High-Performance Thin Film Transistor with an Neodymium-Doped Indium Zinc Oxide/Al2O3 Nanolaminate Structure Processed at Room Temperature

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

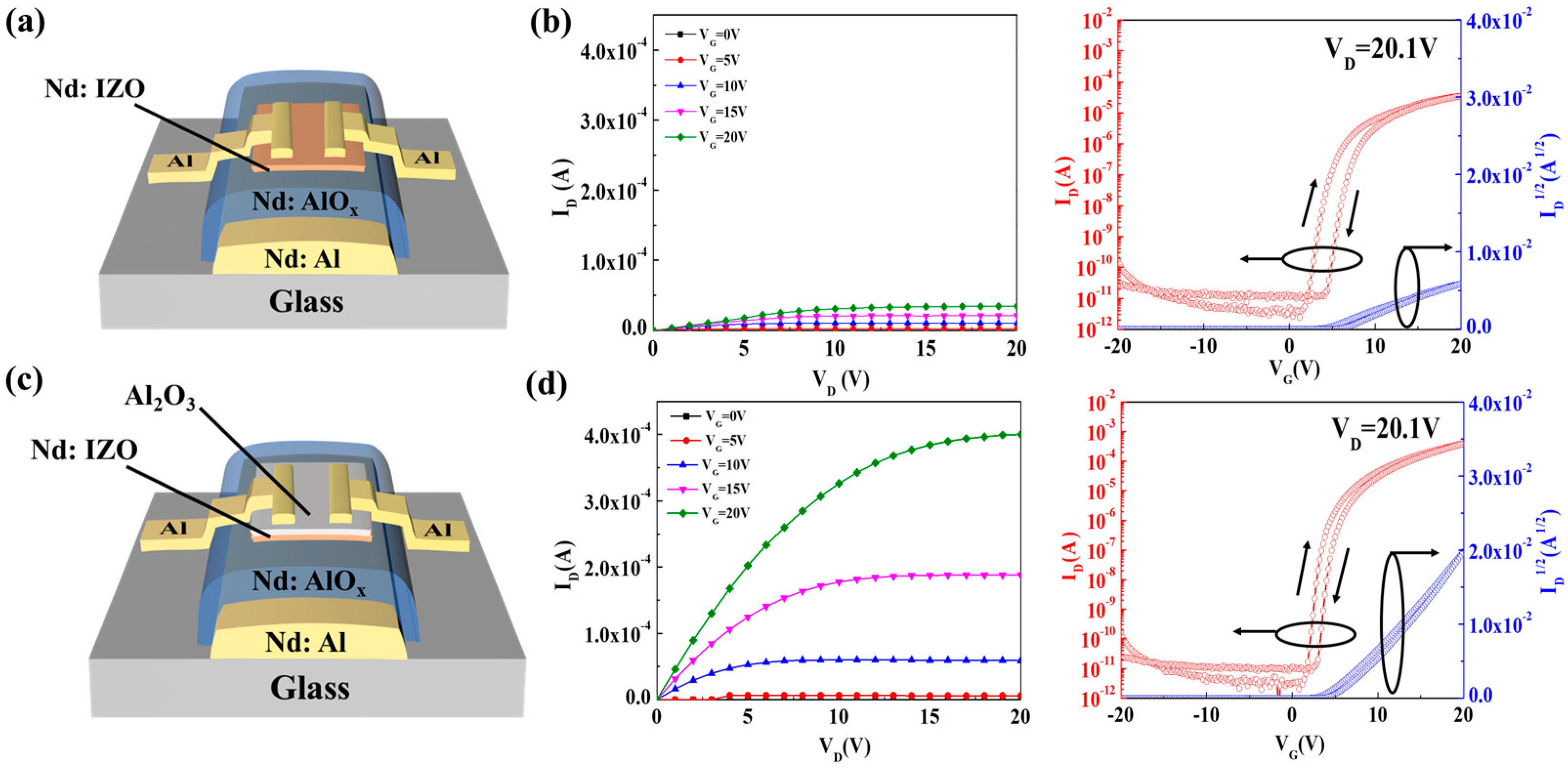

3.1. Effect of the Ultrathin Al2O3 Layer

