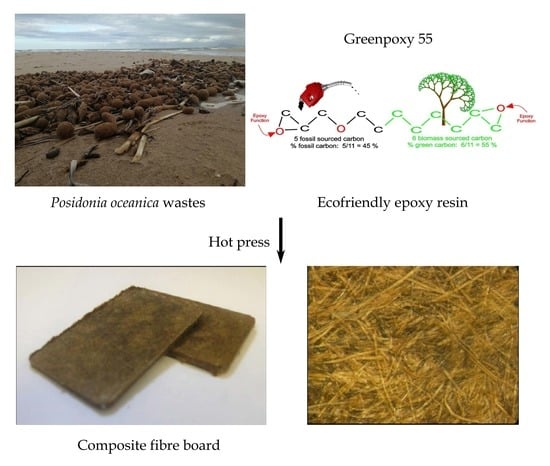

Manufacturing and Characterization of Composite Fibreboards with Posidonia oceanica Wastes with an Environmentally-Friendly Binder from Epoxy Resin

Abstract

:1. Introduction

2. Materials and Methods

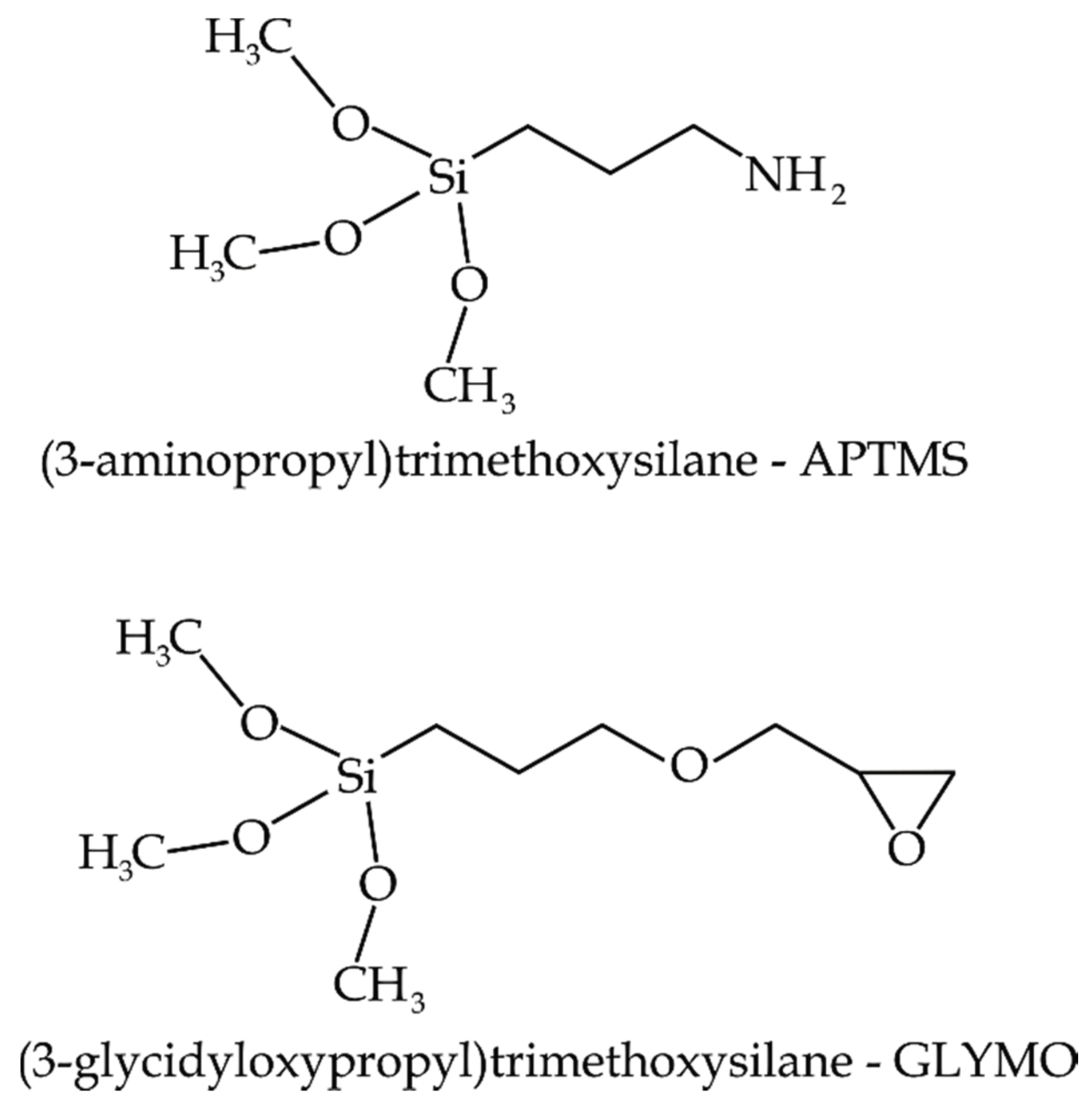

2.1. Materials

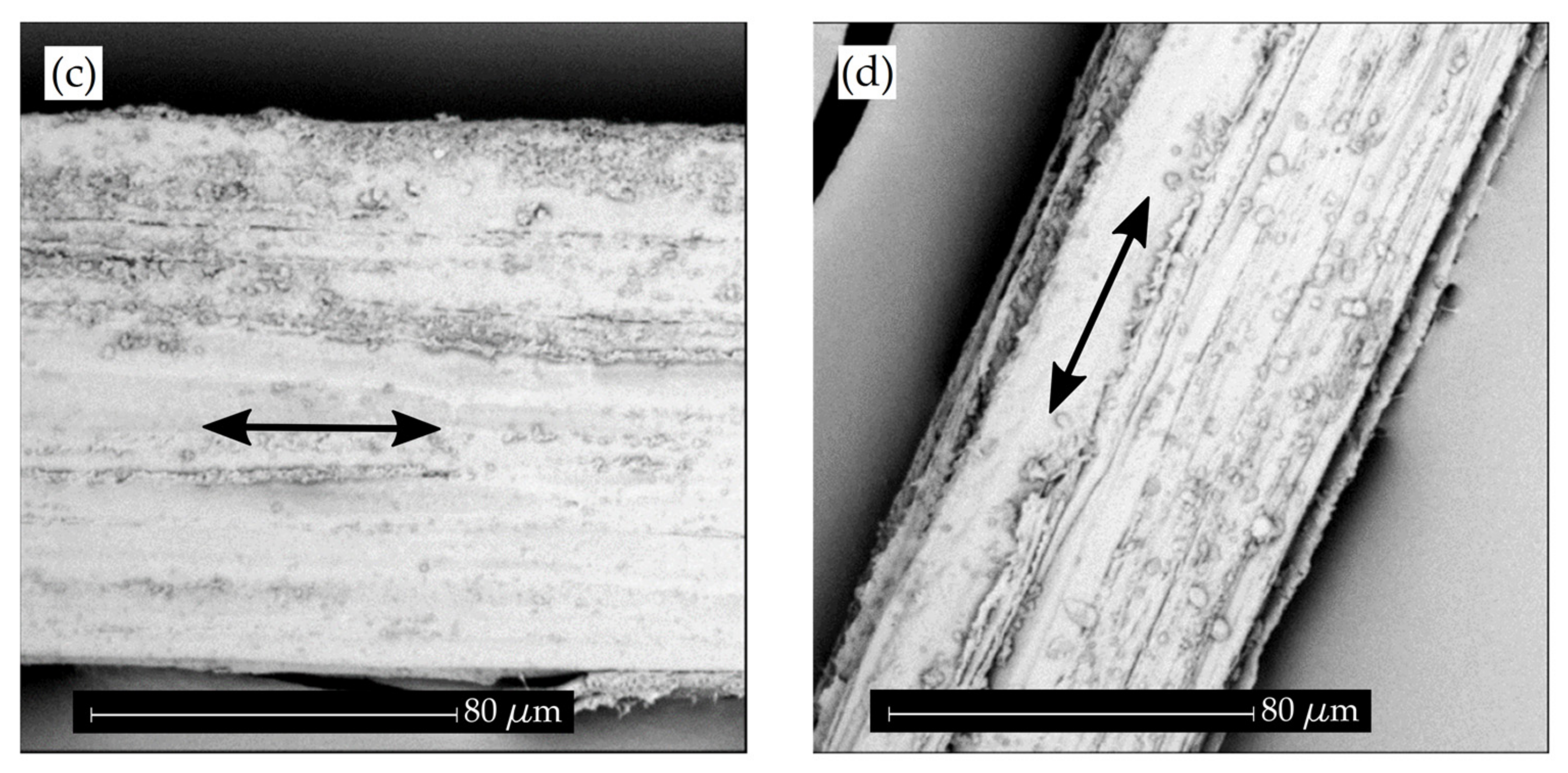

2.2. Surface Treatments on Posidonia oceanica

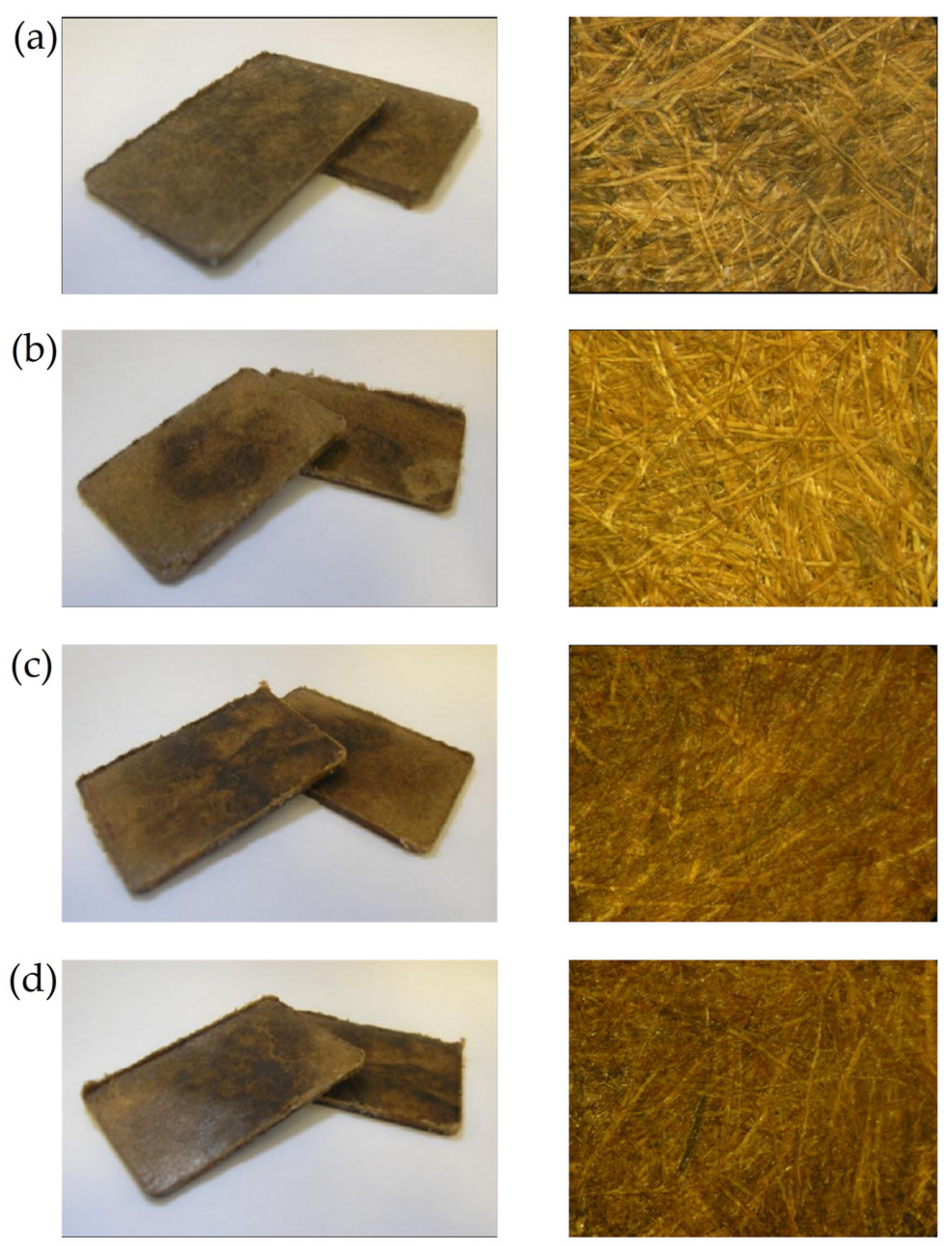

2.3. Manufacturing of Fibreboards

2.4. Mechanical Characterization

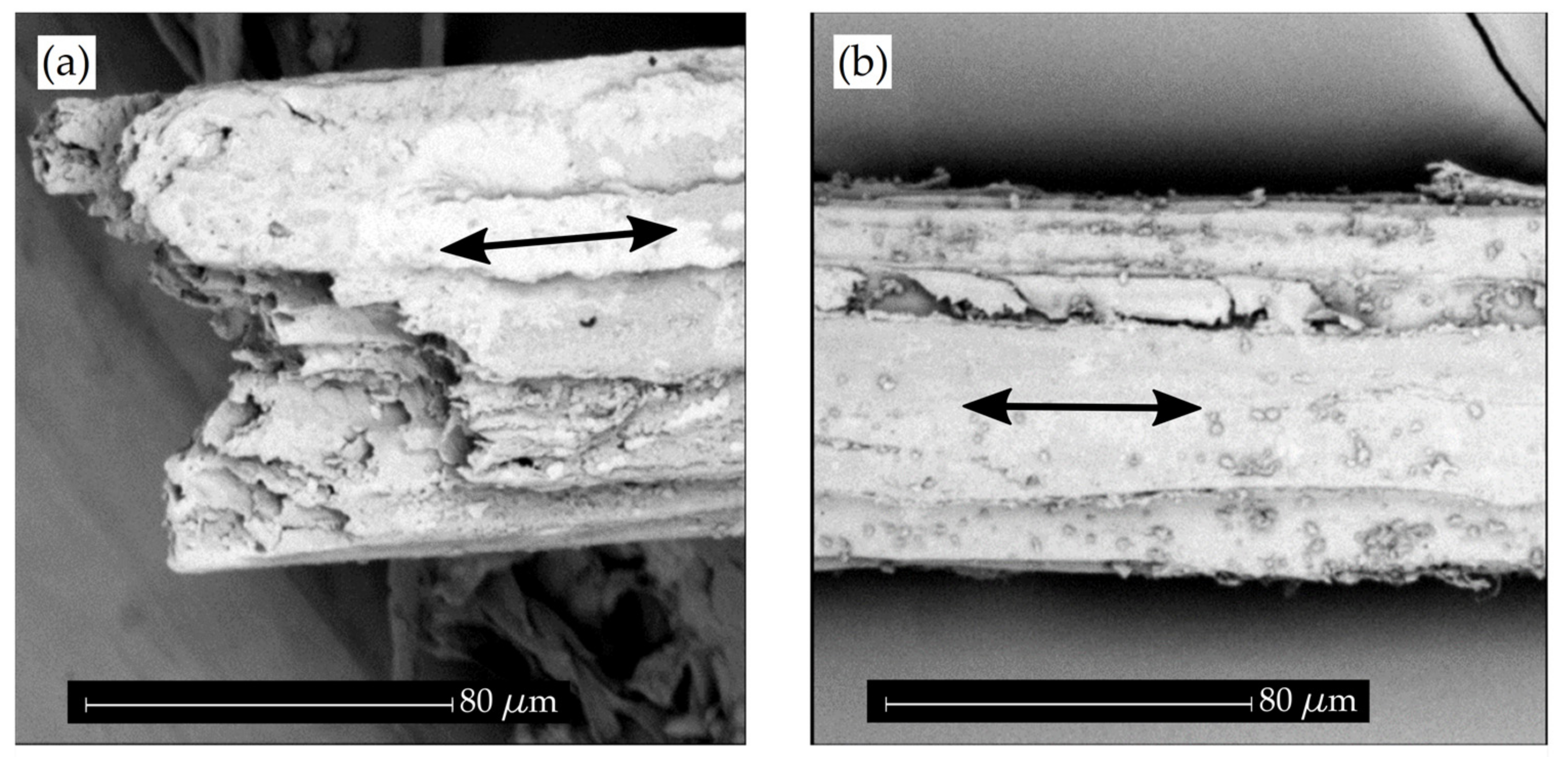

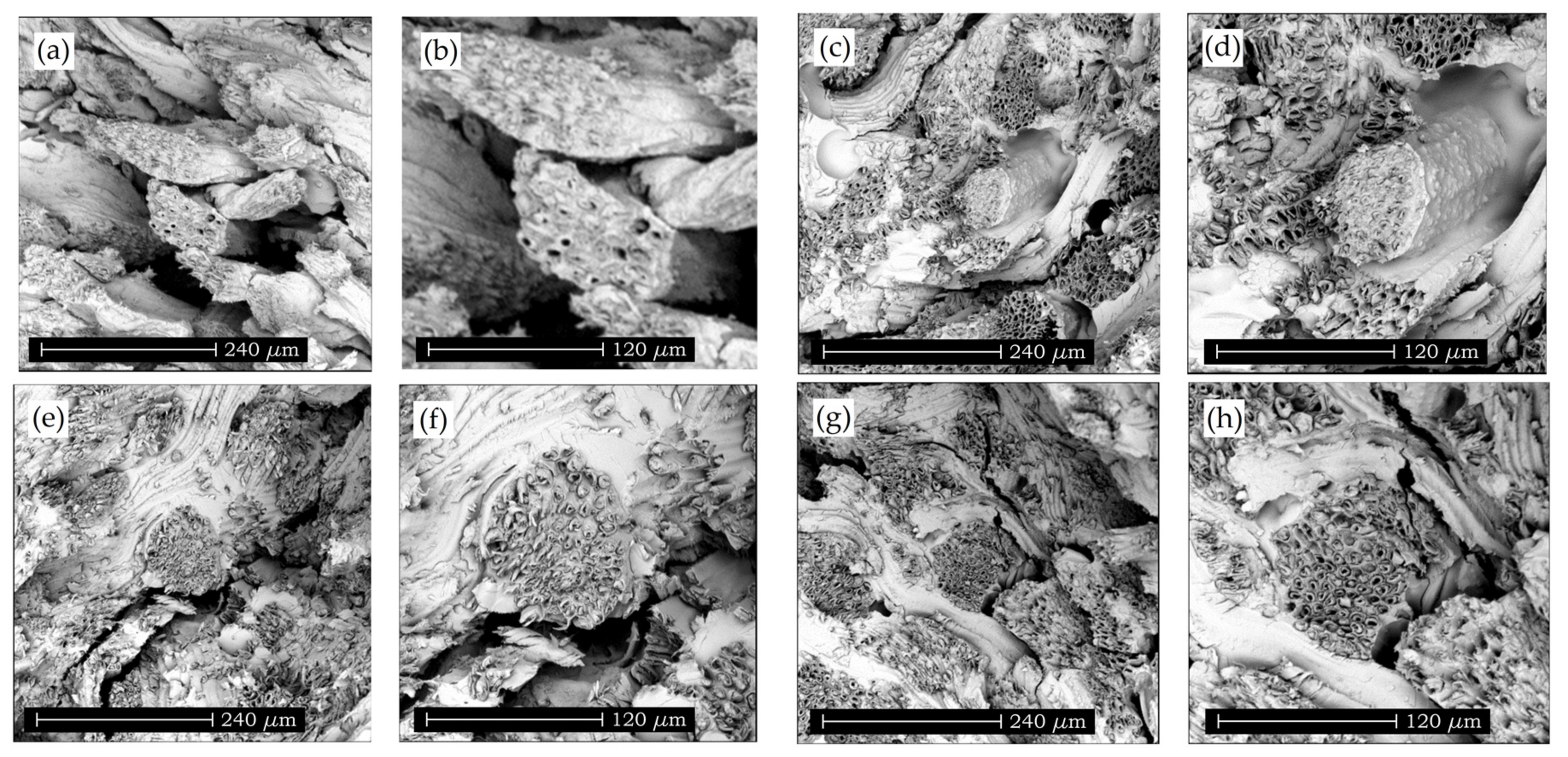

2.5. Morphology of Composite Fibreboards

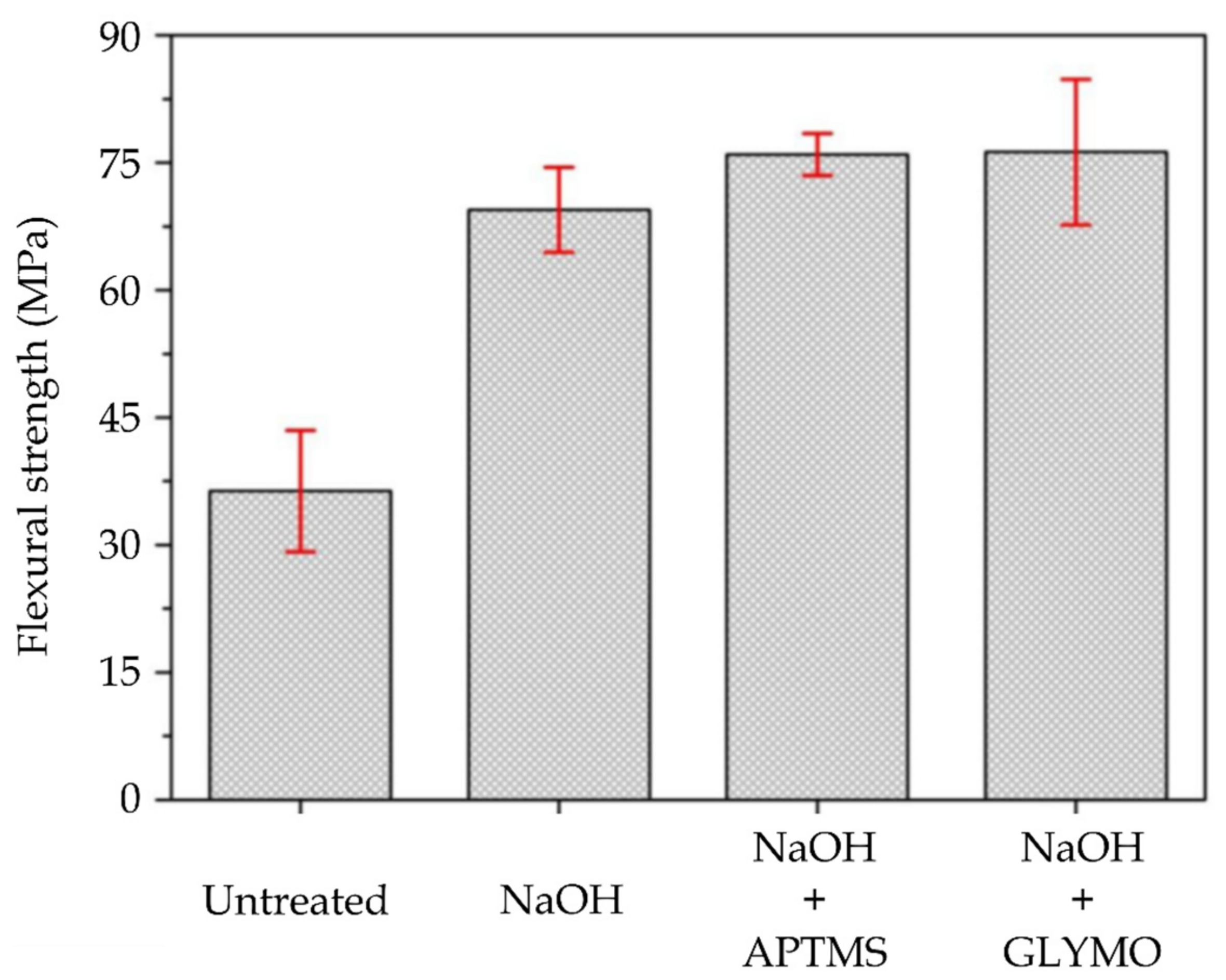

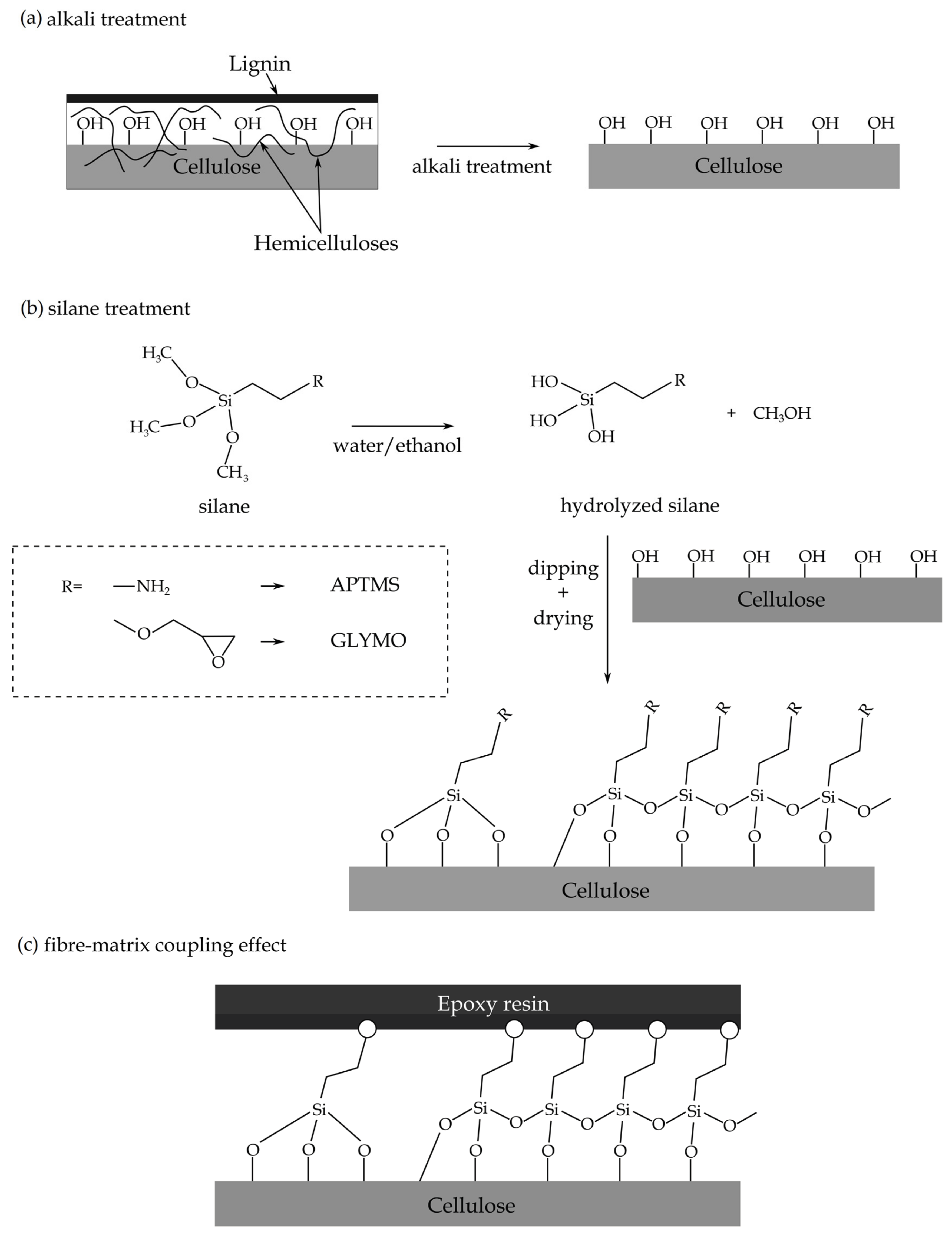

