Bonding Behavior of Deformed Steel Rebars in Sustainable Concrete Containing both Fine and Coarse Recycled Aggregates

Abstract

:1. Introduction

2. Experimental Program

2.1. Materials

2.1.1. Aggregate

2.1.2. Binder

2.1.3. Mix Proportions

2.1.4. Steel Rebars

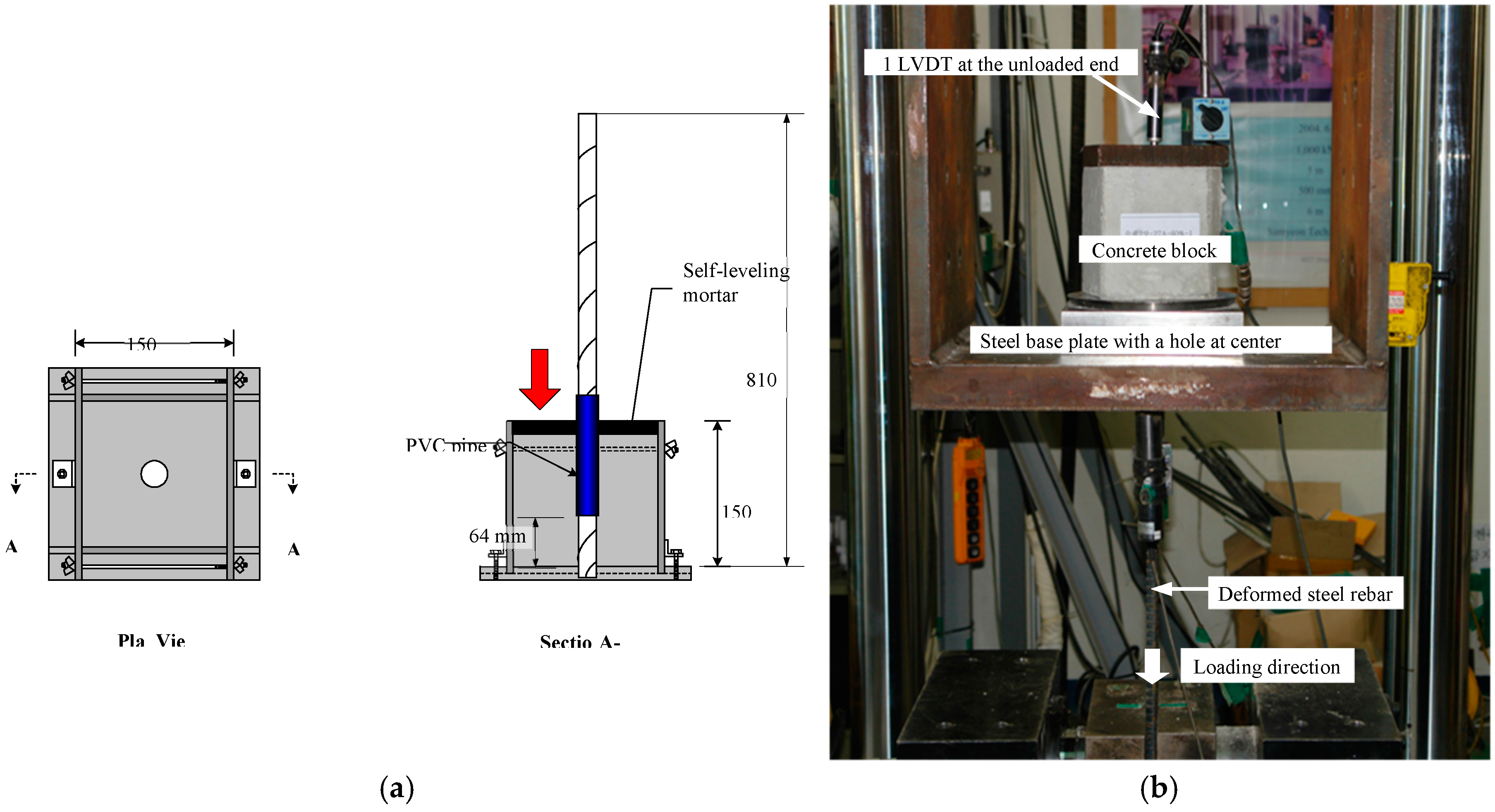

2.2. Pull-Out Specimen and Test Method

- V type: To evaluate bond behavior of vertical reinforcement in concrete, a deformed bar was vertically installed at the center of each specimen.

- H type: To evaluate bond behavior of horizontal reinforcement in concrete, deformed bars were horizontally installed at depths of 75 (HB), 225 mm (HT) from the bottom of the specimen.

- R type: To evaluate the experimental modification factor related to top-cast rebars and the bond slip in pull-out test specimens, deformed bars were horizontally installed at depths of 75 (RB), 225 (RM) and 375 mm (RT) from the bottom of the specimen.