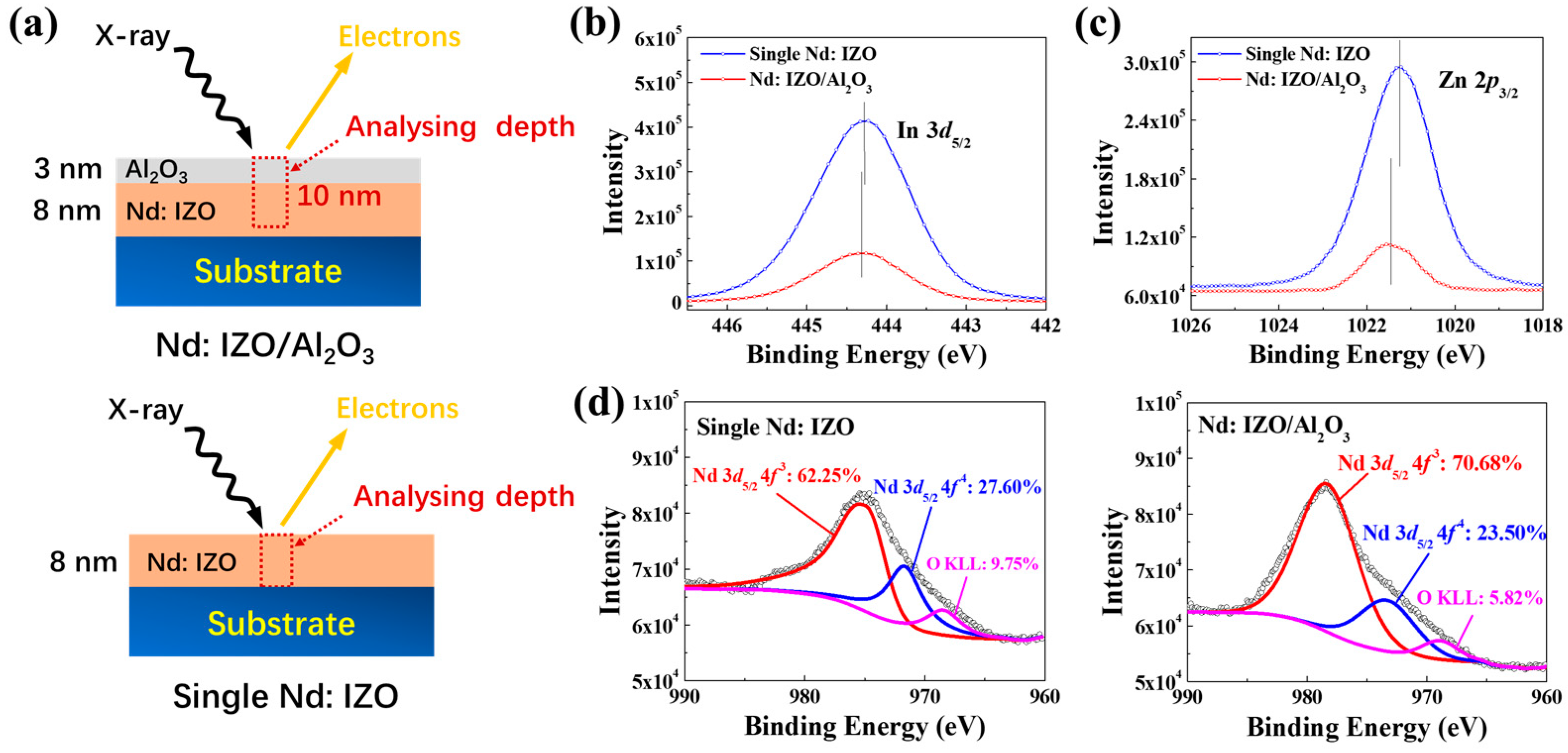

3.1.1. Chemical Structure

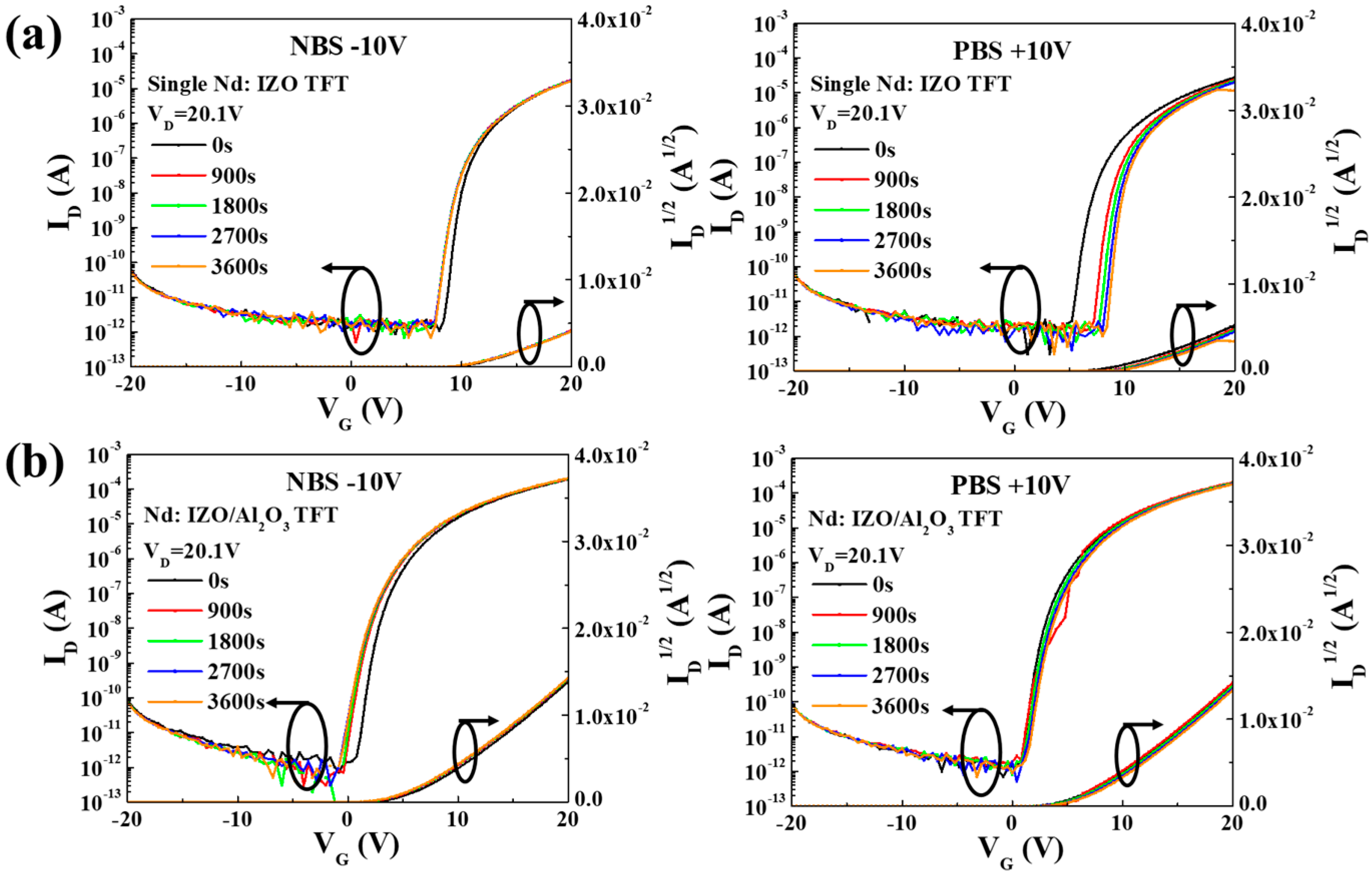

3.1.2. Electrical Stabilities

3.2. Effect of the Thickness of the Nd:IZO Layer in an Nd:IZO/Al2O3 Structure

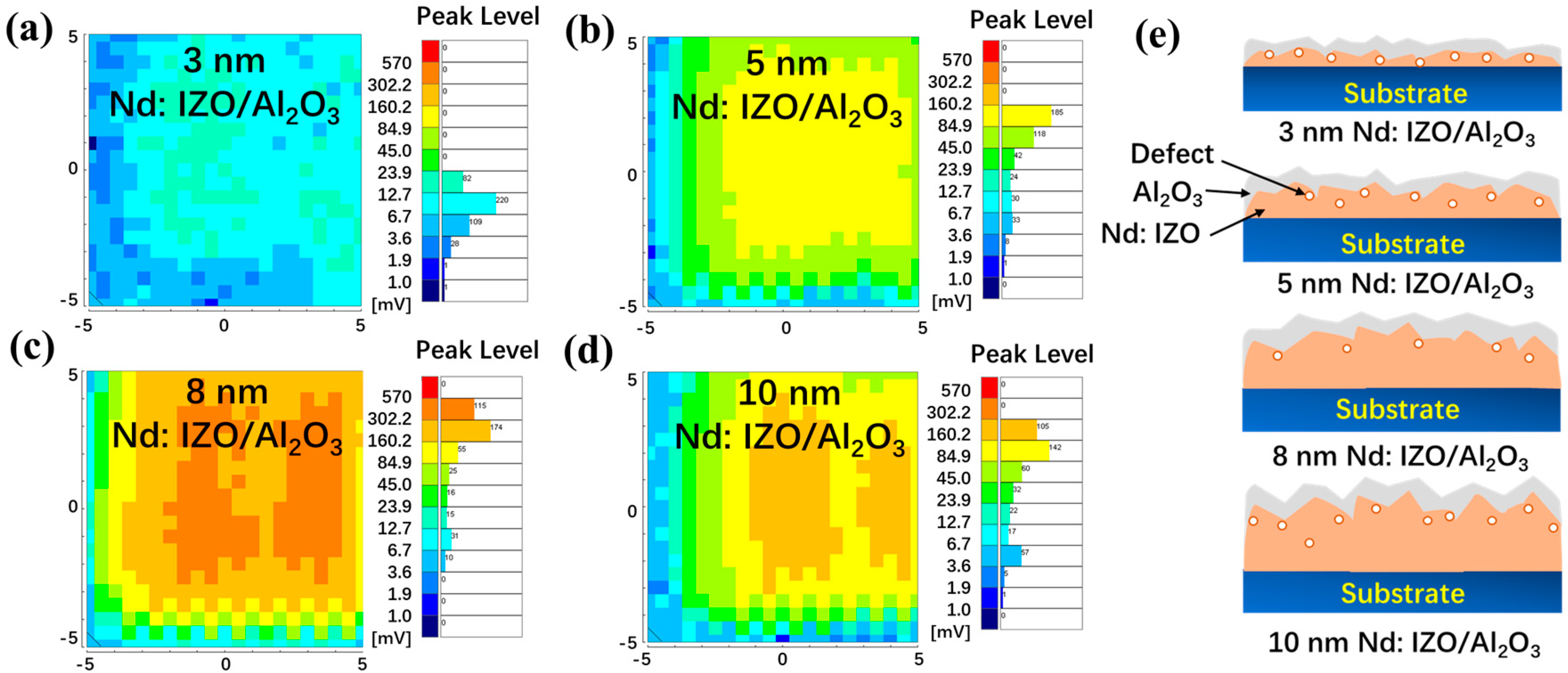

3.2.1. Device Performance and Film Qualities

3.2.2. The Nd:IZO/Al2O3 Interfaces

3.2.3. Effect of Neodymium Concentrations

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lin, C.-L.; Chen, F.-H.; Huang, C.-C.; Chen, P.-S.; Deng, M.-Y.; Lu, C.-M.; Huang, T.-H. New a-IGZO Pixel Circuit Composed of Three Transistors and One Capacitor for Use in High-Speed-Scan AMOLED Displays. J. Disp. Technol. 2015, 11, 1031–1034. [Google Scholar]

- Eda, G.; Fanchini, G.; Chhowalla, M. Large-area ultrathin films of reduced graphene oxide as a transparent and flexible electronic material. Nat. Nanotechnol. 2008, 3, 270–274. [Google Scholar] [CrossRef] [PubMed]

