In Situ TEM Multi-Beam Ion Irradiation as a Technique for Elucidating Synergistic Radiation Effects

Abstract

:1. Introduction

2. Materials and Methods

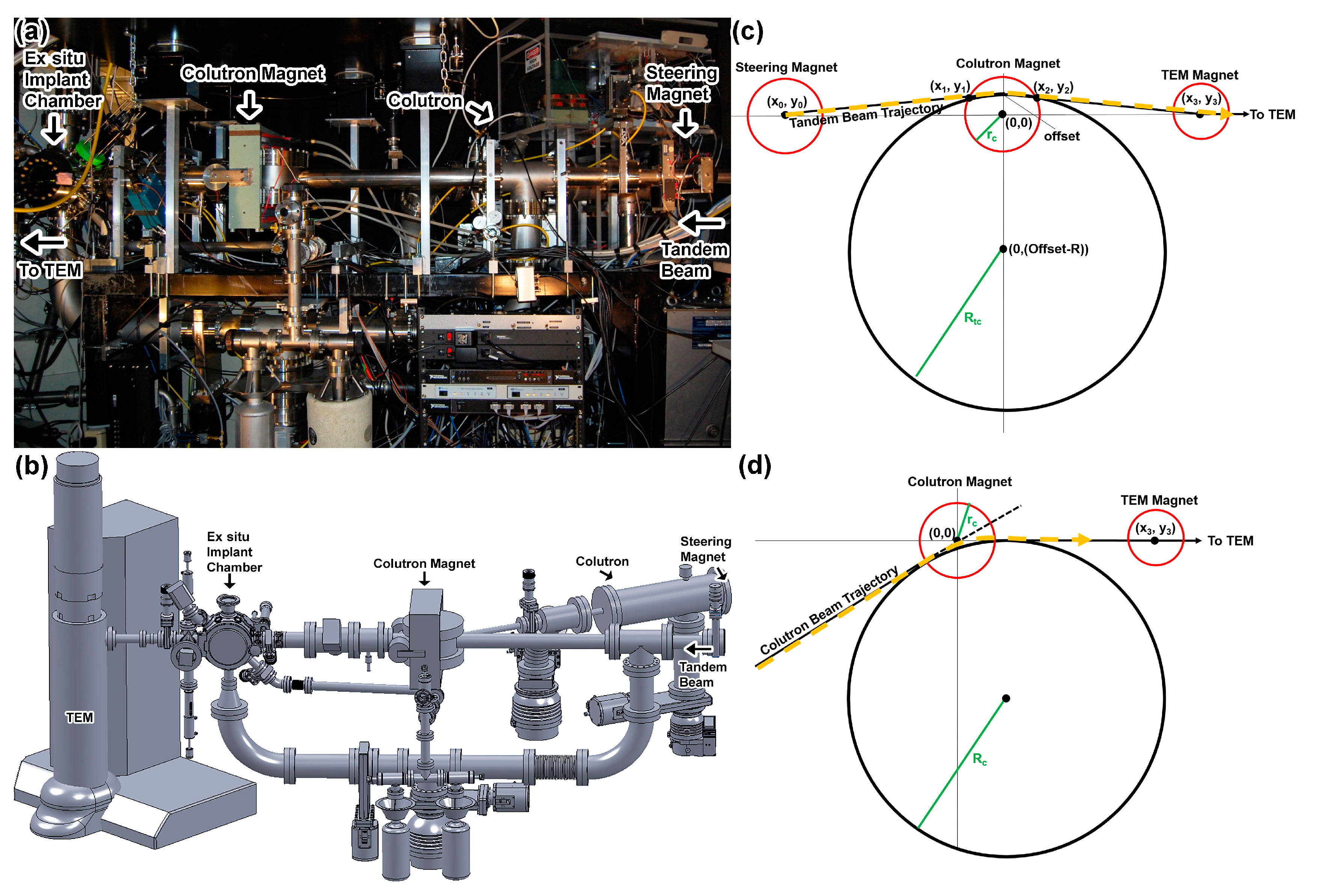

