Design and Optimization of the Slide Guide System of Hydraulic Press Based on Energy Loss Analysis

Abstract

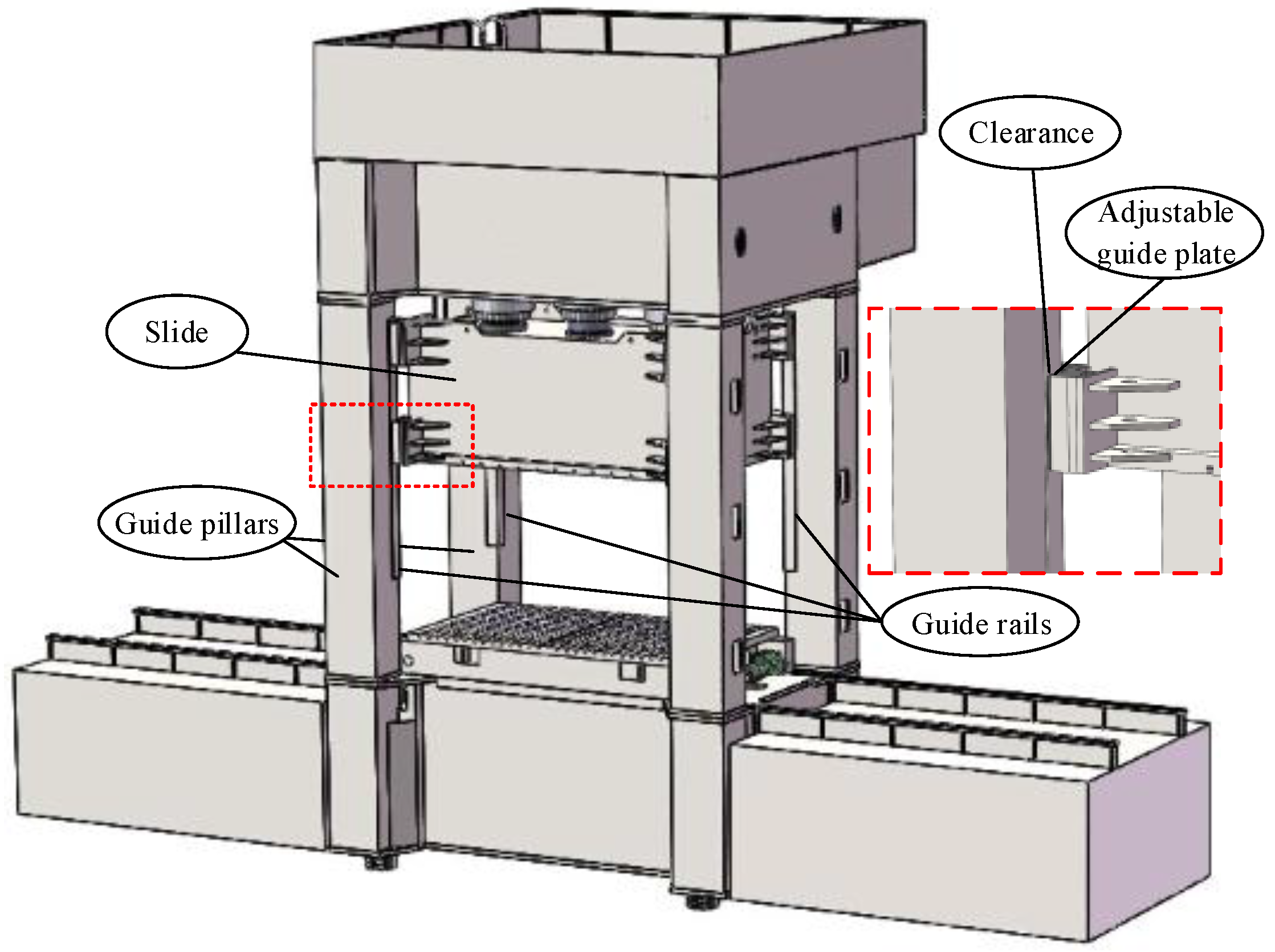

:1. Introduction

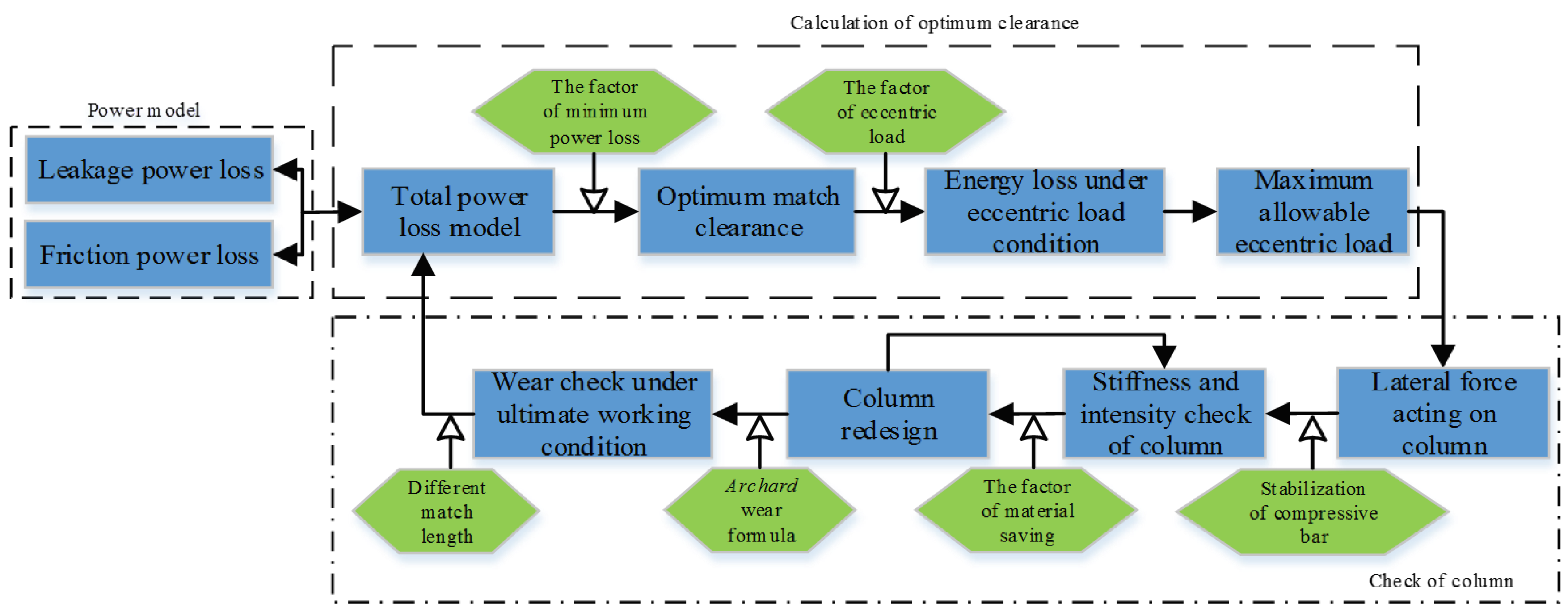