3. Results and Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Moubarik, A.; Mansouri, H.R.; Pizzi, A.; Charrier, F.; Allal, A.; Charrier, B. Corn flour-mimosa tannin-based adhesives without formaldehyde for interior particleboard production. Wood Sci. Technol. 2013, 47, 675–683. [Google Scholar] [CrossRef]

- Akinyemi, A.B.; Afolayan, J.O.; Oluwatobi, E.O. Some properties of composite corn cob and sawdust particle boards. Constr. Build. Mater. 2016, 127, 436–441. [Google Scholar] [CrossRef]

- Sommerhuber, P.F.; Welling, J.; Krause, A. Substitution potentials of recycled hdpe and wood particles from post-consumer packaging waste in wood-plastic composites. Waste Manag. 2015, 46, 76–85. [Google Scholar] [CrossRef] [PubMed]

- Ghofrani, M.; Ashori, A.; Mehrabi, R. Mechanical and acoustical properties of particleboards made with date palm branches and vermiculite. Polym. Test. 2017, 60, 153–159. [Google Scholar] [CrossRef]

- Khazaeian, A.; Ashori, A.; Dizaj, M.Y. Suitability of sorghum stalk fibers for production of particleboard. Carbohydr. Polym. 2015, 120, 15–21. [Google Scholar] [CrossRef] [PubMed]

- Sabbatini, A.; Lanari, S.; Santulli, C.; Pettinari, C. Use of almond shells and rice husk as fillers of poly(methyl methacrylate) (PMMA) composites. Materials 2017, 10, 872. [Google Scholar] [CrossRef] [PubMed]

- Vaisanen, T.; Haapala, A.; Lappalainen, R.; Tomppo, L. Utilization of agricultural and forest industry waste and residues in natural fiber-polymer composites: A review. Waste Manag. 2016, 54, 62–73. [Google Scholar] [CrossRef] [PubMed]

- Ashori, A.; Nourbakhsh, A. Characteristics of wood-fiber plastic composites made of recycled materials. Waste Manag. 2009, 29, 1291–1295. [Google Scholar] [CrossRef] [PubMed]

