The Effect of Milling Time on the Microstructural Characteristics and Strengthening Mechanisms of NiMo-SiC Alloys Prepared via Powder Metallurgy

Abstract

:1. Introduction

2. Methods

3. Results and Discussion

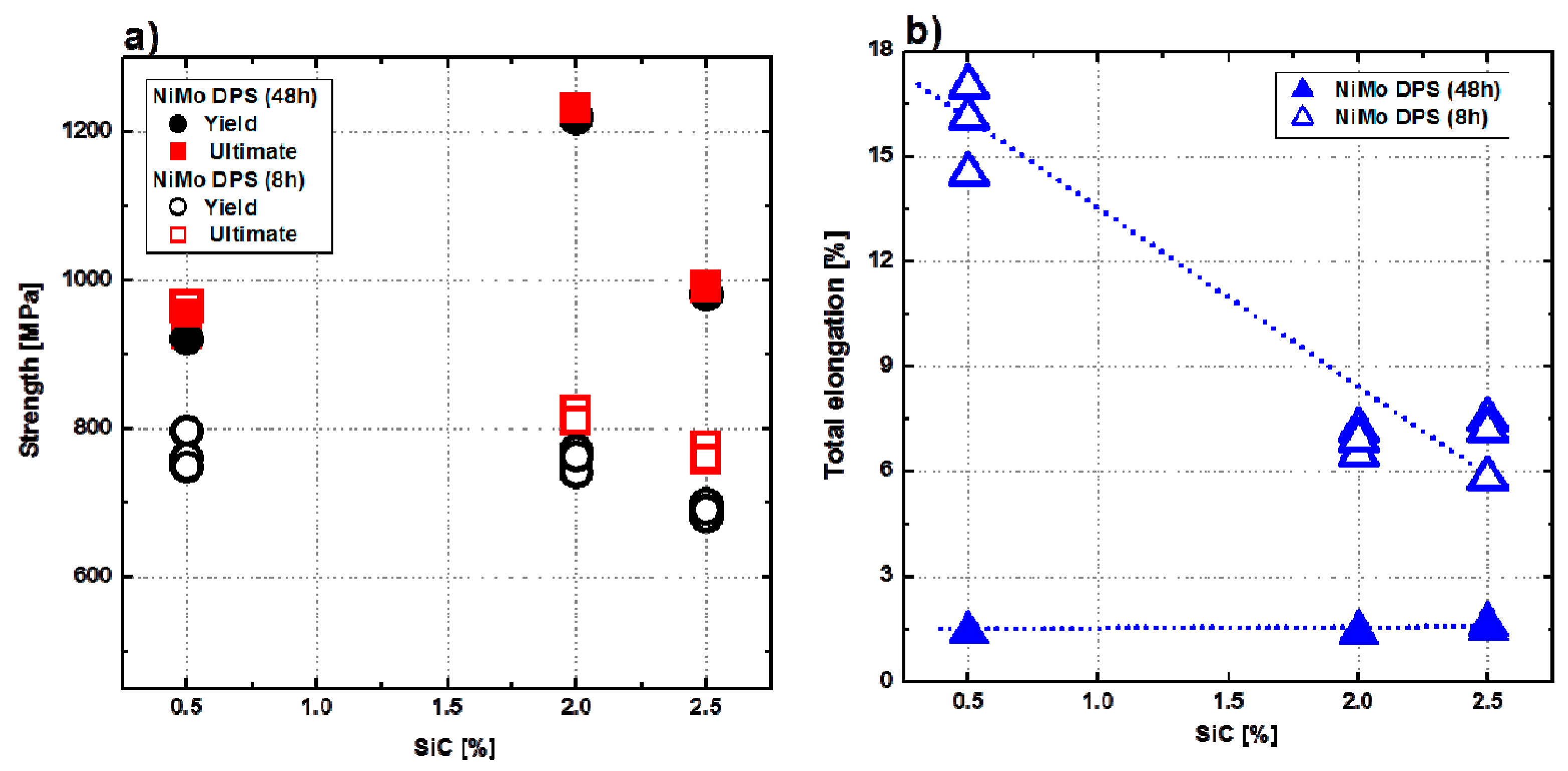

3.1. Mechanical Properties

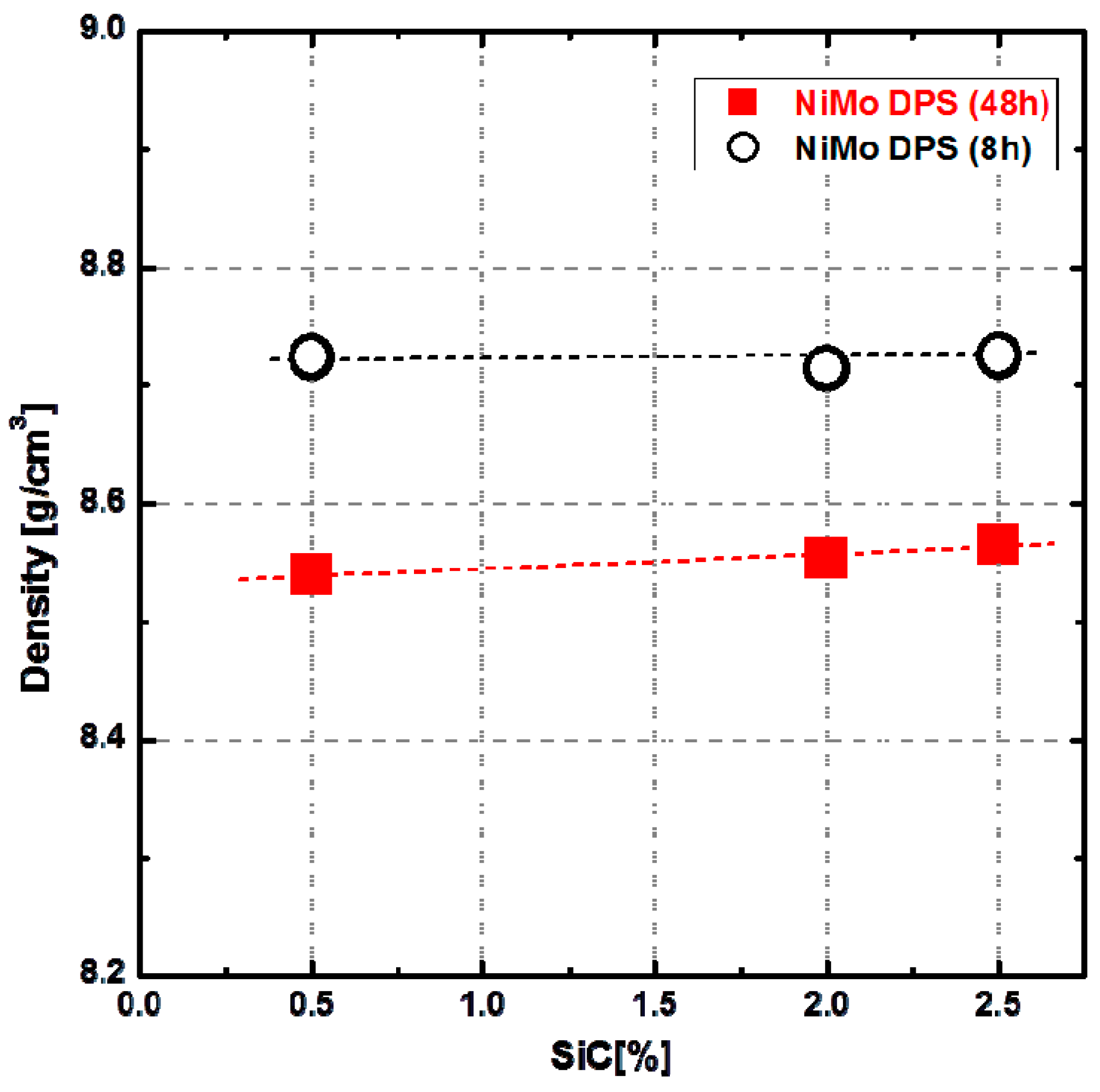

3.2. Density Analysis

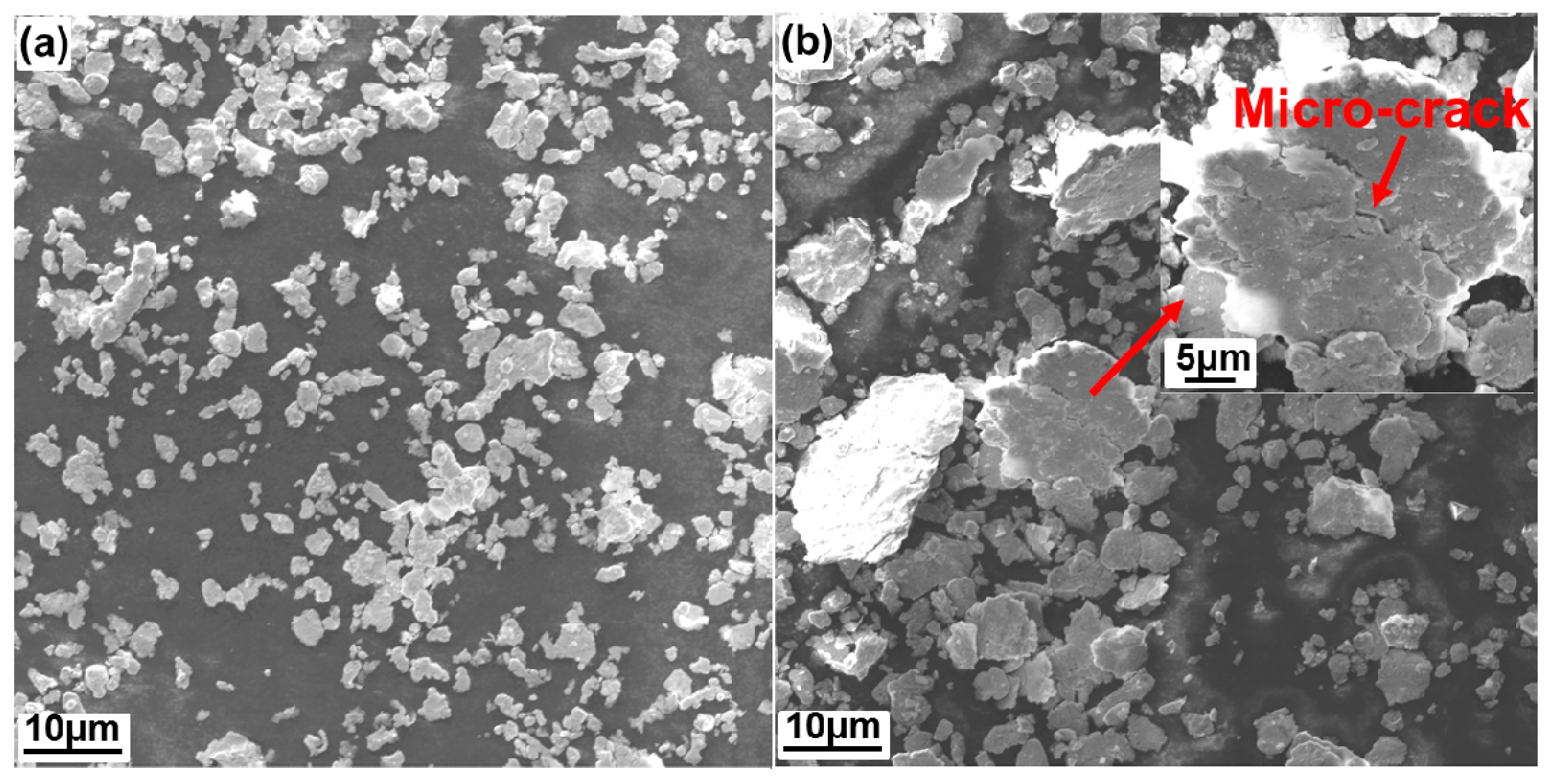

3.3. Microstructure Characterization

