Strain Evolution in Cold-Warm Forged Steel Components Studied by Means of EBSD Technique

Abstract

:1. Introduction

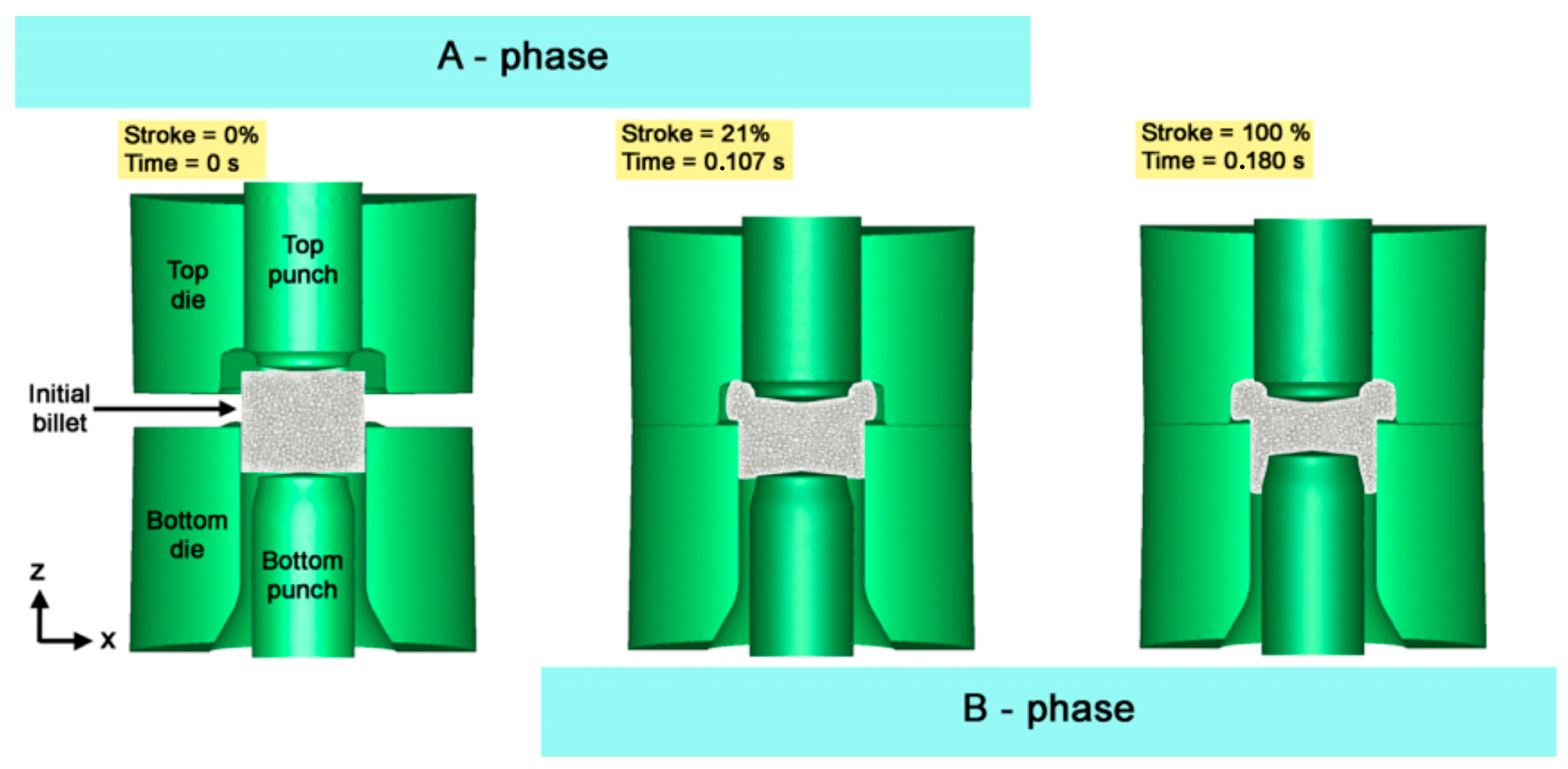

2. Materials and Methods

3. Results and Discussion

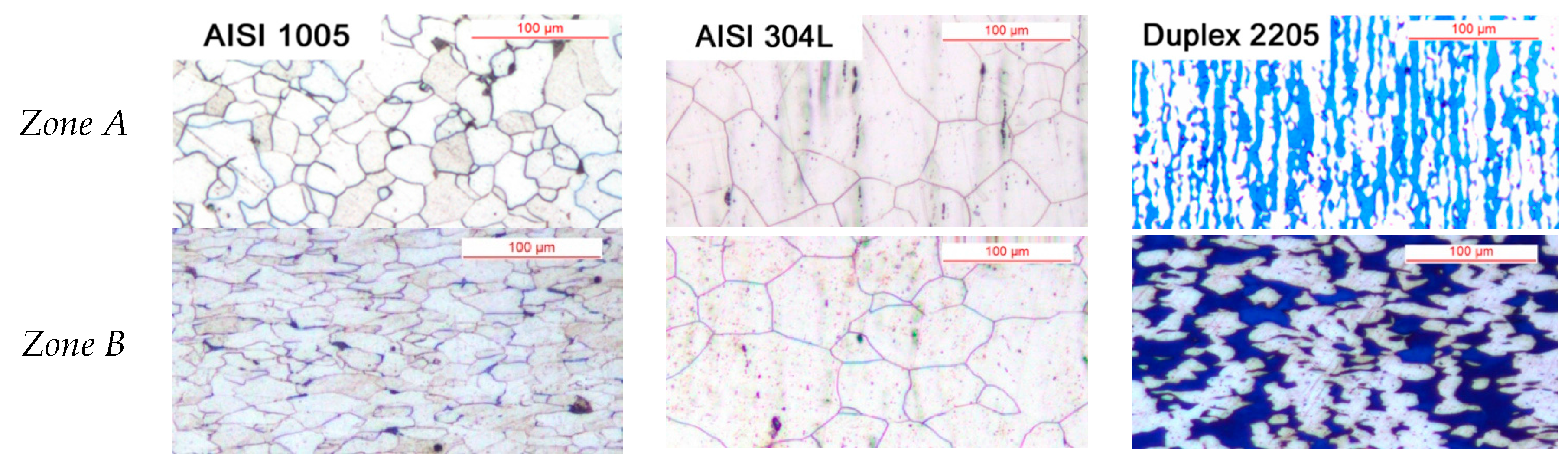

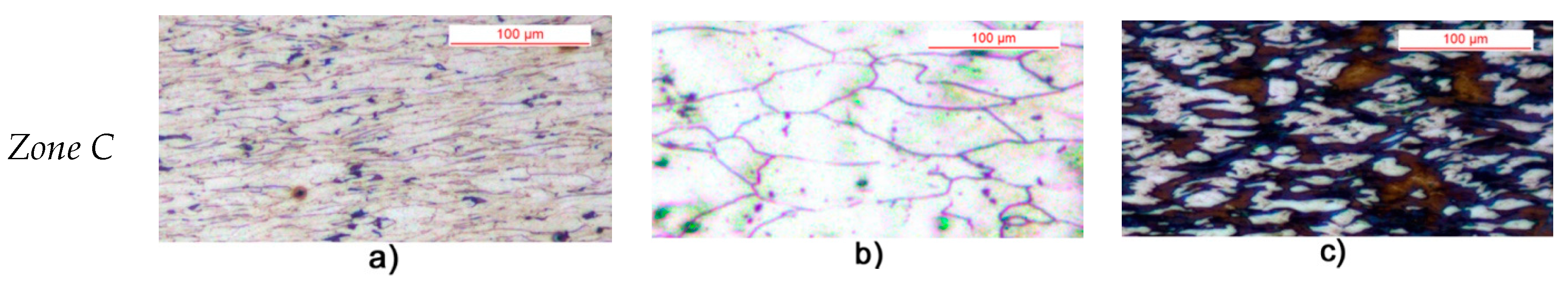

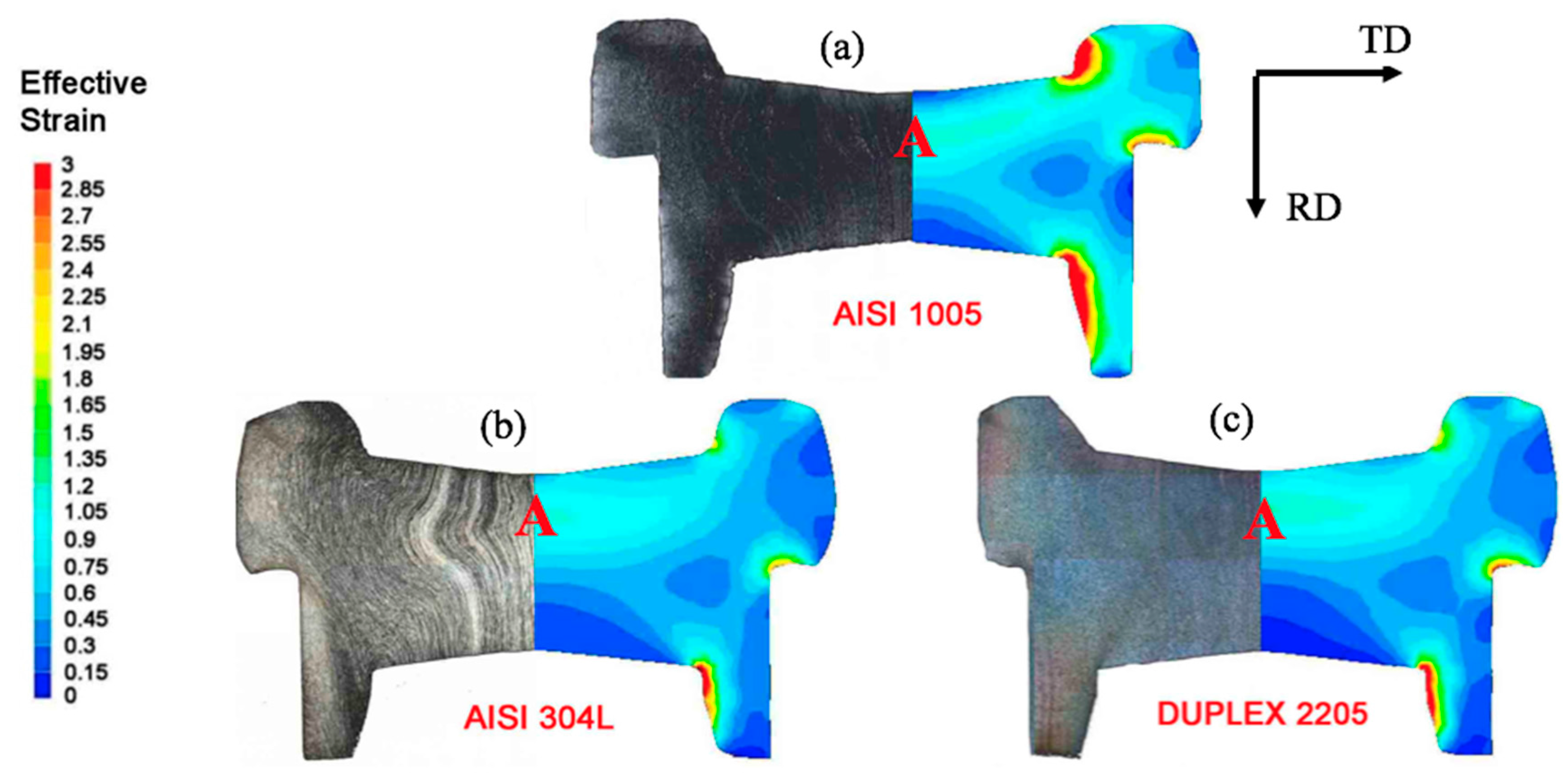

3.1. Optical Microscope Observations (Forging Temperature, 20 °C)

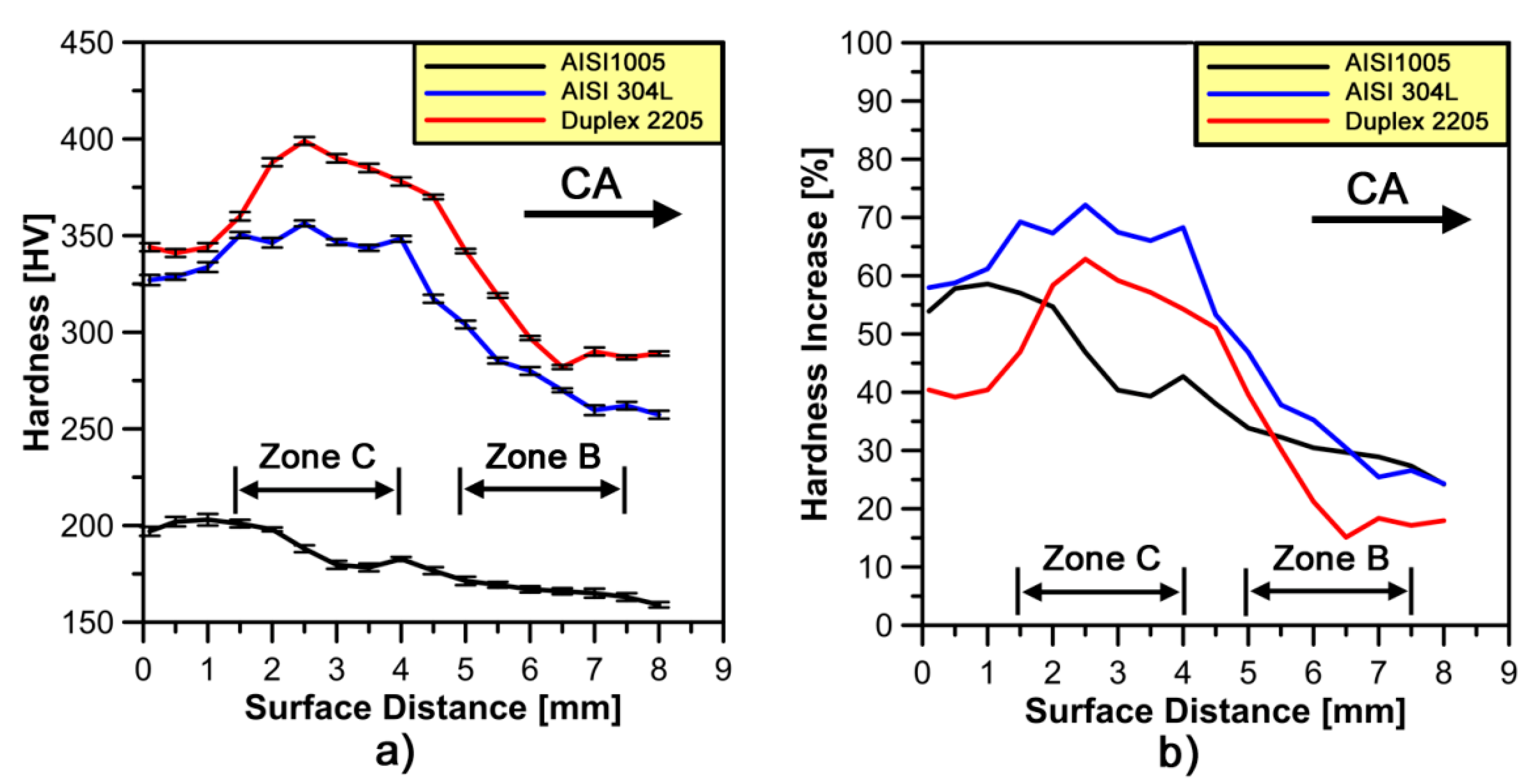

3.2. Micro-Hardness Evolution (Forging Temperature, 20 °C)

3.3. Electron Backscatter Diffraction Analysis (Forging Temperature, 20 °C)

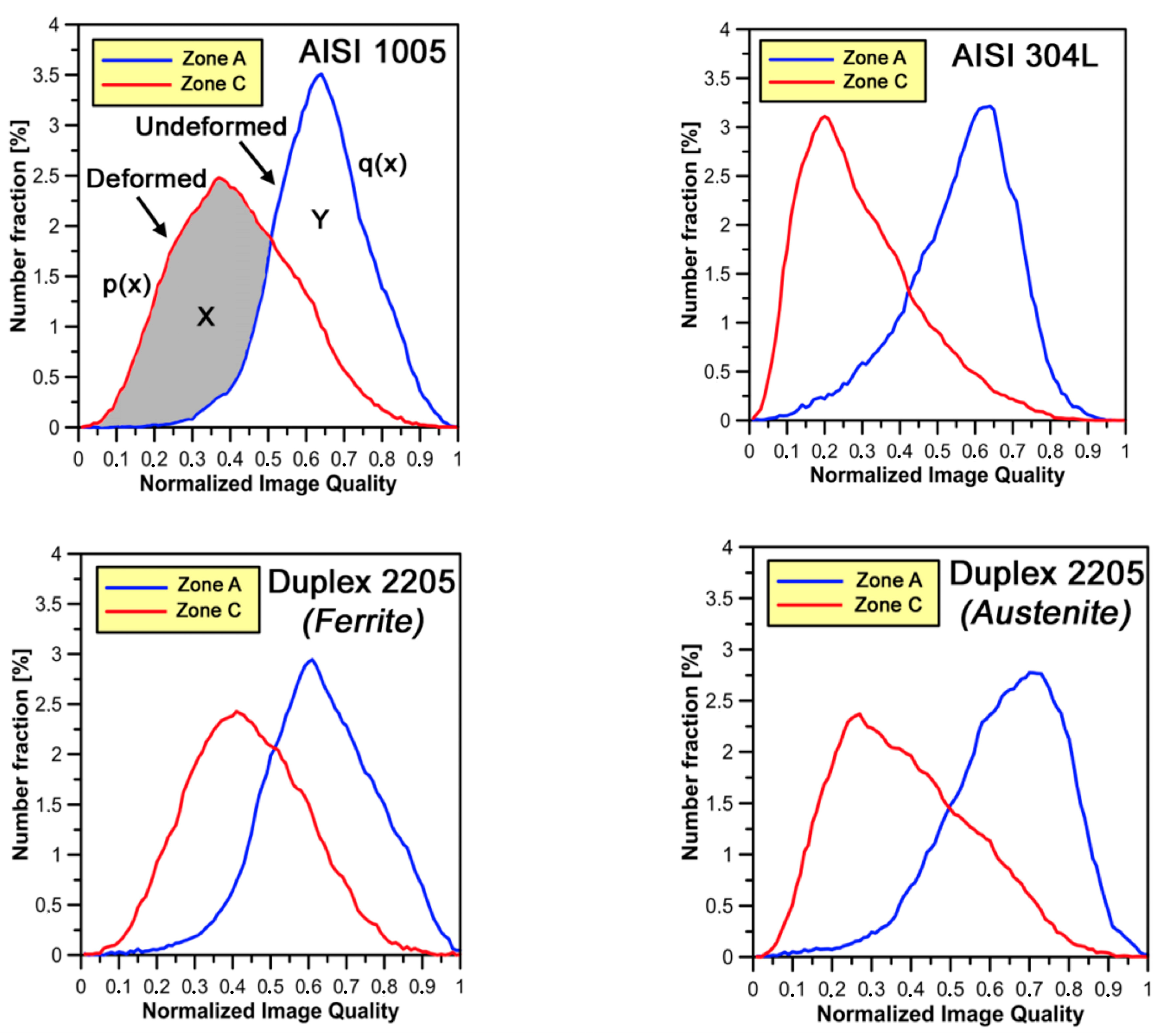

3.3.1. Image Quality (IQ) Factor

3.3.2. Microstructural Evolution (Forging Temperature, 20 °C)

4. Effect of Temperature on Microstructural Evolution of γ-phase

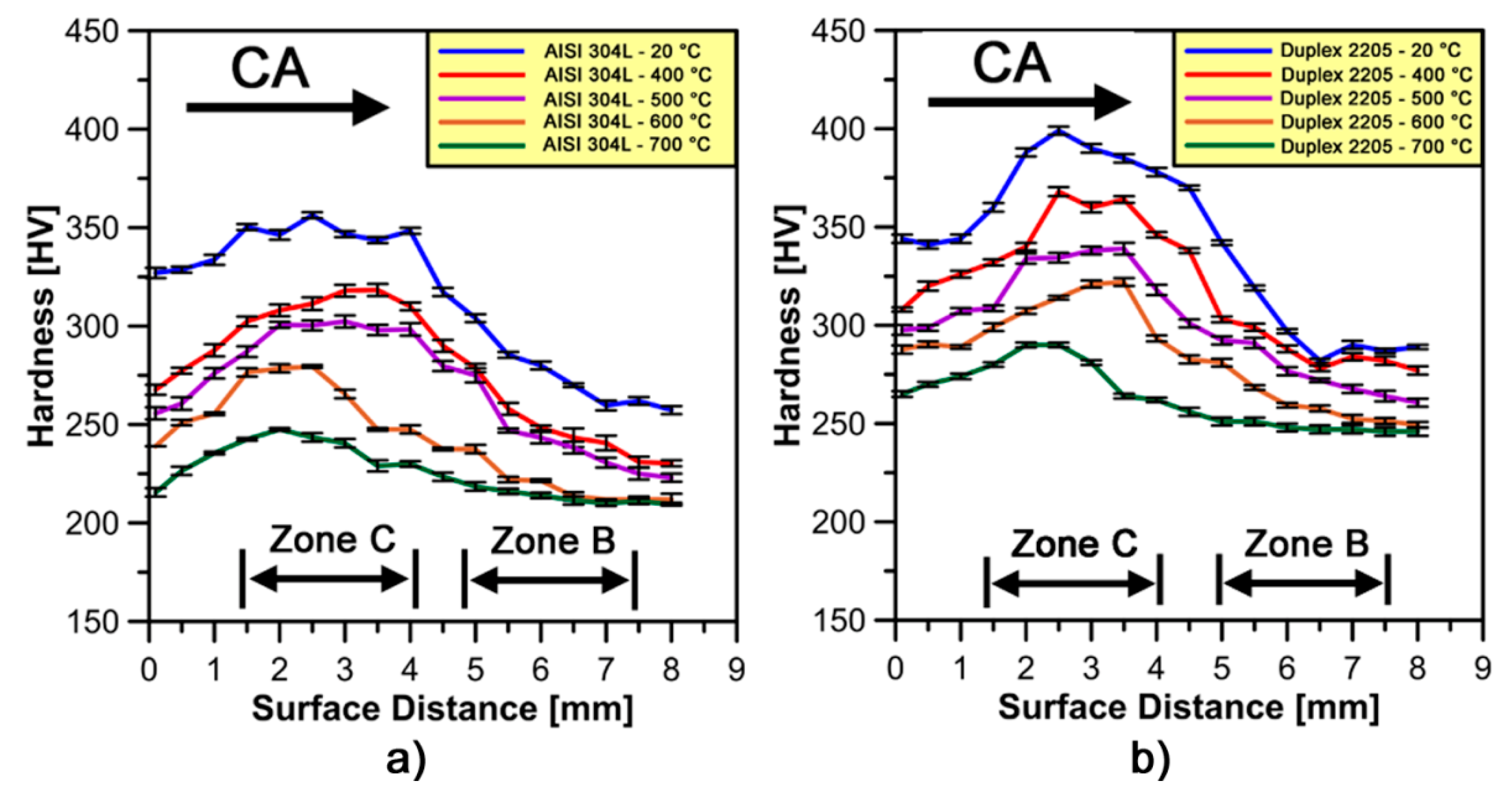

4.1. Micro-Hardness Evolution on Zones B and C at Different Warm Forging Temperatures

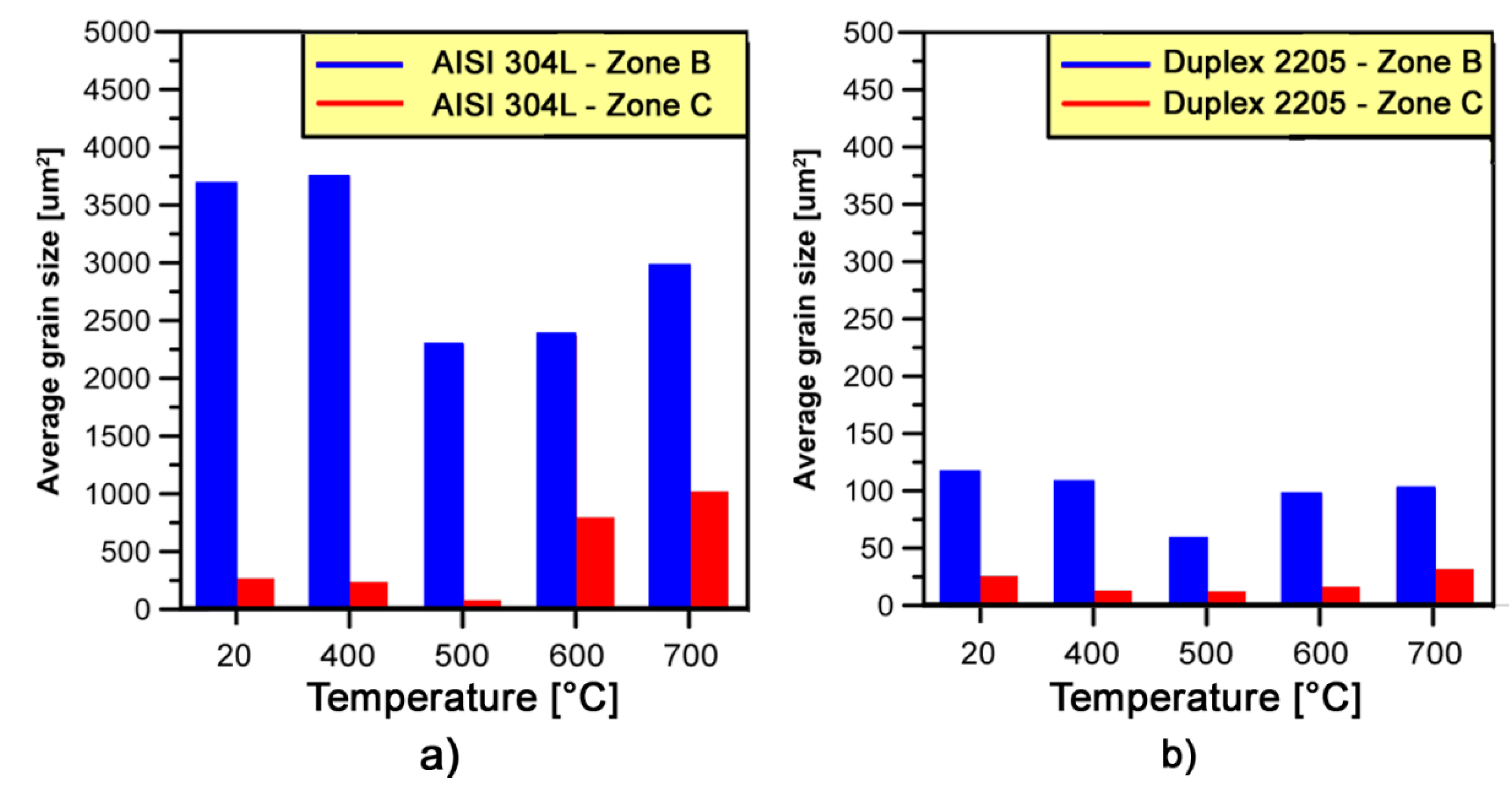

