Experimental Study of Natural Convection Cooling of Vertical Cylinders with Inclined Plate Fins

Abstract

:1. Introduction

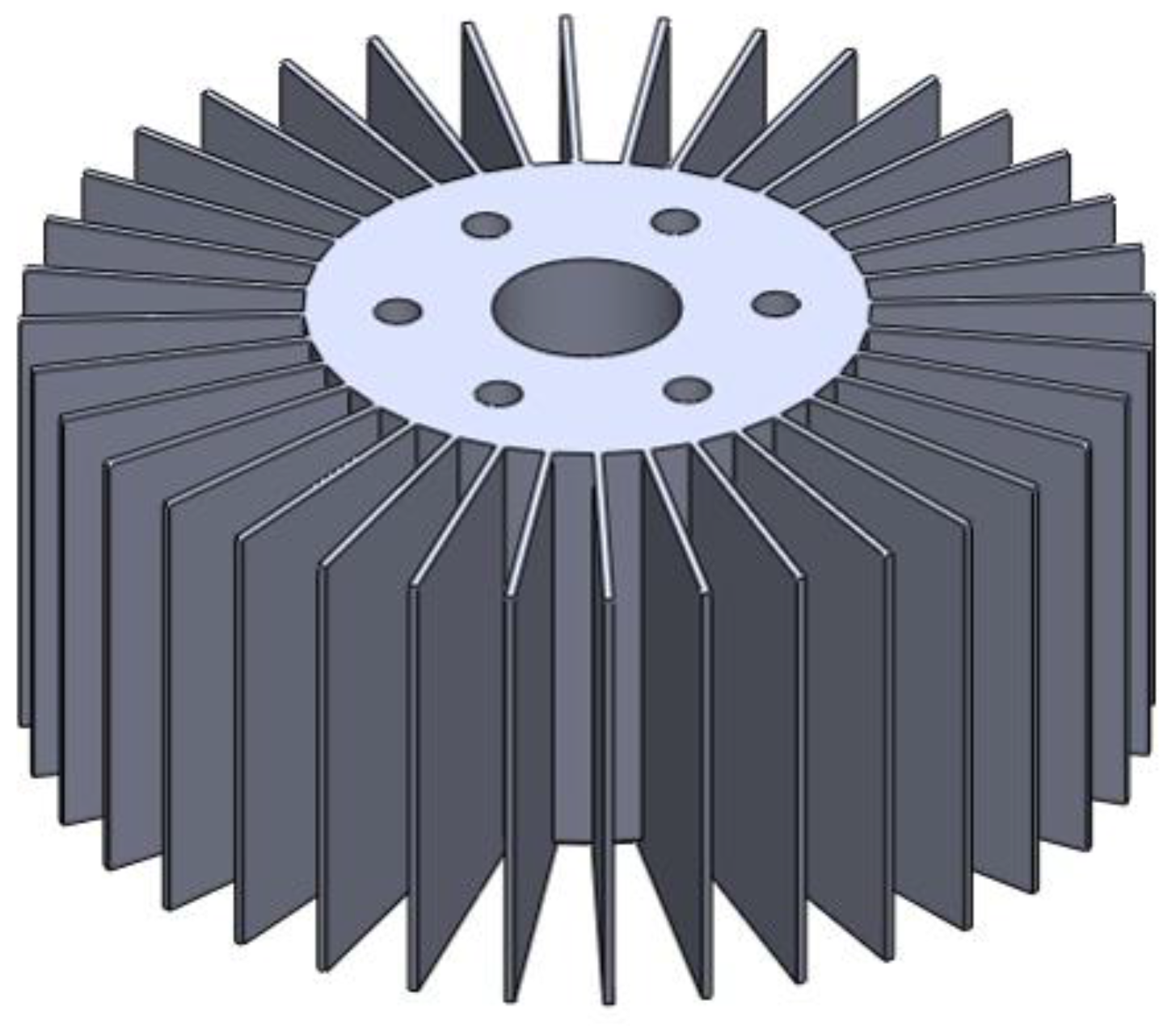

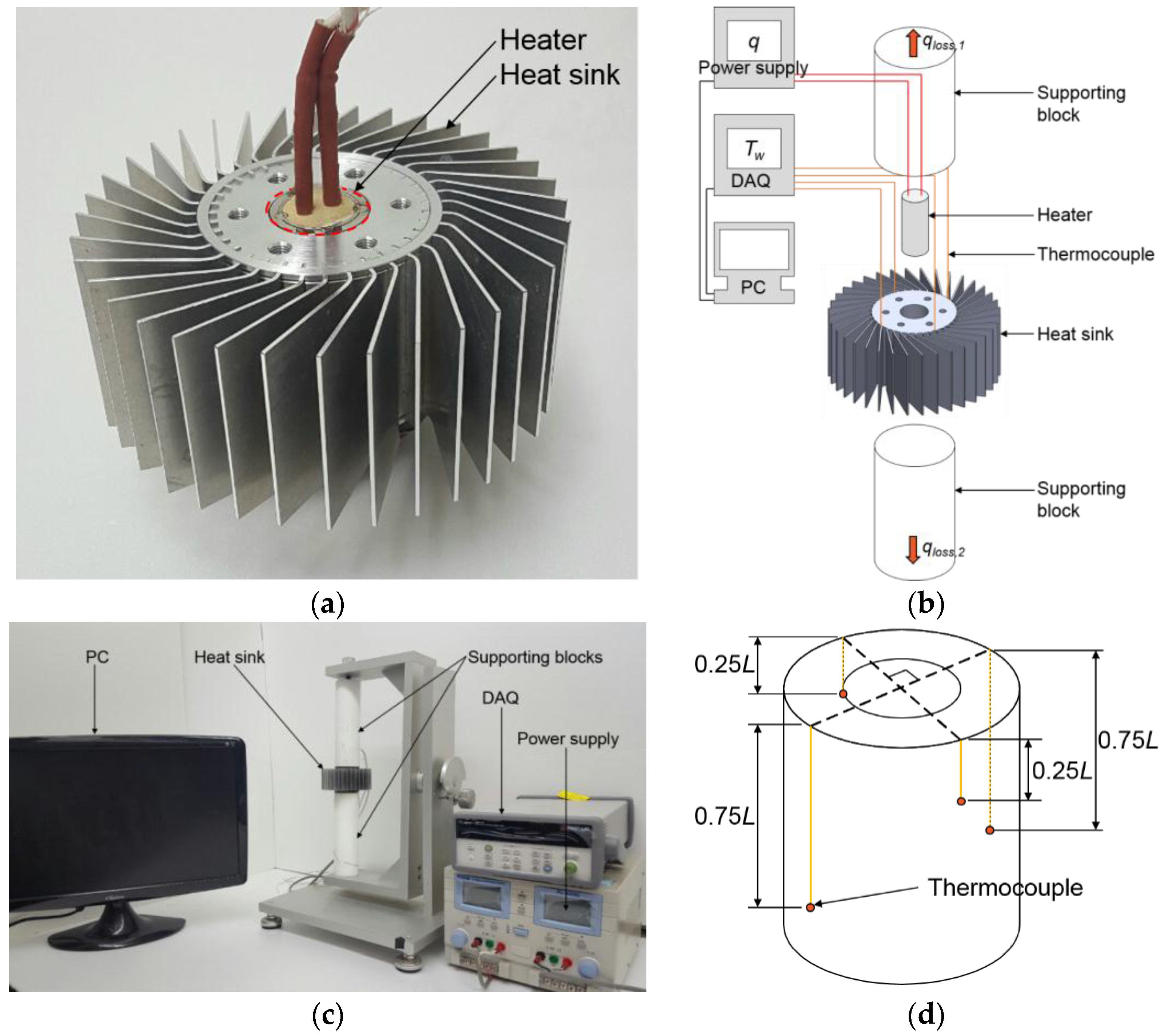

2. Experimental Investigation

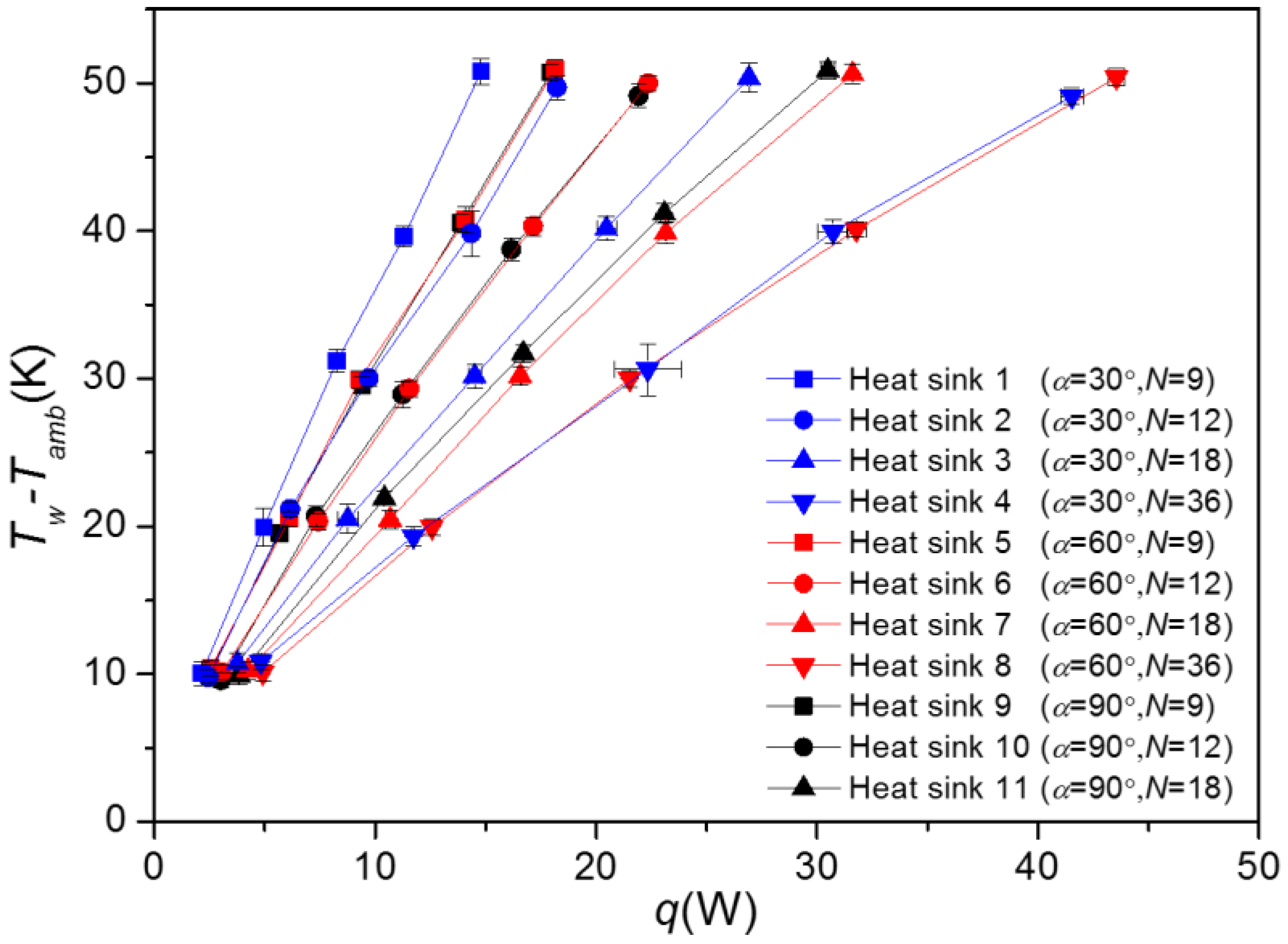

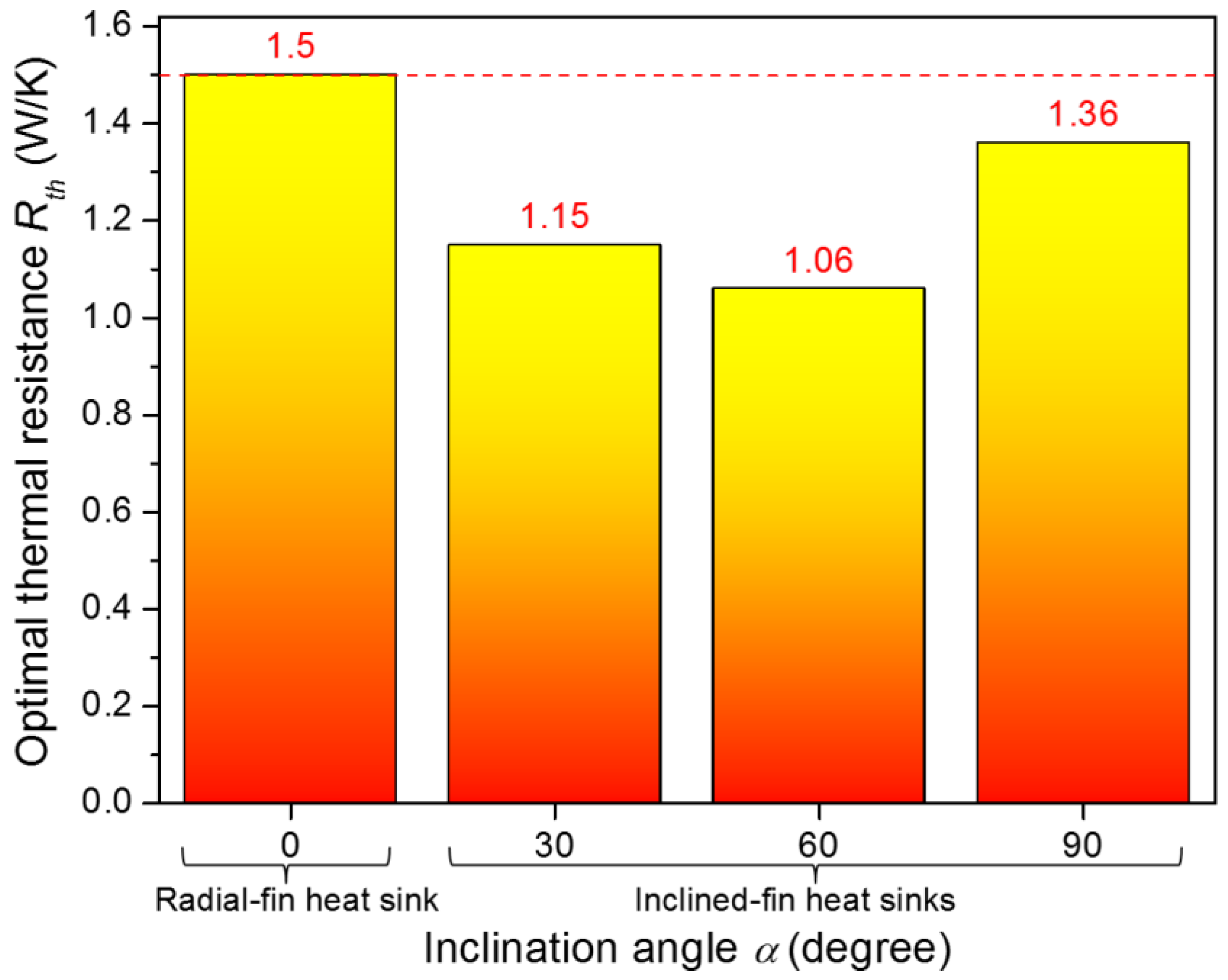