2.1. Accelerator Beam Line Design

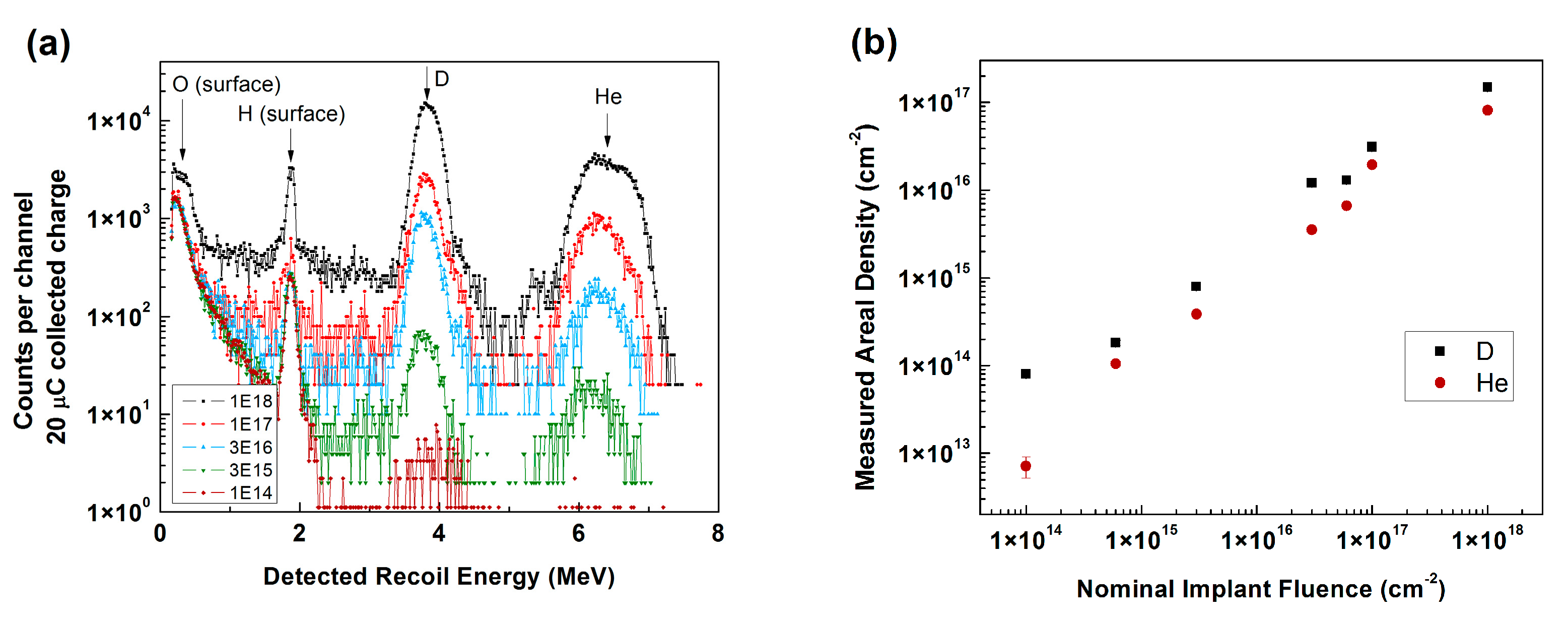

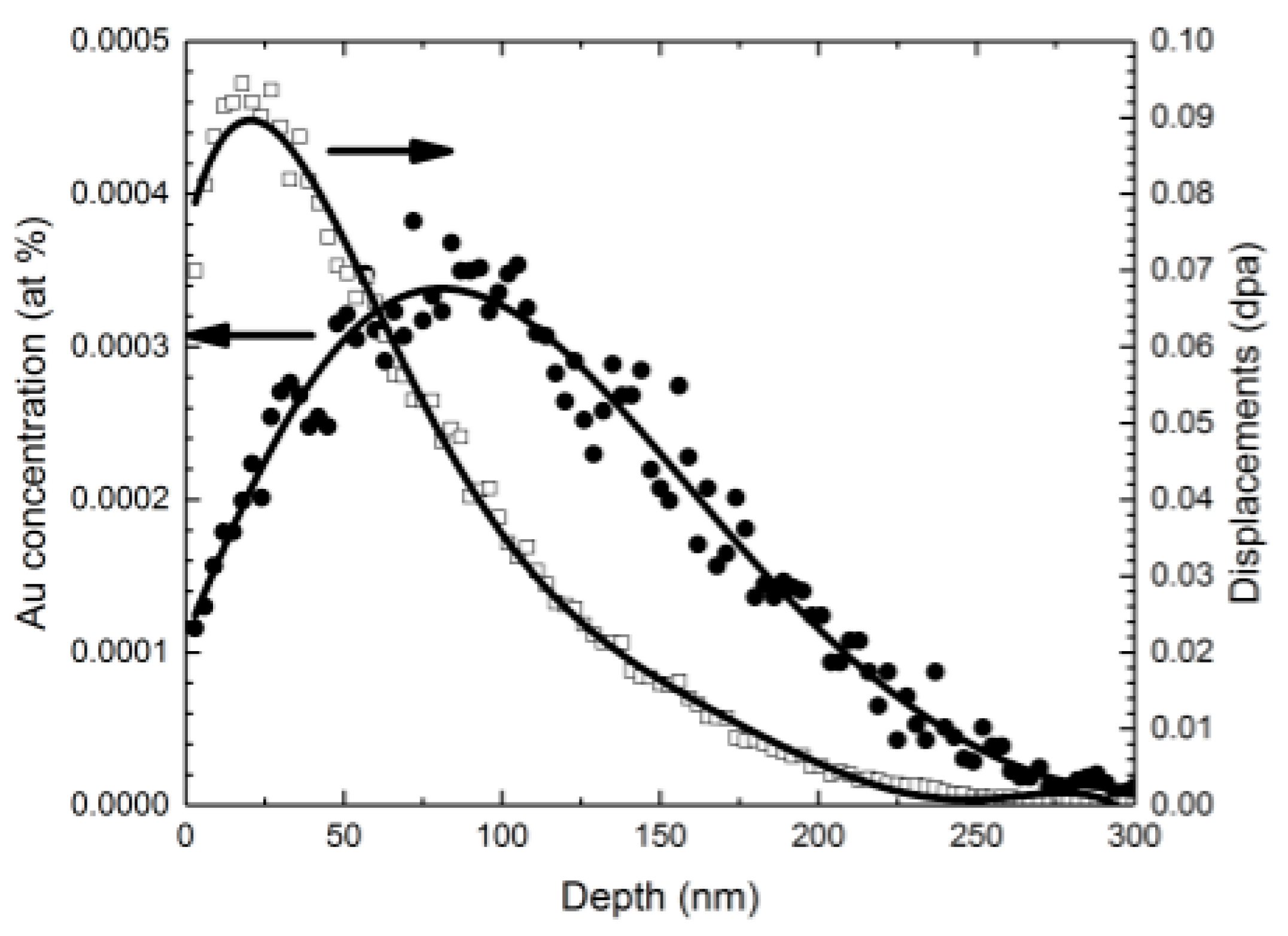

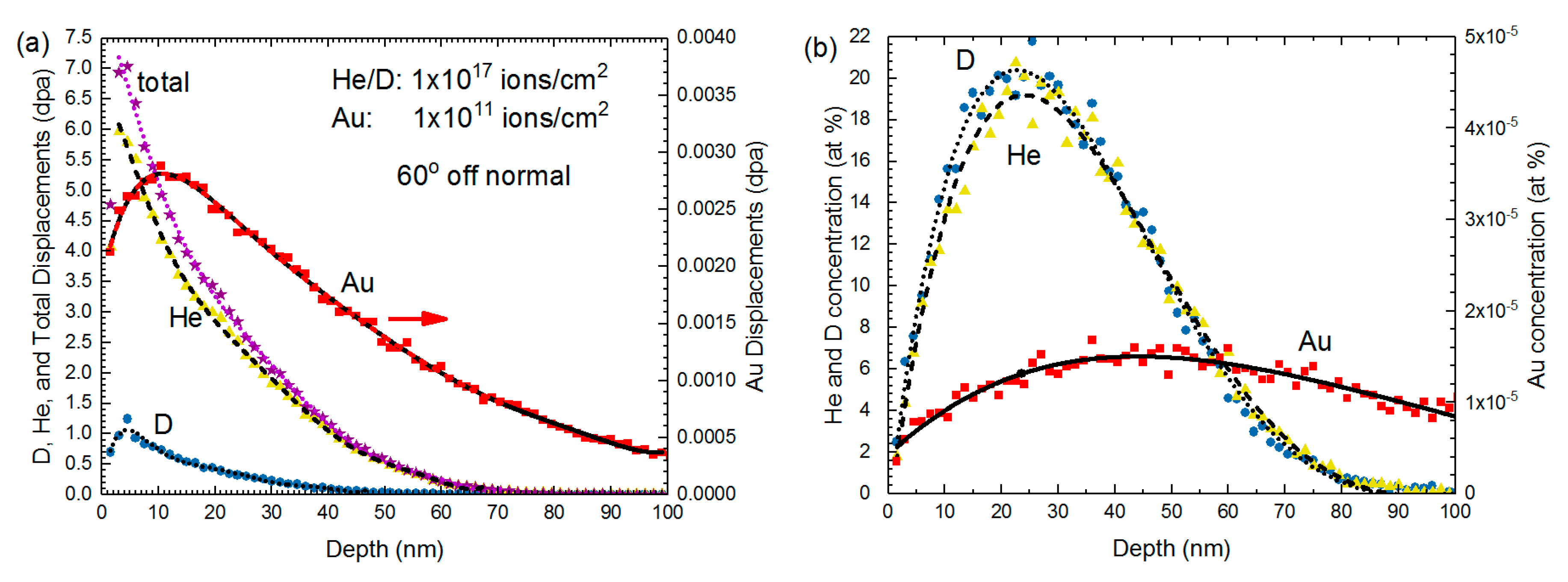