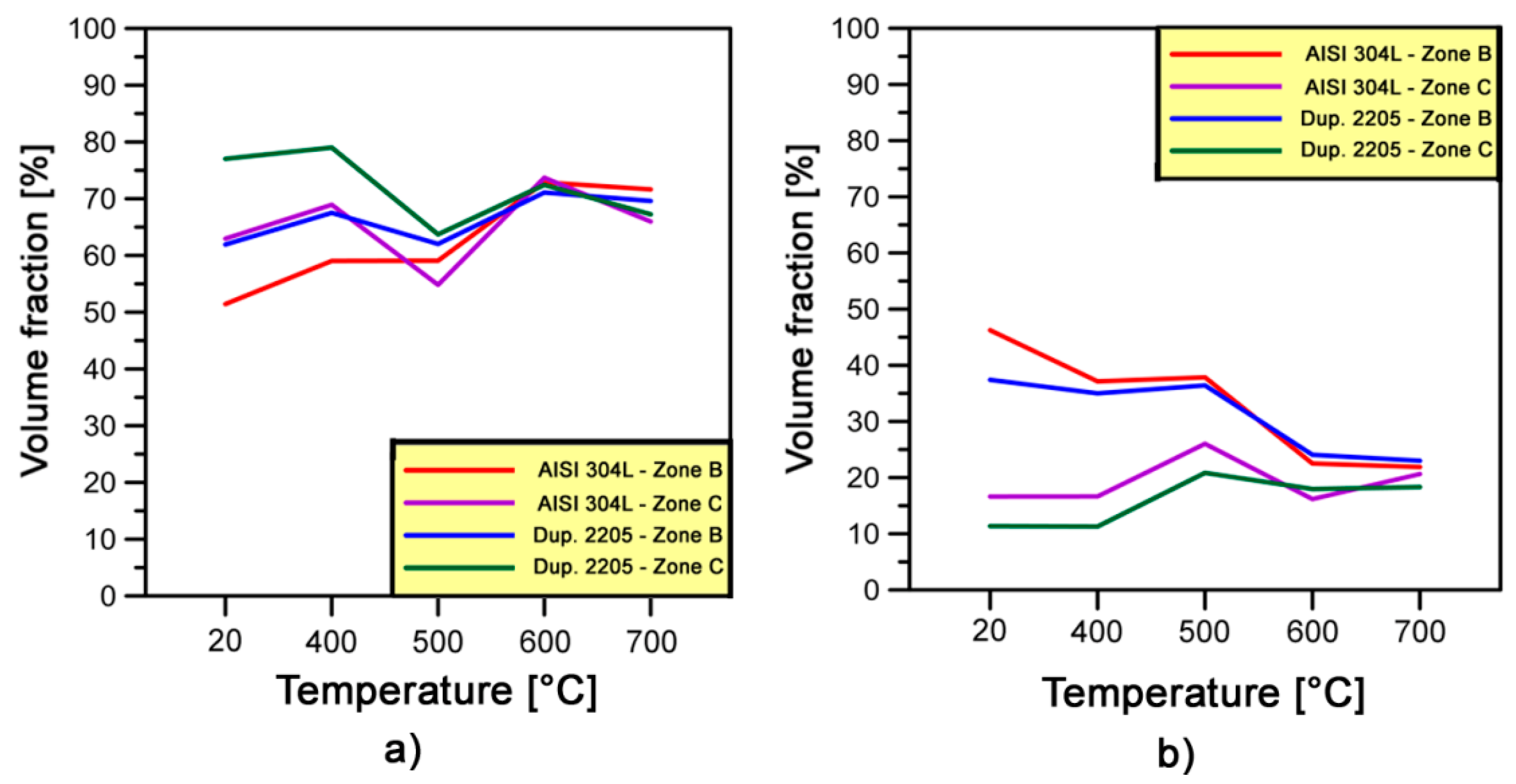

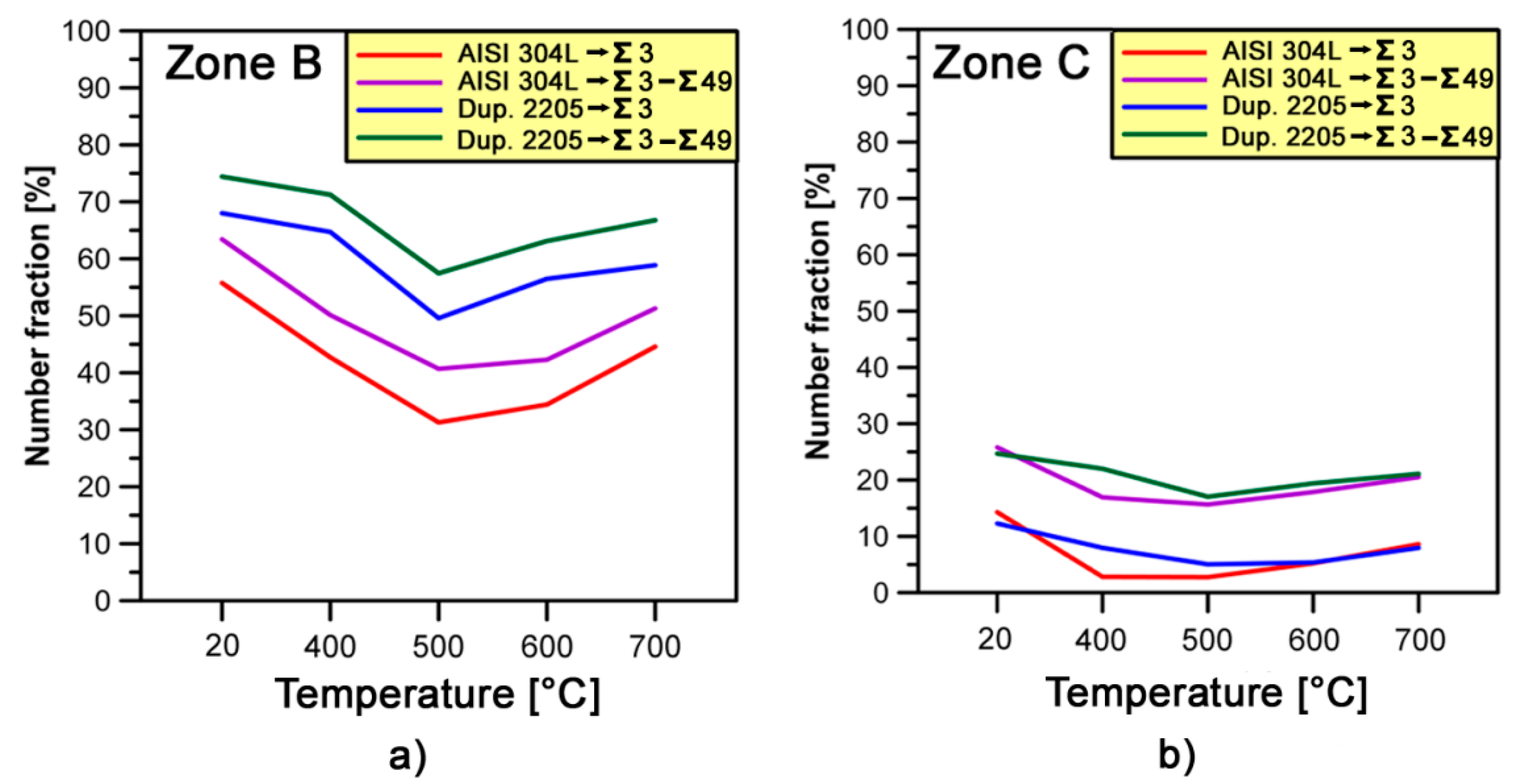

4.2. Electron Backscatter Diffraction Analysis of Zones B and C at Different Warm Forging Temperatures

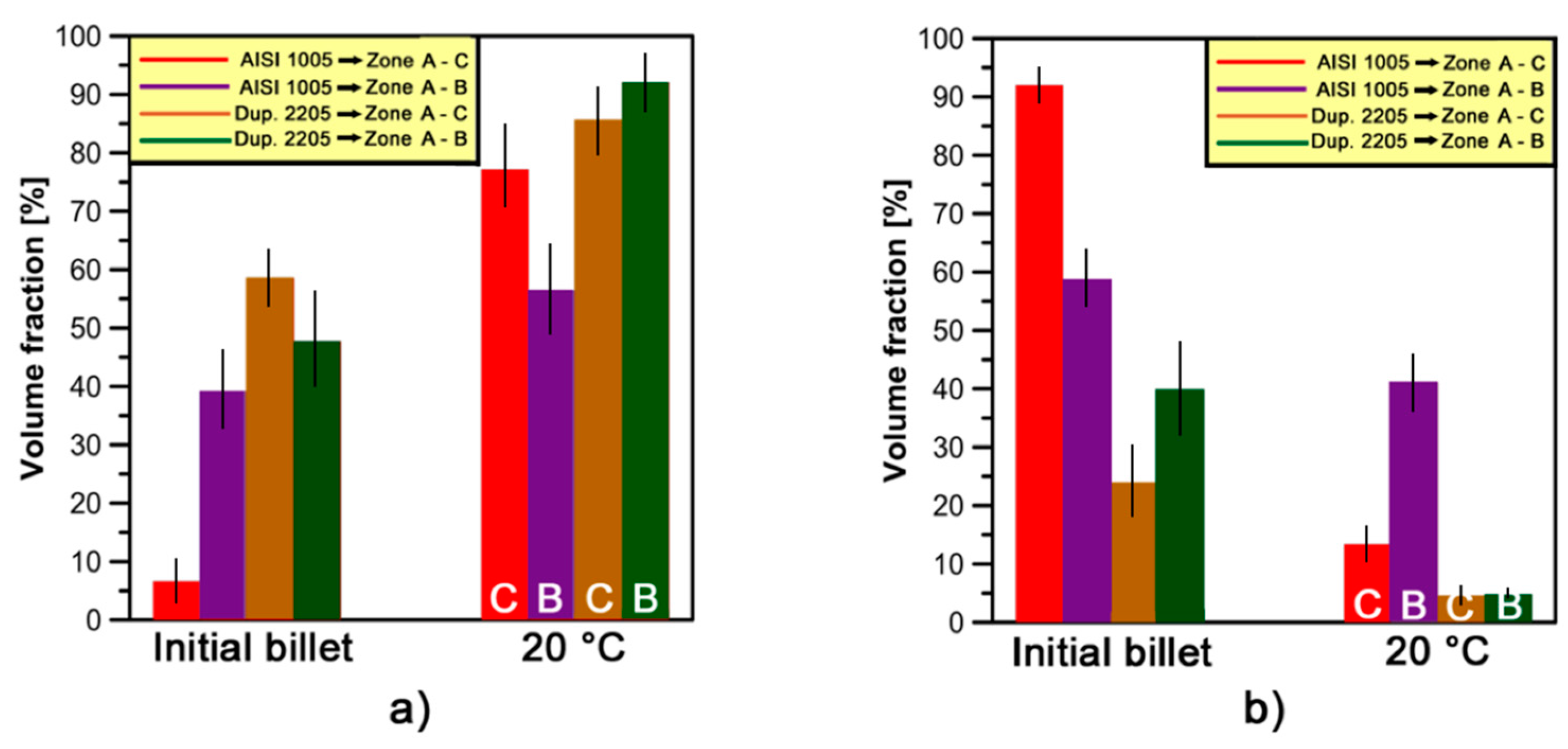

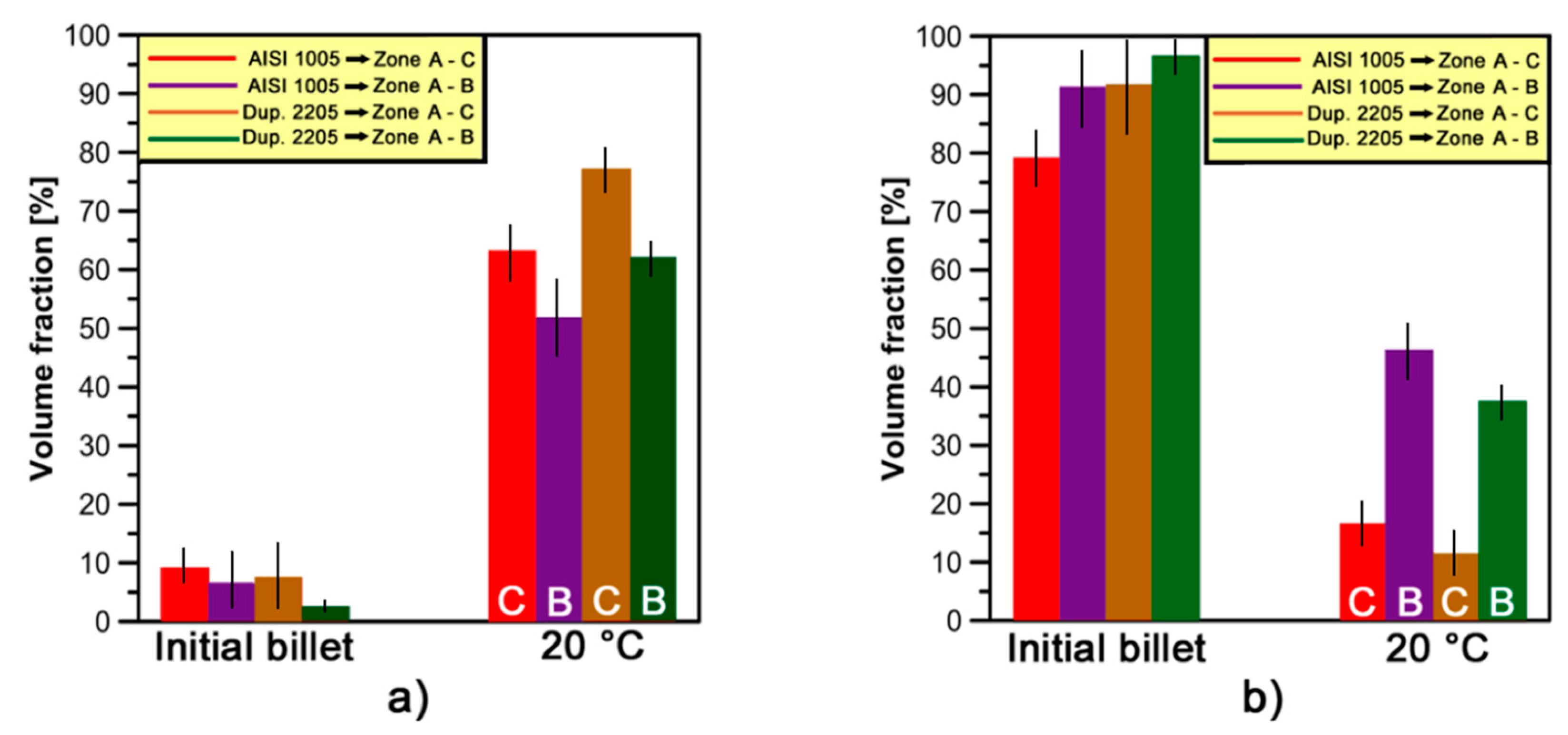

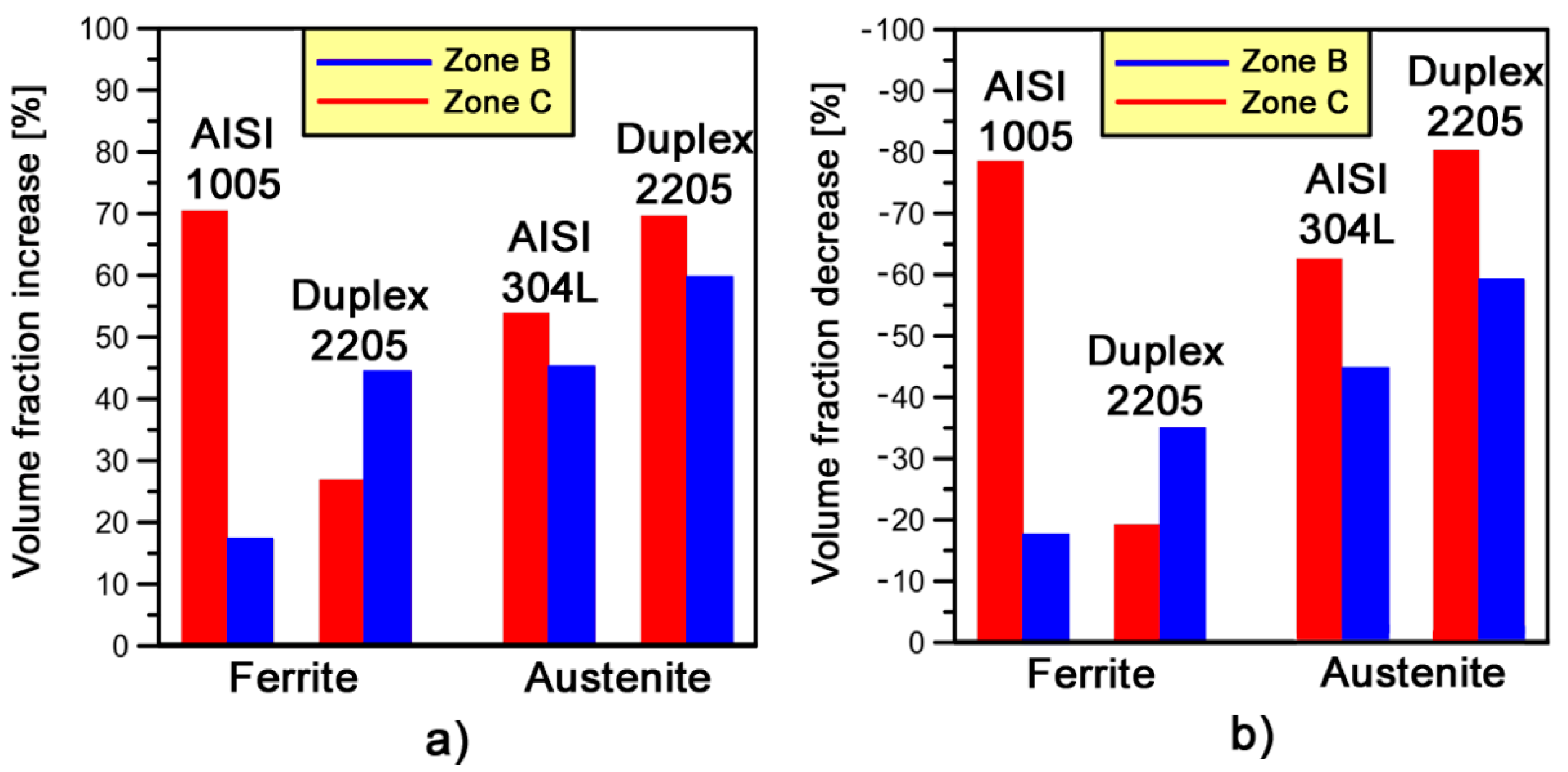

4.2.1. Minimum Deformed Volume Fractions

4.2.2. Microstructural Evolution of γ-phase on Zones B and C at Different Warm Forging Temperatures

5. Conclusions

- The α-phase in AISI 1005 steel has a lower tendency to harden compared to γ-phase of AISI 304L steel. On the other hand, γ-phase tends to harden easier on austenitic than on duplex stainless steel. The highest strain hardening effect of γ-phase is associated to the crossing of slip planes, twin boundaries formation, the increase of dislocation and stacking fault density in the deformed regions.

