The Detection of Burn-Through Weld Defects Using Noncontact Ultrasonics

Abstract

:1. Introduction

2. Materials and Methods

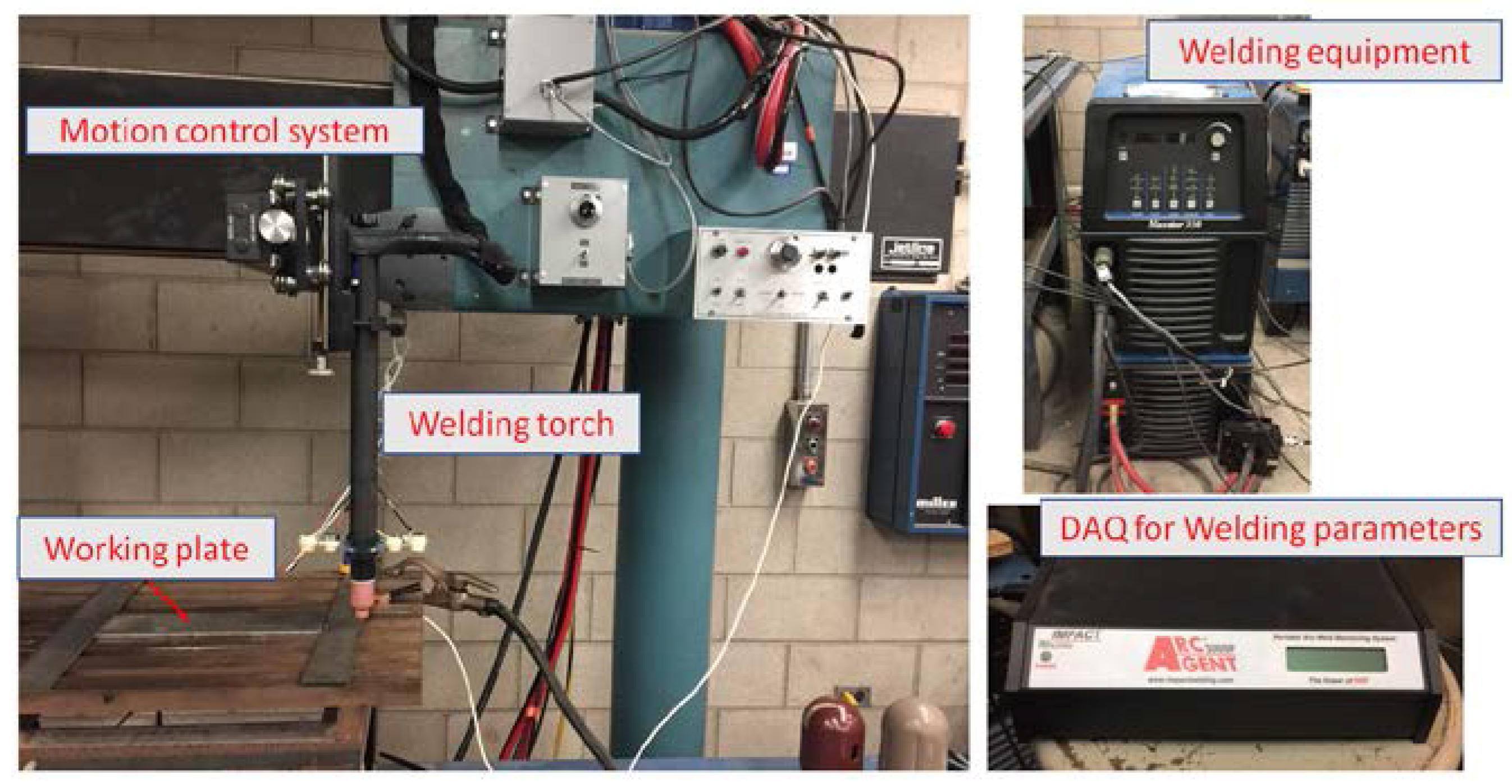

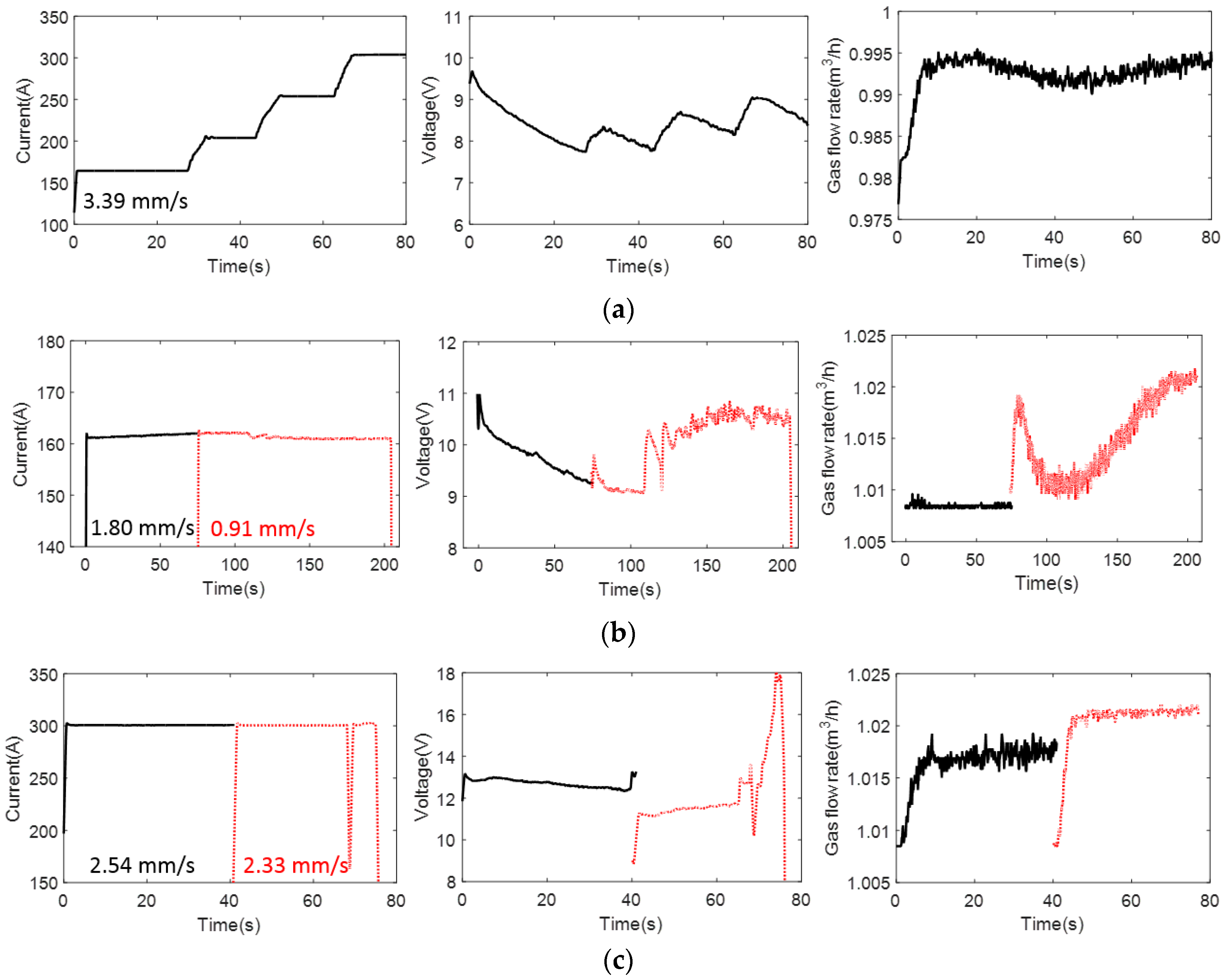

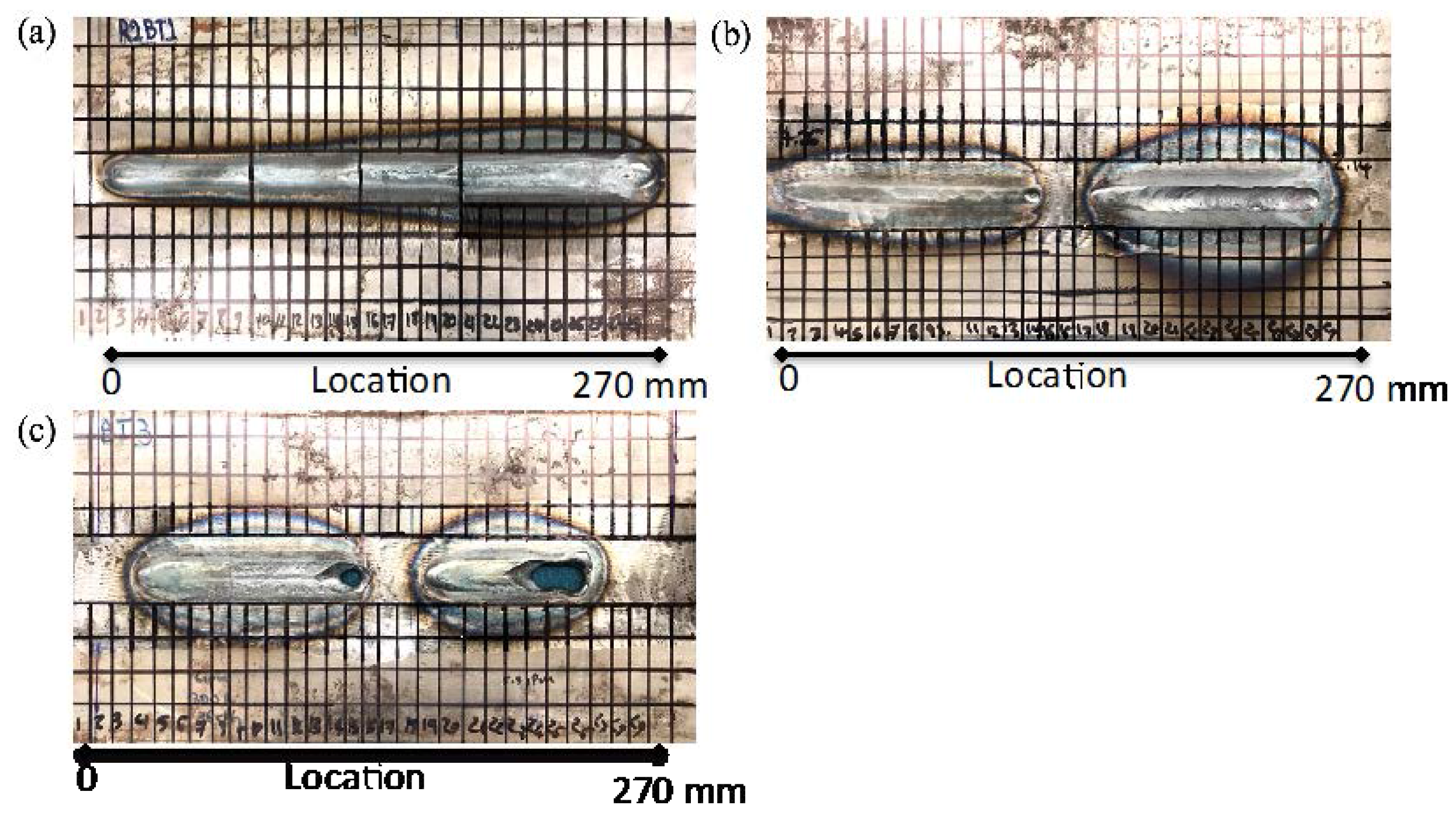

2.1. Sample Preparation and Weld Procedure

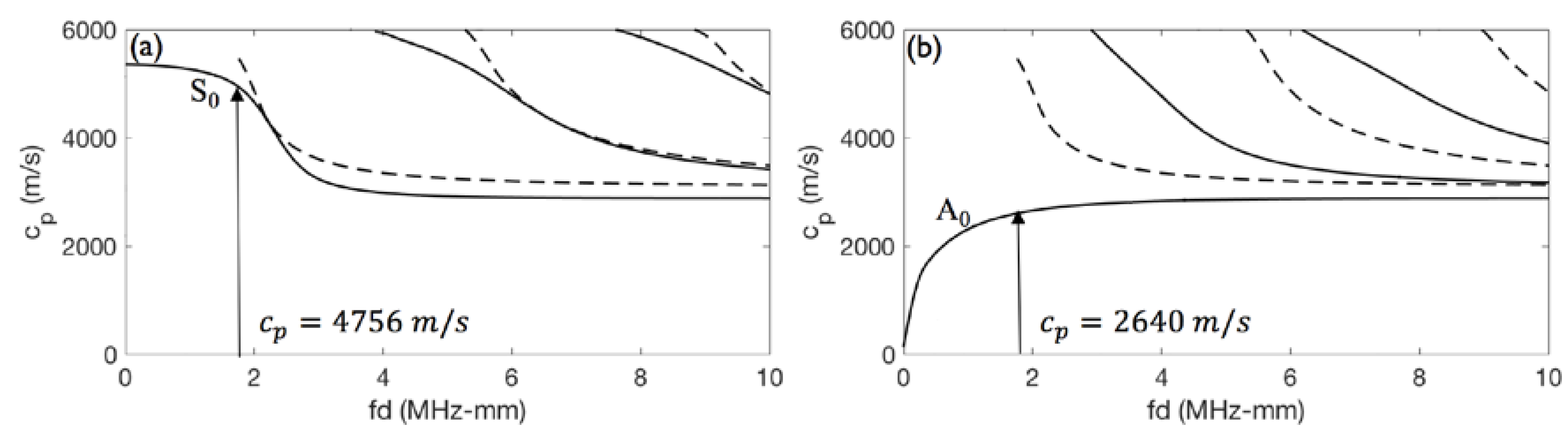

