A Comparative Computational Fluid Dynamics Study on an Innovative Exhaust Air Energy Recovery Wind Turbine Generator

Abstract

:1. Introduction

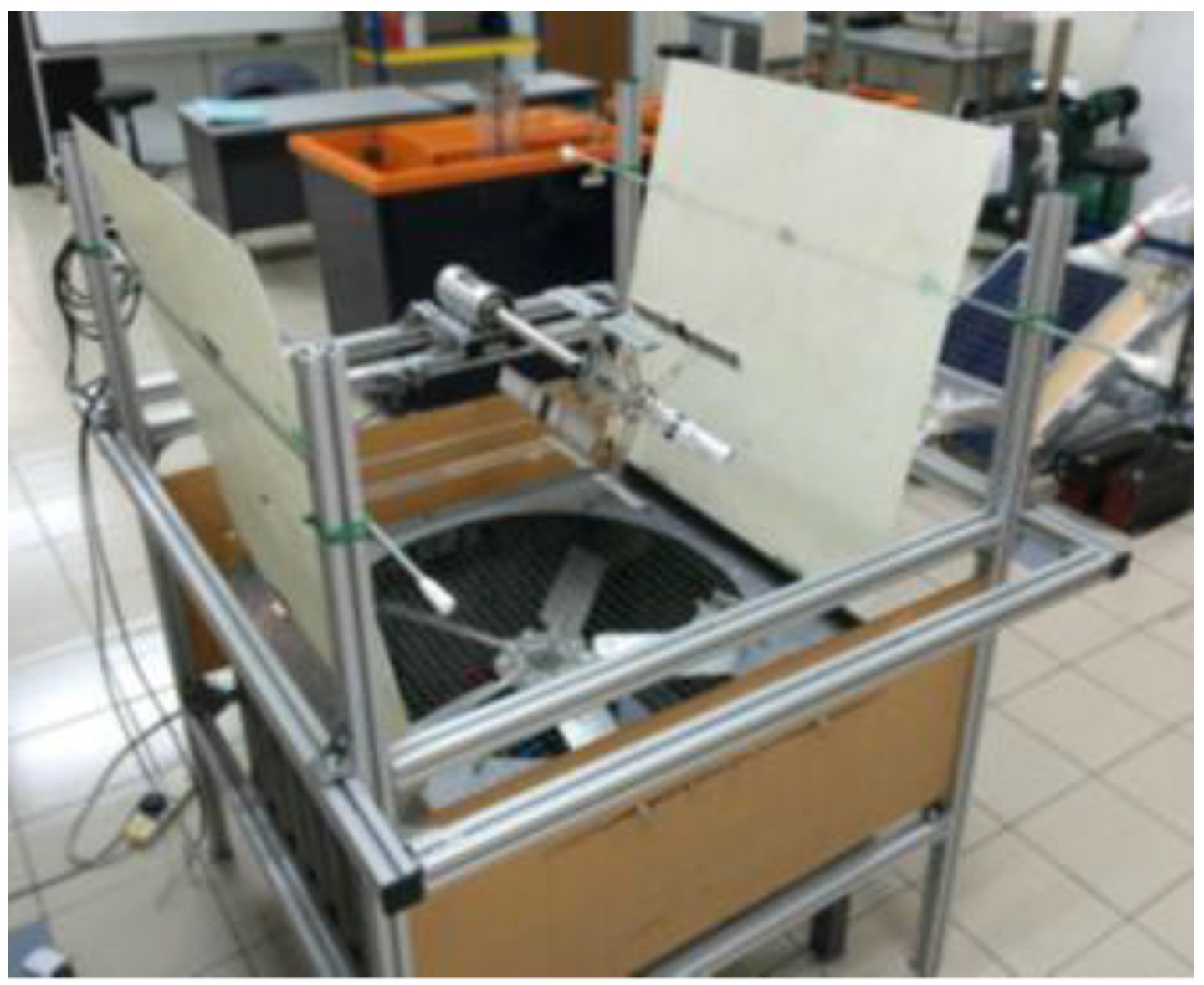

2. Working Principles of VAWT

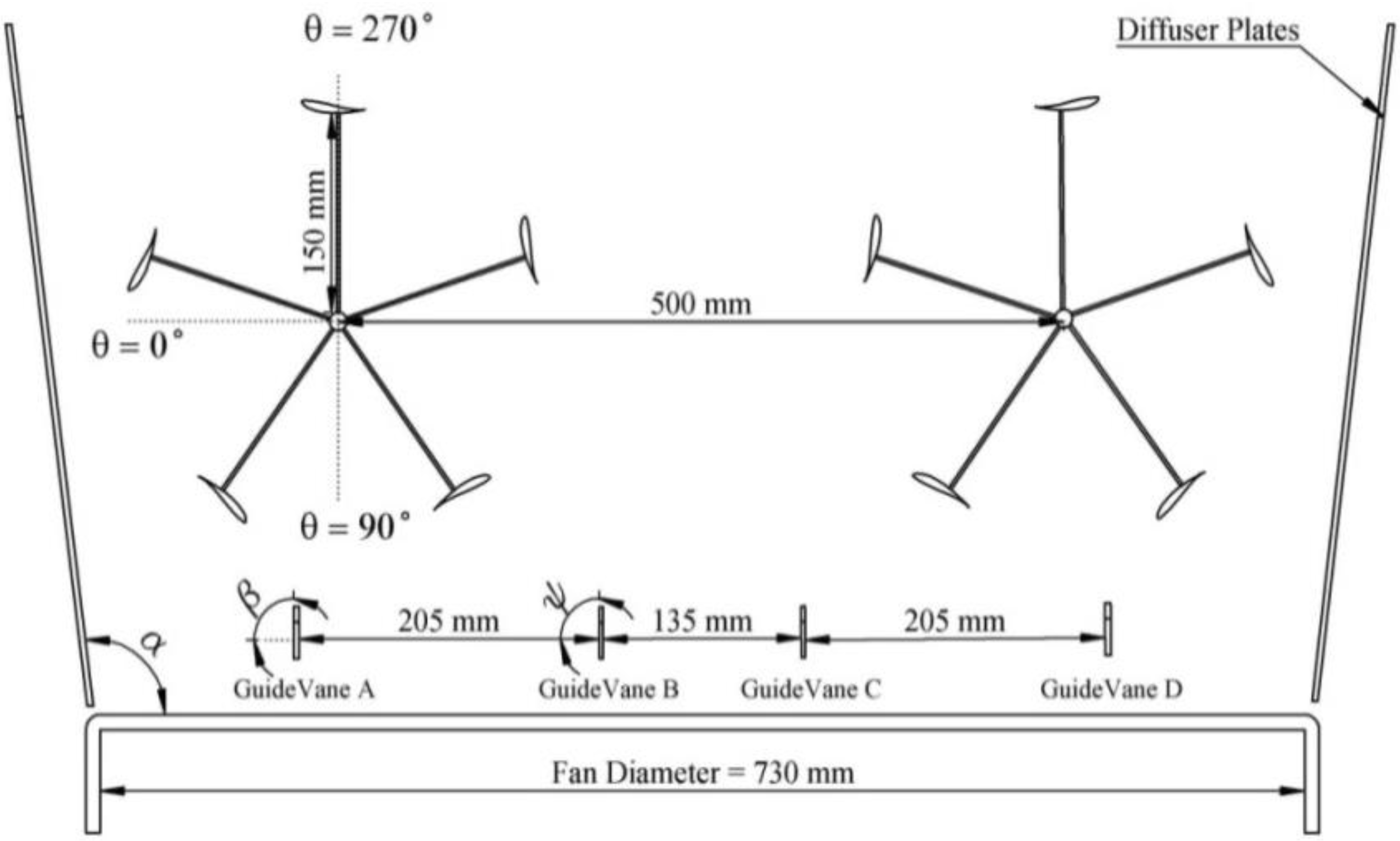

3. Numerical Model

4. Parametric Study

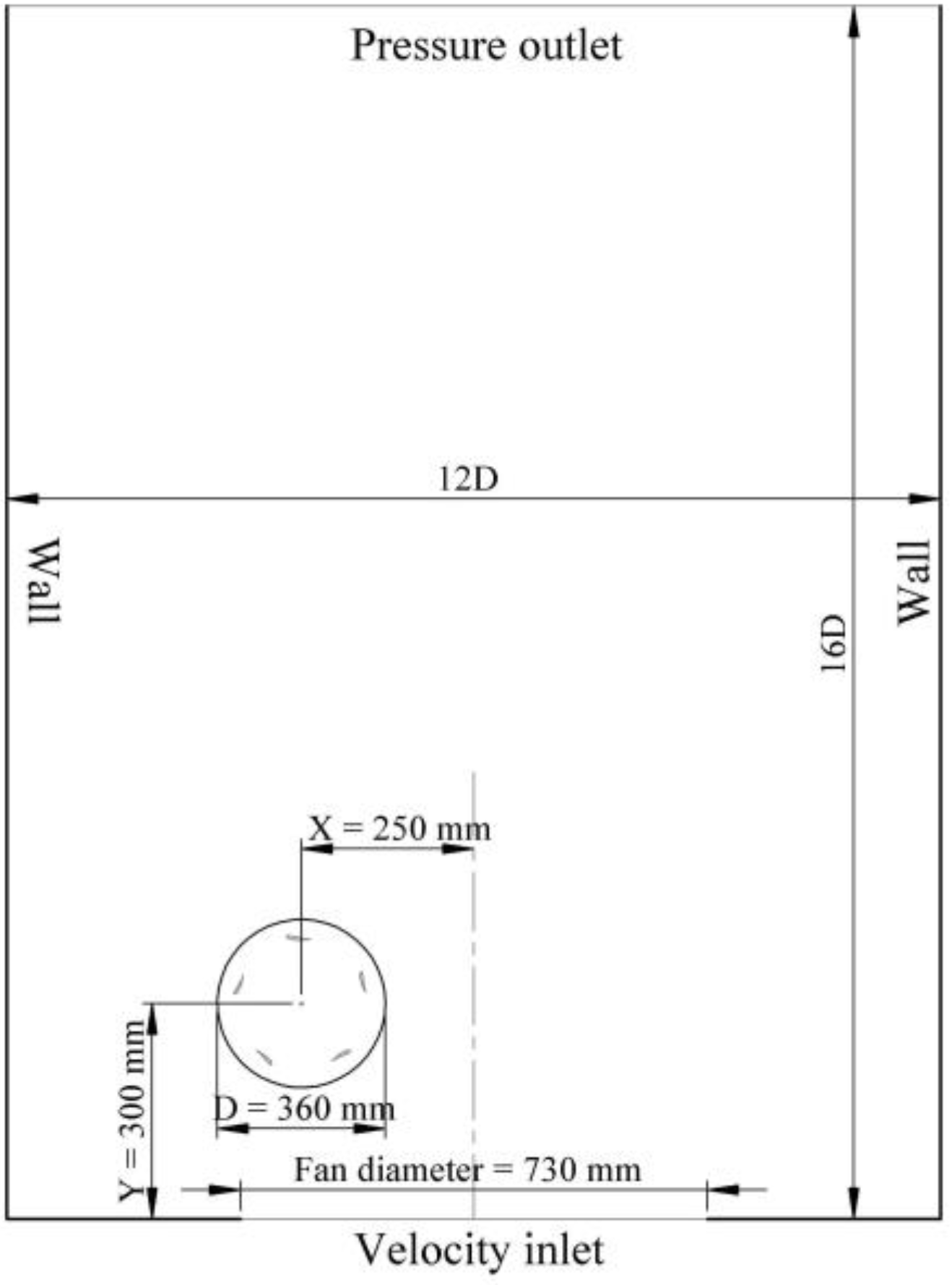

4.1. Computational Domain

4.2. Turbulence Testing

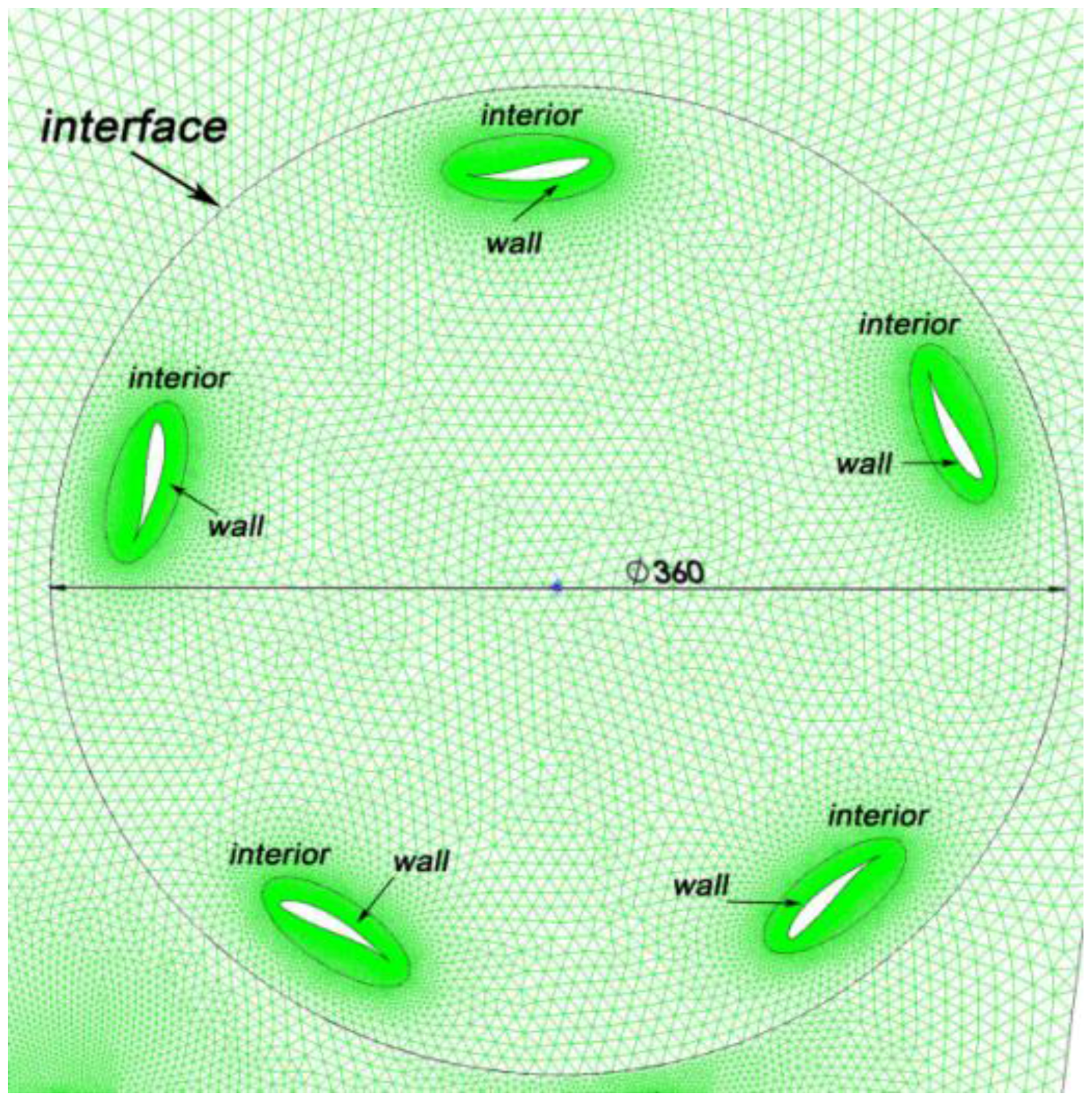

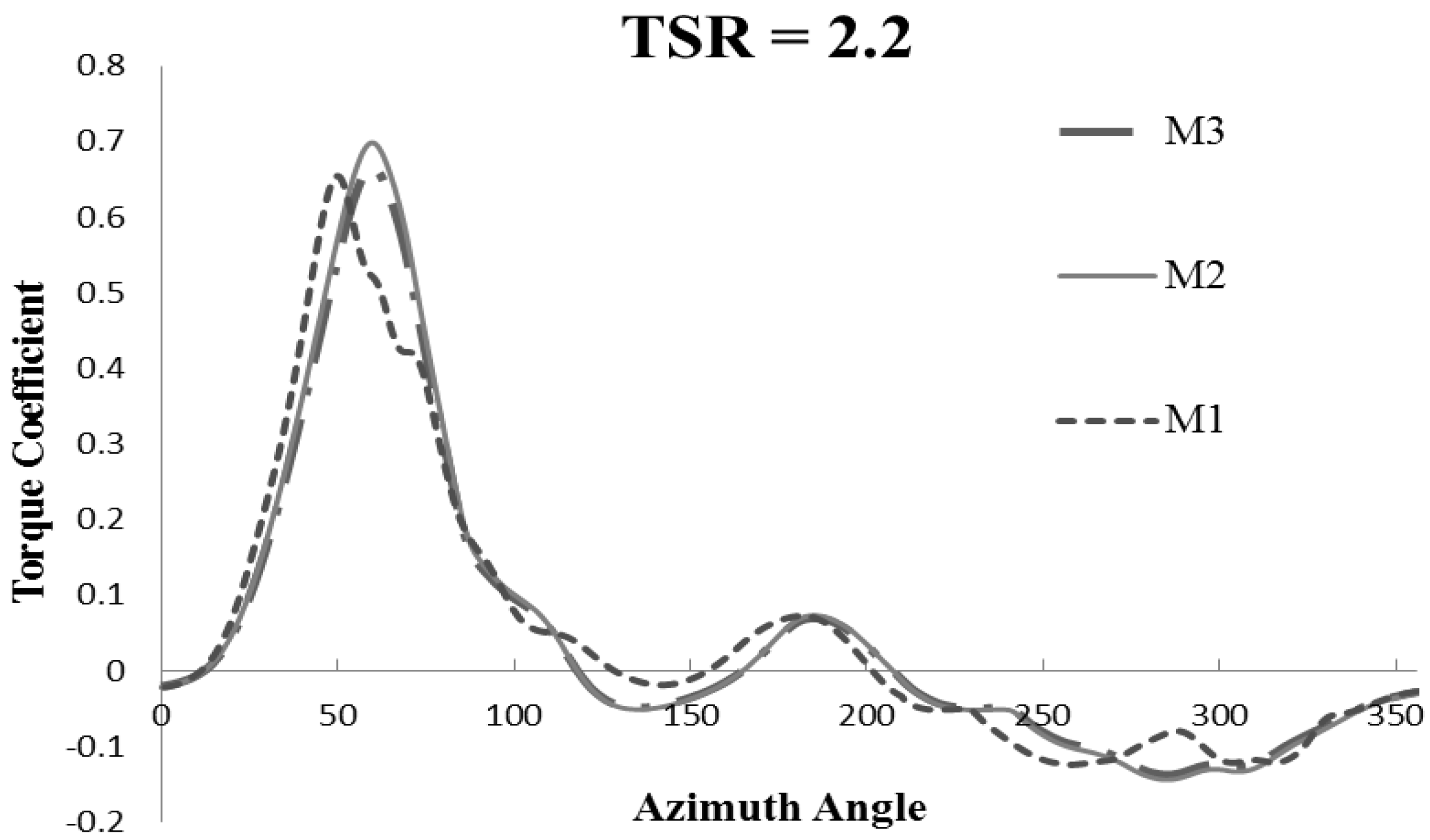

4.3. Mesh Dependency Study

- If,

- R* >1 Monotonic divergence

- 1 > R* > 0 Monotonic convergence

- 0 > R*> −1 Oscillatory convergence

- R* < −1 Oscillatory divergence

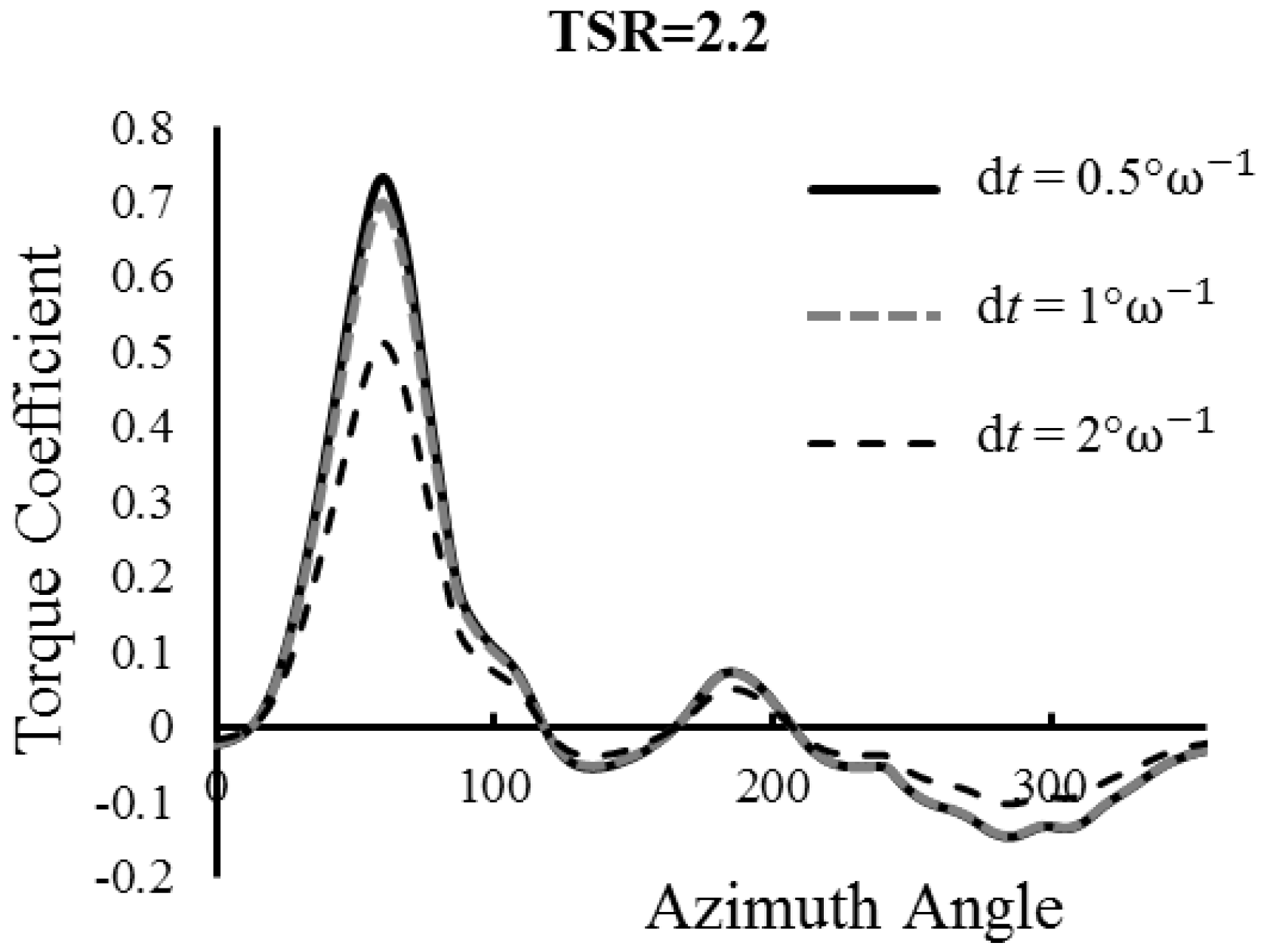

4.4. Dependency of Time Increment

4.5. Final Parameters

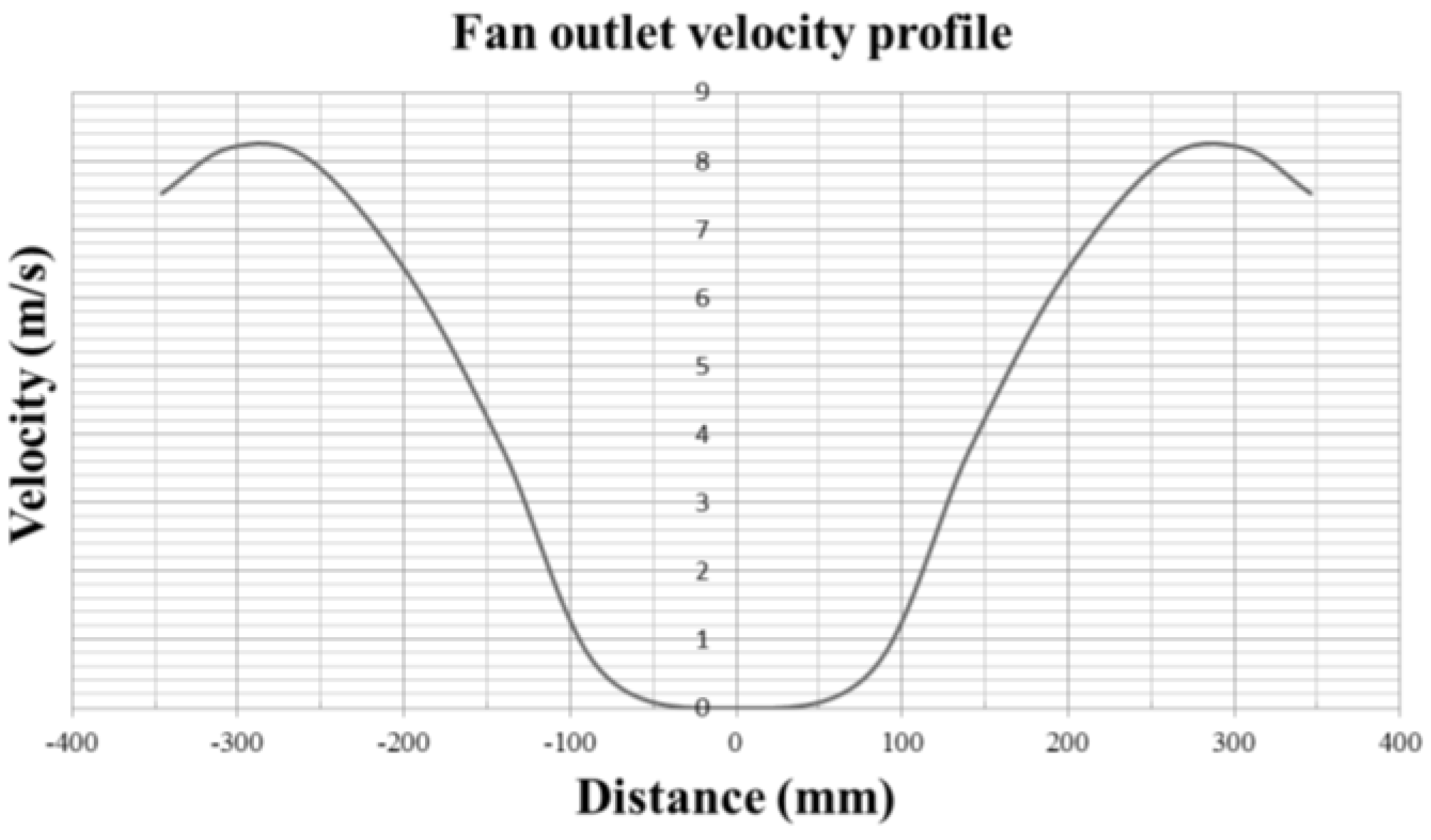

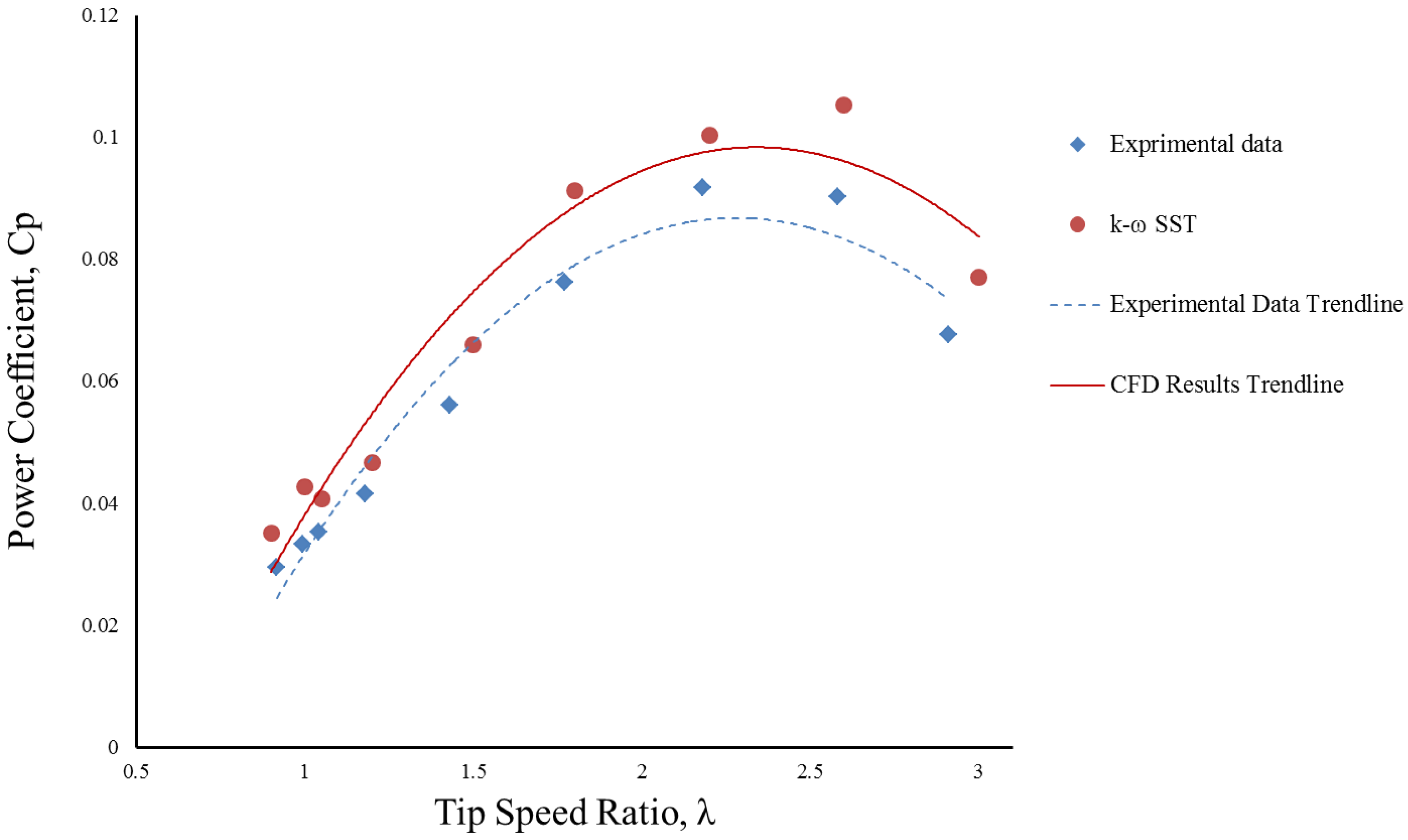

4.6. CFD Validation

5. Results and Discussion

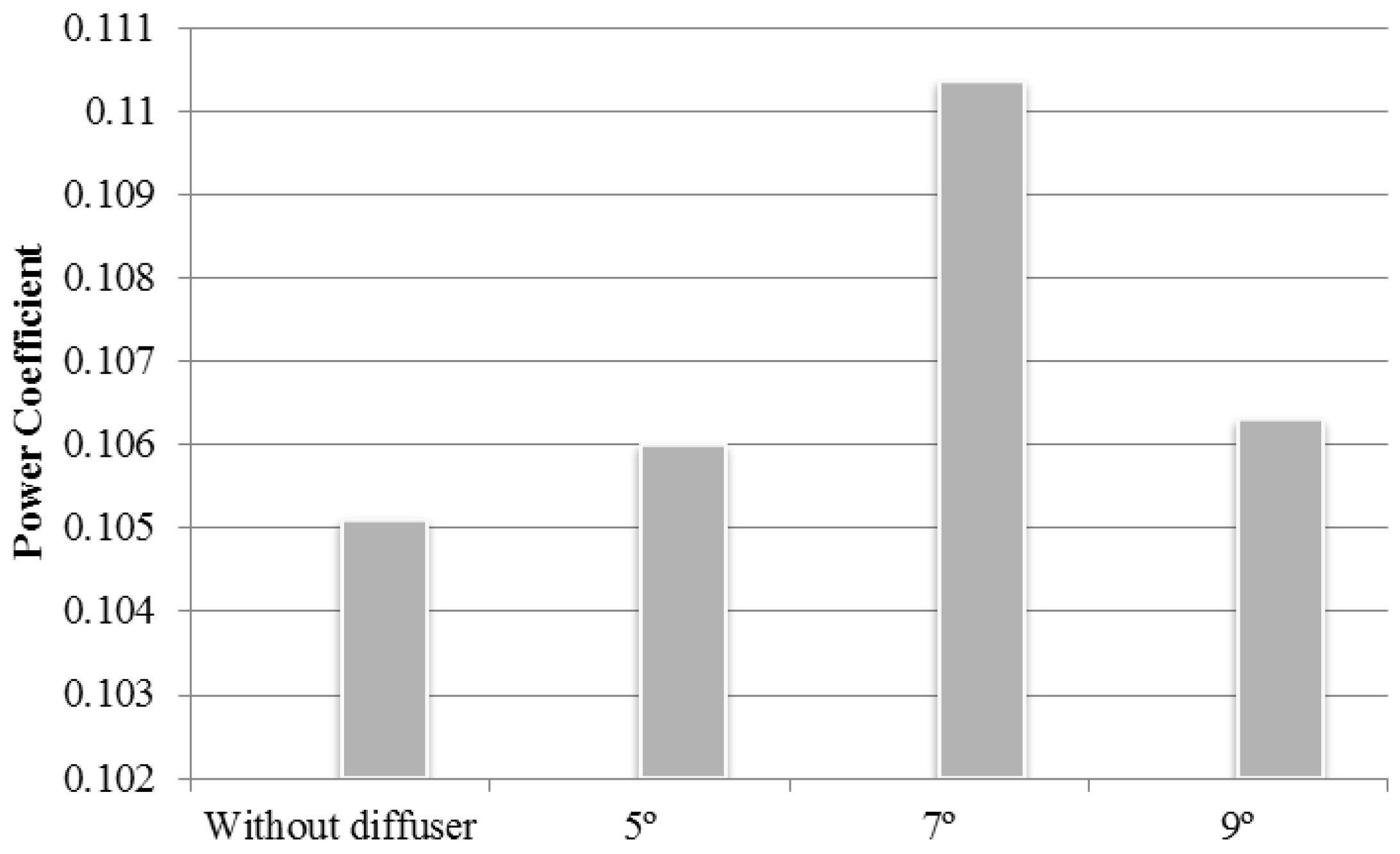

