Simulation of the Continuous Casting and Cooling Behavior of Metallic Glasses

Abstract

:1. Introduction

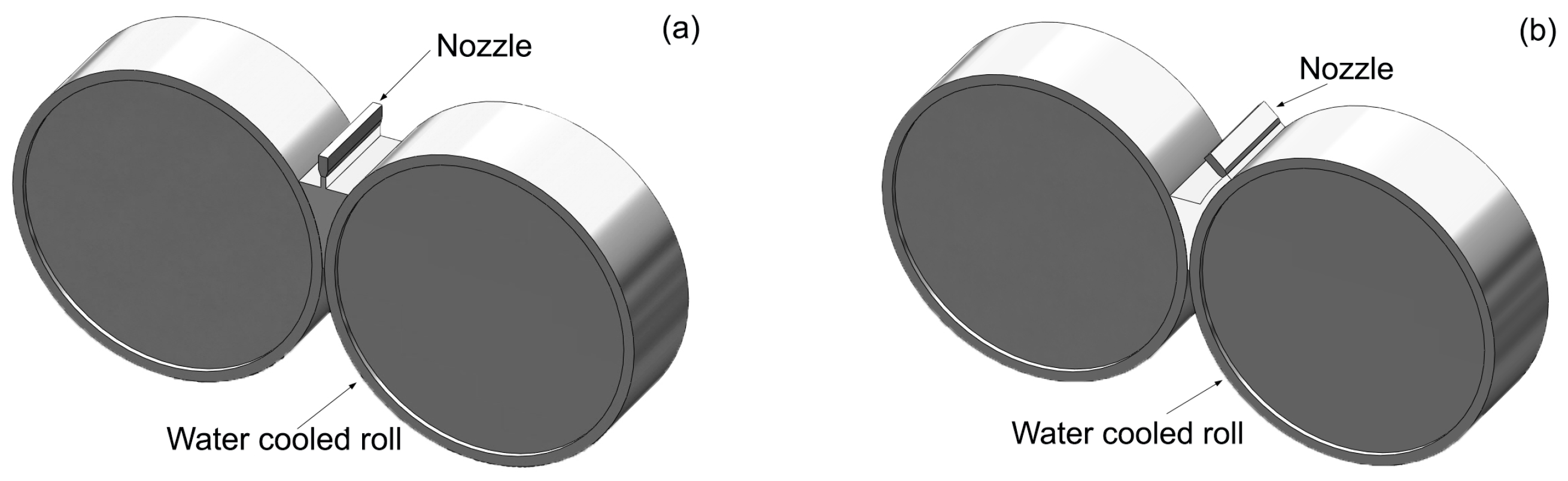

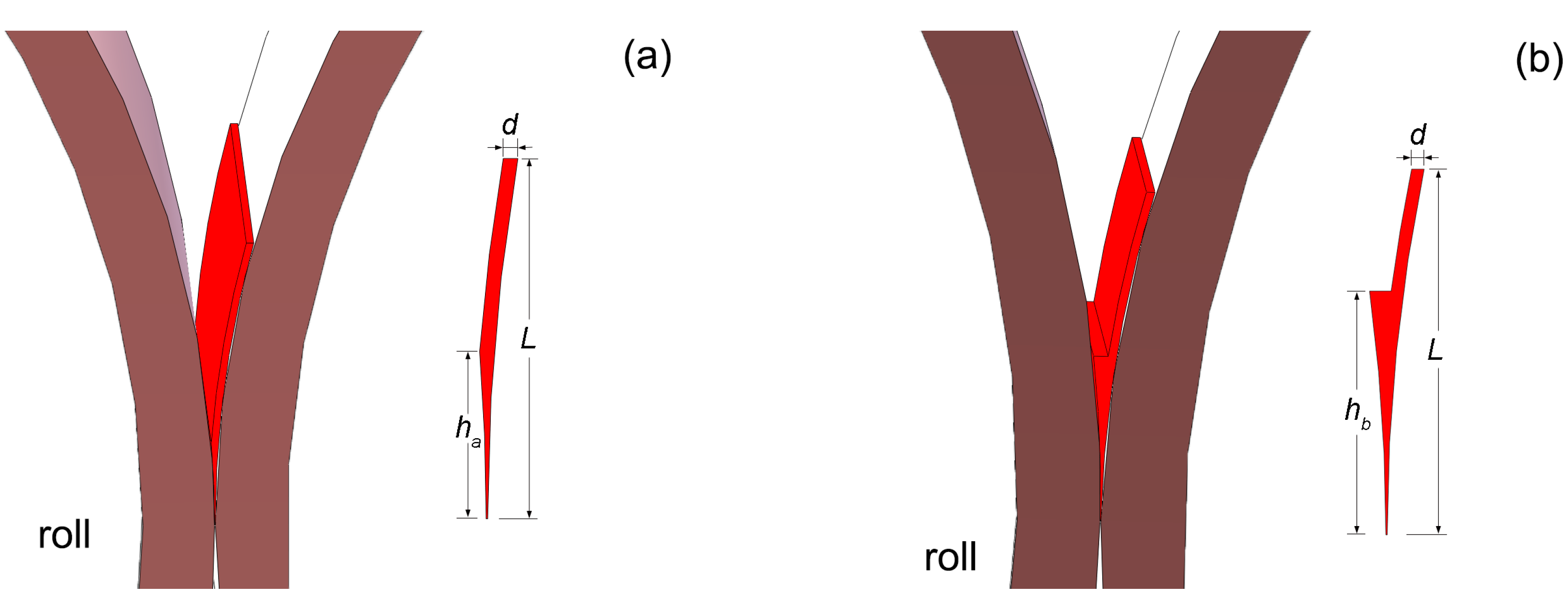