2. Energy Loss Analysis in the Slide Guide System

2.1. Energy Loss Model

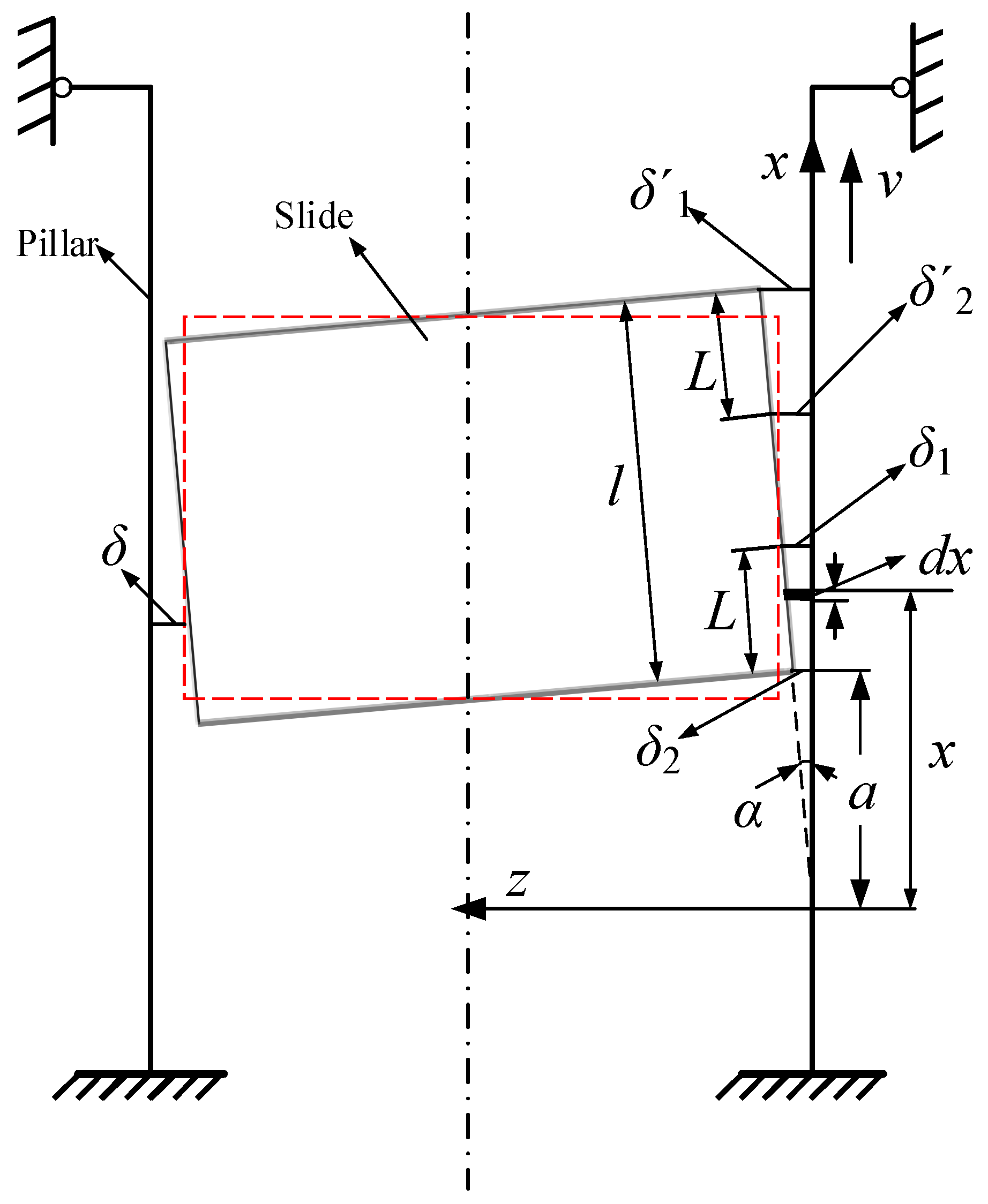

2.2. Energy Loss Considering Eccentric Load

3. Optimization of the Slide Guide System