5.1. The Effect of the Diffuser Angle

5.2. The Effect of Guide Vanes

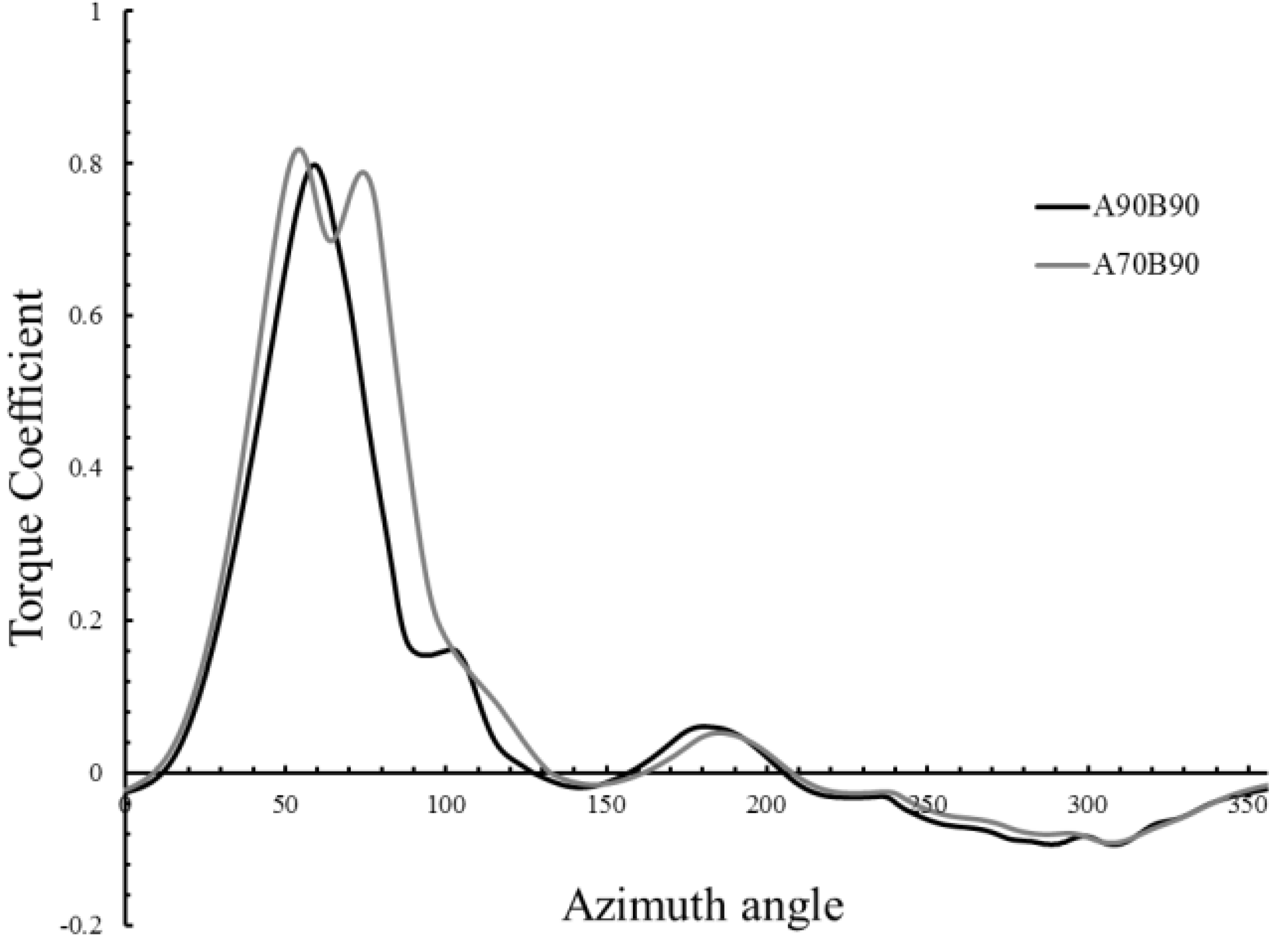

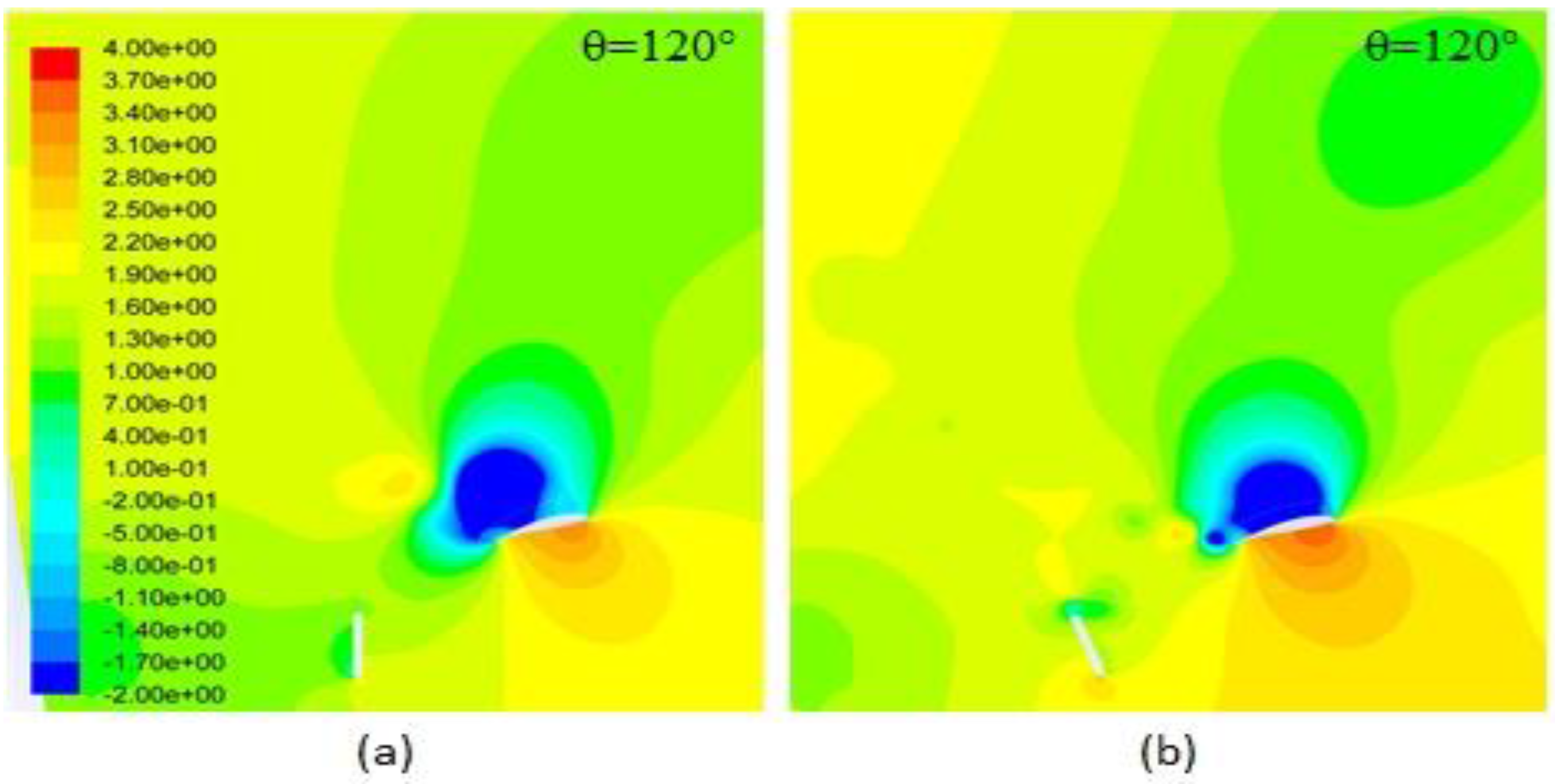

5.2.1. Guide Vane A

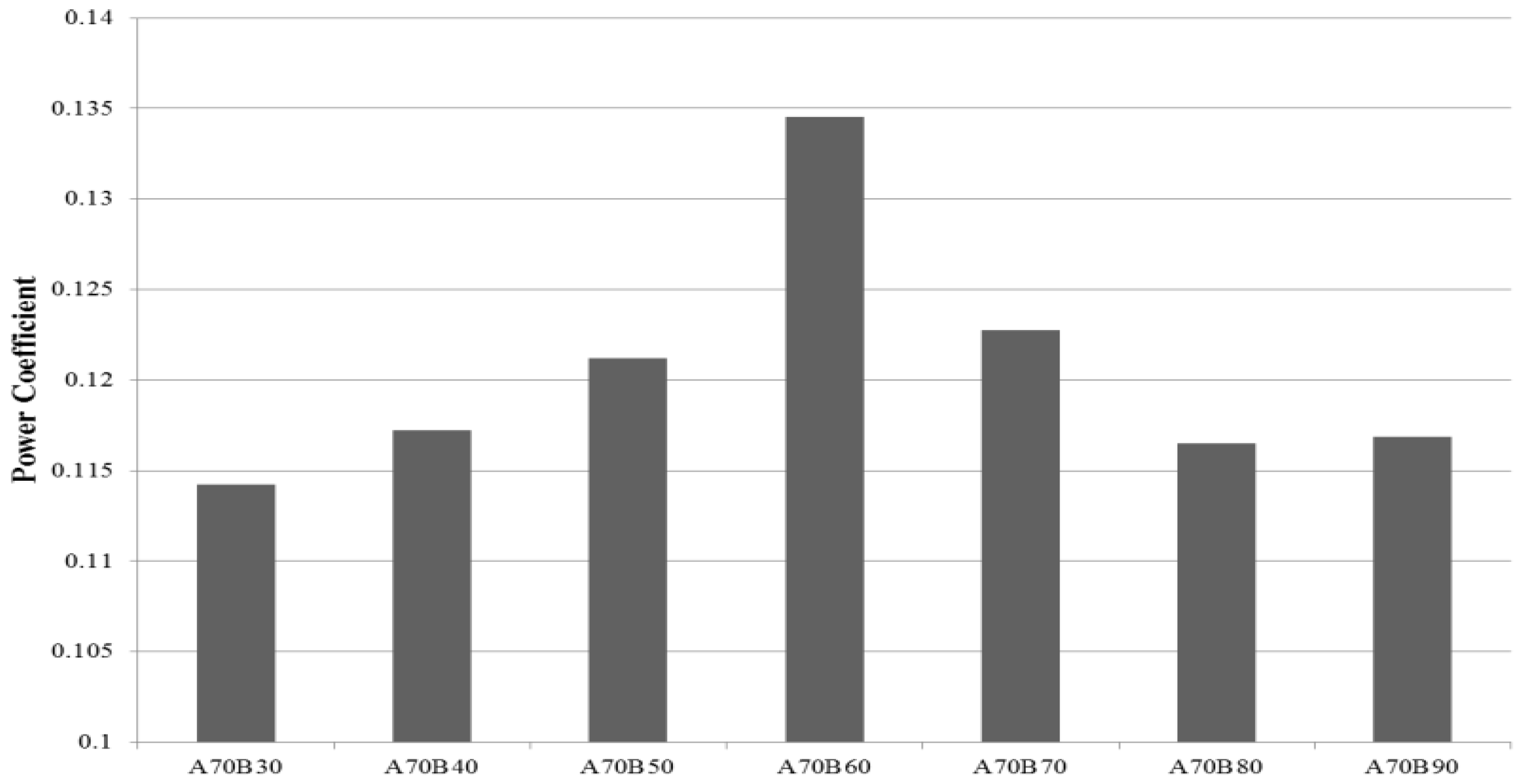

5.2.2. Guide Vane B

6. Economic Feasibility

7. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Nomenclature

| A | Swept turbine area |

| BEM | Blade element momentum |

| CFD | Computational fluid dynamics |

| Ct, average | Average of mechanical torque coefficient |

| Cp, average | Average power coefficient |

| FT | Tangential force |

| GIT | Grid independency test |

| k | Kinetic energy |

| L | Turbulent length |

| R* | Monotonic divergence |

| P | Dynamic pressure |

| SST | Shear stress transport |

| URANS | Unsteady Reynolds averaged Navier-Stokes |

| U | Air velocity |

| VAWT | Vertical axis wind turbine |

| W | Relative velocity |

| Greek | |

| α | Diffuser angle |

| β | Angle of guide-vane A |

