Device Performance Improvement of Double-Pass Wire Mesh Packed Solar Air Heaters under Recycling Operation Conditions

Abstract

:1. Introduction

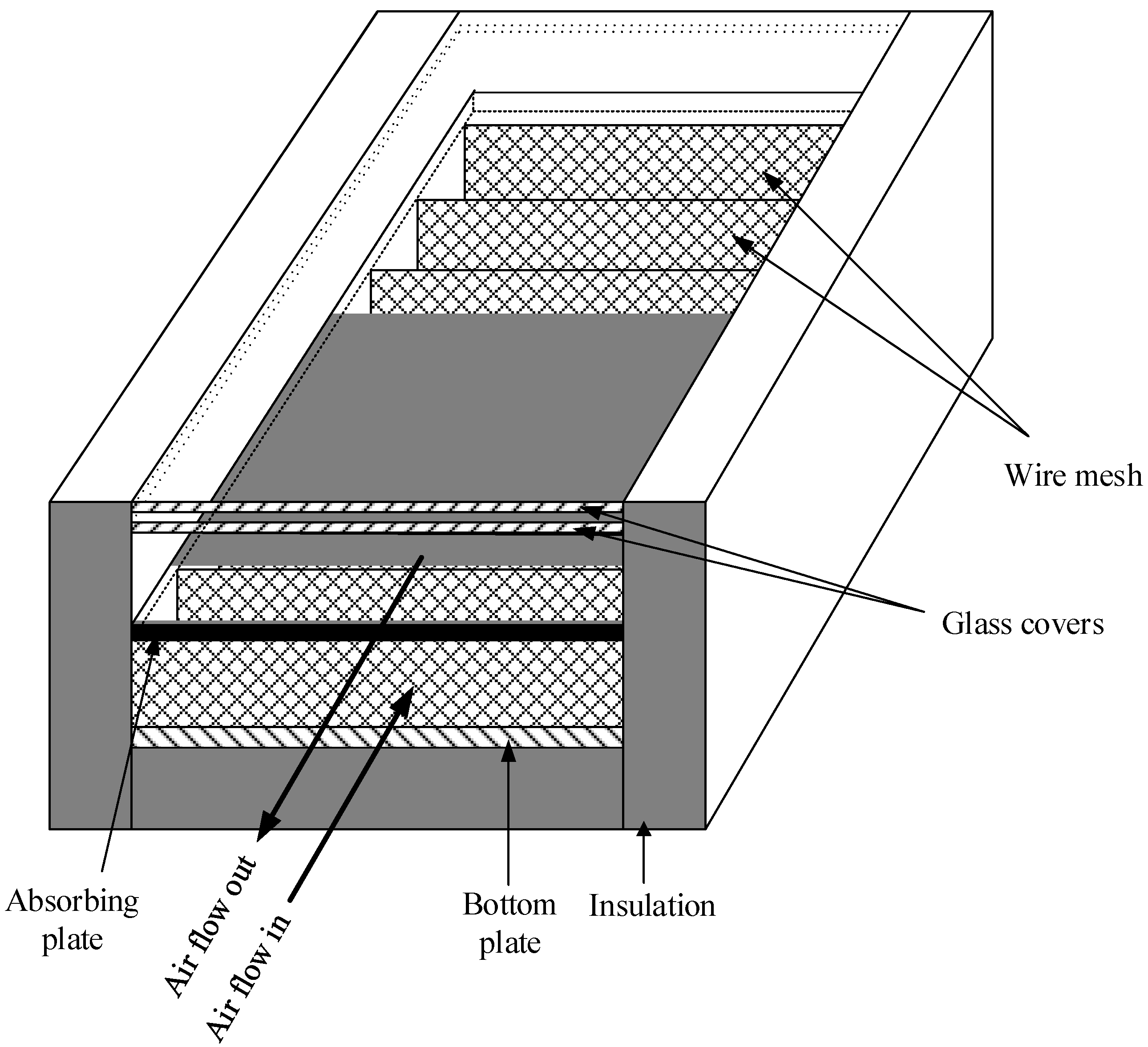

2. Temperature Distributions

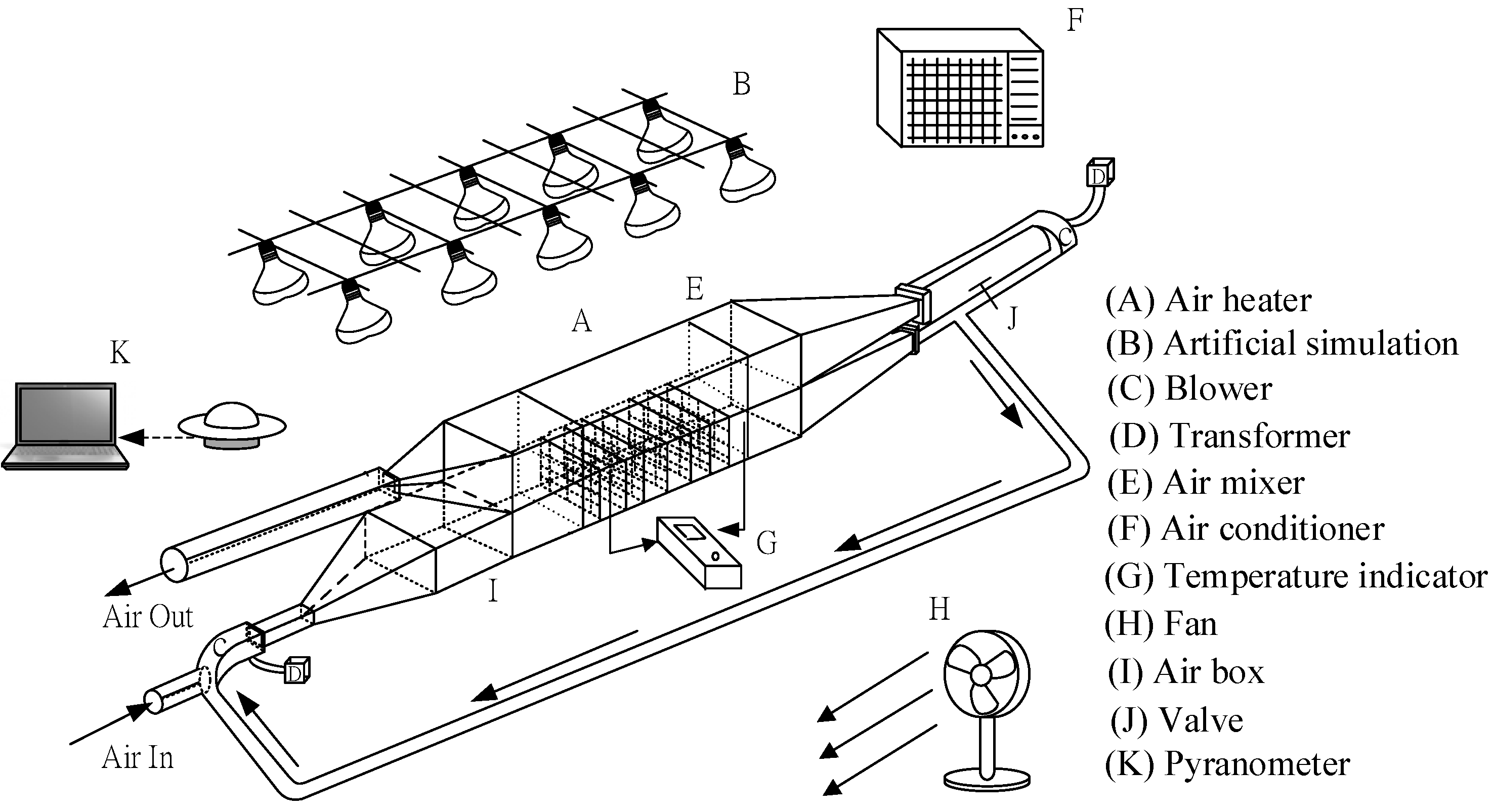

3. Experimental Studies

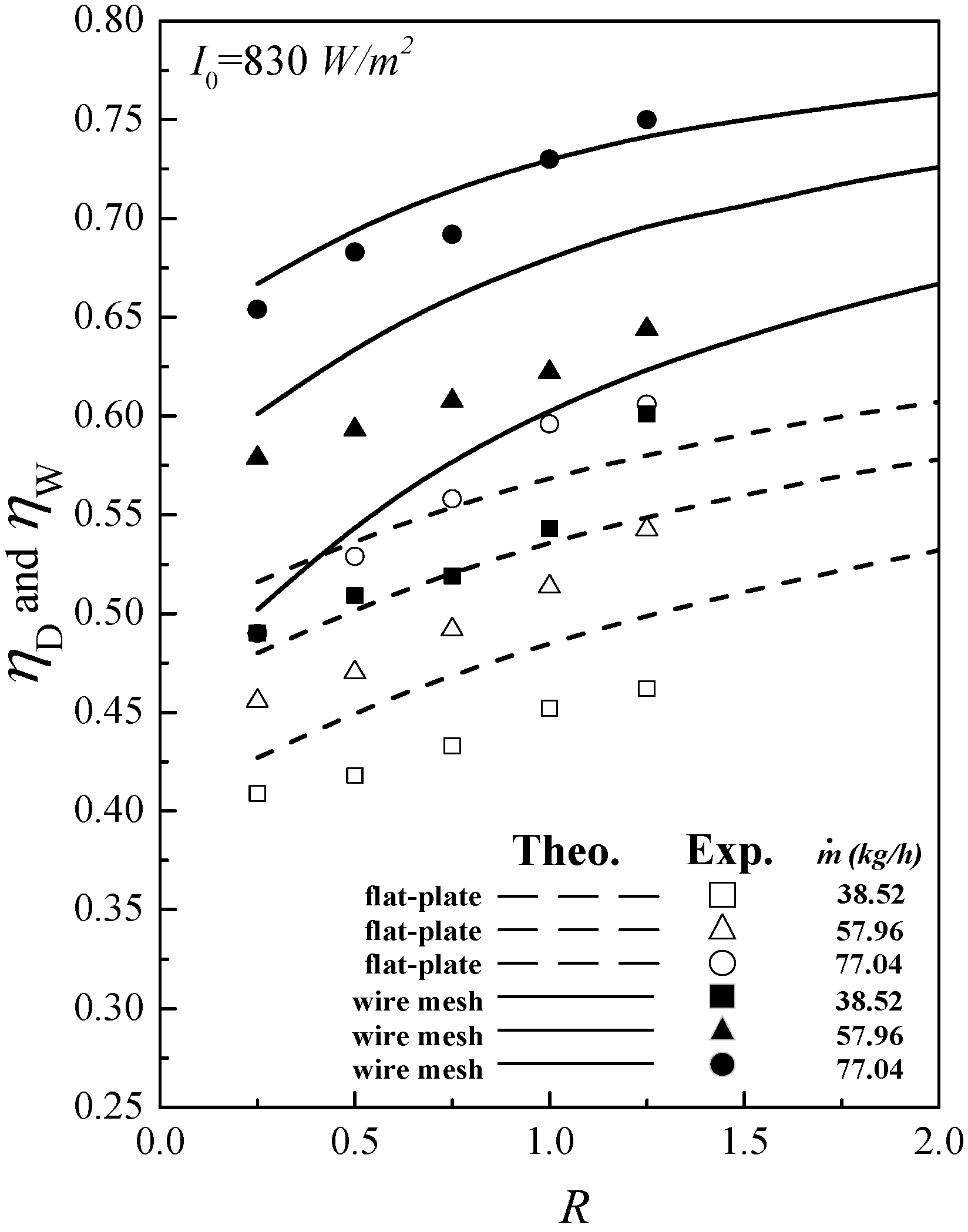

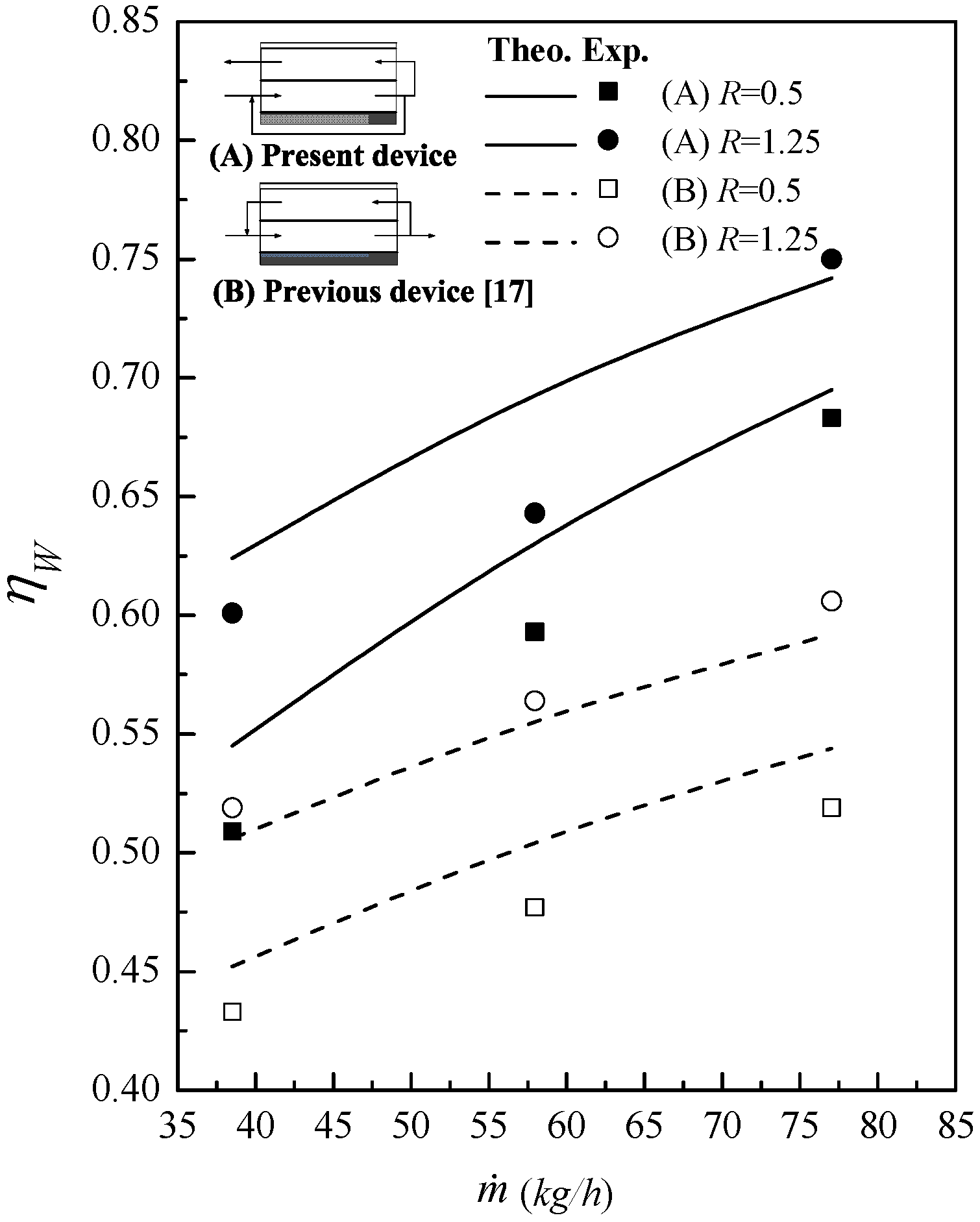

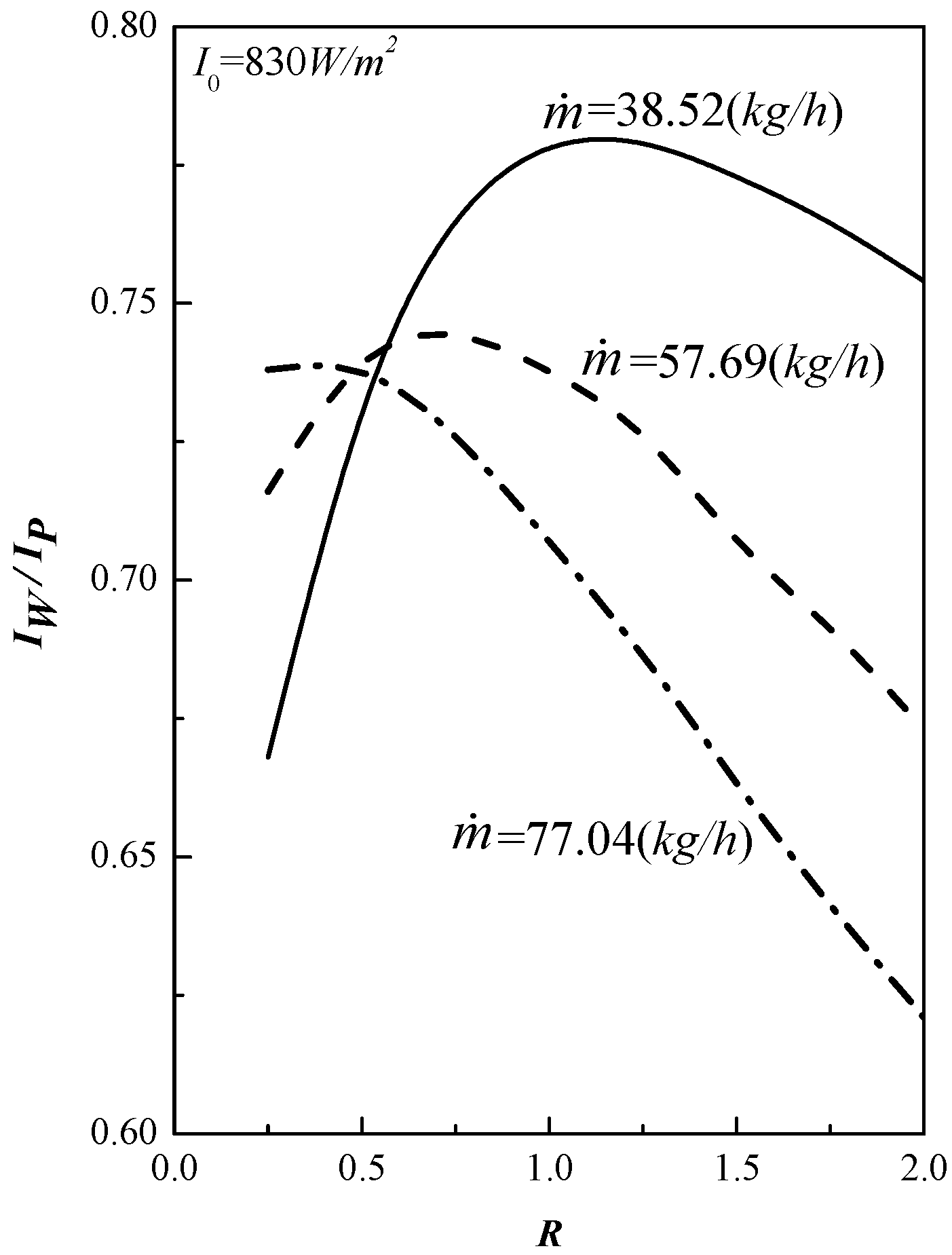

4. Results and Discussion

| Flat-Plate Type | Wire Mesh Packed | |||

|---|---|---|---|---|

| I0 (W/m2) | I0 (W/m2) | |||

| (kg/h) | 830 | 1100 | 830 | 1100 |

| 38.52 | 7.17 | 9.32 | 1.65 | 1.07 |

