Cooling Performance Characteristics of the Stack Thermal Management System for Fuel Cell Electric Vehicles under Actual Driving Conditions

Abstract

:1. Introduction

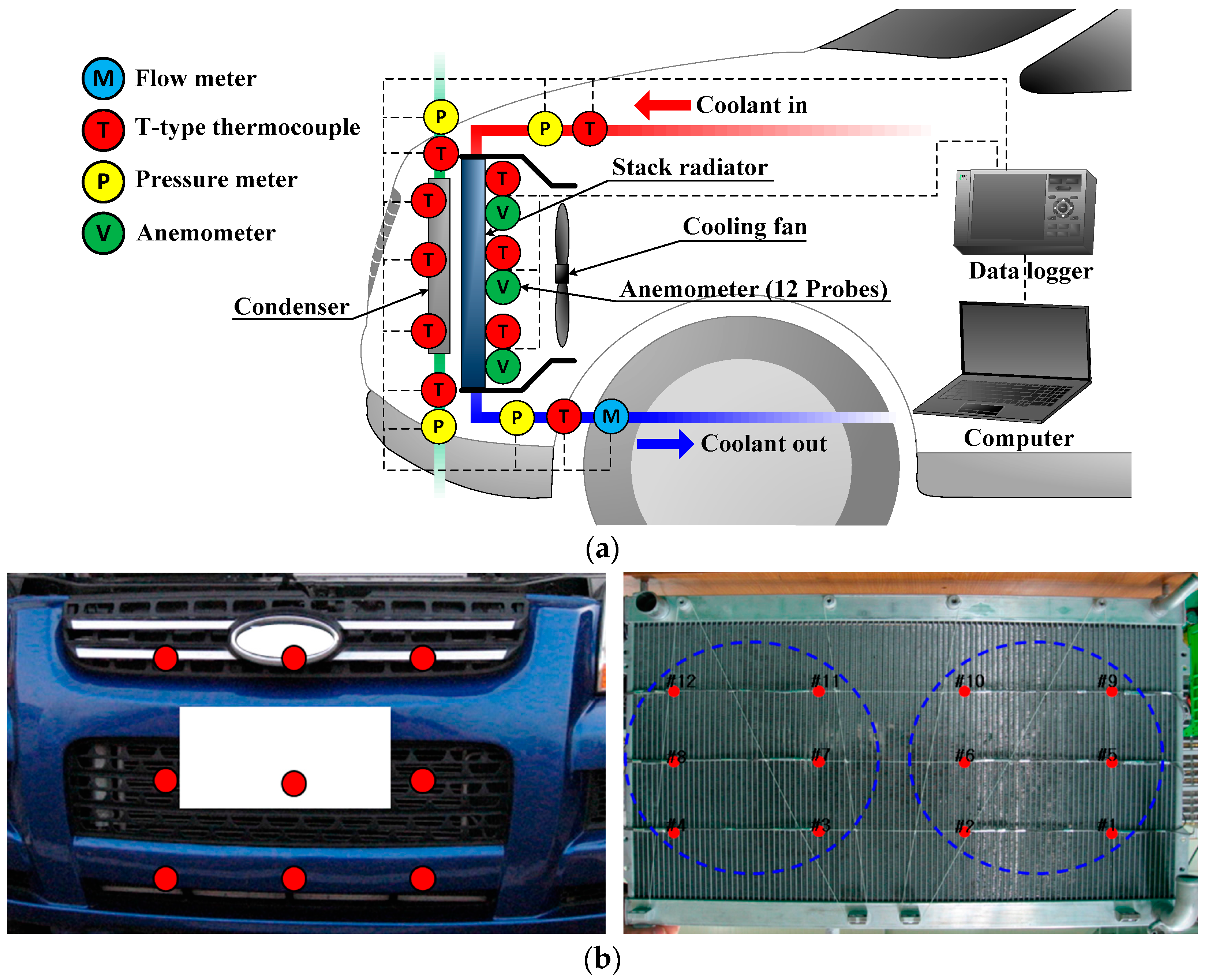

2. Experimental Method

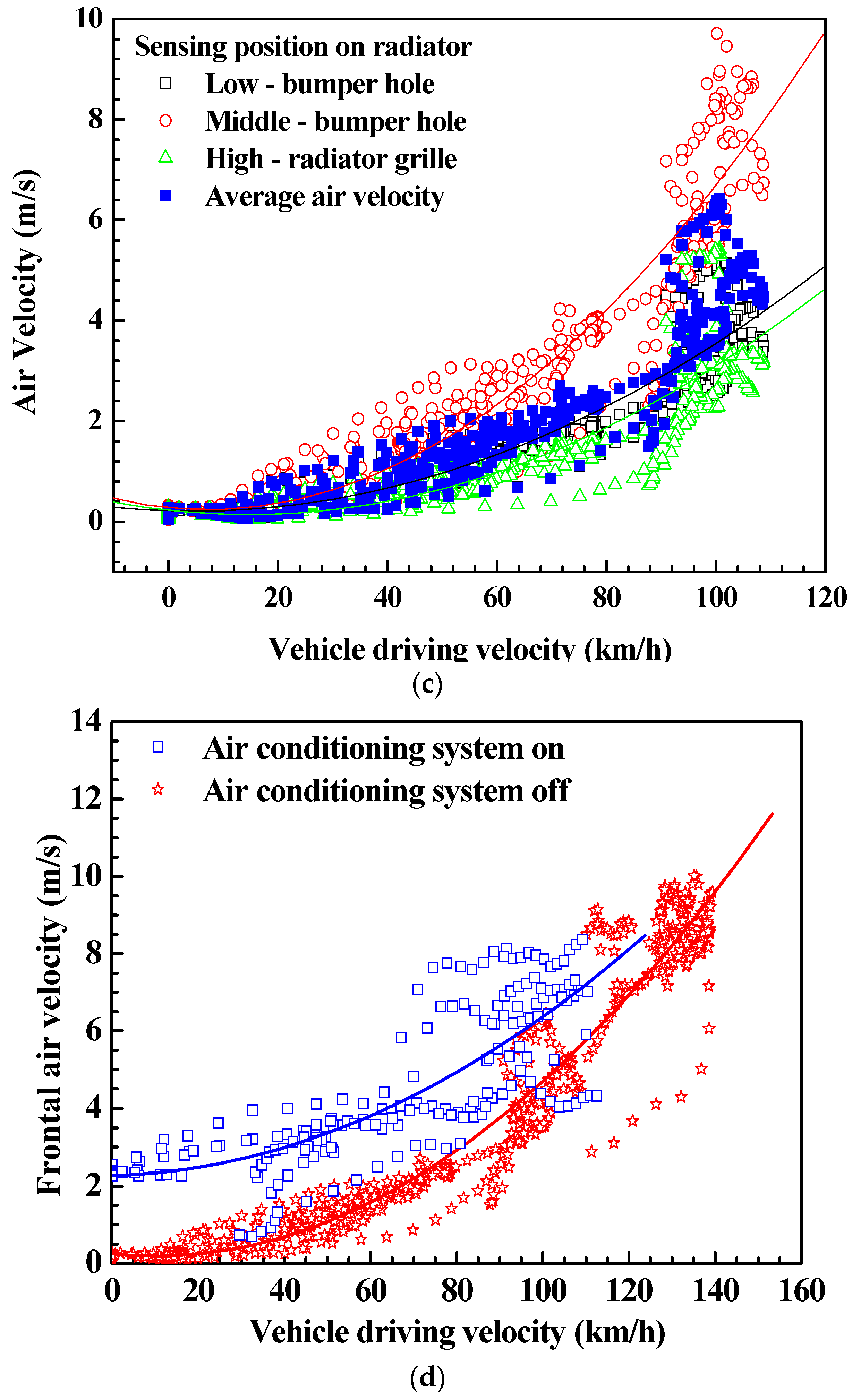

2.1. Experimental Setup

2.2. Analytical Method

3. Results and Discussion

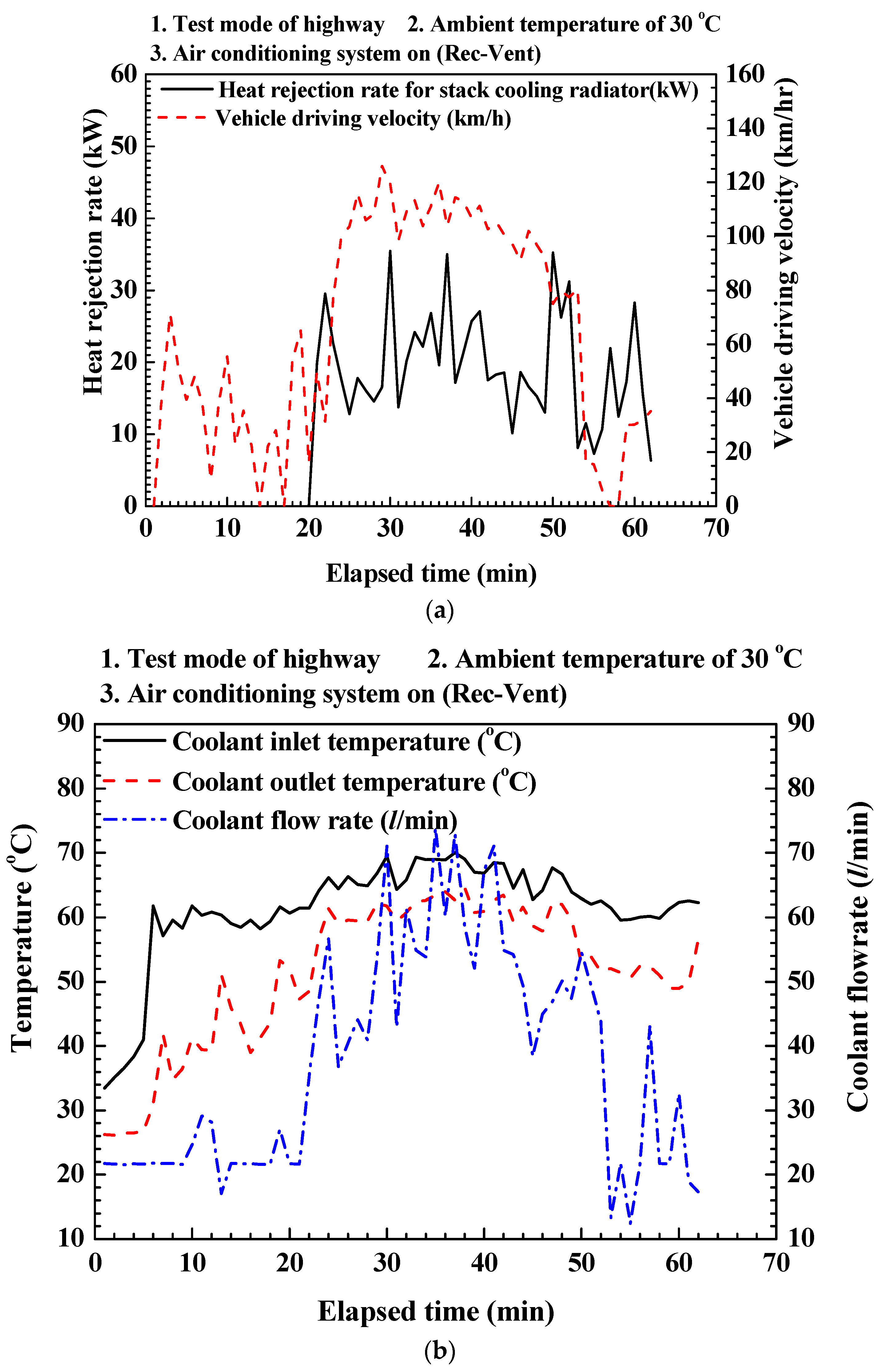

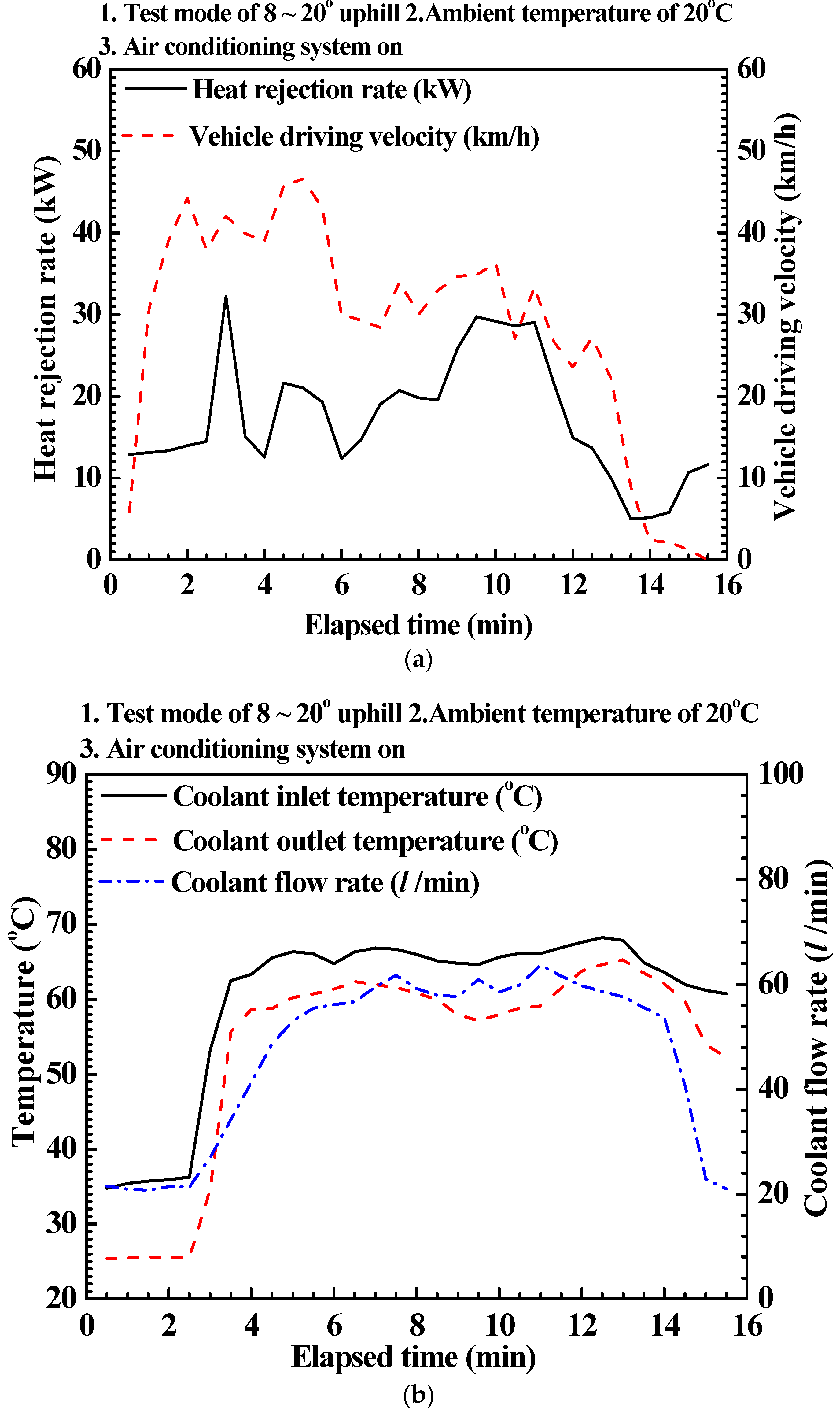

3.1. Cooling Performance of the Stack Thermal Management System under Actual Driving Conditions

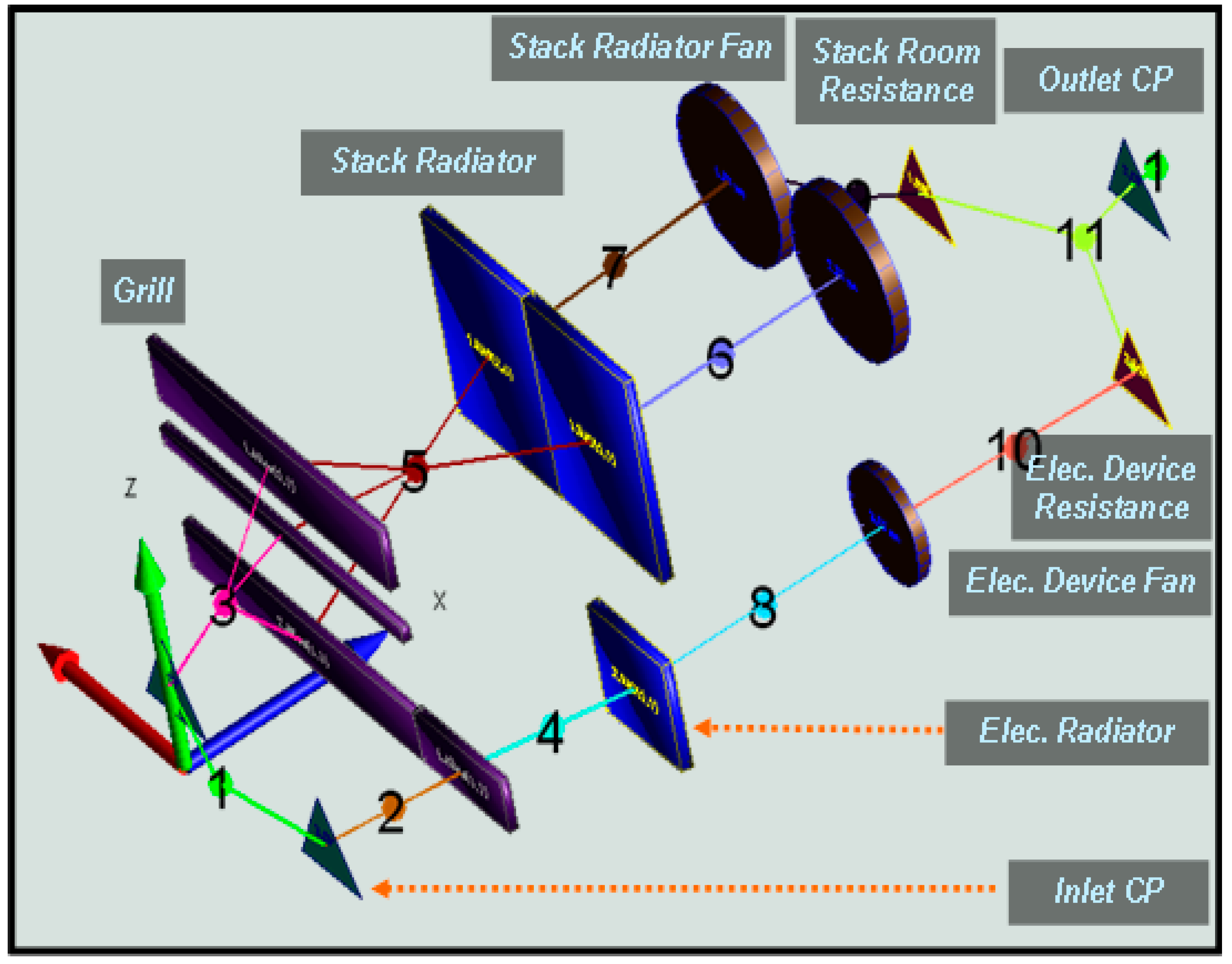

