A Novel Extrusion for Manufacturing TiBw/Ti6Al4V Composite Tubes with a Quasi-Continuous Reinforced Structure

Abstract

:1. Introduction

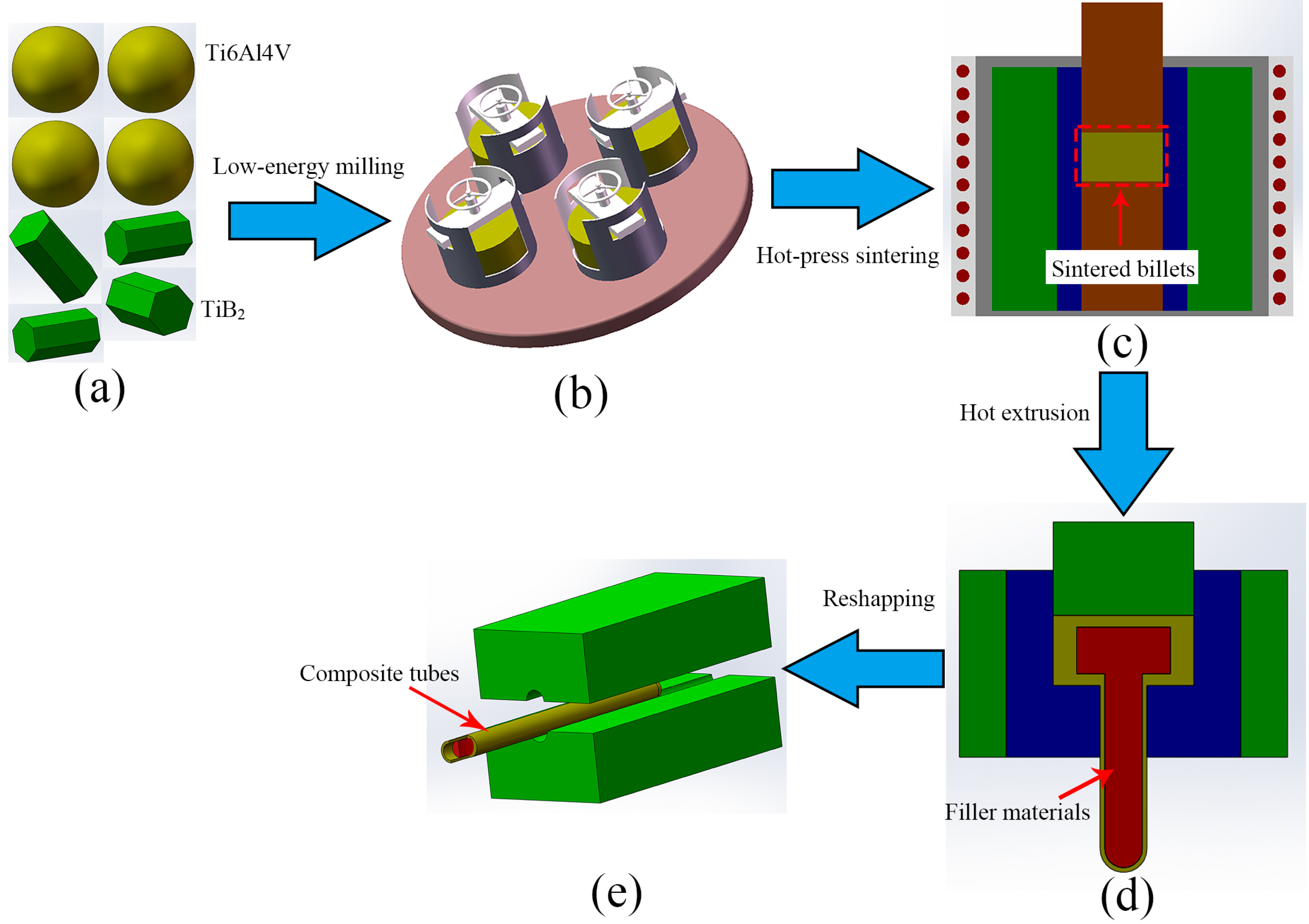

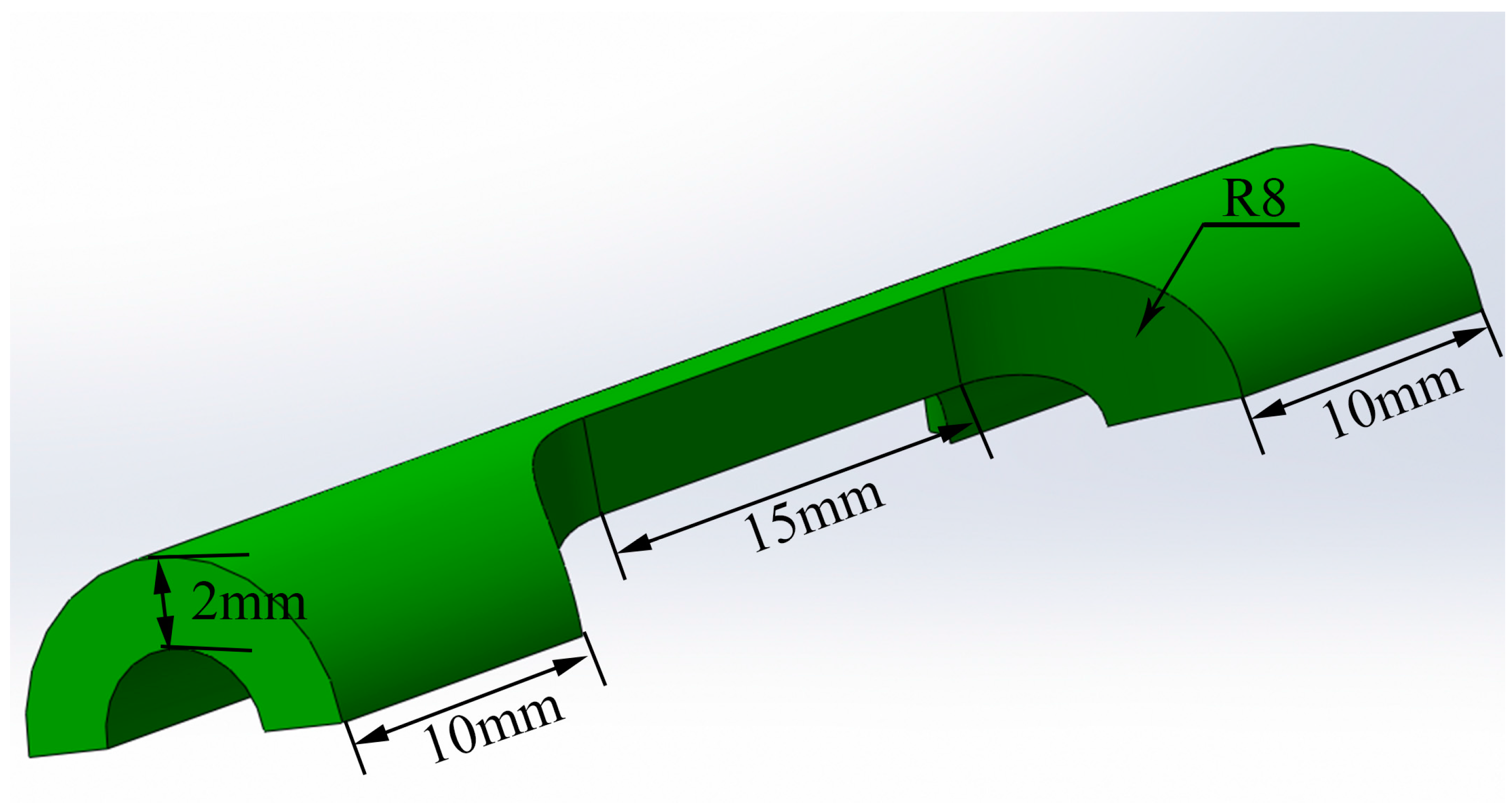

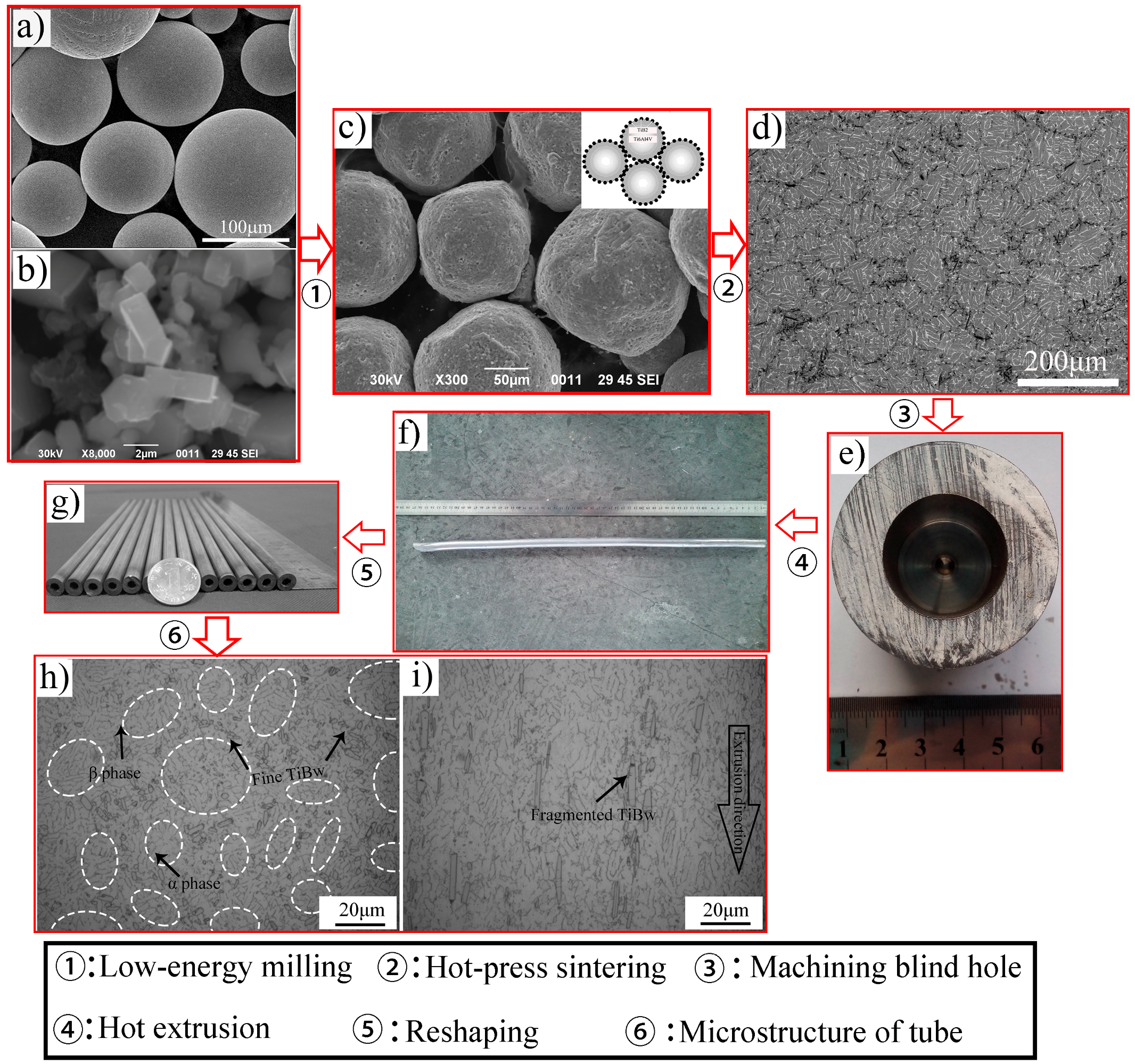

2. Experimental Section

3. Results and Discussion

