Effect of Polymer Matrix on the Structure and Electric Properties of Piezoelectric Lead Zirconatetitanate/Polymer Composites

Abstract

:1. Introduction

2. Experimental

2.1. Materials

2.2. Preparation of PZT/Polymer Composites

2.3. Measurements

3. Results and Discussion

3.1. Structure and Morphology

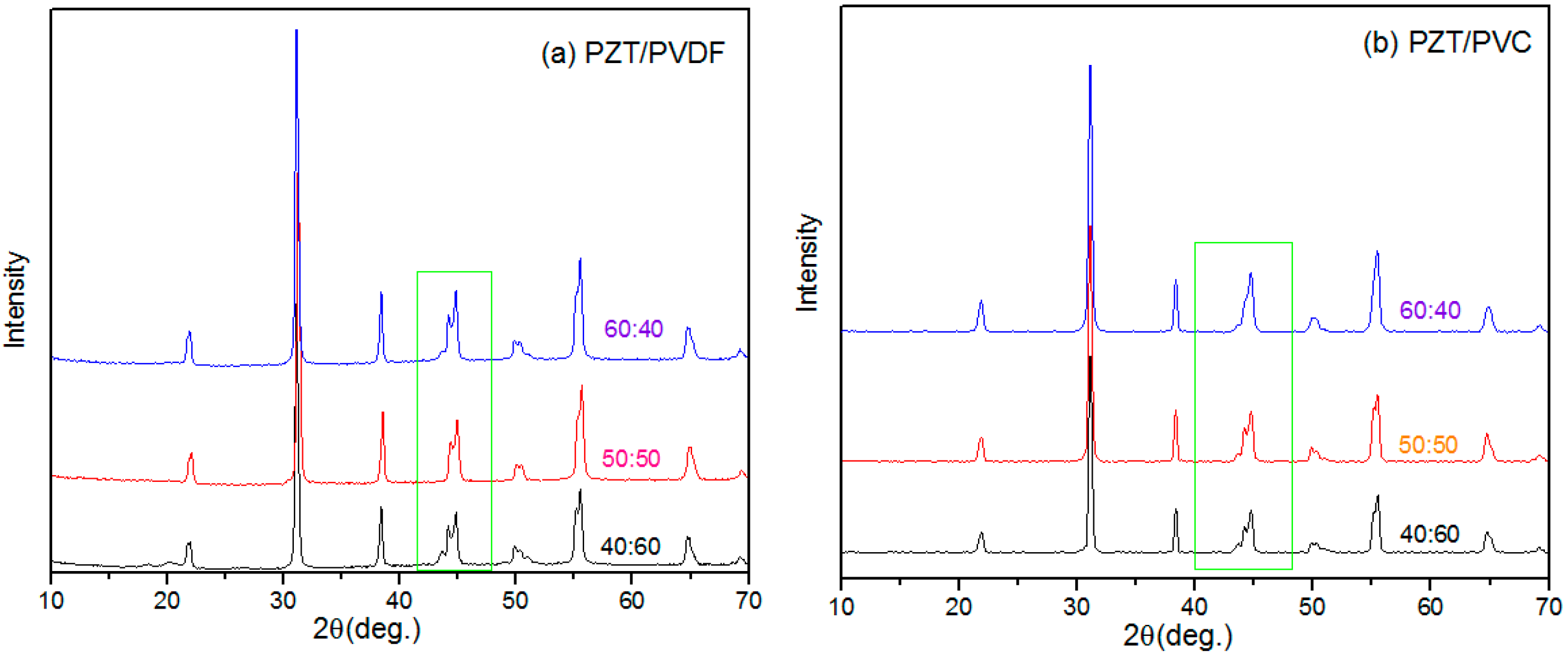

3.1.1. XRD

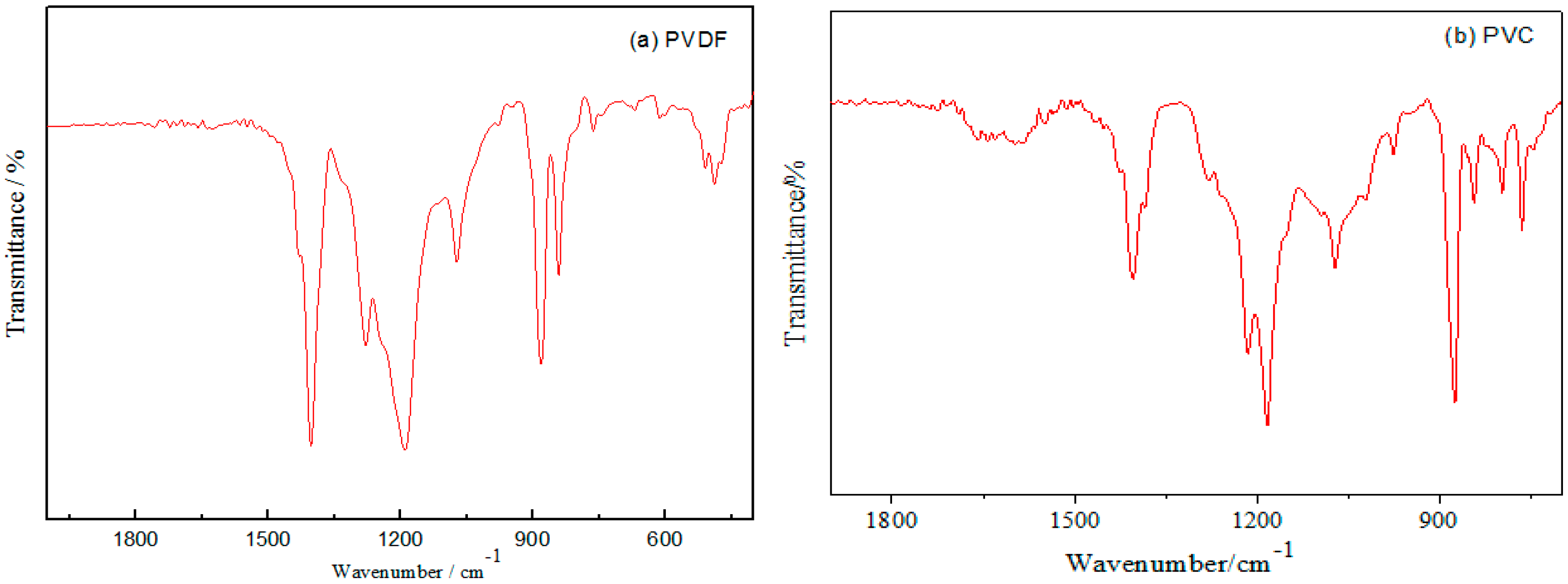

3.1.2. FT-IR