- Nomura, K.; Ohta, H.; Takagi, A.; Kamiya, T.; Hirano, M.; Hosono, H. Room-temperature fabrication of transparent flexible thin-film transistors using amorphous oxide semiconductors. Nature 2004, 432, 488–492. [Google Scholar] [CrossRef] [PubMed]

- Kim, Y.-H.; Heo, J.-S.; Kim, T.-H.; Park, S.; Yoon, M.-H.; Kim, J.; Oh, M.S.; Yi, G.-R.; Noh, Y.-Y.; Park, S.K. Flexible metal-oxide devices made by room-temperature photochemical activation of sol-gel films. Nature 2012, 489, 128–191. [Google Scholar] [CrossRef] [PubMed]

- Yao, R.; Zheng, Z.; Fang, Z.; Zhang, H.; Zhang, X.; Ning, H.; Wang, L.; Peng, J.; Xie, W.; Lu, X. High-performance flexible oxide TFTs: Optimization of a-IGZO film by modulating the voltage waveform of pulse DC magnetron sputtering without post treatment. J. Mater. Chem. C 2018, 6, 2522–2532. [Google Scholar] [CrossRef]

- Zheng, Z.; Zeng, Y.; Yao, R.; Fang, Z.; Zhang, H.; Hu, S.; Li, X.; Ning, H.; Peng, J.; Xie, W.; et al. All-sputtered, flexible, bottom-gate IGZO/Al2O3 bi-layer thin film transistors on PEN fabricated by a fully room temperature process. J. Mater. Chem. C 2017, 5, 7043–7050. [Google Scholar] [CrossRef]

- Arai, T. Oxide-TFT technologies for next-generation AMOLED displays. J. Soc. Inf. Disp. 2012, 20, 156–161. [Google Scholar] [CrossRef]

- Zheleva, T.S.; Nam, O.-H.; Bremser, M.D.; Davis, D.F. Dislocation density reduction via lateral epitaxy in selectively grown GaN structures. Appl. Phys. Lett. 1997, 71, 2472–2474. [Google Scholar] [CrossRef]

- Macdonald, F.; Lide, D.R. CRC Handbook of Chemistry and Physics: From Paper to Web; Abstracts of Papers of the American Chemical Society; Amer Chemical Soc: Washington, DC, USA, 2003; Volume 225, p. U552. [Google Scholar]

- Xu, H.; Luo, D.X.; Li, M.; Xu, M.; Zou, J.H.; Tao, H.; Lan, L.F.; Wang, L.; Peng, J.B.; Cao, Y. A flexible AMOLED display on the PEN substrate driven by oxide thin-film transistors using anodized aluminium oxide as dielectric. J. Mater. Chem. C 2014, 2, 1255–1259. [Google Scholar] [CrossRef]

- Ning, H.L.; Zeng, Y.; Zheng, Z.K.; Zhang, H.K.; Fang, Z.Q.; Yao, R.H.; Hu, S.B.; Li, X.Q.; Peng, J.B.; Xie, W.G.; et al. Facile Room Temperature Routes to Improve Performance of IGZO Thin-Film Transistors by an Ultrathin Al2O3 Passivation Layer. IEEE Trans. Electron Devices 2017, 65, 537–541. [Google Scholar] [CrossRef]

- Ahn, C.H.; Cho, H.K.; Kim, H. Carrier confinement effect-driven channel design and achievement of robust electrical/photostability and high mobility in oxide thin-film transistors. J. Mater. Chem. C 2016, 4, 727–735. [Google Scholar] [CrossRef]

- Ahn, C.H.; Senthil, K.; Cho, H.K.; Lee, S.Y. Artificial semiconductor/insulator superlattice channel structure for high-performance oxide thin-film transistors. Sci. Rep. 2013, 3, 2737. [Google Scholar] [CrossRef] [PubMed]

- Lan, L.F.; Song, W.; Lin, Z.G.; Xiao, P.; Wang, L.; Ning, H.L.; Wang, D.; Peng, J.B. Effects of Nd in NdxIn1−xO3 Semiconductors for Thin-Film Transistors. IEEE Trans. Electron Devices 2015, 62, 2226–2230. [Google Scholar]