2.2. Characterization of the He + D Beam

2.3. Experimental Details

3. Results

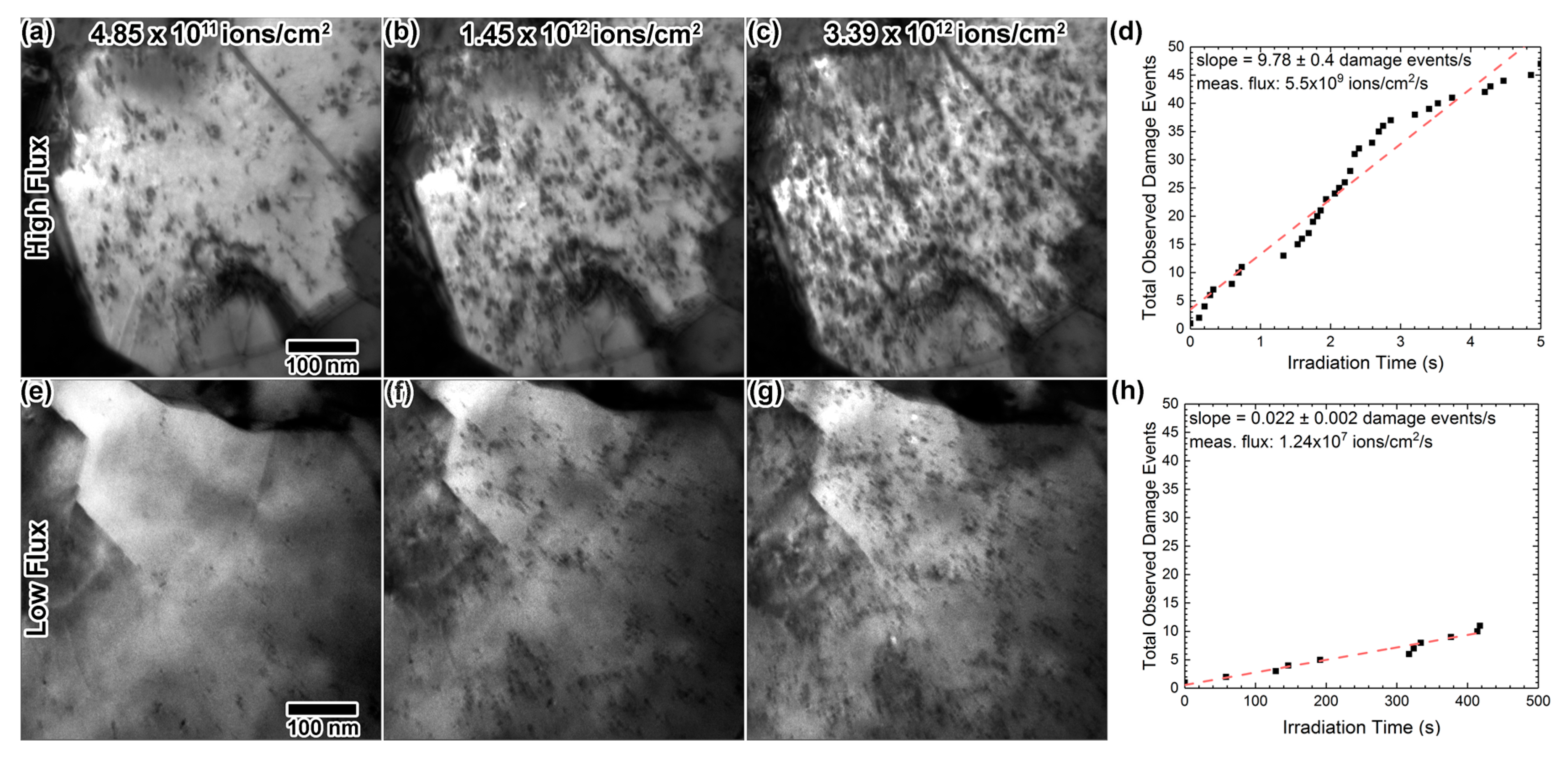

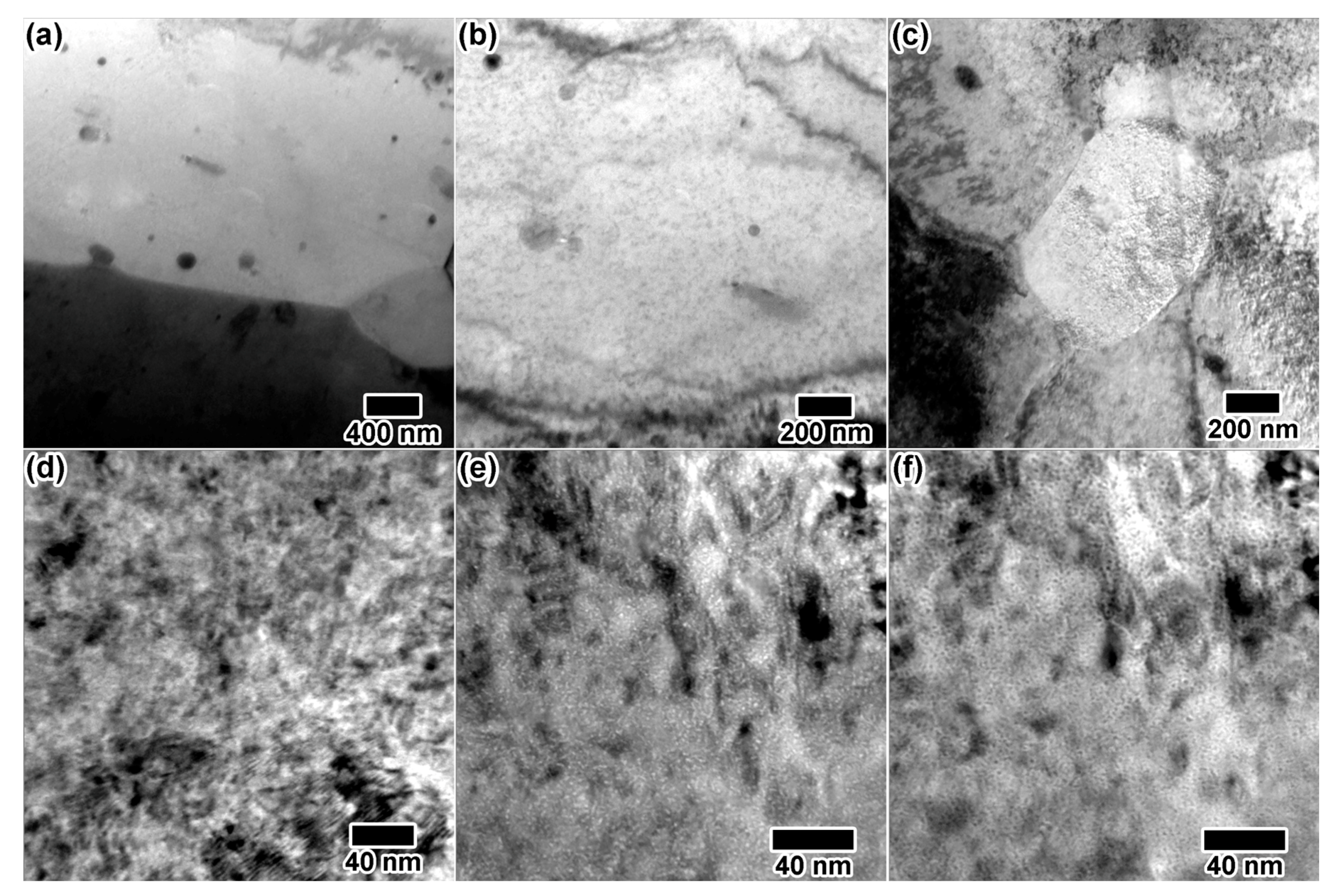

3.1. Dose Rate Effects of In Situ Single Beam Au Irradiation into Au

