3.1. Effects of Welding Process on Microstructures

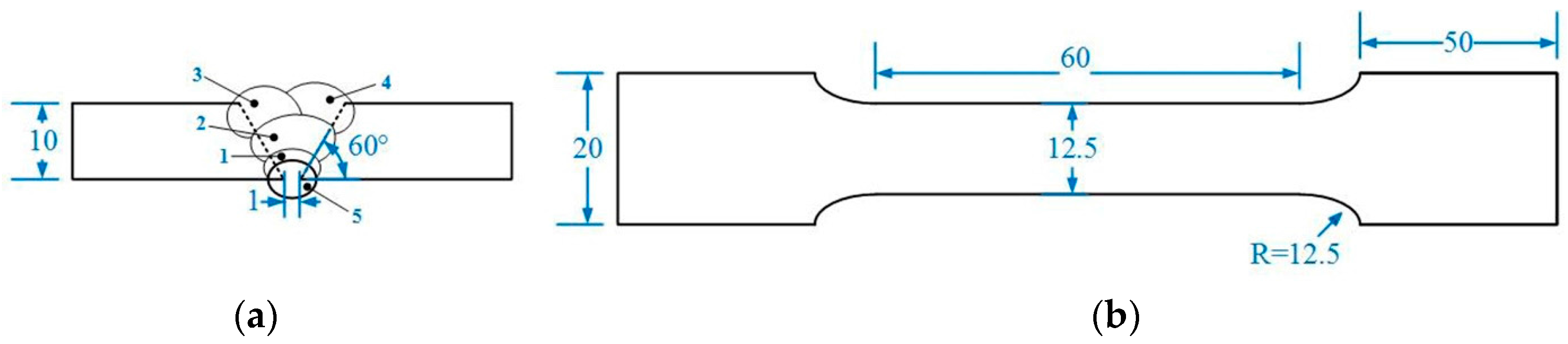

The macrograph of a ULCW joint of Q690E steel (

Figure 3) reveals three distinct regions namely, the fusion zone (FZ), HAZ, and BM. During the welding process, the peak temperature varies with position in the HAZ and, hence, the sub-zones of the HAZ are characterized by different microstructures. Based on the microstructure, the HAZ can be further divided into four different sub-zones, i.e., the: coarse-grained HAZ (CGHAZ), fine-grained HAZ (FGHAZ), intercritical HAZ (ICHAZ), and sub-critical HAZ (SCHAZ) adjacent to the BM, as shown in

Figure 4.

The microstructural evolution within each sub-zone of the welded joints is controlled mainly by the peak temperature and the cooling rate. The microstructures comprising each of the sub-zones (SCHAZ, ICHAZ, FGHAZ, CGHAZ, and FZ) of the UDW joint and the ULCW joint are examined by optical microscopy (OM) and SEM; the corresponding micrographs are shown in

Figure 4 and

Figure 5, respectively. Above the Ac

3 temperature, the CGHAZ and FGHAZ experience high peak temperatures, resulting in re-austenization of the original grains. The CGHAZ experiences the highest peak temperature and remains above the Ac

3 temperature for the longest period, leading to an increase in the grain size. Therefore, the CGHAZ has the largest grain size in both the UDW and ULCW joints (see

Figure 4). This grain size decreases, however, with increasing distance from the fusion line.

The FZ is melted during the heating process, and subsequently solidifies during the cooling process. As shown in

Figure 5a or

Figure 5e, the microstructures of FZ within the UDW joint and ULCW joint consist mainly of three types of ferrite: acicular ferrite (AF), proeutectoid ferrite (PF), and ferrite side plate (FSP). Compared with those of the UDW joint, the No. 4 (see

Figure 5e for microstructure) and 5 passes of FZ within the ULCW joint yield more PF and FSP. This results from the fact that the cooling rate, due to the water quenching effect, of the ULCW joint is higher than that of the UDW joint [

1]. Moreover, the No. 5 pass of FZ is performed without a subsequent welding cycle and duration of the No. 4 pass of FZ are shorter, because of water quench following the No. 4 and 5 pass and without the experience of subsequent reheating from neighboring pass. The ferrite distribution associated with other passes of FZ within the ULCW joint is similar to the ferrite distribution of the UDW joint. We identify the different phases by SEM examination of the microstructures composing the CGHAZ in both joints (see

Figure 5b or

Figure 5f). After ULCW, the coarse-grained austenite transforms completely to martensite (M) and a small amount of B, owing to water quenching (

Figure 5f). Some of this M then transforms to TM due to tempering after the welding process. After UDW, the austenite transforms to M and some B. This M can self-temper during the subsequent cooling process, owing to the relatively low cooling rate and tempering after the welding process. Therefore, CGHAZ of the UDW joint contains more TM than CGHAZ of the ULCW joint, but both zones consist of a mixture of equiaxed M, B, and auto-TM. The peak temperature of FGHAZ is slightly higher than the Ac

3 temperature. Although the material in this region also undergoes complete re-austenization, short periods of time at these temperatures limit the austenite grain growth of the FGHAZ. This limited growth raises a fine austenite grain size within the FGHAZ. Moreover, the microstructures in the FGHAZ are similar to those of the CGHAZ in the UDW joint and the ULCW joint.

At the same time, the ICHAZ is exposed to temperatures lying between the Ac

1 and Ac

3 temperatures, and the grains in this region are partially transformed into austenite. During the rapid cooling process of the ULCW joint, the austenite transforms to M and B, and the BM microstructure is retained in the other regions (

Figure 5g). The cooling rate of the ULCW joint is higher than that of the UDW joint and, hence, more M form in the ICHAZ of the ULCW joint. In the ICHAZ of the UDW joint, the un-transformed base material is over-tempered by the welding thermal cycle. Some of the austenite is partially transformed to M and B, and the BM microstructure is retained in other regions (

Figure 5c).

Figure 5d,h show the microstructures composing the SCHAZ of the UDW joint and the ULCW joint, respectively. The peak temperatures of the SCHAZ are lower than the Ac

1 temperature and, therefore this region undergoes re-tempering [

14]. Similar to that of the BM, the microstructure of SCHAZ consists of a mixture of TM and B.