- Elbadawi, M.; Osman, Z.; Paridah, T.; Nasroun, T.; Kantiner, W. Properties of particleboards made from acacia seyal var. Using uf-tannin modified adhesives. Cellul. Chem. Technol. 2015, 49, 369–374. [Google Scholar]

- Zhao, Z.Y.; Umemura, K. Investigation of a new natural particleboard adhesive composed of tannin and sucrose. 2. Effect of pressing temperature and time on board properties, and characterization of adhesive. Bioresources 2015, 10, 2444–2460. [Google Scholar] [CrossRef]

- Koumba-Yoya, G.; Stevanovic, T. Study of organosolv lignins as adhesives in wood panel production. Polymers 2017, 9, 46. [Google Scholar] [CrossRef]

- Santiago-Medina, F.; Foyer, G.; Pizzi, A.; Caillol, S.; Delmotte, L. Lignin-derived non-toxic aldehydes for ecofriendly tannin adhesives for wood panels. Int. J. Adhes. Adhes. 2016, 70, 239–248. [Google Scholar] [CrossRef]

- Ferguson, R.C.; Mendon, S.K.; Rawlins, J.W.; Thames, S.F. Formaldehyde-free wood composites from soybean protein adhesive. J. Renew. Mater. 2014, 2, 166–172. [Google Scholar] [CrossRef]

- Gu, K.; Huang, J.; Li, K.C. Preparation and evaluation of particleboard bonded with a soy flour-based adhesive with a new curing agent. J. Adhes. Sci. Technol. 2013, 27, 2053–2064. [Google Scholar] [CrossRef]

- Prasittisopin, L.; Li, K.C. A new method of making particleboard with a formaldehyde-free soy-based adhesive. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1447–1453. [Google Scholar] [CrossRef]

- Baroncini, E.A.; Yadav, S.K.; Palmese, G.R.; Stanzione, J.F. Recent advances in bio-based epoxy resins and bio-based epoxy curing agents. J. Appl. Polym. Sci. 2016, 133. [Google Scholar] [CrossRef]

