Analysis of the Influence of Starting Materials and Processing Conditions on the Properties of W/Cu Alloys

Abstract

:1. Introduction

2. Materials and Methods

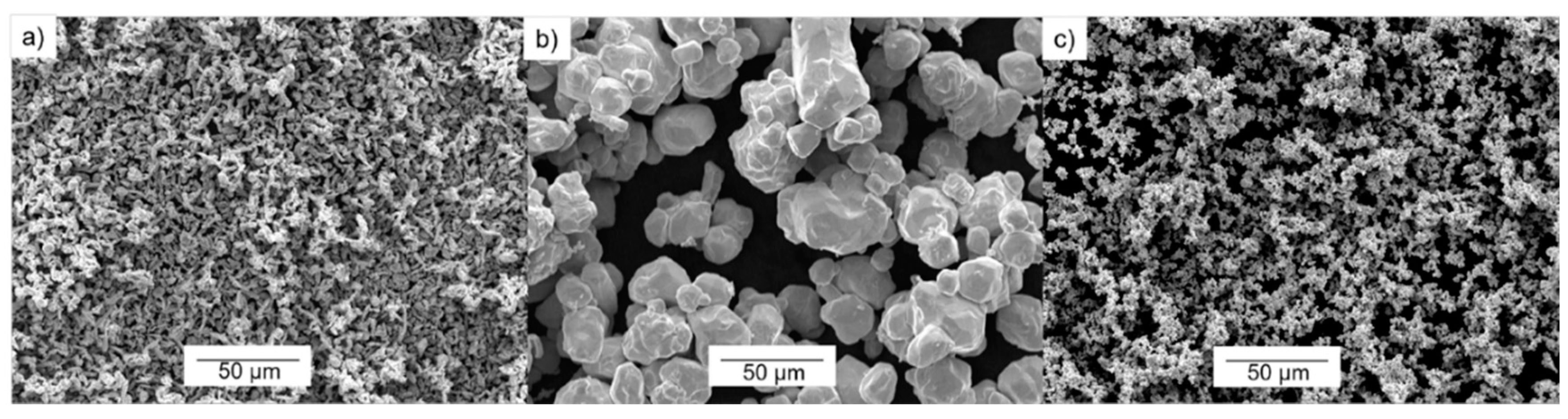

2.1. Materials

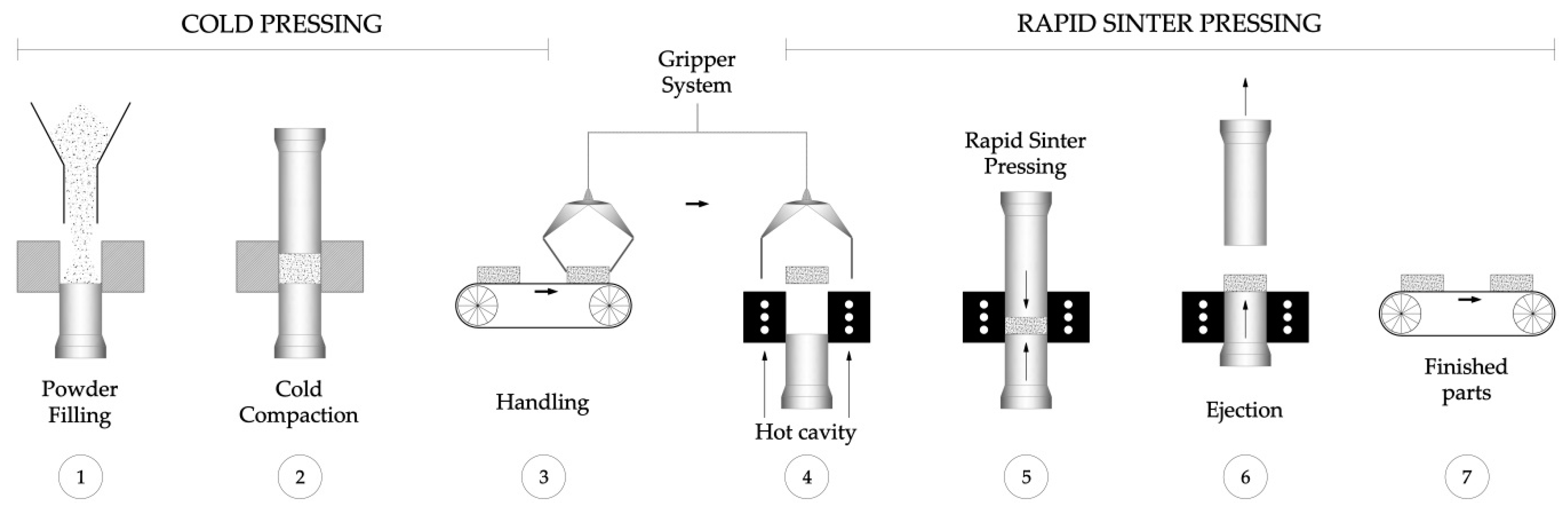

2.2. Methods

2.3. Characterization of the Specimens

3. Results and Discussion

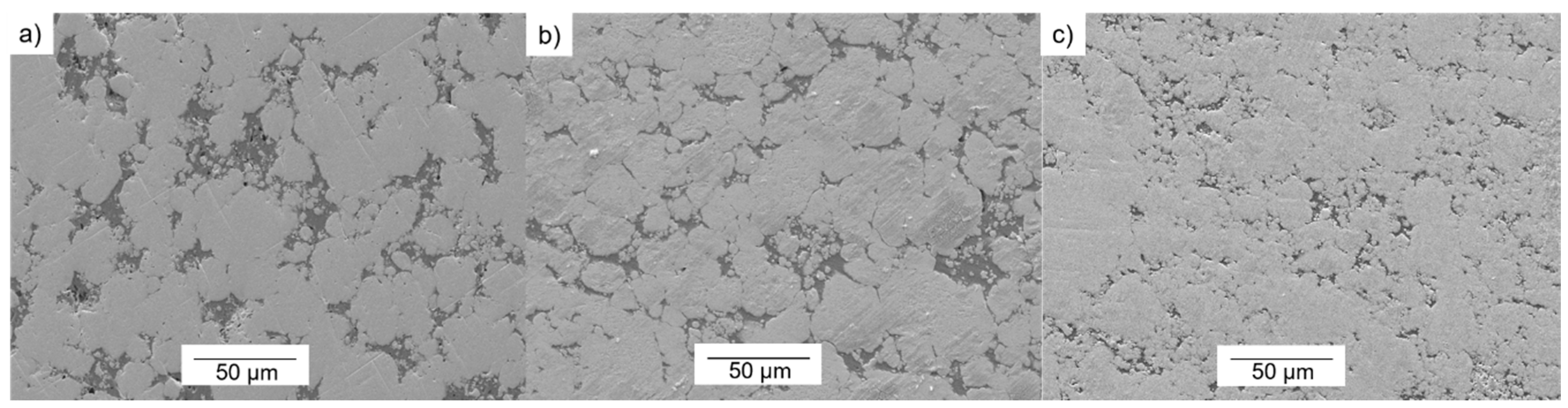

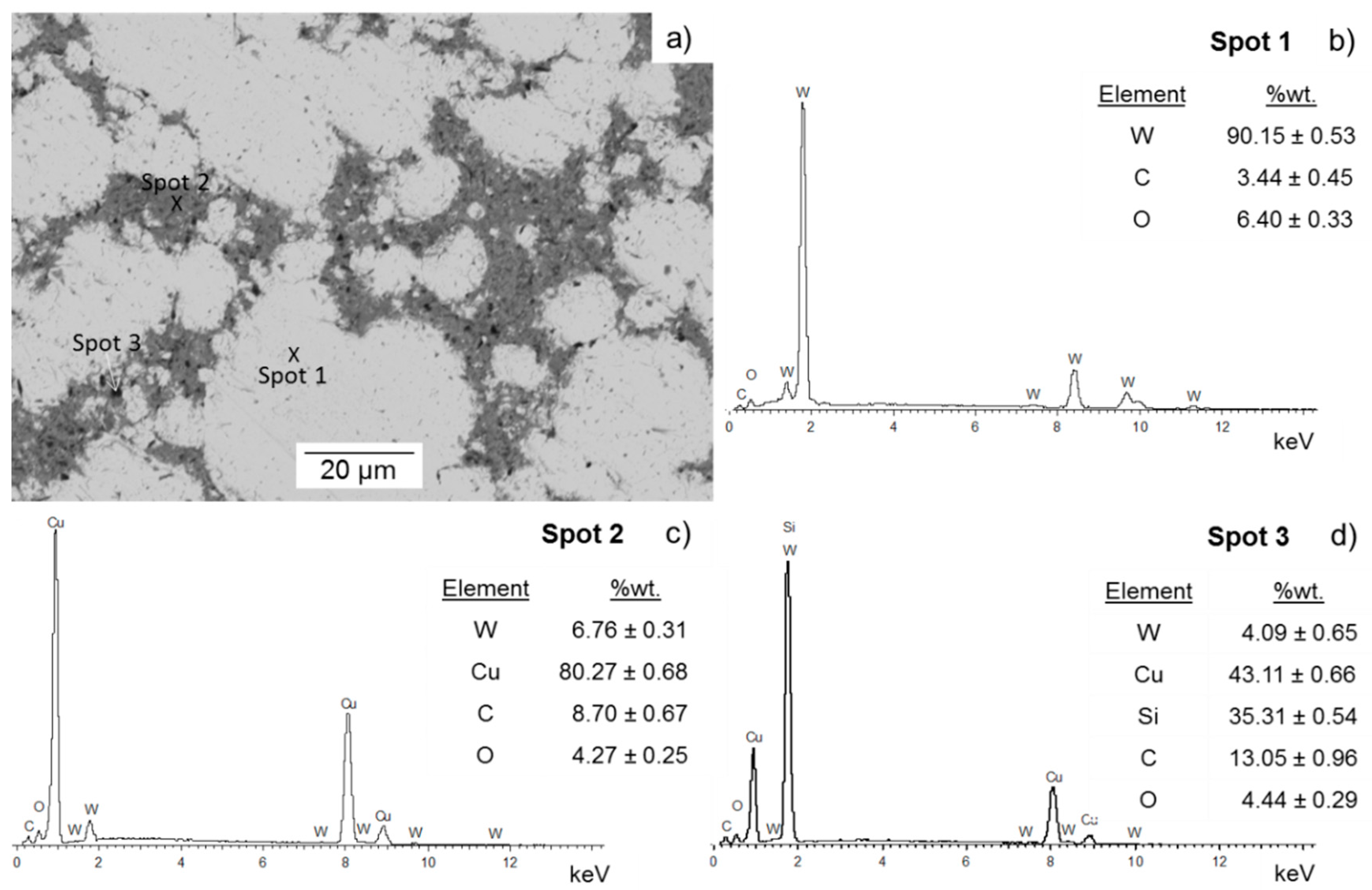

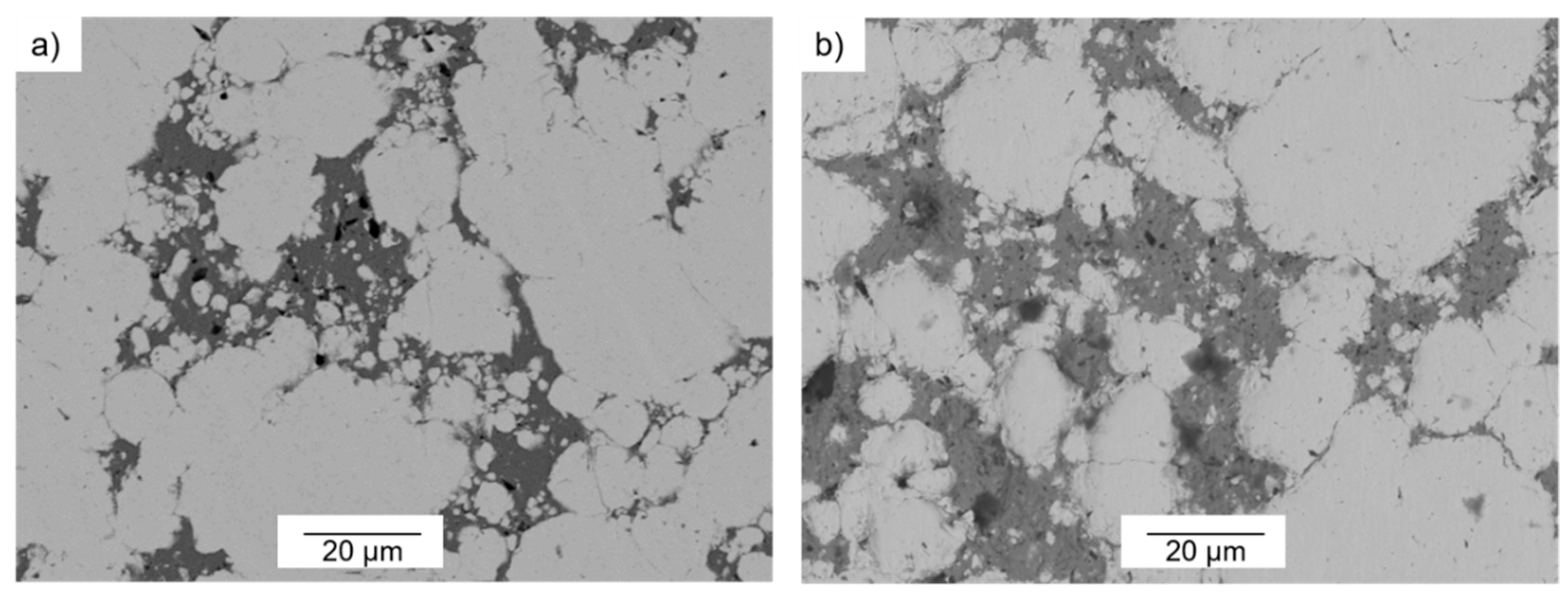

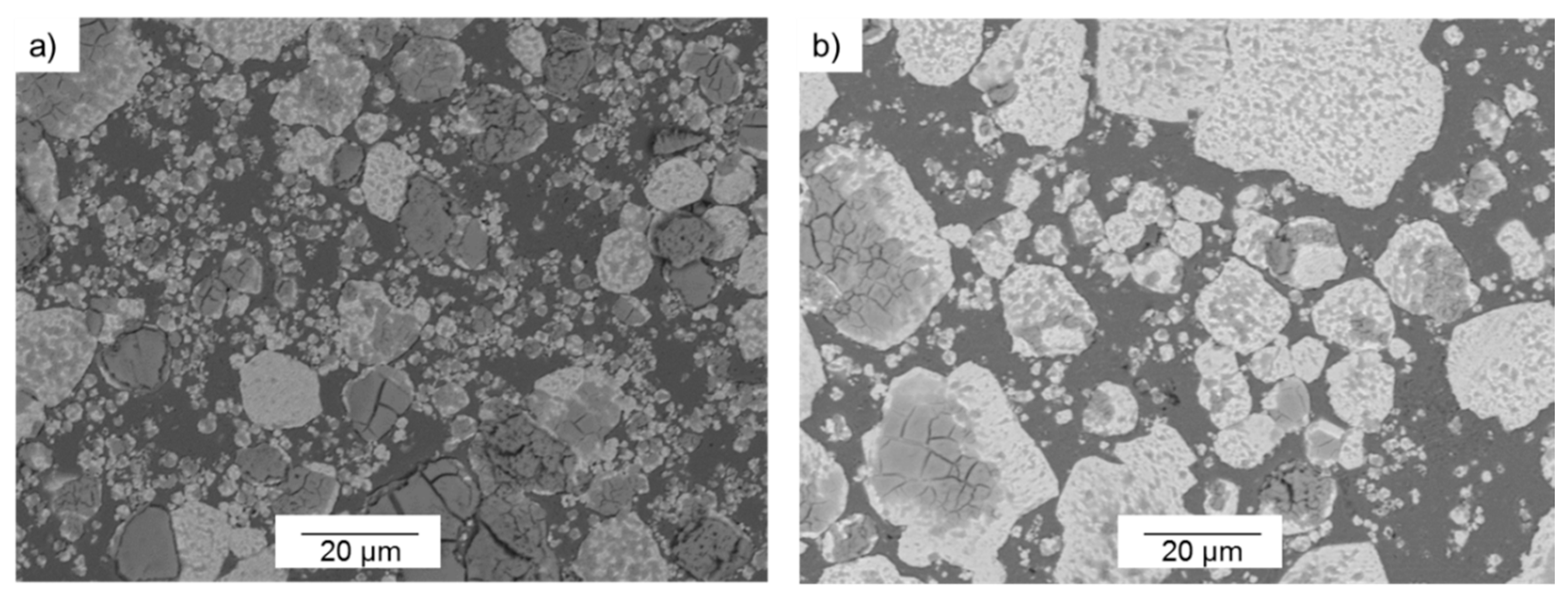