- During the cold forging process, the estimated deformed volume fraction is higher in the γ-phase compared to the α-phase. Furthermore, the γ-phase grains deform more homogeneously than the initially large α-phase grains.

- Samples forged at 20 °C result in the development of fine grained microstructures. Low-angle boundaries (LABs) increase and high-angle boundaries (HABs) decrease, as a direct consequence of the dislocation microstructures formation.

- The γ-phase microstructure which develops during single-stage forging from 400 to 500 °C is characterized by fine grained microstructure at different strain levels. The fraction of special boundaries decreases rapidly from 400 to 500 °C for both stainless steel analyzed. On the other hand, the microstructures of γ-phase detected at higher forging temperatures (i.e., 600 and 700 °C) are almost fully composed of large-elongated and fine nearly-equiaxed grains, which are considered to be discontinuous dynamic recrystallized (DRX). Similar values of LABs and HABs fractions and annealing twins formation are observed on the stainless steels investigated.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Altan, T.; Boulger, F.W.; Becker, J.R.; Akgerman, N.; Henning, H.J. Forging Equipment, Materials and Practices; Batelle: Columbus, OH, USA, 1973. [Google Scholar]

- Hertzberg, R.W. Deformation and Fracture Mechanics of Engineering Materials, 4th ed.; John Wiley & Sons Inc.: New York, NY, USA, 1996. [Google Scholar]

- McQueen, H.J. The production and utility of recovered dislocation substructures. Metall. Trans. A 1977, 8, 807–823. [Google Scholar] [CrossRef]

- Marchand, A.; Duffy, J. An experimental study of the formation process of adiabatic shear bands in a structural steel. J. Mech. Phys. Solids 1988, 36, 251–283. [Google Scholar] [CrossRef]

- Mataya, M.C.; Brown, E.L.; Riendeau, M.P. Effect of hot working on structure and strength of type 304L austenitic stainless steel. Metall. Trans. A 1990, 21, 1969–1987. [Google Scholar] [CrossRef]