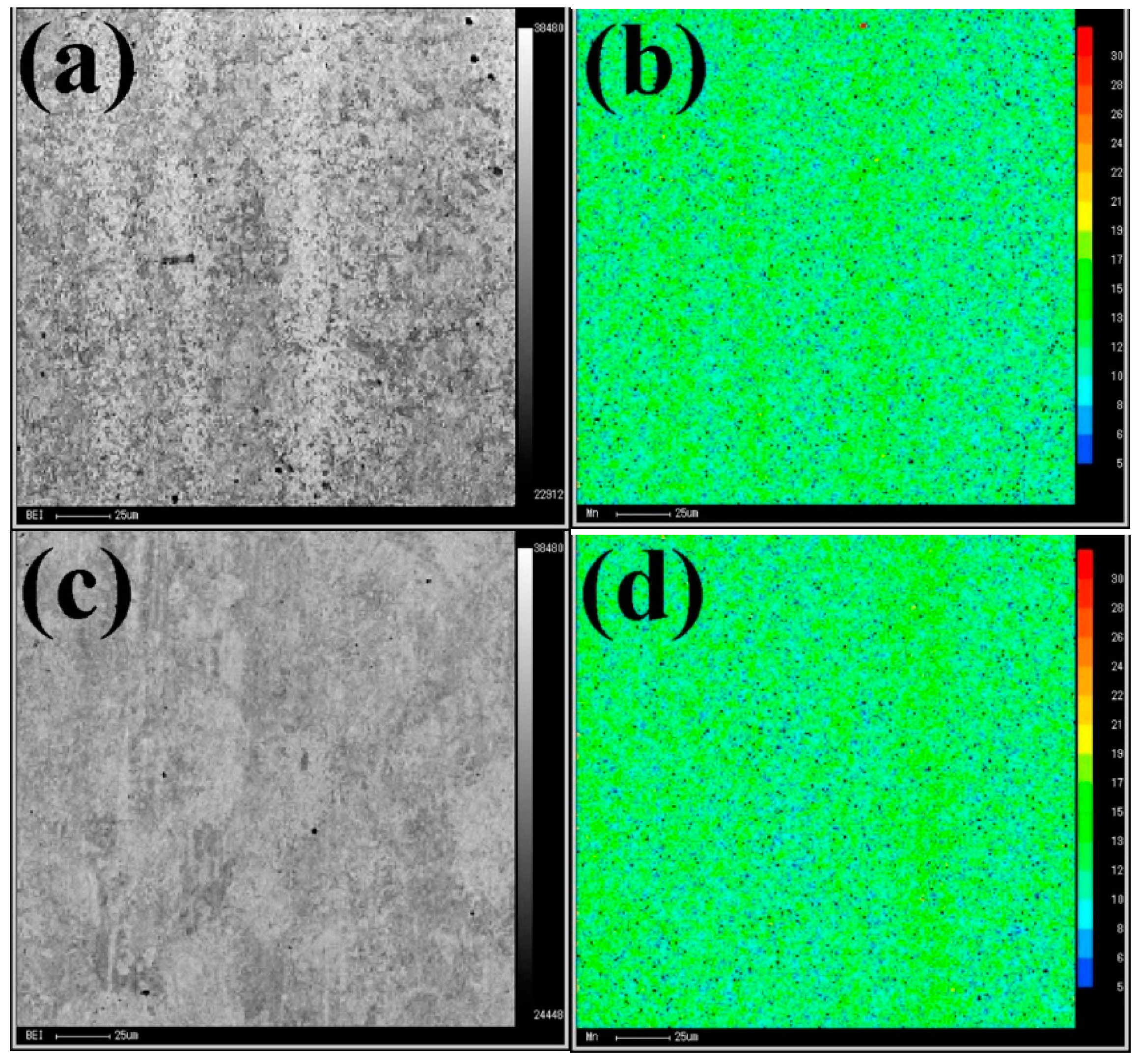

As shown in

Figure 4a, two types of banded structures form in the FGHAZ, ICHAZ, SCHAZ and BM of the ULCW joint. Banded structure1 was circled by red ellipse and banded structure2 was circled by white ellipse. Etching the ULCW joint with Lepera etchant revealed that M banded structures are the main banded structures formed in the CGHAZ and ICHAZ. We examine banded structure1 (

Figure 5i) and banded structure2 (

Figure 5j) by SEM. The SEM micrographs revealed that banded structure1 is a mixed structure composed mainly of M, TM, and B, and banded structure2 consists of TM. Chemical inhomogeneity and hot rolling yield a banded structure in HSLA, which (owing to strain anisotropy) is detrimental to the mechanical properties of steel [

15]. During the ULCW process, the ULCW joint is subjected to multiple rapid heating and cooling (water quenching) steps, which reduced the chemical homogeneity of the material. During the UDW process, preheating, maintaining the inter-pass temperature at 100 °C, and air cooling lead to a decrease in the cooling rate during UDW. This yield increased time for diffusion of the alloying elements thereby mitigating chemical inhomogeneity. Further, the less banded structure in the UDW joint could be due to inevitable variations of chemical inhomogeneity between different pieces of the base plate, which is a common feature of lab-made materials.