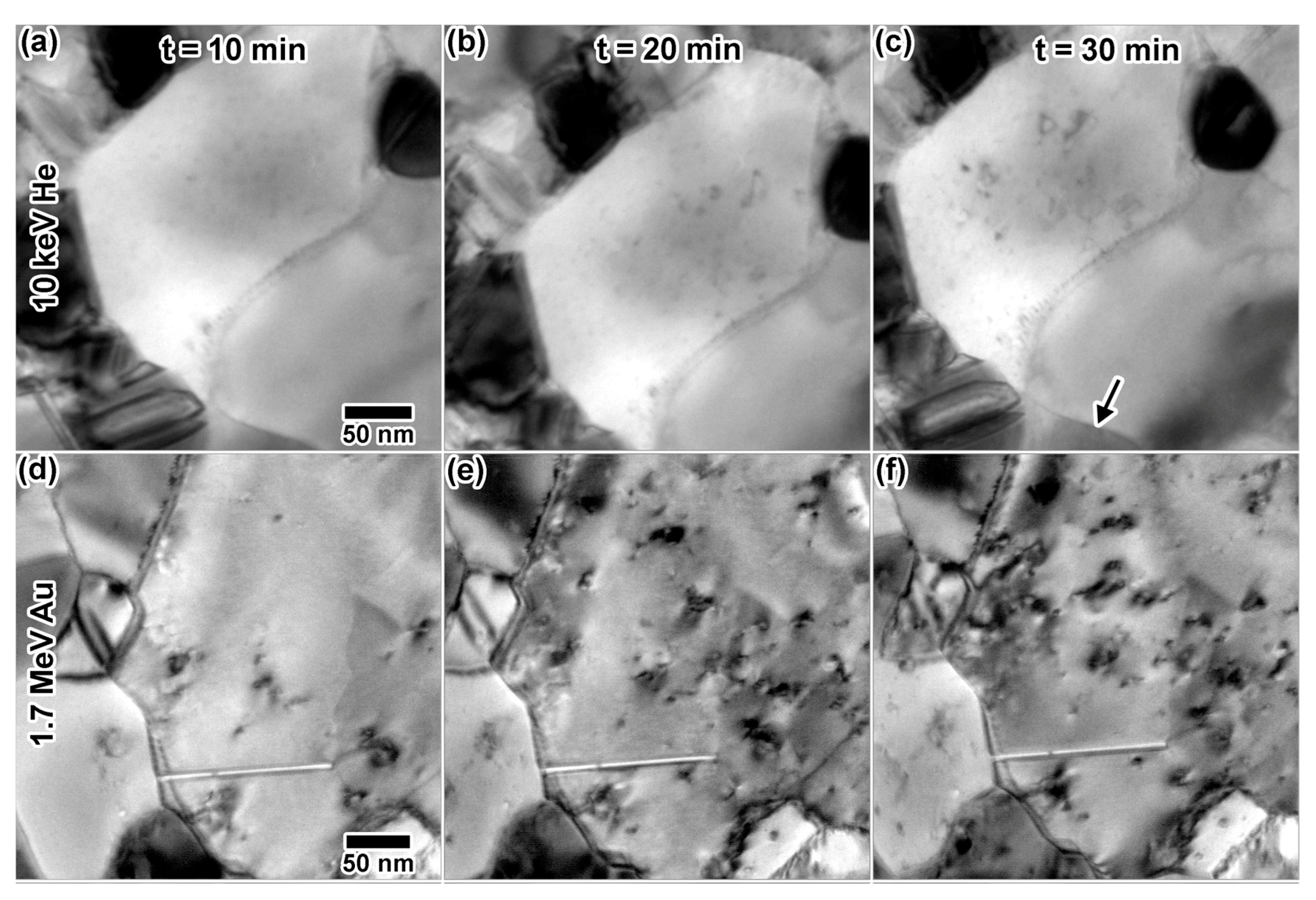

3.2. In Situ Single Ion Irradiation into Au

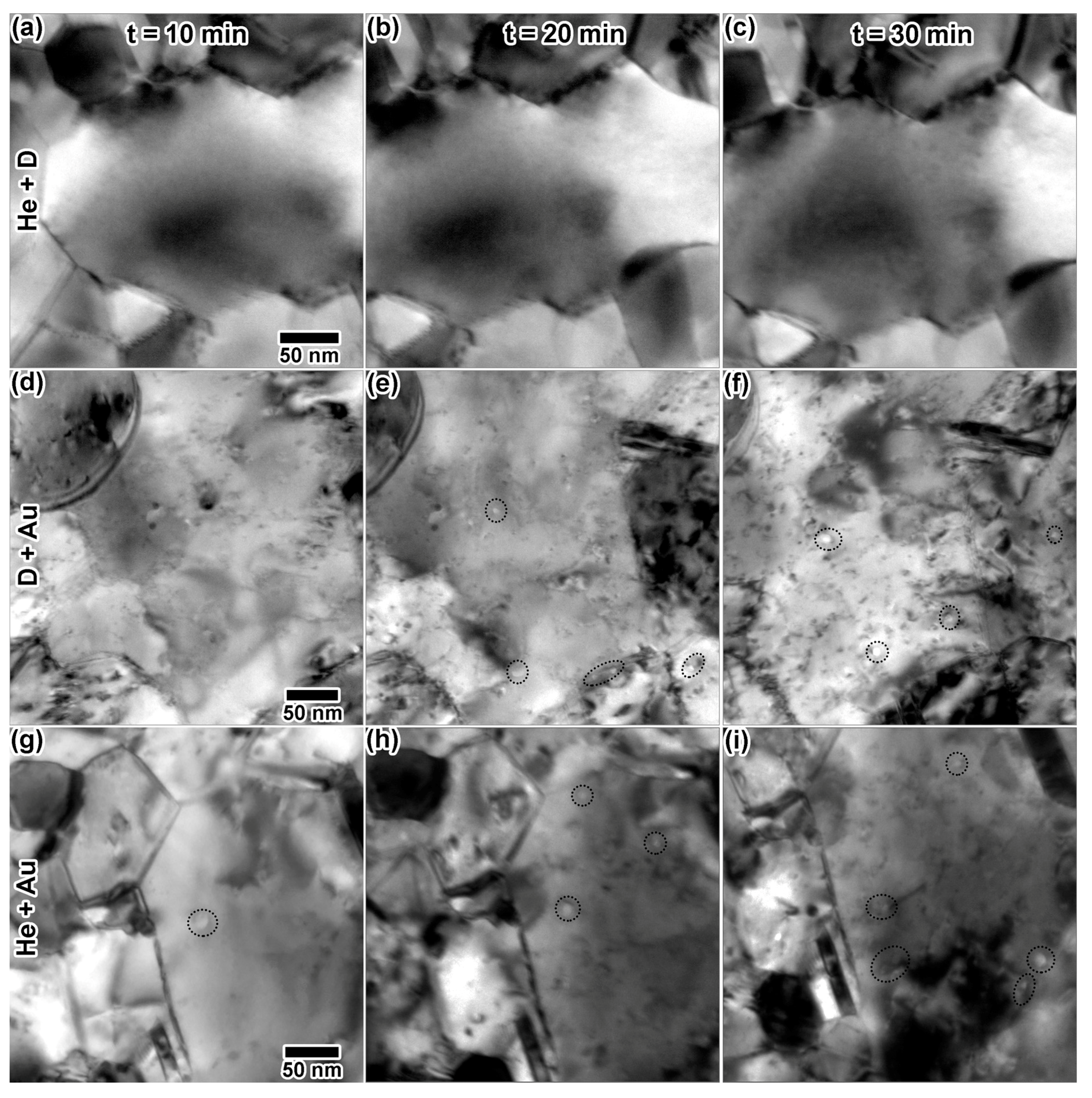

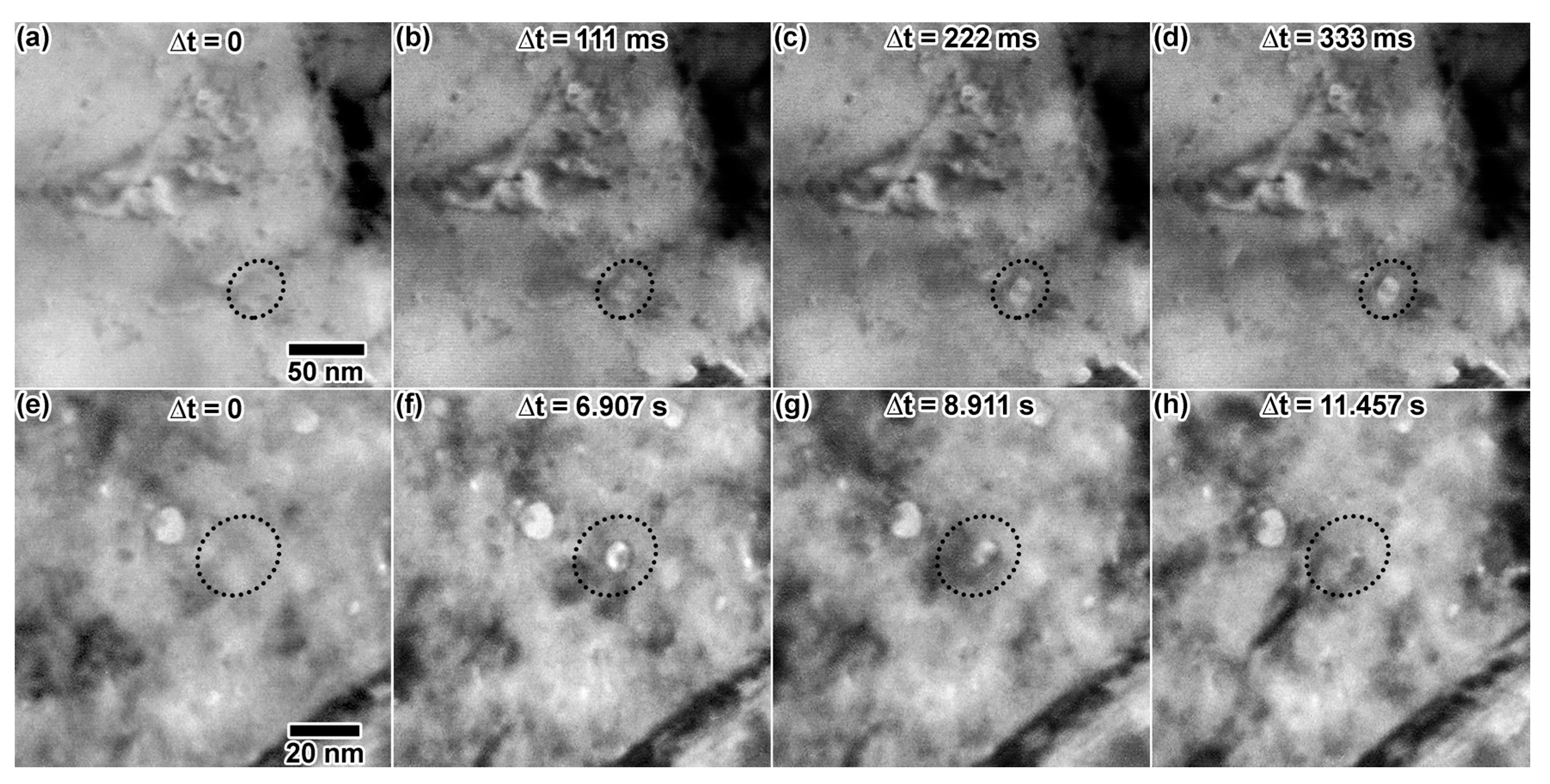