3. Results and Discussion

4. Conclusions

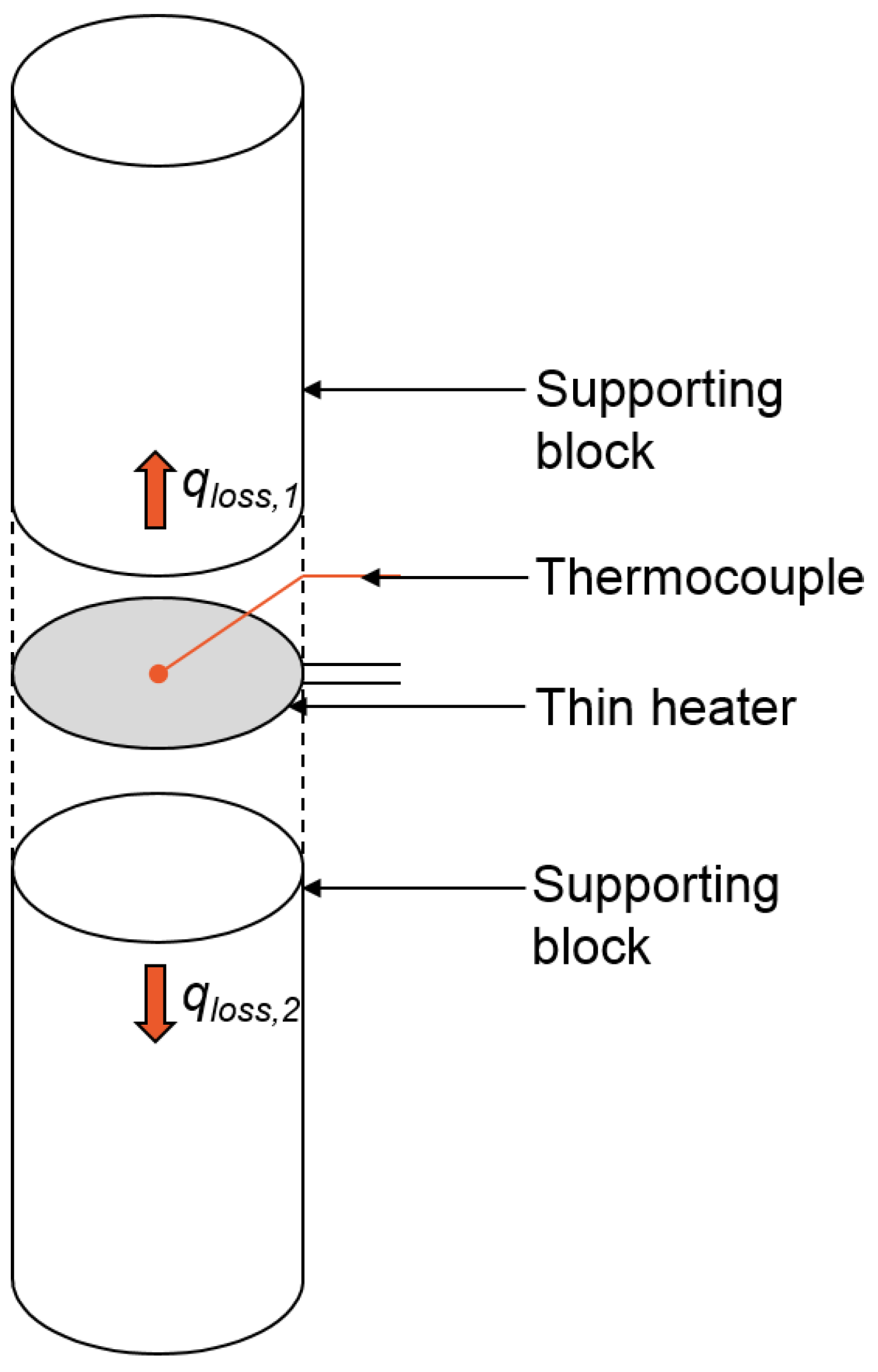

Appendix A. Measurement of the Heat Loss through the Supporting Blocks

Appendix B. Comparison of Nusselt Numbers for the Radial Heat Sinks Calculated Using the Proposed Correlation and Those from Experimental Data

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Oktay, S.; Hannemann, R.J.; Bar-Cohen, A. High Heat from a Small Package. Mech. Eng. 1986, 108, 36–42. [Google Scholar]

- Bar-Cohen, A. Thermal Management of Electric Components with Dielectric Liquids. JSME Int. J. Fluids Therm. Eng. 1993, 36, 1–25. [Google Scholar] [CrossRef]

- Pop, E. Energy dissipation and transport in nanoscale devices. Nano Res. 2010, 3, 147–169. [Google Scholar] [CrossRef]

- Park, J.; Shin, M.; Lee, C.C. Measurement of temperature profiles on visible light-emitting diodes by use of a nematic liquid crystal and an infrared laser. Opt. Lett. 2004, 29, 2656–2658. [Google Scholar] [CrossRef] [PubMed]

- Luo, X.; Liu, S. A microjet array cooling system for thermal management of high-brightness LEDs. IEEE Trans. Adv. Packag. 2007, 30, 475–484. [Google Scholar] [CrossRef]

- Incropera, F.P. Convection Heat Transfer in Electronic Equipment Cooling. J. Heat Transf. 1988, 110, 1097–1111. [Google Scholar] [CrossRef]