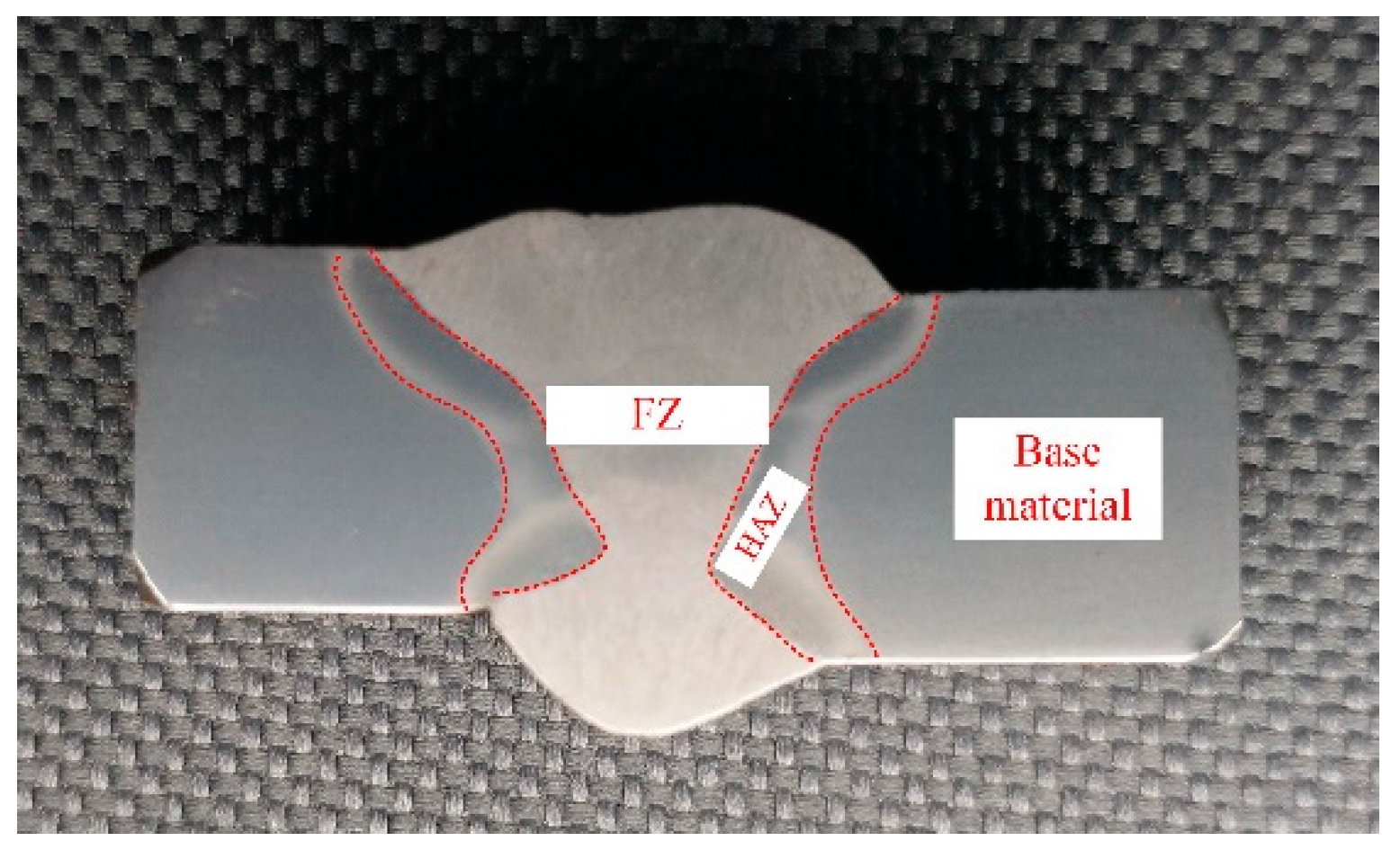

The elemental distribution of Mn in the banded structures (see

Figure 6) was determined with an Electron Probe Microanalyzer (EPMA). In

Figure 6b or

Figure 6d, blue and green represent low content and medium content, respectively, while yellow and red correspond to high content. Mn is inhomogeneously distributed in both banded structures. As

Figure 6b shows, Mn-segregated bands parallel to the rolling direction occur in the FGHAZ and ICHAZ of the ULCW joint. The Mn-poor bands (level value: 5–12; unit: X-ray counts) and Mn-rich bands (level value: 12–21) are composed of B and M, respectively. The Mn-poor bands (level value: 5–12) are mainly composed of TM, and Mn-rich bands (level value: 12–21) within the SCHAZ of the joint are mainly composed of B (

Figure 6d). The occurrence of banded structures is attributed to the inhomogeneous distribution of Mn in welded joints.

The distribution and fraction of martensite–austenite islands (M–A) within ICHAZ (see

Figure 7a–c) is revealed through etching with Lepera etchant. The distribution of M and M-A components within the HAZ of the ULCW joint and the UDW joint are schematically illustrated in

Figure 7d. Compared with the UDW joint, the CGHAZ of the ULCW joint has less TMs and Bs, but more Ms, owing to water quenching. Different trends are observed for the FGHAZ of the ULCW joint. Compared with that occurring in the ICHAZ of the UDW joint, (i) more M-banded structures form in the starting region of the ICHAZ of the ULCW joint, and (ii) the formation of M-A components is more likely along grain boundaries within the ICHAZ of the ULCW joint. These components also form along the grain boundaries at another edge of the ICHAZ of the ULCW joint. In contrast, a uniform distribution of M-A components is formed at the starting region of the ICHAZ of the UDW joint. The amount of M-A components decreases with increasing distance to the FGHAZ within both joints. These components are almost absent from another edge of the ICHAZ of the UDW joint.

3.2. Micro-Hardness

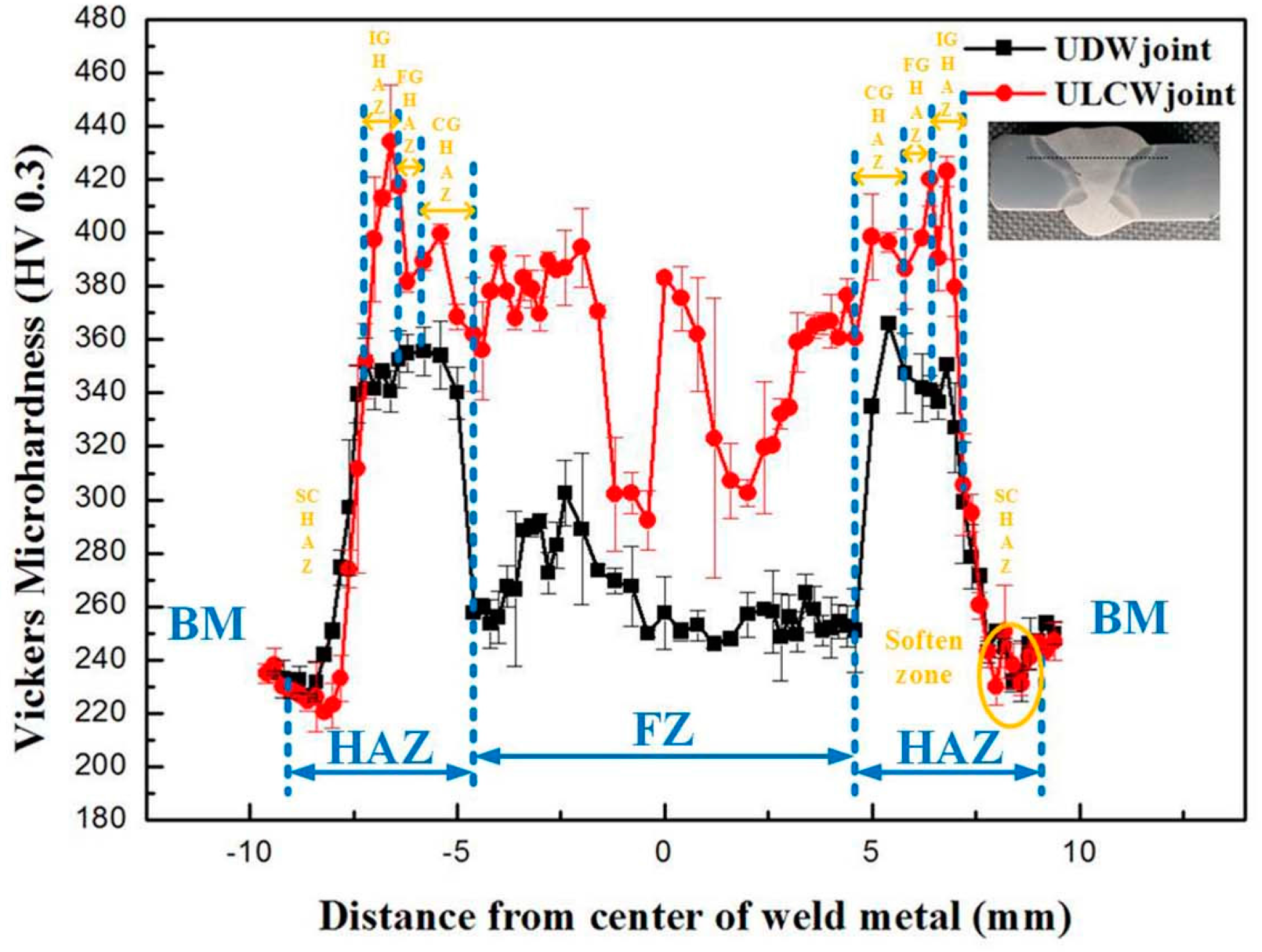

The variation in micro-hardness across the weld zone is shown in

Figure 8. The FZ, HAZ, and BM can be clearly distinguished based on this variation. The micro-hardness of the material is influenced mainly by the microstructure and grain size. Generally, the different phases in steel can be arranged in descending order of micro-hardness magnitude, as follows: martensite > bainite > pearlite > ferrite [

16].