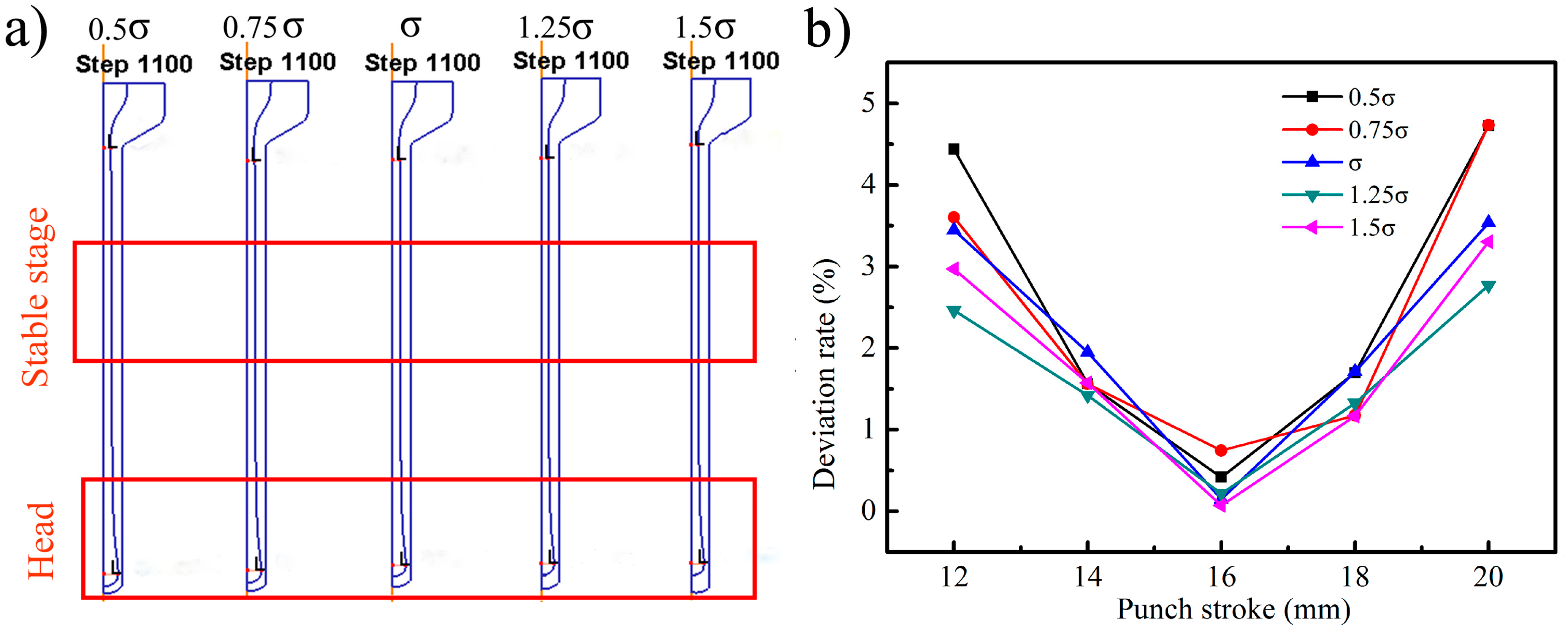

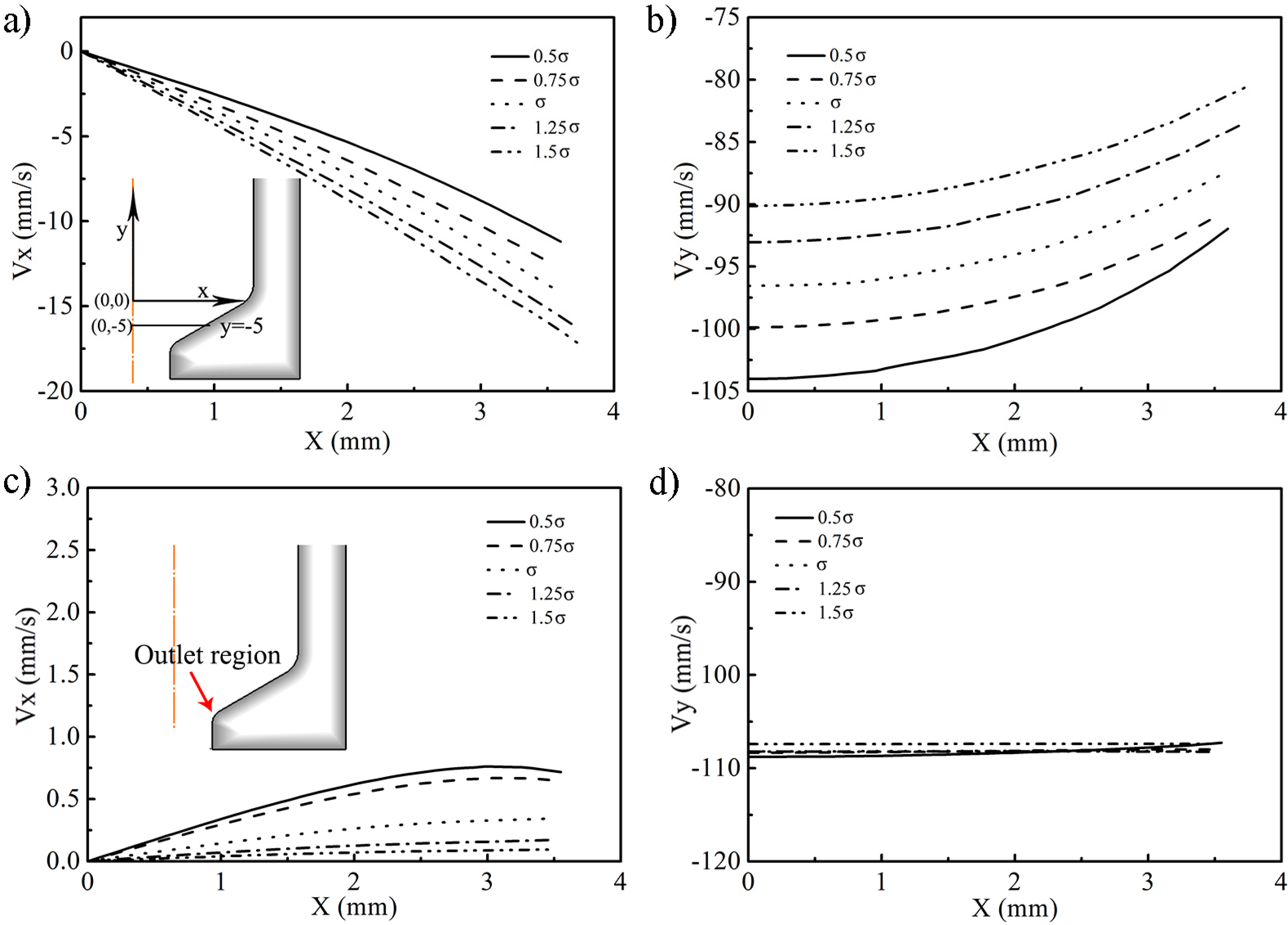

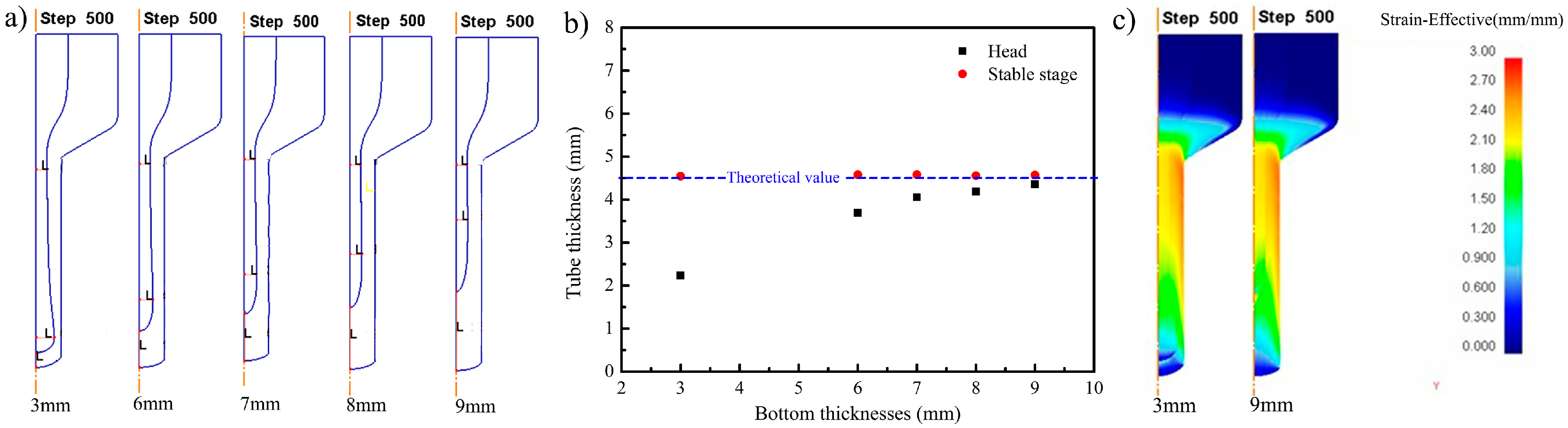

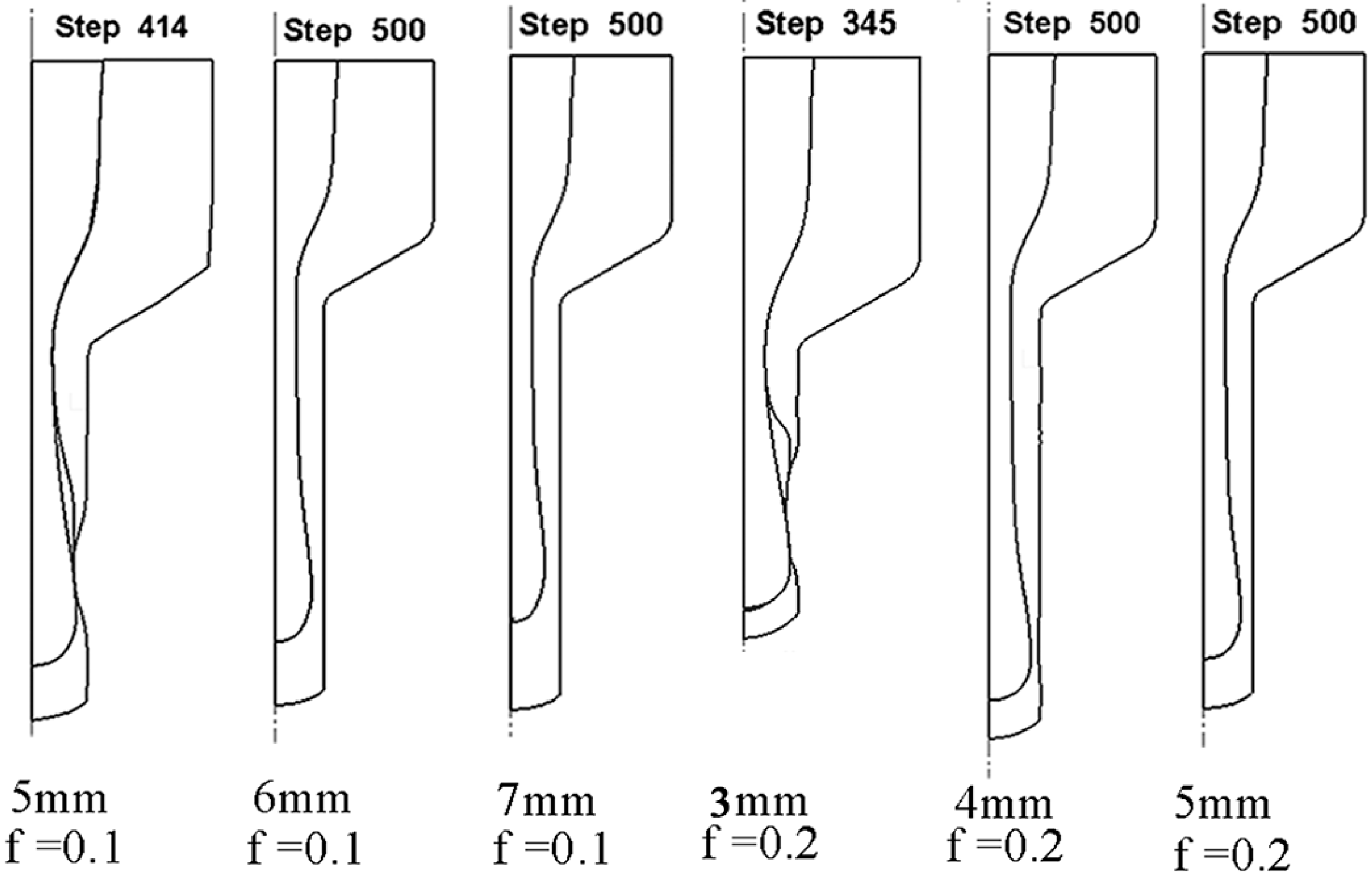

3.1. Numerical Modeling

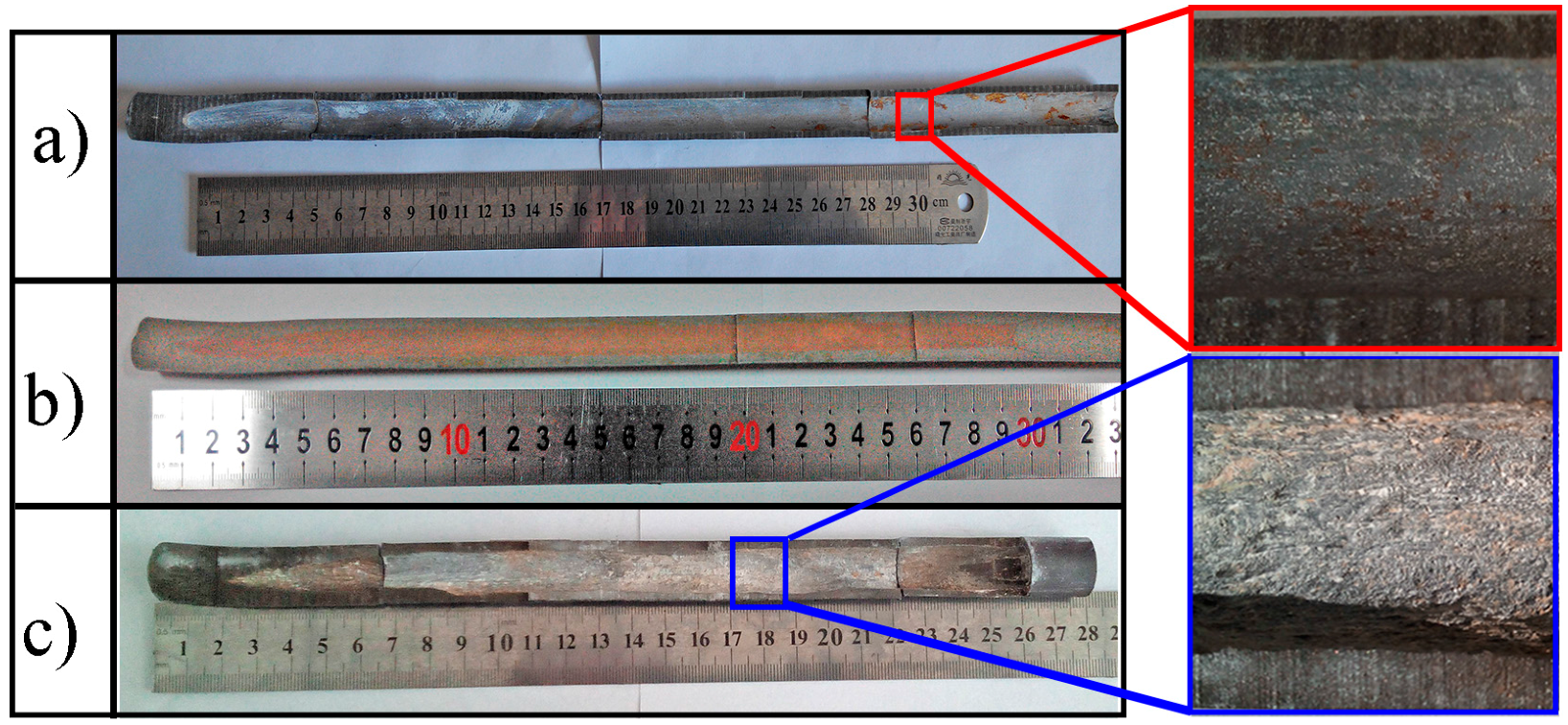

3.2. TiBw/Ti6Al4V Composite Tube

4. Conclusions