- Saba, N.; Jawaid, M.; Alothman, O.Y.; Paridah, M.T.; Hassan, A. Recent advances in epoxy resin, natural fiber-reinforced epoxy composites and their applications. J. Reinf. Plast. Compos. 2016, 35, 447–470. [Google Scholar] [CrossRef]

- Kim, N.; Li, Y.H.; Sun, X.S. Epoxidation of camelina sativa oil and peel adhesion properties. Ind. Crops Prod. 2015, 64, 1–8. [Google Scholar] [CrossRef]

- Obradovic, J.; Voutilainen, M.; Virtanen, P.; Lassila, L.; Fardim, P. Cellulose fibre-reinforced biofoam for structural applications. Materials 2017, 10, 619. [Google Scholar] [CrossRef] [PubMed]

- Arevalo, R.; Peijs, T. Binderless all-cellulose fibreboard from microfibrillated lignocellulosic natural fibres. Compos. Part A Appl. Sci. Manuf. 2016, 83, 38–46. [Google Scholar] [CrossRef]

- Kojima, Y.; Isa, A.; Kobori, H.; Suzuki, S.; Ito, H.; Makise, R.; Okamoto, M. Evaluation of binding effects in wood flour board containing ligno-cellulose nanofibers. Materials 2014, 7, 6853–6864. [Google Scholar] [CrossRef] [PubMed]

- Krika, F.; Azzouz, N.; Ncibi, M.C. Adsorptive removal of cadmium from aqueous media using posidonia oceanica biomass: Equilibrium, dynamic and thermodynamic studies. Int. J. Environ. Sci. Tecnol. 2015, 12, 983–994. [Google Scholar] [CrossRef]

- Krika, F.; Benlahbib, O.E. Removal of methyl orange from aqueous solution via adsorption on cork as a natural and low-coast adsorbent: Equilibrium, kinetic and thermodynamic study of removal process. Desalination Water Treat. 2015, 53, 3711–3723. [Google Scholar] [CrossRef]

- Ncibi, M.C.; Ranguin, R.; Pintor, M.J.; Jeanne-Rose, V.; Sillanpaa, M.; Gaspard, S. Preparation and characterization of chemically activated carbons derived from mediterranean Posidonia oceanica (L.) fibres. J. Anal. Appl. Pyrolysis 2014, 109, 205–214. [Google Scholar] [CrossRef]

- Ben Douissa, N.; Bergaoui, L.; Mansouri, S.; Khiari, R.; Mhenni, M.F. Macroscopic and microscopic studies of methylene blue sorption onto extracted celluloses from posidonia oceanica. Ind. Crops Prod. 2013, 45, 106–113. [Google Scholar] [CrossRef]

- Nakhli, A.; Bergaoui, M.; Aguir, C.; Khalfaoui, M.; M'Henni, M.F.; Ben Lamine, A. Adsorption thermodynamics in the framework of the statistical physics formalism: Basic blue 41 adsorption onto posidonia biomass. Desalination Water Treat. 2016, 57, 12730–12742. [Google Scholar] [CrossRef]

- Venault, A.; Ncibi, M.C.; Pochat-Bohatier, C.; Vachoud, L.; Bouyer, D.; Faur, C. On the adsorption mechanisms of diethylamine by medically-certified activated carbons: Investigation of critical parameters controlling sorption properties. J. Taiwan Inst. Chem. Eng. 2014, 45, 1937–1946. [Google Scholar] [CrossRef]

- Bettaieb, F.; Khiari, R.; Dufresne, A.; Mhenni, M.F.; Belgacem, M.N. Mechanical and thermal properties of posidonia oceanica cellulose nanocrystal reinforced polymer. Carbohydr. Polym. 2015, 123, 99–104. [Google Scholar] [CrossRef] [PubMed]

- Bettaieb, F.; Khiari, R.; Dufresne, A.; Mhenni, M.F.; Putaux, J.L.; Boufi, S. Nanofibrillar cellulose from posidonia oceanica: Properties and morphological features. Ind. Crops Prod. 2015, 72, 97–106. [Google Scholar] [CrossRef]

- Bettaieb, F.; Nechyporchuk, O.; Khiari, R.; Mhenni, M.F.; Dufresne, A.; Belgacem, M.N. Effect of the oxidation treatment on the production of cellulose nanofiber suspensions from posidonia oceanica: The rheological aspect. Carbohydr. Polym. 2015, 134, 664–672. [Google Scholar] [CrossRef] [PubMed]

- Khiari, R.; Marrakchi, Z.; Belgacem, M.N.; Mauret, E.; Mhenni, F. New lignocellulosic fibres-reinforced composite materials: A stepforward in the valorisation of the posidonia oceanica balls. Compos. Sci. Technol. 2011, 71, 1867–1872. [Google Scholar] [CrossRef]

- Fortunati, E.; Luzi, F.; Puglia, D.; Petrucci, R.; Kenny, J.M.; Torre, L. Processing of pla nanocomposites with cellulose nanocrystals extracted from posidonia oceanica waste: Innovative reuse of coastal plant. Ind. Crops Prod. 2015, 67, 439–447. [Google Scholar] [CrossRef]

- Luzi, F.; Fortunati, E.; Puglia, D.; Petrucci, R.; Kenny, J.M.; Torre, L. Modulation of acid hydrolysis reaction time for the extraction of cellulose nanocrystals from posidonia oceanica leaves. J. Renew. Mater. 2016, 4, 190–198. [Google Scholar] [CrossRef]

- Coletti, A.; Valerio, A.; Vismara, E. Posidonia oceanica as a renewable lignocellulosic biomass for the synthesis of cellulose acetate and glycidyl methacrylate grafted cellulose. Materials 2013, 6, 2043–2058. [Google Scholar] [CrossRef] [PubMed]

- Cocozza, C.; Parente, A.; Zaccone, C.; Mininni, C.; Santamaria, P.; Miano, T. Comparative management of offshore posidonia residues: Composting vs. Energy recovery. Waste Manag. 2011, 31, 78–84. [Google Scholar] [CrossRef] [PubMed]

- Puglia, D.; Petrucci, R.; Fortunati, E.; Luzi, F.; Kenny, J.M.; Torre, L. Revalorisation of posidonia oceanica as reinforcement in polyethylene/maleic anhydride grafted polyethylene composites. J. Renew. Mater. 2014, 2, 66–76. [Google Scholar] [CrossRef]

