1. Introduction

With growing concerns about environmental problems, the huge energy consumption of urban rail transit systems has attracted much attention. The energy consumption of train traction makes up nearly half of a subway system’s total energy consumption. In an urban rail transit, more and more lines are using the Communication Based Train Control (CBTC) systems. Based on these systems, trains are controlled by tracking a target speed curve, and this allows the control center operators to change in real-time the planned interstation running time according to whether the train arrived at a station early or late. This requires that the system have the ability of computing real-time target distance curves online. Therefore, optimizing the energy-expenditure of those speed curves is regarded as one of the most effective ways to realize energy-efficient train operation. However, energy-saving target speed curves must be calculated with real-time performance data, as the distances between two adjacent stations can be relatively short, causing frequent acceleration and deceleration switches. Thus, this paper aims to design a fast and efficient real-time algorithm for optimization of energy-saving train speed curves.

Many studies dating as far back as the1960s have previously focused on energy-efficient train operation, For example, Ishikawa et al. carried out the first study focusing on energy-efficient train operation strategies [

1], followed by Howlett et al. [

2,

3] who confirmed the fundamental optimality of a maximum acceleration-coasting, minimum-braking, train control strategy. In addition, they designed the “Metromiser”, which can be used to advise drivers when to coast and brake, so that the train arrives on time and consumes as little energy as possible [

4].

In studies on energy-efficient train operations, off-line optimization has attracted more attention. In 1994, Wang studied optimized control methods for energy-efficient operation, and proposed corresponding operator sequences and optimization strategies [

5]. González-Gil et al. gave an insightful overview on the potential of urban rail systems to reduce their energy consumption [

6]. Ding et al. discussed an optimized model and the corresponding heuristic algorithm for locomotives to work under a fixed running time regime between given stations in a practical operating environment [

7,

8,

9]. In 2009, Fu et al. studied the control strategies of a train when disturbed and obtained target speed profiles using a genetic algorithm (GA) based on an optimized model [

10]. Also, Howlett et al. proposed a method for calculation of critical switching points for a globally optimal strategy on a track with steep gradients [

11]. In 2011, Ke et al. proposed MMAS to search for the optimal speed codes of each section and train acceleration was controlled by a fuzzy-PID gain scheduler to meet the determined speed commands [

12]. Yong et al. presented the two-level optimization model based on a Genetic Algorithm for minimal energy consumption of trains. Then, Domínguez et al. proposed a Multi Objective Particle Swarm Optimization (MOPSO) algorithm to obtain the consumption or time Pareto front based on the simulation of a train with a real Automatic Train Operation (ATO) system [

13,

14]. Besides, Huang et al. optimized both trip time and driving strategy for multiple interstation segments by using a multi-population genetic algorithm (MPGA) [

15]. The works of Roberts et al. have assessed Enhanced Brute Force (EBF), Ant Colony Optimization (ACO), and GA searching methods for calculating the most appropriate train target speed series to optimize the train operation and suggested that both GA and ACO are suitable. In addition, Li et al. have explored the merits of optimizing the speed curve using ACO for train operation [

16,

17].

The real-time optimization of energy-efficient train operation needs to be considered in further studies. From 2009 to 2011, Ke et al. discretized the optimization problem of train energy-efficient operation and made a combinatorial optimization using an ant colony algorithm, based on linear computing discrete combination optimization [

18,

19]. Wong et al. presented an application of GA to search for the appropriate coasting points and investigates the possible improvement on fitness of genes. Single and multiple coasting point control with simple GA are developed to attain the solutions and their corresponding train movement is examined [

20]. In 2010, Miyatake studied the problems of energy-consumption minimization with energy storage equipment, and discussed three methods: the gradient method, the dynamic programming method and the quadratic programming method, and real-time control methods are mentioned in research [

21]. Jin et al. discussed the optimization problem of energy-efficient train operation with variable gradients, and proposed a simulation optimization model which combined local optimization with global optimization strategies. Then, they created an optimized speed profile online, using this model, to guide the train to energy-efficient operation [

22]. Su et al. proposed an integrated energy-efficient train operation algorithm combined with optimal timetabling [

23,

24]. Sicre et al. proposed a GA with fuzzy parameters to calculate a new efficient driving mode in real-time to be manually executed on high speed trains when significant delays arise [

25]. Furthermore, Yin et al. considered multiple train operation objectives and proposed two intelligent train operation algorithms in order to minimize the energy consumption of train operation online [

26]. Khmelnitsky used the Pontryagin maximum principle and proved the optimization problem, under which the optimal driving strategy consisted of acceleration, cruising, coasting and maximum braking; he derived a numerical solution based on a successive model, and the method can be added in real-time feedback design in many different ways [

27]. Gu et al. proposed a novel multiple-model-based switching optimization framework to reduce energy consumption while guaranteeing the punctuality during train’s real-time tracking operation [

28]. Yang et al.’s survey of energy-efficient train operation assessed the existing literature, including the use of several optimization algorithms, and the MMAS mentioned in the research is more suitable to study discretization intervals and online optimization problem [

29].

In conclusion, train energy-efficient operation can be researched from several perspectives such as driving strategy, timetable, real time, comfortableness and so on. Different research contents correspond to different research methods. This paper researches train energy-efficient operation mainly from a real-time perspective. A method is therefore needed that achieves energy-efficient operation together with good real-time optimization-performance. Consequently, this paper proposes an improved ant colony algorithm, based on a two-stage optimization, to search for the optimal target speed profile capable of fast operation as well as achieving enhanced energy efficiency.

2. Problem Statement

Generally speaking, the core problem of energy-efficient train operation is to find the energy-optimal speed-curve for trains to track. To do so, we first discretize a subway segment between two adjacent stations into

intervals i.e.,:

Similarly, the target speed corresponding to the distance point is:

where

is the train discrete point location and

is the tracking target speed code(in km/h). A target speed sequence builds up a target speed curve.