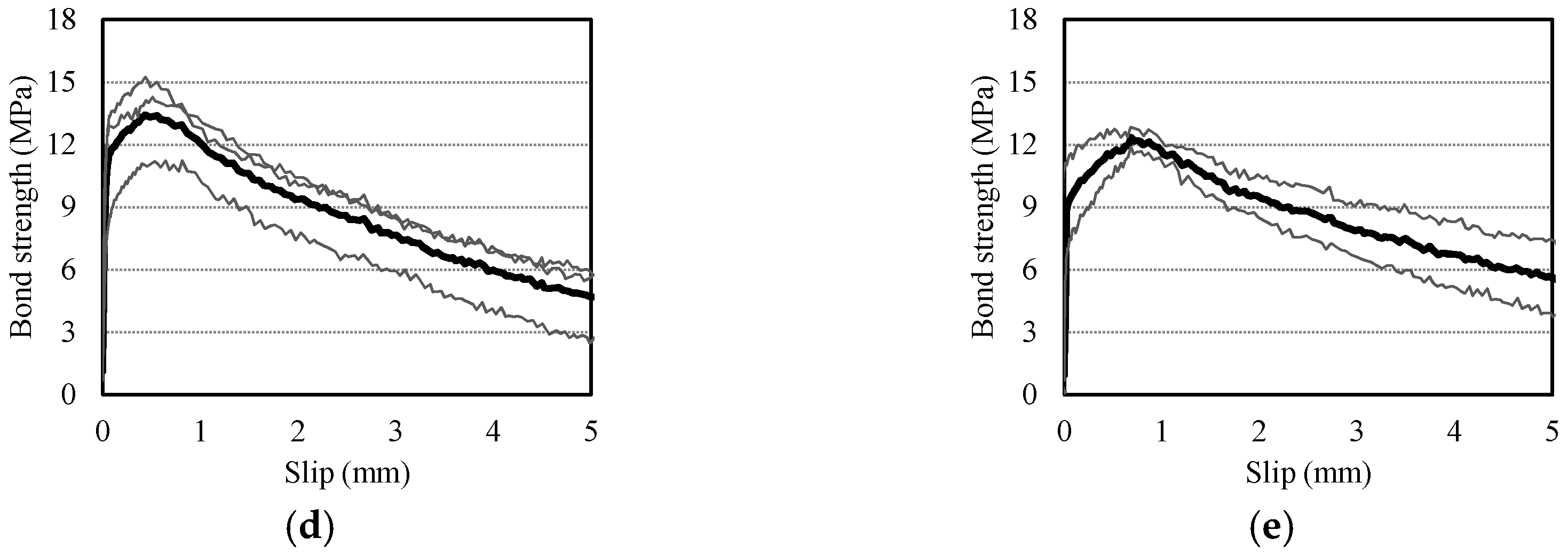

3. Results and Discussion

3.1. Mechanical Properties of Concrete

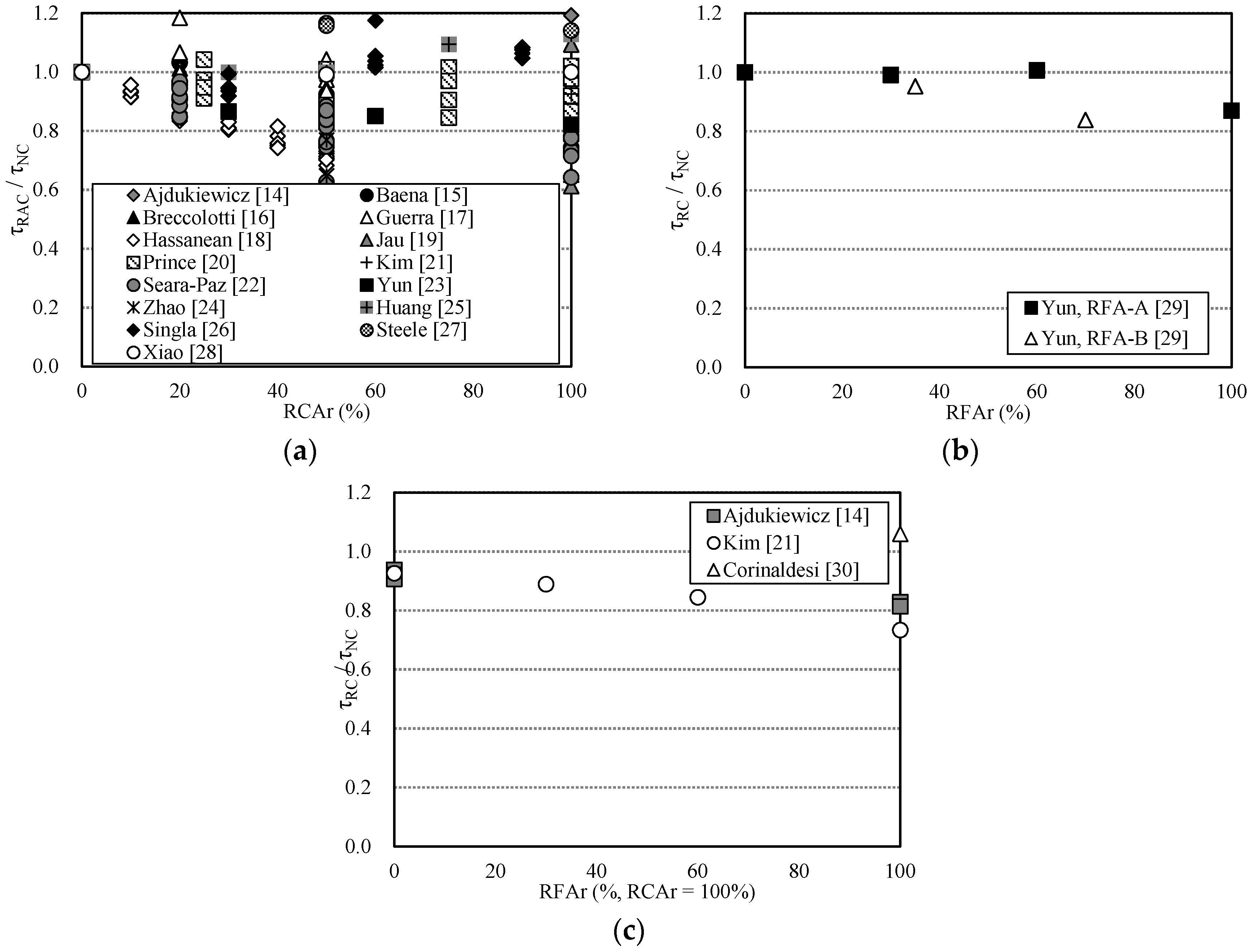

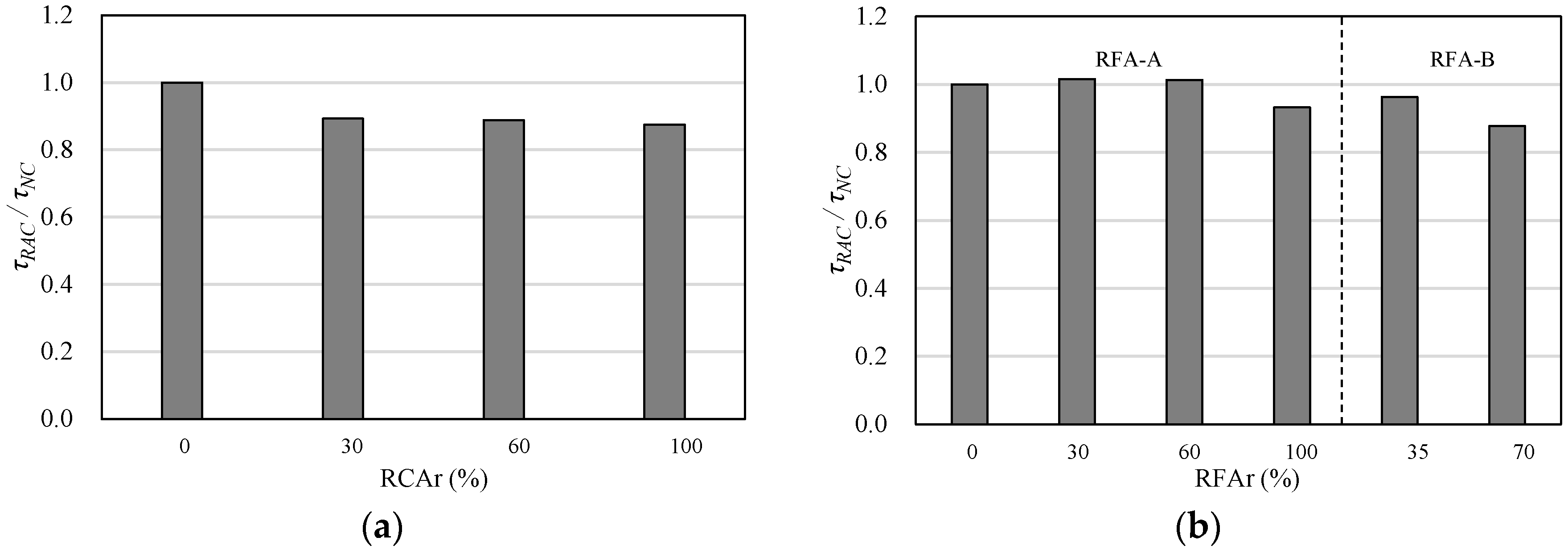

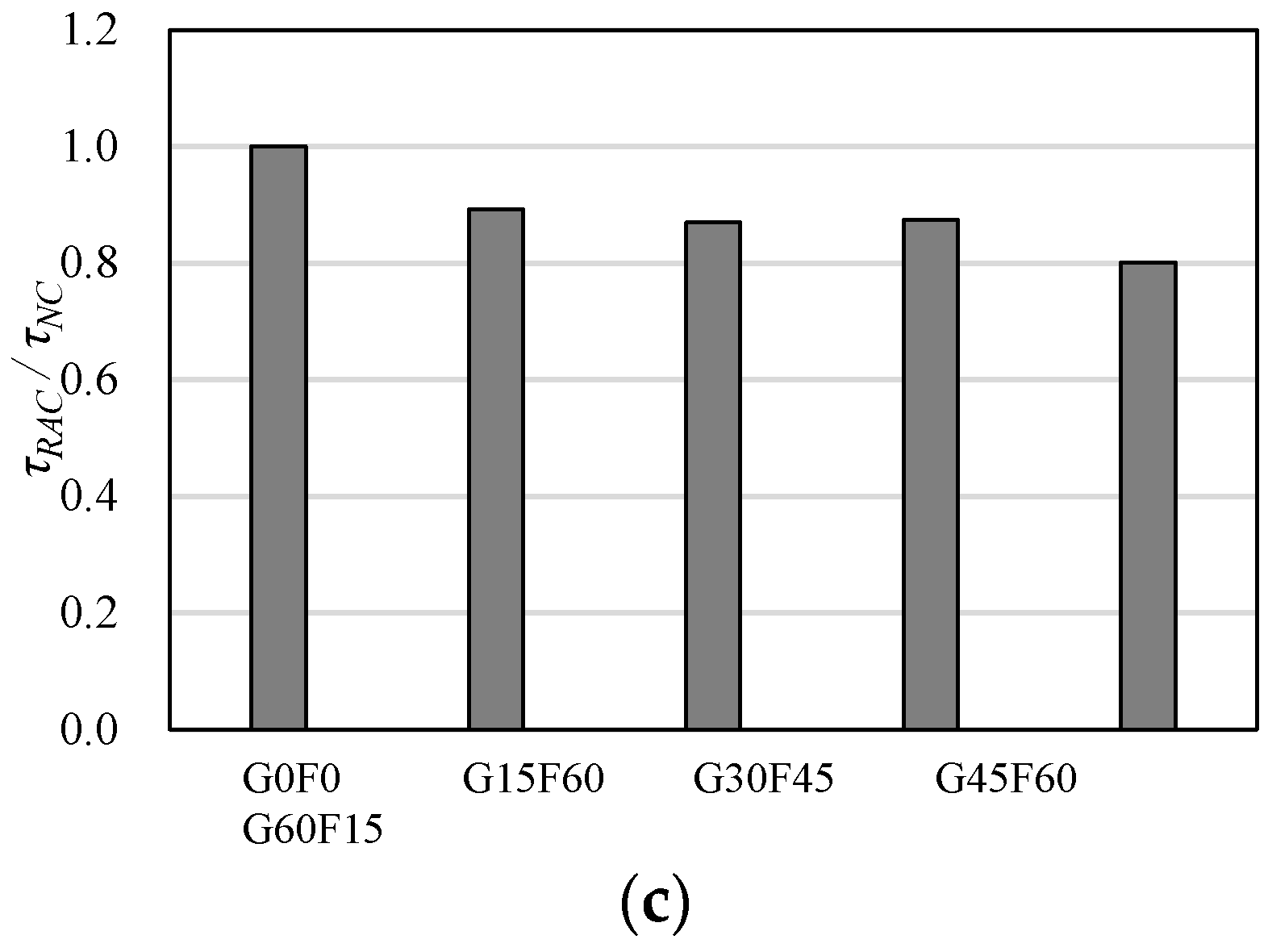

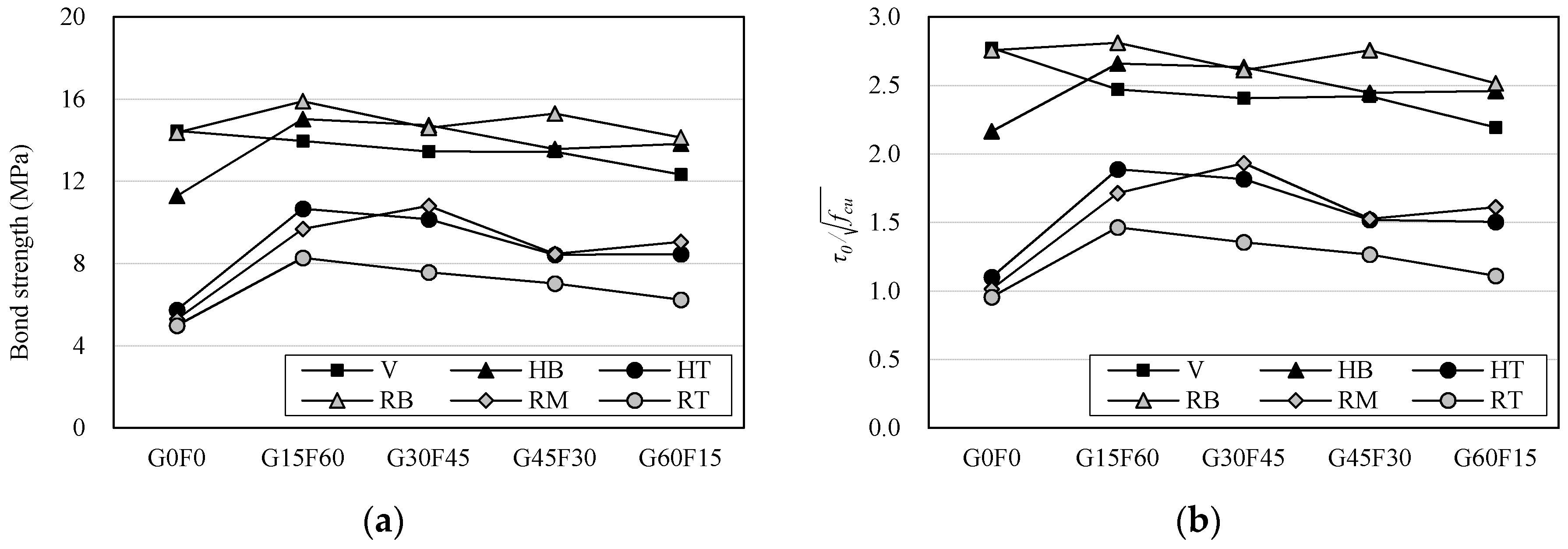

3.2. Effect of Recycled-Aggregate Replacement Level on Bond Strength

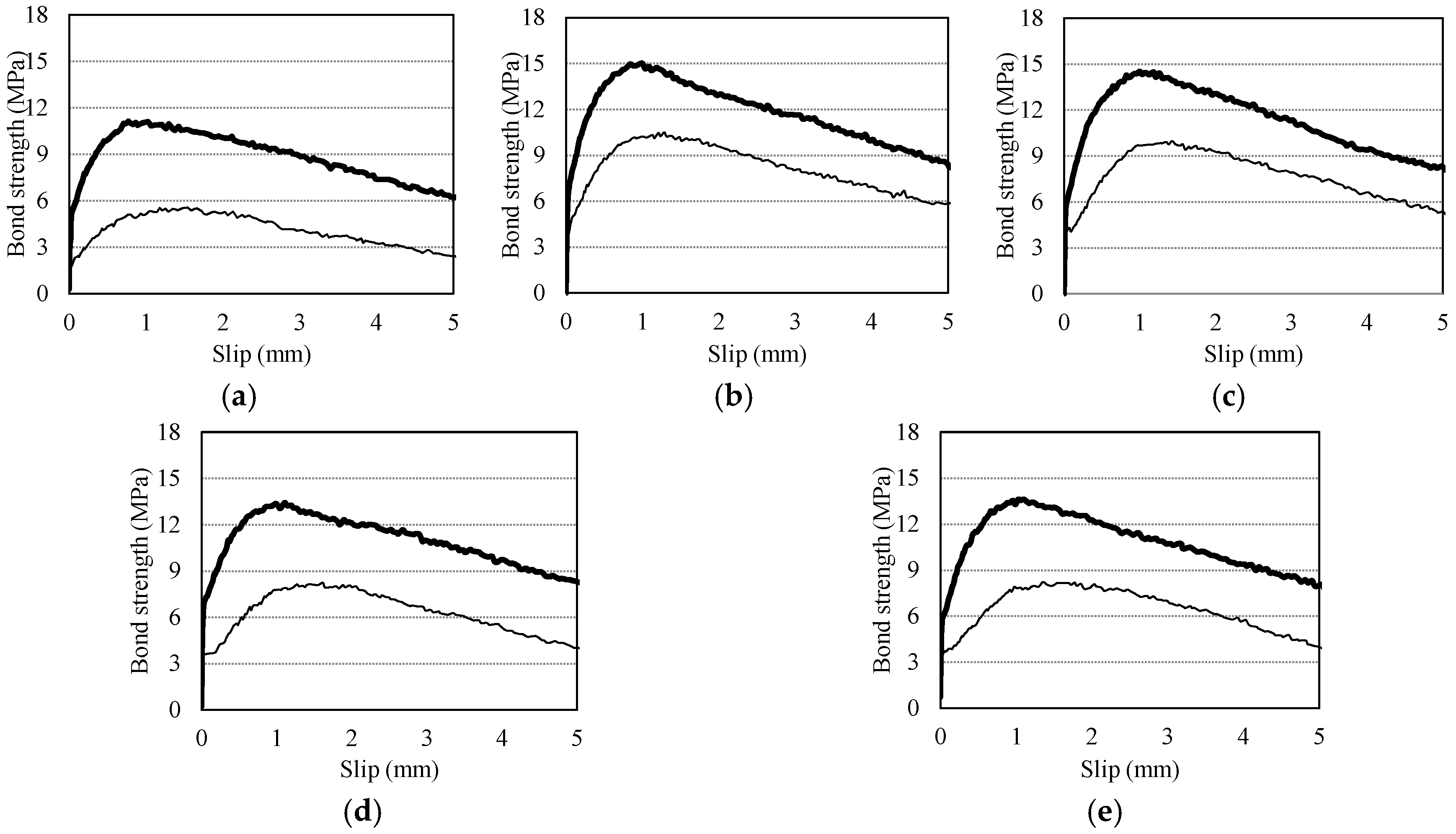

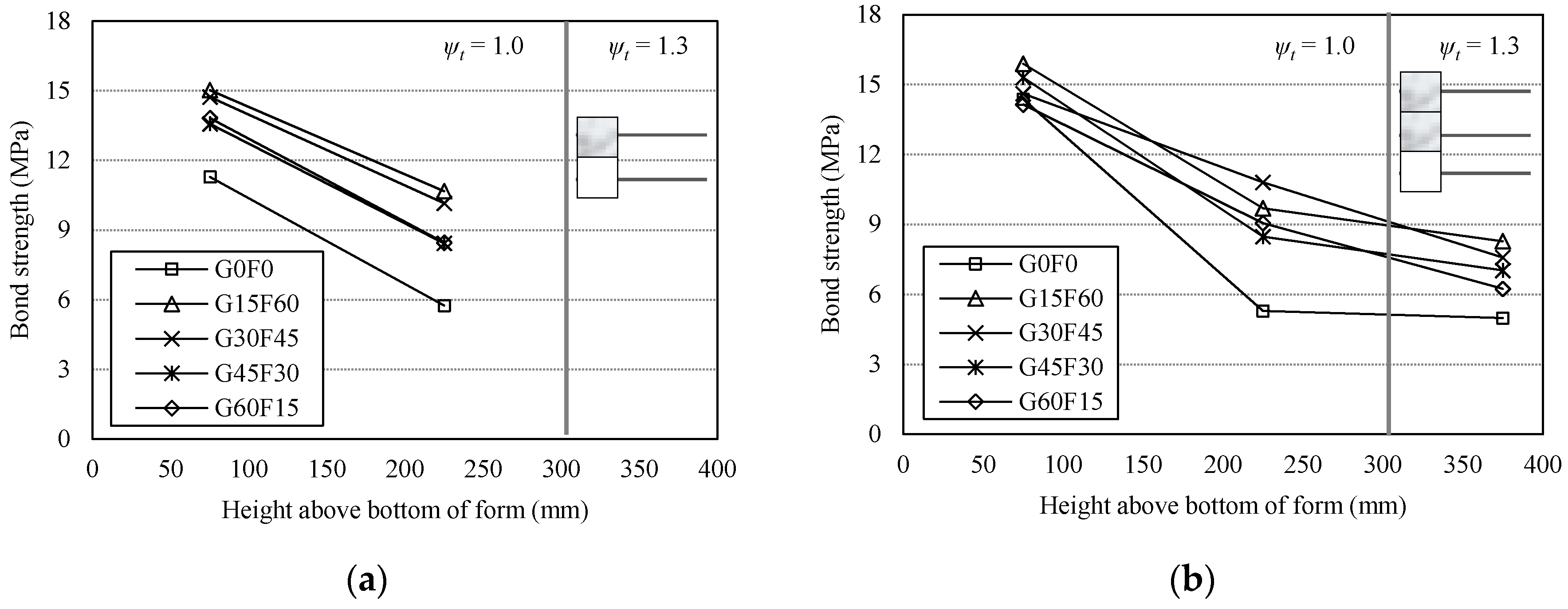

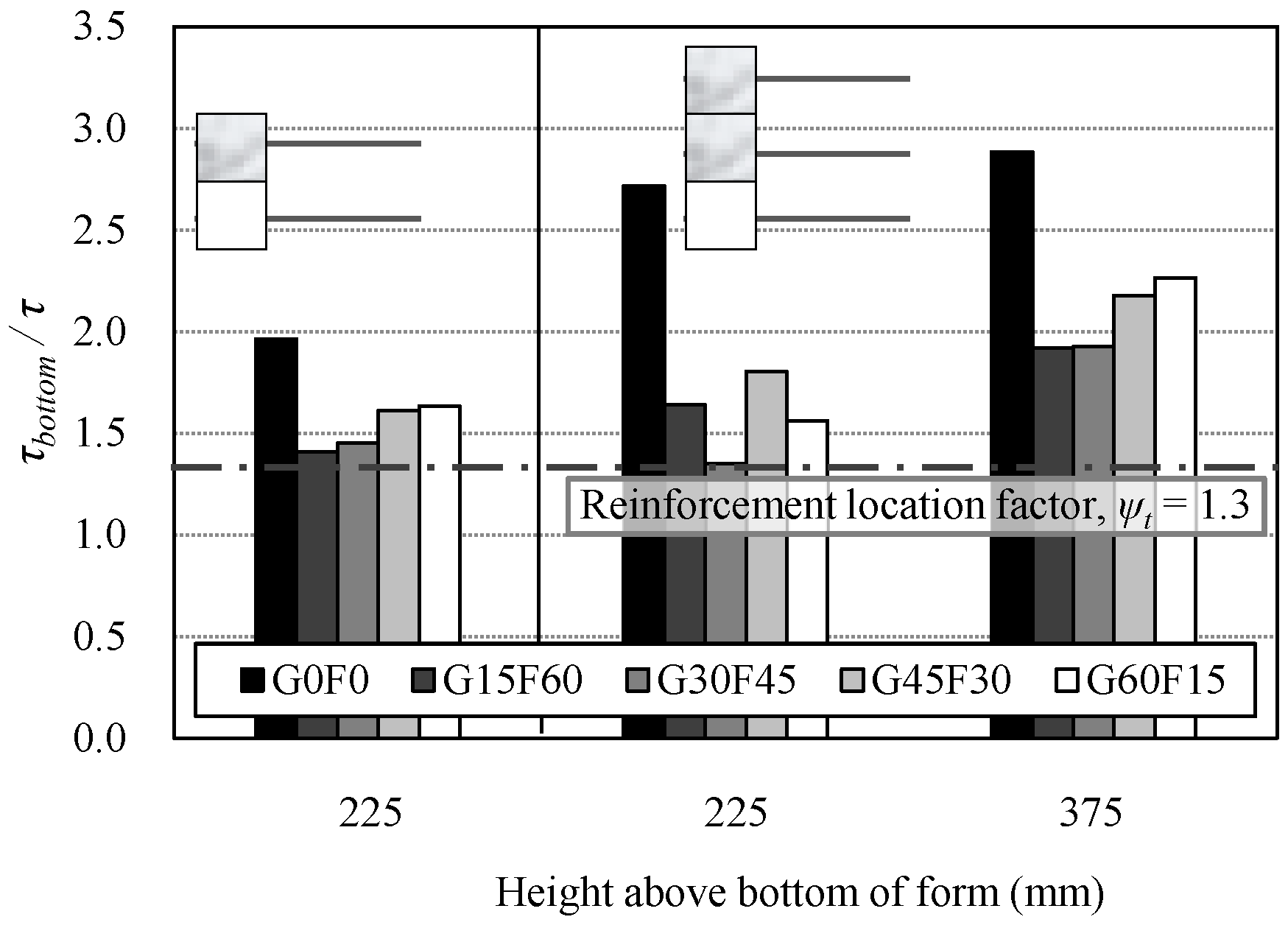

3.3. Casting Position Effect between Horizontal Rebars and RAC

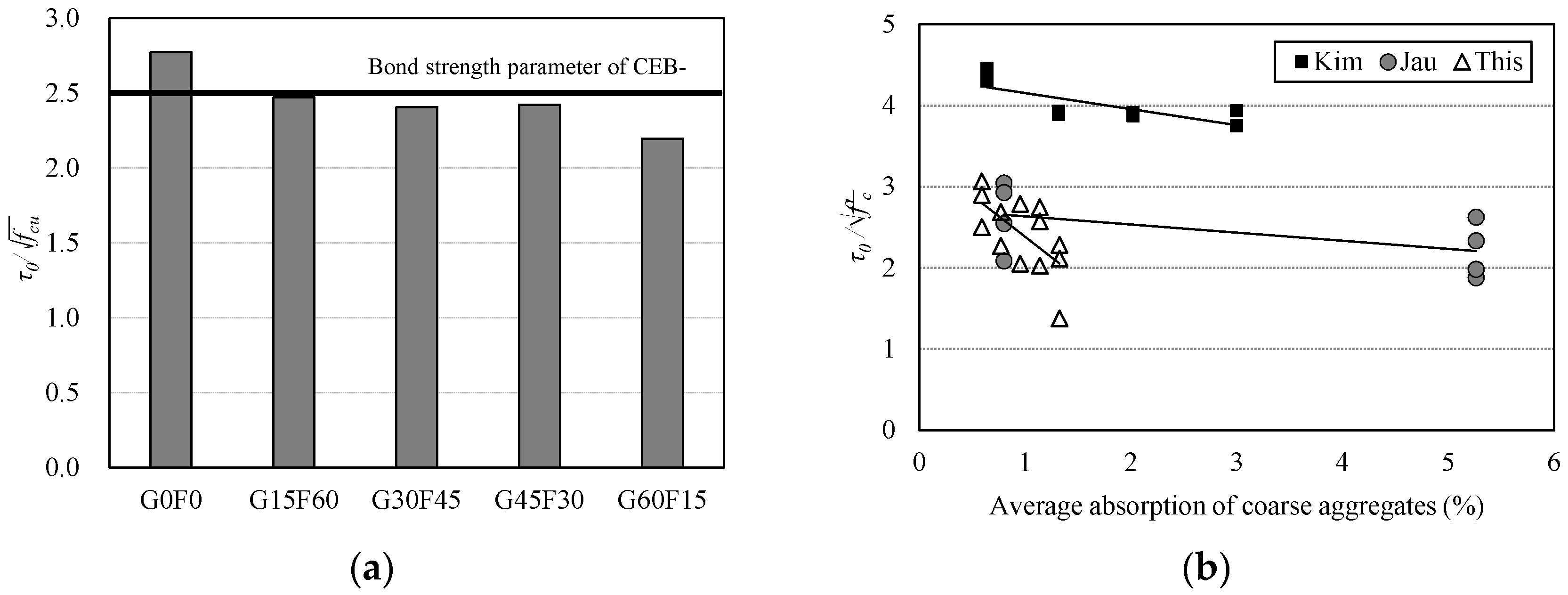

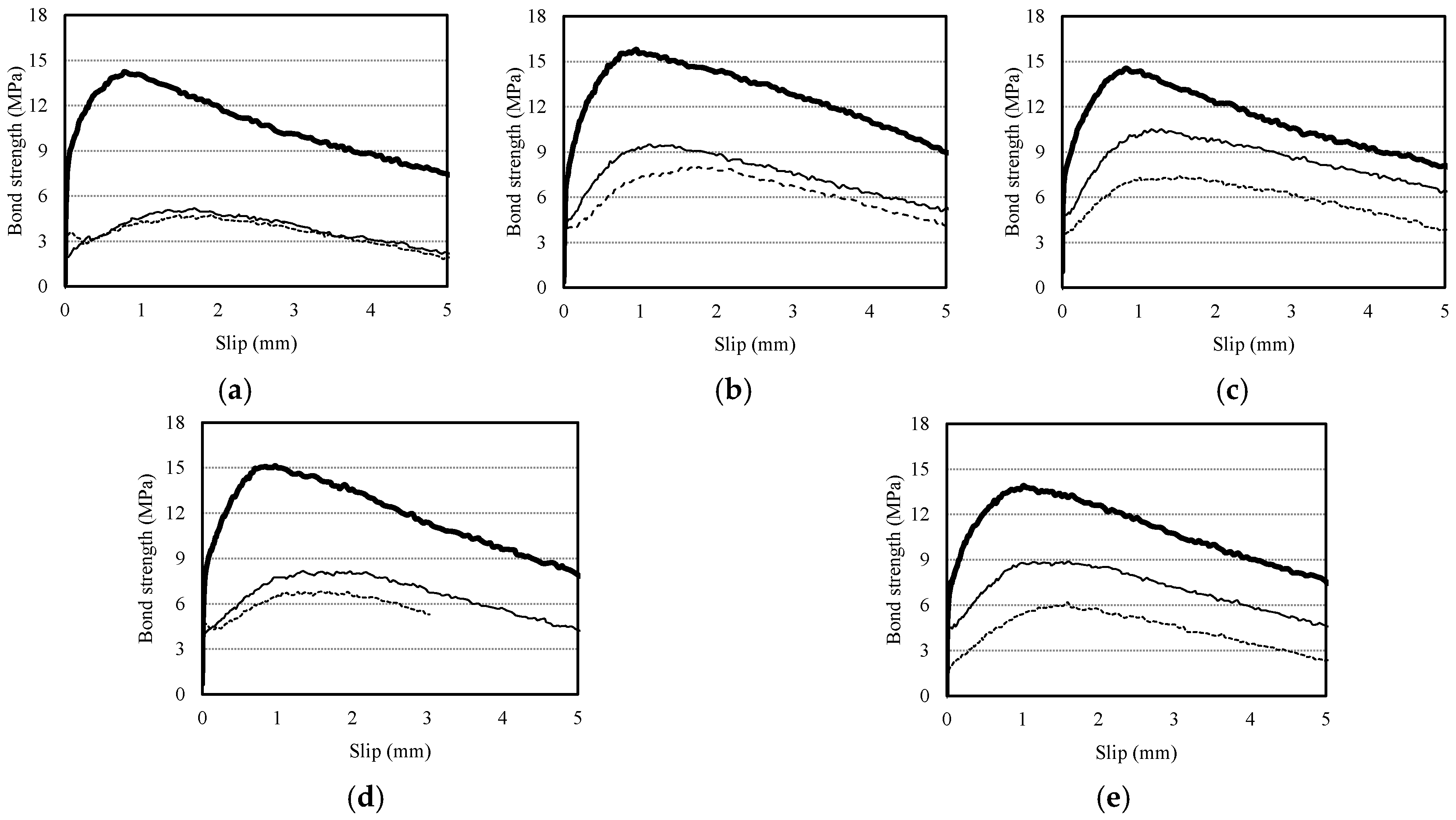

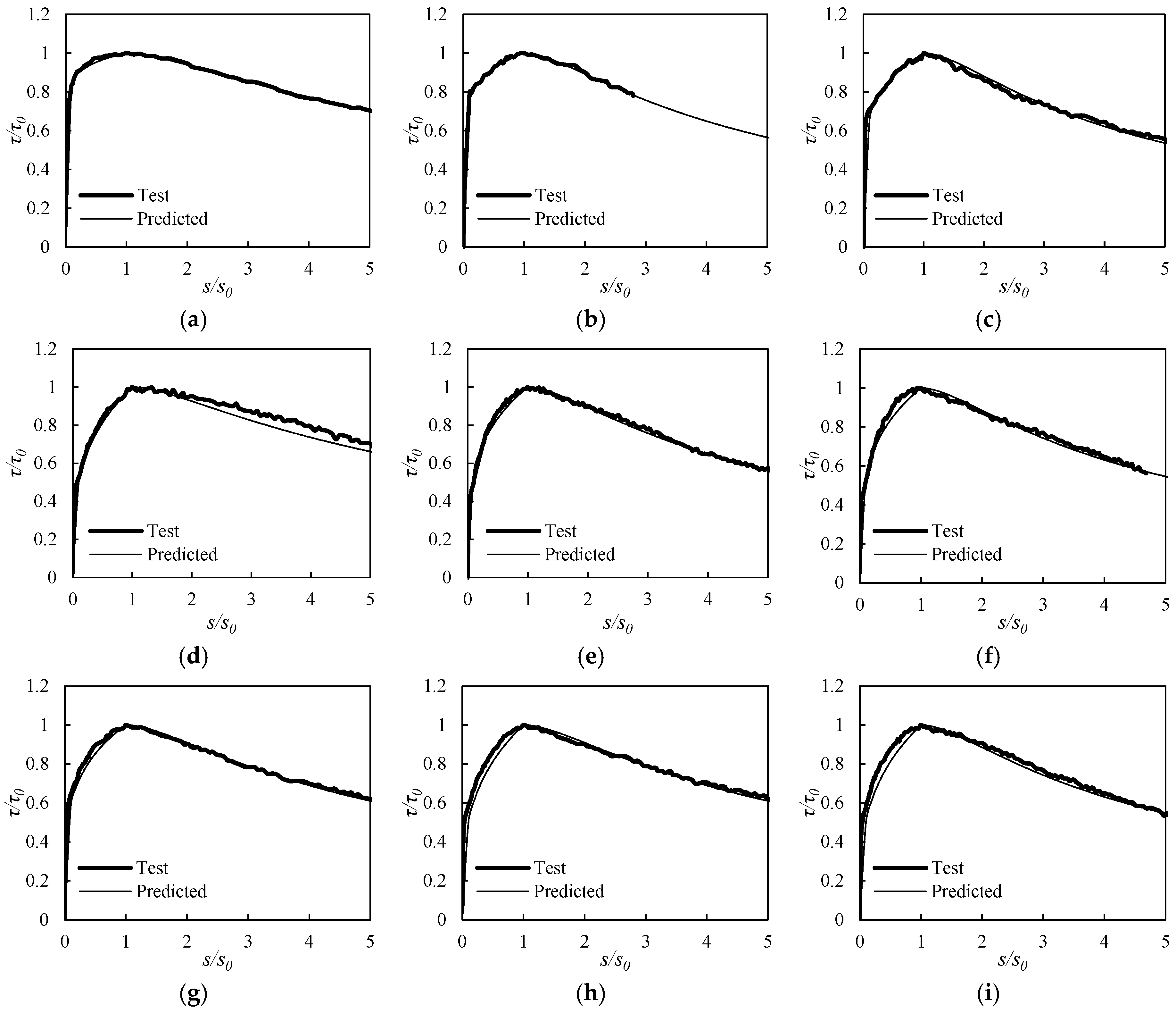

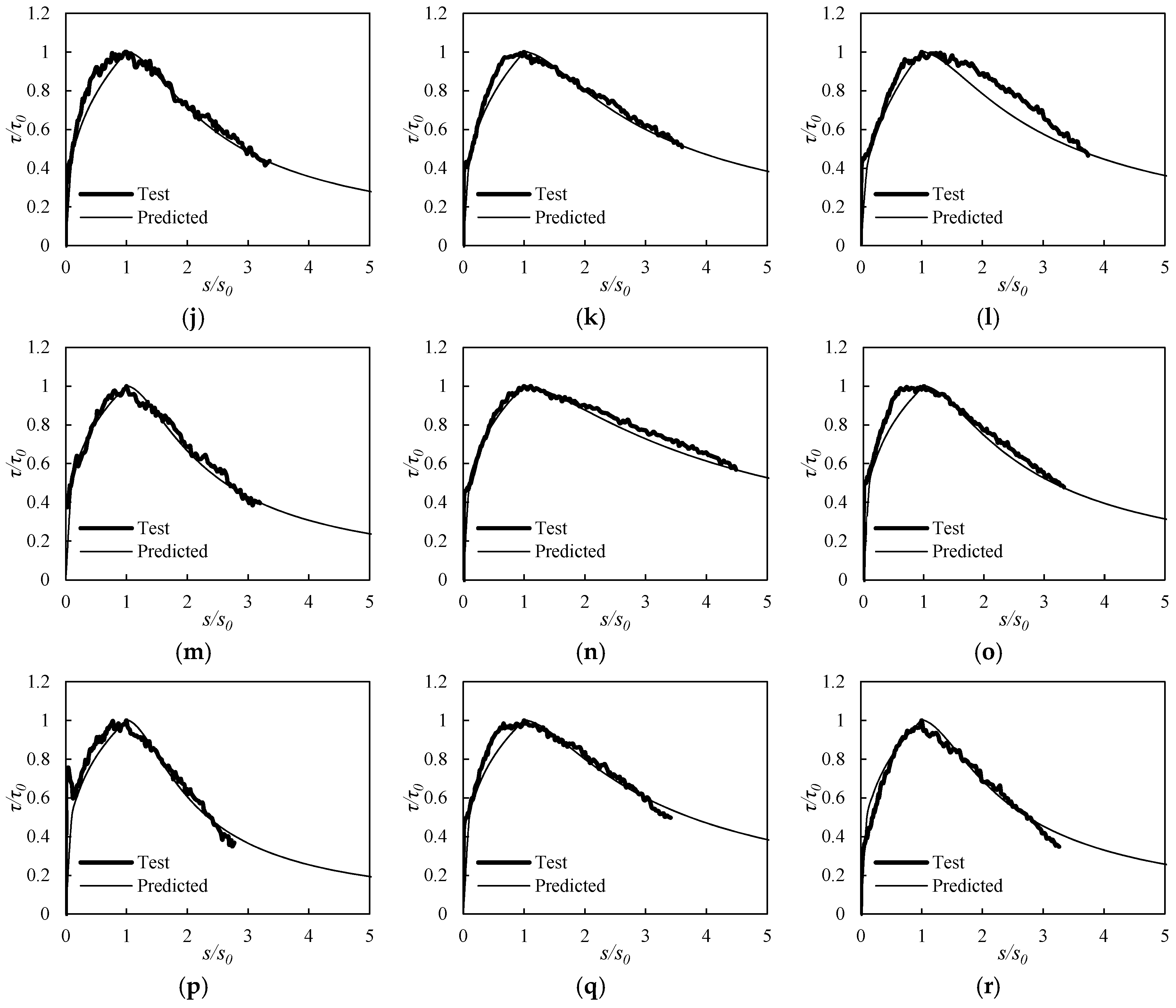

3.4. Analytical Predictions for Bond-Slip Relationship of RAC

4. Conclusions

- (1)

- The maximum bond strength (τ0) tends to decrease and the slip at the maximum bond strength (s0) increases as the recycled coarse aggregate replacement level increases, irrespective of the rebar orientation and placement location.