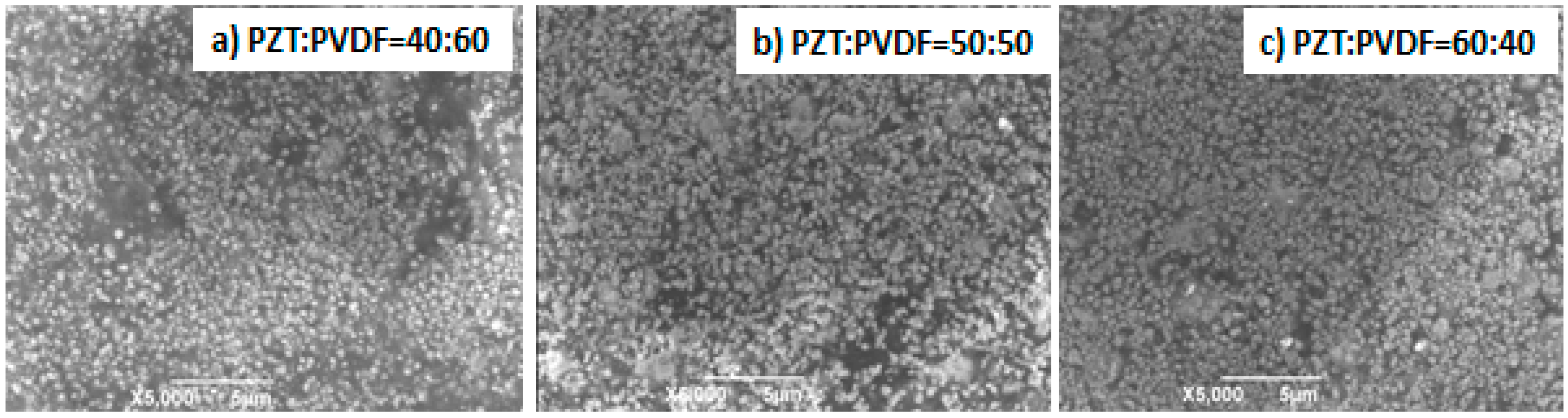

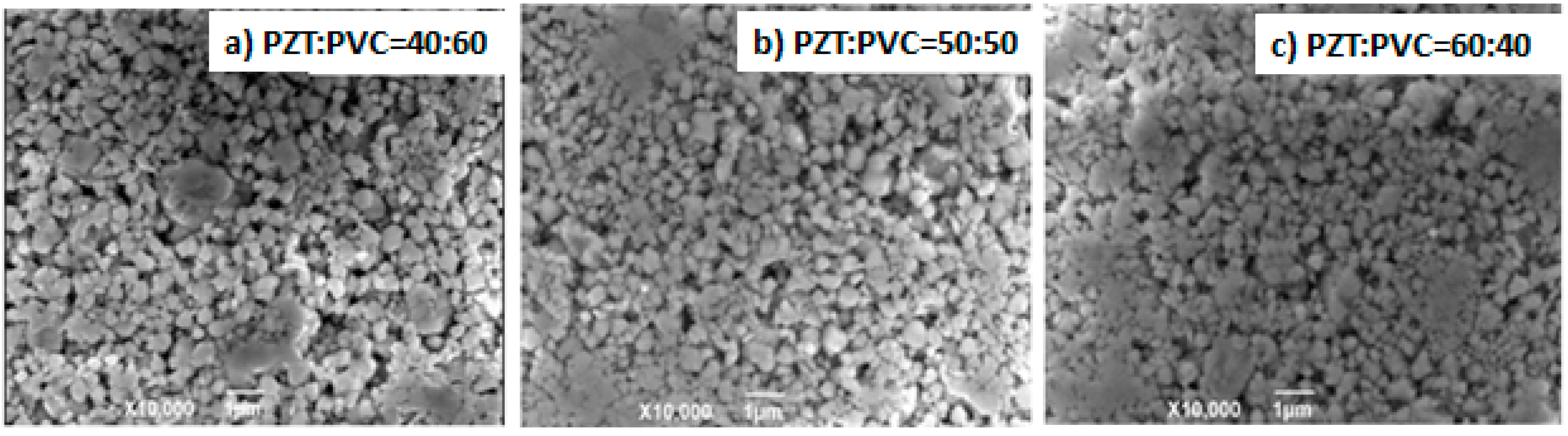

3.1.3. SEM

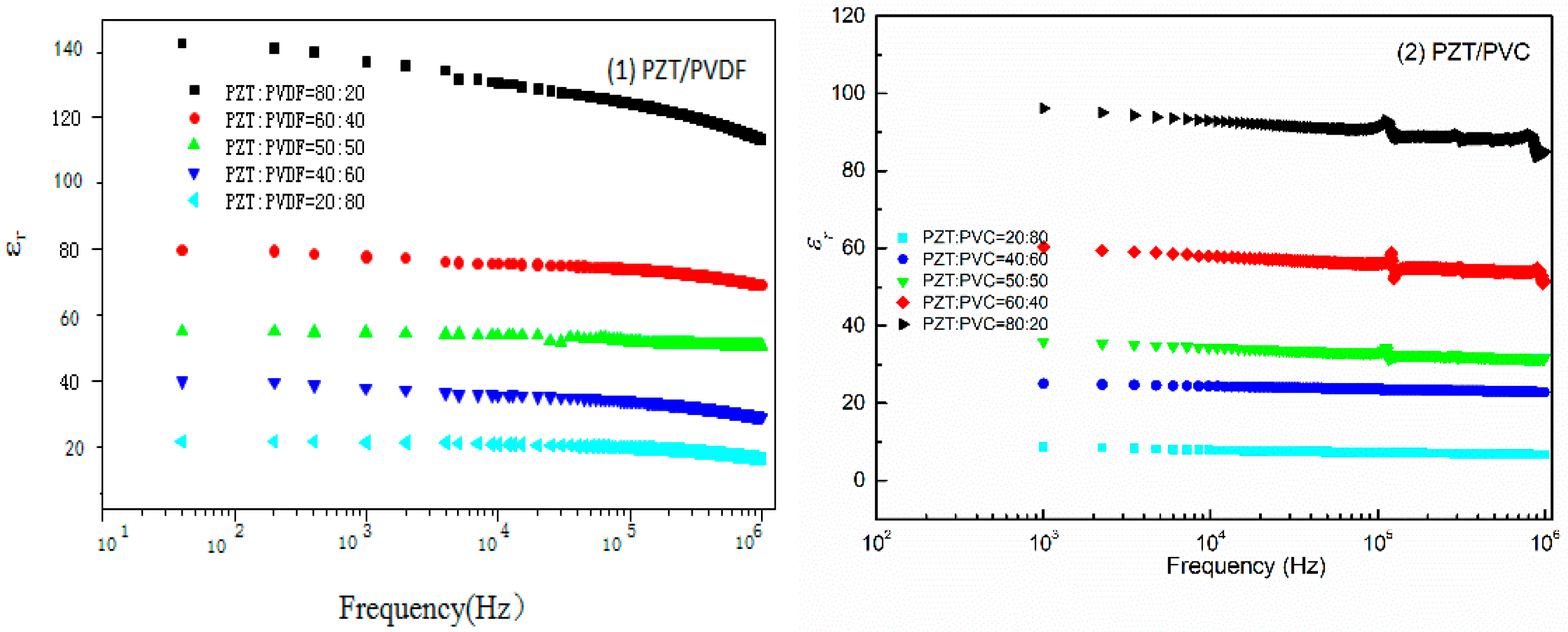

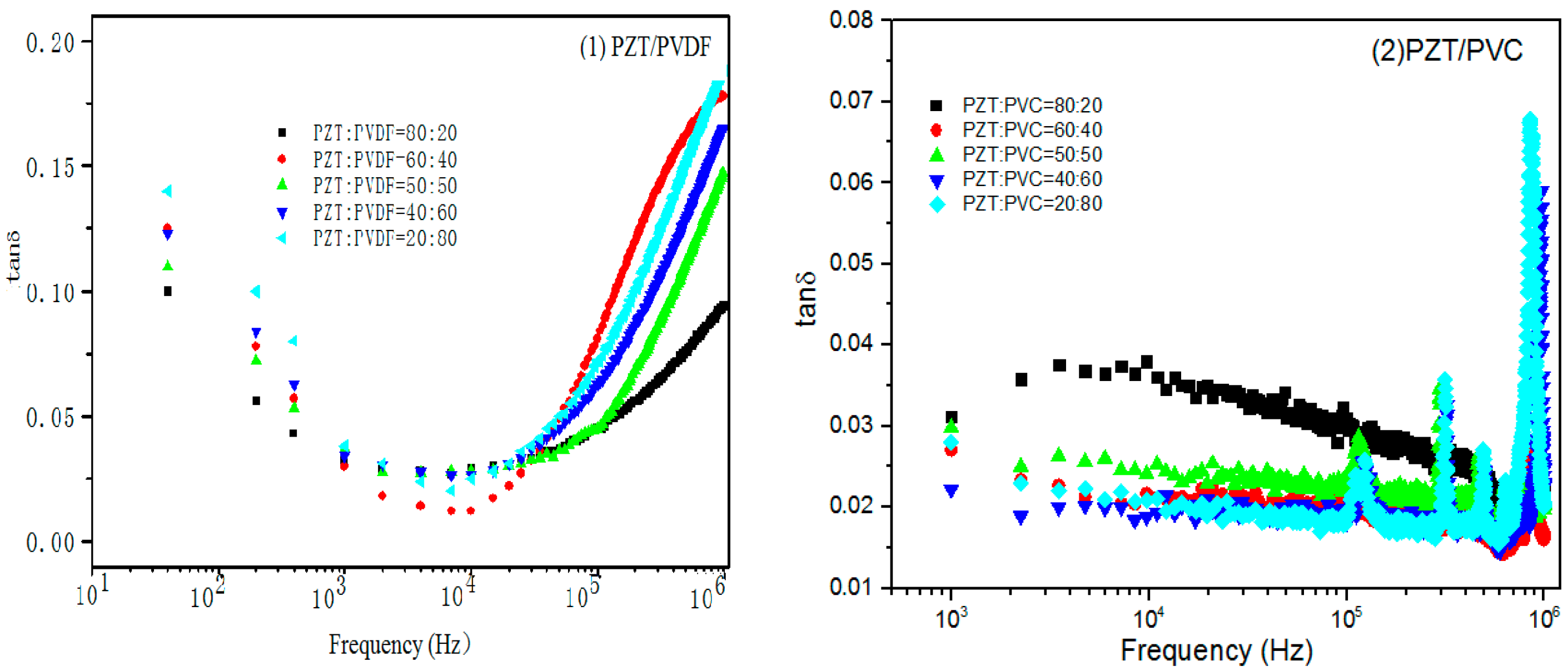

3.2. Effects of Polymer on the Dielectric Properties of PZT/Polymers