- Nakayama, W. Thermal Management of Electronic Equipment: A Review of Technology and Research Topics. Appl. Mech. Rev. 1986, 39, 1847–1868. [Google Scholar] [CrossRef]

- Welling, J.R.; Wooldridge, C.B. Free Convection Heat Transfer Coefficients from Rectangular Vertical Fins. J. Heat Transf. 1965, 87, 439–444. [Google Scholar] [CrossRef]

- Martynenko, O.G.; Khramtsov, P.P. Free-Convective Heat Transfer; Springer: New York, NY, USA, 2005. [Google Scholar]

- Raithby, G.D.; Hollands, K.G.T. Natural Convection. In Handbook of Heat Transfer, 3rd ed.; Rohsenow, W.M., Hartnett, J.P., Cho, Y.I., Eds.; McGraw-Hill: New York, NY, USA, 1998. [Google Scholar]

- Sparrow, E.M.; Bahrami, P.A. Experiments on Natural Convection Heat Transfer on the Fins of a Finned Horizontal Tube. Int. J. Heat Mass Transf. 1980, 23, 1555–1560. [Google Scholar] [CrossRef]

- Chen, H.-T.; Chou, J.-C. Investigation of Natural-Convection Heat Transfer Coefficient on a Vertical Square Fin of Finned-Tube Heat Exchangers. Int. J. Heat Mass Transf. 2006, 49, 3034–3044. [Google Scholar] [CrossRef]

- Yildiz, Ş.; Yüncü, H. An Experimental Investigation on Performance of Annular Fins on a Horizontal Cylinder in Free Convection Heat Transfer. Heat Mass Transf. 2004, 40, 239–251. [Google Scholar] [CrossRef]

- Hahne, E.; Zhu, D. Natural Convection Heat Transfer on Finned Tubes in Air. Int. J. Heat Mass Transf. 1994, 37, 59–63. [Google Scholar] [CrossRef]

- An, B.H.; Kim, H.J.; Kim, D.-K. Nusselt Number Correlation for Natural Convection from Vertical Cylinders with Vertically Oriented Plate Fins. Exp. Therm. Fluid Sci. 2012, 41, 59–66. [Google Scholar] [CrossRef]

- Takeishi, K.; Oda, Y.; Miyake, Y.; Motoda, Y. Convective Heat Transfer and Pressure Loss in Rectangular Ducts With Inclined Pin-Fin on a Wavy Endwall. J. Eng. Gas Turbines Power 2013, 135, 061902. [Google Scholar] [CrossRef]

- Hagote, R.B.; Dahake, S.K. Study of Natural Convection Heat Transfer on Horizontal, Inclined and Vertical Heated Plate by V-Fin Array. Int. J. Sci. Eng. Res. 2014, 5, 1366–1374. [Google Scholar]

- Karagiozis, A.; Raithby, G.D.; Hollands, K.G.T. Natural Convection Heat Transfer from Arrays of Isothermal Triangular Fins in Air. J. Heat Transf. 1994, 116, 105–111. [Google Scholar] [CrossRef]