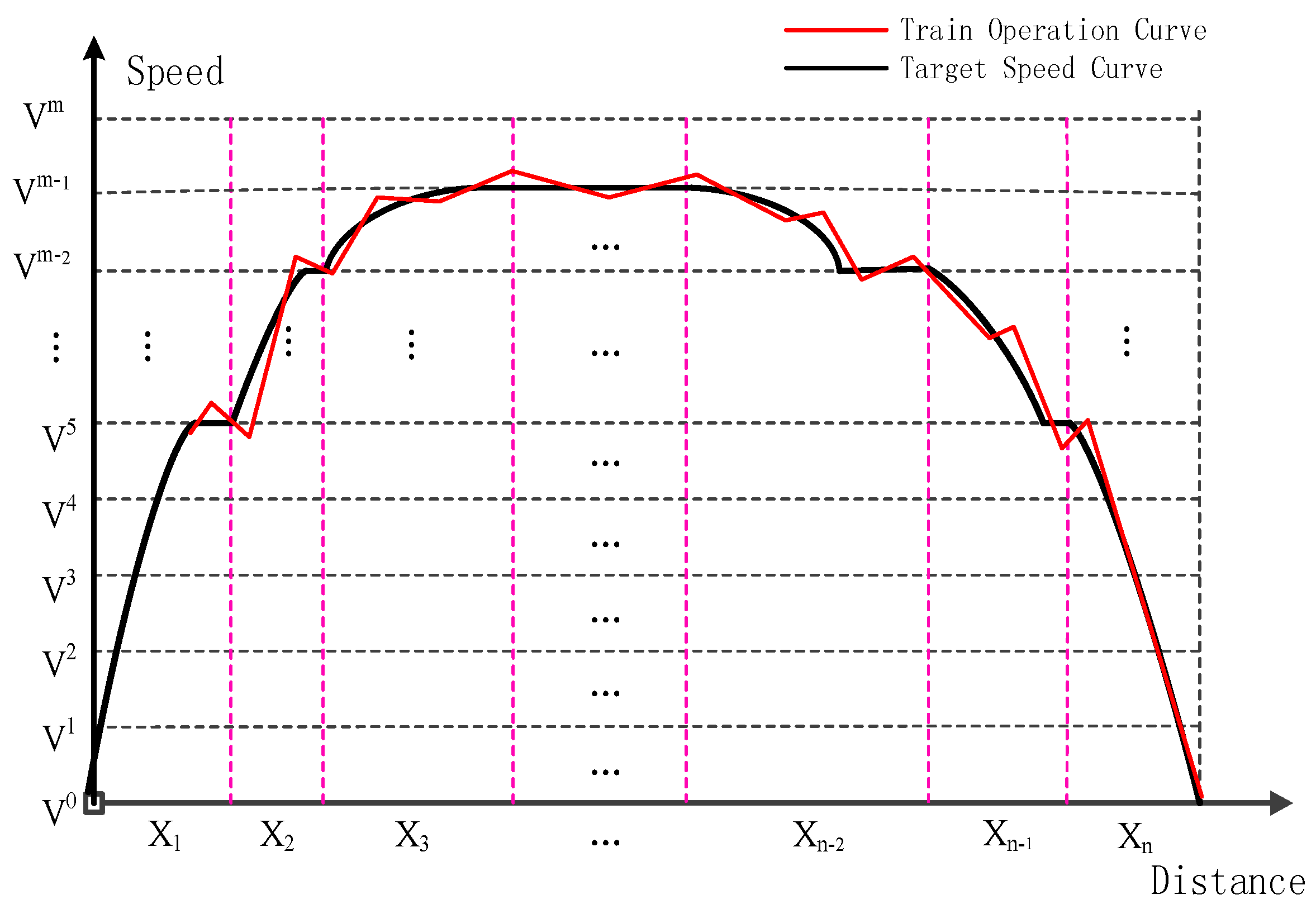

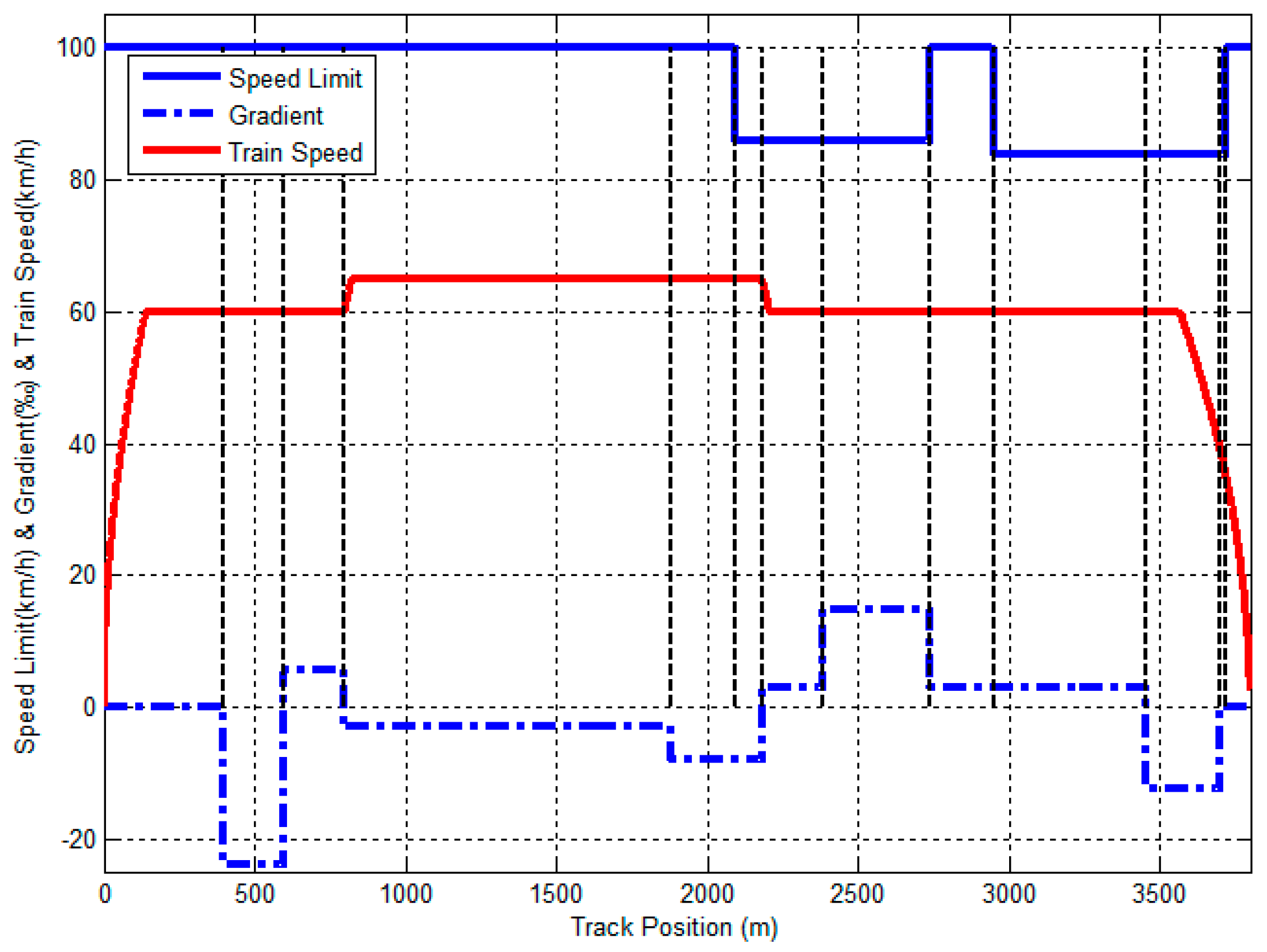

As shown in

Figure 1, the object this paper researches is the train target speed curve, which needs to be calculated off-line in some literatures. The train reaches this target speed by traction, coasting or braking. Different operation mode is related to line conditions and running time constraints. The train tracks the target speed curve by cycles of traction-braking-coasting around the objective speed, but that problem is the optimization of ATO control, which is different with the problem this paper researches. The optimization of ATO control is also one of the hotspots in train energy-efficient operation research [

30].

Therefore, the objective function of the energy-efficient train operation model is:

where

is the total mass of the train;

is acceleration of the train in the

th interval;

is the basic resistance of the train in the

th interval;

is the gradient resistance of the train in the

th interval;

is traction force in acceleration process of the train in the

th interval,

is traction force in cruising process of the train in the

th interval,

is acceleration distance of the train of the

th interval;

is cruising distance of the train in the

th interval;

is tracking energy consumption in the

th interval;

is the total energy that the train consumes after completing all discrete-points speed code selection (in kWh); and

is the number of discrete points after discretization of the line.

Under normal circumstances, the running time of the train on the segments will strictly conform to the requirements of the schedule. The driving strategies will attempt to achieve the train operation and running times specified in the schedule are the same [