The FZ, HAZ, and BM zones of both specimens may be arranged in descending order of micro-hardness magnitude, as follows: HAZ > FZ > BM (average micro-hardness of BM: ~256 HV

0.3). The hardness of the HAZ may be attributed to the fact that both welds are subjected to a non-uniform welding thermal cycle, which rises an inhomogeneous microstructure (see

Figure 4 and

Figure 5). These hardness values improve with the formation of M and B within HAZ. As shown in

Figure 5a or

Figure 5e, the microstructure of each FZ consists of a mixture of PF, FSP, and fine-grained AF. In addition, the Mn concentration (1.6%, see

Table 2) and, hence, the micro-hardness of the FZs are higher than those of the BM [

17].

The micro-hardness values of the FZ (average: ~370 HV

0.3) and HAZ in the ULCW joint are higher than those of the corresponding regions of the UDW joint (FZ average micro-hardness: ~270 HV

0.3, see

Figure 8). However, similar micro-hardness values are obtained for the BM regions of the joints. Water quenching following the welding process of the ULCW joint results in an increase in the dislocation density of the microstructure. This dislocation density, which is higher than those of the FZ of the UDW joint, yield improved micro-hardness of the FZ. As

Figure 5 and

Figure 6 show, the microstructure of each sub-zone (CGHAZ, FGHAZ, and IGHAZ) of the ULCW joint contains significant amounts of M and B. The rapid cooling rate of the ULCW joint may result in an increase in the dislocation density of the microstructure composing these zones and, in turn, improved micro-hardness of the HAZs in this joint.

As

Figure 8 shows, the peak micro-hardness (~430 HV

0.3) of the HAZ-ULCW joint occurs for the ICHAZ, which consists primarily of M, M-A, B, and TM (see

Figure 5g). Several carbides and a significant amount of Ms and M-As (

Figure 5i) with high hardness precipitated in this zone, due to the relatively high cooling rate and the tempering effect associated with the subsequent welding passes. In contrast, the peak micro-hardness of the HAZ-UDW joint (~360 HV

0.3) occurs in the CGHAZ that consists mainly of M with a mixture of B and TM (

Figure 5b), which increases the micro-hardness. The micro-hardness of both joints decreases rapidly from the CGHAZ to the SCHAZ, as shown in

Figure 8. Moreover, the peak temperature of the sub-zones decreases (from Ac

1 to 630 °C) from the CGHAZ to the SCHAZ. Therefore, the homogeneity of the microstructure increases and the M and M-A regions gradually disappear. The micro-hardness of the softened zone within the SCHAZ (~220 HV

0.3) is lower than that of the BM. This is attributed to the fact that the SCHAZ undergoes high-temperature (although lower than the Ac

1 temperature) re-tempering during the welding process. The re-tempering process may have resulted in a reduction in the dislocation density and softening of the microstructure comprising this zone [

18].