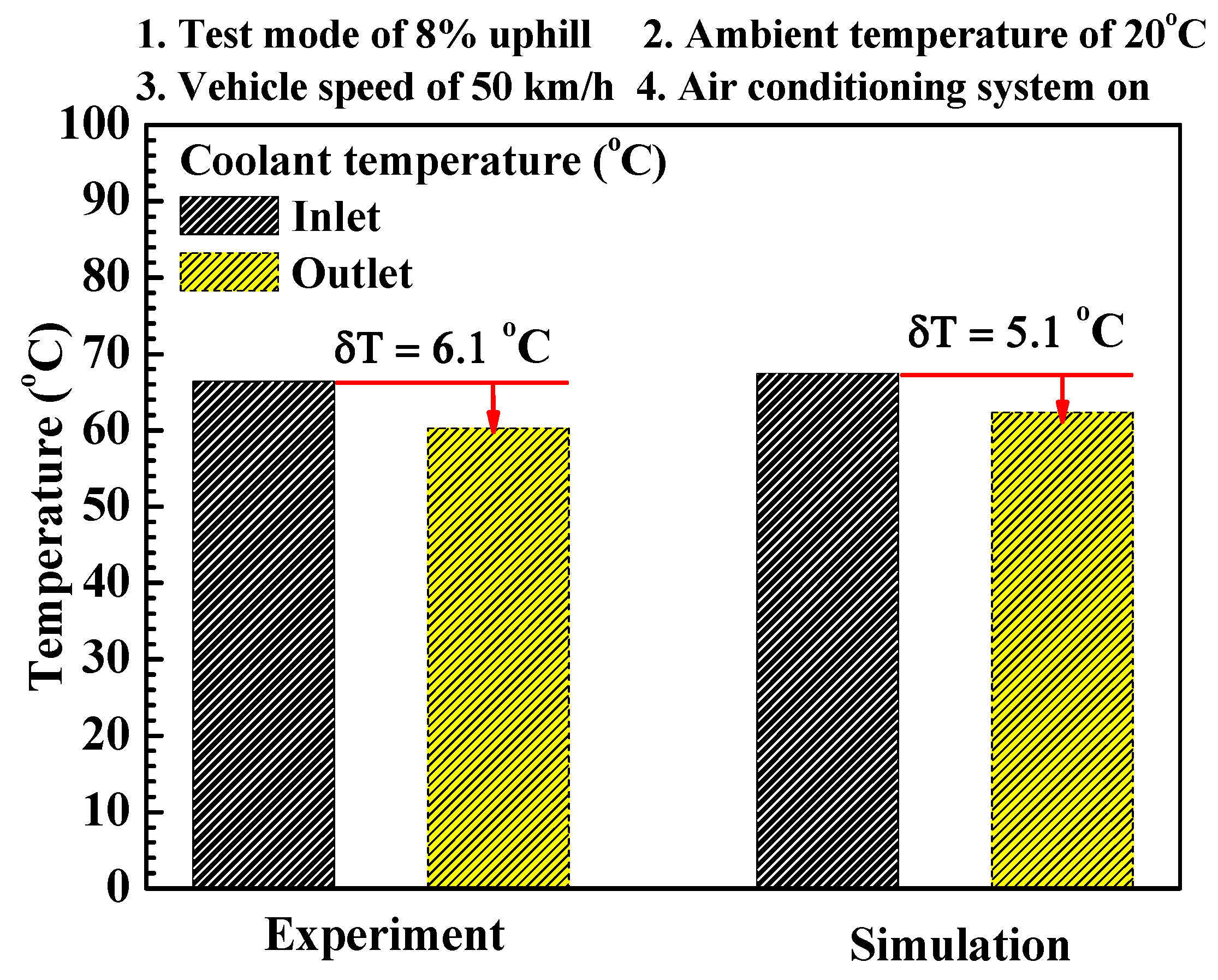

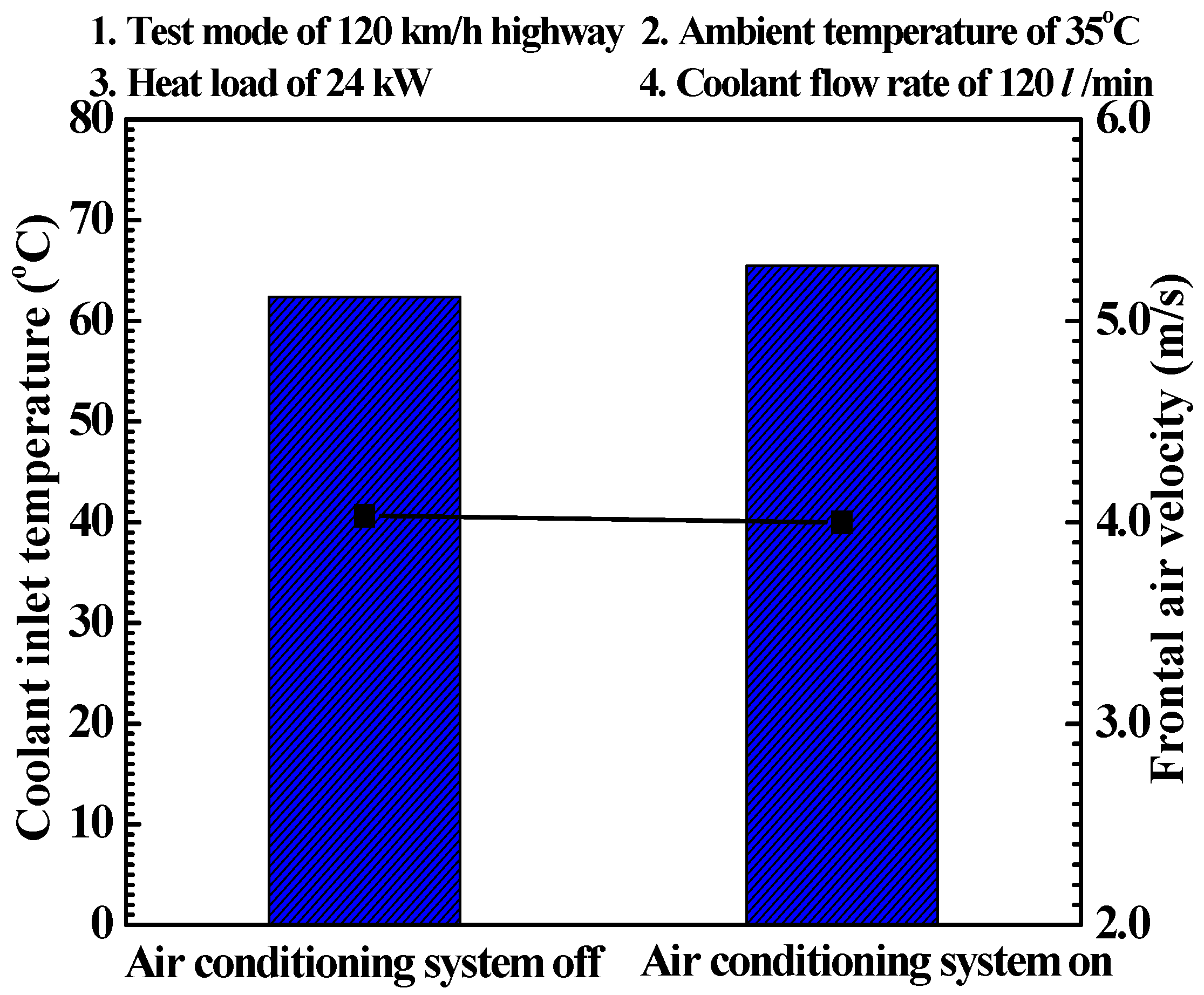

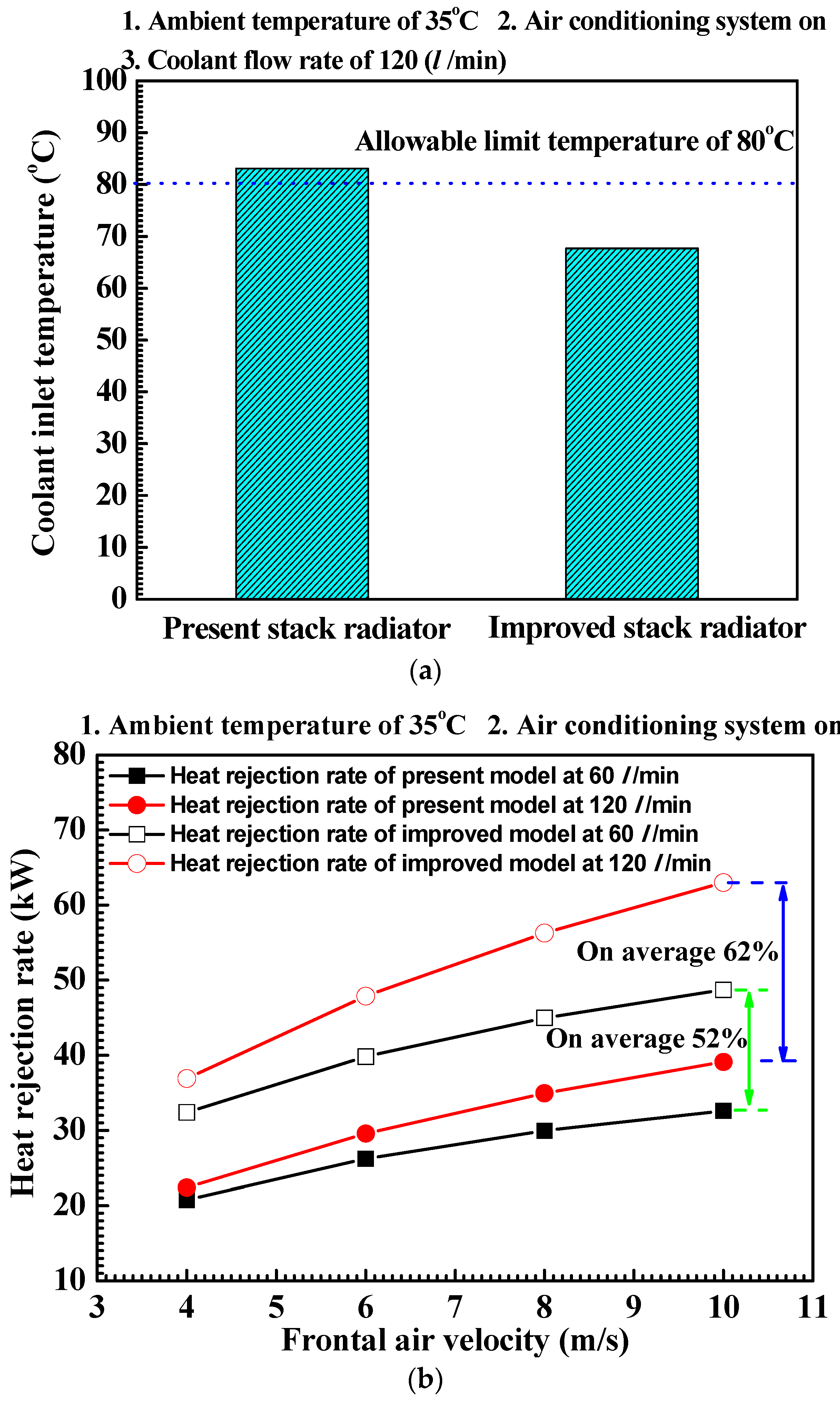

3.2. Cooling Performance Simulations of the Stack Thermal Management System under Actual Driving Condition

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Lim, D.H.; Lee, M.-Y.; Lee, H.-S.; Kim, S.C. Performance evaluation of an in-wheel motor cooling system in an electric vehicle/hybrid electric vehicle. Energies 2014, 7, 961–971. [Google Scholar] [CrossRef]

- Lee, M.-Y.; Lee, D.