| 57.96 | 4.70 | 2.82 | 7.44 | 6.87 |

| 77.04 | 3.25 | 1.33 | 7.08 | 5.54 |

| m (kg/h) | R | I0 = 830 (W/m2) | I0 = 1100 (W/m2) | ||

|---|---|---|---|---|---|

| Flat-Plate | Wire Mesh | Flat-Plate | Wire Mesh | ||

| ID (%) | IW (%) | ID (%) | IW (%) | ||

| 38.52 | 0.25 | 38.19 | 62.46 | 39.16 | 63.11 |

| 0.5 | 45.63 | 76.38 | 46.60 | 77.67 | |

| 0.75 | 51.78 | 87.06 | 52.75 | 89.00 | |

| 1 | 56.96 | 95.15 | 57.93 | 98.06 | |

| 1.25 | 61.49 | 101.94 | 62.46 | 105.18 | |

| 1.5 | 65.37 | 107.12 | 66.34 | 110.68 | |

| 1.75 | 68.93 | 111.97 | 69.90 | 115.53 | |

| 2 | 72.17 | 115.86 | 72.82 | 119.42 | |

| 57.96 | 0.25 | 29.73 | 62.43 | 31.08 | 64.59 |

| 0.5 | 35.68 | 71.62 | 37.03 | 74.59 | |

| 0.75 | 40.81 | 78.65 | 41.89 | 81.89 | |

| 1 | 44.86 | 83.78 | 45.95 | 87.57 | |

| 1.25 | 48.38 | 88.38 | 49.46 | 91.89 | |

| 1.5 | 51.35 | 90.81 | 52.43 | 95.41 | |

| 1.75 | 54.05 | 94.05 | 55.14 | 98.11 | |

| 2 | 56.22 | 96.22 | 57.30 | 100.27 | |

| 77.04 | 0.25 | 23.74 | 59.95 | 24.94 | 61.87 |

| 0.5 | 28.78 | 66.67 | 29.98 | 69.31 | |

| 0.75 | 32.85 | 71.46 | 34.05 | 74.34 | |

| 1 | 36.45 | 75.06 | 37.41 | 78.18 | |

| 1.25 | 39.09 | 77.94 | 40.29 | 81.29 | |

| 1.5 | 41.73 | 79.86 | 42.69 | 83.45 | |

| 1.75 | 43.88 | 81.53 | 44.60 | 85.13 | |