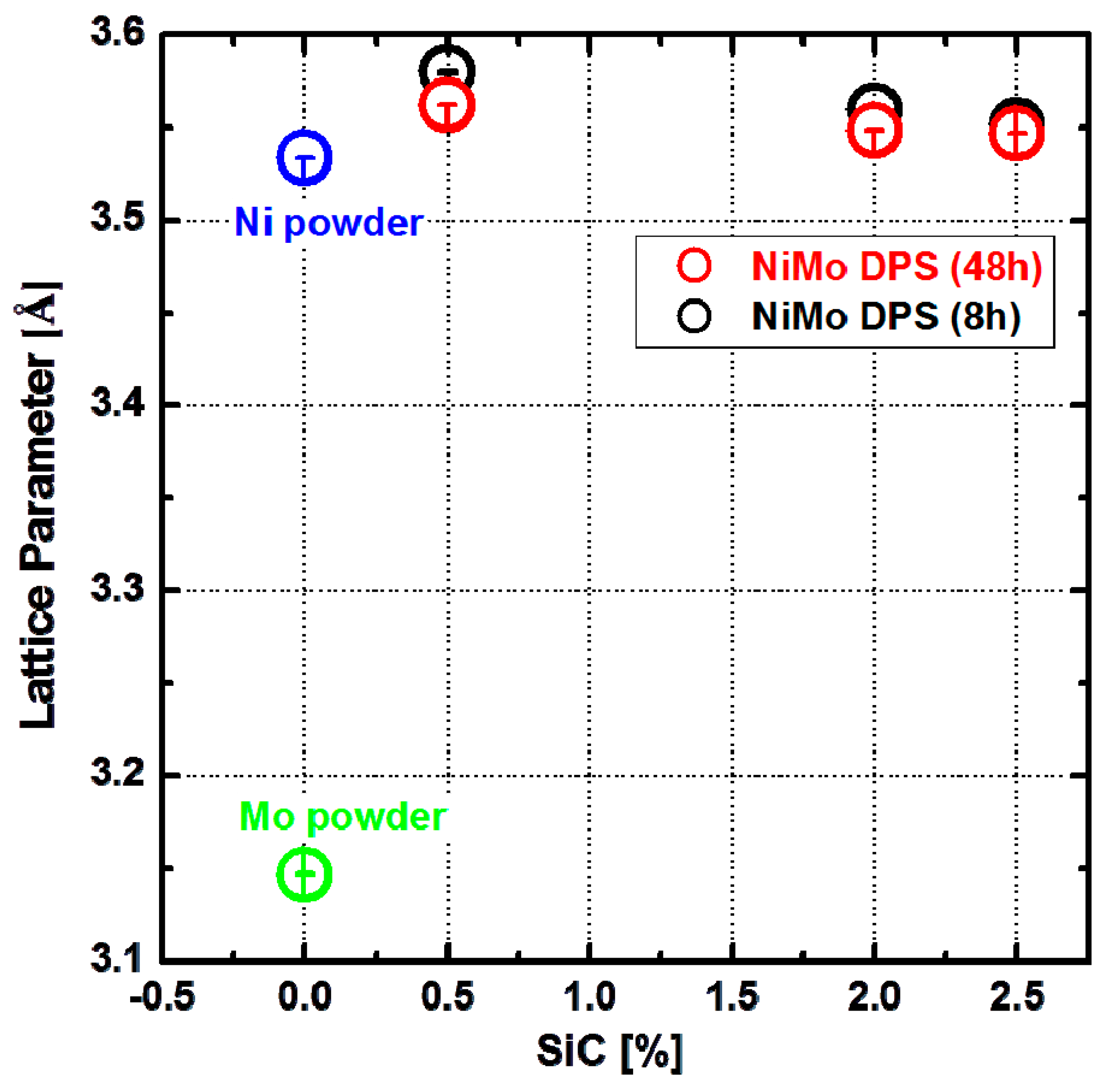

3.3.1. Neutron Diffraction Analysis

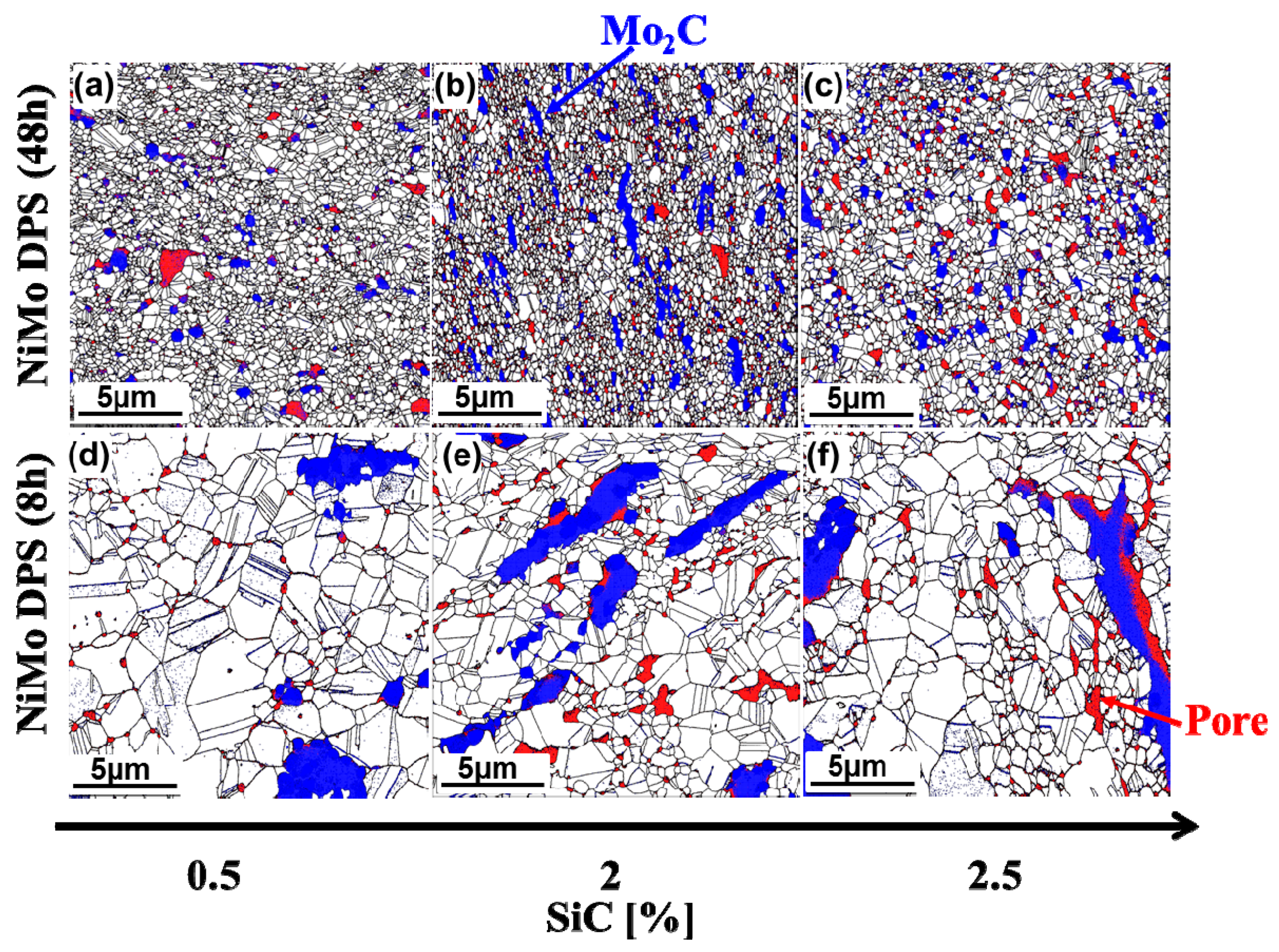

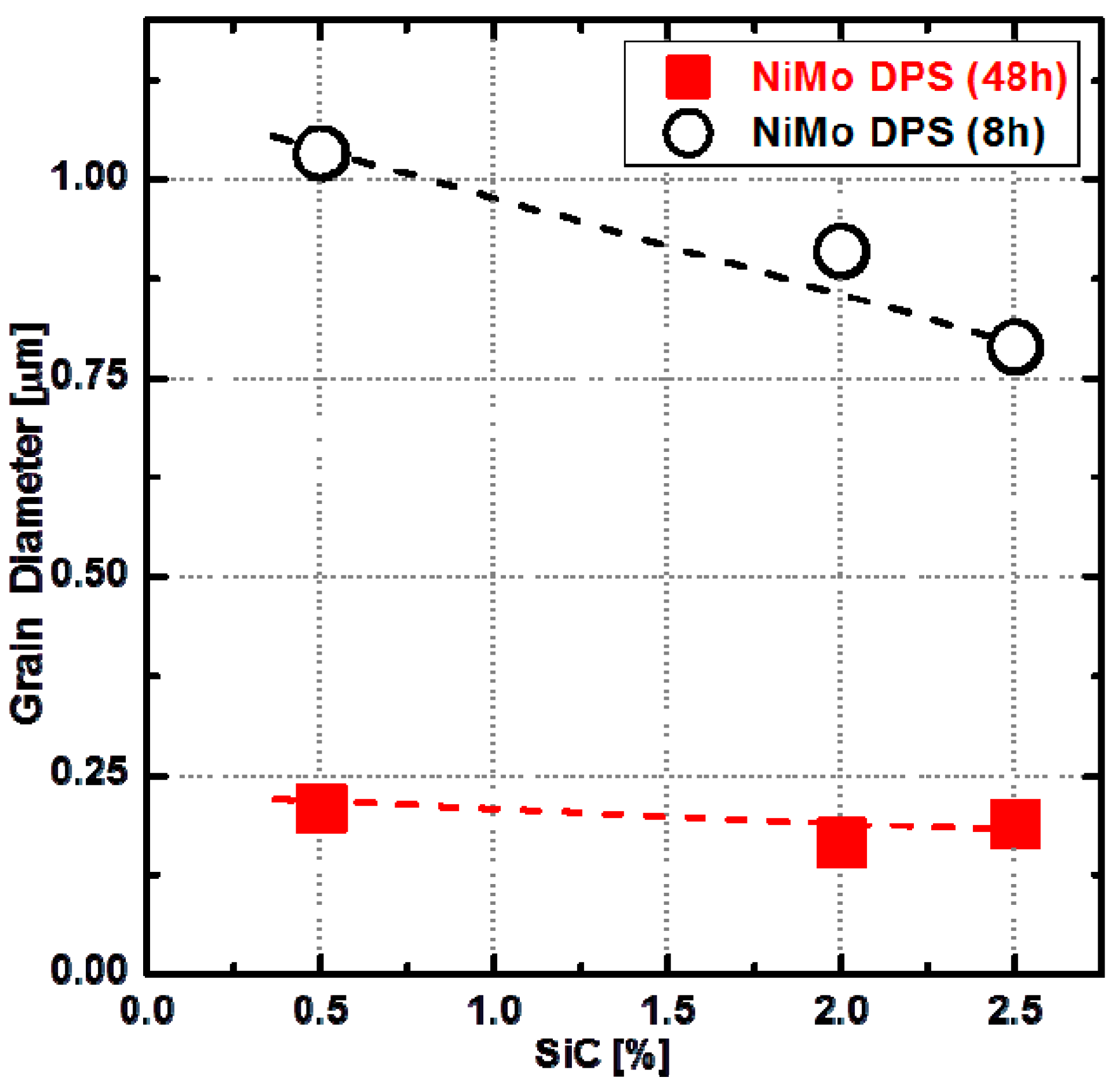

3.3.2. EBSD Analysis

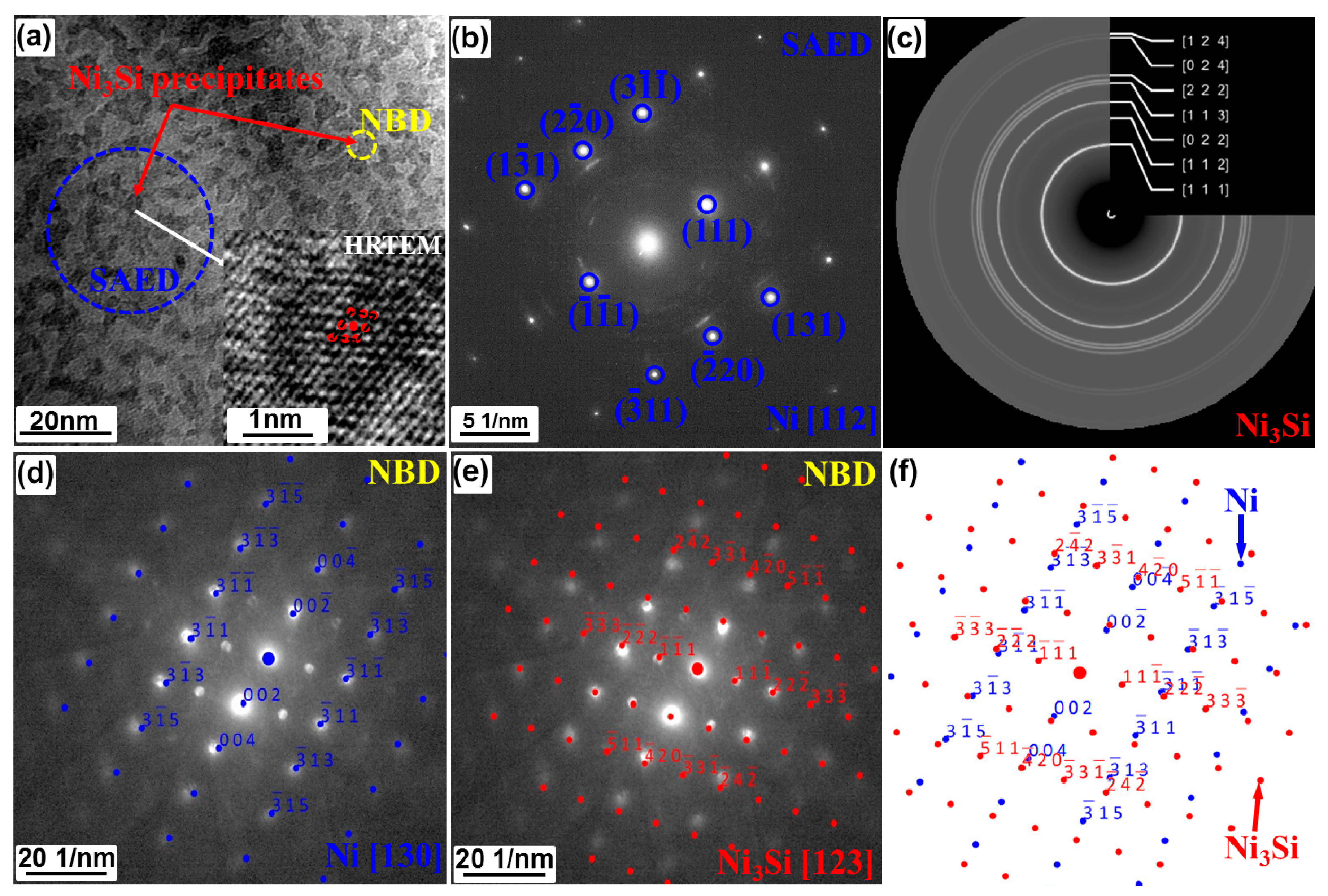

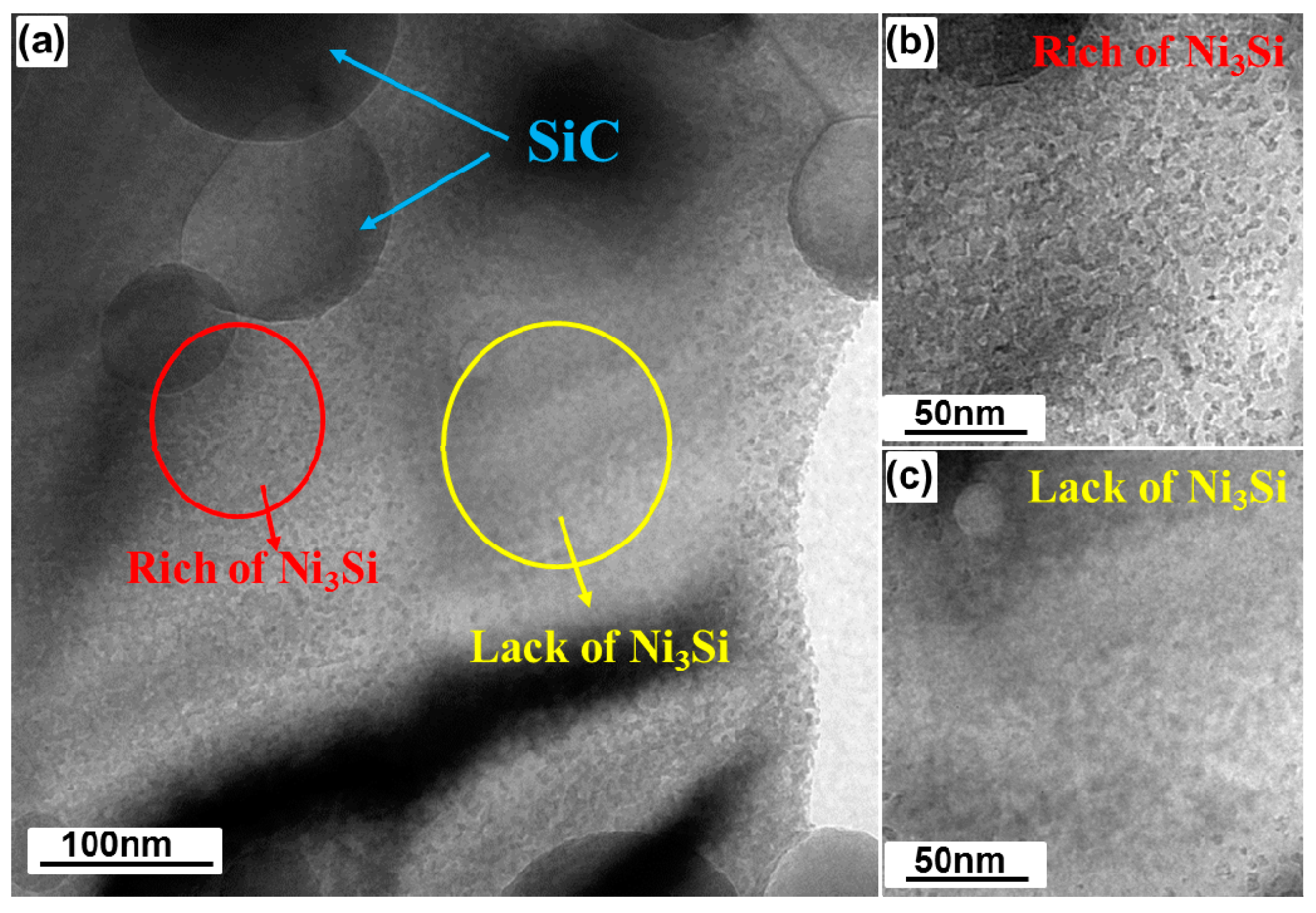

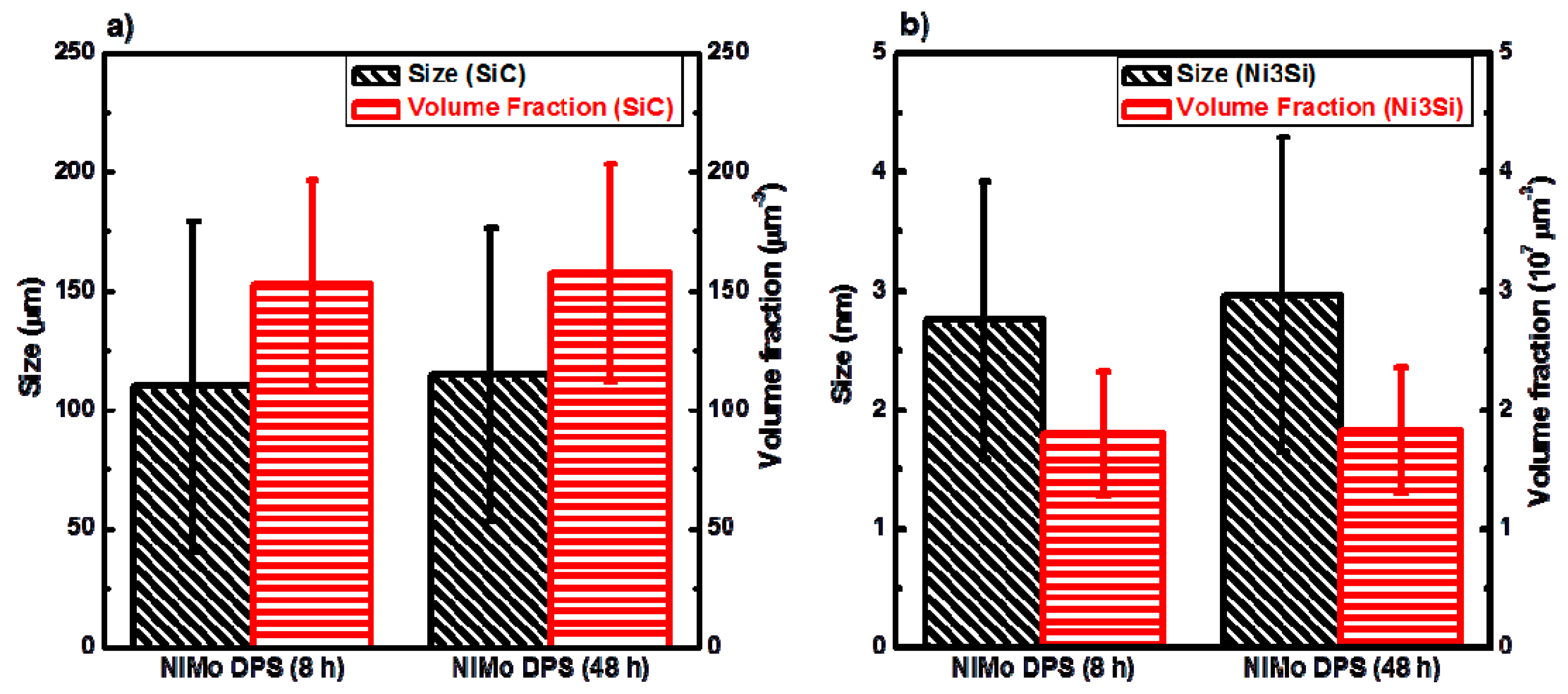

3.3.3. TEM Analysis

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Waldrop, M.M. Nuclear energy: Radical