Study on Topology Optimization Design, Manufacturability, and Performance Evaluation of Ti-6Al-4V Porous Structures Fabricated by Selective Laser Melting (SLM)

Abstract

:1. Introduction

2. Materials and Methods

2.1. Equipment and Materials

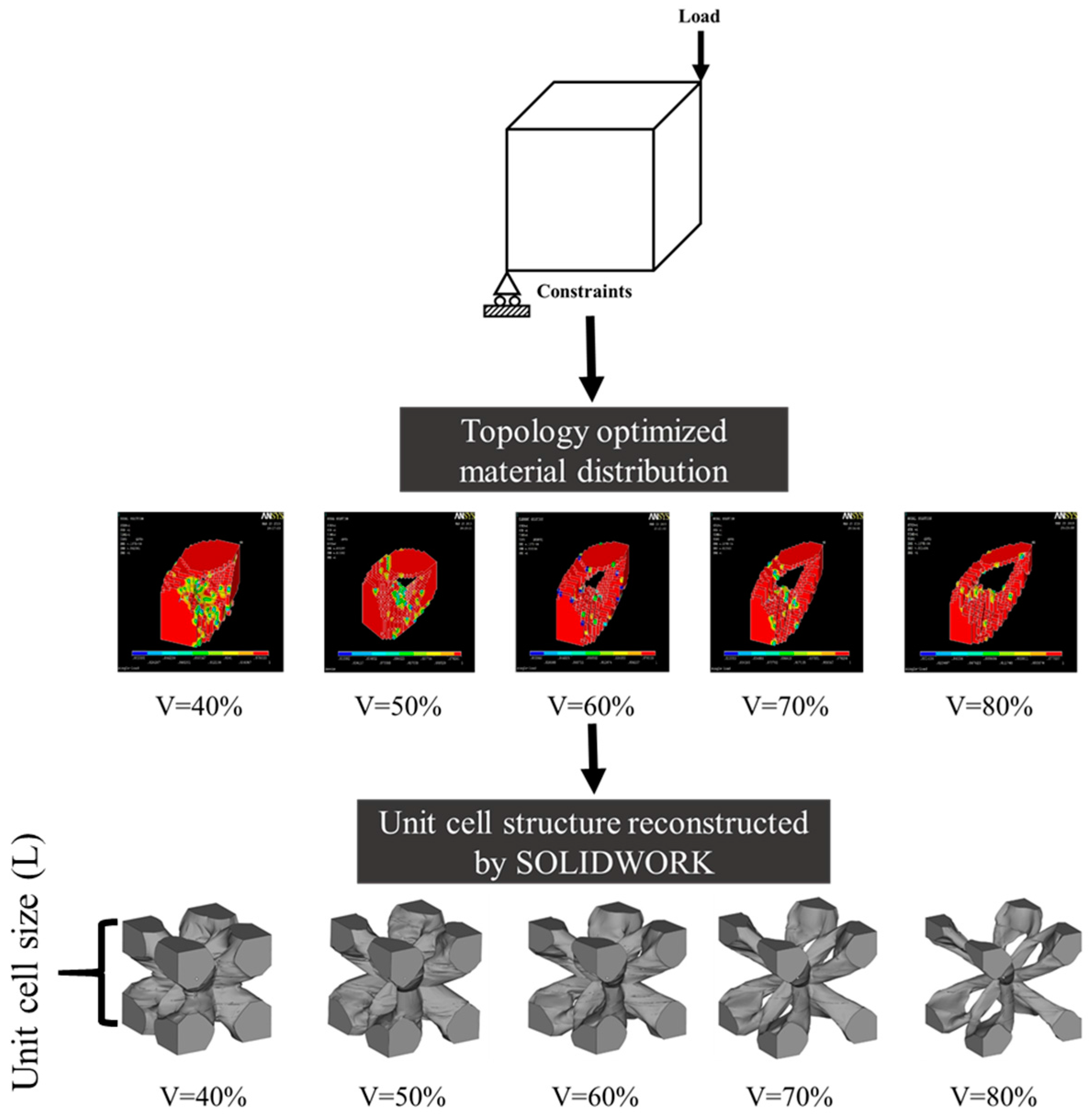

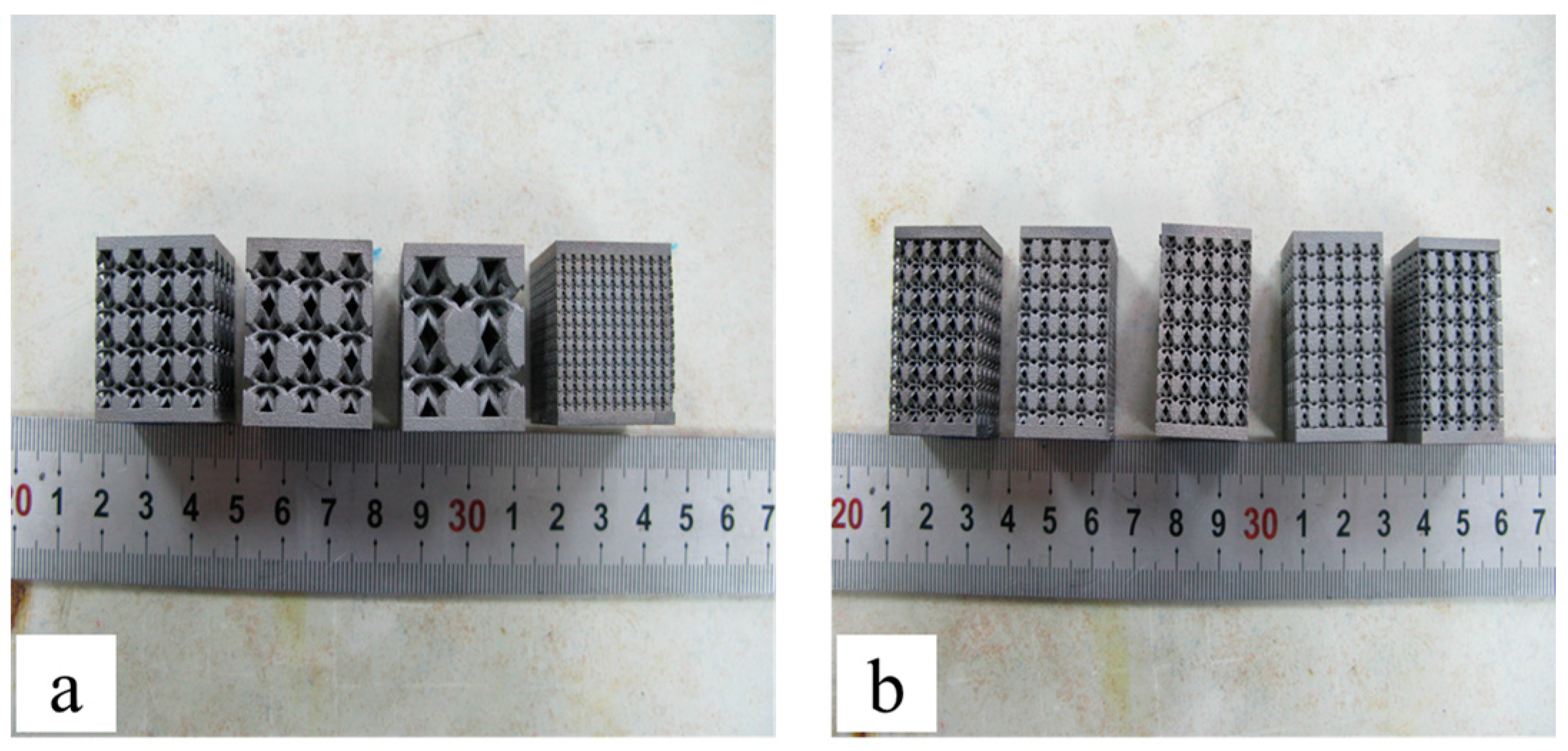

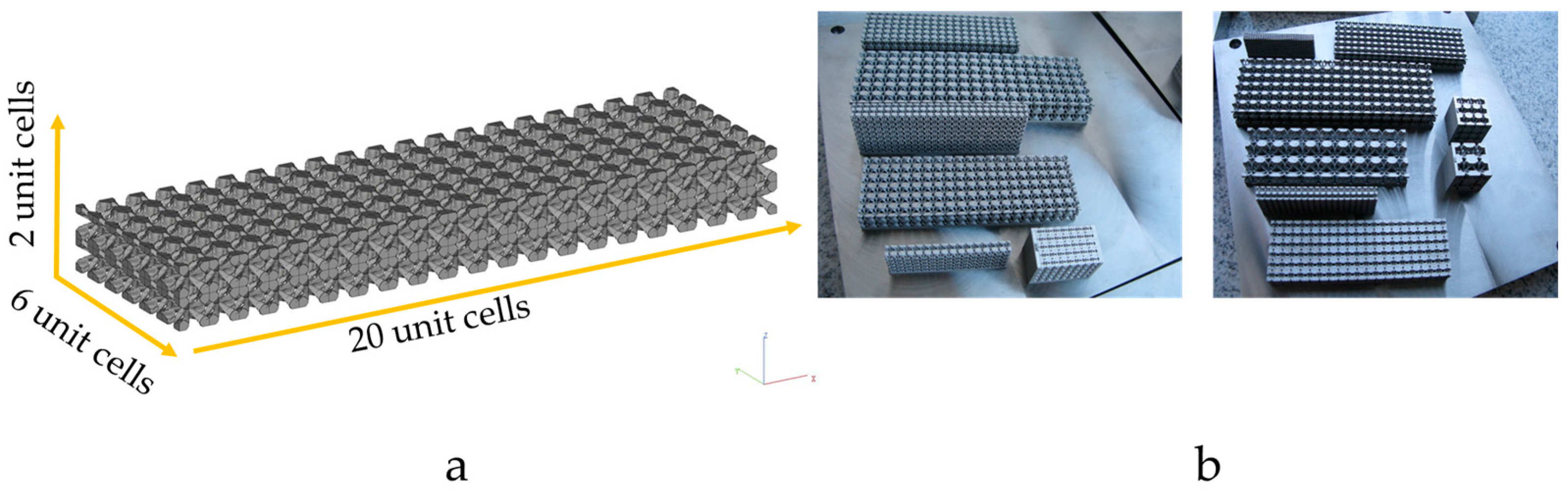

2.2. Design of Unit Cell and Porous Structures Using Topology Optimization

2.3. Compression Test

2.4. Calculation of Porosity and Measurement of Dynamic Elastic Modulus

3. Results and Discussion

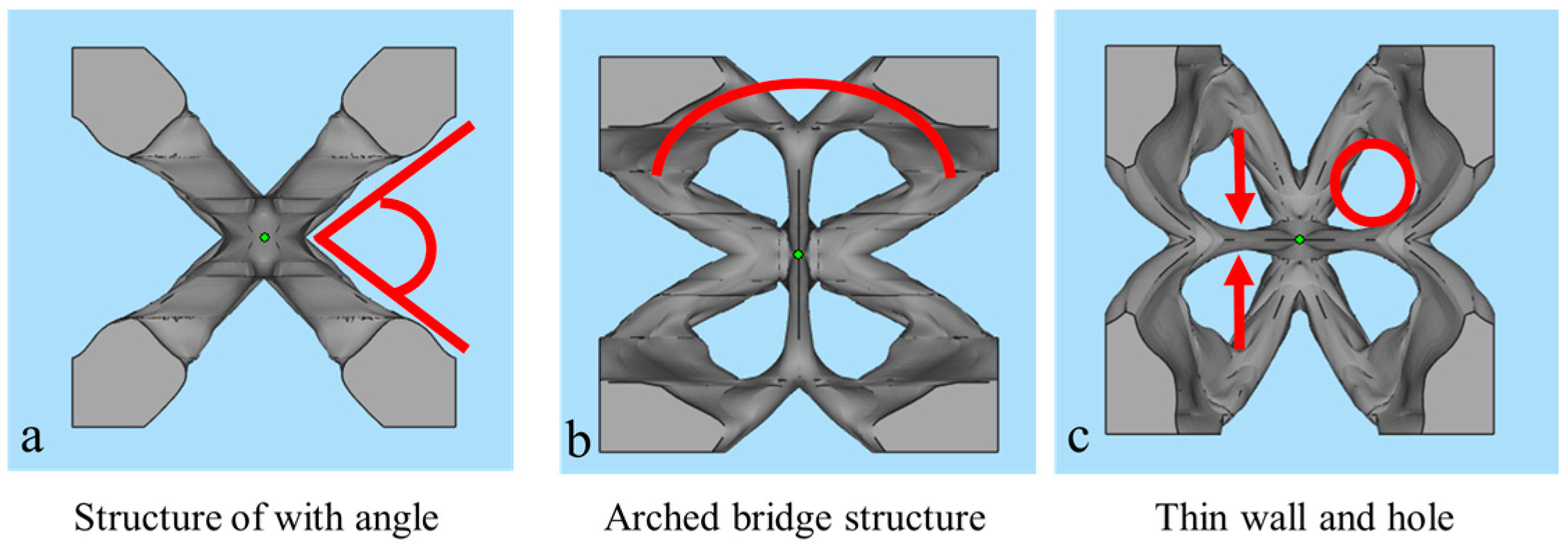

3.1. Manufacturability of Topology Optimization Structure

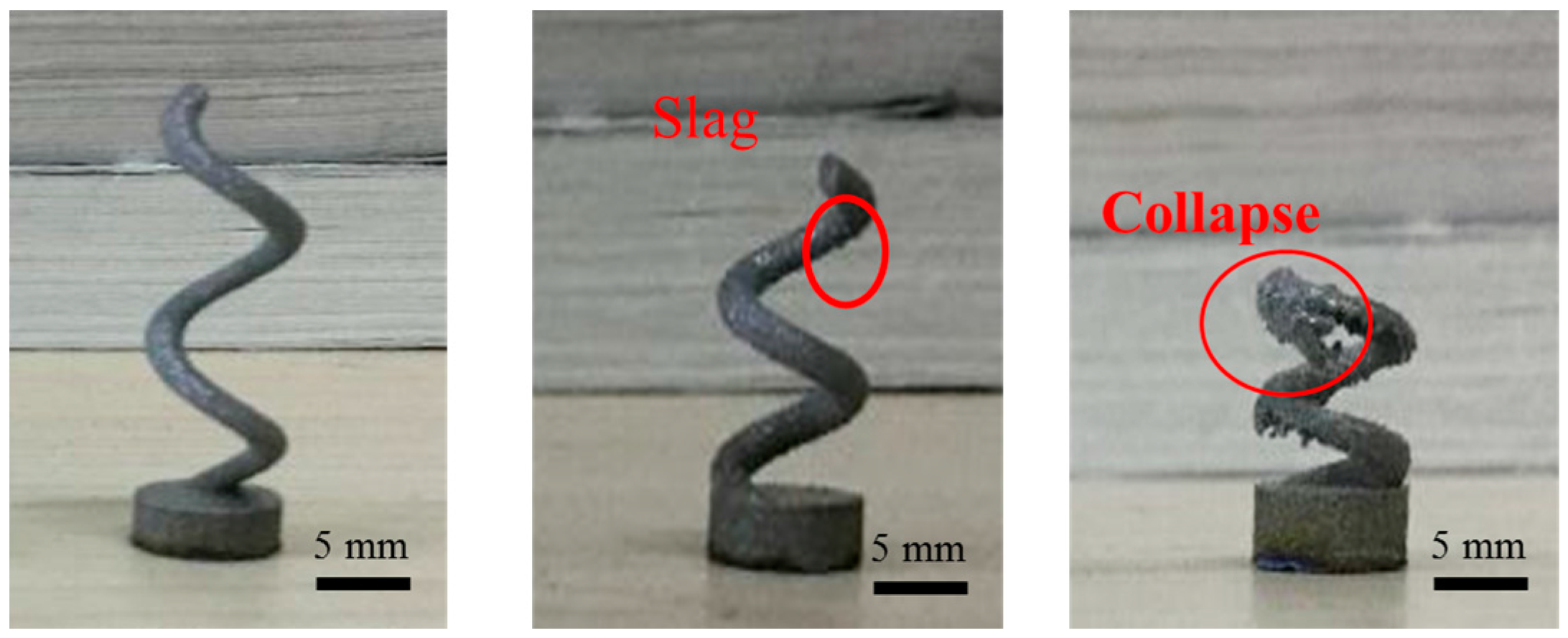

3.1.1. Manufacturing Limits of Spiral Structure

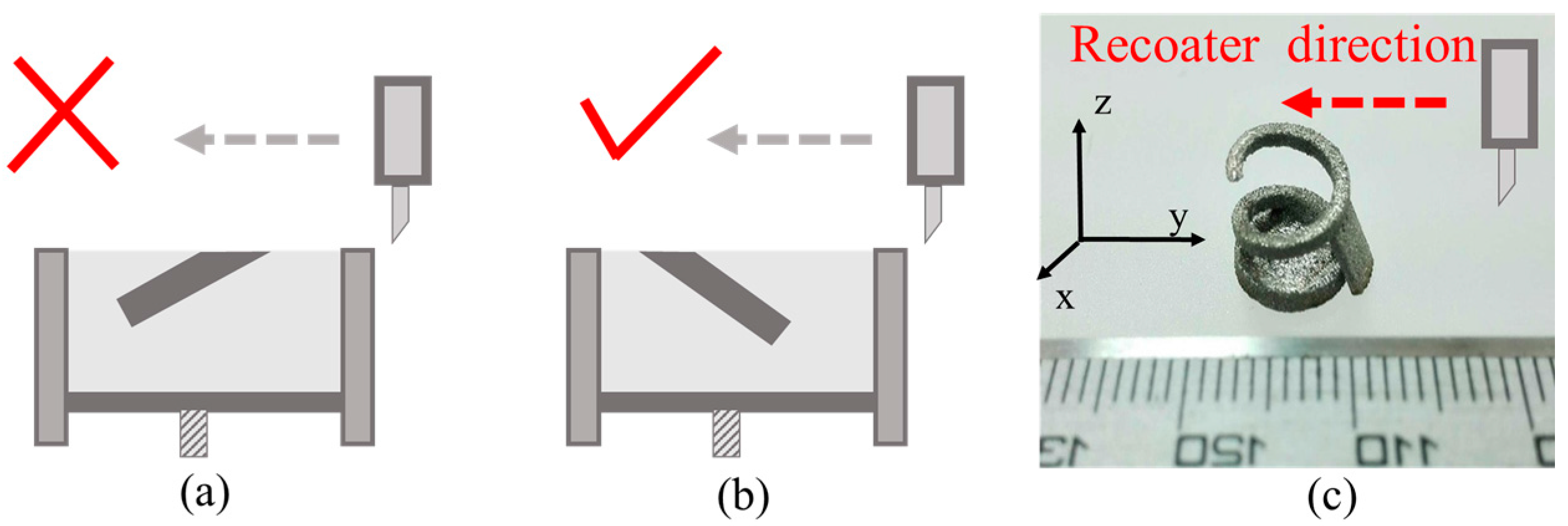