| θ | Azimuth angle |

| λ | Tip speed ratio |

| μ | Viscosity |

| νeff | Effective kinematic viscosity |

| ρ | Density |

| ψ | Angle of guide-vane B |

| ω | Angular velocity |

References

- Manwell, J.F.; McGowan, J.G.; Rogers, A.L. Wind Energy Explained: Theory, Design and Application; John Wiley & Sons: Hoboken, NJ, USA, 2010. [Google Scholar]

- Energy Commission of Malaysia. Malaysia Energy Statistics Handbook 2014; Suruhanjaya Tenaga: Putrajaya, Malaysia. Available online: http://www.meih.st.gov.my (accessed on 24 May 2015).

- Sung, C.T.B. Possibility of electricity from wind energy in Malaysia: Some rough calculations. Available online: http://www.christopherteh.com/blog/2010/11/wind-energy/ (accessed on 24 May 2015).

- Chong, W.T.; Fazlizan, A.; Poh, S.C.; Pan, K.C.; Hew, W.P.; Hsiao, F.B. The design, simulation and testing of an urban vertical axis wind turbine with the omni-direction-guide-vane. Appl. Energy 2013, 112, 601–609. [Google Scholar] [CrossRef]

- Ohya, Y.; Karasudani, T. A shrouded wind turbine generating high output power with wind-lens technology. Energies 2010, 3, 634–649. [Google Scholar] [CrossRef]

- Chong, W.T.; Pan, K.C.; Poh, S.C.; Fazlizan, A.; Oon, C.S.; Badarudin, A.; Nik-Ghazali, N. Performance investigation of a power augmented vertical axis wind turbine for urban high-rise application. Renew. Energy 2013, 51, 388–397. [Google Scholar] [CrossRef]

- Foreman, K.; Gilbert, B. Technical development of the Diffuser Augmented Wind Turbine/DAWT/concept. Wind Eng. 1979, 3, 153–166. [Google Scholar]

- Foreman, K.; Gilbert, B.; Oman, R. Diffuser augmentation of wind turbines. Solar Energy 1978, 20, 305–311. [Google Scholar] [CrossRef]

- Foreman, K. Preliminary Design and Economic Investigations of Diffuser-Augmented Wind Turbines (DAWT); Grumman Aerospace Corp.: Bethpage, NY, USA, 1981. [Google Scholar]