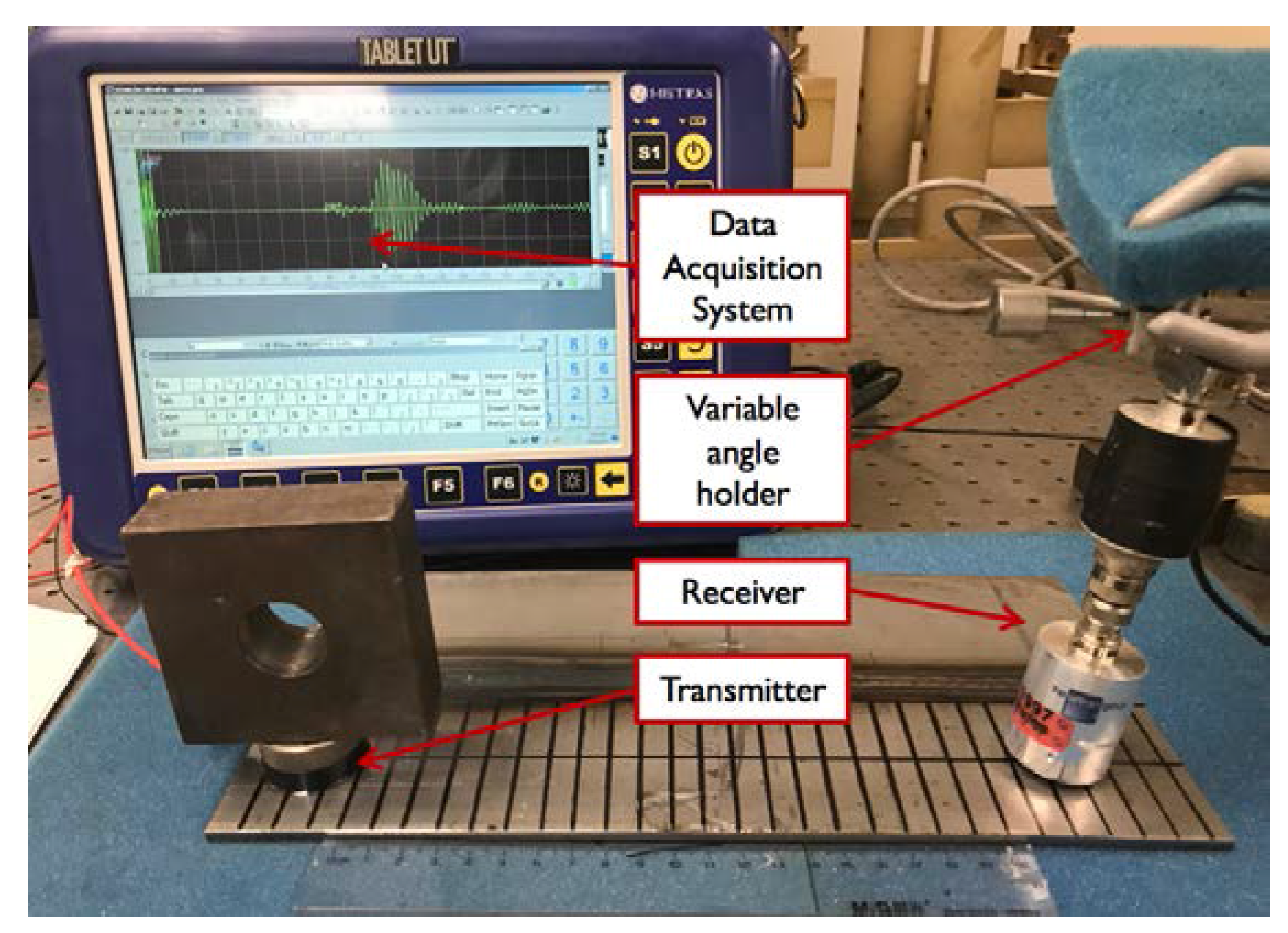

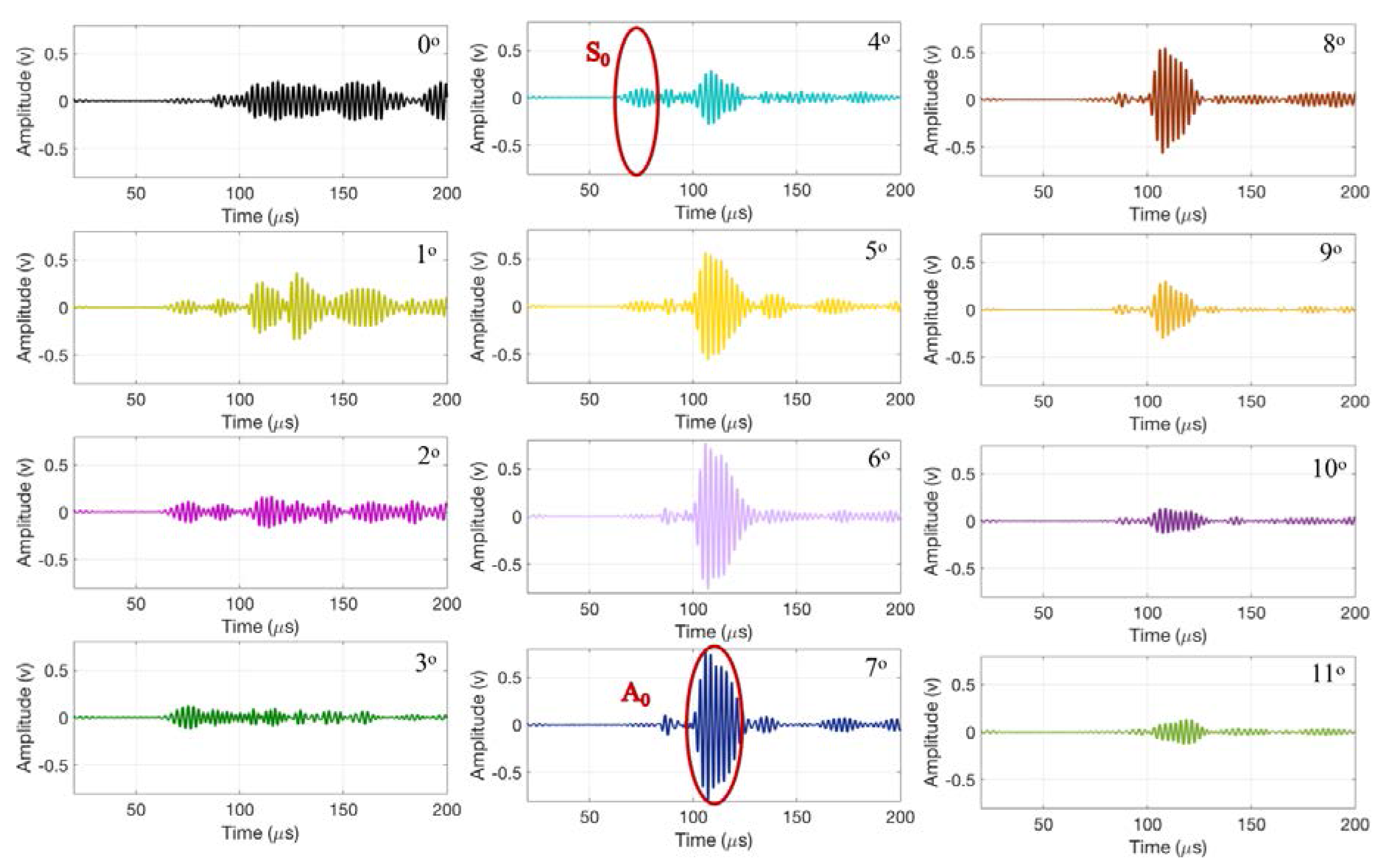

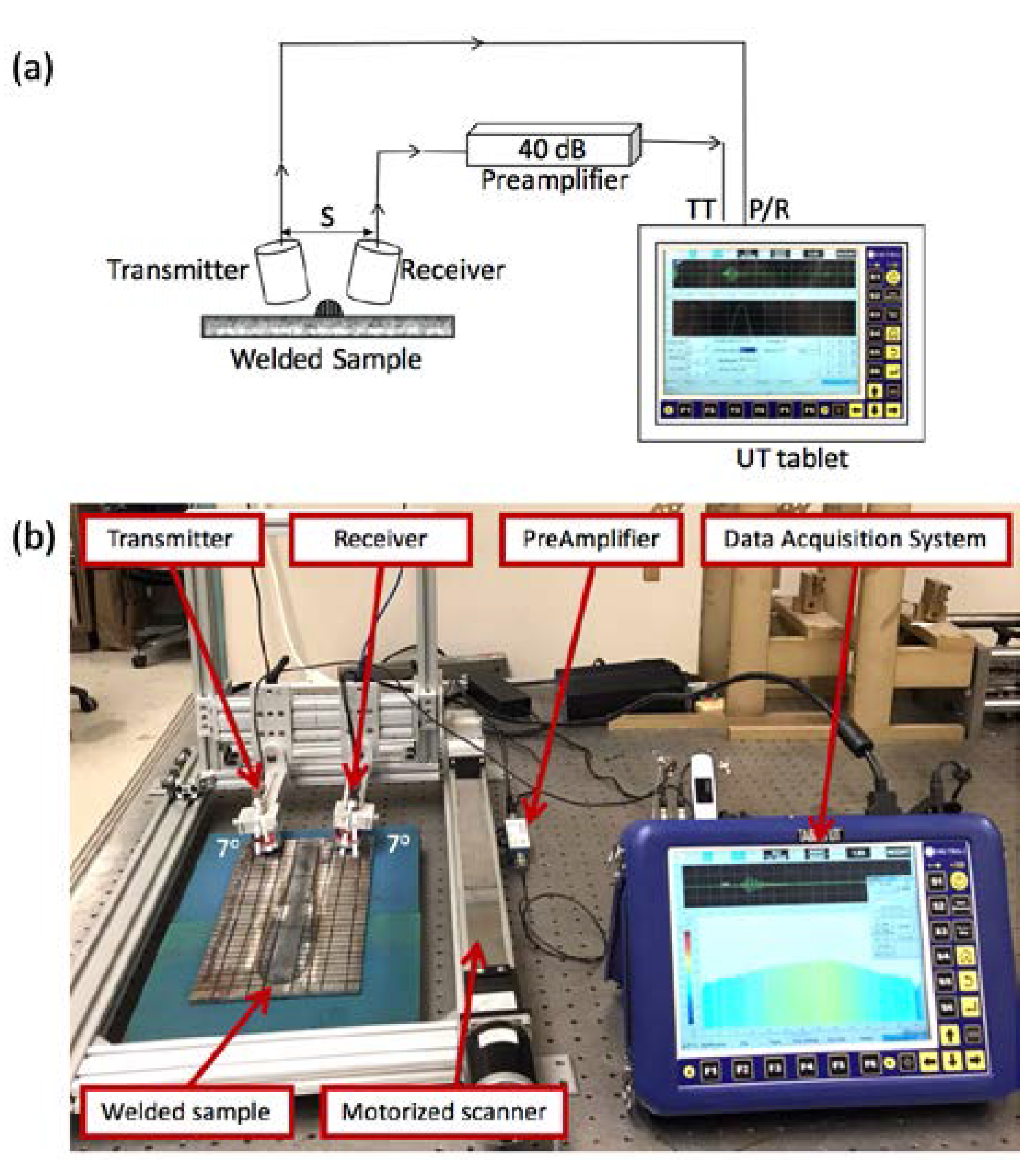

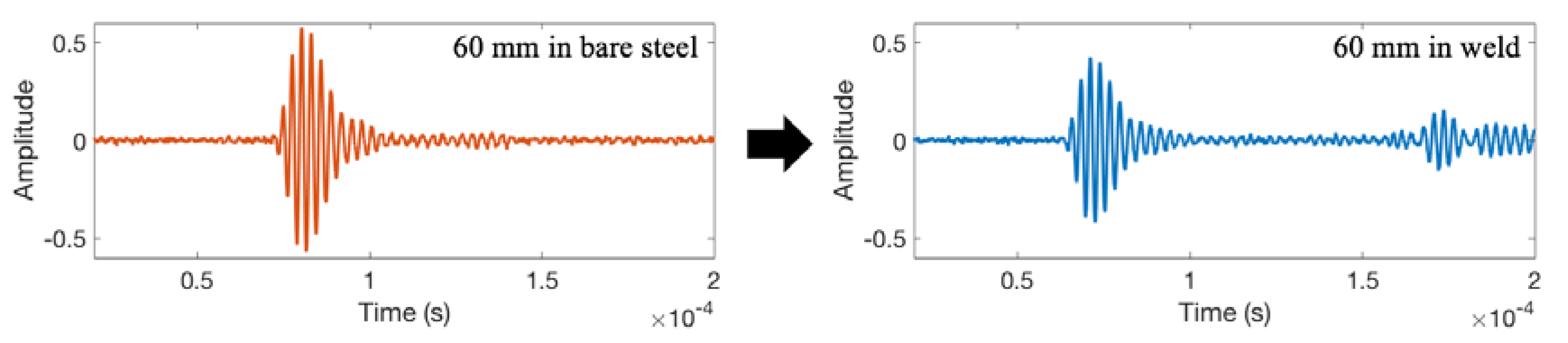

2.2. Lamb Wave Detection Using Air-Coupled Transducers

2.3. Experimental Investigation of Weld Defects

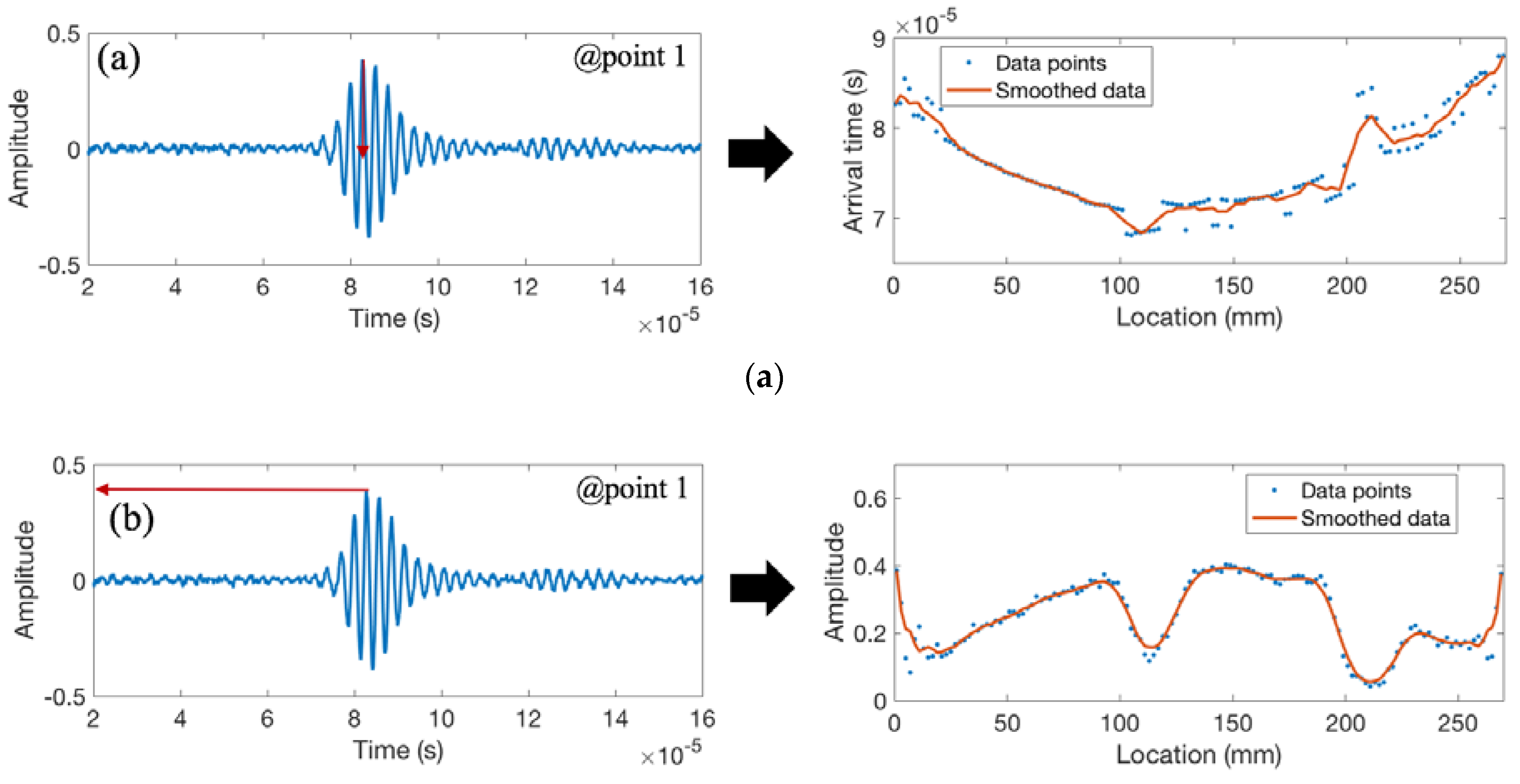

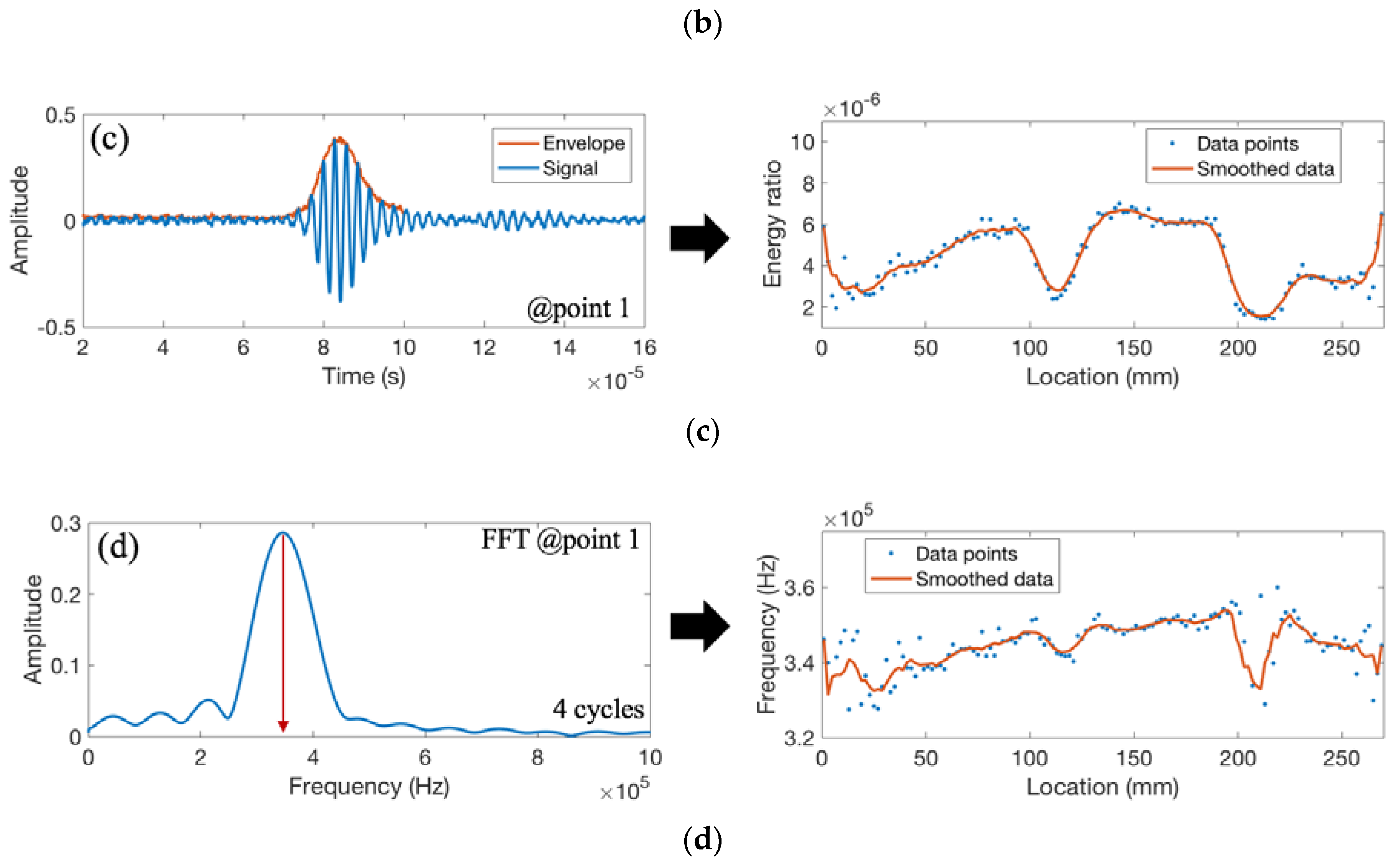