2. TRC Simulation

3. Calculation of Time Reduced Temperature Transformation (T-Tr-T) and CCT Diagrams

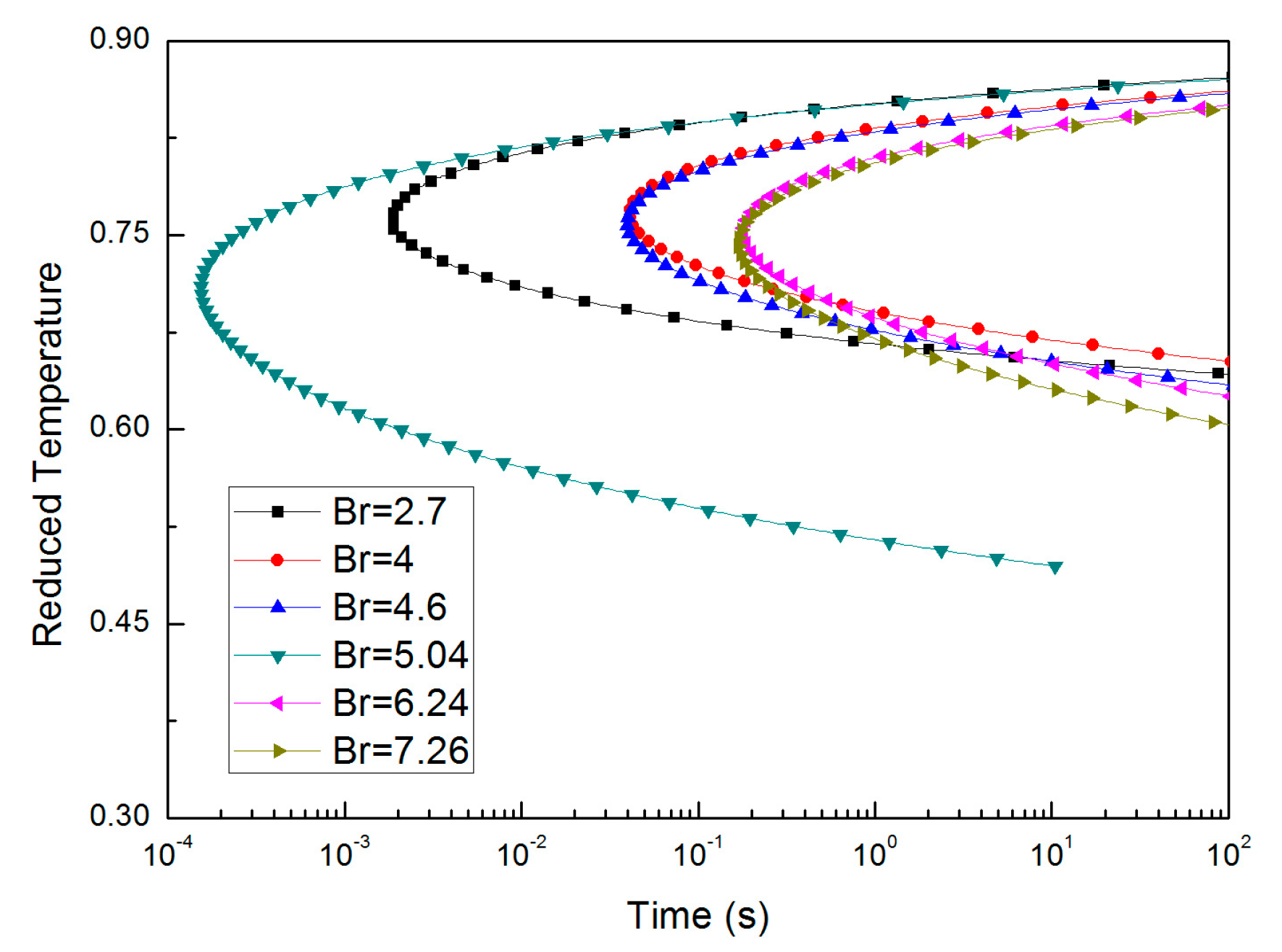

3.1. Calculation of T-Tr-T Diagram