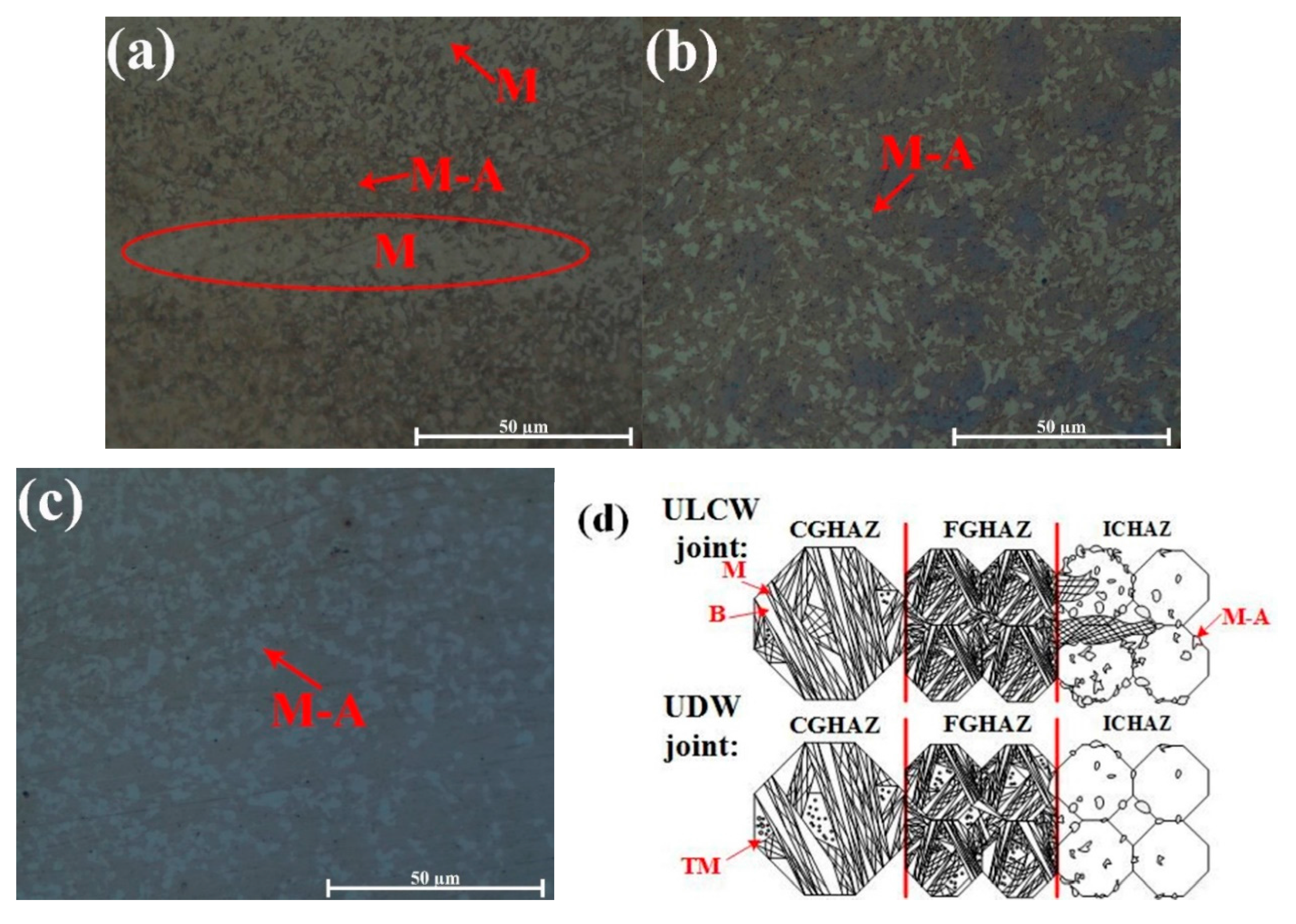

3.3. Uniaxial Tensile Strength

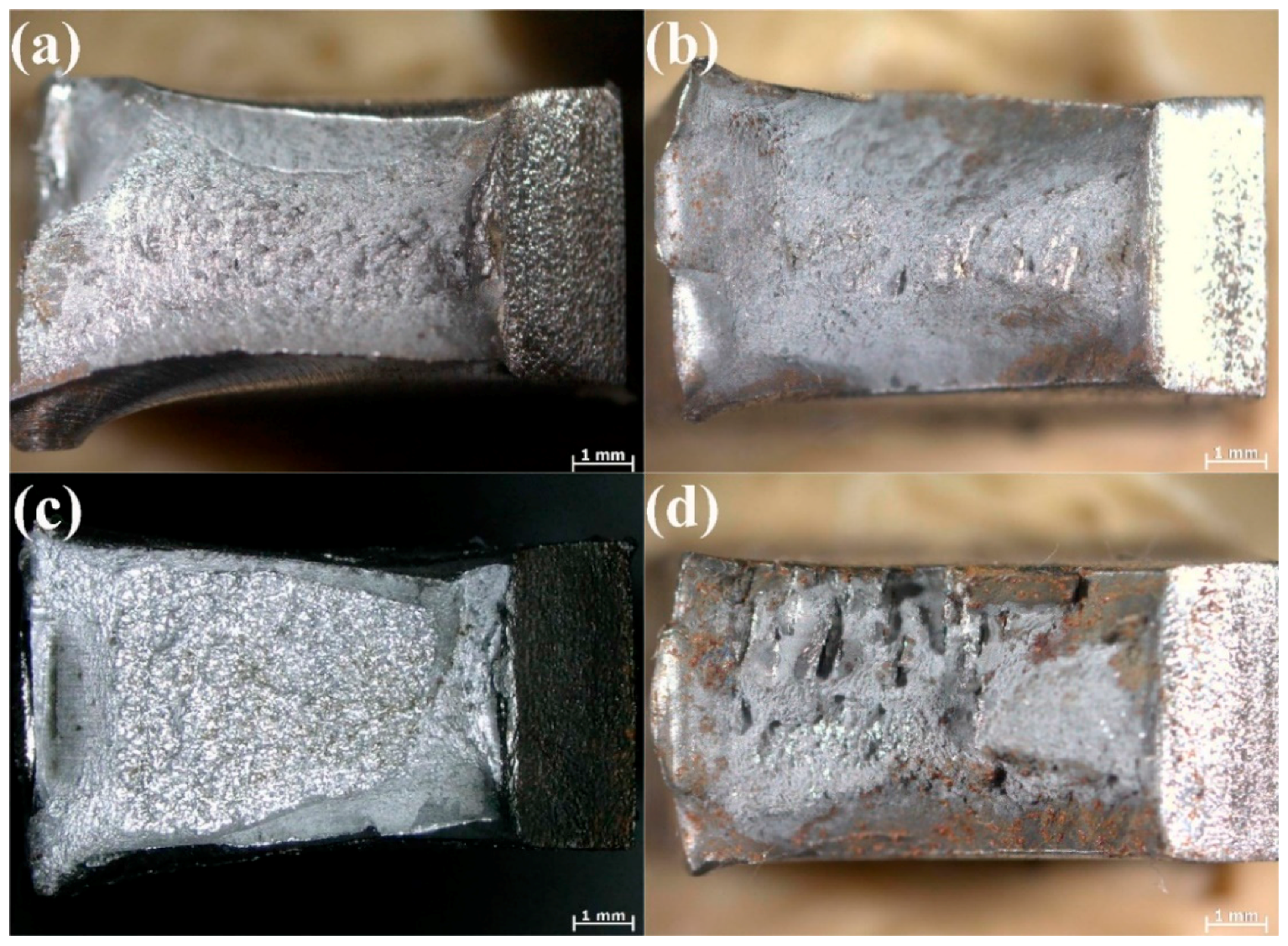

The tensile specimens that underwent tensile testing at room temperature are shown in

Figure 9. The tensile weld specimens all fail in the soft HAZ, but exhibit differing strength properties.

The representative tensile stress-strain plots of the BM, UDW, and ULCW joints of Q690E steel are shown in

Figure 10. The yield strength (YS) and ultimate tensile strength (UTS) of the joints and BM are summarized in

Table 4. The welded specimens (especially the FZ and HAZ) are inhomogeneous and, hence, the values recorded for the YS and the UTS are non-representative of the sub-zones of the samples [

18]. The BM specimen presents the best tensile properties. However, the tensile properties of the ULCW joint sample are inferior to those of the Q690E BM. The YS and UTS of the BM (843 MPa and 896 MPa, respectively) are higher than those (YS: 831 MPa, UTS: 876 MPa) of the UDW joint. However, the YS: 722 MPa and UTS: 799 MPa of the ULCW joint are ~120 MPa lower and 97 MPa lower, respectively, than those of the BM.

The micro-hardness is correlated with the yield strength and tensile strength, and an increase in the hardness results in increasing strength [

19]. A comparison of the micro-hardness distributions (see

Figure 8 and

Figure 9) reveals that the tensile specimens all fail in the soft HAZ. Failure of all the tensile specimens in the soft HAZs indicates that these are the weakest region of the joints. This is attributed to the fact that the (i) high micro-hardness of regions in the FZ and HAZ (except for the SCHAZ) may result in improved yield strength and tensile strength, whereas the (ii) low micro-hardness of the softened zone may lead to a decrease in the welded-joint strength [

20]. The harder FZ and the harder regions of the HAZ (compared with the softened zone) can act as a strong constraint on plastic deformation. Therefore, most of the tensile plastic deformation accumulates in the soft HAZ zones. However, under a uniaxial tensile stress, the BM specimen undergoes uniform deformation and, owing to the uniform microstructure, necking and fracture occur when an external load is applied [

16]. The coarse necklacing M-A components occurring preferentially along the grain boundaries in the ICHAZ of the ULCW joint (

Figure 7), have a negative effect on the strength. Therefore, the ULCW joint sample exhibits lower yield strength and tensile strength than the UDW joint.