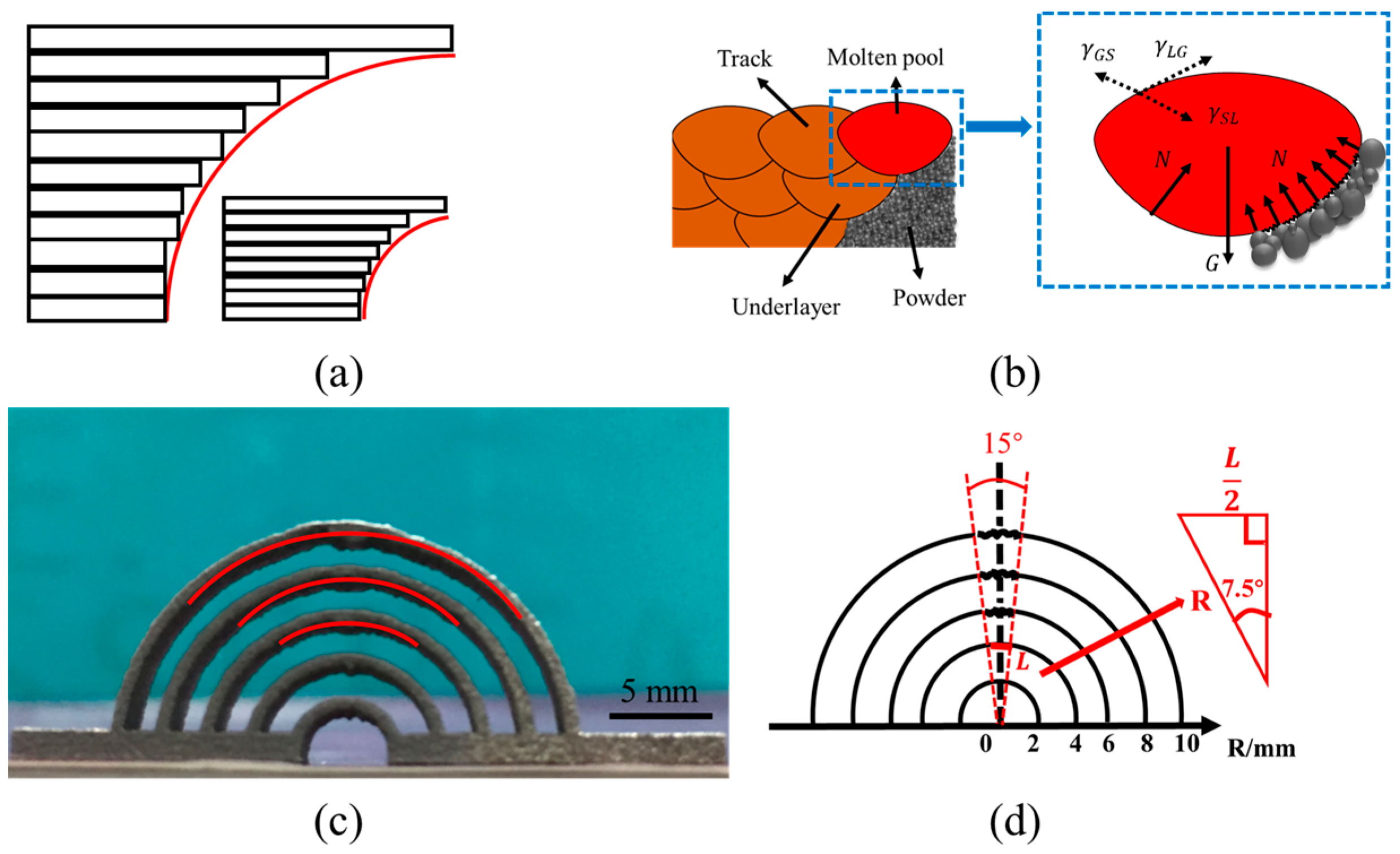

3.1.2. Manufacturing Limit of the Arched Bridge Structure

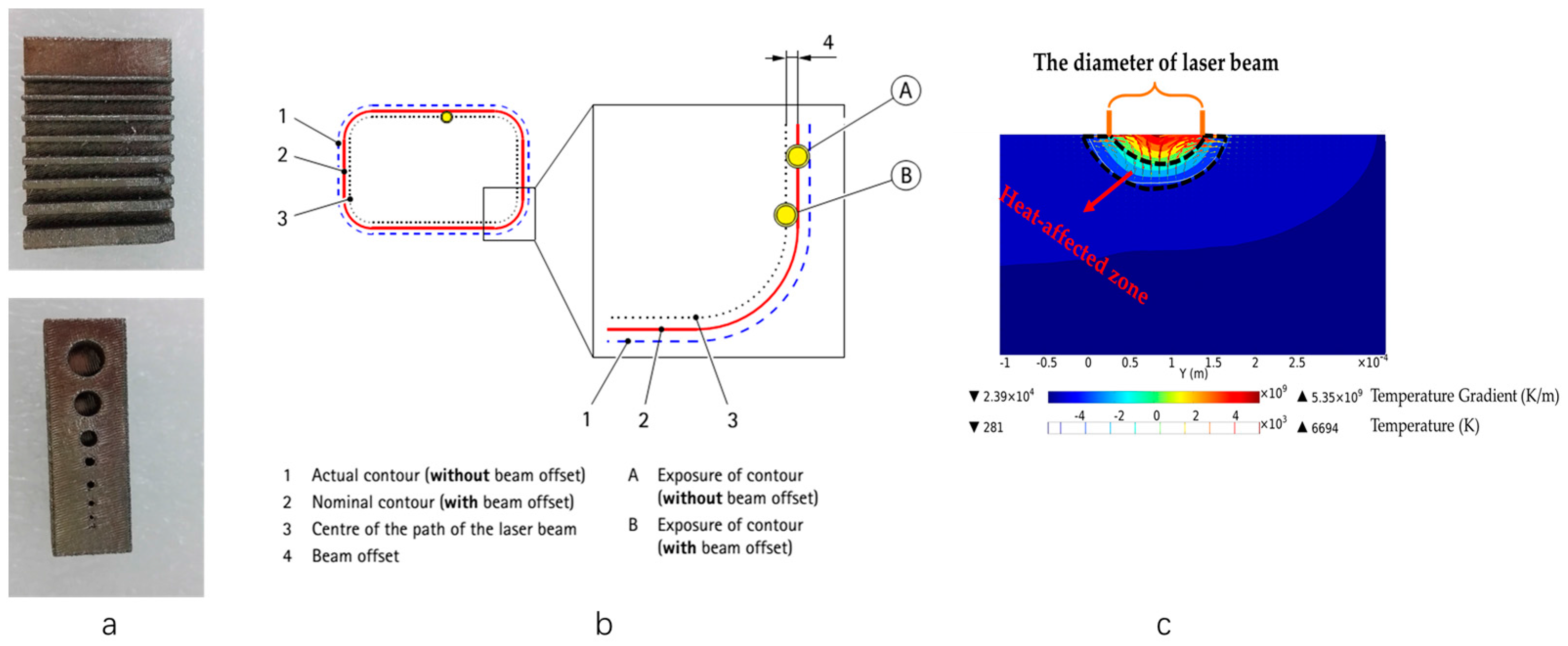

3.1.3. Manufacturing Limit of Thin Walls and Small Holes

3.2. Compressive Properties of the Porous Structures

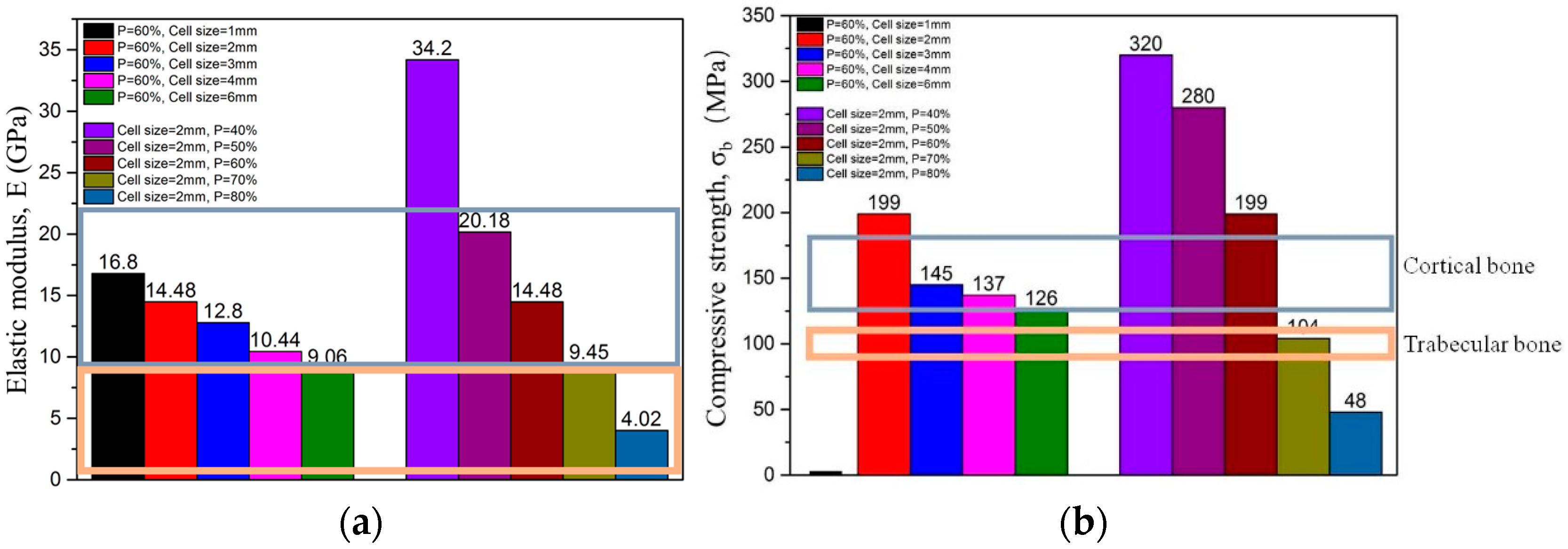

3.2.1. Static Elastic Modulus and Compressive Strength

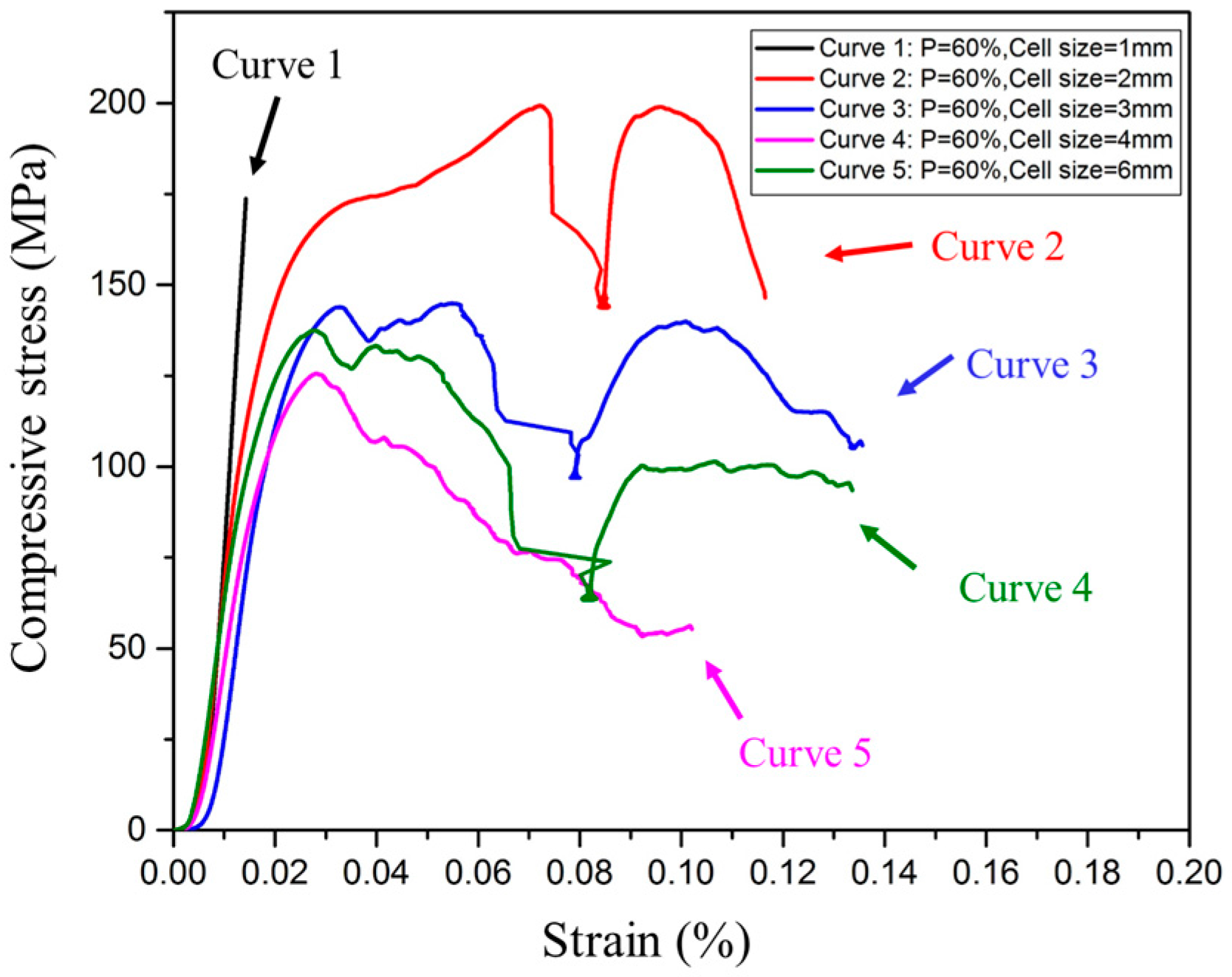

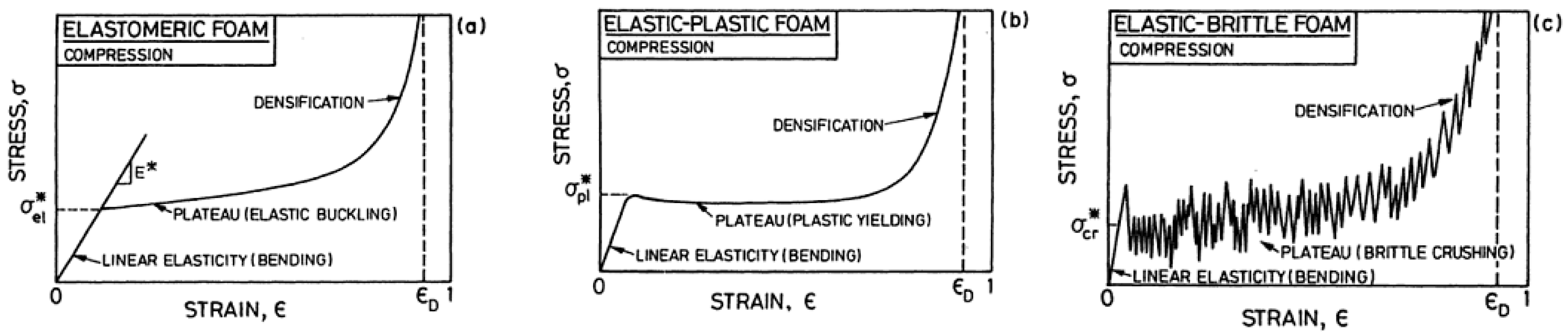

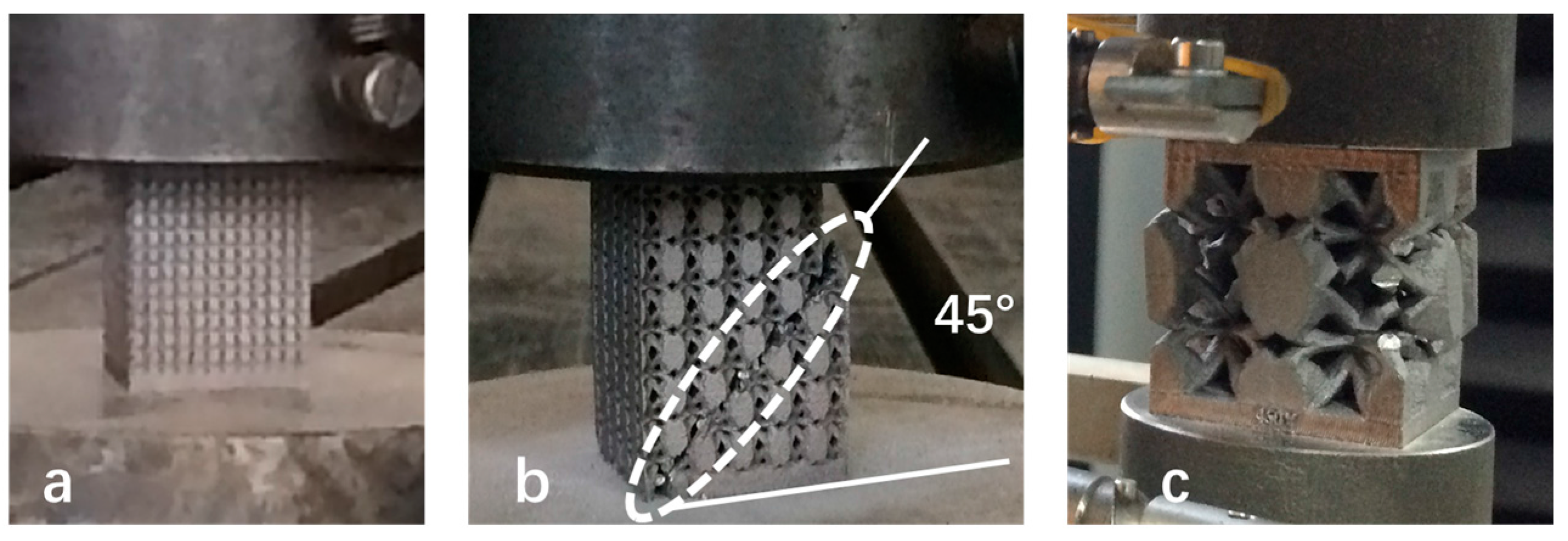

3.2.2. Compressive Behavior of Porous Structure

3.3. Evaluations of the Porous Structures

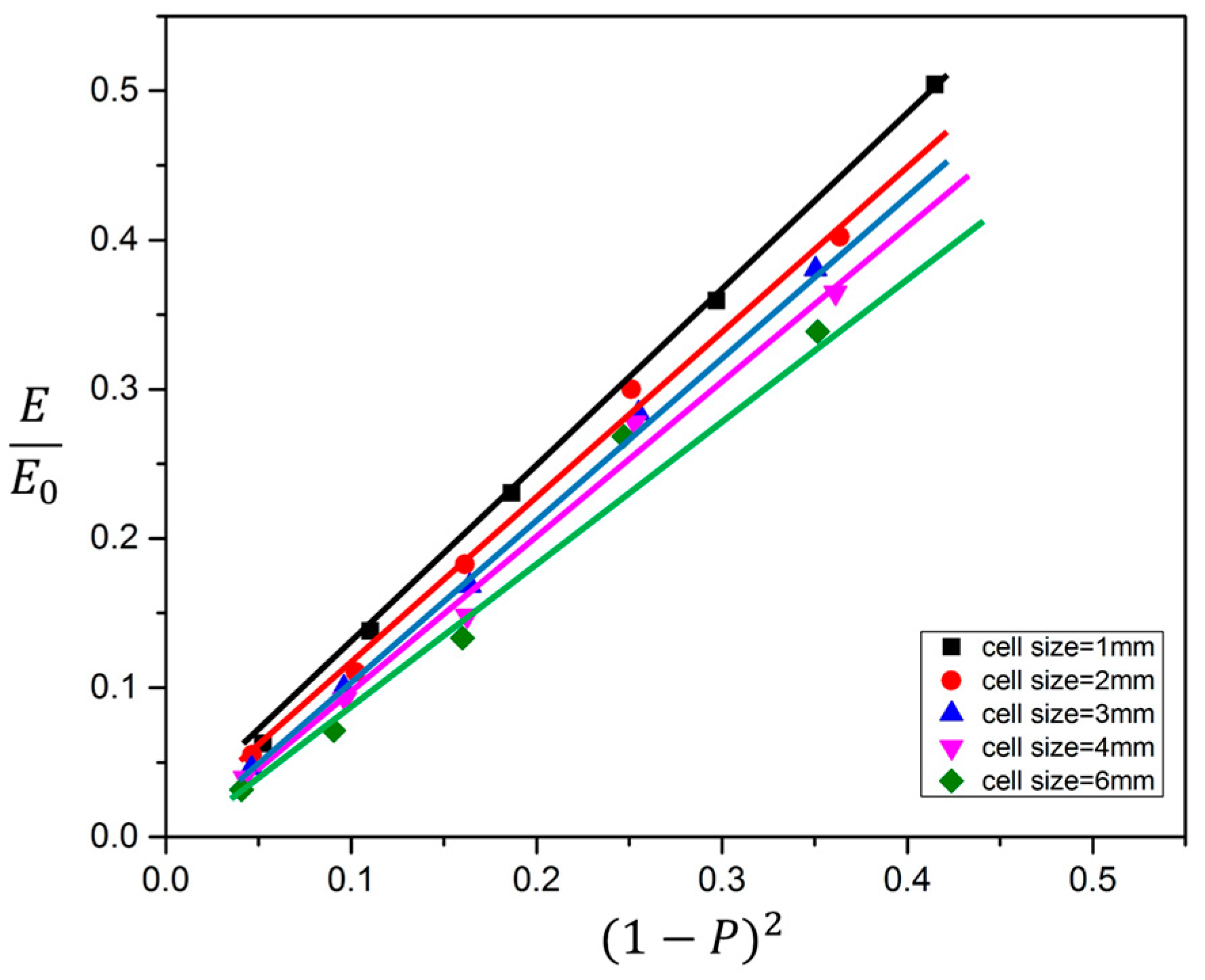

3.3.1. Measurement of Dynamic Elastic Modulus

3.3.2. Evaluations for Stability of the Porous Structures

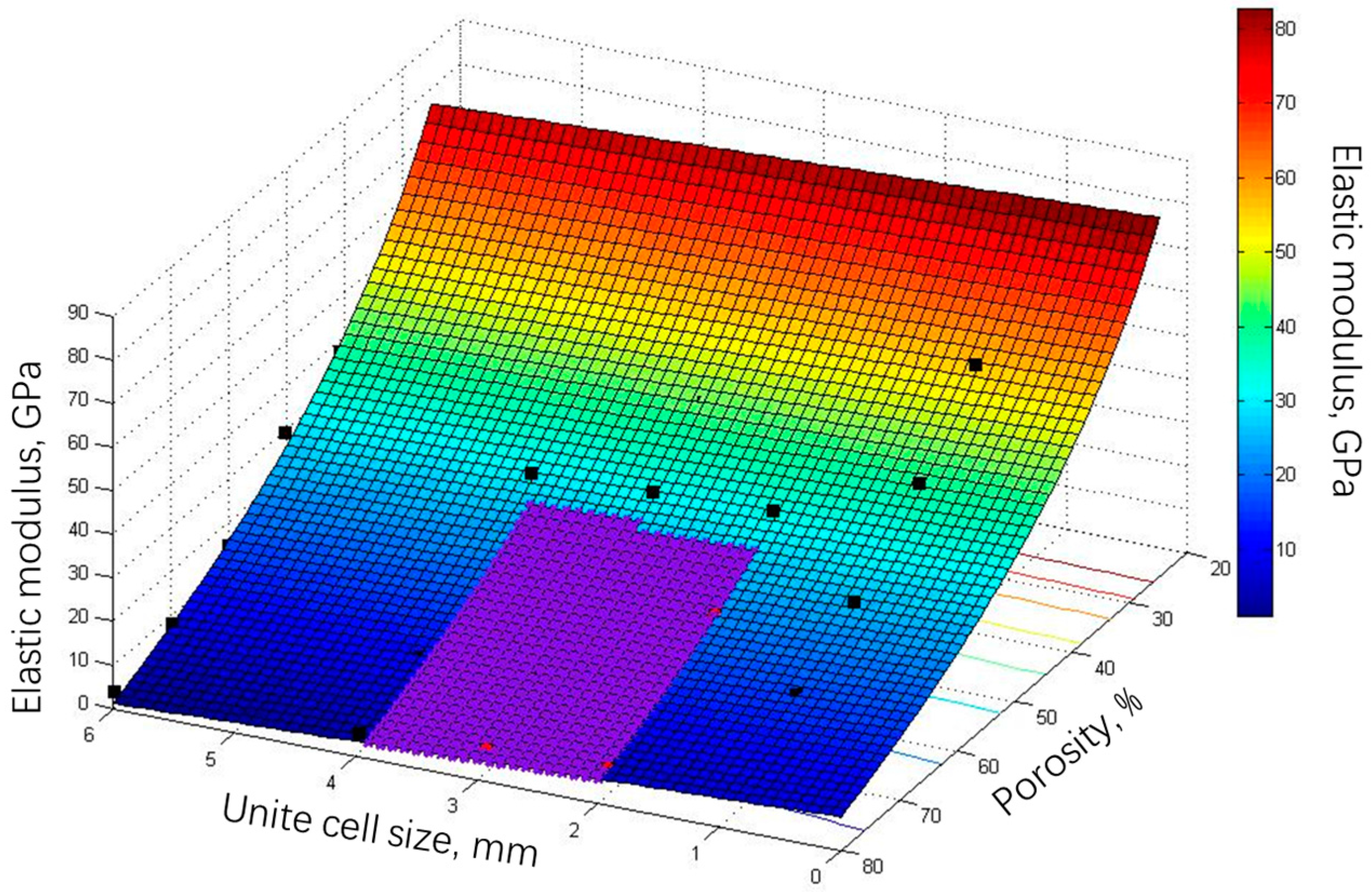