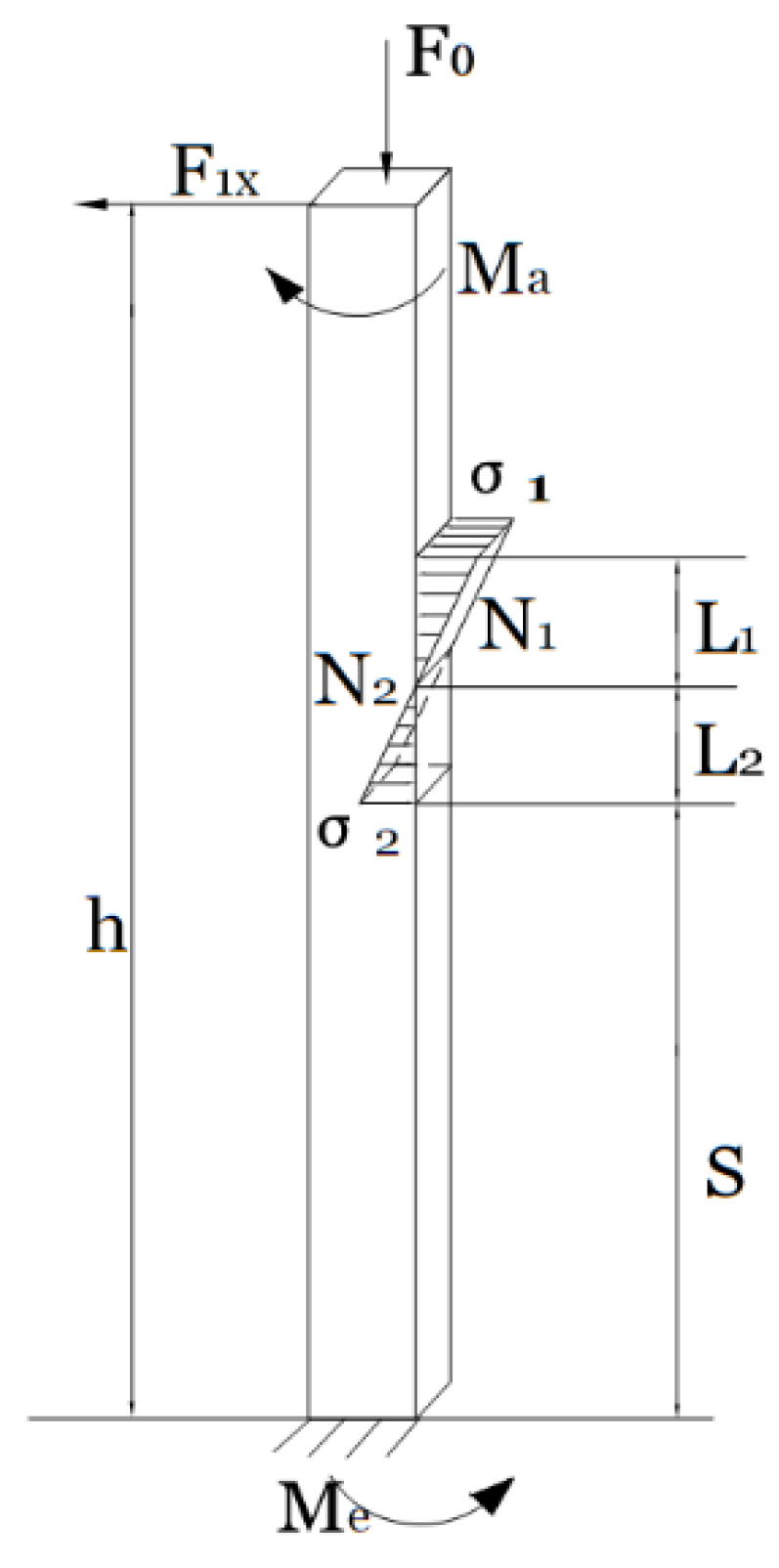

3.1. Lateral Force Analysis

3.2. Stiffness Check of Guide Pillars

3.3. Wear Check in the Slide Guide System

4. Case Study

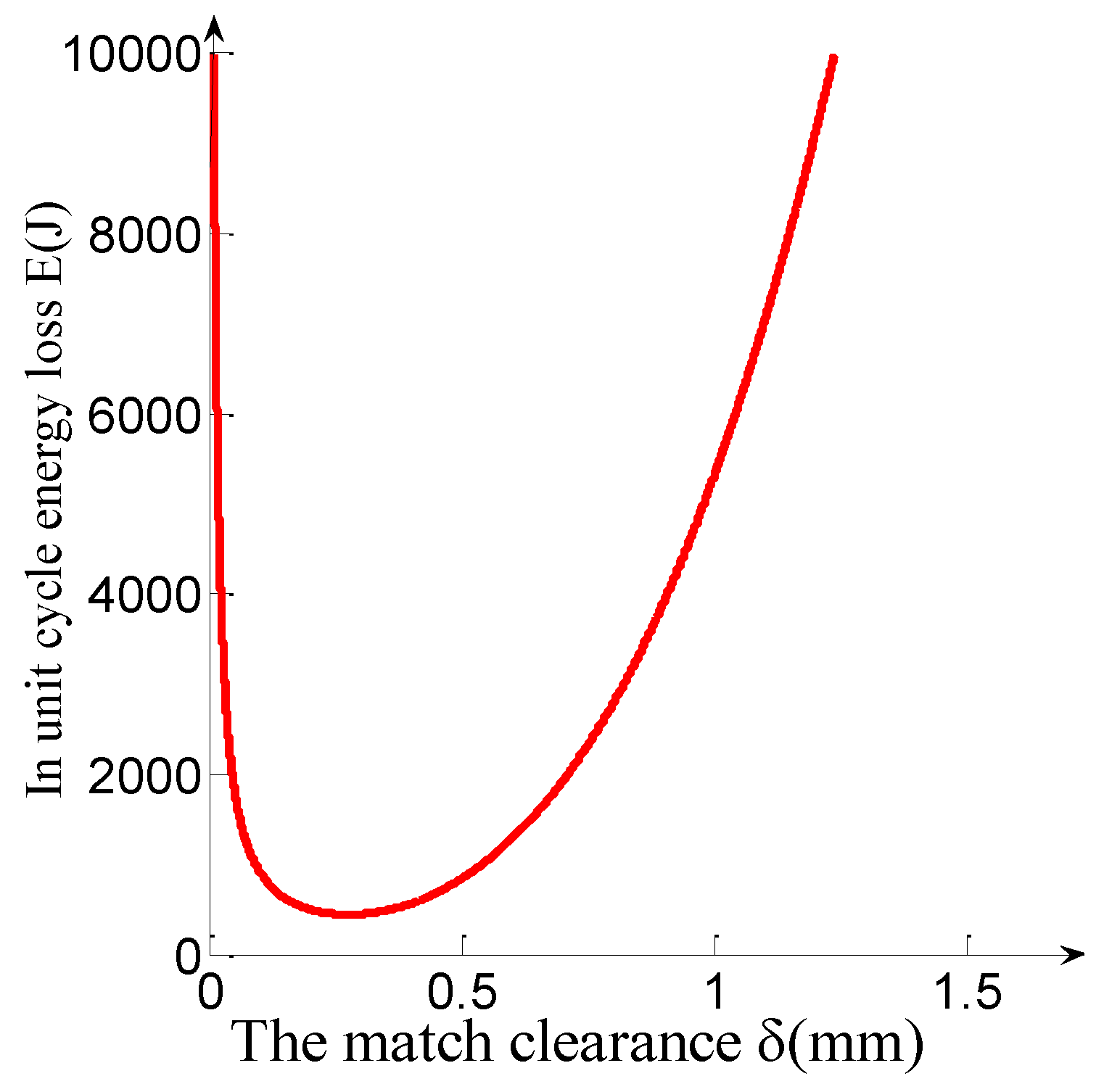