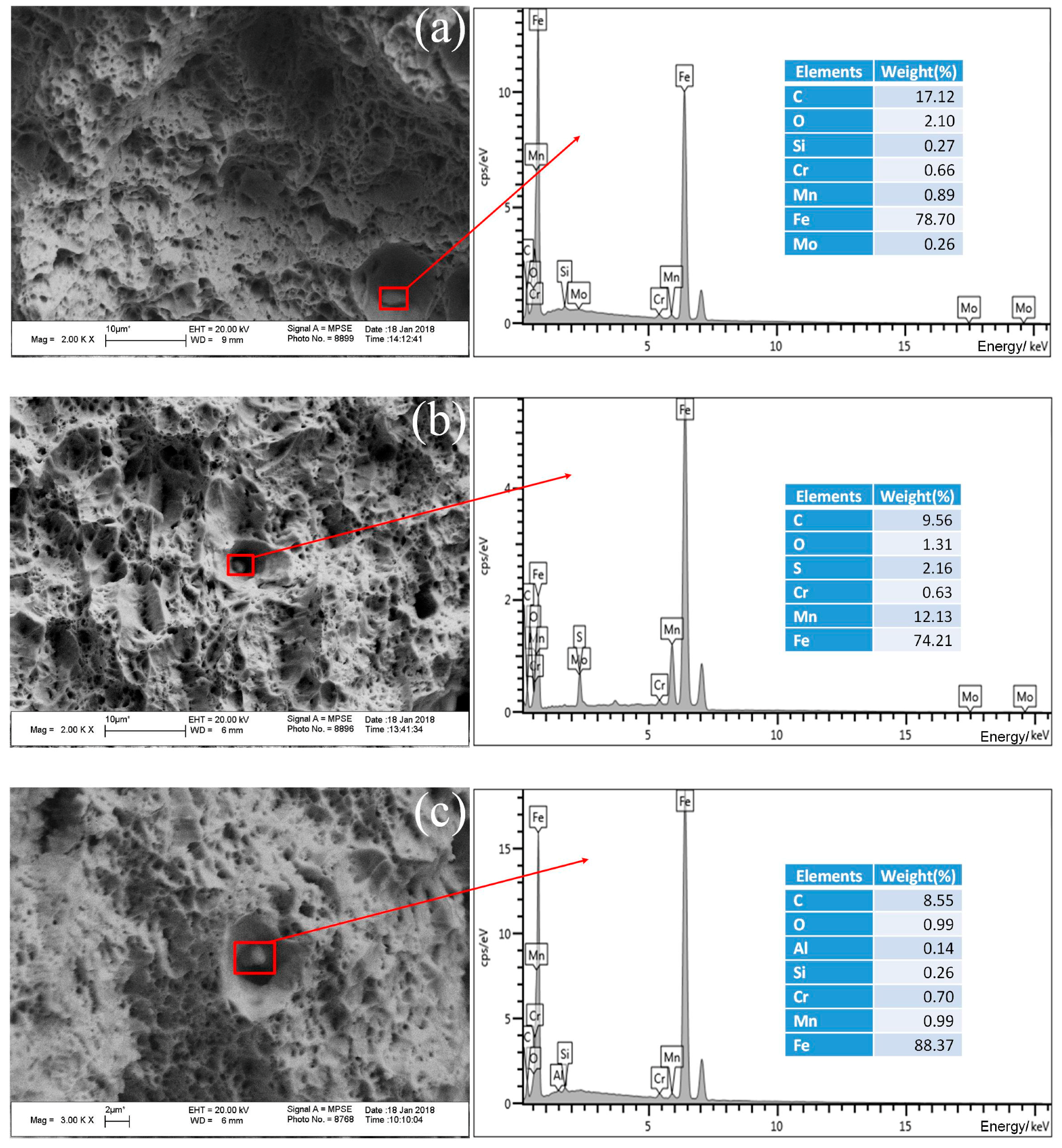

The fracture mechanism of tensile test samples of the BM, UDW joint, and ULCW joint was identified by examining optical and scanning electron micrographs (

Figure 11) of the surfaces of the failed specimens. The fracture surfaces are characterized by dimples of various sizes and depthsand a few small cleavage facets. This indicates that fracture of the BM sample is governed primarily by the quasi-cleavage fracture mechanism.

Figure 11b,c show representative fractographs of the central fracture region of the UDW joint and the ULCW joint samples, respectively. The tensile fracture surface of both samples consists of cleavage facets and dimples of various sizes and depths. This indicates that fracture of both types of joints is governed by the quasi-cleavage fracture mechanism, although the ULCW joint has a lower YS and UTS than the UDW joint. In addition, many spherically shaped inclusion particles are present in the large voids of both types of joints.

As determined by energy dispersive spectroscopy (EDS), the inclusion particles within (i) BM contain Fe, Cr, Mn, Mo, O, Si, and C (see

Figure 11a–c); (ii) the UDW joint contain Fe, Cr, Mn, S, O and C; and (iii) the ULCW joint are rich in Fe, Cr, Mn, Al, Si, O and C.

3.4. Charpy Impact Toughness

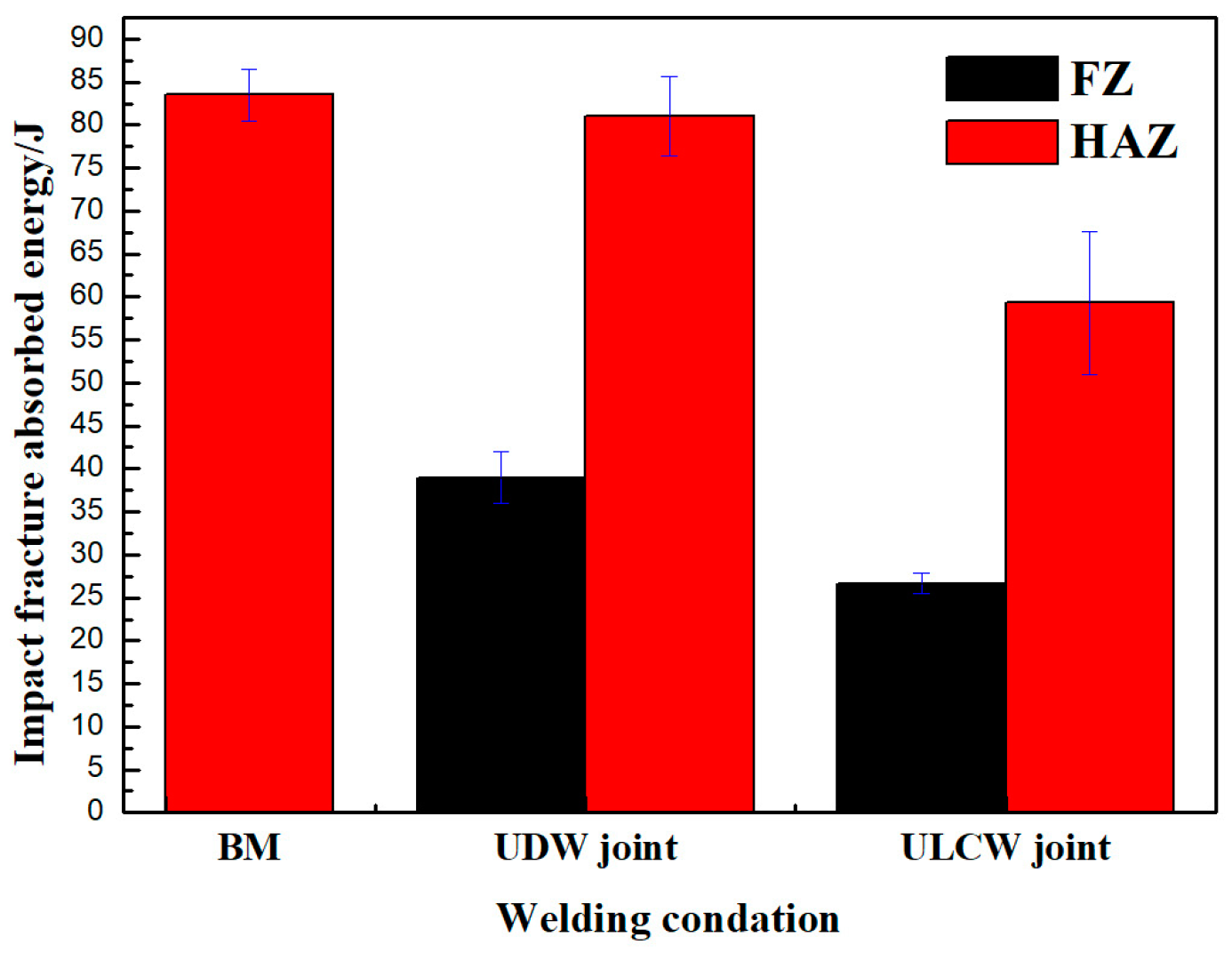

Sub-sized (55.0 × 10.0 × 5.0 mm

3) specimens are subjected to Charpy impact testing at a temperature of −40 °C. The original absorbed impact energy of the BM, UDW joint, and ULCW specimens with notches opened at the weld center line and in the HAZ region is shown in

Figure 12 and

Table 5.