- Ferrero, B.; Fombuena, V.; Fenollar, O.; Boronat, T.; Balart, R. Development of natural fiber-reinforced plastics (NFRP) based on biobased polyethylene and waste fibers from posidonia oceanica seaweed. Polym. Compos. 2015, 36, 1378–1385. [Google Scholar] [CrossRef]

- Seggiani, M.; Cinelli, P.; Mallegni, N.; Balestri, E.; Puccini, M.; VItolo, S.; Lardicci, C.; Lazzeri, A. New bio-composites based on polyhydroxyalkanoates and posidonia oceanica fibres for applications in a marine environment. Materials 2017, 10, 326. [Google Scholar] [CrossRef] [PubMed]

- Macia, A.; Baeza, F.J.; Saval, J.M.; Ivorra, S. Mechanical properties of boards made in biocomposites reinforced with wood and posidonia oceanica fibers. Compos. Part B Eng. 2016, 104, 1–8. [Google Scholar] [CrossRef]

- Ferrero, B.; Boronat, T.; Moriana, R.; Fenollar, O.; Balart, R. Green composites based on wheat gluten matrix and posidonia oceanica waste fibers as reinforcements. Polym. Compos. 2013, 34, 1663–1669. [Google Scholar] [CrossRef]

- Obi Redy, K.; Raja Narender Reddy, K.; Zhang, J.; Zhang, J.; Varada Rajulu, A. Effect of alkali treatment on the properties of century fibers. J. Nat. Fibers 2013, 10, 282–296. [Google Scholar] [CrossRef]

- Jayaramudu, J.; Guduri, B.R.; Rajulu, A.V. Characterization of natural fabric sterculia urens. Int. J. Polym. Anal. Charact. 2009, 14, 115–125. [Google Scholar] [CrossRef]

- Goud, G.; Rao, R.N. Effect of fibre content and alkali treatment on mechanical properties of roystonea regia-reinforced epoxy partially biodegradable composites. Bull. Mater. Sci. 2011, 34, 1575–1581. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Khan, M.A.; Hinrichsen, G. Surface modification of jute and its influence on performance of biodegradable jute-fabric/biopol composites. Compos. Sci. Technol. 2000, 60, 1115–1124. [Google Scholar] [CrossRef]

- Siregar, J.P.; Sapuan, S.M.; Rahman, M.Z.A.; Zaman, H. The effect of alkali treatment on the mechanical properties of short pineapple leaf fibre (PALF) reinforced high impact polystyrene (HIPS) composites. J. Food Agric. Environ. 2010, 8, 1103–1108. [Google Scholar]

- Zhu, J.; Zhu, H.; Njuguna, J.; Abhyankar, H. Recent development of flax fibres and their reinforced composites based on different polymeric matrices. Materials 2013, 6, 5171–5198. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nishitani, Y.; Kajiyama, T.; Yamanaka, T. Effect of silane coupling agent on tribological properties of hemp fiber-reinforced plant-derived polyamide 1010 biomass composites. Materials 2017, 10, 1040. [Google Scholar] [CrossRef] [PubMed]

- Oushabi, A.; Sair, S.; Hassani, F.O.; Abboud, Y.; Tanane, O.; El Bouari, A. The effect of alkali treatment on mechanical, morphological and thermal properties of date palm fibers (DPFs): Study of the interface of DPF-polyurethane composite. S. Afr. J. Chem. Eng. 2017, 23, 116–123. [Google Scholar] [CrossRef]

- Roudsari, G.M.; Mohanty, A.K.; Misra, M. Exploring the effect of poly(propylene carbonate) polyol in a biobased epoxy interpenetrating network. ACS Omega 2017, 2, 611–617. [Google Scholar] [CrossRef]

- Bertomeu, D.; Garcia-Sanoguera, D.; Fenollar, O.; Boronat, T.; Balart, R. Use of eco-friendly epoxy resins from renewable resources as potential substitutes of petrochemical epoxy resins for ambient cured composites with flax reinforcements. Polym. Compos. 2012, 33, 683–692. [Google Scholar] [CrossRef]