-Y. Review on conventional air conditioning, alternative refrigerants and CO2 heat pumps for vehicles. Adv. Mech. Eng. 2013, 5. [Google Scholar] [CrossRef]

- Lee, H.S.; Lee, M.-Y. Cooling performance characteristics on mobile air-conditioning system for hybrid electric vehicles. Adv. Mech. Eng. 2013, 5. [Google Scholar] [CrossRef]

- Fronk, M.H.; Wetter, D.L.; Masten, D.A.; Bosco, A. PEM Fuel Cell System Solutions for Transportation; SAE Technical Paper, Paper No. 2000-01-0373; Society of Automotive Engineers: Warrendale, PA, USA, 2000. [Google Scholar]

- Yamashita, T.; Ishikawa, T.; Shimonsono, H.; Yamada, M.; Iwasai, M. The development of the cooling system for FCV. In Proceedings of the JAMA Annual Conference, Tokyo, Japan, 27 October 2004.

- Islam, M.R.; Shabani, B.; Rosengarten, G.; Andrews, J. The potential of using nanofluids in PEM fuel cell cooling systems: A review. Renew. Sustain. Energy Rev. 2015, 48, 523–539. [Google Scholar] [CrossRef]

- Zhang, G.; Kandlikar, S.G. A critical review of cooling techniques in proton exchange membrane fuel cell stakcs. Int. J. Hydrog. Energy 2012, 37, 2412–2429. [Google Scholar] [CrossRef]