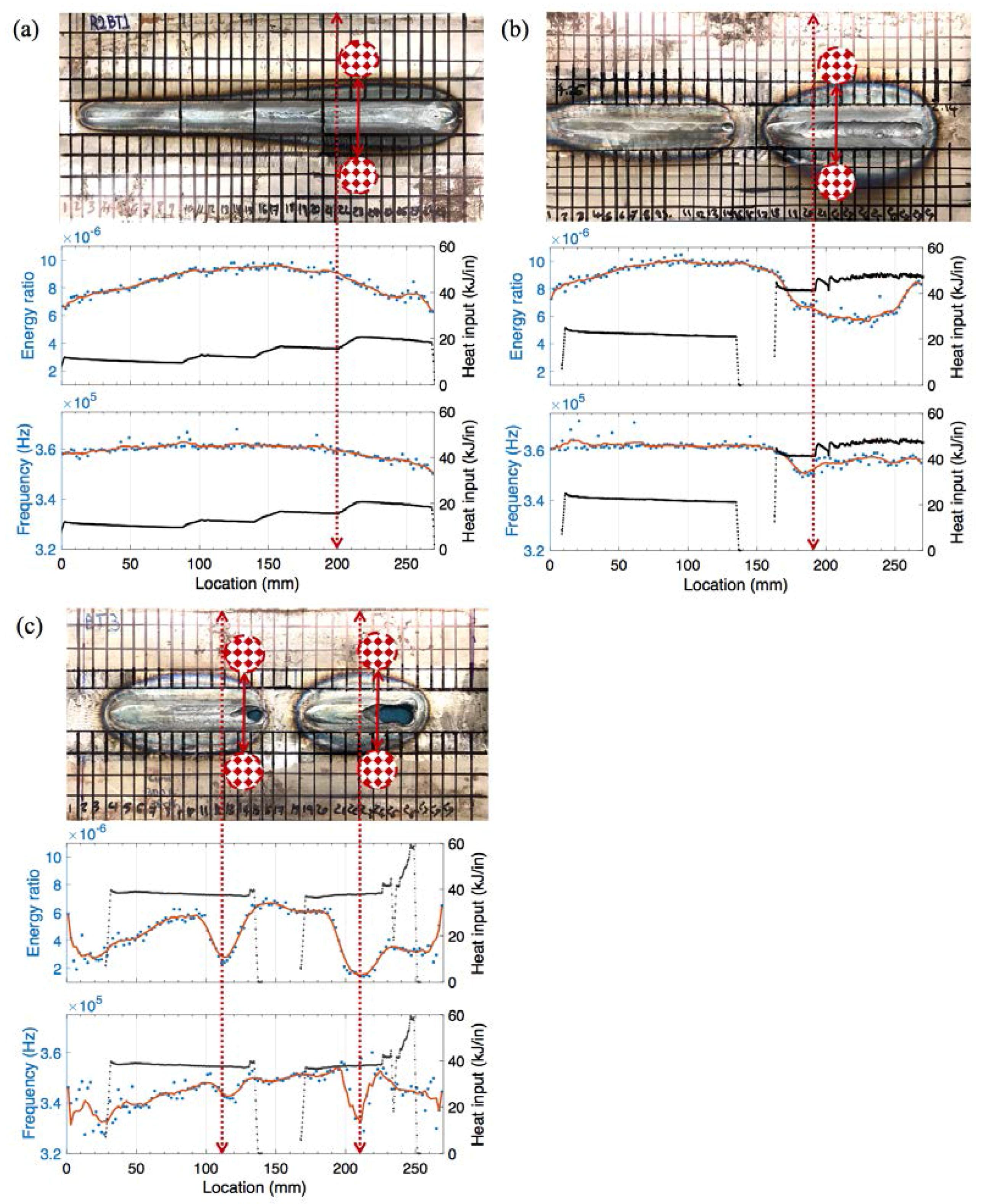

3. Results and Discussion

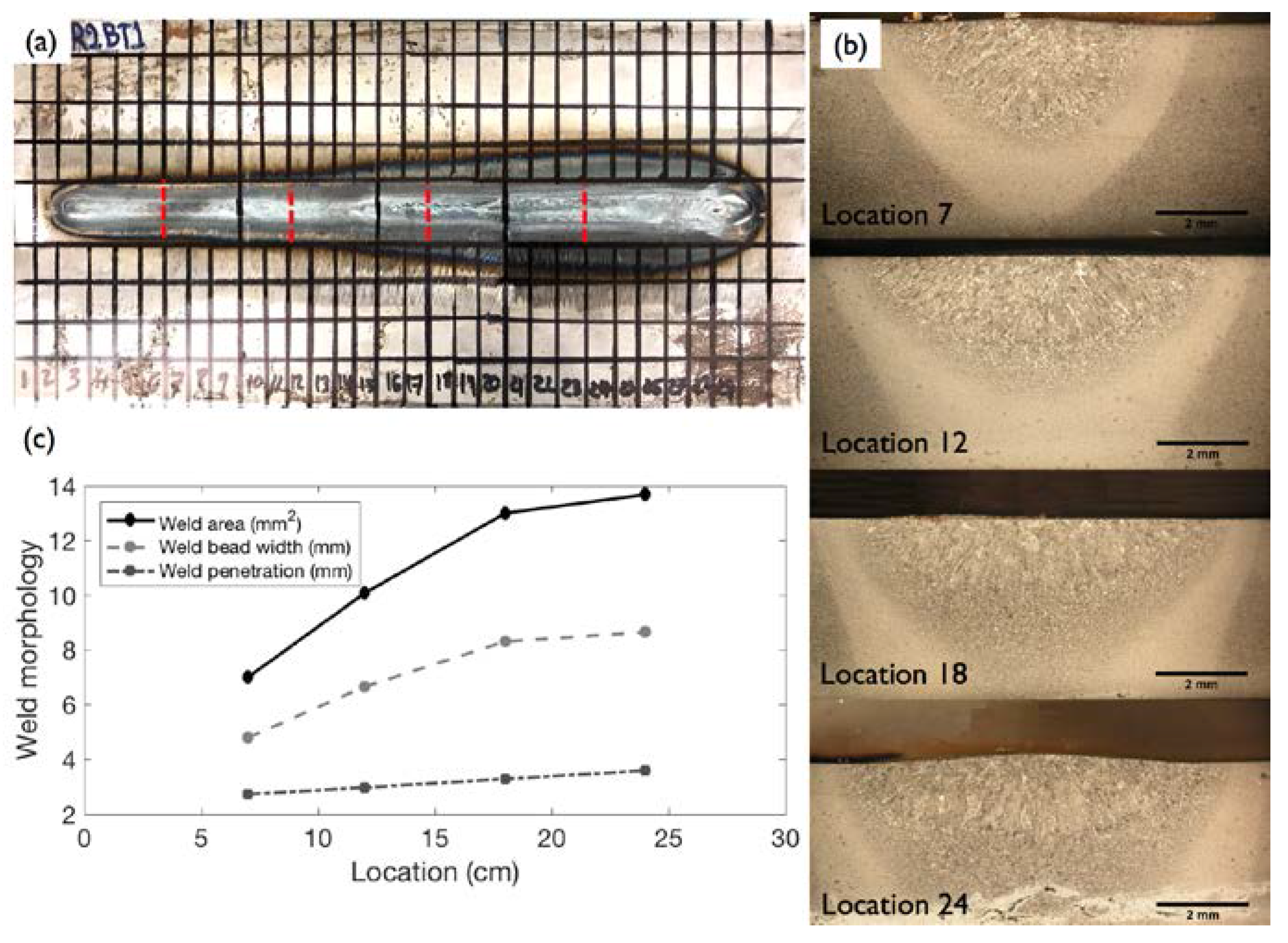

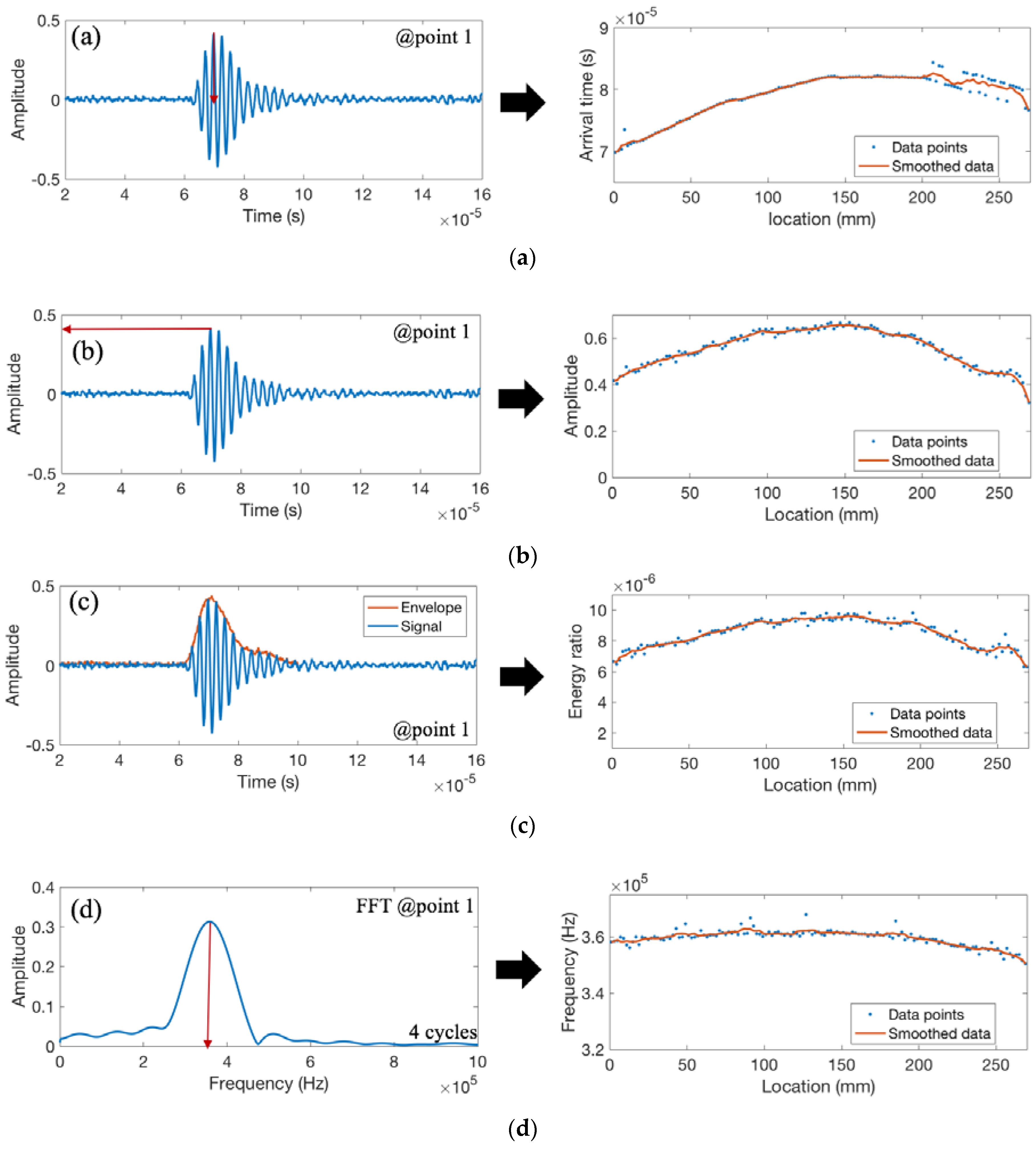

3.1. Identification of Weld Microstructure

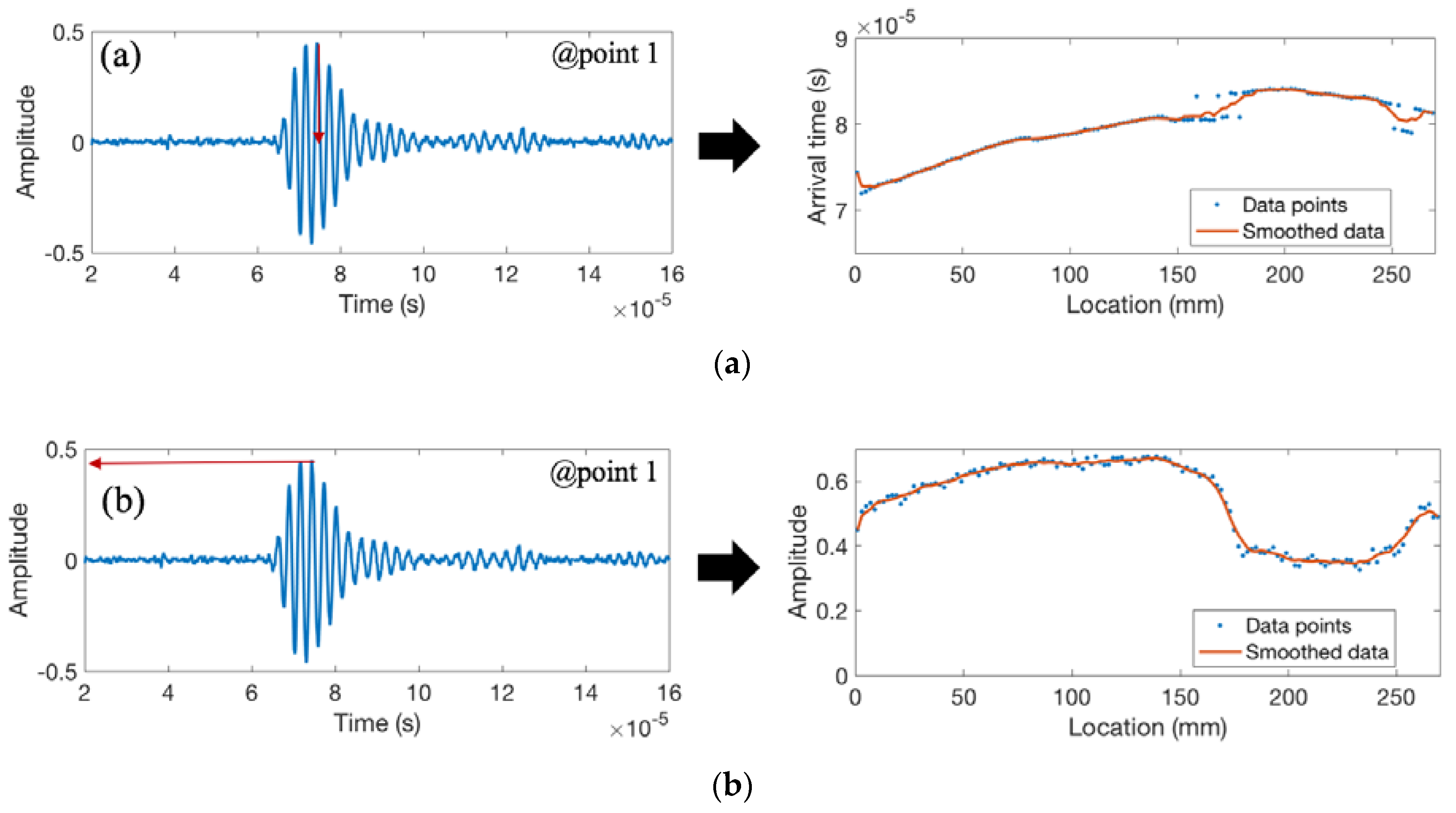

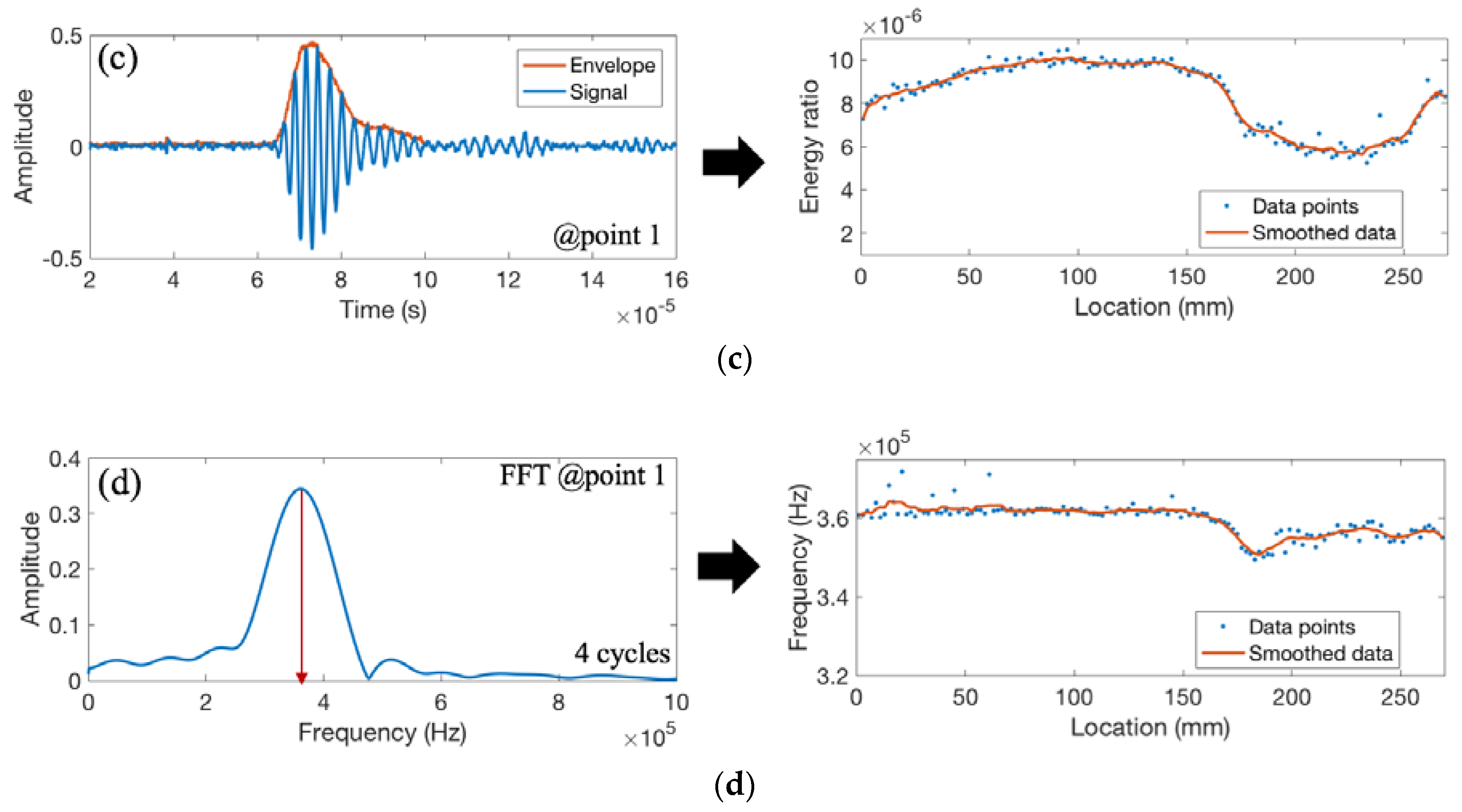

3.2. Correlation of UT Signals with Burn-Through Damage