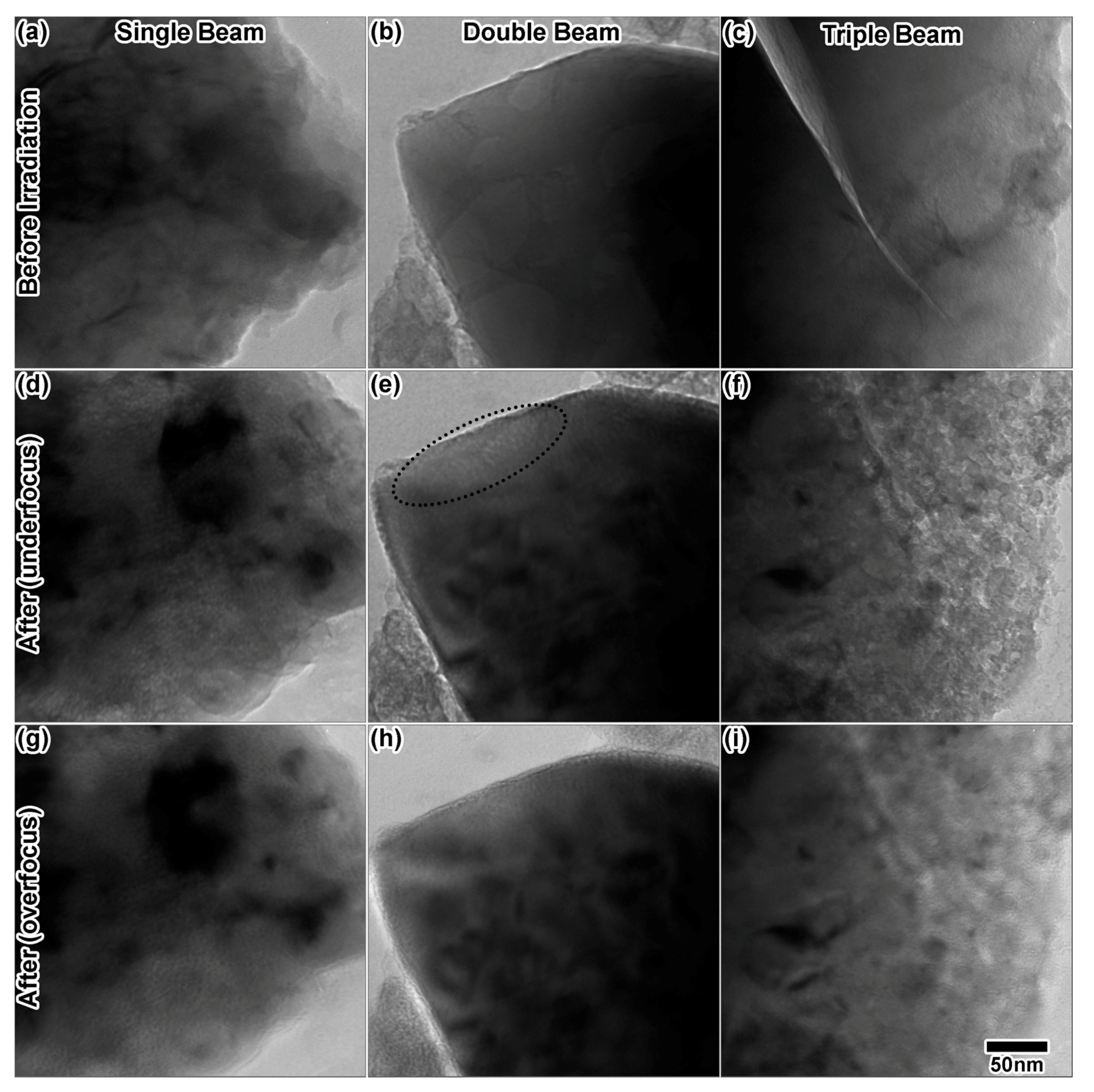

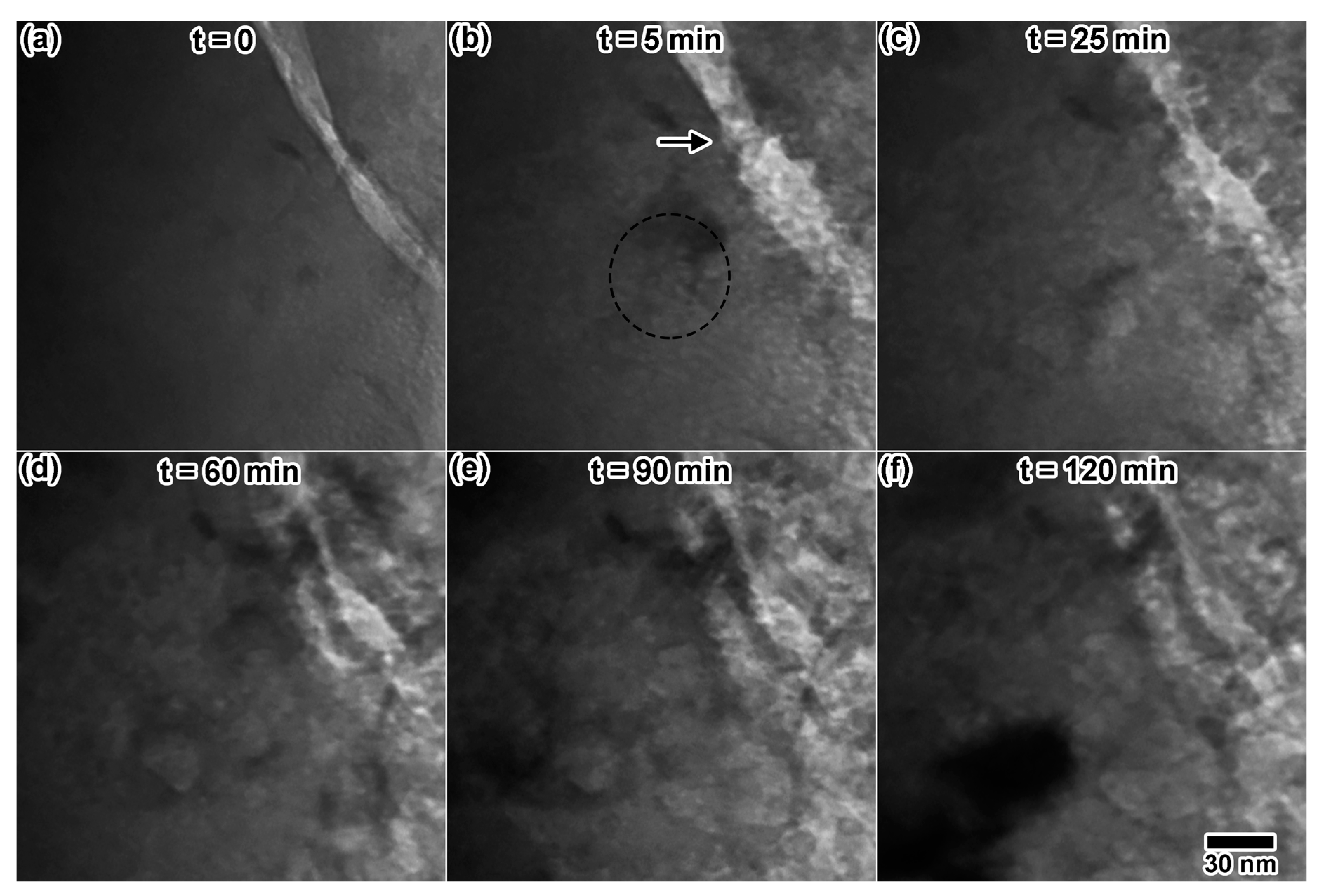

3.3. In Situ Double Ion Irradiation into Au

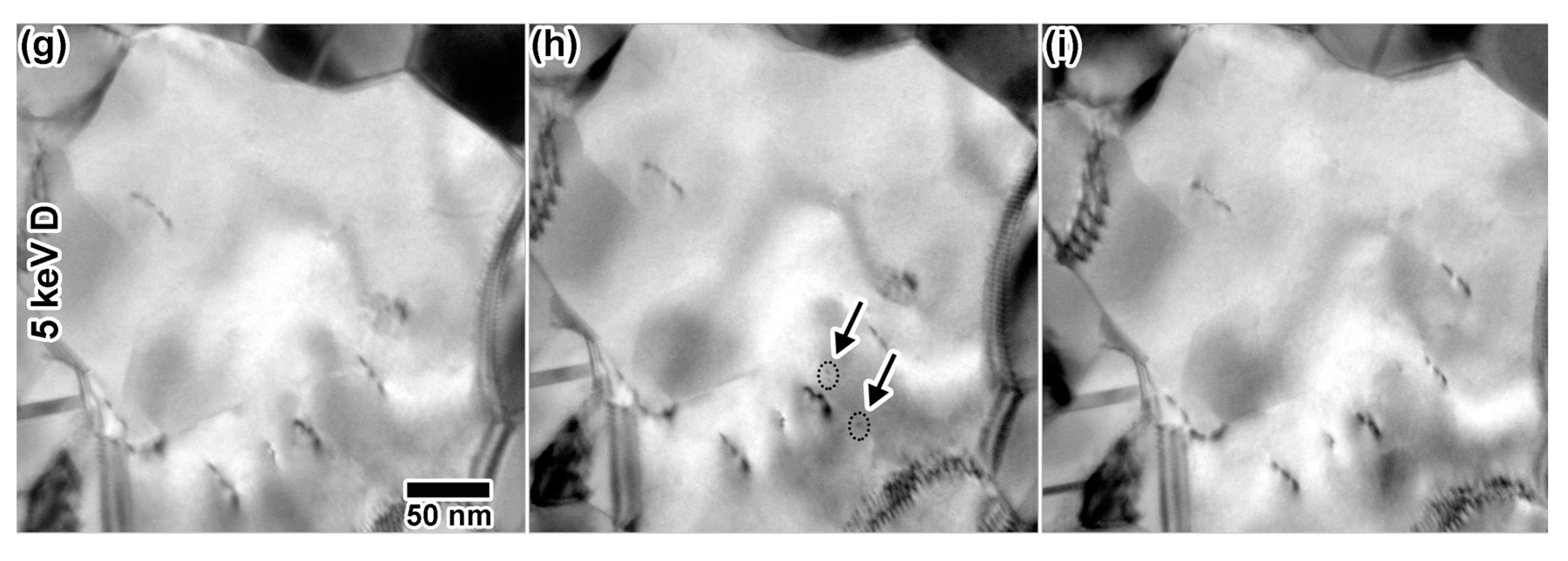