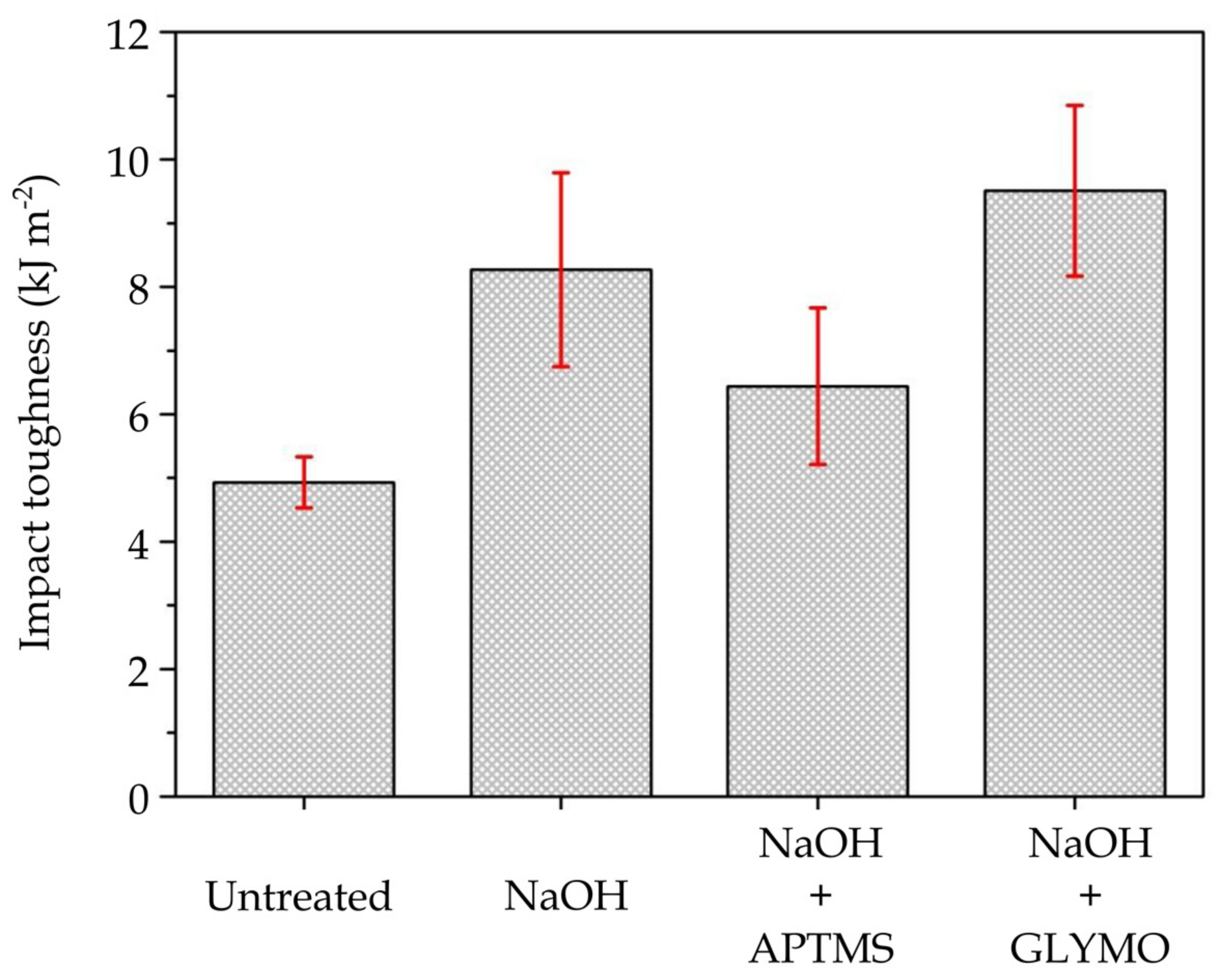

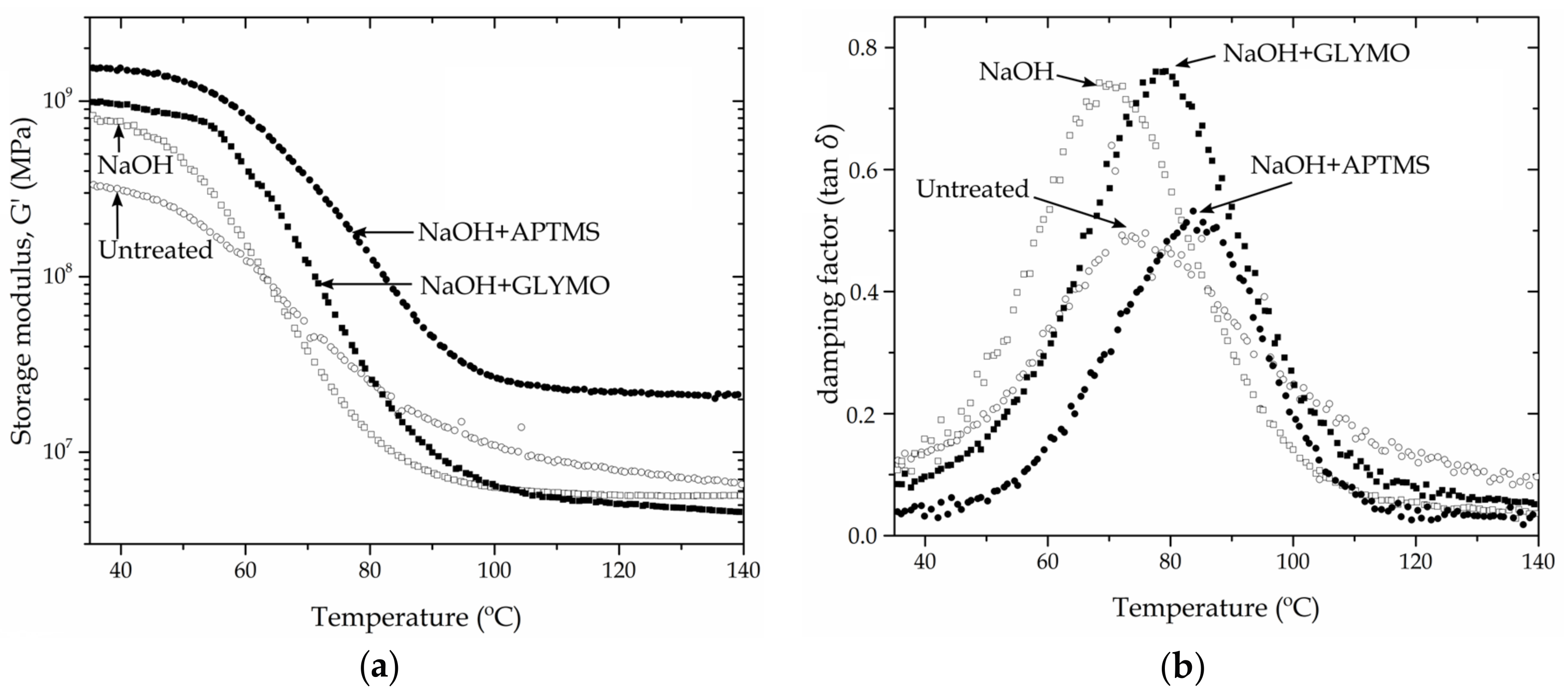

| Surface Treatment | G′ (MPa) at 35 °C | G′ (MPa) at 100 °C | Tg (°C) |

|---|---|---|---|

| Untreated | 344.7 | 11.0 | 73.7 |

| NaOH | 808.6 | 6.6 | 70.0 |

| NaOH + APTMS | 1551.0 | 26.4 | 83.7 |

| NaOH + GLYMO | 1014.0 | 6.3 | 79.2 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Garcia-Garcia, D.; Quiles-Carrillo, L.; Montanes, N.; Fombuena, V.; Balart, R. Manufacturing and Characterization of Composite Fibreboards with Posidonia oceanica Wastes with an Environmentally-Friendly Binder from Epoxy Resin. Materials 2018, 11, 35. https://doi.org/10.3390/ma11010035

Garcia-Garcia D, Quiles-Carrillo L, Montanes N, Fombuena V, Balart R. Manufacturing and Characterization of Composite Fibreboards with Posidonia oceanica Wastes with an Environmentally-Friendly Binder from Epoxy Resin. Materials. 2018; 11(1):35. https://doi.org/10.3390/ma11010035

Chicago/Turabian StyleGarcia-Garcia, Daniel, Luis Quiles-Carrillo, Nestor Montanes, Vicent Fombuena, and Rafael Balart. 2018. "Manufacturing and Characterization of Composite Fibreboards with Posidonia oceanica Wastes with an Environmentally-Friendly Binder from Epoxy Resin" Materials 11, no. 1: 35. https://doi.org/10.3390/ma11010035