31]. The driving strategy will also ensure that the actual operation time of the train is within the allowable difference between the two, even under extreme circumstances. Therefore, in the process of the algorithm design, the operation time needs to be constrained:

where

is the actual running time of the train in the

th interval;

is acceleration of the train in the

th interval;

is the tracking target speed code in the

th interval;

is cruising distance of the train in the

th interval;

is the actual total running time of the train (in seconds);

is the running time according to the timetable scheduled requirements (in seconds);

is the permissible value of the train running time, which is a positive value,

is the number of discrete points after discretization of the line.

The ant ACO is modeled on ants’ foraging process in the natural world. Generally, the ants’ foraging space describes the problem search space and the ant colony can be regarded as a set of effective solutions to the search space, and ant paths are used to represent feasible solutions. Therefore each ant can independently search the problem space for feasible solutions. The pheromone will be left behind during the foraging process. Meanwhile, the pheromone in the path will evaporate as time goes by. Therefore, the ant will choose the right path through perceiving the pheromone concentration, and then by continuous iteration obtain the optimal solution. Finally, the ant colony will centralize to the optimal path, which is the optimal solution to the problem. The correspondence between actual ant phenomena and our model are shown in

Table 1.

By summarizing the above fundamental elements of the ACO algorithm, we can summarize its main features as follows:

It possesses positive feedback, and heuristic hunting characters

It uses distributed control but not centralized control

It is has strong robustness

Each individual can perceive only local information, but not global information

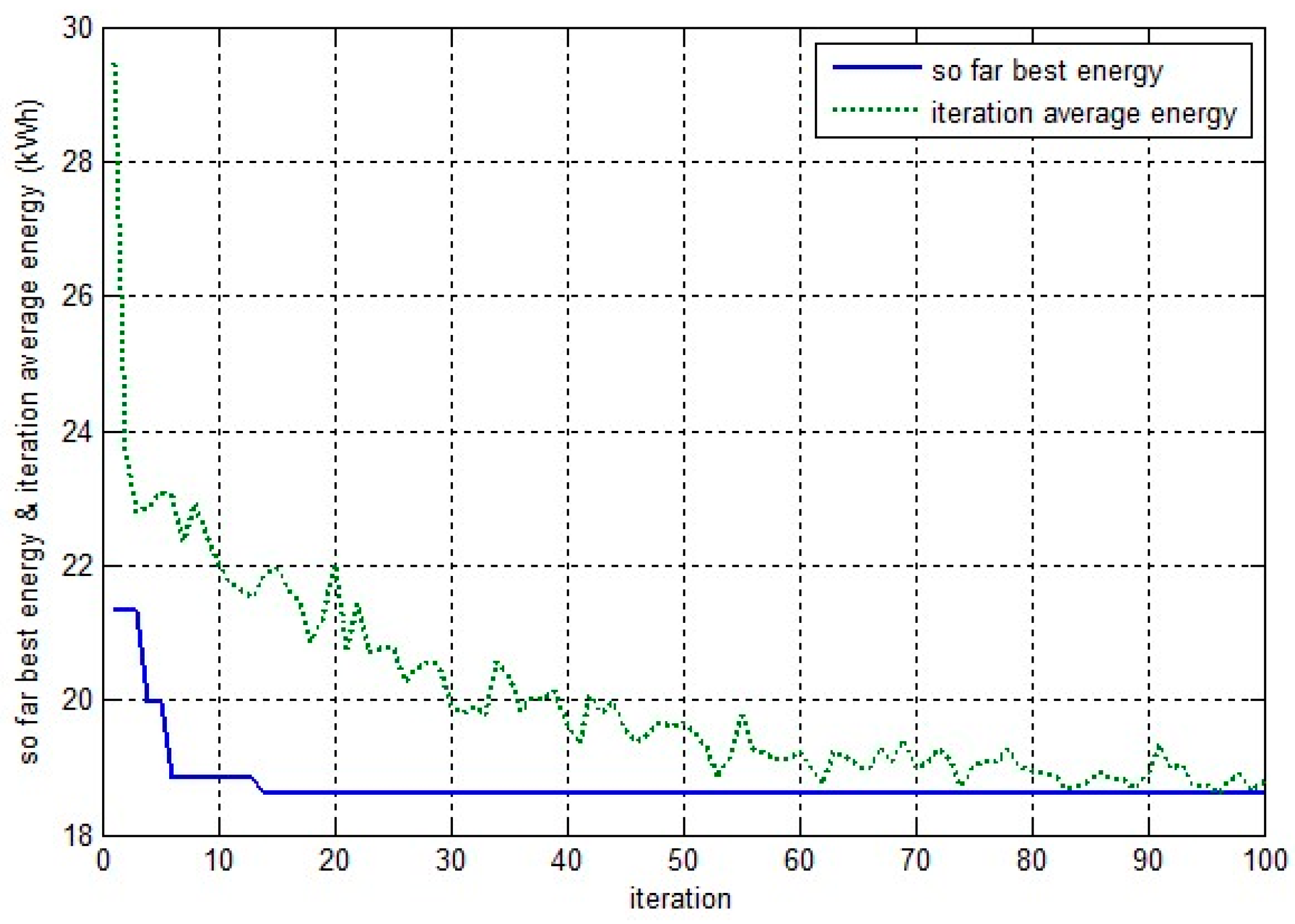

MAX-MIN Ant System (MMAS) is one of the most effective algorithms in ACO. In addition, focusing on the optimization of the energy-efficient train operation, compared with other optimization algorithms, MMAS has the following three advantages:

It has good real-time performance of the energy-efficient train operation

The setting of heuristic pheromone can effectively improve the convergence speed of the algorithm

The method can avoid getting the local optical solution and has better search capabilities of global information

To the best of our knowledge, there is little research in energy-efficient train operation that uses the two-stage MMAS optimization algorithm. By considering the characteristics of the two-stage MMAS algorithm, and the present research conditions, using this algorithm is expected to expand on prevailing ideas and methods in the field of energy-efficient train operation.

3. Improved Ant Colony Algorithm Modeling

The ant colony optimization algorithm is motivated by simulating the process of ants foraging to solve discrete combination-optimization problems. The advantage of the ant colony optimization algorithm is that it is superior to other algorithms [

32], as it is more effective in terms of computing speed and convenience. MMAS is a type of improved ACO algorithm that aims to solve a discrete optimization problem. It generally contains two important parts: path construction and pheromone updating. Therefore, the problem of energy-efficient train operation using MMAS is divided into two parts as respectively described in the following two sections.