The rapid cooling rate of the ULCW joint process results in increased generation of M in the FZ, CGHAZ, FGHAZ, and IGHAZ and, consequently, a decrease in the toughness of the joint. The results in

Figure 12 and

Table 5 show that: the absorbed energy values of the ULCW specimens with notches opened in the HAZ is lower than BM tested at −40 °C. The absorbed energy of the HAZ (59.3 J) is considerably lower than those of the HAZ of the UDW joint and the BM, suggesting that the HAZ of the ULCW specimen has lower toughness than these materials. Furthermore, the volume fraction of coarse necklacing M-A formed along the grain boundaries in the ICHAZ of the ULCW joint (

Figure 7) increases with increasing cooling rate, thereby leading to the lowest toughness [

21]. Banded structures formed in the HAZ of the ULCW joint (

Figure 4a) have a negative effect on the toughness [

22]. Nevertheless, a low absorbed energy value (26.7 J) is also obtained for the ULCW joint with a notch in the FZ. The relatively high fraction of PF, and FSP (due to water quenching, see

Figure 5e) in the FZ of the ULCW joint results in a decreasing toughness.

The absorbed energy values of the UDW specimens with a notch opened at the FZ and HAZ are higher than those of the ULCW joint with a notch opened at the FZ and HAZ at −40 °C. Compared with the HAZ of the ULCW joint, the HAZ of the UDW joint experiences a lower cooling rate (due to preheat, high inter-pass temperature, and air cooling). Therefore, the HAZ of the UDW joint contains a lower volume fraction of M and M-A constituents than the HAZ of the ULCW joint. Banded structures are absent from the HAZ of the UDW joint (as shown in

Figure 4) and, hence, the toughness of this region is extremely high. In addition, the microstructure comprising the FZ of the UDW joint consists mainly of fine AF (see

Figure 5a), which results in high toughness. This AF-dominated microstructure is more effective in preventing crack propagation [

23].

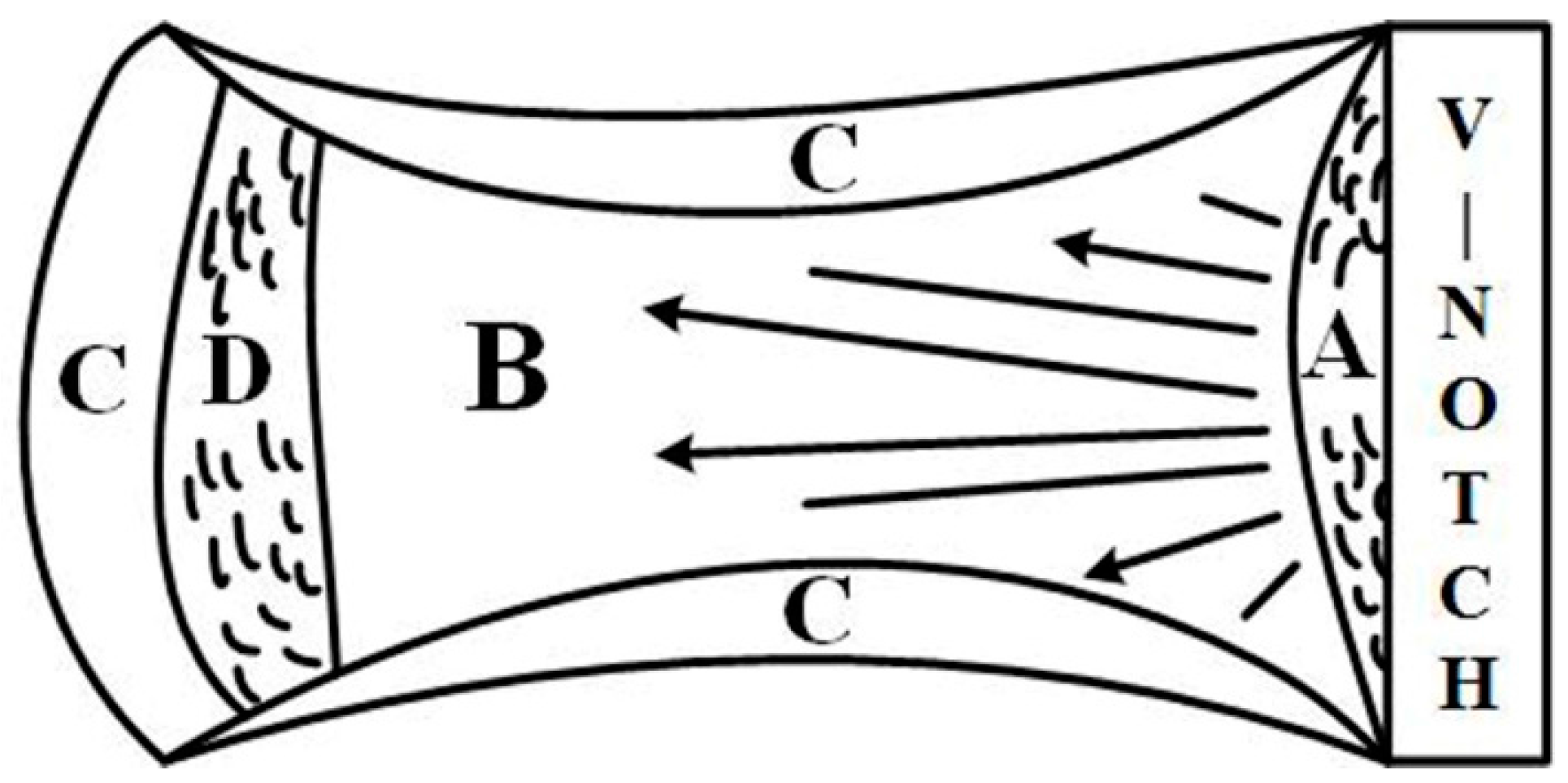

The fracture surface after Charpy impact testing can be divided into four regions, i.e., the fibrous zone (A), radial zone (B), shear lip zone (C), and second fibrous zone (D), as shown in

Figure 13. Generally, the fibrous zone and shear lip zone are expected to absorb higher impact energy than the radial zone [

24]. The macro-fracture surfaces of the UDW and ULCW specimens subjected to impact testing at −40 °C are examined by optical microscopy, as shown in

Figure 14. The fracture surface of the UDW specimen with a notch in the HAZ and the FZ is characterized by a large ductile fracture region and a small brittle fracture region. Compared with the corresponding zones of the ULCW specimen, the fibrous zone and shear lip zone constitute a larger fraction of the UDW specimen with a notch in the HAZ and the FZ, respectively. Therefore, the toughness values of the HAZ and FZ of the UDW joint are higher than those of the HAZ and FZ, respectively, of the ULCW joint. The brittle fracture region constitutes a very large fraction (~75–85%, see

Figure 14c) of the ULCW specimen with a notch in the HAZ fracture surfaces. The fibrous zone and shear lip zone constitute small fractions. Many large cleavage cracks form in an edge (without a shear lip zone) of the ULCW specimen with a notch in the FZ, indicative of the poor toughness of this sample. The radial zone of the ULCW specimen with a notch in the FZ consists of a large brittle fracture region and a small ductile fracture region (

Figure 14d). The fractographic observations submit a powerful substantiation for the Charpy impact testing results.