- It is feasible to fabricate the TiBw/Ti6Al4V composite tubes via hot extrusion with a filler material.

- Based on the simulation results, the deformation resistance of the filler material is relatively unimportant for the tube shape compared with the friction coefficient and the bottom thickness. Considering the difficulty of removing the filler material, BN powder can be adopted. In addition, with increasing the friction coefficient, inhomogeneous deformation at the head region tends to weaken. The cracking at the head region can be avoided by the coordination of the friction coefficient and the bottom thickness.

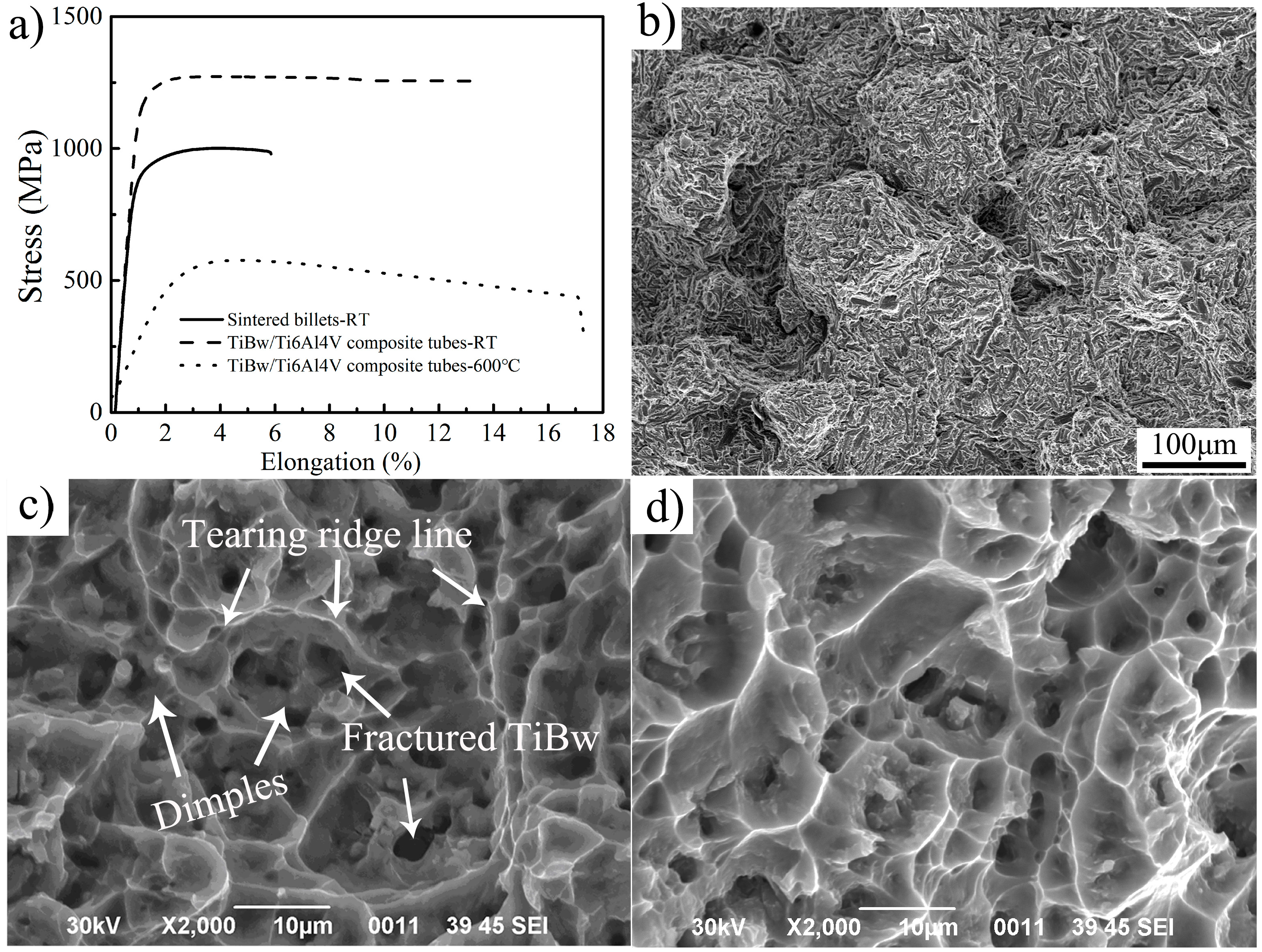

- After extrusion, the transverse section microstructure of the TiBw/Ti6Al4V composite tube remained in the quasi-continuous structure and the TiBw were rotated to align along the extrusion direction. Moreover, the tensile strength and elongation can reach 1240 MPa, 13.5% at room temperature and 577 MPa, 17.1% at 600 °C, which result from dynamic recrystallization and TiB whisker strengthening.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Tjong, S.; Mai, Y. Processing-structure-property aspects of particulate and whisker-reinforced titanium matrix composites. Compos. Sci. Technol. 2008, 68, 583–601. [Google Scholar] [CrossRef]