3.4. Evaluations of the Porous Structures

4. Conclusions

- The manufacturing limits of three typical structures abstracted from designed porous structures is given out: the rising angle of spiral structure >30°, the length of overhang from arched structure <1.04 mm, the diameter of hole >0.1 mm, and the thickness of wall >0.1 mm.

- Properties such as compression strength and dynamic elastic modulus of porous structures fabricated with SLM are measured. The compression test showed the compressive strength and elastic modulus of topology optimized structures can match the requirements of the trabecular and cortical bones of humans. The compressive strength of porous structures decreases with the increase of either unit cell size (porosity constant) or porosity (unit cell size constant). The compressive behavior of porous structures is evaluated and three failure models are proposed based on the Gibson-Ashby model, which can be attributed to that of elastic-brittle foam material.

- The Ashby-Gibson model was also used to evaluate the stability of porous structures, indicating better stability of the porous structure with smaller unit cell size, which is comparable with the evaluation of compressive strength.

- The numerical model for correlation among parameters of porous structural and elastic modulus was established, as well as a purple region which was further limited in the effective fitting surface for design implant, indicating the methods for parameter choice during design of porous structure.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Markhoff, J.; Wieding, J.; Weissmann, V.; Pasold, J.; Jonitz-Heincke, A.; Bader, R. Influence of different three-dimensional open porous titanium scaffold designs on human osteoblasts behavior in static and dynamic cell investigations. Materials 2015, 8, 5490–5507. [Google Scholar] [CrossRef] [PubMed]

- Langer, R.S.; Vacanti, J.P. Tissue engineering: The challenges ahead. Sci. Am. 1999, 280, 86. [Google Scholar] [CrossRef] [PubMed]

- Arabnejad, S.; Johnston, B.; Tanzer, M.; Pasini, D. Fully porous 3D printed titanium femoral stem to reduce stress-shielding following total hip arthroplasty. J. Orthop. Res. Off. Publ. Orthop. Res. Soc. 2016, 35, 1774–1783. [Google Scholar] [CrossRef] [PubMed]

- Langer, R.; Cima, L.G.; Tamada, J.A.; Wintermantel, E. Future directions in biomaterials. Biomaterials 1990, 11, 738. [Google Scholar] [CrossRef]