4.1. The Clearances Optimization Based on Energy Loss

4.2. The Pillars Optimization in Slide Guide System

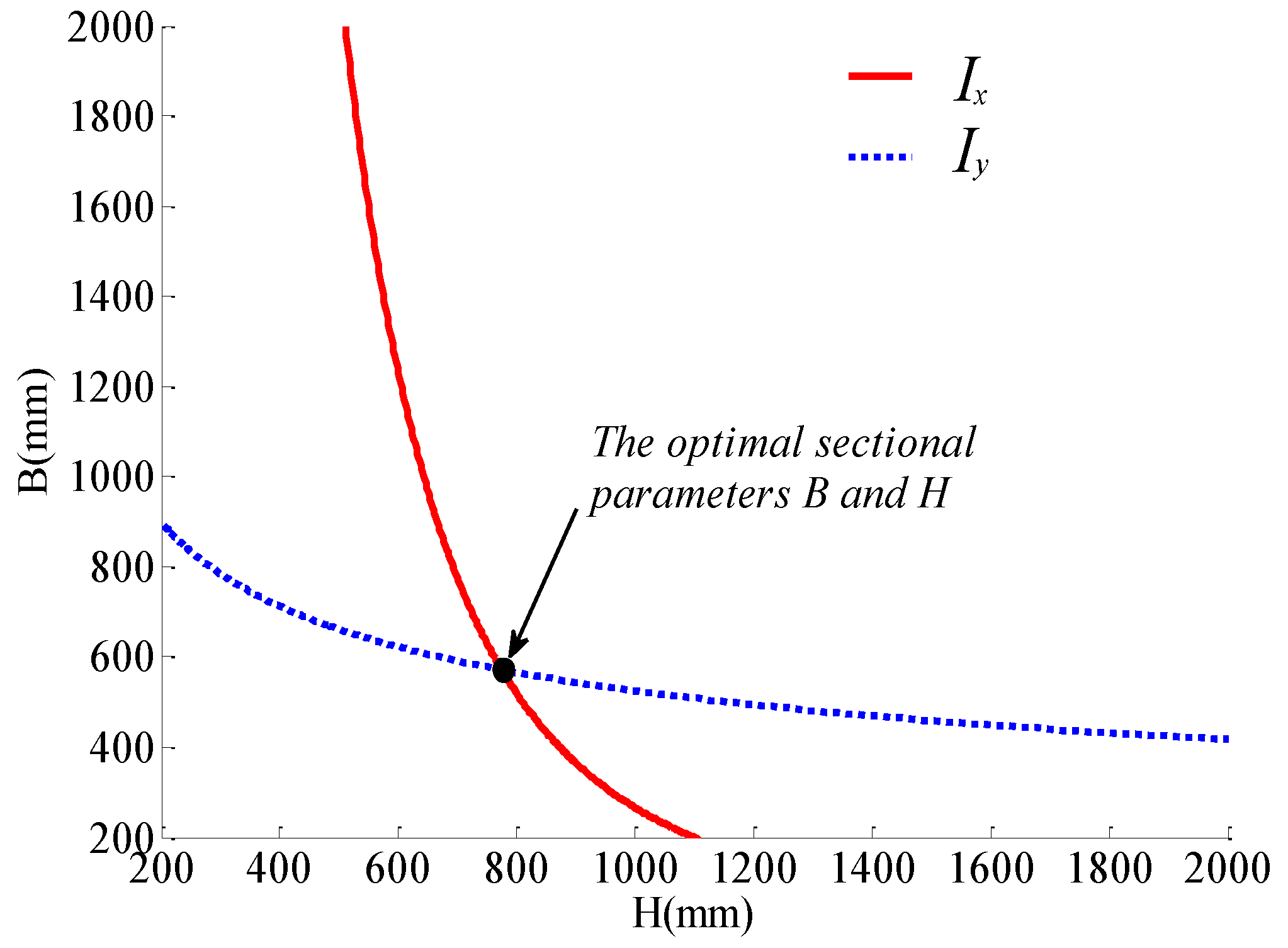

4.2.1. Optimization Based on Stiffness Check