- Kandlikar, S.G.; Lu, Z. Thermal management issues in a PEMFC stack—A brief review of current status. Appl. Therm. Eng. 2009, 29, 1276–1280. [Google Scholar] [CrossRef]

- Shabani, B.; Andrews, J. An experimental investigation of a PEM fuel cell to supply both heat and power in a solar-hydrogen RAPS system. Int. J. Hydrog. Energy 2011, 36, 5442–5452. [Google Scholar] [CrossRef]

- Lee, H.S.; Won, J.P.; Cho, C.W.; Kim, Y.C.; Lee, M.Y. Heating performance characteristics of stack coolant source heat pump using R744 for fuel cell electric vehicles. J. Mech. Sci. Technol. 2012, 26, 2065–2071. [Google Scholar] [CrossRef]

- Kim, S.C.; Kim, M.S.; Hwang, I.C.; Lim, T.W. Heating performance enhancement of a CO2 heat pump system recovering stack exhaust thermal energy in fuel cell vehicles. Int. J. Refrig. 2007, 30, 1215–1226. [Google Scholar] [CrossRef]

- Lee, M.-Y.; Lee, H.-S.; Won, H.-P. Characteristic evaluation on the cooling performance of an electrical air conditioning system using R744 for a fuel cell electric vehicle. Energies 2012, 5, 1371–1383. [Google Scholar] [CrossRef]

- Kim, S.C.; Won, J.P.; Park, Y.S.; Lim, T.W.; Kim, M.S. Performance evaluation of a stack cooling system using CO2 air conditioning system in fuel cell vehicles. Int. J. Refrig. 2009, 32, 70–77. [Google Scholar] [CrossRef]

- Hager, J.; Schickmair, L. Fuel Cell Vehicle Thermal Management System Simulation in Contrast to Conventional Vehicle Concepts; SAE Technical Paper, Paper No. 2005-01-2050; Society of Automotive Engineers: Warrendale, PA, USA, 2005. [Google Scholar]

- Ngy-Srun, A.P. Influence of Front End Vehicle, Fan and Fan Shroud on the Cooling System of Fuel Cell Electric Vehicle (FCEV). In Proceedings of the 18th International Electric Vehicle Symposium—EVS 18, Berlin, Germany, 20–24 October 2001.