3.1. Microstructure Characteristics

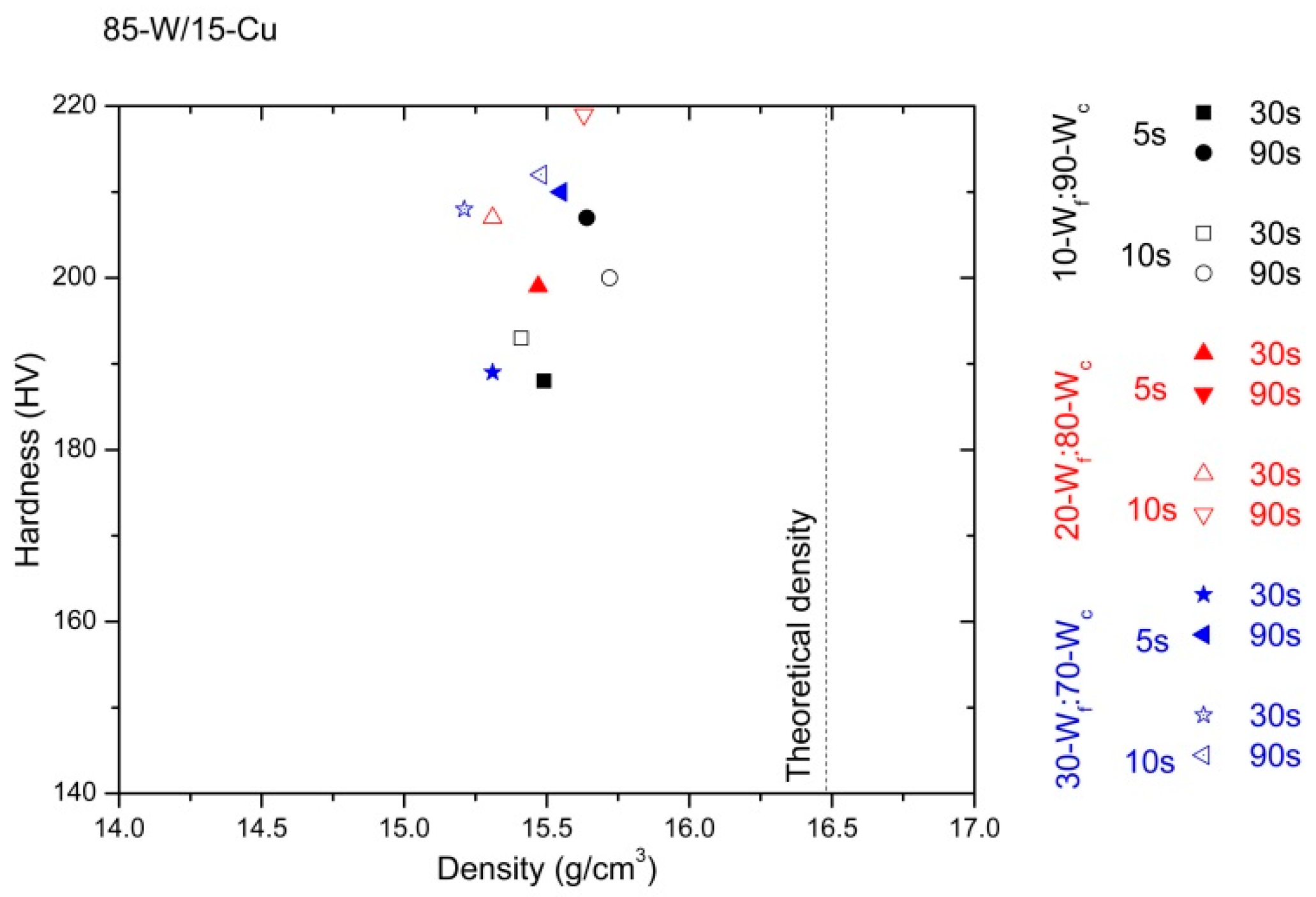

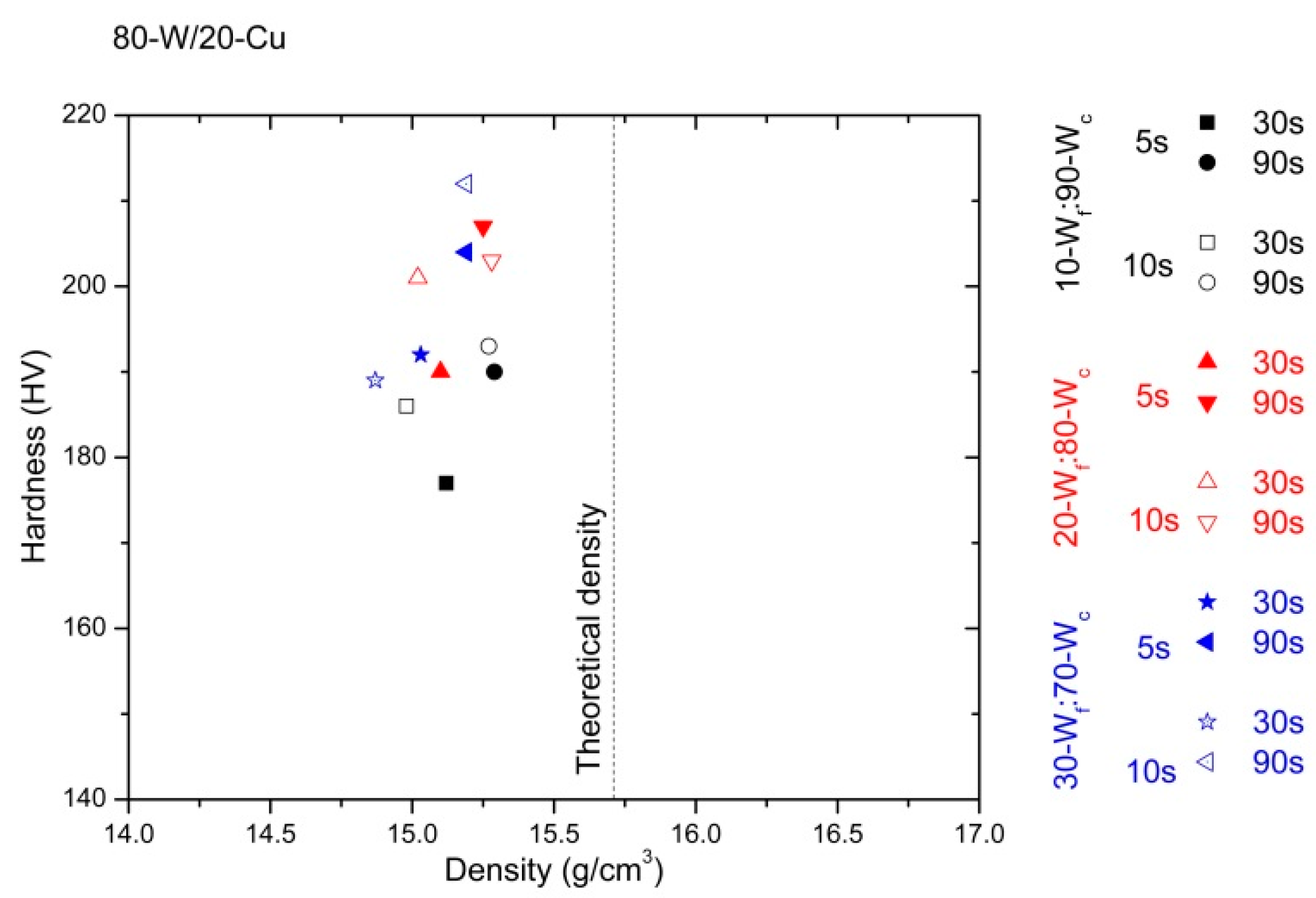

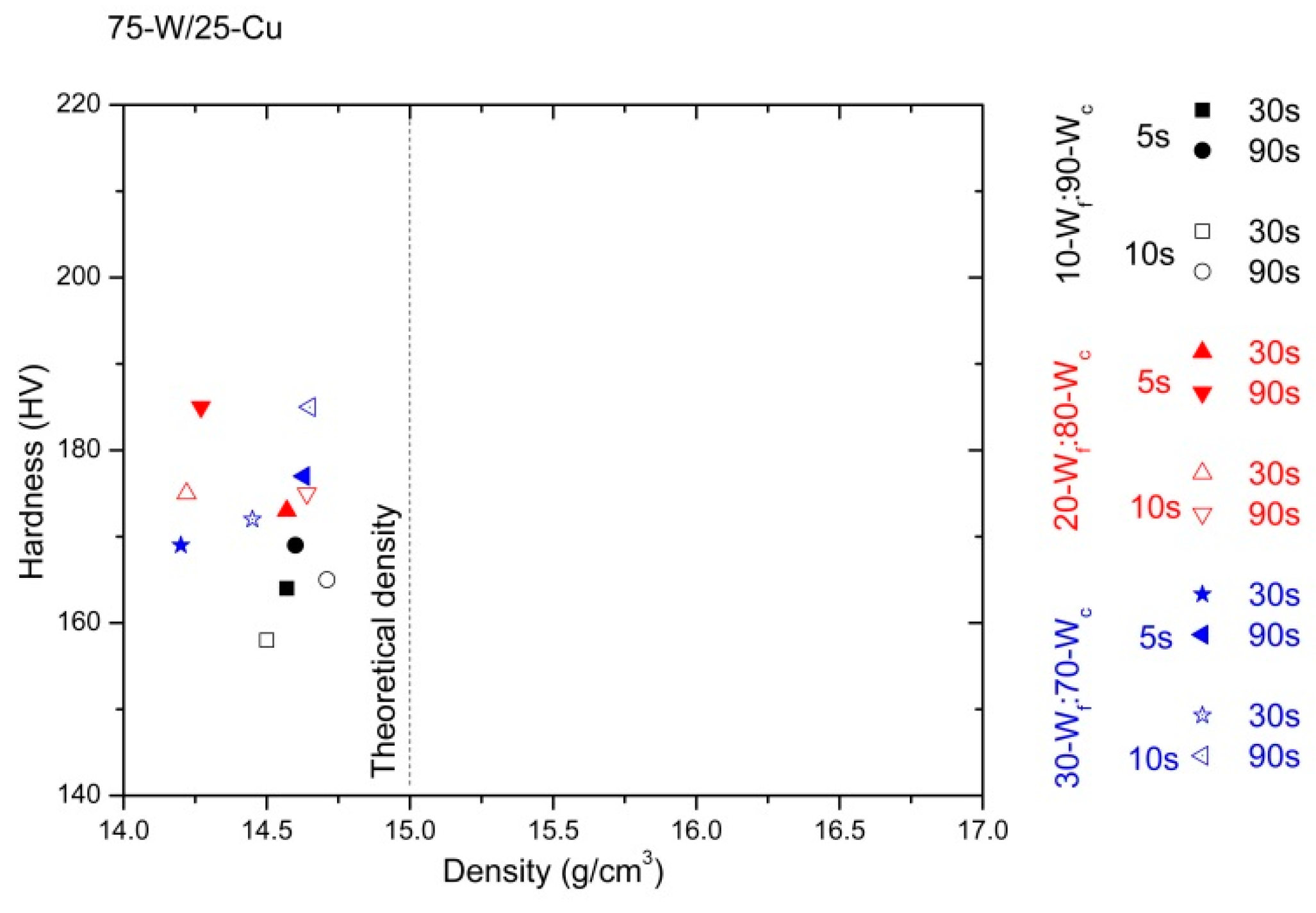

3.2. Densification and Hardness

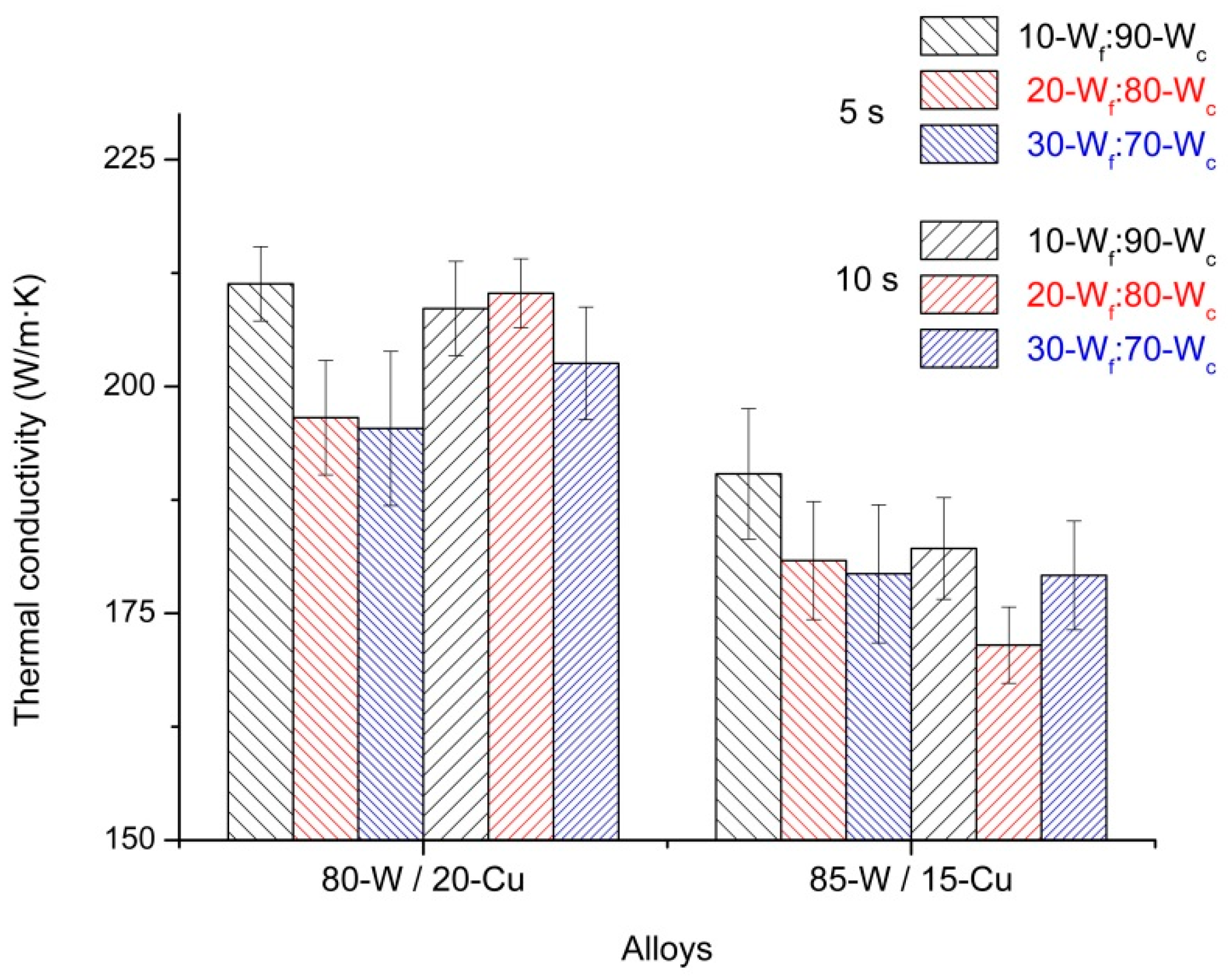

3.3. Thermal Conductivity

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Chen, P.; Shen, Q.; Luo, G.; Li, M.; Zhang, L. The mechanical properties of W-Cu composite by activated sintering. Int. J. Refract. Met. Hard Mater. 2013, 36, 220–224. [Google Scholar] [CrossRef]