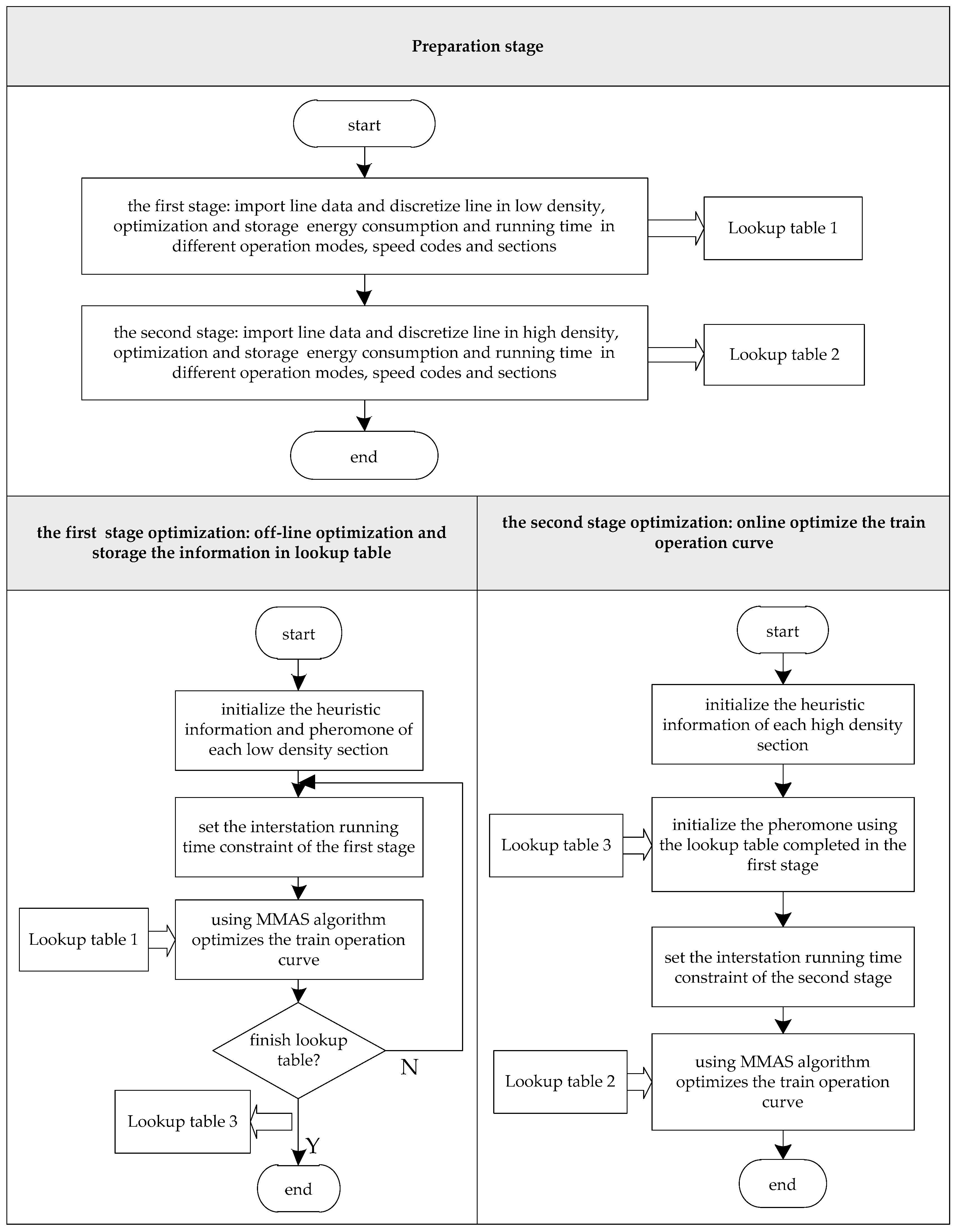

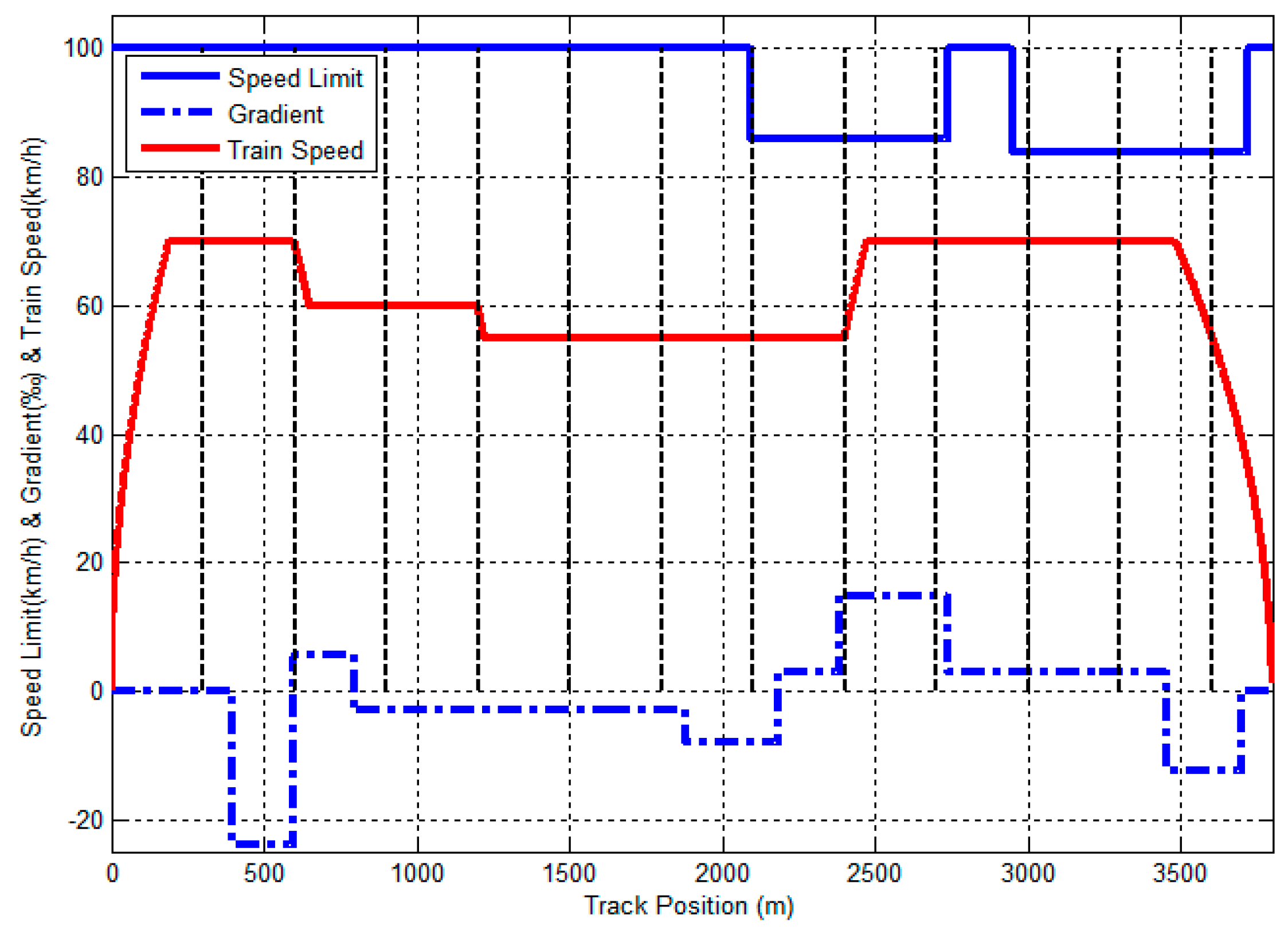

3.1. Partition of the Algorithm

Discretization in the ACO algorithm affects the size of the problem: a reasonable discretization can reduce the solution-space energy-saving train-operation optimization, and accelerate the convergence speed.