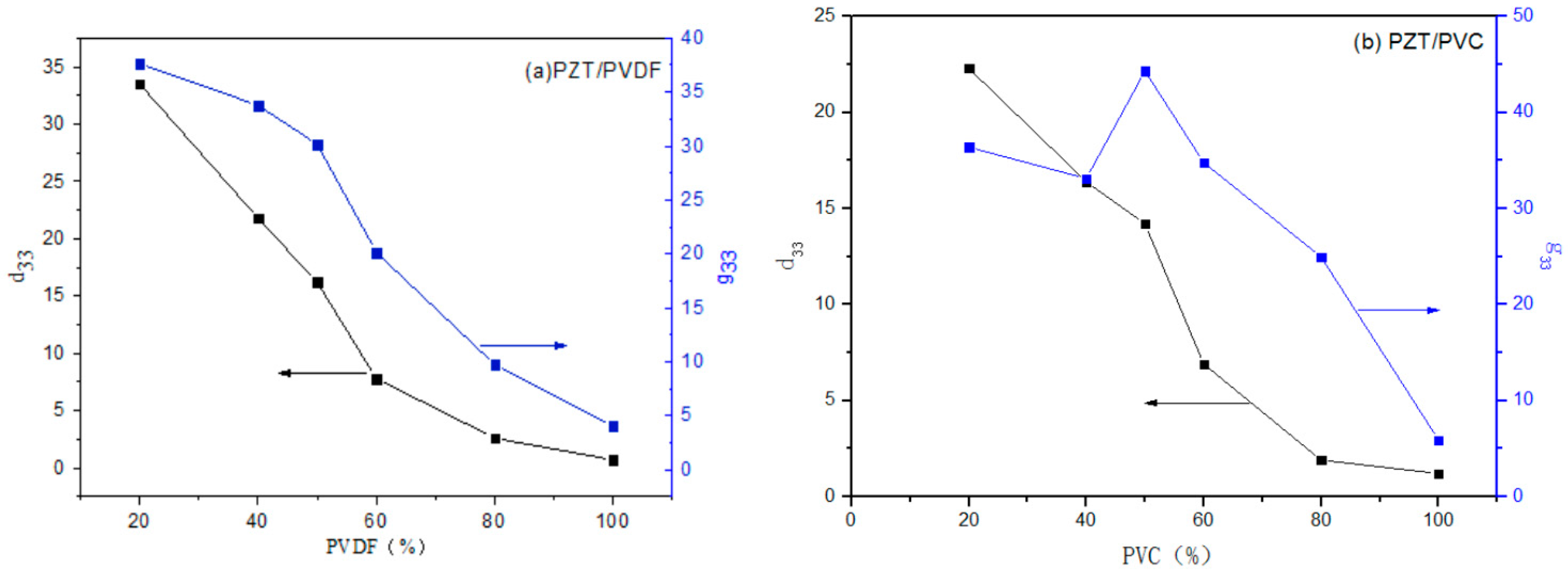

3.3. Effects of Polymer on the Piezoelectric Properties of PZT/Polymers

4. Conclusions

- (1)

- Two kinds of PZT/polymer composites were prepared by the hot pressing process using two thermoplastic polymers as the matrix. The results show that the polymer matrix has a great influence on the piezoelectric and dielectric properties of the PZT/polymer composites.