- (2)

- For the effect of recycled-coarse aggregate on the bond strength, water absorption of the coarse aggregate is more considerable than their replacement level.

- (3)

- In case of the three-tiered specimens, the bond strength levels at the middle height (225 mm depth) are similar to those of the top rebar in case of the two-tiered specimens. Therefore it can be inferred that the top bar effect can be found from the mid-height of a member, irrespective of the member’s height.

- (4)

- It can be concluded that the recycled aggregate concrete mixtures used in this study could be used in actual construction practices that employ ready-mixed concrete.

Author Contributions

Conflicts of Interest

References

- Ministry of Government Legislation. A Law on Recycling for Construction Waste. 2003. Available online: http://www.moleg.go.kr (accessed on 17 August 2017).

- Ministry of Environment. Statics on Waste Occurrence and Disposal. 2012. Available online: http://www.me.go.kr (accessed on 17 August 2017).

- Ministry of Land, Infrastructure and Transport. Recycled Aggregate Quality Standard. 2003. Available online: http://www.molit.go.kr (accessed on 17 August 2017).

- Oikonomou, N.D. Recycled concrete aggregates. Cem. Concr. Compos. 2005, 27, 315–318. [Google Scholar] [CrossRef]

- Zhou, C.; Chen, Z. Mechanical properties of recycled concrete made with different types of coarse aggregate. Constr. Build. Mater. 2017, 134, 497–506. [Google Scholar] [CrossRef]

- Rahal, K. Mechanical properties of concrete with recycled coarse aggregate. Build. Environ. 2007, 42, 407–415. [Google Scholar] [CrossRef]

- Sri Ravindrarajah, R.; Tam, C.T. Properties of concrete made with crushed concrete as coarse aggregate. Mag. Concr. Res. 1985, 37, 29–38. [Google Scholar] [CrossRef]

- Lotfy, A.; Al-Fayez, M. Performance evaluation of structural concrete using controlled quality coarse and fine recycled concrete aggregate. Cem. Concr. Compos. 2015, 61, 36–43. [Google Scholar] [CrossRef]

