Dynamic Recrystallization of the Constituent γ Phase and Mechanical Properties of Ti-43Al-9V-0.2Y Alloy Sheet

Abstract

:1. Introduction

2. Material and Experimental Procedure

3. Results and Discussion

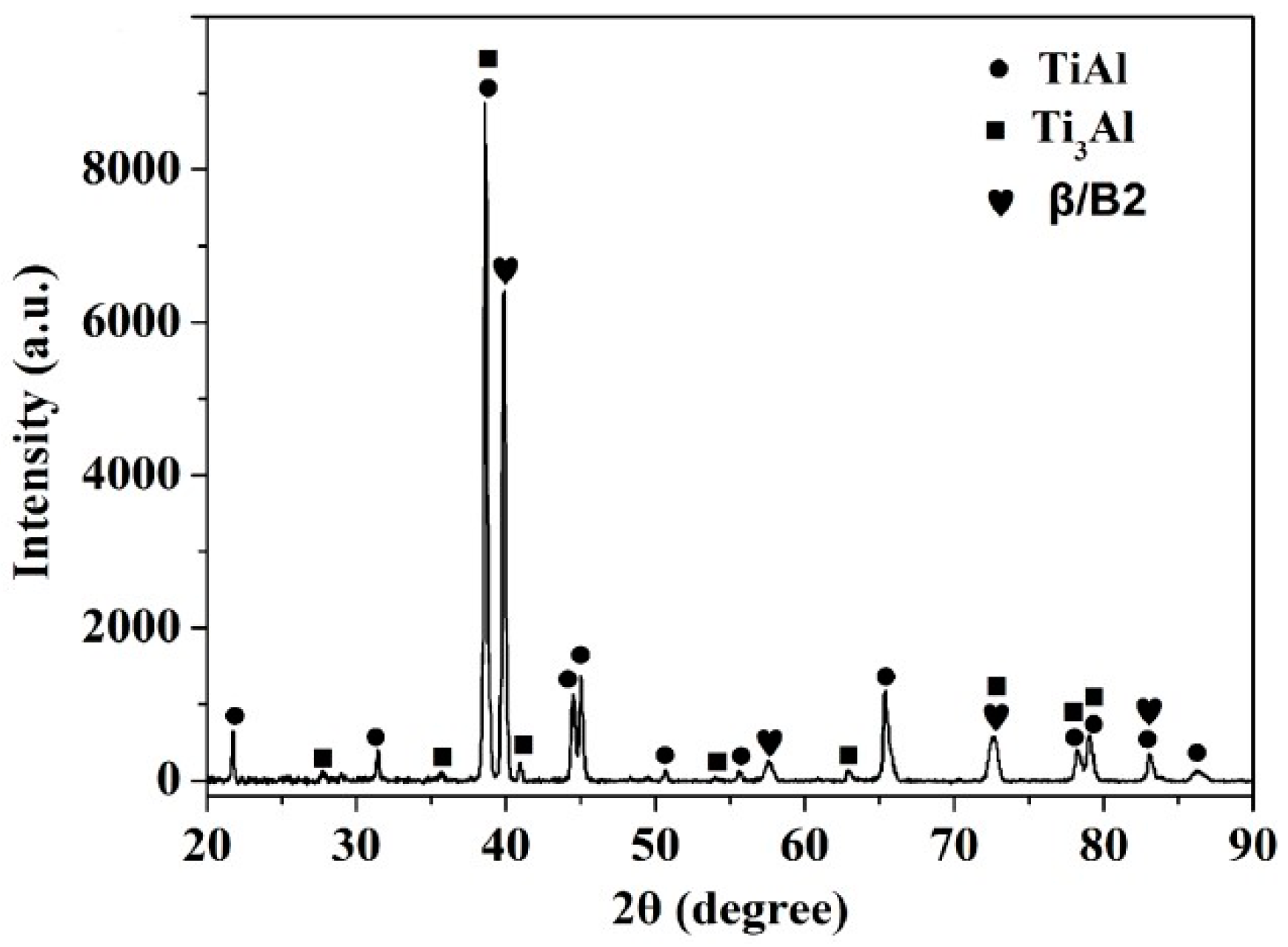

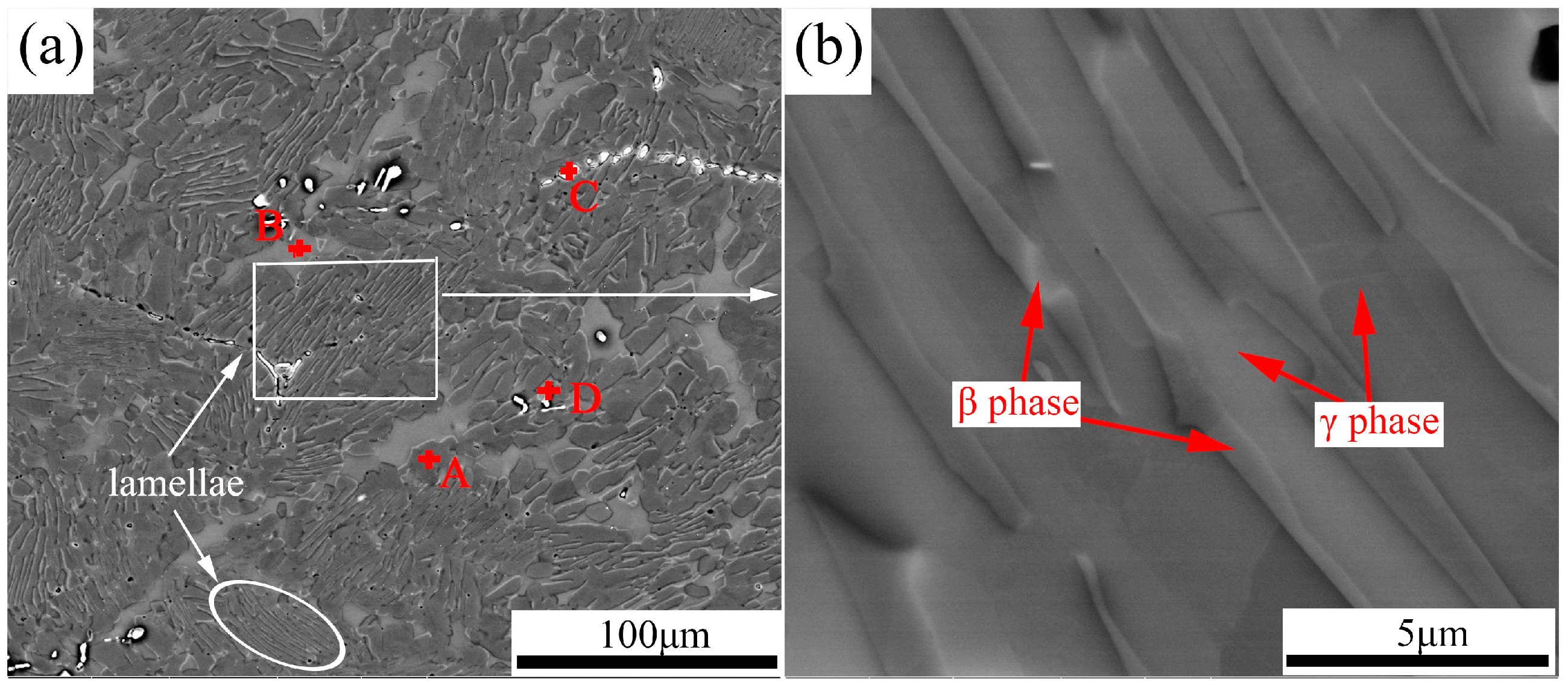

