-based alloy powder. Surf. Coat. Technol. 2014, 248, 54–62. [Google Scholar] [CrossRef]

- Liu, J.; Li, J.; Xu, C.; Wang, H.M. Microstructures and tensile properties of laser cladded AerMet100 steel coating on 300M steel. J. Mater. Sci. Technol. 2018, 34, 643–652. [Google Scholar] [CrossRef]

- Ju, J.; Fu, H.G.; Fu, D.M.; Wei, S.Z.; Sang, P.; Wu, Z.W.; Tang, K.Z.Y.; Lei, Y.P. Effects of Cr and V additions on the microstructure and properties of high-vanadium wear-resistant alloy steel. Ironmak. Steelmak. 2016, 45, 1–11. [Google Scholar] [CrossRef]

- Wang, Z.H.; Wan, G.L.; He, D.Y.; Jiang, J.M.; Cui, L. Microstructures and Wear Resistance of Fe-Cr-B-C Hardfacing Alloys. J. Mater. Sci. 2014, 4, 57–62. [Google Scholar]

- Zhou, Y.; Wang, G.H.; He, D.Y.; Zhou, Z.; Wang, Y.M.; Wu, X. Effects of Chromium Content on Microstructure and Wear Resistance of Fe-Cr-B Surfacing Alloys. Surf. Technol. 2017, 46, 88–92. [Google Scholar]

| Element | C | Cr | Ni | Mo | Mn | Si | B | Co | Fe |

|---|---|---|---|---|---|---|---|---|---|

| Alloy powder | 0.2 | 16.0 | 2.5 | 0.5 | - | 0.75 | 1.0 | 0.5 | Bal. |

| 42CrMo steel | 0.38 | 0.90 | - | 0.19 | 0.60 | 0.17 | - | - | Bal. |

| Group Number | No. 1 | No. 2 | No. 3 | No. 4 | No. 5 | No. 6 | No. 7 | No. 8 | No. 9 |

|---|---|---|---|---|---|---|---|---|---|

| Laser power (kW) | 1 | 1 | 1 | 2 | 2 | 2 | 3 | 3 | 3 |

| Scanning speed (mm/s) | 2 | 4 | 6 | 2 | 4 | 6 | 2 | 4 | 6 |

| Feeding rate (g/min) | 10 | 15 | 20 | 15 | 20 | 10 | 20 | 10 | 15 |

| Number | No. 1 | No. 2 | No. 3 | No. 4 | No. 5 | No. 6 | No. 7 | No. 8 | No. 9 |

|---|---|---|---|---|---|---|---|---|---|

| Height (μm) | 2506.8 | 2335.0 | 1961.1 | 2914.2 | 2140.4 | 944.4 | 3311.9 | 1228.8 | 1296.5 |

| Depth (μm) | 22.8 | 15.9 | 10.8 | 115 | 50.6 | 48 | 262.9 | 183.8 | 100.9 |

| Width (μm) | 4175.6 | 3618.8 | 2226.9 | 6189.6 | 5331.2 | 4805.4 | 7323.5 | 6137.6 | 6009.6 |

| Laser Power (kW) | Scanning Speed (mm/s) | Powder Feeding Rate (g/min) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Height (μm) | Depth (μm) | Width (μm) | Height (μm) | Depth (μm) | Width (μm) | Height (μm) | Depth (μm) | Width (μm) | |

| K1 | 2003.1 | 16.5 | 3340.4 | 2911.0 | 133.6 | 5896.2 | 1560.0 | 84.9 | 5039.5 |

| K2 | 1999.7 | 71.2 | 5442.1 | 1901.4 | 83.4 | 5029.2 | 2181.9 | 77.3 | 5272.7 |

| K3 | 1945.7 | 182.5 | 6490.2 | 1136.1 | 53.2 | 4347.3 | 2206.6 | 108.1 | 4960.5 |

| R | 57.4 | 166.0 | 3149.8 | 1774.9 | 80.4 | 1548.9 | 646.6 | 30.8 | 312.2 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ju, J.; Zhou, Y.; Kang, M.; Wang, J. Optimization of Process Parameters, Microstructure, and Properties of Laser Cladding Fe-Based Alloy on 42CrMo Steel Roller. Materials 2018, 11, 2061. https://doi.org/10.3390/ma11102061

Ju J, Zhou Y, Kang M, Wang J. Optimization of Process Parameters, Microstructure, and Properties of Laser Cladding Fe-Based Alloy on 42CrMo Steel Roller. Materials. 2018; 11(10):2061. https://doi.org/10.3390/ma11102061

Chicago/Turabian StyleJu, Jiang, Yang Zhou, Maodong Kang, and Jun Wang. 2018. "Optimization of Process Parameters, Microstructure, and Properties of Laser Cladding Fe-Based Alloy on 42CrMo Steel Roller" Materials 11, no. 10: 2061. https://doi.org/10.3390/ma11102061