- Moeller, M.; Visser, K. Experimental and numerical studies of a high solidity, low tip speed ratio DAWT. In Proceedings of the 48th AIAA Aerospace Sciences Meeting and Exhibit, Orlando, FL, USA, 4–7 January 2010.

- Tong, C.W.; Chew, P.S.; Abdullah, A.F.; Sean, O.C.; Ching, T.C. Exhaust air and wind energy recovery system for clean energy generation. In Proceedings of the International Conference on Environment and Industrial Innovation, Kuala Lumpur, Malaysia, 4–5 June 2011; IACSIT Press: Kuala Lumpur, Malaysia, 2011. [Google Scholar]

- Shahizare, B.; Ghazali, N.N.B.N.; Chong, W.T.; Tabatabaeikia, S.; Izadyar, N. Investigation of the optimal omni-direction-guide-vane design for vertical axis wind turbines based on unsteady flow CFD simulation. Energies 2016, 9, 146. [Google Scholar] [CrossRef]

- Shahizare, B.; Nik-Ghazali, N.; Chong, W.; Tabatabaeikia, S.; Izadyar, N.; Esmaeilzadeh, A. Novel investigation of the different Omni-direction-guide-vane angles effects on the urban vertical axis wind turbine output power via three-dimensional numerical simulation. Energy Conv. Manag. 2016, 117, 206–217. [Google Scholar] [CrossRef]

- Mertens, S.; van Kuik, G.; van Bussel, G. Performance of an H-Darrieus in the skewed flow on a roof. J. Sol. Energy Eng. 2003, 125, 433–440. [Google Scholar] [CrossRef]

- Simms, D.A.; Schreck, S.; Hand, M.; Fingersh, L. NREL Unsteady Aerodynamics Experiment in the NASA-Ames Wind Tunnel: A Comparison of Predictions to Measurements; National Renewable Energy Laboratory: Golden, CO, USA, 2001. [Google Scholar]

- McTavish, S.; Feszty, D.; Sankar, T. Steady and rotating computational fluid dynamics simulations of a novel vertical axis wind turbine for small-scale power generation. Renew. Energy 2012, 41, 171–179. [Google Scholar] [CrossRef]

- McLaren, K.; Tullis, S.; Ziada, S. Computational fluid dynamics simulation of the aerodynamics of a high solidity, small-scale vertical axis wind turbine. Wind Energy 2012, 15, 349–361. [Google Scholar] [CrossRef]

- Edwards, J.M.; Danao, L.A.; Howell, R.J. Novel experimental power curve determination and computational methods for the performance analysis of vertical axis wind turbines. J. Sol. Energy Eng. 2012, 134. [Google Scholar] [CrossRef]

- Chowdhury, A.M.; Akimoto, H.; Hara, Y. Comparative CFD analysis of Vertical Axis Wind Turbine in upright and tilted configuration. Renew. Energy 2016, 85, 327–337. [Google Scholar] [CrossRef]

- Qin, N.; Howell, R.; Durrani, N.; Hamada, K.; Smith, T. Unsteady flow simulation and dynamic stall behaviour of vertical axis wind turbine blades. Wind Eng. 2011, 35, 511–528. [Google Scholar] [CrossRef]

- Castelli, M.R.; Englaro, A.; Benini, E. The Darrieus wind turbine: Proposal for a new performance prediction model based on CFD. Energy 2011, 36, 4919–4934. [Google Scholar] [CrossRef]