- Fan, C.C.; Huang, R.; Hwang, H.; Chao, S.J. The effects of different fine recycled concrete aggregates on the properties of mortar. Materials 2015, 8, 2658–2672. [Google Scholar] [CrossRef]

- Pereira, P.; Evangelista, L.; de Brito, J. The effect of superplasticizers on the mechanical performance of concrete made with fine recycled concrete aggregates. Cem. Concr. Compos. 2012, 34, 1044–1052. [Google Scholar] [CrossRef]

- Evangelista, L.; Guedes, M.; de Brito, J.; Ferro, A.C.; Pereira, M.F. Physical, chemical and mineralogical properties of fine recycled aggregates made from concrete waste. Constr. Build. Mater. 2015, 86, 178–188. [Google Scholar] [CrossRef]

- Evangelista, L.; de Brito, J. Mechanical behaviour of concrete made with fine recycled concrete aggregates. Cem. Concr. Compos. 2007, 29, 397–401. [Google Scholar] [CrossRef]

- Khoshkenari, A.G.; Shafigh, P.; Moghimi, M.; Mahmud, H.B. The role of 0–2 mm fine recycled concrete aggregate on the compressive and splitting tensile strengths of recycled concrete aggregate concrete. Mater. Des. 2014, 64, 345–354. [Google Scholar] [CrossRef]

- Ajdukiewicz, A.; Kliszczewicz, A. Influence of recycled aggregates on mechanical properties of HS/HPC. Cem. Concr. Compos. 2002, 24, 269–279. [Google Scholar] [CrossRef]

- Baena, M.; Torres, L.; Turaon, A.; Barris, C.; Mias, C. Experimental study on the bond behaviour between recycled aggregate concrete and fibre reinforced polymer bars. In Proceedings of the Ninth International Symposium on Fiber Reinforced Polymer Reinforcement for Concrete Structures, Sydney, Australia, 13–15 July 2009. [Google Scholar]

- Breccolotti, M.; Materazzi, A.L. Structural reliability of bonding between steel rebars and recycled aggregate concrete. Constr. Build. Mater. 2013, 47, 927–934. [Google Scholar] [CrossRef]

- Guerra, M.; Ceia, F.; de Brito, J.; Júlio, E. Anchorage of steel rebars to recycled aggregates concrete. Constr. Build. Mater. 2014, 72, 113–123. [Google Scholar] [CrossRef]