- Yang, X.; Liang, S.; Wang, X.; Xiao, P.; Fan, Z. Effect of WC and CeO2 on microstructure and properties of W-Cu electrical contact material. Int. J. Refract. Met. Hard Mater. 2010, 28, 305–311. [Google Scholar] [CrossRef]

- Duan, L.; Lin, W.; Wang, J.; Yang, G. Thermal properties of W-Cu composites manufactured by copper infiltration into tungsten fiber matrix. Int. J. Refract. Met. Hard Mater. 2014, 46, 96–100. [Google Scholar] [CrossRef]

- Johnson, J.L.; German, R.M. Chemically activated liquid phase sintering of tungsten-copper. Int. J. Powder Metall. 1994, 30, 91–102. [Google Scholar]

- Maneshian, M.H.; Simchi, A. Solid state and liquid phase sintering of mechanically activated W-20wt % Cu powder mixture. J. Alloys Compd. 2008, 463, 153–159. [Google Scholar] [CrossRef]

- Hamidi, A.G.; Arabi, H.; Rastegari, S. Tungsten–copper composite production by activated sintering and infiltration. Int. J. Refract. Met. Hard Mater. 2011, 29, 538–541. [Google Scholar] [CrossRef]

- Mondal, A.; Upadhyaya, A.; Agrawal, D. Comparative study of densification and microstructural development in W–18Cu composites using microwave and conventional heating. Mater. Res. Innov. 2010, 14, 355–360. [Google Scholar] [CrossRef]

- Lee, J.S.; Kim, T.H. Densification and microstructure of the nanocomposite WCu powders. Nanostruct. Mater. 1995, 6, 691–694. [Google Scholar] [CrossRef]