- Ahmadi, S.M.; Campoli, G.; Amin, Y.S.; Sajadi, B.; Wauthle, R.; Schrooten, J.; Weinans, H.; Zadpoor, A.A. Mechanical behavior of regular open-cell porous biomaterials made of diamond lattice unit cells. J. Mech. Behav. Biomed. Mater. 2014, 34, 106. [Google Scholar] [CrossRef] [PubMed]

- Murr, L.E.; Gaytan, S.M.; Medina, F.; Lopez, H.; Martinez, E.; Machado, B.I.; Hernandez, D.H.; Martinez, L.; Lopez, M.I.; Wicker, R.B. Next-generation biomedical implants using additive manufacturing of complex, cellular and functional mesh arrays. Philos. Trans. 2010, 368, 1999. [Google Scholar] [CrossRef] [PubMed]

- Giannitelli, S.M.; Accoto, D.; Trombetta, M.; Rainer, A. Current trends in the design of scaffolds for computer-aided tissue engineering. Acta Biomater. 2014, 10, 580. [Google Scholar] [CrossRef] [PubMed]

- Arabnejad, K.S.; Pasini, D. Multiscale design and multiobjective optimization of orthopedic hip implants with functionally graded cellular material. J. Biomech. Eng. 2012, 134, 031004. [Google Scholar] [CrossRef] [PubMed]

- Xiao, D.M.; Yang, Y.Q.; Su, X.B.; Wang, D.; Luo, Z.Y. Topology optimization of microstructure and selective laser melting fabrication for metallic biomaterial scaffolds. Trans. Nonferrous Met. Soc. China 2012, 22, 2554–2561. [Google Scholar] [CrossRef]

- Wang, D.; Song, C.; Yang, Y.; Liu, R.; Ye, Z.; Xiao, D.; Liu, Y. Research on the redesign of precision tools and their manufacturing process based on selective laser melting (SLM). Rapid Prototyp. J. 2016, 22, 104–114. [Google Scholar] [CrossRef]