- Hassanean, Y.A.; Rashwan, M.M.; Assaf, K.A.; Samee, K.A. Influence of size and replacement ratio of recycled concrete aggregate on concrete properties. J. Eng. Sci. 2013, 42, 50–63. [Google Scholar]

- Jau, W.C.; Fu, C.W.; Yang, C.T. Study of feasibility and mechanical properties for producing high-flowing concrete with recycled coarse aggregates. In Proceedings of the International Workshop on Sustainable Development and Concrete Technology, Beijing, China, 20–21 May 2004; pp. 89–102. [Google Scholar]

- Prince, J.R.M.; Singh, B. Bond behaviour of deformed steel bars embedded in recycled aggregate concrete. Constr. Build. Mater. 2013, 49, 852–862. [Google Scholar] [CrossRef]

- Kim, Y.J.; Sim, J.S.; Park, C.W. Mechanical properties of recycled aggregate concrete with deformed steel re-bar. J. Mar. Sci. Technol. 2012, 20, 274–280. [Google Scholar]

- Seara-Paz, S.; González-Fonteboa, B.; Eiras-López, J.; Herrador, M.F. Bond behavior between steel reinforcement and recycled concrete. Mater. Struct. 2014, 47, 323–334. [Google Scholar] [CrossRef]

- Kim, S.W.; Yun, H.D. Influence of recycled coarse aggregates on the bond behavior of deformed bars in concrete. Eng. Struct. 2013, 48, 133–143. [Google Scholar] [CrossRef]

- Zhao, Y.; Lin, H.; Wu, K.; Jin, W. Bond behaviour of normal/recycled concrete and corroded steel bars. Constr. Build. Mater. 2013, 48, 348–359. [Google Scholar] [CrossRef]

- Huang, Q.; Wang, D. Experimental study on bond-slip between steel bar and recycled aggregate concrete. Adv. Mater. Res. 2011, 250–253, 1651–1656. [Google Scholar] [CrossRef]

- Singla, S. Compressive Strength and Bond Behaviour of Recycled Coarse Aggregate Concrete. Ph.D. Thesis, Thapar University, Patiala, India, 2013. [Google Scholar]

- Steele, A.R. Bond Performance of Recycled Aggregate Concrete. Master’s Thesis, Missouri University of Science and Technology, Rolla, MO, USA, 2014. [Google Scholar]

- Xiao, J.; Falkner, H. Bond behaviour between recycled aggregate concrete and steel rebars. Constr. Build. Mater. 2007, 21, 395–401. [Google Scholar] [CrossRef]

- Kim, S.W.; Yun, H.D. Evaluation of the bond behavior of steel reinforcing bars in recycled fine aggregate concrete. Cem. Concr. Compos. 2014, 46, 8–18. [Google Scholar] [CrossRef]

- Corinaldesi, V.; Moriconi, G. Influence of mineral additions on the performance of 100% recycled aggregate concrete. Constr. Build. Mater. 2009, 23, 2869–2876. [Google Scholar] [CrossRef]

- Orangun, C.O.; Jirsa, I.O.; Breen, J.E. A reevaluation of test data on development length and splices. ACI J. 1977, 74, 114–122. [Google Scholar]

- Darwin, D.; McCabe, S.L.; Idun, E.K.; Schoenekase, S.P. Development length criteria: Bars not confined by transverse reinforcement. ACI Struct. J. 1992, 89, 709–720. [Google Scholar]

- Comité Euro-International du Béton, and the Fédération Internationale de la Précontrainte. CEB-FIP Model Code 1990; Thomas Telford: Lausanne, Switzerland, 1993. [Google Scholar]

- ACI Committee 318. Building Code for Structural Concrete (318R–2014) and Commentary (318R–2014); American Concrete Institute: Farmington Hills, MI, USA, 2014. [Google Scholar]

- Canadian Standards Association (CSA). Design of Concrete Structures; CSA CAN3-A23.3; Canadian Standards Association: Rexdale, ON, Canada, 2004. [Google Scholar]

- Korea Agency for Technology and Standards. Korean Industrial Standards. 2005. Available online: http://www.kssn.net/english (accessed on 17 August 2017).

- Bamonte, P.F.; Gambarova, P.G. High-bond bars in NSC and HPC: Study on size effect and on the local bond stress-slip law. J. Struct. Eng. 2007, 133, 225–234. [Google Scholar] [CrossRef]

- ASTM C234-91a. Standard Test Method for Comparing Concrete on the Basis of the Bond Developed with Reinforcing Steel; ASTM International: West Conshohocken, PA, USA, 1991. [Google Scholar]

- Haraji, M.H. Development/splice strength of reinforcing bars embedded in plain and fiber reinforced concrete. ACI Struct. J. 1994, 91, 511–520. [Google Scholar]

- Guo, Z. Strength and Deformation of Concrete—Experimental Foundation and Constitutive Relationship; Press of Tsinghua University: Beijing, China, 1997. [Google Scholar]

| Aggregate | Maximum Grain Size (mm) | Density (g/cm3) | Water Absorption (%) | Fineness Modulus |

|---|---|---|---|---|

| NCA | 25 | 2.68 | 0.59 | 6.66 |

| RCA | 25 | 2.51 | 1.84 | 5.40 |

| NFA | 5 | 2.46 | 2.70 | 2.53 |

| RFA | 5 | 2.35 | 4.43 | 2.99 |

| Mix. | Recycled-Aggregate Replacement Level (%) | W/C | S/a | Unit Weight (kg/m3) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| RCA | RFA | W | C | NCA | RCA | NFA | RFA | AD | |||

| G0F0 | 0 | 0 | 0.41 | 0.46 | 180 | 435 | 884 | 0 | 730 | 0 | 2.18 |

| G15F60 | 15 | 60 | 180 | 435 | 790 | 133 | 307 | 438 | 2.18 | ||

| G30F45 | 30 | 45 | 177 | 435 | 650 | 265 | 422 | 328 | 2.18 | ||

| G45F30 | 45 | 30 | 177 | 435 | 511 | 398 | 538 | 219 | 2.18 | ||

| G60F15 | 60 | 15 | 177 | 435 | 372 | 530 | 653 | 109 | 2.18 | ||

| Specimen | fck (MPa) | Rebar Orientation and Placement | |||||

|---|---|---|---|---|---|---|---|

| V | HB | HT | RB | RM | RT | ||

| G0F0 | 27 | 3 | 3 | 3 | 3 | 3 | 3 |

| G15F60 | 3 | 3 | 3 | 3 | 3 | 3 | |

| G30F45 | 3 | 3 | 3 | 3 | 3 | 3 | |

| G45F30 | 3 | 3 | 3 | 3 | 3 | 3 | |

| G60F15 | 3 | 3 | 3 | 3 | 3 | 3 | |

| Specimen | fcu (MPa) | εcu (×10−6) | Ec (GPa) | fsp (MPa) | λ |

|---|---|---|---|---|---|

| G0F0 | 27.2 | 1905 | 24.7 | 2.04 | 0.70 |

| G15F60 | 32.0 | 1937 | 23.8 | 2.50 | 0.80 |

| G30F45 | 31.3 | 1942 | 24.9 | 2.33 | 0.75 |

| G45F30 | 30.8 | 2065 | 23.4 | 2.48 | 0.80 |

| G60F15 | 31.6 | 2002 | 23.8 | 2.31 | 0.74 |

| Specimen | τ0 (MPa) | s0 (mm) | S.D. 1 (MPa) | C.V. 2 (%) | Calculated Bond Strength (MPa) | |||

|---|---|---|---|---|---|---|---|---|

| Orangun | Darwin | CEB-FIP | ||||||

| G0F0 | 14.46 | 0.48 | 2.77 | 1.23 | 8.54 | 11.37 | 12.42 | 13.03 |

| G15F60 | 13.97 | 0.84 | 2.47 | 1.18 | 8.42 | 12.33 | 13.47 | 14.13 |

| G30F45 | 13.46 | 0.63 | 2.41 | 2.06 | 15.28 | 12.20 | 13.32 | 13.98 |

| G45F30 | 13.44 | 0.43 | 2.42 | 1.71 | 12.72 | 12.10 | 13.22 | 13.87 |

| G60F15 | 12.34 | 0.69 | 2.22 | 0.47 | 3.82 | 12.27 | 13.41 | 14.07 |

| Unconfined Concrete 1 | Confined Concrete 2 | ||

|---|---|---|---|

| Good Bond Conditions | All Other Bond Conditions | Good Bond Conditions | All Other Bond Conditions |