| Number | N | α (°) | H (mm) | D (mm) | L (mm) | T (mm) |

|---|---|---|---|---|---|---|

| Heat sink 1 | 9 | 30 | 30 | 60 | 50 | 1.0 |

| Heat sink 2 | 12 | |||||

| Heat sink 3 | 18 | |||||

| Heat sink 4 | 36 | |||||

| Heat sink 5 | 9 | 60 | ||||

| Heat sink 6 | 12 | |||||

| Heat sink 7 | 18 | |||||

| Heat sink 8 | 36 | |||||

| Heat sink 9 | 9 | 90 | ||||

| Heat sink 10 | 12 | |||||

| Heat sink 11 | 18 |

| Number | α (°) | N | q (W) | Tw − Tamb (K) | Rth (K/W) | NuDh |

|---|---|---|---|---|---|---|

| 1 | 30 | 9 | 2.15 ± 0.06 | 10.1 ± 0.8 | 4.69 ± 0.4 | 9.13 ± 0.78 |

| 4.94 ± 0.11 | 19.9 ± 1.3 | 4.04 ± 0.27 | 10.6 ± 0.71 | |||

| 8.26 ± 0.12 | 31.2 ± 0.8 | 3.78 ± 0.11 | 11.32 ± 0.33 | |||

| 11.29 ± 0.05 | 39.6 ± 0.7 | 3.51 ± 0.07 | 12.19 ± 0.23 | |||

| 14.79 ± 0.07 | 50.8 ± 0.9 | 3.44 ± 0.06 | 12.45 ± 0.23 | |||

| 2 | 30 | 12 | 2.46 ± 0.01 | 9.8 ± 0.5 | 3.98 ± 0.21 | 6.77 ± 0.36 |

| 6.16 ± 0.01 | 21.2 ± 0.5 | 3.44 ± 0.09 | 7.86 ± 0.2 | |||

| 9.7 ± 0.01 | 30 ± 0.5 | 3.1 ± 0.05 | 8.72 ± 0.15 | |||

| 14.34 ± 0.13 | 39.8 ± 1.5 | 2.78 ± 0.11 | 9.72 ± 0.38 | |||

| 18.22 ± 0.19 | 49.7 ± 0.8 | 2.73 ± 0.05 | 9.89 ± 0.19 | |||

| 3 | 30 | 18 | 3.77 ± 0.23 | 10.8 ± 0.6 | 2.85 ± 0.24 | 4.7 ± 0.4 |

| 8.75 ± 0.45 | 20.5 ± 1 | 2.34 ± 0.16 | 5.72 ± 0.4 | |||

| 14.5 ± 0.29 | 30.2 ± 0.8 | 2.08 ± 0.07 | 6.44 ± 0.22 | |||

| 20.47 ± 0.44 | 40.2 ± 0.8 | 1.96 ± 0.06 | 6.83 ± 0.2 | |||

| 26.91 ± 0.07 | 50.4 ± 1 | 1.87 ± 0.04 | 7.16 ± 0.14 | |||

| 4 | 30 | 36 | 4.82 ± 0.09 | 10.8 ± 0.5 | 2.25 ± 0.12 | 1.6 ± 0.08 |

| 11.71 ± 0.07 | 19.4 ± 0.7 | 1.65 ± 0.06 | 2.17 ± 0.08 | |||

| 22.32 ± 1.53 | 30.6 ± 1.8 | 1.37 ± 0.12 | 2.62 ± 0.23 | |||

| 30.71 ± 0.68 | 40 ± 0.8 | 1.3 ± 0.04 | 2.76 ± 0.08 | |||

| 41.52 ± 0.51 | 49.1 ± 0.6 | 1.18 ± 0.02 | 3.04 ± 0.05 | |||

| 5 | 60 | 9 | 2.56 ± 0.01 | 10.4 ± 0.5 | 4.07 ± 0.2 | 7.69 ± 0.38 |

| 6.11 ± 0.04 | 20.5 ± 0.5 | 3.36 ± 0.09 | 9.31 ± 0.24 | |||

| 9.3 ± 0.03 | 30 ± 0.6 | 3.22 ± 0.06 | 9.71 ± 0.19 | |||

| 14.09 ± 0.05 | 40.8 ± 0.9 | 2.89 ± 0.06 | 10.81 ± 0.23 | |||

| 18.15 ± 0.03 | 51 ± 0.6 | 2.81 ± 0.03 | 11.13 ± 0.13 | |||

| 6 | 60 | 12 | 3.05 ± 0.02 | 10.1 ± 0.5 | 3.33 ± 0.17 | 5.81 ± 0.3 |

| 7.42 ± 0.02 | 20.3 ± 0.6 | 2.74 ± 0.08 | 7.05 ± 0.19 | |||

| 11.55 ± 0.03 | 29.3 ± 0.6 | 2.54 ± 0.05 | 7.61 ± 0.15 | |||