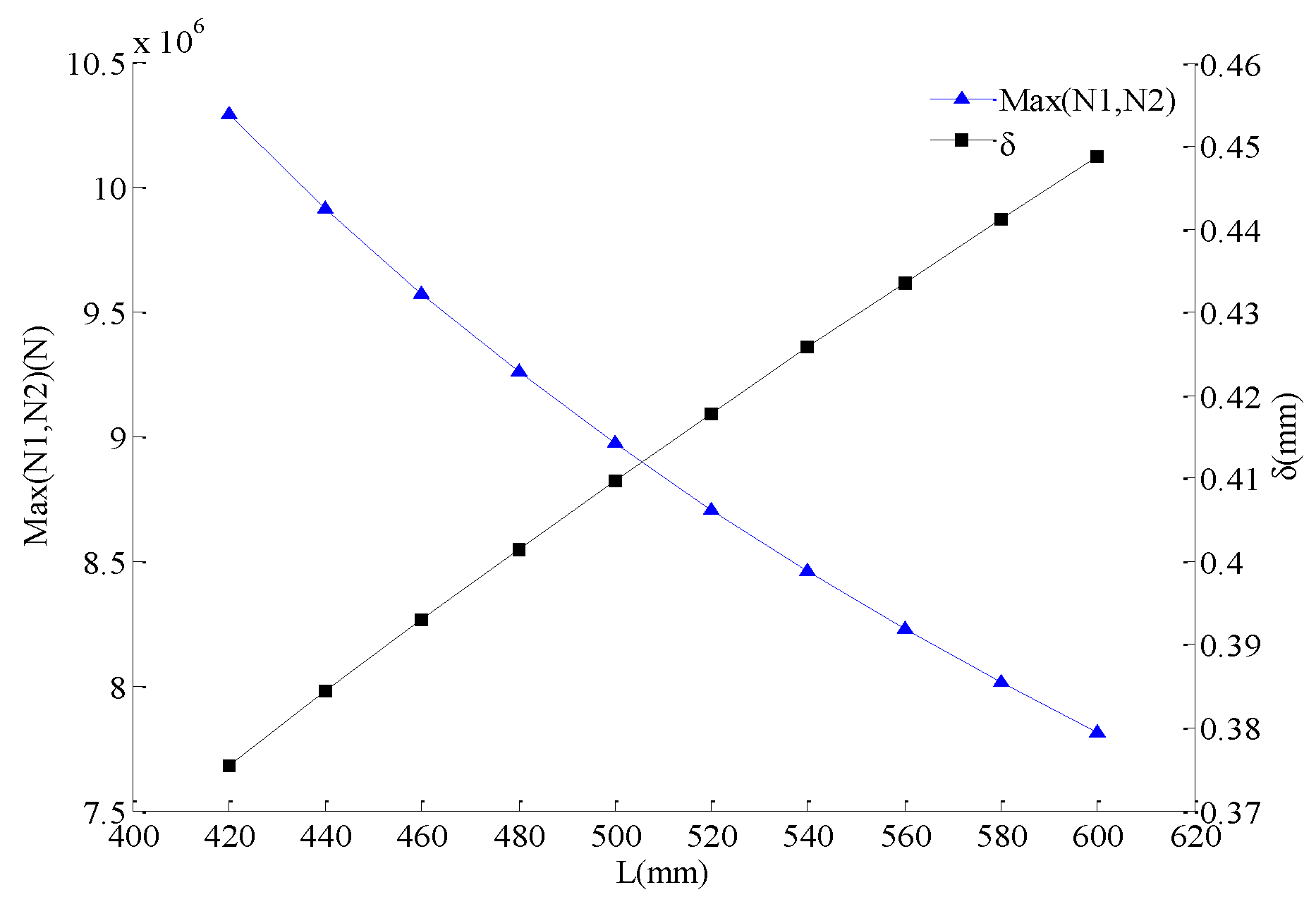

4.2.2. Optimization Based on Wear Check

5. Summary and Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| δ | clearances in slide guide system between slide and pillars |