3.1. Microstructure Evolution and Phase Composition of the Ti-43Al-9V-0.2Y Sheet

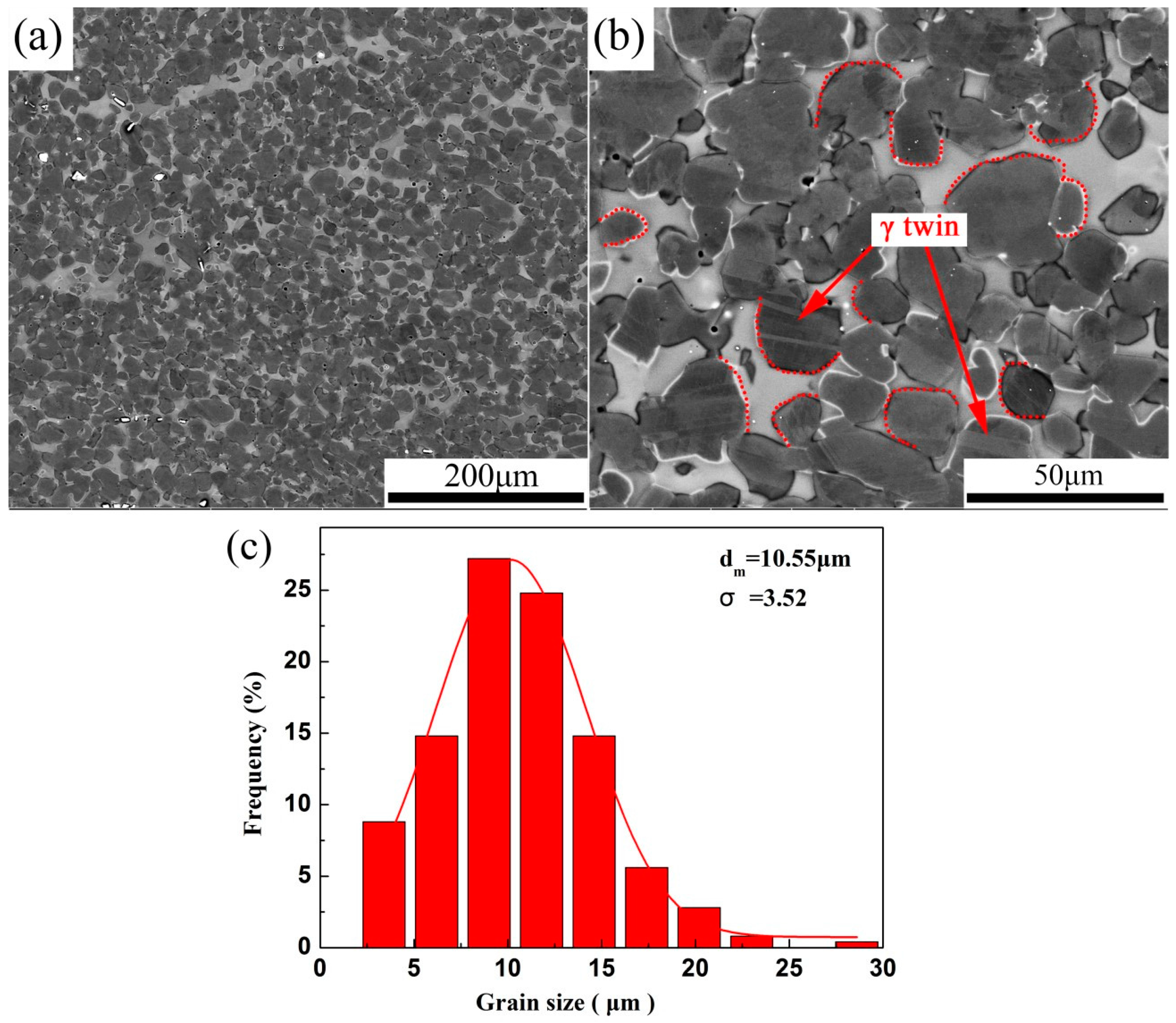

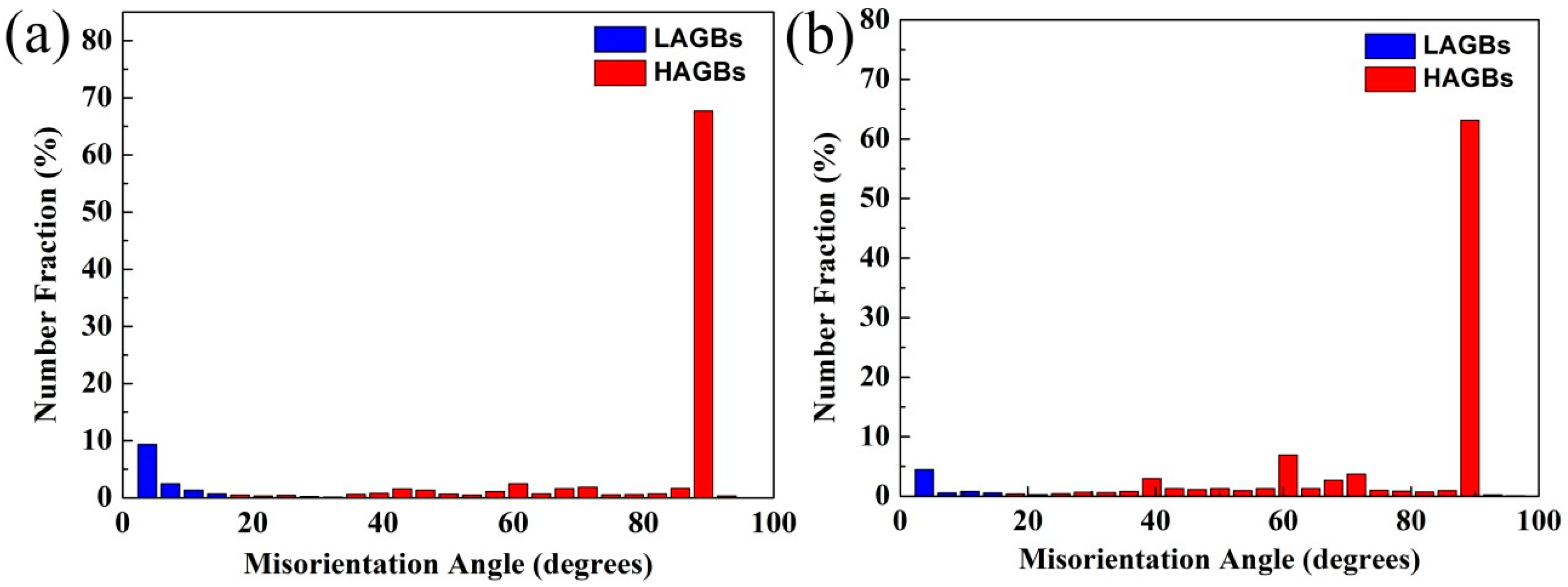

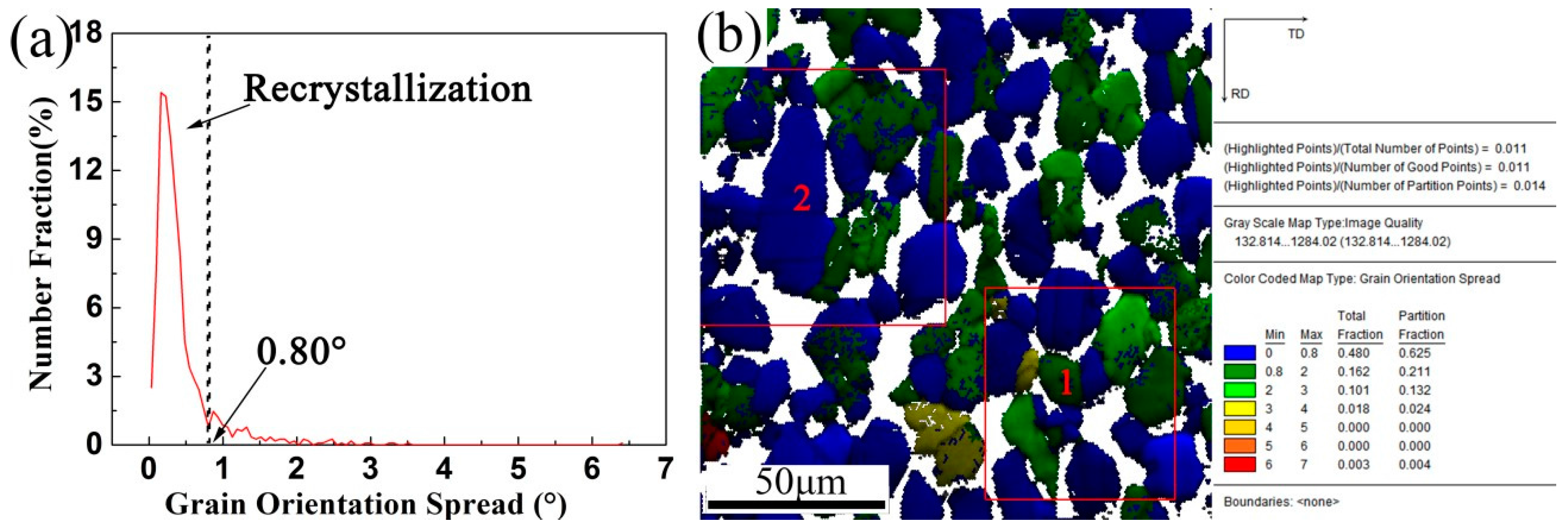

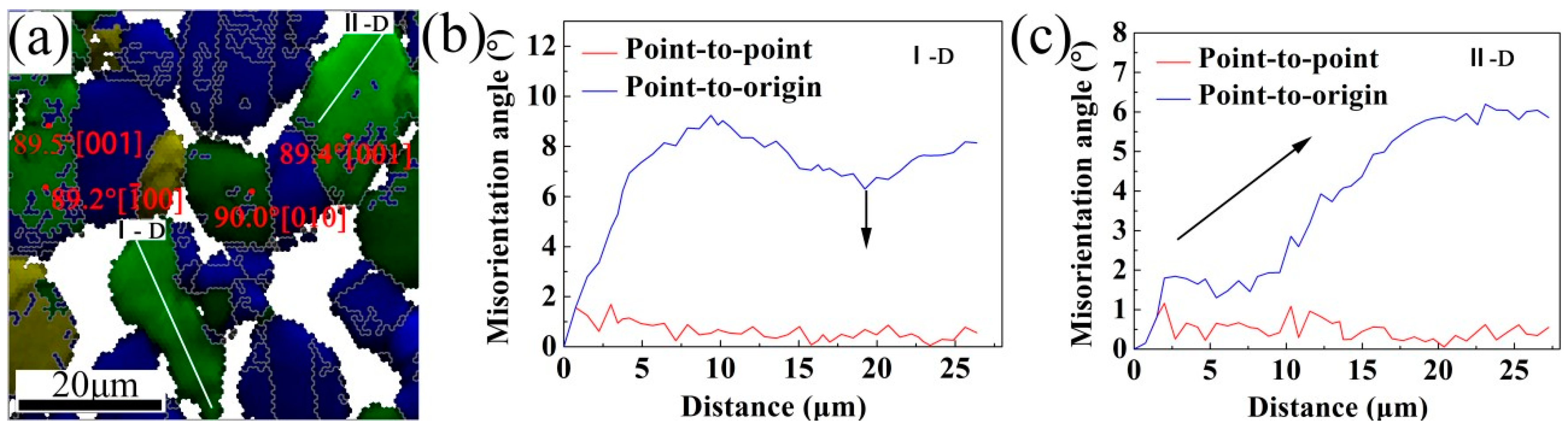

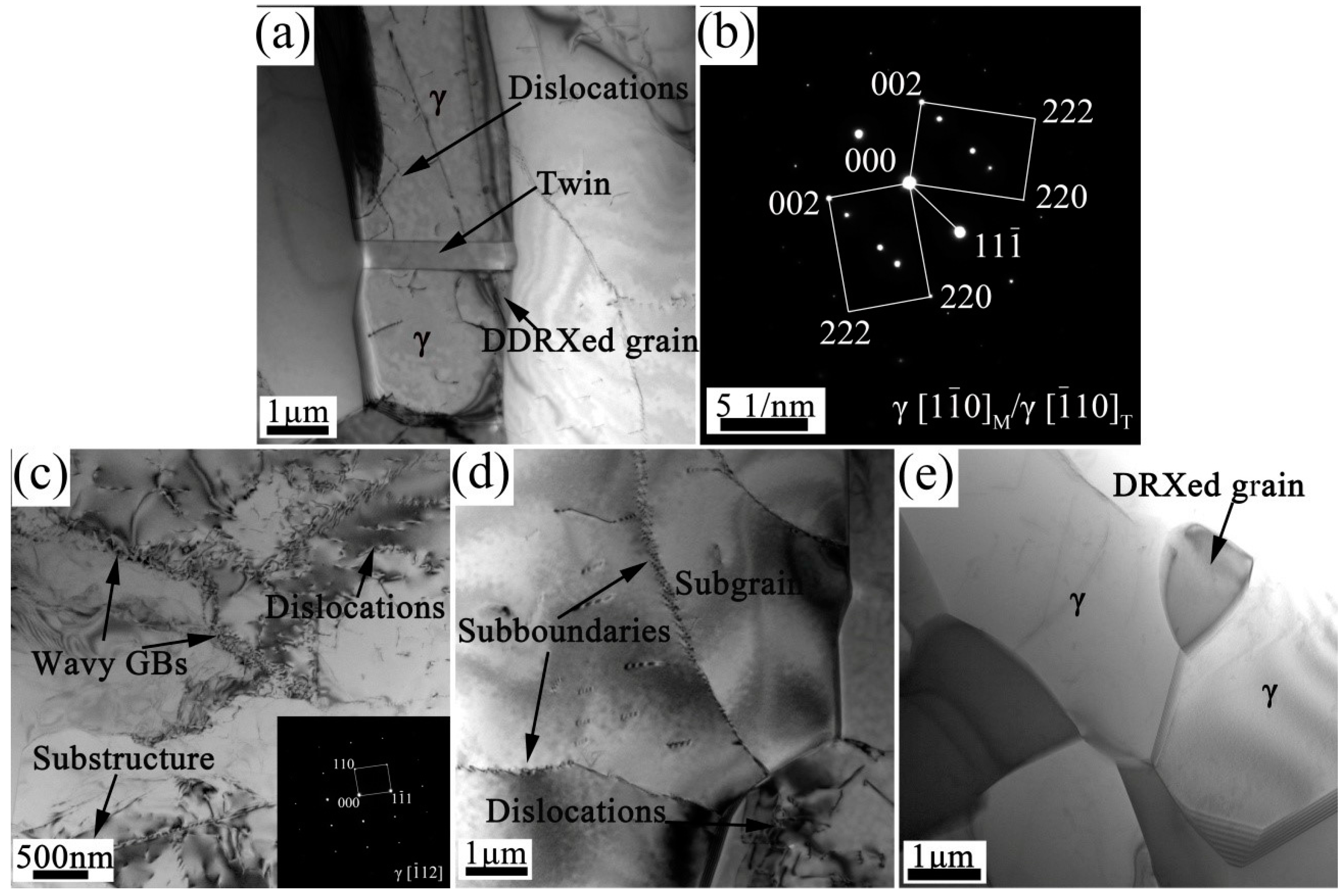

3.2. DRX of the TiAl Alloy Sheet

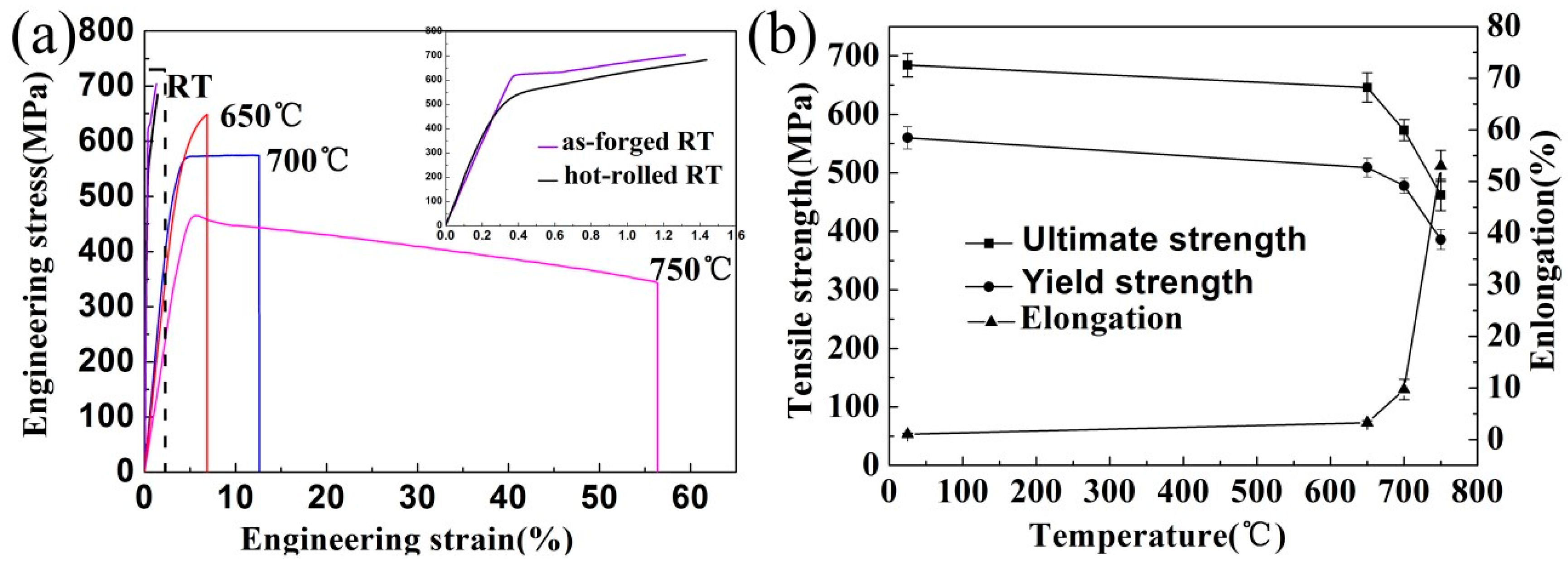

3.3. Mechanical Properties of the Ti-43Al-9V-0.2Y Sheet

4. Conclusions

- The volume fraction of dynamically recrystallized grains increases after hot-rolling and multi-pass rolling promotes DDRX of the γ phase during hot-rolling. Furthermore, the θ = 89° ± 3°<100> misorientation angle occurs in both the DRX grains and the deformed grains. The twin boundaries are conducive for the occurrence of DDRX and provide ideal nucleation sites for γ grains.

- The dislocations, sub-grain boundaries, and GNBs within the deformed grains are generated by the high strain rates and high stress associated with the hot-rolling process. These strain rates and stress provide a continuous driving force for the transformation of LAGBs into HAGBs, in preparation for the CDRX process. The DRX of the γ phase in the current TiAl alloy sheet results from the occurrence of both DDRX and CDRX during hot-rolling and plays a key role in microstructure refinement.