- Harvey, D.P.; Terrell, J.B.; Sudarshan, T.S.; Louthan, M.R. Participation of hydrogen in the impact behavior of 304L stainless steel. Eng. Fract. Mech. 1993, 46, 455–465. [Google Scholar] [CrossRef]

- Lee, W.S.; Lam, H.F. The deformation behavior and microstructure evolution of high-strength alloy steel at high rate of strain. J. Mater. Process. Technol. 1996, 57, 233–240. [Google Scholar] [CrossRef]

- Lee, W.S.; Lin, C.F. High-temperature deformation behavior of Ti6Al4V alloy evaluated by high strain-rate compression tests. J. Mater. Process. Technol. 1998, 75, 127–136. [Google Scholar] [CrossRef]

- Meyers, M.A.; Chen, Y.J.; Marquis, F.D.S.; Kim, D.S. High-strain, high-strain rate behavior of tantalum. Metall. Mater. Trans. A 1995, 26, 2493–2501. [Google Scholar] [CrossRef]

- Cabrera, J.M.; Mateo, A.; Llanes, L.; Prado, J.M.; Anglada, M. Hot deformation of duplex stainless steels. J. Mater. Process. Technol. 2003, 143–144, 321–325. [Google Scholar] [CrossRef]

- Llanes, L.; Mateo, A.; Iturgoyen, L.; Anglada, M. Aging effects on the cyclic deformation mechanisms of a duplex stainless steel. Acta Mater. 1996, 44, 3967–3978. [Google Scholar] [CrossRef]

- Mateo, A.; Llanes, L.; Akdut, N.; Anglada, M. High cycle fatigue behavior of a standard duplex stainless steel plate and bar. Mater. Sci. Eng. A 2001, 319–321, 516–520. [Google Scholar] [CrossRef]

- Valiev, R.Z. Nanomaterial advantage. Nature 2002, 419, 887–889. [Google Scholar] [CrossRef] [PubMed]

- Nakao, Y.; Miura, H. Nano-grain evolution in austenitic stainless steel during multi-directional forging. Mater. Sci. Eng. A 2011, 528, 1310–1317. [Google Scholar] [CrossRef]

- Yanushkevich, Z.; Mogucheva, A.; Tikhonova, M.; Belyakov, A.; Kaibyshev, R. Structural strengthening of an austenitic stainless steel subjected to warm-to-hot working. Mater. Charact. 2011, 62, 432–437. [Google Scholar] [CrossRef]

- Andrievski, R.A.; Glezer, A.M. Strength of nanostructures. Physics-Uspekhi 2009, 52, 315–334. [Google Scholar] [CrossRef]

- Belyakov, A.; Sakai, T.; Miura, H.; Tsuzaki, K. Grain refinement in copper under large strain deformation. Philos. Mag. A 2001, 81, 2629–2643. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Langdon, T.G. Principles of equal channel angular pressing as a processing tool for grain refinement. Prog. Mater. Sci. 2006, 51, 881–981. [Google Scholar] [CrossRef]

- Dudova, N.; Belyakov, A.; Sakai, T.; Kaibyshev, R. Dynamic recrystallization mechanisms operating in a Ni-20%Cr alloy under hot-to-warm working. Acta Mater. 2010, 58, 3624–3632. [Google Scholar] [CrossRef]

- Humphreys, F.J.; Hatherly, M. Recrystallisation and Related Annealing Phenomena; Pergamon Press: Oxford, UK, 2004. [Google Scholar]

- Yanushkevich, Z.; Belyakov, A.; Kaibyshev, R. Structural changes in a 304-type austenitic stainless steel processed by multiple hot rolling. Adv. Mater. Res. 2012, 409, 730–735. [Google Scholar] [CrossRef]