- Mazur, M.; Leary, M.; Sun, S.; Vcelka, M.; Shidid, D.; Brandt, M. Deformation and failure behaviour of Ti-6Al-4V lattice structures manufactured by selective laser melting (SLM). Int. J. Adv. Manuf. Technol. 2016, 84, 1391–1411. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Bertrand, P.H.; Smurov, I. Parametric analysis of the selective laser melting process. Appl. Surf. Sci. 2007, 253, 8064–8069. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Smurov, I. Selective laser melting technology: From the single laser melted track stability to 3D parts of complex shape. Phys. Procedia 2010, 5, 551–560. [Google Scholar] [CrossRef]

- Cheng, X.Y.; Li, S.J.; Murr, L.E.; Zhang, Z.B.; Hao, Y.L.; Yang, R.; Medina, F.; Wicker, R.B. Compression deformation behavior of Ti-6Al-4V alloy with cellular structures fabricated by electron beam melting. J. Mech. Behav. Biomed. Mater. 2012, 16, 153. [Google Scholar] [CrossRef] [PubMed]

- Gibson, L.J.; Ashby, M.F. Cellular Solids Structures and Properties, 2nd ed.; Cambridge University Press: Cambridge, UK, 1999. [Google Scholar]

- Sing, S.L.; Yeong, W.Y.; Wiria, F.E.; Tay, B.Y. Characterization of Titanium Lattice Structures Fabricated by Selective Laser Melting Using an Adapted Compressive Test Method. Exp. Mech. 2016, 56, 735–748. [Google Scholar] [CrossRef]

- Chahine, G.; Smith, P.; Kovacevic, R. Application of topology optimization in modern additive manufacturing. Solid Freeform Fabr. Symp. 2010, 606–618. [Google Scholar]

- Roebben, G.; Bollen, B.; Brebels, A.; Humbeeck, J.V.; Biest, O.V.D. Impulse excitation apparatus to measure resonant frequencies, elastic moduli, and internal friction at room and high temperature. Rev. Sci. Instrum. 1997, 68, 4511–4515. [Google Scholar] [CrossRef]

- Li, Q.; Xu, Y.B.; Bassim, M.N. Dynamic mechanical behavior of pure titanium. J. Mater. Process. Technol. 2004, 155–156, 1889–1892. [Google Scholar] [CrossRef]

- Zhang, S.; Wei, Q.; Cheng, L.; Li, S.; Shi, Y. Effects of scan line spacing on pore characteristics and mechanical properties of porous Ti6Al4V implants fabricated by selective laser melting. Mater. Des. 2014, 63, 185–193. [Google Scholar] [CrossRef]

- Li, J.P.; Li, S.H.; Van Blitterswijk, C.A.; De Groot, K. A novel porous Ti6Al4V: Characterization and cell attachment. J. Biomed. Mater. Res. Part A 2005, 73, 223. [Google Scholar] [CrossRef] [PubMed]

- Weißmann, V.; Bader, R.; Hansmann, H.; Laufer, N. Influence of the structural orientation on the mechanical properties of selective laser melted Ti6Al4V open-porous scaffolds. Mater. Des. 2016, 95, 188–197. [Google Scholar] [CrossRef]

- Ashman, R.B.; Cowin, S.C.; Van Buskirk, W.C.; Rice, J.C. A continuous wave technique for the measurement of the elastic properties of cortical bone. J. Biomech. 1984, 17, 349–361. [Google Scholar] [CrossRef]

- Kuhn, J.L.; Goldstein, S.A.; Choi, R.; London, M.; Feldkamp, L.A.; Matthews, L.S. Comparison of the trabecular and cortical tissue moduli from human iliac crests. J. Orthop. Res. 1989, 7, 876–884. [Google Scholar] [CrossRef] [PubMed]

- Ryan, S.D.; Williams, J.L. Tensile testing of rodlike trabeculae excised from bovine femoral bone. J. Biomech. 1989, 22, 351–355. [Google Scholar] [CrossRef]

- Choi, K.; Kuhn, J.L.; Ciarelli, M.J.; Goldstein, S.A. The elastic moduli of human subchondral, trabecular, and cortical bone tissue and the size-dependency of cortical bone modulus. J. Biomech. 1990, 23, 1103–1113. [Google Scholar] [CrossRef]

- Li, Q.; Zhang, Y.; Wang, D.; Wang, H.; He, G. Porous polyether ether ketone: A candidate for hard tissue implant materials. Mater. Des. 2017, 116, 171–175. [Google Scholar] [CrossRef]

| Thin Wall | Small Hole | |||

|---|---|---|---|---|

| Designed Value | Measured Value | Designed Value | Measured Value | |

| 1 | 0.05 | - | 0.05 | - |

| 2 | 0.1 | 0.16 | 0.1 | 0.07 |

| 3 | 0.2 | 0.24 | 0.2 | 0.16 |

| 4 | 0.3 | 0.33 | 0.3 | 0.27 |

| 5 | 0.4 | 0.42 | 0.4 | 0.38 |

| 6 | 0.6 | 0.61 | 0.6 | 0.58 |

| 7 | 0.8 | 0.81 | 0.8 | 0.78 |

| 8 | 1.0 | 1.06 | 1.0 | 0.99 |

| Unit Cell Size = 1 mm | 2 mm | 3 mm | 4 mm | 6 mm | |||||

|---|---|---|---|---|---|---|---|---|---|

| P a (%) | E b (GPa) | P (%) | E (GPa) | P (%) | E (GPa) | P (%) | E (GPa) | P (%) | E (GPa) |

| 35.60 | 55.47 | 39.71 | 44.25 | 40.8 | 41.86 | 39.9 | 40.13 | 40.70 | 37.26 |

| 45.50 | 39.53 | 49.9 | 33.01 | 49.5 | 31.24 | 49.7 | 30.52 | 50.30 | 29.52 |

| 56.80 | 25.36 | 59.83 | 20.09 | 59.5 | 18.53 | 59.7 | 16.31 | 60.00 | 14.68 |

| 66.80 | 15.17 | 68.0 | 12.16 | 69.0 | 11.05 | 68.9 | 10.19 | 69.90 | 7.85 |

| 77.10 | 6.90 | 78.4 | 6.07 | 78.5 | 5.11 | 79.4 | 4.35 | 79.80 | 3.50 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, Y.; Zhang, D.; Zhou, Y.; Wang, W.; Cao, X. Study on Topology Optimization Design, Manufacturability, and Performance Evaluation of Ti-6Al-4V Porous Structures Fabricated by Selective Laser Melting (SLM). Materials 2017, 10, 1048. https://doi.org/10.3390/ma10091048

Xu Y, Zhang D, Zhou Y, Wang W, Cao X. Study on Topology Optimization Design, Manufacturability, and Performance Evaluation of Ti-6Al-4V Porous Structures Fabricated by Selective Laser Melting (SLM). Materials. 2017; 10(9):1048. https://doi.org/10.3390/ma10091048

Chicago/Turabian StyleXu, Yangli, Dongyun Zhang, Yan Zhou, Weidong Wang, and Xuanyang Cao. 2017. "Study on Topology Optimization Design, Manufacturability, and Performance Evaluation of Ti-6Al-4V Porous Structures Fabricated by Selective Laser Melting (SLM)" Materials 10, no. 9: 1048. https://doi.org/10.3390/ma10091048