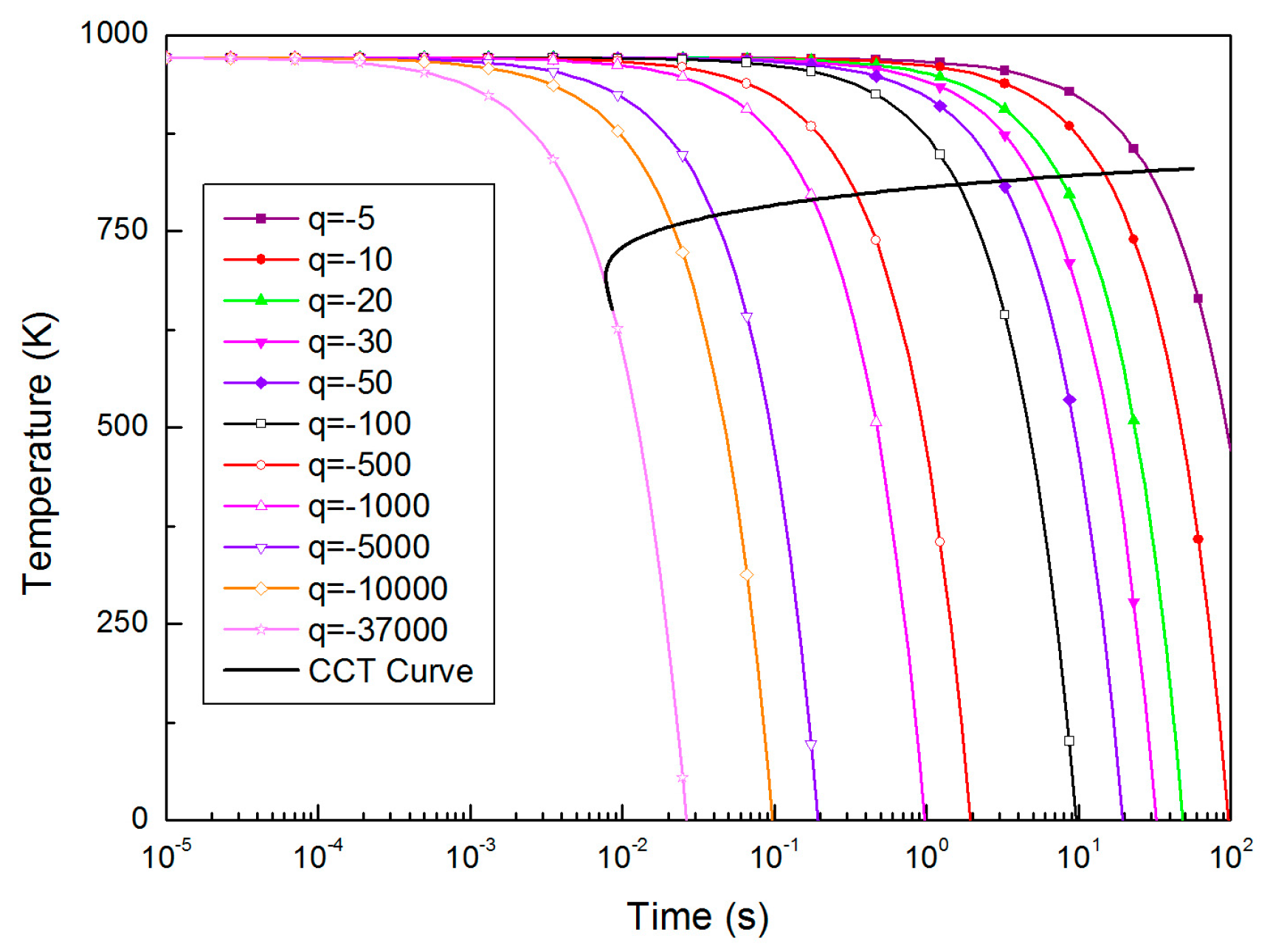

3.2. Calculation of CCT Diagram

4. Results and Discussion

4.1. Estimation of the Critical Cooling Rates Using CCT Curves

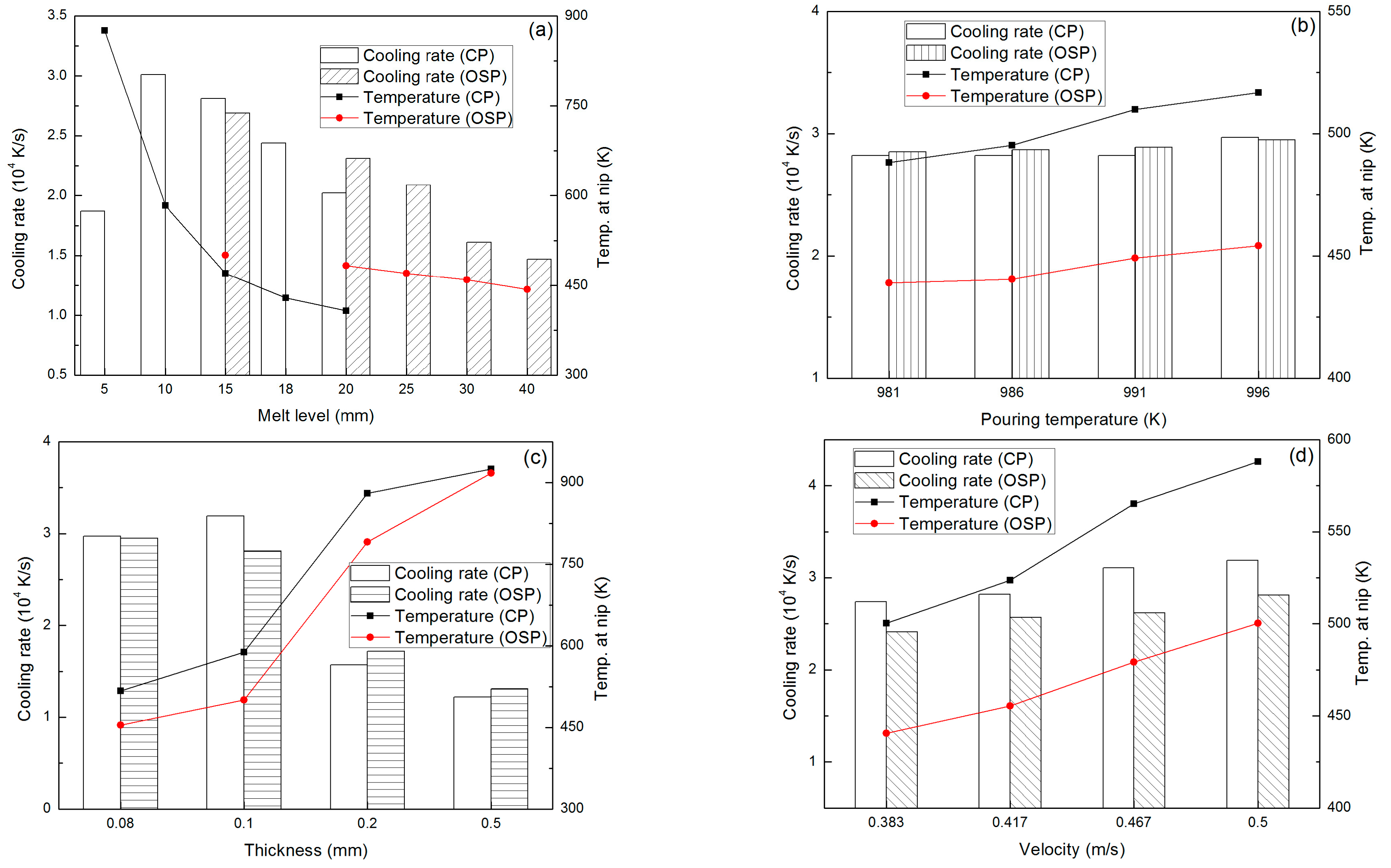

4.2. Influence of Casting Parameters

5. Conclusions

- A CCT diagram of a certain alloy could be attained by the combination of an equation derived by Inoue and the additivity rule.