- Kim, S.C.; Park, J.C.; Kim, M.S. Performance characteristics of a supplementary stack-cooling system for fuel-cell vehicles using a carbon dioxide air-conditioning unit. Int. J. Automot. Technol. 2010, 11, 893–900. [Google Scholar] [CrossRef]

- Ngy-Srun, A.P. Fuel Cell Electric Vehicle (FCEV) Cooling System versus Internal Combustion Engine Vehicle (ICEV) Cooling System. In Proceedings of the 19th International Battery, Hybrid and Fuel Cell Electric Vehicle Symposium & Exhibition—EVS 19, Busan, Korea, 19–23 October 2002.

- Lee, H.S.; Lee, M.Y.; Won, J.P. Numerical study on the thermal performance characteristics of the stack system for FCEV. J. Korea Acad. Ind. Coop. Soc. 2015, 16, 3708–3713. [Google Scholar] [CrossRef]

- Kuli: automotive thermal management software KULI. Available online: http://www.kuli-software.com/ (accessed on 2 February 2016).

- Back, Y.R. A design program for cooling system of vehicle (KULI). J. Korean Soc. Mech. Eng. 1999, 39, 26–27. [Google Scholar]

- Lee, H.S.; Won, J.P.; Kim, S.C.; Cho, C.W.; Park, Y.S.; Kim, S.K.; Suh, H.C. A study on performance analysis and evaluation for fuel cell electric vehicle stack cooling system. In Proceedings of the 15th Pacific Automotive Engineering Conference—APAC15, Hanoi, Vietnam, 26–28 October 2009; pp. 1–3.

- Lee, J.H.; Myung, N.S.; Kim, T.S. The effect of heat management on the performance of a PEM fuel cell system. In Proceedings of the KSME 2010 Fall Annual Meeting, Jeju, Korea, 3–5 November 2010; pp. 3685–3690.

- Lee, H.S.; Won, J.P.; Lee, E.W.; Lee, M.Y. Numerical investigation on cooling performances of the stack cooling system for a passenger FCEV. Int. J. Appl. Eng. Res. 2015, 10, 33726–33728. [Google Scholar]

| Components | Specifications | |

|---|---|---|

| Stack capacity of the fuel-cell electric vehicle | Capacity (kW) | 80.0 |

| Radiator | Capacity (kW) | 36.0 at 100 L/min |

| Type Core size (mm) | Multi-flow type W 690 × H 435 × D 26 | |

| Radiator Fan | Motor power (W) | 120 |

| Fan diameter (mm) | 320 | |

| Condenser | Capacity (kW) | 5.2 at 2 m/s |

| Type Core size (mm) | Multi-flow type W 590 × H 360 × D 16 | |

| Pump | Type | Electric-driven pump |

| Flow rate (L/min) | 200 at 5000 rpm, 202.6 kPa | |

| Parameters | Conditions | |

|---|---|---|

| Highway Mode | Uphill Mode | |

| Vehicle speed (km/h) | 100–120 | 30–50 |

| Ambient temperature (°C) | 35 | 35 |

| Inclination angle of the road (°) | 0 | 8–20 |

| Parameters | Conditions | |||

|---|---|---|---|---|

| Mode 1 | Mode 2 | Mode 3 | Mode 4 | |

| Vehicle speed (km/h) | 120 | 120 | 50 | 50 |

| Ambient temperature (°C) | 35 | 35 | 35 | 35 |

| Heat load of the fuel cell stack (kW) | 27 | 27 | 24 | 24 |

| Volume flow rate (L/min) | 120 | 120 | 120 | 120 |

| Inclination angle of the road (°) | 0 | 0 | 8 | 8 |

| Air-conditioning (A/C) system | Off | On | Off | On |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, H.-S.; Cho, C.-W.; Seo, J.-H.; Lee, M.-Y. Cooling Performance Characteristics of the Stack Thermal Management System for Fuel Cell Electric Vehicles under Actual Driving Conditions. Energies 2016, 9, 320. https://doi.org/10.3390/en9050320

Lee H-S, Cho C-W, Seo J-H, Lee M-Y. Cooling Performance Characteristics of the Stack Thermal Management System for Fuel Cell Electric Vehicles under Actual Driving Conditions. Energies. 2016; 9(5):320. https://doi.org/10.3390/en9050320

Chicago/Turabian StyleLee, Ho-Seong, Choong-Won Cho, Jae-Hyeong Seo, and Moo-Yeon Lee. 2016. "Cooling Performance Characteristics of the Stack Thermal Management System for Fuel Cell Electric Vehicles under Actual Driving Conditions" Energies 9, no. 5: 320. https://doi.org/10.3390/en9050320