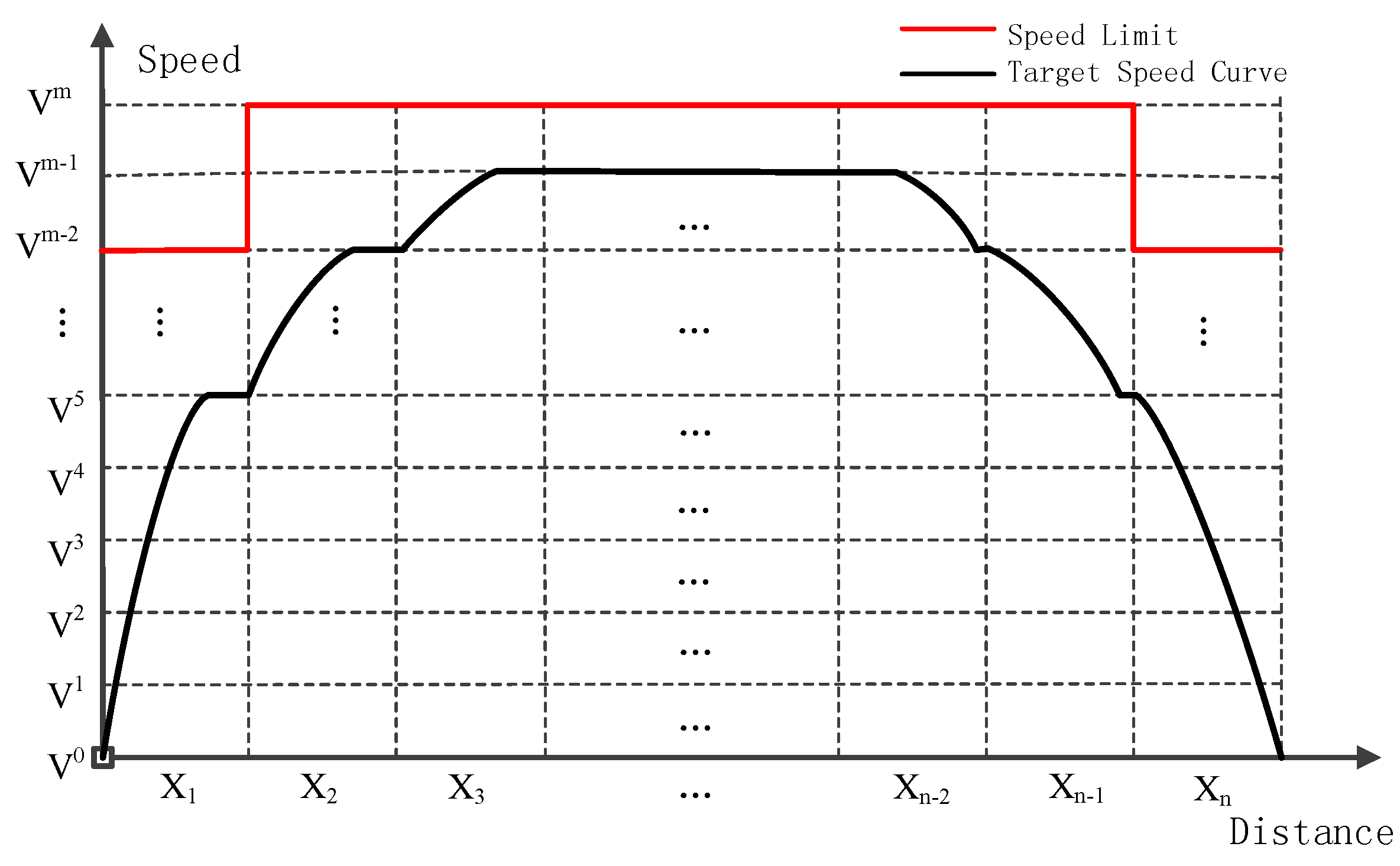

ACO algorithms usually use equal discretization when solving the discrete combination optimization problem.

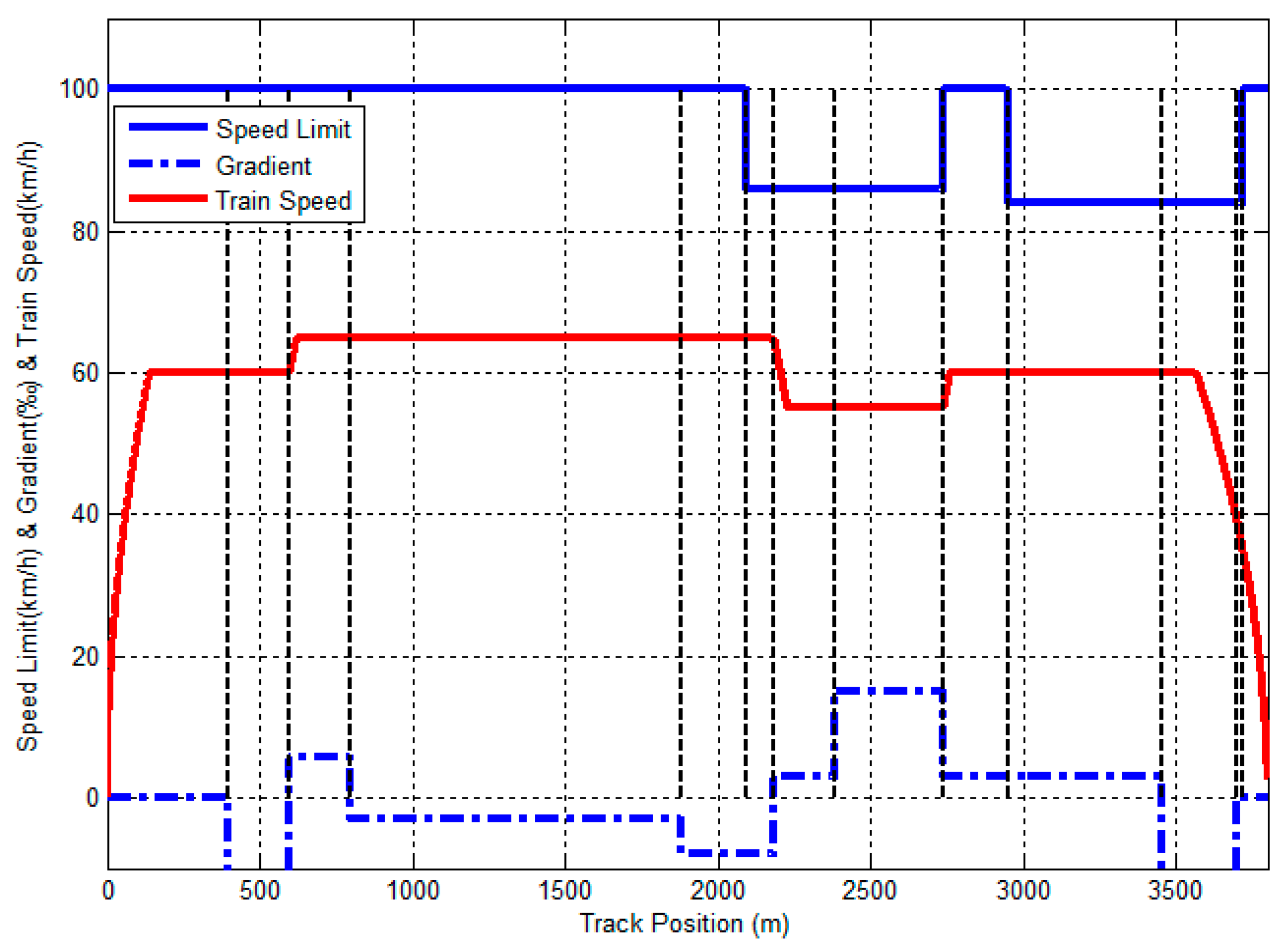

Figure 2 shows the equal discretization: the train can choose the corresponding target speed of every segment. A target speed sequence builds up a target speed curve.