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Jou, M. Real time monitoring weld quality of resistance spot welding for the fabrication of sheet metal assemblies. J. Mater. Process. Technol. 2003, 132, 102–113. [Google Scholar] [CrossRef]

- Sumesh, A.; Rameshkumar, K.; Mohandas, K.; Babu, R.S. Use of machine learning algorithms for weld quality monitoring using acoustic signature. Procedia Comput. Sci. 2015, 50, 316–322. [Google Scholar] [CrossRef]

- Atabaki, M.M.; Ma, J.; Liu, W.; Kovacevic, R. Pore formation and its mitigation during hybrid laser/arc welding of advanced high strength steel. Mater. Des. 2015, 67, 509–521. [Google Scholar] [CrossRef]

- Zhu, S.; Li, Q.; Zhang, Z.; Tian, X. Online welding quality monitoring for large-size electrical contact high frequency induction brazing. Measurement 2015, 69, 64–71. [Google Scholar] [CrossRef]

- Zhang, Z.; Chen, H.; Xu, Y.; Zhong, J.; Lv, N.; Chen, S. Multisensor-based real-time quality monitoring by means of feature extraction, selection and modeling for Al alloy in arc welding. Mech. Syst. Signal Process. 2015, 60, 151–165. [Google Scholar] [CrossRef]

- Suder, W.J.; Williams, S. Power factor model for selection of welding parameters in CW laser welding. Opt. Laser Technol. 2014, 56, 223–229. [Google Scholar] [CrossRef]

- Ferjutz, K.; Davis, J.R. Welding, brazing, and soldering. In ASM Handbook; ASM International: Geauga, OH, USA, 1993; Volume 6, ISBN 0-87170-382-3. [Google Scholar]