| Δp | differential pressure between the two ends of clearances |

| L | length of adjustable guide plate on slide |

| b | width of adjustable guide plate on slide |

| μ | dynamic viscosity of hydraulic oil |

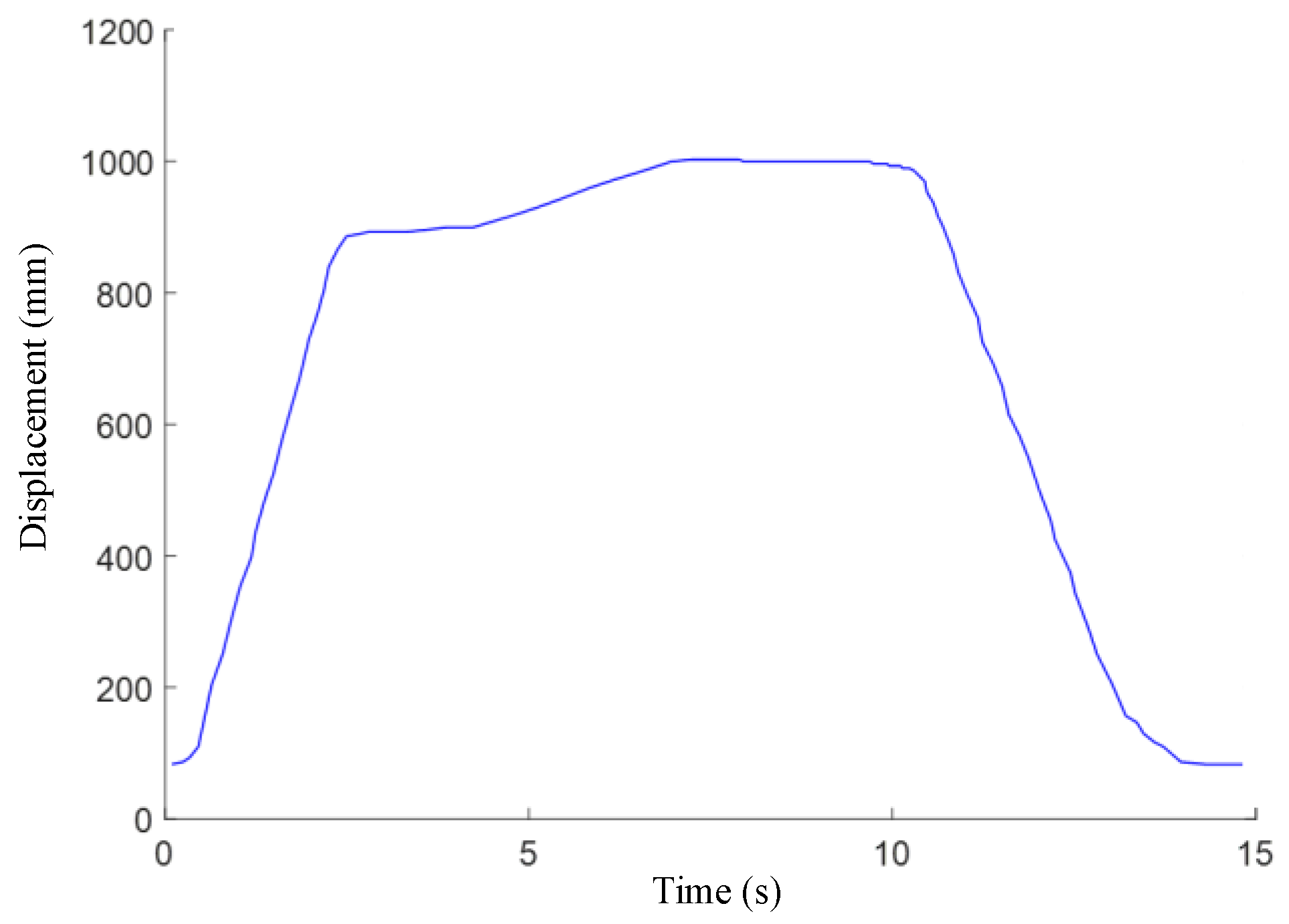

| V,v(t) | velocity of slide |

| q | leakage through the parallel clearances |

| τ | liquid shear stress |

| Ff | friction force caused by shearing oil in parallel clearances |

| PT | total power loss in parallel clearances |

| Pq | power loss caused by leakage in parallel clearances |

| Pf | power loss caused by friction force in parallel clearances |

| T | working cycle |

| E | energy loss in a working cycle T in parallel clearances |

| δ1,δ′1 | sizes of the upper end of the wedge clearances |

| p1,p′1 | pressure of inlet in wedge clearances |

| δ2,δ′2 | sizes of the lower end of the wedge clearances |

| a | intermediate parameter according to the coordinate system in Figure 2 |

| l | height of slide |

| p | pressure distribution in wedge clearances |

| α | tilt angle of slide |

| q′ | leaking caused by the up and down wedge clearances |

| F′f | friction force caused by shearing oil in wedge clearances |

| E′ | unit energy loss in a working cycle T in wedge clearances |

| [Fp] | maximum allowable lateral force under the condition of minimum thickness of oil-film δ1 |

| Fworking | operational load |

| Fe | eccentric moment |

| F1 | side thrust |

| F1x | maximum eccentric load in the X direction |

| h | distance from lower surface of upper crossbeam to top surface of bottom crossbeam |

| Zh | distance from force bearing point on guide bush out of plunger in cylinder to the lower surface of upper crossbeam (Z < 1) |

| Yh | distance from bearing reaction force point on adjustable guide plates of slide to the bottom surface of top crossbeam (Y < 1) |

| F0 | total axial force |

| σ1,σ2 | distribution stress |

| L1,L2 | length of the distribution stress |

| N1,N2 | resultant force of the distribution stress |