| Concrete Type | Maximum Grain Size (mm) | Specific Gravity | Water Absorption (%) | (MPa) | |||||

|---|---|---|---|---|---|---|---|---|---|

| Coarse | Fine | RCA | RFA-A | RFA-B | RCA | RFA-A | RFA-B | ||

| RCA (Jau) [19] | 19 | 5 | 2.29 | - | - | 5.26 | - | - | 21–35 |

| RCA (Kim) [23] | 25 | 5 | 2.48 | - | - | 3.01 | - | - | 29–33 |

| RFA (Kim) [29] | 25 | 5 | - | 2.29 | 2.15 | - | 5.83 | 7.95 | 27–32 |

| Specimen | (MPa) | Location | (MPa) | Location Factor | Current Code (MPa) | |

|---|---|---|---|---|---|---|

| ACI | CSA | |||||

| G0F0H | 27.18 | Bottom | 11.29 | 2.71 | 3.39 | |

| Top | 5.75 | 1.96 | 2.08 | 2.60 | ||

| G15F60H | 31.95 | Bottom | 15.04 | 2.94 | 3.67 | |

| Top | 10.67 | 1.41 | 2.26 | 2.82 | ||

| G30F45H | 31.28 | Bottom | 14.74 | 2.91 | 3.63 | |

| Top | 10.16 | 1.45 | 2.24 | 2.79 | ||

| G45F30H | 30.79 | Bottom | 13.58 | 2.88 | 3.60 | |

| Top | 8.43 | 1.61 | 2.22 | 2.77 | ||

| G60F15H | 31.66 | Bottom | 13.83 | 2.92 | 3.65 | |

| Top | 8.46 | 1.63 | 2.25 | 2.81 | ||

| Specimen | (MPa) | Location | (MPa) | Location Factor | Current Code (MPa) | |

|---|---|---|---|---|---|---|

| ACI | CSA | |||||

| G0F0R | 27.18 | Bottom | 14.38 | 2.71 | 3.39 | |

| Middle | 5.29 | 2.72 | ||||

| Top | 4.98 | 2.89 | 2.08 | 2.60 | ||

| G15F60R | 31.95 | Bottom | 15.90 | 2.94 | 3.67 | |

| Middle | 9.69 | 1.64 | ||||

| Top | 8.28 | 1.92 | 2.26 | 2.82 | ||

| G30F45R | 31.28 | Bottom | 14.61 | 2.91 | 3.63 | |

| Middle | 10.81 | 1.35 | ||||

| Top | 7.58 | 1.93 | 2.24 | 2.79 | ||

| G45F30R | 30.79 | Bottom | 15.30 | 2.88 | 3.60 | |

| Middle | 8.48 | 1.81 | ||||

| Top | 7.03 | 2.18 | 2.22 | 2.77 | ||

| G60F15R | 31.66 | Bottom | 14.14 | 2.92 | 3.65 | |

| Middle | 9.06 | 1.56 | ||||

| Top | 6.25 | 2.26 | 2.25 | 2.81 | ||

| Specimen | V | HB | HT | RB | RM | RT |

|---|---|---|---|---|---|---|

| G0F0 | 0.07 | 0.30 | 0.35 | 0.23 | 0.30 | 0.30 |

| G15F60 | 0.18 | 0.23 | 0.35 | 0.30 | 0.30 | 0.30 |

| G30F45 | 0.12 | 0.26 | 0.35 | 0.30 | 0.30 | 0.30 |

| G45F30 | 0.09 | 0.22 | 0.40 | 0.30 | 0.30 | 0.30 |

| G60F15 | 0.18 | 0.26 | 0.40 | 0.30 | 0.30 | 0.30 |

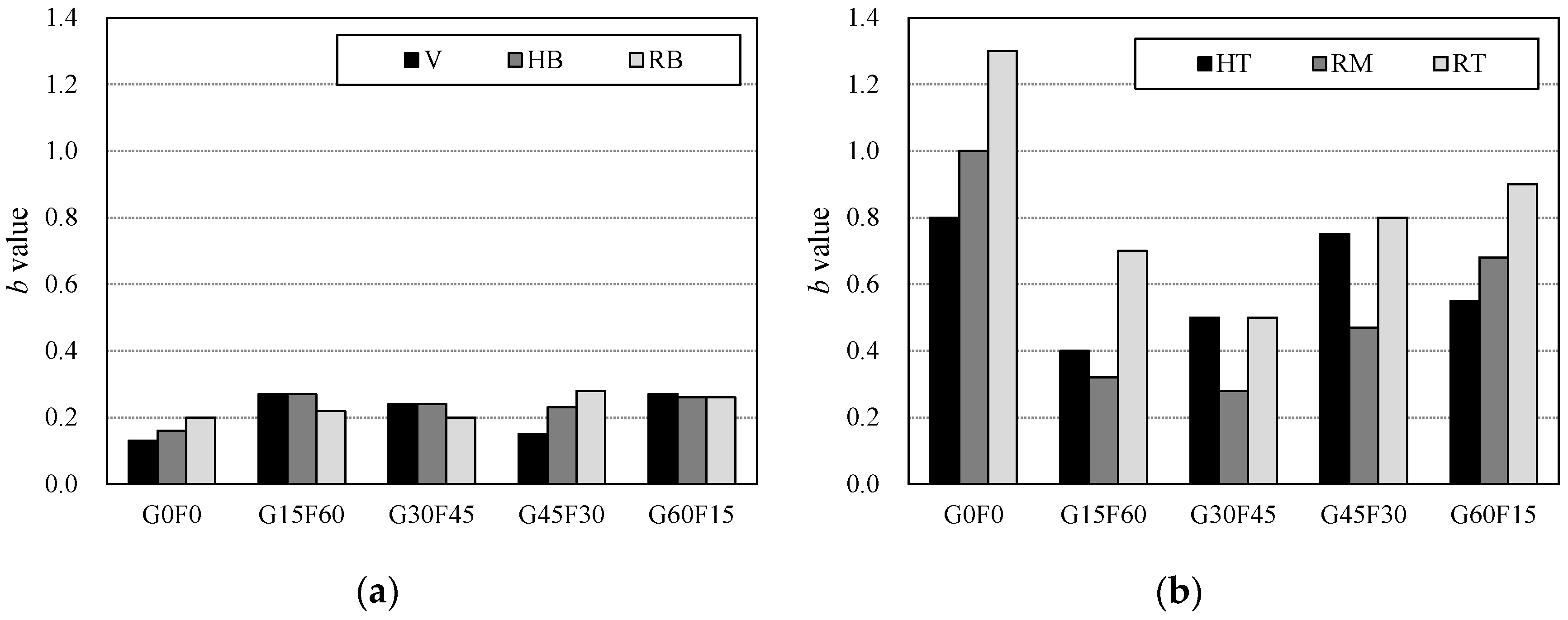

| Specimen | V | HB | HT | RB | RM | RT |

|---|---|---|---|---|---|---|

| G0F0 | 0.13 | 0.16 | 0.80 | 0.20 | 1.00 | 1.30 |

| G15F60 | 0.27 | 0.27 | 0.40 | 0.22 | 0.32 | 0.70 |

| G30F45 | 0.24 | 0.24 | 0.50 | 0.20 | 0.28 | 0.50 |

| G45F30 | 0.15 | 0.23 | 0.75 | 0.28 | 0.47 | 0.80 |

| G60F15 | 0.27 | 0.26 | 0.55 | 0.26 | 0.68 | 0.90 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, S.-W.; Park, W.-S.; Jang, Y.-I.; Jang, S.-J.; Yun, H.-D. Bonding Behavior of Deformed Steel Rebars in Sustainable Concrete Containing both Fine and Coarse Recycled Aggregates. Materials 2017, 10, 1082. https://doi.org/10.3390/ma10091082

Kim S-W, Park W-S, Jang Y-I, Jang S-J, Yun H-D. Bonding Behavior of Deformed Steel Rebars in Sustainable Concrete Containing both Fine and Coarse Recycled Aggregates. Materials. 2017; 10(9):1082. https://doi.org/10.3390/ma10091082

Chicago/Turabian StyleKim, Sun-Woo, Wan-Shin Park, Young-Il Jang, Seok-Joon Jang, and Hyun-Do Yun. 2017. "Bonding Behavior of Deformed Steel Rebars in Sustainable Concrete Containing both Fine and Coarse Recycled Aggregates" Materials 10, no. 9: 1082. https://doi.org/10.3390/ma10091082