- Chimenti, D.E. Review of air-coupled ultrasonic materials characterization. Ultrasonics 2014, 54, 1804–1816. [Google Scholar] [CrossRef] [PubMed]

- Schindel, D.W. Air-coupled generation and detection of ultrasonic bulk waves in metals using micromachined capacitance transducers. Ultrasonics 1997, 35, 179–181. [Google Scholar] [CrossRef]

- Krauss, O.; Gerlach, R.; Fricke, J. Experimental and theoretical investigations of SiO2-aerogel matched piezo-transducers. Ultrasonics 1994, 32, 217–222. [Google Scholar] [CrossRef]

- Toda, M. New type of matching layer for air-coupled ultrasonic transducers. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2002, 49, 972–979. [Google Scholar] [CrossRef] [PubMed]

- Robertson, T.J.; Hutchins, D.A.; Billson, D.R.; Rakels, J.H.; Schindel, D.W. Surface metrology using reflected ultrasonic signals in air. Ultrasonics 2002, 39, 479–486. [Google Scholar] [CrossRef]

- Hutchins, D.A.; Robertson, T.J.; Billson, D.R.; Solanki, P. A conical air-coupled capacitance transducer for surface imaging. Ultrasonics 2003, 41, 163–173. [Google Scholar] [CrossRef]

- Chertov, A.M.; Karloff, A.C.; Perez, W.; Lui, A.; Maev, R.G. In-process ultrasound NDE of resistance spot welds. Insight 2012, 54, 257–261. [Google Scholar] [CrossRef]

- Harb, M.S.; Yuan, F.G. Barely visible impact damage imaging using non-contact air-coupled transducer/laser Doppler vibrometer system. Struct. Health Monit. 2016, 16, 663–673. [Google Scholar] [CrossRef]

- Harb, M.S.; Yuan, F.G. Damage imaging using non-contact air-coupled transducer/laser Doppler vibrometer system. Struct. Health Monit. 2016, 15, 193–203. [Google Scholar] [CrossRef]

- Ke, W.; Castaings, M.; Bacon, C. 3D finite element simulations of an air-coupled ultrasonic NDT system. NDT&E Int. 2009, 42, 524–533. [Google Scholar] [CrossRef]

- Kažys, R.; Mažeika, L.; Barauskas, R.; Raišutis, R.; Cicėnas, V.; Demčenko, A. 3D analysis of interaction of Lamb waves with defects in loaded steel plates. Ultrasonics 2006, 44, e1127–e1130. [Google Scholar] [CrossRef] [PubMed]

- Cho, Y. Estimation of ultrasonic guided wave mode conversion in a plate with thickness variation. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2000, 47, 591–603. [Google Scholar] [PubMed]

- Marical, P.; Ech-Cherif El-Kettani, M.; Predoi, M.V. Guided waves in elastic plates with Gaussian section variation: Experimental and numerical results. Ultrasonics 2007, 47, 1–9. [Google Scholar] [CrossRef] [PubMed]

- ASTM Standard. A36/A36M-08–Standard Specification for Carbon Structural Steel, or A992/A992M-06A, Grade 50–Standard Specification for Structural Steel Shapes. Available online: https://www.astm.org/DATABASE.CART/HISTORICAL/A36A36M-08.htm (accessed on 10 January 2018).

- Harb, M.S.; Yuan, F.G. A rapid, fully non-contact, hybrid system for generating Lamb wave dispersion curves. Ultrasonics 2015, 61, 62–70. [Google Scholar] [CrossRef] [PubMed]

- Kichou, H.B.; Chavez, J.A.; Turo, A.; Salazar, J.; Garcia-Hernandez, M.J. Lamb waves beam deviation due to small inclination of the test structure in air-coupled ultrasonic NDT. Ultrasonics 2006, 44, e1077–e1082. [Google Scholar] [CrossRef] [PubMed]

- Egle, D.M.; Bray, D.E. Measurement of acoustoelastic and third-order elastic constants for rail steel. J. Acoust. Soc. Am. 1976, 60, 741–744. [Google Scholar] [CrossRef]

- Waag, G.; Hoff, L.; Norli, P. Air-coupled Thickness Measurements of Stainless Steel. 2012. Available online: https://arxiv.org/pdf/1210.0428.pdf (accessed on 9 January 2018).

- Fan, Z.; Lowe, M.J. Elastic waves guided by a welded joint in a plate. Proc. R. Soc. Lond. A Math. Phys. Eng. Sci. (2009, January) 2009, 465, 2053–2068. Available online: http://rspa.royalsocietypublishing.org/content/royprsa/465/2107/2053.full.pdf (accessed on 9 January 2018).

- Philtron, J.H.; Rose, J.L. Mode perturbation method for optimal guided wave mode and frequency selection. Ultrasonics 2014, 54, 1817–1824. [Google Scholar] [CrossRef] [PubMed]

| ASTM Specification | Content % | |||||

|---|---|---|---|---|---|---|

| C | Mn | P | S | Si | Cu | |

| A36 | 0.25 | – | 0.03 | 0.03 | 0.40 | 0.20 |

| Weld Coupon | Sample | Current | Voltage | Gas Flow | Travel Speed | Tungsten Diameter | Heat Input | Visual Inspection |

|---|---|---|---|---|---|---|---|---|

| (A) | (V) | (m3/h) | (mm/s) | (mm) | (kJ/mm) | |||

| Onset burn-through due to variation of Amperages | ||||||||

| No. 1 | 1 | 160 | 8.41 | 0.99 | 3.39 | 3.175 | 0.40 | Good Weld |

| 2 | 200 | 8.41 | 0.99 | 3.39 | 3.175 | 0.50 | Intermediate heat input | |

| 3 | 250 | 8.41 | 0.99 | 3.39 | 3.175 | 0.62 | High heat input | |

| 4 | 300 | 8.41 | 0.99 | 3.39 | 3.175 | 0.74 | Initiation of burn-through | |

| Burn-through due to variation of travel speed with normal Amperage | ||||||||

| No. 2 | 1 | 160 | 9.65 | 1.02 | 1.80 | 3.175 | 0.86 | Burn-through with small amount of melting material |

| 2 | 160 | 9.99 | 1.02 | 0.91 | 3.175 | 1.76 | Burn-through with large amount of melting material | |

| Burn-through due to variation of travel speed with high Amperage | ||||||||

| No. 3 | 1 | 300 | 12.32 | 1.02 | 2.54 | 3.175 | 1.46 | Burn-through with small hole |

| 2 | 300 | 11.84 | 1.02 | 2.33 | 3.175 | 1.53 | Burn-through with large hole | |

| Property | Values | |||

|---|---|---|---|---|

| Density (kg/m3) | 7850 | |||

| Young’s modulus (MPa) | 200 × | |||

| Poisson’s ratio | 0.33 | |||

| Lame constants (MPa) | λ = 150 × | μ = 75 × | ||

| Murnaghan constants (MPa) | l = −300 × | m = −620 × | n = −720 × | |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abbasi, Z.; Yuhas, D.; Zhang, L.; Basantes, A.-D.-C.; Tehrani, N.N.; Ozevin, D.; Indacochea, E. The Detection of Burn-Through Weld Defects Using Noncontact Ultrasonics. Materials 2018, 11, 128. https://doi.org/10.3390/ma11010128

Abbasi Z, Yuhas D, Zhang L, Basantes A-D-C, Tehrani NN, Ozevin D, Indacochea E. The Detection of Burn-Through Weld Defects Using Noncontact Ultrasonics. Materials. 2018; 11(1):128. https://doi.org/10.3390/ma11010128

Chicago/Turabian StyleAbbasi, Zeynab, Donald Yuhas, Lu Zhang, Alexandra-Del-Carmen Basantes, Niloofar Nabili Tehrani, Didem Ozevin, and Ernesto Indacochea. 2018. "The Detection of Burn-Through Weld Defects Using Noncontact Ultrasonics" Materials 11, no. 1: 128. https://doi.org/10.3390/ma11010128