| f | friction coefficient |

| [P] | allowable pressure |

| Kc | coefficient of wear |

| P | contact pressure |

| t | wear time |

| H | contact surface hardness |

| h′ | average wear depth |

| d | distance between two pillars |

| B, H | parameters of the section of pillar |

References

- Energy Statistics of National Bureau of Statistics of China. China Enrgy Statistical Yearbook 2010; China Statistics Press: Beijing, China, 2010. [Google Scholar]

- Wagener, H.-W. New developments in sheet metal forming: Sheet materials, tools and machinery. J. Mater. Process. Technol. 1997, 72, 342–357. [Google Scholar] [CrossRef]

- Lee, M.; Kim, C.; Pavlina, E.; Barlat, F. Advances in sheet forming—Materials modeling, numerical simulation, and press technologies. J. Manuf. Sci. Eng. 2011, 133. [Google Scholar] [CrossRef]

- Statistical Review of World Energy. Available online: http://www.bp.com/en/global/corporate/about-bp/energy-economics/statistical-review-of-world-energy.html (accessed on 2 June 2015).

- Duflou, J.R.; Sutherland, J.W.; Dornfeld, D.; Herrmann, C.; Jeswiet, J.; Kara, S.; Hauschild, M.; Kellens, K. Towards energy and resource efficient manufacturing: A processes and systems approach. CIRP Ann. - Manuf. Technol. 2012, 61, 587–609. [Google Scholar] [CrossRef]

- Zhao, K.; Liu, Z.; Yu, S.; Li, X.; Huang, H.; Li, B. Analytical energy dissipation in large and medium-sized hydraulic press. J. Clean. Prod. 2015, 103, 908–915. [Google Scholar] [CrossRef]

- Hu, Z.; Dean, T. A study of surface topography, friction and lubricants in metalforming. Int. J. Mach. Tools Manuf. 2000, 40, 1637–1649. [Google Scholar] [CrossRef]

- Hasegawa, K.; Inada, A.; Kawachi, N.; Endou, J.-I. Effect of parallel control of press with eccentric load. Steel Res. Int. 2010, 81, 690–693. [Google Scholar]

- Osakada, K.; Mori, K.; Altan, T.; Groche, P. Mechanical servo press technology for metal forming. CIRP Ann. - Manuf. Technol. 2011, 60, 651–672. [Google Scholar] [CrossRef]