| 2 | 45.56 | 82.97 | 46.52 | 86.57 | |

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Nomenclature

| = surface area of the collector = LW (m2) |

| = specific heat of air at constant pressure (J/(kg·K)) |

| = deviation of the experimental measurements from theoretical predictions, defined in Equation (8) |

| = convection coefficient between the bottom and lower subchannel (W/m2·K) |

| = convection coefficient between the absorber plate and upper subchannel (W/m2·K) |

| = radiation heat transfer coefficient between cover 1 and absorber plate (W/m2·K) |

| = radiation heat transfer coefficient between absorber plate and bottom plate (W/m2·K) |

| = height of both upper and lower channels (m) |

| = incident solar radiation (W/m2) |

| = percentage of collector efficiency improvement in flat-plate air heater, defined in Equation (11) |

| = collector efficiency improvement index, defined in Equation (12) |

| = power consumption increment, defined in Equation (13) |

| = channel length (m) |

| = total air mass flow rate (kg/h) |

| = number of experimental measurements |

| = power consumption of the double-pass air heater (W) |

| = power consumption of downward-type single-pass device (W) |

| = useful energy gained by air (W) |

| = recycle ratio |

| = the precision index of an individual measurement |

| = the mean value of |

| = inlet air temperature (K) |

| = the mixing temperature of the subchannel a at x = 0 (K) |

| = the temperature of the subchannel a at x = L (K) |

| = the temperature of the subchannel b at x = 0 (K) |

| = the temperature of the subchannel b at x = L (K) |

| = axial fluid temperature distribution in the lower subchannel (K) |

| = axial fluid temperature distribution in the upper subchannel (K) |

| = loss coefficient from the bottom of solar air heater to the ambient environment (W/m2·K) |