- Lin, Z.G.; Lan, L.F.; Xiao, P.; Sun, S.; Li, Y.Z.; Song, W.; Gao, P.X.; Wang, L.; Ning, H.L.; Peng, J.B. High-mobility thin film transistors with neodymium-substituted indium oxide active layer. Appl. Phys. Lett. 2015, 107, 112108. [Google Scholar] [CrossRef]

- Lee, J.M.; Cho, I.T.; Lee, J.H.; Kwon, H.I. Bias-stress-induced stretched-exponential time dependence of threshold voltage shift in InGaZnO thin film transistors. Appl. Phys. Lett. 2008, 93, 0935049. [Google Scholar] [CrossRef]

- Suresh, A.; Muth, J.F. Bias stress stability of indium gallium zinc oxide channel based transparent thin film transistors. Appl. Phys. Lett. 2008, 92, 0335023. [Google Scholar] [CrossRef]

- Zeng, Y.; Ning, H.L.; Zheng, Z.K.; Zhang, H.K.; Fang, Z.Q.; Yao, R.H.; Xu, M.; Wang, L.; Lan, L.F.; Peng, J.B.; et al. A room temperature strategy towards enhanced performance and bias stability of oxide thin film transistor with a sandwich structure channel layer. Appl. Phys. Lett. 2017, 110, 15350315. [Google Scholar] [CrossRef]

- Yasuno, S.; Kugimiya, T.; Morita, S.; Miki, A.; Ojima, F.; Sumie, S. Correlation of photoconductivity response of amorphous In-Ga-Zn-O films with transistor performance using microwave photoconductivity decay method. Appl. Phys. Lett. 2011, 98, 102107. [Google Scholar] [CrossRef]

- Yasuno, S.; Kita, T.; Morita, S.; Hino, A.; Hayashi, K.; Kugimiya, T.; Sumie, S. Application of Microwave Photoconductivity Decay Method to Characterization of Amorphous In-Ga-Zn-O Films. IEICE Trans. Electron. 2012, E95C, 1724–1729. [Google Scholar] [CrossRef]

- Yasuno, S.; Kita, T.; Morita, S.; Kugimiya, T.; Hayashi, K.; Sumie, S. Transient photoconductivity responses in amorphous In-Ga-Zn-O films. J. Appl. Phys. 2012, 112, 053715. [Google Scholar] [CrossRef]

- Xiao, P.; Dong, T.; Lan, L.F.; Lin, Z.G.; Song, W.; Luo, D.X.; Xu, M.; Peng, J.B. High-mobility ZrInO thin-film transistor prepared by an all-DC-sputtering method at room temperature. Sci. Rep.-UK 2016, 6, 25000. [Google Scholar] [CrossRef] [PubMed] [Green Version]