- Chong, W.T.; Hew, W.P.; Yip, S.Y.; Fazlizan, A.; Poh, S.C.; Tan, C.J.; Ong, H.C. The experimental study on the wind turbine’s guide-vanes and diffuser of an exhaust air energy recovery system integrated with the cooling tower. Energy Convers. Manag. 2014, 87, 145–155. [Google Scholar] [CrossRef]

- Chong, W.T.; Fazlizan, A.; Poh, S.C.; Pan, K.C.; Ping, H.W. Early development of an innovative building integrated wind, solar and rain water harvester for urban high rise application. Energy Build. 2012, 47, 201–207. [Google Scholar] [CrossRef]

- Fazlizan, A.; Chong, W.; Yip, S.; Hew, W.; Poh, S. Design and experimental analysis of an exhaust air energy recovery wind turbine generator. Energies 2015, 8, 6566–6584. [Google Scholar] [CrossRef]

- Paraschivoiu, I. Wind Turbine Design: With Emphasis on Darrieus Concept; Presses Inter Polytechnique: Montréal, QC, Canada, 2002. [Google Scholar]

- Fluent, A. 14.5 User’s Guide; Fluent Inc.: New York, NY, USA, 2012. [Google Scholar]

- Almohammadi, K.; Ingham, D.; Ma, L.; Pourkashanian, M. CFD sensitivity analysis of a straight-blade vertical axis wind turbine. Wind Eng. 2012, 36, 571–588. [Google Scholar] [CrossRef]

- Almohammadi, K.M.; Ingham, D.B.; Ma, L.; Pourkashan, M. Computational fluid dynamics (CFD) mesh independency techniques for a straight blade vertical axis wind turbine. Energy 2013, 58, 483–493. [Google Scholar] [CrossRef]

- Howell, R.; Qin, N.; Edwards, J.; Durrani, N. Wind tunnel and numerical study of a small vertical axis wind turbine. Renew. Energy 2010, 35, 412–422. [Google Scholar] [CrossRef]

- Yakhot, V.; Orszag, S.; Thangam, S.; Gatski, T.; Speziale, C. Development of turbulence models for shear flows by a double expansion technique. Phys. Fluids A Fluid Dyn. (1989–1993) 1992, 4, 1510–1520. [Google Scholar] [CrossRef]

- Chong, W.T.; Naghavi, M.S.; Poh, S.C.; Mahlia, T.M.I.; Pan, K.C. Techno-economic analysis of a wind-solar hybrid renewable energy system with rainwater collection feature for urban high-rise application. Appl. Energy 2011, 88, 4067–4077. [Google Scholar] [CrossRef]

- Lim, Y.C.; Chong, W.T.; Hsiao, F.B. Performance Investigation and Optimization of a Vertical Axis Wind Turbine with the Omni-Direction-Guide-Vane. Procedia Eng. 2013, 67, 59–69. [Google Scholar] [CrossRef]

- Schaffarczyk, A. Introduction to Wind Turbine Aerodynamics; Springer: Berlin, Germany, 2014. [Google Scholar]

- Lilley, G.; Rainbird, W. A Preliminary Report on the Design and Performance of Ducted Windmills; College of Aeronautics Cranfield: Cranfield, UK, 1956. [Google Scholar]

- Van Bussel, G.J. The science of making more torque from wind: Diffuser experiments and theory revisited. In Journal of Physics: Conference Series; IOP Publishing: Bristol, UK, 2007. [Google Scholar]

- Abe, K.; Nishida, M.; Sakurai, A.; Ohya, Y.; Kihara, H.; Wada, E.; Sato, K. Experimental and numerical investigations of flow fields behind a small wind turbine with a flanged diffuser. J. Wind Eng. Ind. Aerodyn. 2005, 93, 951–970. [Google Scholar] [CrossRef]

| Mesh Description | M3 | M2 | M1 |

|---|---|---|---|

| Number of cells | 260,531 | 850,054 | 901,560 |

| No. of nodes on a blade | 350 | 700 | 900 |

| Description | Power Coefficient | Computational Time for 1 s of Computational Case |

|---|---|---|

| RNG k-epsilon | 0.0820 | 45.2 h |

| SST k-omega | 0.1003 | 48.6 h |

| S-A | 0.114 | 31.4 h |

| Experimental | 0.0918 | - |

| Cm | T | TSR | Cp | P | Deviation from Baseline Design (%) | |

|---|---|---|---|---|---|---|

| A30B90 | 0.032 | 0.024 | 2.2 | 0.071 | 1.86 | −31.6176 |

| A40B90 | 0.045 | 0.033 | 2.2 | 0.099 | 2.59 | −4.77941 |

| A50B90 | 0.045 | 0.033 | 2.2 | 0.098 | 2.57 | −5.51471 |

| A60B90 | 0.049 | 0.036 | 2.2 | 0.108 | 2.82 | 3.676471 |

| A70B90 | 0.053 | 0.039 | 2.2 | 0.116 | 3.03 | 11.39706 |

| A80B90 | 0.046 | 0.033 | 2.2 | 0.101 | 2.63 | −3.30882 |

| A90B90 | 0.047 | 0.035 | 2.2 | 0.105 | 2.72 | 0 |

| A100B90 | 0.038 | 0.028 | 2.2 | 0.083 | 2.18 | −19.8529 |

| A110B90 | 0.042 | 0.031 | 2.2 | 0.093 | 2.42 | −11.0294 |

| A120B90 | 0.045 | 0.033 | 2.2 | 0.099 | 2.57 | −5.51471 |

| A130B90 | 0.036 | 0.027 | 2.2 | 0.08 | 2.09 | −23.1618 |

| Cm | T | TSR | Cp | P | Deviation from Baseline Design (%) | |

|---|---|---|---|---|---|---|

| A70B30 | 0.051 | 0.038 | 2.2 | 0.114 | 2.96 | 8.823529 |

| A70B40 | 0.053 | 0.039 | 2.2 | 0.117 | 3.04 | 11.76471 |

| A70B50 | 0.055 | 0.04 | 2.2 | 0.121 | 3.15 | 15.80882 |

| A70B60 | 0.061 | 0.045 | 2.2 | 0.134 | 3.49 | 28.30882 |

| A70B70 | 0.055 | 0.041 | 2.2 | 0.122 | 3.19 | 17.27941 |

| A70B80 | 0.052 | 0.039 | 2.2 | 0.1165 | 3.02 | 11.02941 |

| A70B90 | 0.053 | 0.0392 | 2.2 | 0.1168 | 3.03 | 11.39706 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tabatabaeikia, S.; Bin Nik-Ghazali, N.N.; Chong, W.T.; Shahizare, B.; Fazlizan, A.; Esmaeilzadeh, A.; Izadyar, N. A Comparative Computational Fluid Dynamics Study on an Innovative Exhaust Air Energy Recovery Wind Turbine Generator. Energies 2016, 9, 346. https://doi.org/10.3390/en9050346

Tabatabaeikia S, Bin Nik-Ghazali NN, Chong WT, Shahizare B, Fazlizan A, Esmaeilzadeh A, Izadyar N. A Comparative Computational Fluid Dynamics Study on an Innovative Exhaust Air Energy Recovery Wind Turbine Generator. Energies. 2016; 9(5):346. https://doi.org/10.3390/en9050346

Chicago/Turabian StyleTabatabaeikia, Seyedsaeed, Nik Nazri Bin Nik-Ghazali, Wen Tong Chong, Behzad Shahizare, Ahmad Fazlizan, Alireza Esmaeilzadeh, and Nima Izadyar. 2016. "A Comparative Computational Fluid Dynamics Study on an Innovative Exhaust Air Energy Recovery Wind Turbine Generator" Energies 9, no. 5: 346. https://doi.org/10.3390/en9050346