- Critical cooling rate of a metallic alloy for forming metallic glass could be evaluated using the current method.

- Changing the casting conditions or adopting the one side pouring mode could improve the temperature distribution of the pool metal, and the rolling block can be avoided in the VTRC process.

- Cooling rates with 4 orders of magnitude by the VTRC process under the current conditions can be attained, which shows that the VTRC technique has a potential ability in continuous fabrication of Al-rich bulk metallic alloys in sheet form.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Klement, W.; Willens, R.H.; Duwez, P.O.L. Non-crystalline Structure in Solidified Gold-Silicon Alloys. Nature 1960, 187, 869–870. [Google Scholar] [CrossRef]

- Löffler, J.F.; Kündig, A.A.; Dalla Torre, F.H. Rapid Solidification and Bulk Metallic Glasses—Processing and Properties. In Materals Processing Handbook; Powers, M.T., Lavernia, E.J., Groza, J.R., Shackelford, J.F., Eds.; CRC Press: Boca Raton, FL, USA, 2007; pp. 17-1–17-44. [Google Scholar]

- Bedell, J.R.; Polk, D.E. Method of Continuous Casting Metal Filament on Interior Groove of Chill Roll. Patents US3,881,542 A, 6 May 1975. [Google Scholar]

- Sheldon, K. Method of Forming Metallic Filament Cast on Interior Surface of Inclined Annular Quench Roll. U.S. Patent 3,881,540, 6 May 1975. [Google Scholar]

- Liebermann, H.; Graham, C. Production of amorphous alloy ribbons and effects of apparatus parameters on ribbon dimensions. In Proceedings of the IEEE Transactions on Magnetics, New York, NY, USA, 6 January 1976; Volume 12, pp. 921–923. [Google Scholar]

- Johnson, W.L. Bulk Glass-Forming Metallic Alloys: Science and Technology. MRS Bull. 1999, 24, 42–56. [Google Scholar] [CrossRef]

- Aqida, S.N.; Shah, L.H.; Naher, S.; Brabazon, D. Rapid Solidification Processing and Bulk Metallic Glass Casting. In Comprehensive Materials Processing; Hashmi, S., Ed.; Elsevier: Singapore, 2014; pp. 69–88. [Google Scholar]

- Huang, S.C.; Fiedler, H.C. Amorphous ribbon formatin and the effects of casting velocity. Mater. Sci. Eng. 1981, 51, 39–46. [Google Scholar] [CrossRef]

- Carpenter, J.; Steen, P. Planar-flow spin-casting of molten metals: Process behaviour. J. Mater. Sci. 1992, 27, 215–225. [Google Scholar] [CrossRef]

- Wilde, P.D.; Matthys, E.F. Experimental investigation of the planar flow casting process: Development and free surface characteristics of the solidification puddle. Mater. Sci. Eng. A 1992, 150, 237–247. [Google Scholar] [CrossRef]

- Sohrabi, S.; Arabi, H.; Beitollahi, A.; Gholamipour, R. Planar Flow Casting of Fe71Si13.5B9Nb3Cu1Al1.5Ge1 Ribbons. J. Mater. Eng. Perform. 2013, 22, 2185–2190. [Google Scholar] [CrossRef]

- Metglas®. Avaliable online: http://www.metglas.com/ (accessed on 25 October 2016).