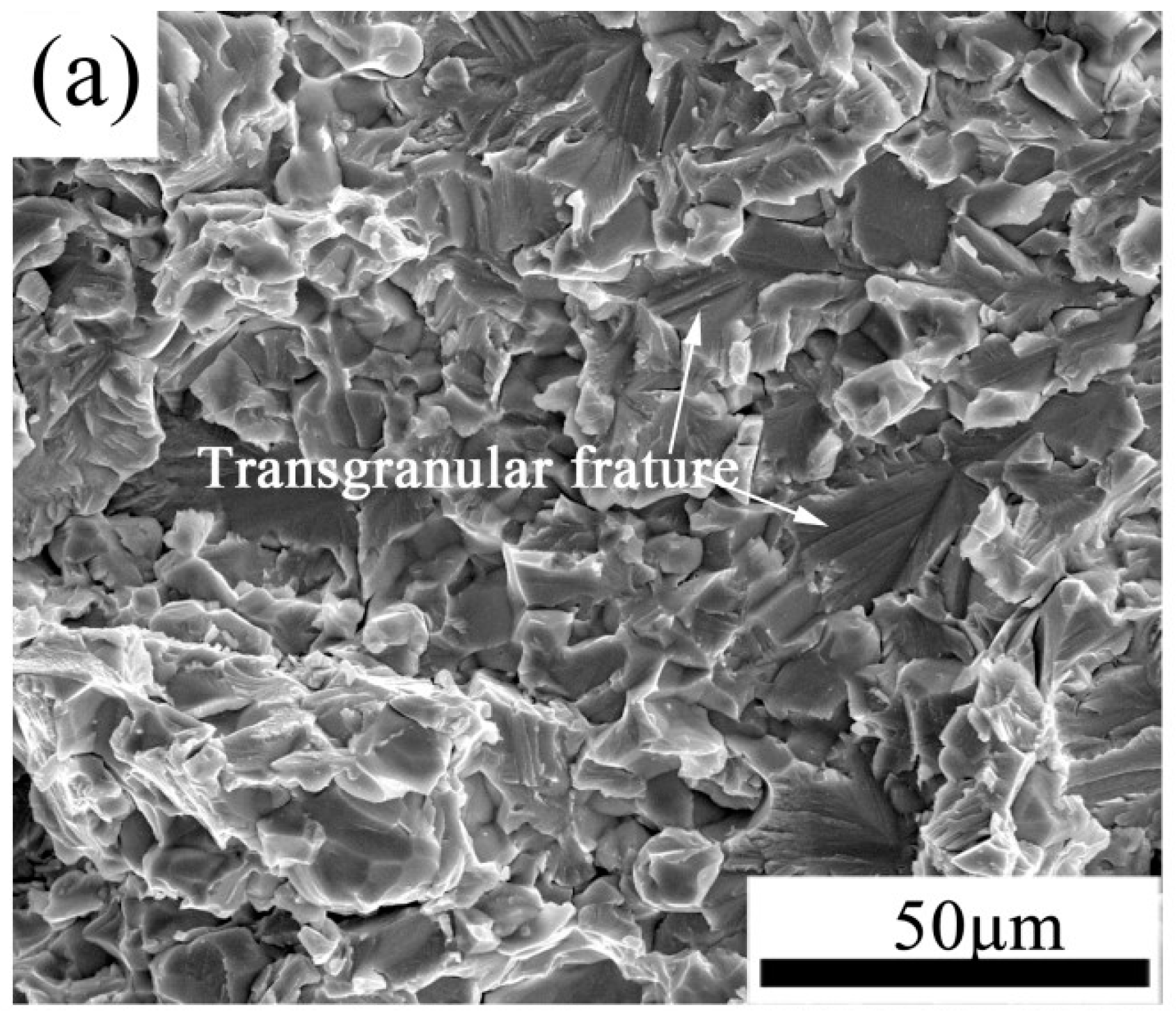

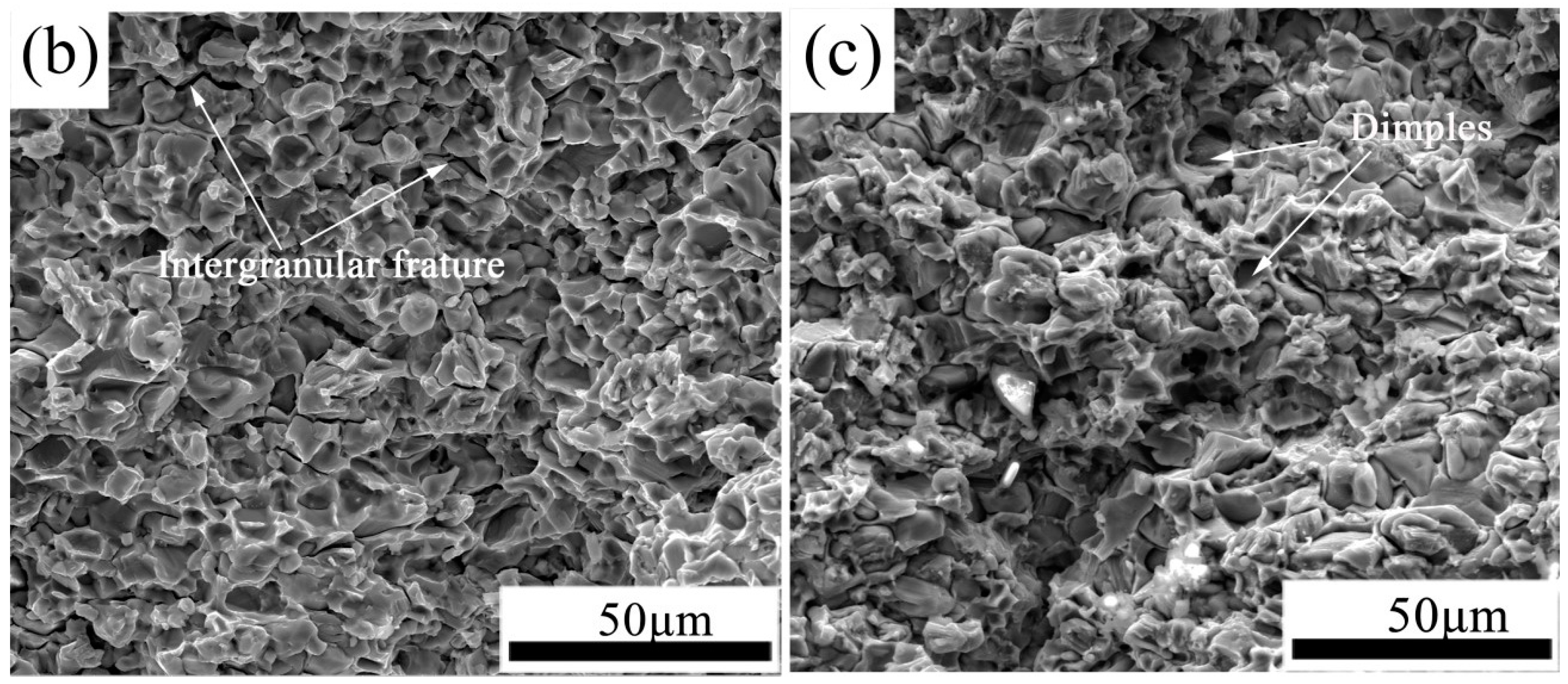

- The Ti-43Al-9V-0.2Y alloy sheet exhibits a UTS and ductility of 684 MPa and 1.02%, respectively, at room temperature. When the tensile-test temperature is increased to 750 °C, the sheet exhibits an excellent elongation (53%), with a failure strength of 467 MPa. The brittle–ductile transition temperature of the TiAl alloy sheet lies between 700 °C and 750 °C.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Clemens, H.; Mayer, S. Design, Processing, Microstructure, Properties, and Applications of Advanced Intermetallic TiAl Alloys. Adv. Eng. Mater. 2013, 15, 191–215. [Google Scholar] [CrossRef]

- Tetsui, T. Application of TiAl in a turbocharger for passenger vehicles. Adv. Eng. Mater. 2001, 3, 307–310. [Google Scholar] [CrossRef]

- Appel, F.; Clemens, H.; Fischer, F.D. Modeling concepts for intermetallic titanium aluminides. Prog. Mater. Sci. 2016, 81, 55–124. [Google Scholar] [CrossRef]

- Wang, X.S.; Zhang, M.; Song, X.P.; Jia, S.; Chen, Q.; Kawagoishi, N. Fatigue Failure Analyses on a Ti-45Al-8Nb-0.2W-0.2B-0.1Y Alloy at Different Temperatures. Materials 2012, 5, 2280–2291. [Google Scholar] [CrossRef]

- Harrison, W.; Abdallah, Z.; Whittaker, M. A Model for Creep and Creep Damage in the γ-Titanium Aluminide Ti-45Al-2Mn-2Nb. Materials 2014, 7, 2194–2209. [Google Scholar] [CrossRef] [PubMed]