- Ryu, S.S.; Park, H.R.; Kim, H.T.; Kim, Y.D. On sinterability of Cu-coated W nanocomposite powder prepared by a hydrogen reduction of a high-energy ball-milled WO3-CuO mixture. J. Mater. Sci. 2012, 47, 7099–7109. [Google Scholar] [CrossRef]

- Zhao, P.; Guo, S.; Liu, G.; Chen, Y.; Li, J. Fabrication of W–Cu functionally graded material with improved mechanical strength. J. Alloys Compd. 2014, 601, 289–292. [Google Scholar] [CrossRef]

- Liang, S.; Chen, L.; Yuan, Z.; Li, Y.; Zou, J.; Xiao, P.; Zhuo, L. Infiltrated W-Cu composites with combined architecture of hierarchical particulate tungsten and tungsten fibers. Mater. Charact. 2015, 110, 33–38. [Google Scholar] [CrossRef]

- Zhou, Q.; Chen, P. Fabrication of W-Cu composite by shock consolidation of Cu-coated W powders. J. Alloys Compd. 2016, 657, 215–223. [Google Scholar] [CrossRef]

- Niu, Y.; Lu, D.; Huang, L.; Zhao, J.; Zheng, X.; Chen, G. Comparison of W–Cu composite coatings fabricated by atmospheric and vacuum plasma spray processes. Vacuum 2015, 117, 98–103. [Google Scholar] [CrossRef]