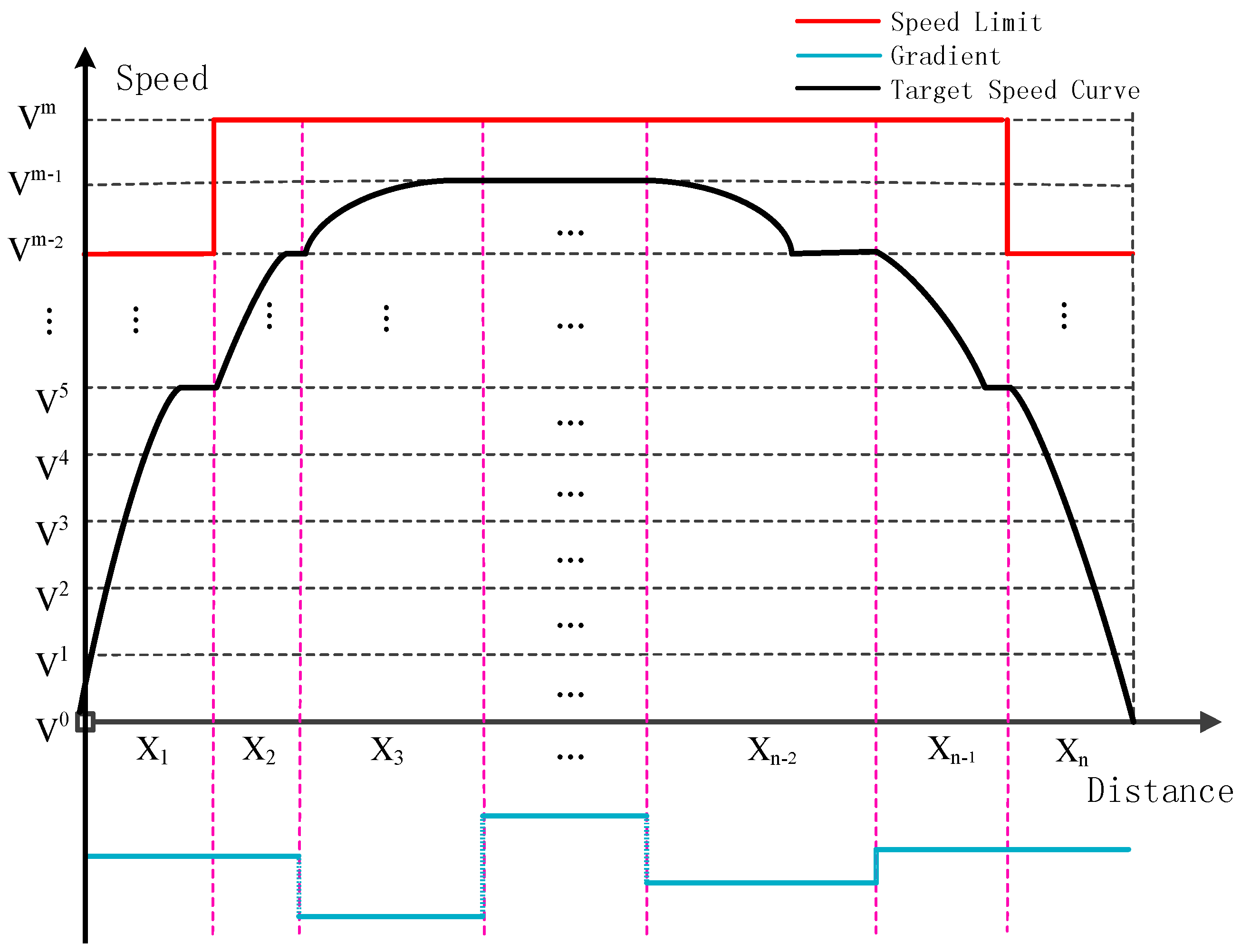

In reality, the line information and traffic operation characteristics must be taken into consideration. Therefore it discretizes the line into

segments based on the variety of static gradient and speed limit. As shown in

Figure 3, the speed limit and gradient in each discretized segment are constant, so that the algorithm can optimize conveniently.

3.2. Pheromone

The pheromone plays a guiding role for the algorithm allowing it to find the optimal speed profile. It reflects the effect of the a priori factors and the certainty factors and so is critical in the search process described herein. In this paper, the pheromone setting studies the driving experience of train drivers. The principle is as follows: taking the real driving experience into account, the train speed tends to accelerate when downhill and tends to decelerate when uphill. This principle affects the probability when searching the next path in solution space, can change the searching direction, accelerate the convergence rate of the algorithm, and improve the performance of the algorithm. Based on the two aspects of the improvement, a target speed curve optimization method based on MMAS is proposed in this paper.

3.3. Path Construction

Path construction uses random proportion rules to choose the next step: the random proportion rule of the MMAS algorithm is basically consistent with the earliest ant system (AS) algorithm, and the specific proportion random rule is defined as follows:

where

is the selection probability of the tracking target speed

when the

th ant is in the

th discrete point to the

th discrete point;

is a constant value to regulate the proportion of pheromone trails and the heuristic information, with

;

is the heuristic information values for the tracking target speed

;

being the pheromone trail values of the tracking target speed

when the

th ant is in the

th discrete point to the

th discrete point;

is the collection of all the feasible tracking target speeds in the

th discrete point;

n is the grade of the ant.

3.4. Pheromone Updating

In the MMAS algorithm, the pheromone updating rule has evolved significantly compared with traditional ACO. The MMAS algorithm focuses on the larger improvements of the pheromone updating, which enhances algorithm performance. The specific pheromone updating rule is defined as follows:

where

being the pheromone trail values of the tracking target speed

when the

th ant is in the

th discrete point to the

th discrete point;

is the released pheromone trail values of the tracking target speed

when the

th ant is in the

th discrete point to the

th discrete point;

is the weighting factor of the iteration-best solutions, with

;

is the weighting factors of the best-so-far solutions;

is the pheromone evaporation rate, with

;

is a constant which can be set to determine whether a pheromone is initialized again;

is the minimum energy consumption in this iteration (in kWh);

is the minimum energy consumption so far (in kWh). The process of line discretization is described as follows:

- Step 1.

Import line data containing the gradients and speed limits, and initialize the related parameters;

- Step 2.

Set the discretization density, and then discretize lines and running target speeds;

- Step 3.

Calculate the equivalent value based on the gradient data;

- Step 4.

Calculate the energy-consumption and running time, including the train starting phase, train running phase and train braking phase;

- Step 5.

Store the data and create the energy consumption and running time lookup table;

- Step 6.

Output the lookup table.