- (2)

- The process for preparation of PZT/PVDF composite from semi-crystalline polymer PVDF was investigated. The piezoelectric properties of PZT/PVDF are the best when the PZT content is higher than 50%. The dielectric constant of PZT/PVDF composites is better than PZT/PVC, and the dielectric loss is slightly higher than that of the PZT/PVC when the frequency is 1 kHz.

- (3)

- The PZT/PVC composites prepared by combining PZT with PVC can measure the resonance peak of the PZT when the content of PZT was 40%. The g33 of PZT/PVC composites is better than that of PZT/PVDF composites when the PZT content is 30–50%. The d33 of PZT/PVC composite is obviously better than that of PZT/PVDF composite. Therefore, the PZT/PVC composites will achieve high electromechanical coupling coefficients.

- (4)

- Under the condition of frequency is 103 Hz, the dielectric and piezoelectric properties of the PZT/PVC were both better than PZT/PVDF. When the volume fraction of PZT was 50%, the PZT/PVC composites prepared by the hot-press method could achieve excellent electrical performance. The εr was 65.75, the d33 was 16.2 Pc/N, the g33 was 28.26 mV·m/N, and the tan δ was only 0.037.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Gowdhaman, P.; Annamalai, V.; Thakur, O.P. Piezo, ferro and dielectric properties of ceramic-polymer composites of 0–3 connectivity. Ferroelectrics 2016, 493, 120–129. [Google Scholar] [CrossRef]

- Li, Q.; Chen, L.; Gadinski, M.R.; Zhang, S.; Li, H.; Haque, A.; Jackson, T.; Wang, Q. Flexible high-temperature dielectric materials from polymer nanocomposites. Nature 2015, 523, 576–579. [Google Scholar] [CrossRef] [PubMed]

- He, C.; Chen, W.G. Preparation and application of piezoelectric materials and its research status. Funt. Mater. 2010, 41, 11–13. [Google Scholar]

- Ghosh, M.; Rao, M.G. Growth mechanism of ZnO nanostructures for ultrahigh piezoelectric d33 coefficient. Mater. Express 2013, 3, 319–327. [Google Scholar] [CrossRef]

- KumaráThakur, V.; JináTan, E.; SeeáLee, P. Surface functionalization of BaTiO3 nanoparticles and improved electricalal properties of BaTiO3/polyvinylidene fluoride composite. RSC Adv. 2011, 1, 576–578. [Google Scholar]

- Li, H.T.; Sun, X.H. Research progress and development trend of piezoelectric ceramic materials. Adv. Ceram. 2009, 14, 28–31. [Google Scholar]

- Tiwari, V.; Srivastava, G. Structural, dielectric and piezoelectric properties of 0–3 PZT/PVDF composite. Ceram. Int. 2005, 41, 8008–8013. [Google Scholar] [CrossRef]

- Mendes, S.F.; Costa, C.M.; Sencadas, V.; Nunes, J.S.; Costa, P.; Grégório, R. Effect of the ceramic grain size and concentration on the dynamical mechanical and dielectric behavior of poly(vinilidene fluoride)/Pb (Zr0.53Ti0.47) O3 composites. Appl. Phys. A 2009, 96, 899–908. [Google Scholar]

- Zhang, L.M.; You, D. The preparation and properties of 0–3 PZT/PVDF piezoelectric composites. Acta Mater. Compos. Sin. 2004, 21, 142–145. [Google Scholar] [CrossRef]

- Li, R.; Pei, J.Z. High dielectric performance of polyamide 11/poly(vinylidene fluoride) blend films induced by interfacial glycidyl methacrylate. Polym. Sci. Ser. A 2015, 57, 792–798. [Google Scholar] [CrossRef]

- Hu, N.; Liu, X.N. Piezoelectric properties of 0–3 PZT/PVDF piezoelectric composites. J. Funt. Mater. 2008, 39, 406–409. [Google Scholar]

- Pardo, L.; Mendiola, J.; Alemany, C. Theoretical treatment of ferroelectric composites using Monte Carlo calculations. J. Appl. Phys. 1988, 64, 5092–5097. [Google Scholar] [CrossRef]

- Jaitanong, N.; Yimnirun, R.; Zeng, H.R.; Li, G.R.; Yin, Q.R.; Chaipanich, A. Piezoelectric properties of cement based/PVDF/PZT composites. Mater. Lett. 2014, 130, 146–149. [Google Scholar] [CrossRef]