- Praisner, T.J.; Chen, J.S.; Tseng, A.A. An experimental study of process behavior in planar flow melt spinning. Metall. Mater. Trans. B 1995, 26, 1199–1208. [Google Scholar] [CrossRef]

- Jones, H. A perspective on the development of rapid solidification and nonequilibrium processing and its future. Mater. Sci. Eng. A 2001, 304, 11–19. [Google Scholar] [CrossRef]

- Chen, H.S.; Miller, C.E. A Rapid Quenching Technique for the Preparation of Thin Uniform Films of Amorphous Solids. Rev. Sci. Instrum. 1970, 41, 1237–1238. [Google Scholar] [CrossRef]

- Suzuki, T.; Anthony, A.M. Rapid quenching on the binary systems of high temperature oxides. Mater. Res. Bull. 1974, 9, 745–753. [Google Scholar] [CrossRef]

- Lee, J.G.; Park, S.S.; Lee, S.B.; Chung, H.T.; Kim, N.J. Sheet fabrication of bulk amorphous alloys by twin-roll strip casting. Scr. Mater. 2005, 53, 693–697. [Google Scholar] [CrossRef]

- Lee, J.G.; Lee, H.; Oh, Y.S.; Lee, S.; Kim, N.J. Continuous fabrication of bulk amorphous alloy sheets by twin-roll strip casting. Intermetallics 2006, 14, 987–993. [Google Scholar] [CrossRef]

- Oh, Y.S.; Lee, H.; Lee, J.G.; Kim, N.J. Twin-Roll Strip Casting of Iron-Base Amorphous Alloys. Mater. Trans. 2007, 48, 1584–1588. [Google Scholar] [CrossRef]

- Urata, A.; Nishiyama, N.; Amiya, K.; Inoue, A. Continuous casting of thick Fe-base glassy plates by twin-roller melt-spinning. Mater. Sci. Eng. A 2007, 449, 269–272. [Google Scholar] [CrossRef]

- Hofmann, D.C.; Roberts, S.N.; Johnson, W.L. Twin Roll Sheet Casting of Bulk Metallic Glasses and Composites in an Inert Environment. Patent US20130025746 A1, 31 January 2013. [Google Scholar]

- East, D.R.; Kellam, M.; Gibson, M.A.; Seeber, A.; Liang, D.; Nie, J.F. Amorphous magnesium sheet produced by twin roll casting. Mater. Sci. Forum 2010, 654, 1078–1081. [Google Scholar] [CrossRef]

- Park, Y.S.; Lee, S.B.; Kim, N.J. Microstructure and Mechanical Properties of Strip Cast Al-Mg-Si-X Alloys. Mater. Trans. 2003, 44, 2617–2624. [Google Scholar] [CrossRef]

- Ding, P.D.; Pan, F.S.; Jiang, B.; Wang, J.; Li, H.L.; Wu, J.C.; Wen, Y. Twin-roll strip casting of magnesium alloys in China. Trans. Nonferr. Met. Soci. China 2008, 18, s7–s11. [Google Scholar] [CrossRef]

- Hu, X.D.; Ju, D.Y.; Zhao, H. Y. Thermal flow simulation of twin-roll casting magnesium alloy. J. Shanghai Jiaotong Univ. Sci. 2012, 17, 479–483. [Google Scholar] [CrossRef]

- Haga, T.; Suzuki, S. Melt ejection twin roll caster for the strip casting of aluminum alloy. J. Mater. Process. Technol. 2003, 137, 92–95. [Google Scholar] [CrossRef]

- Sun, B.A.; Pan, M.X.; Zhao, D.Q.; Wang, W.H.; Xi, X.K.; Sandor, M.T.; Wu, Y. Aluminum-rich bulk metallic glasses. Scr. Mater. 2008, 59, 1159–1162. [Google Scholar] [CrossRef]

- Chen, Z.P.; Gao, J.E.; Wu, Y.; Wang, H.; Liu, X.J.; Lu, Z.P. Designing novel bulk metallic glass composites with a high aluminum content. Sci. Rep. 2013, 3. [Google Scholar] [CrossRef] [PubMed]

- Takeuchi, A.; Inoue, A. Evaluation of Glass-Forming Ability for Metallic Glasses from Time-Reduced Temperature-Transformation Diagram. Mater. Trans. 2001, 42, 2374–2381. [Google Scholar] [CrossRef]

- Uhlmann, D.R. A kinetic treatment of glass formation. J. Non-Cryst. Solids 1972, 7, 337–348. [Google Scholar] [CrossRef]

- Lee, S.B.; Kim, N.J. Kinetics of crystallization in continuously cooled BMG. Mater. Sci. Eng. A 2005, 404, 153–158. [Google Scholar] [CrossRef]

- Takeuchi, A.; Inoue, A. Quantitative evaluation of critical cooling rate for metallic glasses. Mater. Sci. Eng. A 2001, 304, 446–451. [Google Scholar] [CrossRef]