- Tikhonova, M.; Dudko, V.; Belyakov, A.; Kaibyshev, R. The formation of fine-grained structure in S304H-type austenitic stainless steel during hot-to-warm working. Mater. Sci. Forum 2012, 715–716, 380–385. [Google Scholar] [CrossRef]

- Belyakov, A.; Tsuzaki, K.; Miura, H.; Sakai, T. Effect of initial microstructures on grain refinement in a stainless steel by large strain deformation. Acta Mater. 2003, 51, 847–861. [Google Scholar] [CrossRef]

- Bassan, F.; Ferro, P.; Bonollo, F. Numerical process simulation and microstructural evolution of carbon and stainless steels forged components. In Proceedings of the 35th AIM National Conference, Vicenza, Italy, 3–7 April 2014; p. 114. [Google Scholar]

- Bassan, F. Optimization of Industrial Processes for Forging of Carbon and Stainless Steels. Ph.D. Thesis, University of Padua, Padua, Italy, 2015. [Google Scholar]

- Kocks, U.F.; Mecking, H. Physics and phenomenology of strain hardening: The FCC case. Prog. Mater. Sci. 2003, 48, 171–273. [Google Scholar] [CrossRef]

- Neuhäuser, H. Dislocations in Solids; FRN Nabarro, Ed.; North-Holland Publishing Co.: Amsterdam, The Netherlands, 1983. [Google Scholar]

- Mecking, H.; Kocks, U.F. Kinetics of flow and strain-hardening. Acta Metall. 1981, 29, 1865–1875. [Google Scholar] [CrossRef]

- Sato, S.; Kwon, E.P.; Imafuku, M.; Wagatsuma, K.; Suzuki, S. Microstructural characterization of high-manganese austenitic steels with different stacking fault energies. Mater. Charact. 2011, 62, 781–788. [Google Scholar] [CrossRef]

- Wardle, S.T.; Lin, L.S.; Cetel, A.D.; Adams, B.L. Orientation imaging microscopy: Monitoring residual stress profiles in single crystals using and imaging quality parameter, IQ. In Proceedings of the 52nd Annual Meeting of the Microscopy Society of America, San Francisco, CA, USA, 31 July–5 August 1994; Bailey, G.W., Garratt-Reed, A.J., Eds.; San Francisco Press: San Francisco, CA, USA, 1994; pp. 680–681. [Google Scholar]

- Tarasiuk, J.; Gerber, P.; Bacroix, B. Estimation of recrystallized volume fraction from EBSD data. Acta Mater. 2002, 50, 1467–1477. [Google Scholar] [CrossRef]

- Badji, R.; Bacroix, B.; Bouabdallah, M. Texture, microstructure and anisotropic properties in annealed 2205 duplex stainless steel welds. Mater. Charact. 2011, 62, 833–843. [Google Scholar] [CrossRef]

- Wroński, S.; Tarasiuk, J.; Bacroix, B.; Baczmański, A.; Braham, C. Investigation of plastic deformation heterogeneities in duplex steel by EBSD. Mater. Charact. 2012, 73, 52–60. [Google Scholar] [CrossRef] [Green Version]

- Tikhonova, M.; Dolzhenko, P.; Kaibyshev, R.; Belyakov, A. Grain Boundary Assemblies in Dynamically-Recrystallized Austenitic Stainless Steel. Metals 2016, 6, 268. [Google Scholar] [CrossRef]

- Cizek, P.; Whiteman, J.A.; Rainforth, W.M.; Beynon, J.H. EBSD and TEM investigation of the hot deformation substructure characteristics of a type 316L austenitic stainless steel. J. Microsc. 2004, 213, 285–295. [Google Scholar] [CrossRef] [PubMed]

- Sakai, T.; Belyakov, A.; Kaibyshev, R.; Miura, H.; Jonas, J. Dynamic and post-dynamic recrystallization under hot, cold and severe plastic deformation conditions. Prog. Mater. Sci. 2014, 60, 130–207. [Google Scholar] [CrossRef]

- Huang, K. Towards the Modelling of Recrystallization Phenomena in Multi-Pass Conditions: Application to 304L Steel. Ph.D. Thesis, École Nationale Supérieure des Mines de Paris, Paris, France, 2011. (In English). [Google Scholar]

- McQueen, H.J.; Jonas, J.J. Recovery and recrystallization during high temperature deformation. In Treatise on Materials Science and Technology; Arsenault, R.J., Ed.; Academic Press: New York, NY, USA, 1975; Volume 6, pp. 394–490. [Google Scholar]

- Belyakov, A.; Sakai, T.; Miura, H.; Kaibyshev, R. Grain refinement under multiple warm deformation in 304 type austenitic stainless steel. Iron Steel Inst. Jpn. Int. 1999, 39, 592–599. [Google Scholar] [CrossRef]

| Steel | C | Si | Mn | Cr | Mo | Ni | Cu | Co | N | Others | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|

| AISI 1005 | 0.051 | 0.07 | 0.30 | 0.11 | 0.02 | 0.13 | 0.17 | 0.01 | 0.01 | <0.07 | bal. |

| AISI 304L | 0.031 | 0.35 | 1.32 | 18.66 | 0.40 | 8.11 | 0.49 | 0.12 | 0.09 | <0.06 | bal. |

| Duplex 2205 | 0.022 | 0.52 | 1.28 | 22.30 | 3.13 | 5.68 | 0.19 | 0.07 | 0.18 | <0.05 | bal. |

| Steel | Height Reduction h (%) | ||||

|---|---|---|---|---|---|

| 20 °C | 400 °C | 500 °C | 600 °C | 700 °C | |

| AISI 1005 | 96.1 | - | - | - | - |

| AISI 304L | 54.0 | 56.5 | 57.4 | 60.9 | 64.5 |

| Duplex 2205 | 49.7 | 53.2 | 54.1 | 57.9 | 61.0 |

| Investigated Area | Vf min Fraction (%) | |||

|---|---|---|---|---|

| α-phase (%) | γ-phase (%) | |||

| AISI 1005 | Duplex 2205 | AISI 304L | Duplex 2205 | |

| Zone B | 12.3 | 24.7 | 14.3 | 25.8 |

| Zone C | 55.8 | 63.4 | 64.7 | 71.3 |

| Investigated Area | CSL Boundaries Volume Fraction (%) | |||

|---|---|---|---|---|

| AISI 304L | Duplex 2205 | |||

| Ʃ3 | Total: Ʃ3–Ʃ49 | Ʃ3 | Total: Ʃ3–Ʃ49 | |

| Zone A | 59.2 | 68.1 | 65.9 | 73.7 |

| Zone B | 55.8 | 63.4 | 64.7 | 71.3 |

| Zone C | 14.3 | 25.8 | 12.3 | 24.7 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ferro, P.; Bonollo, F.; Bassan, F.; Berto, F. Strain Evolution in Cold-Warm Forged Steel Components Studied by Means of EBSD Technique. Materials 2017, 10, 1441. https://doi.org/10.3390/ma10121441

Ferro P, Bonollo F, Bassan F, Berto F. Strain Evolution in Cold-Warm Forged Steel Components Studied by Means of EBSD Technique. Materials. 2017; 10(12):1441. https://doi.org/10.3390/ma10121441

Chicago/Turabian StyleFerro, Paolo, Franco Bonollo, Fabio Bassan, and Filippo Berto. 2017. "Strain Evolution in Cold-Warm Forged Steel Components Studied by Means of EBSD Technique" Materials 10, no. 12: 1441. https://doi.org/10.3390/ma10121441