- Zadra, M.; Girardini, L. High-performance, low-cost titanium metal matrix composites. Mater. Sci. Eng. A 2014, 608, 155–163. [Google Scholar] [CrossRef]

- Choi, C.J.; Kim, I.K.; Lee, Y.Z.; Kim, Y.J. Microstructure and friction/wear behavior of (TiB + TiC) particulate-reinforced titanium matrix composites. Wear 2014, 318, 68–77. [Google Scholar] [CrossRef]

- Miracle, D.B. Metal matrix composites-from science to technological significance. Compos. Sci. Technol. 2005, 65, 2526–2540. [Google Scholar] [CrossRef]

- Kondoh, K. Titanium metal matrix composites by powder metallurgy (PM) routes. In Titanium Powder Metallurg; Elsevier: Amsterdam, The Netherlands, 2015; pp. 277–297. [Google Scholar]

- Liu, D.; Zhang, S.Q.; Li, A.; Wang, H.M. Creep rupture behaviors of a laser melting deposited TiC/TA15 in situ titanium matrix composite. Mater. Des. 2010, 31, 3127–3133. [Google Scholar] [CrossRef]

- Qiu, P.K.; Li, H.; Sun, X.L. Reinforcements stimulated dynamic recrystallization behavior and tensile properties of extruded (TiB + TiC + La2O3)/Ti6Al4V composites. J. Alloys Compd. 2017, 699, 874–881. [Google Scholar] [CrossRef]

- Huang, L.J.; Geng, L.; Li, A.B.; Yang, F.Y.; Peng, H.X. In situ TiBw/Ti-6Al-4V composites with novel reinforcement architecture fabricated by reaction hot pressing. Scr. Mater. 2009, 69, 996–999. [Google Scholar] [CrossRef]

- Zhang, W.C.; Wang, M.M.; Chen, W.Z. Evolution of inhomogeneous reinforced structure in TiBw/Ti-6AL-4V composite prepared by pre-sintering and canned β extrusion. Mater. Des. 2015, 88, 471–477. [Google Scholar] [CrossRef]

- Gorsse, S.; Miracle, D.B. Mechanical properties of Ti-6Al-4V/TiB composites with randomly oriented and aligned TiB reinforcements. Acta Mater. 2003, 51, 2427–2442. [Google Scholar] [CrossRef]

- Boehlert, C.J.; Tamirisakandal, S.; Curtin, W.A.; Miracle, D.B. Assessment of in situ TiB whisker tensile strength and optimization of TiB-reinforced titanium alloy design. Scr. Mater. 2009, 61, 245–248. [Google Scholar] [CrossRef]

- Wang, B.; Huang, L.J.; Geng, L.; Rong, X.D. Compressive behaviors and mechanisms of TiB whiskers reinforced high temperature Ti60 alloy matrix composites. Mater. Sci. Eng. A 2015, 648, 443–451. [Google Scholar] [CrossRef]

- Zhang, W.C.; Feng, Y.J.; Chen, W.Z.; Yang, J.L. Effects of heat treatment on the microstructure and mechanical properties of in situ inhomogeneous TiBw/Ti6Al4V composite fabricated by pre-sintering and canned powder extrusion. J. Alloys Compd. 2017, 693, 1116–1123. [Google Scholar] [CrossRef]

- Ozerov, M.; Klimov, M.; Kolesnikov, A.; Stepanov, N.; Zherebtsov, S. Deformation behavior and microstructure evolution of a Ti/TiB metal-matrix composite during high-temperature compression tests. Mater. Des. 2016, 112, 17–26. [Google Scholar] [CrossRef]

- Yan, Z.Q.; Chen, F.; Cai, Y.X.; Zheng, Y.K. Microstructure and mechanical properties of in-situ synthesized TiB whiskers reinforced titanium matrix composites by high-velocity compaction. Powder Technol. 2014, 267, 309–314. [Google Scholar] [CrossRef]

- Morsi, K.; Patel, V.V. Processing and properties of titanium-titanium boride (TiBw) matrix composites—A review. J. Mater. Sci. 2007, 42, 2037–2047. [Google Scholar] [CrossRef]

- Li, S.F.; Kondoh, K.; Imai, H. Strengthening behavior of in situ-synthesized (TiC-TiB)/Ti composites by powder metallurgy and hot extrusion. Mater. Des. 2016, 95, 127–132. [Google Scholar] [CrossRef]

- Huang, L.J.; Geng, L.; Peng, H.X.; Balasubramaniam, K.; Wang, G.S. Effects of sintering parameters on the microstructure and tensile properties of in situ TiBw/Ti6Al4V composites with a novel network architecture. Mater. Des. 2011, 32, 3347–3353. [Google Scholar] [CrossRef]

- Huang, L.J.; Zhang, Y.Z.; Liu, B.X.; Song, X.Q.; Geng, L.; Wu, L.Z. Superplastic tensile characteristics of in situ TiBw/Ti6Al4V composites with novel network microstructure. Mater. Sci. Eng. A 2013, 581, 128–132. [Google Scholar] [CrossRef]