reactors. Nature 2012, 492, 26–29. [Google Scholar] [CrossRef] [PubMed]

- Moir, R.; Teller, E. Thorium-fueled underground nuclear power plant based on molten salt technology. Fizikai Szemle 2011, 61, 365–371. [Google Scholar]

- Mathieu, L.; Heuer, D.; Brissot, R.; Garzenne, C.; le Brun, C.; Lecarpentier, D.; Liatard, E.; Loiseaux, J.M.; Meplan, O.; Merle-Lucotte, E. The thorium molten salt reactor: Moving on from the MSBR. Prog. Nucl. Energy 2006, 48, 664–679. [Google Scholar] [CrossRef]

- LeBlanc, D. Molten salt reactors: A new beginning for an old idea. Nucl. Eng. Des. 2010, 240, 1644–1656. [Google Scholar] [CrossRef]

- Ren, W.; Muralidharan, G.; Wilson, D.F.; Holcomb, D.E. Considerations of alloy N for fluoride salt-cooled high-temperature reactor applications. In Proceedings of the ASME 2011 Pressure Vessels and Piping Conference, American Society of Mechanical Engineers, Baltimore, MD, USA, 17–21 July 2011; pp. 725–736. [Google Scholar]

- Yang, C.; Huang, H.F.; de los Reyes, M.; Yan, L.; Zhou, X.T.; Xia, T.; Zhang, D.L. Microstructures and tensile properties of ultrafine-grained Ni-(1–3.5) wt% SiCNP composites prepared by a powder metallurgy route. Acta Metall. Sin. (Engl. Lett.) 2015, 28, 809–816. [Google Scholar] [CrossRef]

- Huang, H.; Yang, C.; de los Reyes, M.; Zhou, Y.; Yan, L.; Zhou, X. Effect of milling time on the microstructure and tensile properties of ultrafine grained Ni–SiC composites at room temperature. J. Mater. Sci. Technol. 2015, 31, 923–929. [Google Scholar] [CrossRef]

- Yang, C.; Huang, H.; Zhou, X.; Li, Z.; Zhou, X.; Xia, T.; Zhang, D. High-temperature stability of Ni-3 wt.% SiCNP composite and the effect of milling time. J. Nucl. Mater. 2015, 467, 635–643. [Google Scholar] [CrossRef]

- Nieh, T. Creep rupture of a silicon carbide reinforced aluminum composite. Metall. Trans. A. 1984, 15, 139–146. [Google Scholar] [CrossRef]

- Carreño-Gallardo, C.; Estrada-Guel, I.; López-Meléndez, C.; Martínez-Sánchez, R. Dispersion of silicon carbide nanoparticles in a AA2024 aluminum alloy by a high-energy ball mill. J. Alloys Compd. 2014, 586, S68–S72. [Google Scholar] [CrossRef]