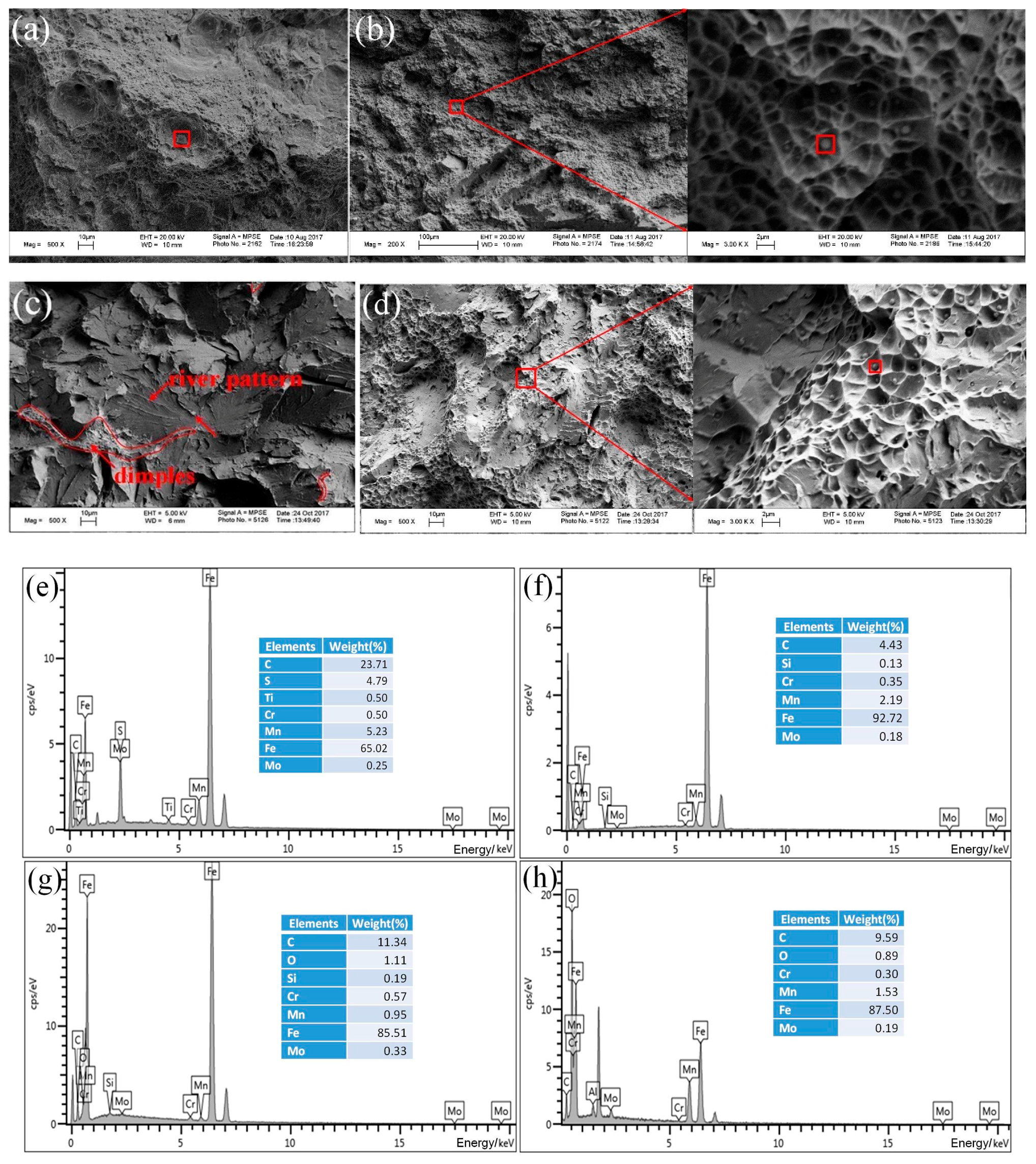

The Charpy impact fracture surfaces of the radial zone tested at −40 °C and the inclusion particles located in the microvoids are examined by SEM and EDS, respectively. High-magnification SEM images (

Figure 15) are obtained of the final fracture zones of the HAZ and FZ of the UDW joint, as well as the FZ of the ULCW joint. As the figure shows, these regions are characterized by cleavage facets, ductile dimples, and microvoids, consistent with the occurrence of quasi-cleavage. The final fracture zone of the HAZ of the ULCW joint consists mainly of cleavage facets and a few dimples (

Figure 15c), consistent with the occurrence of cleavage rupture. This indicates that the specimen fractured at relatively low values of the absorbed energy. The M-A constituents in the HAZ of the ULCW joint regions (see, for example, the smooth blocky particle indicated by the red arrow in

Figure 15c) can act as the initiation sites of cleavage cracking. Compared with those formed in the HAZ of the ULCW joint, (i) a larger number of ductile dimples and microvoids are formed on the fracture surface of the HAZ of the UDW joint (see

Figure 15a) and (ii) small equiaxed dimples and more cleavage facets formed in ULCW specimens with a notch opened at the FZ (see

Figure 15d). The fracture morphology of the FZ regions of the UDW and the ULCW joints, as shown in

Figure 15b or

Figure 15d, reveals a mixed mode of cleavage facets and shear dimples. Compared with that of the FZ of the UDW-joint fracture zone, cleavage constitutes a larger area of the FZ in the ULCW joint-fracture zone. Therefore, the FZ of the UDW specimen has a higher impact toughness than the FZ of the ULCW specimen.

Furthermore, EDS results indicate that the main elements composing the inclusion particles in the (i) HAZ of the UDW joint, (ii) FZ of the UDW joint, (iii) HAZ of the ULCW joint, and (iv) FZ of the ULCW joint are (i) C, S, Ti, Cr, Mn, Mo, Fe (

Figure 15e), (ii) C, Si, Cr, Mn, Mo, Fe (

Figure 15f), (iii) C, O, Si, Cr, Mn, Mo, Fe (

Figure 15g), and (iv) C, O, Cr, Mn, Mo, Fe (

Figure 15h).