- Romancev, B.A.; Goncharuk, A.V.; Aleshchenko, A.S.; Gamin, Y.V. Production of Hollow Thick Walled Profiles and Pipes Made of Titanium Alloys by Screw Rolling. Russ. J. Non-Ferr. Met. 2015, 56, 522–526. [Google Scholar] [CrossRef]

- Shan, D.B.; Yang, G.P.; Xu, W.C. Deformation history and the resultant microstructure and texture in backward tube spinning of Ti–6Al–2Zr–1Mo–1V. J. Mater. Process. Technol. 2009, 209, 5713–5719. [Google Scholar]

- Yuan, R.S.; Wu, Z.L.; Cai, H.M.; Zhao, L.; Zhang, X.P. Effects of extrusion parameters on tensile properties of magnesium alloy tubes fabricated via hydrostatic extrusion integrated with circular ECAP. Mater. Des. 2016, 101, 131–136. [Google Scholar] [CrossRef]

- Hama, T.Y.; Nagao, H.T.; Kobuki, A.; Fujimoto, H.; Takuda, H. Work-hardening and twinning behaviors in a commercially pure titanium sheet under various loading paths. Mater. Sci. Eng. A 2015, 620, 390–398. [Google Scholar] [CrossRef]

- Zhang, Y.W.; Kent, D.; Wang, D. An investigation of the mechanical behaviour of fine tubes fabricated from a Ti-25Nb-3Mo-3Zr-2Sn alloy. Mater. Des. 2015, 85, 256–265. [Google Scholar] [CrossRef]

- Yu, Y.; Zhang, W.C.; Dong, W.Q.; Yang, J.L.; Feng, Y.J. Effects of pre-sintering on microstructure and properties of TiBw/Ti6Al4V composites fabricated by hot extrusion with steel cup. Mater. Sci. Eng. A 2015, 638, 38–45. [Google Scholar] [CrossRef]

- Huang, L.J.; Zhang, Y.Z.; Geng, L.; Wang, B.; Ren, W. Hot compression characteristics of TiBw/Ti6Al4V composites with novel network microstructure using processing maps. Mater. Sci. Eng. A 2013, 580, 242–249. [Google Scholar] [CrossRef]

- Huang, L.J.; Geng, L.; Peng, H.X.; Zhang, J. Room temperature tensile fracture characteristics of in situ TiBw/Ti6Al4V composites with a quasi-continuous network architecture. Scr. Mater. 2011, 64, 844–847. [Google Scholar] [CrossRef]

- Gungor, M.N.; Ucok, I.; Kramer, L.S.; Dong, H.; Martin, N.R.; Tack, W.T. Microstructure and mechanical properties of highly deformed Ti–6Al–4V. Mater. Sci. Eng. A 2005, 410–411, 369–374. [Google Scholar] [CrossRef]

- Zhang, W.C.; Wang, M.M.; Chen, W.Z. Preparation of TiBw/Ti-6Al-4V composite with an inhomogeneous reinforced structure by a canned hot extrusion process. J. Alloys Compd. 2016, 669, 79–90. [Google Scholar] [CrossRef]

| Al | V | Fe | Si | O | C | N | H | Ti |

|---|---|---|---|---|---|---|---|---|

| 6.42 | 4.12 | 0.18 | 0.0.24 | 0.12 | 0.013 | 0.011 | 0.004 | Bal. |

| Flow Stress σ | Frictional Coefficient f | Bottom Thickness t (mm) | Heat Capacity N/mm2 °C | Thermal Conductivity W·(m·K)−1 | Poisson Ratio | Elastic Modulus GPa |

|---|---|---|---|---|---|---|

| 0.5σ, 0.75σ, σ, 1.25σ, 1.5σ | 0.7 | 3 | 7 | 2.4 | 0.3 | 130 |

| σ | 0.1, 0.2, 0.3, 0.5, 0.7 | 3 | ||||

| σ | 0.7 | 3, 6, 7, 8, 9 |

| Bottom Thickness | f = 0.1 | f = 0.2 | f = 0.3 | f > 0.3 |

|---|---|---|---|---|

| 3 mm | × | × | √ | √ |

| 4 mm | × | √ | √ | √ |

| 5 mm | × | √ | √ | √ |

| 6 mm | √ | √ | √ | √ |

| 7 mm | √ | √ | √ | √ |

| Titanium Powders | Milling Powders | Extruded Tubes |

|---|---|---|

| 0.12 | 0.15 | 0.23 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, J.; Jiao, X.; Chen, W.; Zhang, W.; Wang, G. A Novel Extrusion for Manufacturing TiBw/Ti6Al4V Composite Tubes with a Quasi-Continuous Reinforced Structure. Materials 2017, 10, 375. https://doi.org/10.3390/ma10040375

Yang J, Jiao X, Chen W, Zhang W, Wang G. A Novel Extrusion for Manufacturing TiBw/Ti6Al4V Composite Tubes with a Quasi-Continuous Reinforced Structure. Materials. 2017; 10(4):375. https://doi.org/10.3390/ma10040375

Chicago/Turabian StyleYang, Jianlei, Xueyan Jiao, Wenzhen Chen, Wencong Zhang, and Guofeng Wang. 2017. "A Novel Extrusion for Manufacturing TiBw/Ti6Al4V Composite Tubes with a Quasi-Continuous Reinforced Structure" Materials 10, no. 4: 375. https://doi.org/10.3390/ma10040375

APA StyleYang, J., Jiao, X., Chen, W., Zhang, W., & Wang, G. (2017). A Novel Extrusion for Manufacturing TiBw/Ti6Al4V Composite Tubes with a Quasi-Continuous Reinforced Structure. Materials, 10(4), 375. https://doi.org/10.3390/ma10040375