- Ryu, S.S.; Kim, G.S.; Kim, J.C.; Oh, S.T.; Kim, Y.D. The influence of annealing temperature on the microstructural development of W–Cu composite powder prepared by high-energy ball milling. J. Alloys Compd. 2006, 424, 209–212. [Google Scholar] [CrossRef]

- Wei, X.; Tang, J.; Ye, N.; Zhuo, H. A novel preparation method for W–Cu composite powders. J. Alloys Compd. 2016, 661, 471–475. [Google Scholar] [CrossRef]

- Huang, L.M.; Luo, L.M.; Ding, X.Y.; Luo, G.N.; Zan, X.; Cheng, J.G.; Wu, Y.C. Effects of simplified pretreatment process on the morphology of W-Cu composite powder prepared by electroless plating and its sintering characterization. Powder Technol. 2014, 258, 216–221. [Google Scholar] [CrossRef]

- Choi, J.P.; Lee, G.Y.; Song, J.I.; Lee, W.S.; Lee, J.S. Sintering behavior of 316L stainless steel micro-nanopowder compact fabricated by powder injection molding. Powder Technol. 2015, 279, 196–202. [Google Scholar] [CrossRef]

- Arévalo, C.; Montealegre-Meléndez, I.; Neubauer, E.; Pérez-Soriano, E.M.; Kitzmantel, M. Influence of the particle size and raw materials in W-Cu alloys manufactured via rapid sinter pressing. In Proceedings of the World PM2016 Proceedings 2016, Hamburg, Germany, 9–13 October 2016.

- Xu, L.; Yan, M.; Xia, Y.; Peng, J.; Li, W.; Zhang, L.; Liu, C.; Chen, G.; Li, Y. Influence of copper content on the property of Cu-W alloy prepared by microwave vacuum infiltration sintering. J. Alloys Compd. 2014, 592, 202–206. [Google Scholar] [CrossRef]

- Blumm, J. Das Laserflash Verfahren-aktuelle Entwicklungen und Tendenzen. In Proceedings of the Tagungsband zum Symposium Tendenzen in der Materialentwicklung und die Bedeutung von Wärmetransporteigenschaften, Stuttgart, Germany, 22–23 March 2007; pp. 1–2.

- Tipler, P.A. Physics for Scientists and Engineers, 4th ed.; W.H. Freeman and Co.: New York, NY, USA, 1999. [Google Scholar]

- Xu, L.; Srinivasakannan, C.; Zhang, L.; Yan, M.; Peng, J.; Xia, H.; Guo, S. Fabrication of tungsten-copper alloys by microwave hot pressing sintering. J. Alloys Compd. 2016, 658, 23–28. [Google Scholar] [CrossRef]

- Luo, L.M.; Tan, X.Y.; Lu, Z.L.; Zhu, X.Y.; Zan, X.; Luo, G.N.; Wu, Y.C. Sintering behavior of W–30Cu composite powder prepared by electroless plating. Int. J. Refract. Met. Hard Mater. 2014, 42, 51–56. [Google Scholar] [CrossRef]

- Li, Z.; Jia, C.; Sun, L.; He, Y.; Fan, S. Pressure sintering of W-15wt %Cu alloys prepared by mechanical alloying as a subsequent densification treatment method. Rare Met. 2006, 25, 124–128. [Google Scholar] [CrossRef]

| Alloy | 85-W/15-Cu | 80-W/20-Cu | 75-W/25-Cu | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Wf:Wc (%) | 10:90 | 20:80 | 30:70 | 10:90 | 20:80 | 30:70 | 10:90 | 20:80 | 30:70 |

| Degasification Time (s) | Hot Consolidation Time (s) |

|---|---|

| 5, 10 | 30, 60, 90 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Montealegre-Meléndez, I.; Arévalo, C.; Perez-Soriano, E.M.; Neubauer, E.; Rubio-Escudero, C.; Kitzmantel, M. Analysis of the Influence of Starting Materials and Processing Conditions on the Properties of W/Cu Alloys. Materials 2017, 10, 142. https://doi.org/10.3390/ma10020142

Montealegre-Meléndez I, Arévalo C, Perez-Soriano EM, Neubauer E, Rubio-Escudero C, Kitzmantel M. Analysis of the Influence of Starting Materials and Processing Conditions on the Properties of W/Cu Alloys. Materials. 2017; 10(2):142. https://doi.org/10.3390/ma10020142

Chicago/Turabian StyleMontealegre-Meléndez, Isabel, Cristina Arévalo, Eva M. Perez-Soriano, Erich Neubauer, Cristina Rubio-Escudero, and Michael Kitzmantel. 2017. "Analysis of the Influence of Starting Materials and Processing Conditions on the Properties of W/Cu Alloys" Materials 10, no. 2: 142. https://doi.org/10.3390/ma10020142

APA StyleMontealegre-Meléndez, I., Arévalo, C., Perez-Soriano, E. M., Neubauer, E., Rubio-Escudero, C., & Kitzmantel, M. (2017). Analysis of the Influence of Starting Materials and Processing Conditions on the Properties of W/Cu Alloys. Materials, 10(2), 142. https://doi.org/10.3390/ma10020142