- Ahmad, Z.; Prasad, A.; Prasad, K. A comparative approach to predicting effective dielectric, piezoelectric and elastic properties of PZT/PVDF composites. Physica B 2009, 404, 3637–3644. [Google Scholar] [CrossRef]

- Ende, D.A.; Almeida, P.D.; Zwaag, S.V.D. Piezoelectric and mechanical properties of novel composites of PZT and a liquid crystalline thermosetting resin. J. Mater. Sci. 2007, 42, 6417–6425. [Google Scholar] [CrossRef]

- Olhero, S.M.; Garcia, G.L.; Button, T.W.; Alves, F.J.; Ferreira, J.M. Innovative fabrication of PZT pillar arrays by a colloidal approach. J. Eur. Ceram. Soc. 2012, 32, 1067–1075. [Google Scholar] [CrossRef]

- Nan, C.W.; Birringer, R.; Clarke, D.R.; Gleiter, H. Effective thermal conductivity of particulate composites with interfacial thermal resistance. J. Appl. Phys. 1997, 81, 6692–6699. [Google Scholar] [CrossRef]

- Li, R.; Wang, H.F.; Liu, H.J.; Pei, J.Z. Influence of PZT piezoelectric ceramics on the structure and electric properties of PZT/poly(vinylidene fluoride)composites. Mater. Express 2016, 6, 483–492. [Google Scholar] [CrossRef]

- Sulaiman, M.; Rahman, A.A.; Mohamed, N.S. Effect of water-based sol-gel method on structural, thermal and conductivity properties of LiNO3–Al2O3 composite solid electrolytes. Arab. J. Chem. 2015, 34, 31–36. [Google Scholar] [CrossRef]

- Bai, W.; Yang, D.B. Dielectric and piezoelectric properties of 0–3 composite film in PCM/PVDF and PZT/PVDF. Ferroelectrics 2011, 157, 427–430. [Google Scholar]

- Zak, A.K.; Gan, W.C.; Majid, W.H. Experimental and theoretical dielectric studies of PVDF/PZT nanocomposite thin films. Ceram. Int. 2011, 37, 1653–1660. [Google Scholar] [CrossRef]

- Guan, X.; Zhang, Y.; Li, H.; Ou, J. PZT/PVDF composites doped with carbon nanotubes. Sens. Actuators A 2013, 194, 228–231. [Google Scholar] [CrossRef]

- Gregorio, R.; Cestari, M.; Bernardino, F.E. Dielectric behaviour of thin films of β-PVDF/PZT and β-PVDF/BaTiO3 composites. J. Mater. Sci. 1996, 31, 2925–2930. [Google Scholar] [CrossRef]

- Martins, P.; Lopes, A.; Lanceros-Mendez, S. Electroactive phases of poly (vinylidene fluoride): Determination, processing and applications. Prog. Polym. Sci. 2014, 39, 683–706. [Google Scholar] [CrossRef]

- Defebvin, J.; Barrau, S.; Lyskawa, J.; Woisel, P.; Lefebvre, J.M. Influence of nitrodopamine functionalized barium titanate content on the piezoelectric response of poly(vinylidene fluoride) based polymer-ceramic composites. Compos. Sci. Technol. 2017, 147, 16–21. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, R.; Zhou, J.; Liu, H.; Pei, J. Effect of Polymer Matrix on the Structure and Electric Properties of Piezoelectric Lead Zirconatetitanate/Polymer Composites. Materials 2017, 10, 945. https://doi.org/10.3390/ma10080945

Li R, Zhou J, Liu H, Pei J. Effect of Polymer Matrix on the Structure and Electric Properties of Piezoelectric Lead Zirconatetitanate/Polymer Composites. Materials. 2017; 10(8):945. https://doi.org/10.3390/ma10080945

Chicago/Turabian StyleLi, Rui, Jun Zhou, Hujun Liu, and Jianzhong Pei. 2017. "Effect of Polymer Matrix on the Structure and Electric Properties of Piezoelectric Lead Zirconatetitanate/Polymer Composites" Materials 10, no. 8: 945. https://doi.org/10.3390/ma10080945