- Inoue, A.; Nakamura, T.; Sugita, T.; Zhang, T.; Masumoto, T. Bulky La-Al-TM (TM=Transition Metal) Amorphous Alloys with High Tensile Strength Produced by a High-Pressure Die Casting Method. Mater. Trans. JIM 1993, 34, 351–358. [Google Scholar] [CrossRef]

- Yang, G.N.; Shao, Y.; Yao, K.F.; Chen, S.Q. A study of cooling process in bulk metallic glasses fabrication. AIP Adv. 2015, 5. [Google Scholar] [CrossRef]

- Xu, K.; Wang, Y.; Li, J.; Li, Q. Critical cooling rate for the glass formation of ferromagnetic Fe80P13C7 alloy. Acta Metall. Sin. 2013, 26, 56–62. [Google Scholar] [CrossRef]

- Umemoto, M.; Horiuchi, K.; Tamura, I. Pearlite Transformation during Continuous Cooling and Its Relation to Isothermal Transformation. Trans. Iron Steel Inst. Jpn. 1983, 23, 690–695. [Google Scholar] [CrossRef]

- Busch, R.; Liu, W.; Johnson, W.L. Thermodynamics and kinetics of the Mg65Cu25Y10 bulk metallic glass forming liquid. J. Appl. Phys. 1998, 83, 4134–4141. [Google Scholar] [CrossRef]

- Inoue, T.; Ju, D.Y.; Yosihara, N. Temperature and Viscoplastic Stresses During Vertical Semi-Continuous Direct Chill Casting of Aluminum Alloy. In International Conference on Residual Stresses (ICRS2); Beck, G., Denis, S., Simon, A., Eds.; Springer: Dordrecht, The Netherlands, 1989; pp. 523–528. [Google Scholar]

| Year | Type | Cooling Rate (K/s) | Speed (rpm) | References |

|---|---|---|---|---|

| 1970 | Vertical | 105 | 100–5000 | [15] |

| 1974 | Vertical | 105 | --- | [16] |

| 2005 | Horizontal | 102–103 | 1, 3 | [17,18,23] |

| 2007 | Horizontal | --- | 0.75 m/s | [20] |

| 2010 | Horizontal | --- | 102 m/s | [22] |

| 2013 | Vertical | 1–103 | --- | [21] |

| Alloy | η0 (Pa·s) | B (K) | Br | D* | T0 (K) | T0r | Tm (K) | x |

|---|---|---|---|---|---|---|---|---|

| Al35La50Ni15/Hypothetical alloys | 2.39 × 10−5 | 4893.84 | 5.04 | 18 | 271.88 | 0.28 | 971 | 10−6 |

| 7049.46 | 7.26 | 22 | 320.43 | 0.33 | ||||

| 6059.04 | 6.24 | 16 | 378.69 | 0.39 | ||||

| 4466.6 | 4.6 | 10 | 446.66 | 0.46 | ||||

| 3884 | 4 | 8 | 485.5 | 0.5 | ||||

| 2621.7 | 2.7 | 5 | 524.34 | 0.54 |

| Melt Level/L (mm) | 11.63 | 15 | 20 | 25 | 30 | 35 | |

|---|---|---|---|---|---|---|---|

| Cooling Rate (104 K/s) R (737.96) | CP | 3.24 | 3.88 | 3.27 | 38 | 39.6 | --- |

| OSP | --- | 3.53 | 2.77 | 3.59 | 2.21 | 2.74 | |

| Tnip (K) | CP | 497.16 | 445.27 | 405.11 | 396.25 | 395.44 | --- |

| OSP | --- | 470.54 | 501.07 | 458.26 | 423.21 | 417.58 | |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pei, Z.; Ju, D. Simulation of the Continuous Casting and Cooling Behavior of Metallic Glasses. Materials 2017, 10, 420. https://doi.org/10.3390/ma10040420

Pei Z, Ju D. Simulation of the Continuous Casting and Cooling Behavior of Metallic Glasses. Materials. 2017; 10(4):420. https://doi.org/10.3390/ma10040420

Chicago/Turabian StylePei, Zhipu, and Dongying Ju. 2017. "Simulation of the Continuous Casting and Cooling Behavior of Metallic Glasses" Materials 10, no. 4: 420. https://doi.org/10.3390/ma10040420