3.4. In Situ Triple Ion Irradiation into Au

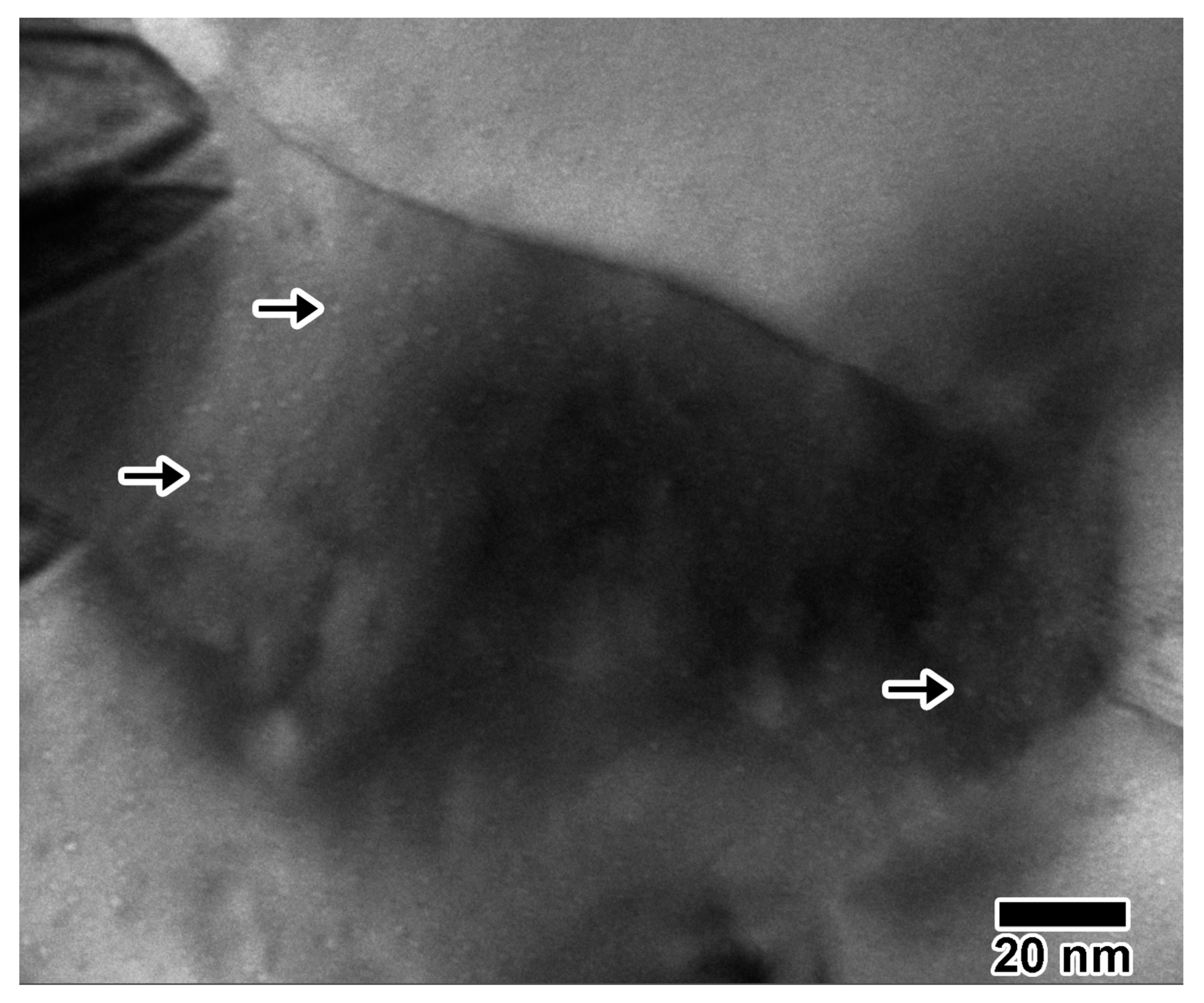

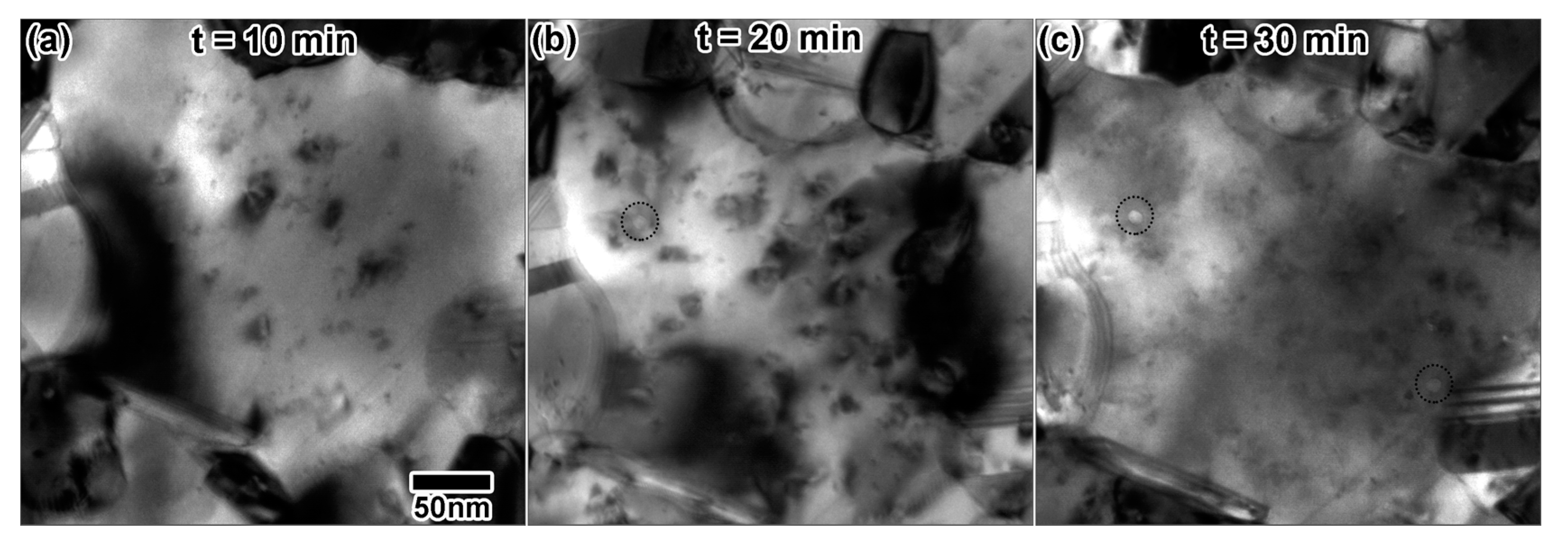

3.5. In Situ Single, Double and Triple Ion Irradiation in TPBAR Materials

4. Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Zinkle, S.J.; Was, G.S. Materials challenges in nuclear energy. Acta Mater. 2013, 61, 735–758. [Google Scholar] [CrossRef]