- Zhou, C.X.; Liu, B.; Liu, Y.; Qiu, C.Z.; He, Y.H. Effect of carbon on microstructures of Ti-45Al-3Fe-2Mo-xC alloy. Trans. Nonferrous Met. Soc. China 2014, 24, 1730–1736. [Google Scholar] [CrossRef]

- Hu, D. Effect of boron addition on tensile ductility in lamellar TiAl alloys. Intermetallics 2002, 10, 851–858. [Google Scholar] [CrossRef]

- Schwaighofer, E.; Clemens, H.; Mayer, S.; Lindemann, J.; Klose, J.; Smarsly, W.; Güther, V. Microstructural design and mechanical properties of a cast and heat-treated intermetallic multi-phase γ-TiAl based alloy. Intermetallics 2014, 44, 128–140. [Google Scholar] [CrossRef]

- Novoselova, T.; Malinov, S.; Sha, W. Experimental study of the effects of heat treatment on microstructure and grain size of a gamma TiAl alloy. Intermetallics 2003, 11, 491–499. [Google Scholar] [CrossRef]

- Zhang, S.Z.; Kong, F.T.; Chen, Y.Y.; Liu, Z.Y.; Lin, J.P. Phase transformation and microstructure evolution of differently processed Ti-45Al-9Nb-Y alloy. Intermetallics 2012, 31, 208–216. [Google Scholar] [CrossRef]

- Xu, W.C.; Shan, D.B.; Zhang, H.; Li, X.A.; Zhang, Y.Z.; Nutt, S. Effects of extrusion deformation on microstructure, mechanical properties and hot workability of β containing TiAl alloy. Mater. Sci. Eng. A 2013, 571, 199–206. [Google Scholar] [CrossRef]

- Shen, Z.Z.; Lin, J.P.; Liang, Y.F.; Zhang, L.Q.; Shang, S.L.; Liu, Z.K. A novel hot pack rolling of high Nb-TiAl sheet from cast ingot. Intermetallics 2015, 67, 19–25. [Google Scholar] [CrossRef]

- Liang, X.P.; Liu, Y.; Li, H.Z.; Gan, Z.Y.; Liu, B.; He, Y.H. An investigation on microstructural and mechanical properties of powder metallurgical TiAl alloy during hot pack-rolling. Mater. Sci. Eng. A 2014, 619, 265–273. [Google Scholar] [CrossRef]

- Niu, H.Z.; Kong, F.T.; Xiao, S.L.; Chen, Y.Y.; Yang, F. Effect of pack rolling on microstructures and tensile properties of as-forged Ti-44Al-6V-3Nb-0.3Y alloy. Intermetallics 2012, 21, 97–104. [Google Scholar] [CrossRef]

- Wu, X.H. Review of alloy and process development of TiAl alloys. Intermetallics 2006, 14, 1114–1122. [Google Scholar] [CrossRef]

- Kim, Y.W. Intermetallic alloys based on gamma titanium aluminide. J. Met. 1989, 41, 24–30. [Google Scholar] [CrossRef]

- Qiu, C.Z.; Liu, Y.; Huang, L.; Liu, B.; Zhang, W.; He, Y.H.; Huang, B.Y. Tuning mechanical properties for β(B2)-containing TiAl intermetallics. Trans. Nonferrous Met. Soc. China 2012, 22, 2593–2603. [Google Scholar] [CrossRef]

- Clemens, H.; Kestler, H. Processing and Applications of Intermetallic γ-TiAl-Based Alloys. Adv. Eng. Mater. 2000, 2, 551–570. [Google Scholar] [CrossRef]

- Clemens, H.; Chladil, H.F.; Wallgram, W.; Zickler, G.A.; Gerling, R.; Liss, K.D.; Kremmer, S.; Güther, V.; Smarsly, W. In and ex situ investigations of the β-phase in a Nb and Mo containing γ-TiAl based alloy. Intermetallics 2008, 16, 827–833. [Google Scholar] [CrossRef]

- Li, H.Z.; Qi, Y.L.; Liang, X.P.; Zhu, Z.X.; Lv, F.; Liu, Y.; Yang, Y. Microstructure and high temperature mechanical properties of powder metallurgical Ti-45Al-7Nb-0.3W alloy sheets. Mater. Des. 2016, 106, 90–97. [Google Scholar] [CrossRef]

- Zhang, D.Y.; Li, H.Z.; Liang, X.P.; Wei, Z.W.; Liu, Y. Microstructure characteristic for high temperature deformation of powder metallurgy Ti-47Al-2Cr-0.2Mo alloy. Mater. Des. 2014, 59, 415–420. [Google Scholar] [CrossRef]

- Jia, J.B.; Zhang, K.F.; Lu, Z. Dynamic recrystallization kinetics of a powder metallurgy Ti-22Al-25Nb alloy during hot compression. Mater. Sci. Eng. A 2014, 607, 630–639. [Google Scholar] [CrossRef]

- Jiang, H.T.; Zeng, S.W.; Zhao, A.M.; Ding, X.N.; Dong, P. Hot deformation behavior of β phase containing γ-TiAl alloy. Mater. Sci. Eng. A 2016, 661, 160–167. [Google Scholar] [CrossRef]

- Zong, Y.Y.; Wen, D.S.; Liu, Z.Y.; Shan, D.B. γ-Phase transformation, dynamic recrystallization and texture of a forged TiAl-based alloy based on plane strain compression at elevated temperature. Mater. Des. 2016, 91, 321–330. [Google Scholar] [CrossRef]

- Su, Y.J.; Kong, F.T.; Chen, Y.Y.; Gao, N.; Zhang, D.L. Microstructure and mechanical properties of large size Ti-43Al-9V-0.2Y alloy pancake produced by pack-forging. Intermetallics 2013, 34, 29–34. [Google Scholar] [CrossRef]

- Cao, Y.; Di, H.S.; Zhang, J.Q.; Zhang, J.C.; Ma, T.J.; Misra, R.D.K. An electron backscattered diffraction study on the dynamic recrystallization behavior of a nickel-chromium alloy (800H) during hot deformation. Mater. Sci. Eng. A 2013, 585, 71–85. [Google Scholar] [CrossRef]