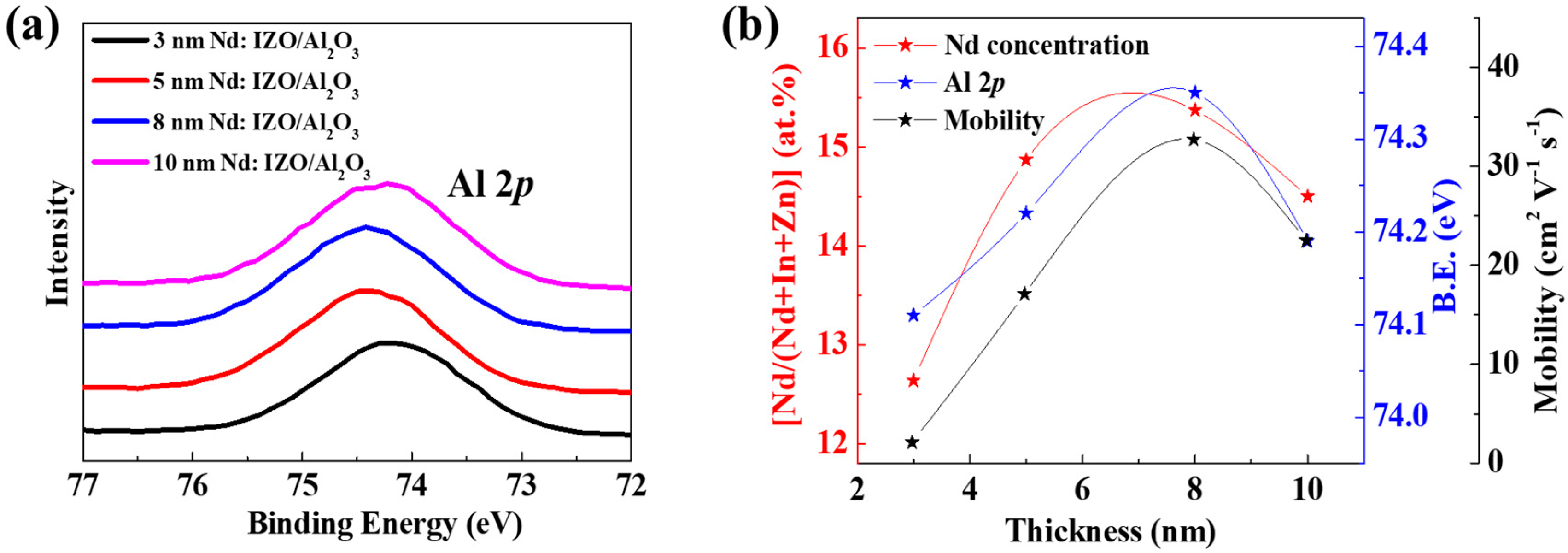

| TFTs/Films | 3 nm Nd:IZO/Al2O3 | 5 nm Nd:IZO/Al2O3 | 8 nm Nd:IZO/Al2O3 | 10 nm Nd:IZO/Al2O3 |

|---|---|---|---|---|

| μsat (cm2·V−1·s−1) | 2.1 | 17.1 | 32.7 | 22.5 |

| Ion/Ioff | 2.7 × 106 | 8.4 × 107 | 1.9 × 108 | 5.6 × 106 |

| SS (V·dec−1) | 0.32 | 0.41 | 0.33 | 0.63 |

| Von (V) | 1.6 | 1.8 | 1.0 | −2.9 |

| Nd:IZO density (g·cm−3) | 6.37 | 6.41 | 6.74 | 6.46 |

| Nd:IZO roughness (nm) | 0.61 | 0.66 | 0.72 | 1.06 |

| μ-PCD peak mean (mV) | 9.0 | 65.6 | 205.6 | 97.4 |

| Nd/[Nd + In + Zn] (at.%) | 12.64 | 14.87 | 15.37 | 14.50 |

| Al 2p Eb (eV) | 74.11 | 74.22 | 74.35 | 74.19 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yao, R.; Li, X.; Zheng, Z.; Zhang, X.; Xiong, M.; Xiao, S.; Ning, H.; Wang, X.; Wu, Y.; Peng, J. High-Performance Thin Film Transistor with an Neodymium-Doped Indium Zinc Oxide/Al2O3 Nanolaminate Structure Processed at Room Temperature. Materials 2018, 11, 1871. https://doi.org/10.3390/ma11101871

Yao R, Li X, Zheng Z, Zhang X, Xiong M, Xiao S, Ning H, Wang X, Wu Y, Peng J. High-Performance Thin Film Transistor with an Neodymium-Doped Indium Zinc Oxide/Al2O3 Nanolaminate Structure Processed at Room Temperature. Materials. 2018; 11(10):1871. https://doi.org/10.3390/ma11101871

Chicago/Turabian StyleYao, Rihui, Xiaoqing Li, Zeke Zheng, Xiaochen Zhang, Mei Xiong, Song Xiao, Honglong Ning, Xiaofeng Wang, Yuxiang Wu, and Junbiao Peng. 2018. "High-Performance Thin Film Transistor with an Neodymium-Doped Indium Zinc Oxide/Al2O3 Nanolaminate Structure Processed at Room Temperature" Materials 11, no. 10: 1871. https://doi.org/10.3390/ma11101871