- Beck, L.; Serruys, Y.; Miro, S.; Trocellier, P.; Bordas, E.; Leprêtre, F.; Brimbal, D.; Loussouarn, T.; Martin, H.; Vaubaillon, S.; et al. Ion irradiation and radiation effect characterization at the JANNUS-Saclay triple beam facility. J. Mater. Res. 2015, 30, 1–12. [Google Scholar] [CrossRef]

- Kurashima, S.; Satoh, T.; Saitoh, Y.; Yokota, W. Irradiation facilities of the Takasaki Advanced Radiation Research Institute. Quantum Beam Sci. 2017, 1, 2. [Google Scholar] [CrossRef]

- Tanaka, T.; Oka, K.; Ohnuki, S.; Yamashita, S.; Suda, T.; Watanabe, S.; Wakai, E. Synergistic effect of helium and hydrogen for defect evolution under multi-ion irradiation of Fe-Cr ferritic alloys. J. Nucl. Mater. 2004, 329, 294–298. [Google Scholar] [CrossRef]

- Butler, E.P. In situ experiments in the transmission electron microscope. Rep. Prog. Phys. 1979, 42, 833–889. [Google Scholar] [CrossRef]

- Ishino, S. A review of in situ observation of defect production with energetic heavy ions. J. Nucl. Mater. 1997, 251, 225–236. [Google Scholar] [CrossRef]

- Birtcher, R.C.; Kirk, M.A.; Furuya, K.; Lumpkin, G.R. In situ transmission electron microscopy investigation of radiation effects. J. Mater. Res. 2017, 20, 1654–1683. [Google Scholar] [CrossRef]

- Hinks, J.A. A review of transmission electron microscopes with in situ ion irradiation. Nucl. Instrum. Methods Phys. Res. Sect. B 2009, 267, 3652–3662. [Google Scholar] [CrossRef]

- Kirk, M.A.; Baldo, P.M.; Liu, A.C.Y.; Ryan, E.A.; Birtcher, R.C.; Yao, Z.; Xu, S.E.N.; Jenkins, M.L.; Hernandez-mayoral, M.; Kaoumi, D.; et al. In situ transmission electron microscopy and ion irradiation of ferritic materials. Microsc. Res. Tech. 2009, 186, 182–186. [Google Scholar] [CrossRef] [PubMed]

- Pashley, D.W.; Presland, A.E.B. Ion damage to metal films inside an electron microscope. Philos. Mag. 1961, 6, 1003–1012. [Google Scholar] [CrossRef]

- Howe, L.M.; McGurn, J.F.; Gilbert, R.W. Direct observation of radiation damage produced in copper, gold, and aluminum during ion bombardments at low temperatures in the electron microscope. Acta Metall. 1966, 14, 801–820. [Google Scholar] [CrossRef]

- Whitmell, D.S.; Kennedy, W.A.D.; Mazey, D.J.; Nelson, R.S.; Kennedy, W.A.D.; Mazey, D.J.; Nelson, R.S.A. A heavy-ion accelerator-electron microscope link for the direct observation of ion irradiation effects. Radiat. Eff. Defects Solids 2017, 7579, 163–168. [Google Scholar] [CrossRef]

- Hattar, K.; Bufford, D.C.; Buller, D.L. Concurrent in situ ion irradiation transmission electron microscope. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interac. Mater. Atoms 2014, 338, 56–65. [Google Scholar] [CrossRef]

- Nastasi, M.; Mayer, J.W.; Wang, Y.-Q. Ion Beam Analysis: Fundamentals and Applications; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar]

- Rasband, W.S. ImageJ, US National Institutes of Health. Available online: http://imagej.nih.gov/ij/ (accessed on 28 September 2017).

- Ziegler, J.F.; Biersack, J.P.; Littmark, U. The Stopping Range of Ions in Solids; Pergamon Press: New York, NY, USA, 1985. [Google Scholar]

- Broeders, C.H.M.; Konobeyev, A.Y. Development of Calculation Methods to Analyze Radiation Damage, Nuclide Production and Energy Deposition in ADS Materials and Nuclear Data Evaluation; Forschungszentrum Karlsruhe: Karlsruhe, Germany, 2006. [Google Scholar]

- Lizunov, Y.; Möslang, A.; Ryazanov, A.; Vladimirov, P. New evaluation of displacement damage and gas production for breeder ceramics under IFMIF, fusion and fission neutron irradiation. J. Nucl. Mater. 2002, 311, 1680–1685. [Google Scholar] [CrossRef]

- Edington, J.W. Practical Electron Microscopy in Materials Science; Van Nostrand Reinhold Co.: New York, NY, USA, 1976. [Google Scholar]

- Donnelly, S.; Birtcher, R. Heavy ion cratering of gold. Phys. Rev. B 1997, 56, 13599–13602. [Google Scholar] [CrossRef]

- Birtcher, R.C.; Donnelly, S.E.; Schlutig, S. Nanoparticle ejection from Au induced by single Xe ion impacts. Phys. Rev. Lett. 2000, 85, 4968–4971. [Google Scholar] [CrossRef] [PubMed]

- Burns, K.A.; Love, E.F.; Thornhill, C.K. Description of the Tritium-Producing Burnable Absorber Rod for the Commercial Light Water Reactor; Technical Report for United States Department of Energy; Pacific Northwest National Laboratory (PNNL): Richland, WA, USA, 2012.

- Chisholm, C.; Hattar, K.; Minor, A.M. In Situ TEM concurrent and successive Au self-ion irradiation and He implantation. Mater. Trans. 2014, 55, 418–422. [Google Scholar] [CrossRef]

- Ghoniem, N.M. Nucleation and growth theory of cavity evolution under conditions of cascade damage and high helium generation. J. Nucl. Mater. 1990, 174, 168–177. [Google Scholar] [CrossRef]

- Donnelly, S.E.; Birtcher, R.C.; Templier, C.; Vishnyakov, V. Response of helium bubbles in gold to displacement-cascade damage. Phys. Rev. B 1995, 52, 3970–3976. [Google Scholar] [CrossRef]

- Lewis, M.B.; Farrell, K. Migration behavior of helium under displacive irradiation in stainless steel, nickel, iron and zirconium. Nucl. Instrum. Methods Phys. Res. Sect. B 1986, 16, 163–170. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Taylor, C.A.; Bufford, D.C.; Muntifering, B.R.; Senor, D.; Steckbeck, M.; Davis, J.; Doyle, B.; Buller, D.; Hattar, K.M. In Situ TEM Multi-Beam Ion Irradiation as a Technique for Elucidating Synergistic Radiation Effects. Materials 2017, 10, 1148. https://doi.org/10.3390/ma10101148

Taylor CA, Bufford DC, Muntifering BR, Senor D, Steckbeck M, Davis J, Doyle B, Buller D, Hattar KM. In Situ TEM Multi-Beam Ion Irradiation as a Technique for Elucidating Synergistic Radiation Effects. Materials. 2017; 10(10):1148. https://doi.org/10.3390/ma10101148

Chicago/Turabian StyleTaylor, Caitlin Anne, Daniel Charles Bufford, Brittany Rana Muntifering, David Senor, Mackenzie Steckbeck, Justin Davis, Barney Doyle, Daniel Buller, and Khalid Mikhiel Hattar. 2017. "In Situ TEM Multi-Beam Ion Irradiation as a Technique for Elucidating Synergistic Radiation Effects" Materials 10, no. 10: 1148. https://doi.org/10.3390/ma10101148