- Takeyama, M.; Kobayashi, S. Physical metallurgy for wrought gamma titanium aluminides: Microstructure control through phase transformations. Intermetallics 2005, 13, 993–999. [Google Scholar] [CrossRef]

- Cui, N.; Kong, F.T.; Wang, X.P.; Chen, Y.Y.; Zhou, H.T. Microstructural evolution, hot workability, and mechanical properties of Ti-43Al-2Cr-2Mn-0.2Y alloy. Mater. Des. 2016, 89, 1020–1027. [Google Scholar] [CrossRef]

- Liu, B.; Liu, Y.; Li, Y.P.; Zhang, W.; Chiba, A. Thermomechanical characterization of β-stabilized Ti-45Al-7Nb-0.4W-0.15B alloy. Intermetallics 2011, 19, 1184–1190. [Google Scholar] [CrossRef]

- Liss, K.D.; Schmoelzer, T.; Yan, K.; Reid, M.; Peel, M.; Dippenaar, R.; Clemens, H. In situ study of dynamic recrystallization and hot deformation behavior of a multiphase titanium aluminide alloy. J. Appl. Phys. 2009, 106, 113526. [Google Scholar] [CrossRef]

- Nieh, T.G.; Hsiung, L.M.; Wadsworth, J. Superplastic behavior of a powder metallurgy TiAl alloy with a metastable microstructure. Intermetallics 1999, 7, 163–170. [Google Scholar] [CrossRef]

- Wang, J.N.; Wang, Y. An investigation of the origin of the superplasticity of cast TiAl alloys. Int. J. Plast. 2006, 22, 1530–1548. [Google Scholar] [CrossRef]

- Greenwood, G.W.; Johnson, R.H. The Deformation of Metals under Small Stresses during Phase Transformations. Proc. R. Soc. A 1965, 283, 403. [Google Scholar] [CrossRef]

- Yang, K.L.; Huang, J.C.; Wang, Y.N. Phase transformation in the β phase of super α2 Ti3Al base alloys during static annealing and superplastic deformation at 700–1000 °C. Acta Mater. 2003, 51, 2577–2594. [Google Scholar] [CrossRef]

- Jin, Z.; Gray, G.T. On deformation twins and twin-related lamellae in TiAl. J. Mater. Sci. 1998, 33, 77–83. [Google Scholar] [CrossRef]

- Yan, H.; Xu, S.W.; Chen, R.S.; Kamado, S.; Honma, T.; Han, E.H. Twins, shear bands and recrystallization of a Mg–2.0%Zn–0.8%Gd alloy during rolling. Scr. Mater. 2011, 64, 141–144. [Google Scholar] [CrossRef]

- Samman, A.T.; Gottstein, G. Dynamic recrystallization during high temperature deformation of magnesium. Mater. Sci. Eng. A 2008, 490, 411–420. [Google Scholar] [CrossRef]

- Mandal, S.; Bhaduri, A.K.; Subramanya, S.V. A Study on Microstructural Evolution and Dynamic Recrystallization during Isothermal Deformation of a Ti-Modified Austenitic Stainless Steel. Metall. Mater. Trans. A 2011, 42, 1062–1072. [Google Scholar] [CrossRef]

- Chen, Y.J.; Li, Y.J.; Walmsley, J.C.; Dumoulin, S.; Roven, H.J. Deformation Structures of Pure Titanium during Shear Deformation. Metall. Mater. Trans. A 2010, 41, 787–794. [Google Scholar] [CrossRef]

- Kim, J.H.; Shin, D.H.; Semiatin, S.L.; Lee, C.S. High temperature deformation behavior of a γ TiAl alloy determined using the load-relaxation test. Mater. Sci. Eng. A 2003, 344, 146–157. [Google Scholar] [CrossRef]

- Zhou, H.T.; Kong, F.T.; Wang, X.P.; Chen, Y.Y. High strength in high Nb containing TiAl alloy sheet with fine duplex microstructure produced by hot pack rolling. J. Alloys Compd. 2017, 695, 3495–3502. [Google Scholar] [CrossRef]

| Point | Alloying Element (at %) | ||||

|---|---|---|---|---|---|

| Al | Ti | V | O | Y | |

| A | 45.8 | 48.0 | 6.2 | - | - |

| B | 32.6 | 49.0 | 18.5 | - | - |

| C | 60.5 | 10.3 | 2.3 | - | 26.9 |

| D | 0.7 | 1.2 | - | 58.5 | 39.7 |

| Alloy | Microstructure | 750 °C | Reference | ||

|---|---|---|---|---|---|

| YS (Mpa) | UTS (Mpa) | δ (%) | |||

| Ti-45Al-7Nb-0.3W | Duplex | 570 | 760 | 8 | [20] |

| Ti-43Al-2Cr-2Mn-0.2Y | Nearly lamellar | - | 410 | 43 | [28] |

| Ti-44Al-8Nb-(W,B,Y) | Nearly lamellar | - | 980 | 13 | [41] |

| Ti-43Al-9V-0.2Y | Duplex | 419 | 467 | 53 | Current alloy |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Wang, X.; Kong, F.; Chen, Y. Dynamic Recrystallization of the Constituent γ Phase and Mechanical Properties of Ti-43Al-9V-0.2Y Alloy Sheet. Materials 2017, 10, 1089. https://doi.org/10.3390/ma10091089

Zhang Y, Wang X, Kong F, Chen Y. Dynamic Recrystallization of the Constituent γ Phase and Mechanical Properties of Ti-43Al-9V-0.2Y Alloy Sheet. Materials. 2017; 10(9):1089. https://doi.org/10.3390/ma10091089

Chicago/Turabian StyleZhang, Yu, Xiaopeng Wang, Fantao Kong, and Yuyong Chen. 2017. "Dynamic Recrystallization of the Constituent γ Phase and Mechanical Properties of Ti-43Al-9V-0.2Y Alloy Sheet" Materials 10, no. 9: 1089. https://doi.org/10.3390/ma10091089