- Yang, C.; Muránsky, O.; Zhu, H.; Thorogood, G.J.; Huang, H.; Zhou, X. On the origin of strengthening mechanisms in Ni-Mo alloys prepared via powder metallurgy. Mater. Des. 2017, 113, 223–231. [Google Scholar] [CrossRef]

- Allison, M.; Avdeev, M.; Schmid, S.; Liu, S.; Söhnel, T.; Ling, C. Synthesis, structure and geometrically frustrated magnetism of the layered oxide-stannide compounds Fe (Fe3− xMnx) Si2Sn7O16. Dalton Trans. 2016, 45, 9689–9694. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.H.; Wang, F.C.; Wang, L.; Li, S.K. Ultrafine-grained copper prepared by spark plasma sintering process. Mater. Sci. Eng. A. 2008, 476, 201–205. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, F.; Wang, L.; Li, S.; Shen, M.; Osamu, S. Microstructural characteristics of large-scale ultrafine-grained copper. Mater. Charact. 2008, 59, 329–333. [Google Scholar] [CrossRef]

- Li, W.; Xiong, C.; Jia, L.; Pu, J.; Chi, B.; Chen, X.; Schwank, J.; Li, J. Strontium-doped samarium manganite as cathode materials for oxygen reduction reaction in solid oxide fuel cells. J. Power Sources. 2015, 284, 272–278. [Google Scholar] [CrossRef]

- Deng, H.; Zhao, Z.; Wang, J.; Hei, Z.; Li, M.; Noh, H.M.; Jeong, J.H.; Yu, R. Photoluminescence properties of a new orange–red emitting Sm 3+-doped Y2 Mo4O15 phosphor. J. Solid State Chem. 2015, 228, 110–116. [Google Scholar] [CrossRef]

- Liu, B.; Jia, X.; Huo, D.; Sun, H.; Zhang, Y.; Sun, B.; Liu, H.; Kong, L.; Ma, H. Evolution of thermoelectric properties of substituted Si-based clathrates prepared by HPHT. J. Alloys Compd. 2016, 666, 93–97. [Google Scholar] [CrossRef]

- Hunter, N.J.; Hasalová, P.; Weinberg, R.F.; Wilson, C.J. Fabric controls on strain accommodation in naturally deformed mylonites: The influence of interconnected micaceous layers. J. Struct. Geol. 2016, 83, 180–193. [Google Scholar] [CrossRef]

- Geiger, F.; Kunze, K.; Etter, T. Tailoring the texture of IN738LC processed by selective laser melting (SLM) by specific scanning strategies. Mater. Sci. Eng. A 2016, 661, 240–246. [Google Scholar] [CrossRef]

- Mainprice, D.; Bachmann, F.; Hielscher, R.; Schaeben, H.; Lloyd, G.E. Calculating anisotropic piezoelectric properties from texture data using the MTEX open source package. Geol. Soc. Lond. Special Publ. 2015, 409, 223–249. [Google Scholar] [CrossRef]

- Klinger, M.; Jäger, A. Crystallographic Tool Box (CrysTBox): Automated tools for transmission electron microscopists and crystallographers. J. Appl. Crystallogr. 2015, 48, 2012–2018. [Google Scholar] [CrossRef] [PubMed]

- Hay, R.; Boakye, E.; Mogilevsky, P.; Fair, G.; Parthasarathy, T.; Davis, J. Transformation plasticity in (GdxDy1−x) PO4 fiber coatings during fiber push out. J. Am. Ceram. Soc. 2013, 96, 1586–1595. [Google Scholar] [CrossRef]

- Delice, S.; Isik, M.; Bulur, E.; Gasanly, N. Thermoluminescence properties of Tl2Ga2S3Se layered single crystals. J. Appl. Phys. 2013, 113, 193510. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, C.; Muránsky, O.; Zhu, H.; Thorogood, G.J.; Avdeev, M.; Huang, H.; Zhou, X. The Effect of Milling Time on the Microstructural Characteristics and Strengthening Mechanisms of NiMo-SiC Alloys Prepared via Powder Metallurgy. Materials 2017, 10, 389. https://doi.org/10.3390/ma10040389

Yang C, Muránsky O, Zhu H, Thorogood GJ, Avdeev M, Huang H, Zhou X. The Effect of Milling Time on the Microstructural Characteristics and Strengthening Mechanisms of NiMo-SiC Alloys Prepared via Powder Metallurgy. Materials. 2017; 10(4):389. https://doi.org/10.3390/ma10040389

Chicago/Turabian StyleYang, Chao, Ondrej Muránsky, Hanliang Zhu, Gordon J. Thorogood, Maxim Avdeev, Hefei Huang, and Xingtai Zhou. 2017. "The Effect of Milling Time on the Microstructural Characteristics and Strengthening Mechanisms of NiMo-SiC Alloys Prepared via Powder Metallurgy" Materials 10, no. 4: 389. https://doi.org/10.3390/ma10040389

APA StyleYang, C., Muránsky, O., Zhu, H., Thorogood, G. J., Avdeev, M., Huang, H., & Zhou, X. (2017). The Effect of Milling Time on the Microstructural Characteristics and Strengthening Mechanisms of NiMo-SiC Alloys Prepared via Powder Metallurgy. Materials, 10(4), 389. https://doi.org/10.3390/ma10040389