| 17.14 ± 0.04 | 40.3 ± 0.6 | 2.35 ± 0.04 | 8.22 ± 0.13 | |||

| 22.35 ± 0.02 | 50 ± 0.5 | 2.24 ± 0.02 | 8.64 ± 0.09 | |||

| 7 | 60 | 18 | 4.24 ± 0.02 | 10.2 ± 0.5 | 2.42 ± 0.13 | 3.87 ± 0.21 |

| 10.67 ± 0.21 | 20.5 ± 0.6 | 1.92 ± 0.07 | 4.88 ± 0.17 | |||

| 16.57 ± 0.03 | 30.2 ± 0.6 | 1.82 ± 0.04 | 5.13 ± 0.1 | |||

| 23.15 ± 0.05 | 39.9 ± 0.7 | 1.72 ± 0.03 | 5.43 ± 0.1 | |||

| 31.6 ± 0.04 | 50.6 ± 0.7 | 1.6 ± 0.02 | 5.83 ± 0.08 | |||

| 8 | 60 | 36 | 4.91 ± 0.06 | 10.1 ± 0.5 | 2.06 ± 0.11 | 1.16 ± 0.06 |

| 12.57 ± 0.02 | 19.9 ± 0.5 | 1.59 ± 0.04 | 1.51 ± 0.04 | |||

| 21.51 ± 0.07 | 30 ± 0.6 | 1.39 ± 0.03 | 1.72 ± 0.03 | |||

| 31.78 ± 0.43 | 40.1 ± 0.5 | 1.26 ± 0.02 | 1.9 ± 0.04 | |||

| 43.55 ± 0.34 | 50.4 ± 0.6 | 1.16 ± 0.02 | 2.07 ± 0.03 | |||

| 9 | 90 | 9 | 2.48 ± 0.04 | 10 ± 0.6 | 4.04 ± 0.26 | 4.8 ± 0.31 |

| 5.68 ± 0.02 | 19.5 ± 0.5 | 3.43 ± 0.09 | 5.64 ± 0.15 | |||

| 9.4 ± 0.03 | 29.6 ± 0.6 | 3.15 ± 0.06 | 6.16 ± 0.12 | |||

| 13.88 ± 0.03 | 40.5 ± 0.6 | 2.92 ± 0.04 | 6.63 ± 0.1 | |||

| 17.95 ± 0.02 | 50.7 ± 0.5 | 2.83 ± 0.03 | 6.85 ± 0.07 | |||

| 10 | 90 | 12 | 3.02 ± 0.01 | 9.6 ± 0.5 | 3.18 ± 0.17 | 3.66 ± 0.2 |

| 7.32 ± 0.04 | 20.7 ± 0.7 | 2.83 ± 0.1 | 4.11 ± 0.14 | |||

| 11.23 ± 0.06 | 28.9 ± 0.9 | 2.58 ± 0.08 | 4.52 ± 0.14 | |||

| 16.16 ± 0.05 | 38.7 ± 0.8 | 2.4 ± 0.05 | 4.85 ± 0.1 | |||

| 21.93 ± 0.06 | 49.2 ± 0.8 | 2.24 ± 0.04 | 5.19 ± 0.09 | |||

| 11 | 90 | 18 | 3.83 ± 0.03 | 9.9 ± 0.6 | 2.58 ± 0.15 | 2.1 ± 0.12 |

| 10.42 ± 0 | 21.9 ± 0.5 | 2.1 ± 0.05 | 2.58 ± 0.06 | |||

| 16.7 ± 0.03 | 31.7 ± 0.6 | 1.9 ± 0.04 | 2.86 ± 0.05 | |||

| 23.1 ± 0.18 | 41.2 ± 0.6 | 1.78 ± 0.03 | 3.04 ± 0.05 | |||

| 30.48 ± 0.33 | 50.9 ± 0.6 | 1.67 ± 0.03 | 3.25 ± 0.05 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, J.B.; Kim, H.J.; Kim, D.-K. Experimental Study of Natural Convection Cooling of Vertical Cylinders with Inclined Plate Fins. Energies 2016, 9, 391. https://doi.org/10.3390/en9060391

Lee JB, Kim HJ, Kim D-K. Experimental Study of Natural Convection Cooling of Vertical Cylinders with Inclined Plate Fins. Energies. 2016; 9(6):391. https://doi.org/10.3390/en9060391

Chicago/Turabian StyleLee, Jong Bum, Hyun Jung Kim, and Dong-Kwon Kim. 2016. "Experimental Study of Natural Convection Cooling of Vertical Cylinders with Inclined Plate Fins" Energies 9, no. 6: 391. https://doi.org/10.3390/en9060391