- Wagener, H.; Schlott, C. Influence of die guidance systems on the angular deflection of press slide and die under eccentric loading. J. Mech. Work. Technol. 1989, 20, 463–475. [Google Scholar] [CrossRef]

- Zhao, C.C.; Yang, S.F.; Liu, P.P.; Haibin, D. Principle and theoretical analysis of the balancing system for large die forging hydraulic press. J. Mech. Eng. 2012, 10. [Google Scholar] [CrossRef]

- Jimma, T.; Sekine, F.; Tozawa, Y. Effect of rigidity of die and press on blanking accuracy of electronic machine parts. CIRP Ann. - Manuf. Technol. 1992, 41, 319–322. [Google Scholar] [CrossRef]

- Chval, Z.; Cechura, M. Optimization of power transmission on mechanical forging presses. Proced. Eng. 2014, 69, 890–896. [Google Scholar] [CrossRef]

- Socrate, S.; Boyce, M.C. A finite element based die design algorithm for sheet-metal forming on reconfigurable tools. J. Eng. Mater. Technol. 2001, 123, 489–495. [Google Scholar] [CrossRef]

- Zhao, H.; Chen, X.-Y.; Dong, Y.-D.; Zhang, J.; Yu, L.-H. Research on lightweight design of press frame structure based on parametric fea. J. Eng. Graph. 2010, 31, 20–25. [Google Scholar]

- Arentoft, M.; Wanheim, T. A new approach to determine press stiffness. CIRP Ann. - Manuf. Technol. 2005, 54, 265–268. [Google Scholar] [CrossRef]

- Wang, D. The study of hydrostatic slide and its use in the design of machine tool. J. Hydraul. Pneum. Seals 2003, 5, 26–28. [Google Scholar]

- Yang, J.; Meng, X. Analysis and application on the optimum restrictive parameters of open hydrostatic sliding way. Lubr. Eng. 2004, 4, 85–86. [Google Scholar]

- Erhuang, S. Hydraulic Liquid Fluid Mechanics; National Defence Industry Press: Beijing, China, 1979. [Google Scholar]

- Massey, A.W.B. Mechanics of Fluids; Springer: New York, NY, USA, 1989. [Google Scholar]

- Xinlu, Y. Hydraulic Press Design and Application; Mechanical Industry Press: Beijing, China, 2006. [Google Scholar]

- Gere, J.M.; Timoshenko, S.P. Mechanics of Materials, 2nd ed.; Van Nostrand Reinhold: New York, NY, USA, 1984. [Google Scholar]

- Cheng, H.; Liu, Z.; Xie, P.; Zhan, Y.; Yuan, H. Calculation method of minimum length retained in cylinder for swash-plate plunger pump based on energy loss. Trans. Chin. Soc. Agric. Mach. 2014, 45, 333–339. [Google Scholar]

- Archard, J. Elastohydrodynamic lubrication of real surfaces. Tribology 1973, 6, 8–14. [Google Scholar] [CrossRef]

- Archard, J. Friction between metal surfaces. Wear 1986, 113, 3–16. [Google Scholar] [CrossRef]

| Parameters | Value | Unit |

|---|---|---|

| b | 185 | mm |

| L | 560 | mm |

| v | 450 | mm |

| Δp | 0.3 | MPa |

| l | 2000 | mm |

| p1 | 0.3 | MPa |

| F | 20,000 | kN |

| h | 5460 | mm |

| d | 5460 | mm |

| H | 820 | mm |

| B | 670 | mm |

| Parameters | Ranges | Values | Unit |

|---|---|---|---|

| Elasticity Modulus E | 200~210 | 200 | GPa |

| Poisson Ratio μ | 0.23~0.33 | 0.27 | ‒ |

| Yield Strength σs | ≥355 | ‒ | MPa |

| The Allowable Stress [σs] | ‒ | 150 | MPa |

| Parameters | Value | Unit | |

|---|---|---|---|

| Nominal Press | 20,000 | kN | |

| The Size of Workbench and Slide | Width in Left-Right Direction | 4600 | mm |

| Width in Anterior-Posterior Direction | 2500 | mm | |

| Height of Slide | 2000 | mm | |

| The Working Velocity of Slide | Quickly Falls | ≥450 | mm/s |

| Slow Press | 25–50 | mm/s | |

| Quickly Returns | ≥400 | mm/s | |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, M.; Huang, H.; Liu, Z.; Li, X.; Sutherland, J.W. Design and Optimization of the Slide Guide System of Hydraulic Press Based on Energy Loss Analysis. Energies 2016, 9, 434. https://doi.org/10.3390/en9060434

Gao M, Huang H, Liu Z, Li X, Sutherland JW. Design and Optimization of the Slide Guide System of Hydraulic Press Based on Energy Loss Analysis. Energies. 2016; 9(6):434. https://doi.org/10.3390/en9060434

Chicago/Turabian StyleGao, Mengdi, Haihong Huang, Zhifeng Liu, Xinyu Li, and John W. Sutherland. 2016. "Design and Optimization of the Slide Guide System of Hydraulic Press Based on Energy Loss Analysis" Energies 9, no. 6: 434. https://doi.org/10.3390/en9060434