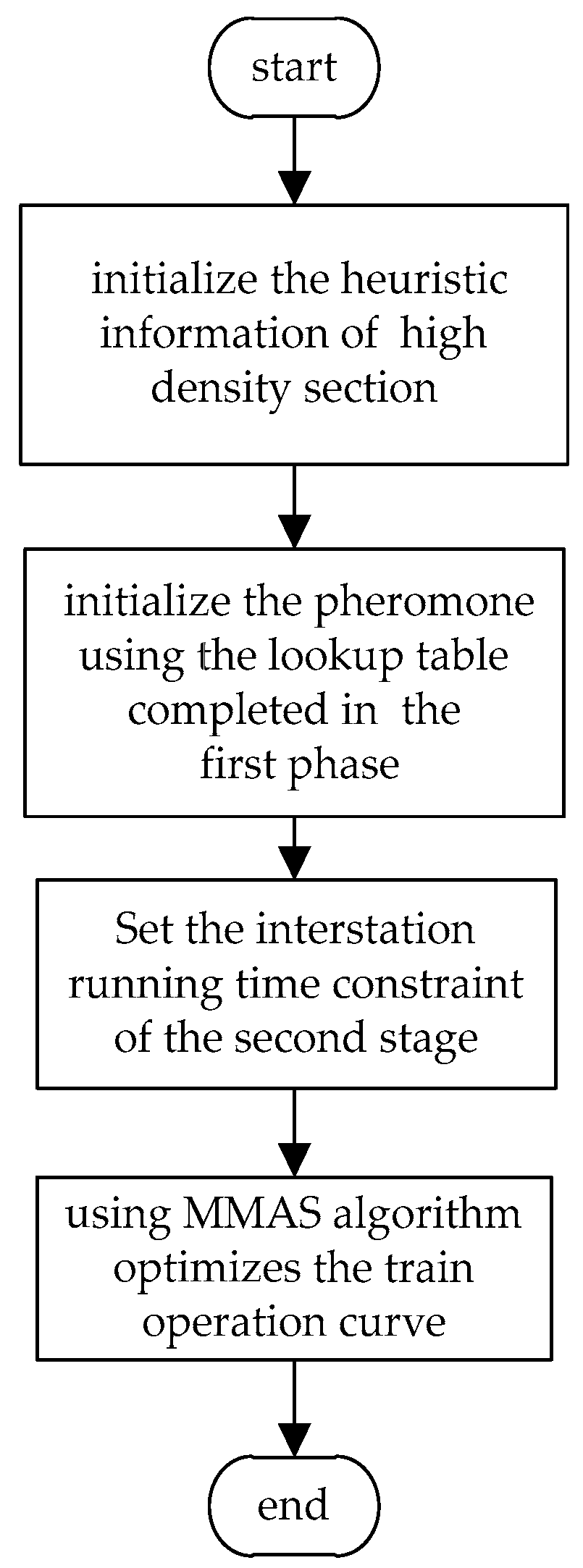

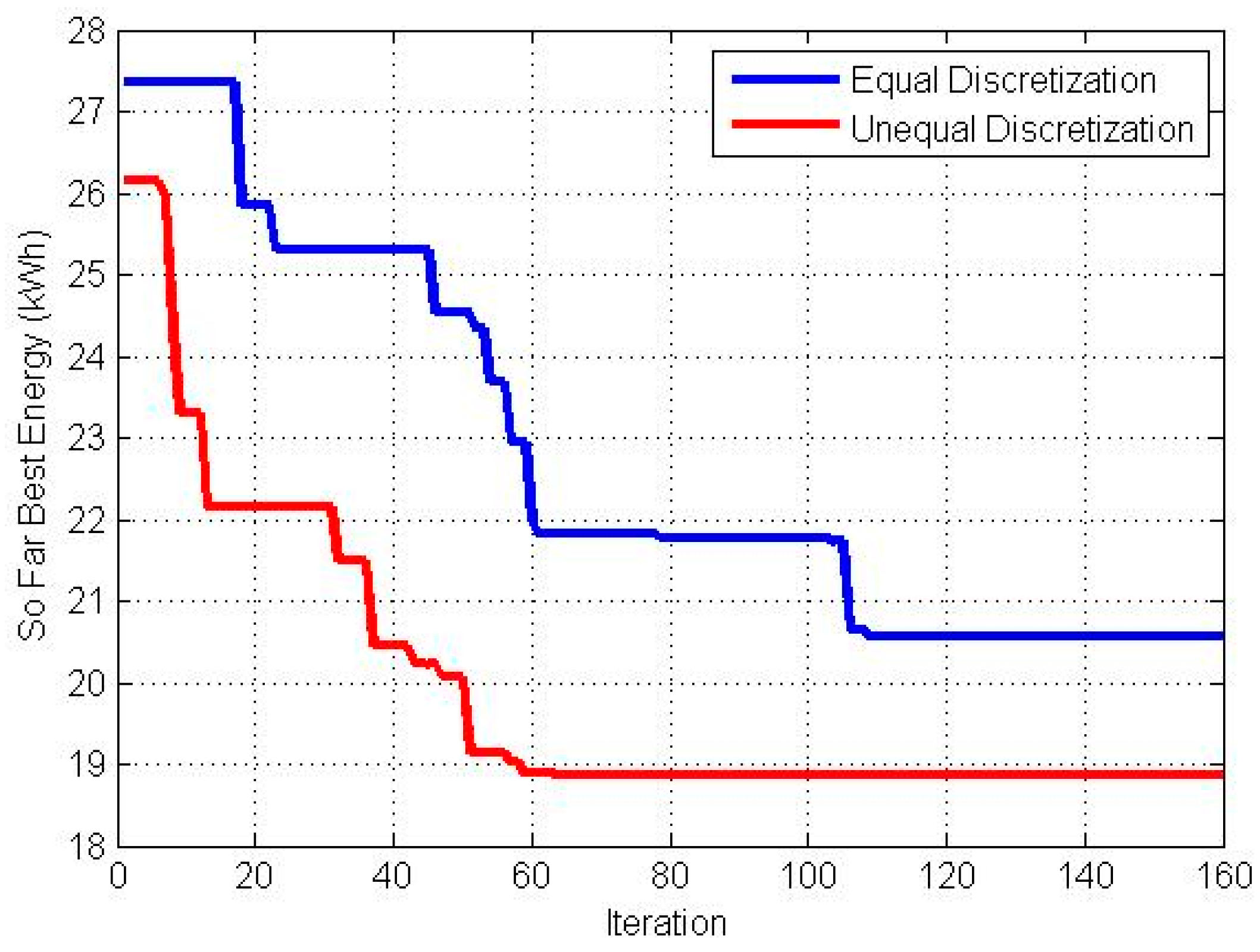

The above provides a concrete model for the discrete optimization and the MMAS algorithm, which lays the foundations for the design of train energy-saving speed curve optimization based on a two-stage optimization algorithm. The first stage, i.e., low density discretization, is fully optimized to search for the best solution; the second-stage, i.e., high density discretization, will refer to the first stage information and quickly search for the optimal solution. The algorithm design is described in the following section.