| = loss coefficient from the surfaces of edges and the bottom of the solar collector to the ambient environment (W/m2·K) |

| = loss coefficient from the inner cover to the ambient environment (W/m2·K) |

| = loss coefficient from the top of solar air heater to the ambient environment (W/m2·K) |

| = width of both upper and lower subchannels (m) |

| = axial coordinate (m) |

| Greek Letters |

| = collector efficiency of the flat-plate double-pass device |

| = collector efficiency of the downward type single-pass device |

| = collector efficiency of the wire mesh packed solar air heater |

| = experimental data of collector efficiency |

| = the mean value of the experimental data |

| = theoretical prediction of collector efficiency |

| = dimensionless channel length |

Appendix

References

- Razika, I.; Nabila, I.; Madani, B.; Zohra, H.F. The effects of volumetric flow rate and inclination angle on the performance of a solar thermal collector. Energy Convers. Manag. 2014, 78, 931–937. [Google Scholar] [CrossRef]

- Al-Kayiem, H.H.; Yassen, T.A. On the natural convection heat transfer in a rectangular passage solar air heater. Sol. Energy 2015, 112, 310–318. [Google Scholar] [CrossRef]

- El-Sebaii, A.A.; Al-Snani, H. Effect of selective coating on thermal performance of flat plate solar air heaters. Energy 2010, 35, 1820–1828. [Google Scholar] [CrossRef]

- Vaziri, R.; Ilkan, M.; Egelioglu, F. Experimental performance of performance of perforated glazed solar air heaters and unglazed transpired solar air heater. Sol. Energy 2015, 119, 251–260. [Google Scholar] [CrossRef]

- Kreith, F.; Kreider, J.F. Principles of Solar Engineering; McGraw-Hill: New York, NY, USA, 1978. [Google Scholar]

- Duffie, J.A.; Beckman, W.A. Solar Engineering of Thermal Processes, 3rd ed.; Wiley: New York, NY, USA, 1980. [Google Scholar]

- Gao, W.; Lin, W.; Liu, T.; Xia, C. Analytical and experimental studies on the thermal performance of cross-corrugated and flat-plate solar air heaters. Appl. Energy 2007, 84, 425–441. [Google Scholar] [CrossRef]

- Ho, C.D.; Yeh, H.M.; Sheu, W.S. An analytical study of heat and mass transfer through a parallel-plate channel with recycle. Int. J. Heat Mass Transfer 1998, 41, 2589–2599. [Google Scholar] [CrossRef]

- Ho, C.D.; Yang, W.Y. An analytical study of heat-transfer efficiency in laminar counterflow concentric circular tubes with external refluxes. Chem. Eng. Sci. 2003, 58, 1235–1250. [Google Scholar] [CrossRef]

- Fudholi, A.; Sopian, K.; Ruslan, M.H.; Othman, M.Y.; Ruslan, M.H.; Bakhtyar, B. Energy analysis and improvement potential of finned double-pass solar collector. Energy Convers. Manag. 2013, 75, 234–240. [Google Scholar] [CrossRef]

- Singh, S.; Dhiman, P. Recyclic double pass packed bed solar air heaters. Int. J. Thermal Sci. 2015, 87, 215–227. [Google Scholar]

- Garg, H.P.; Sharma, V.K.; Bhargava, A.K. Theory of multiple-pass solar air heaters. Energy 1985, 10, 589–599. [Google Scholar] [CrossRef]

- Wijeysundera, N.E.; Ah, L.L.; Tjioe, L.E. Thermal performance study of two-pass solar air heaters. Sol. Energy 1982, 28, 363–370. [Google Scholar] [CrossRef]

- Ho, C.D.; Yeh, C.W.; Hsieh, S.M. Improvement in device performance of multi-pass flat-plate solar air heaters with external recycle. Renew. Energy 2005, 30, 1601–1621. [Google Scholar] [CrossRef]

- Ho, C.D.; Yeh, H.M.; Wang, R.C. Heat-transfer enhancement in double-pass flat-plate solar air heaters with recycle. Energy 2005, 30, 2796–2817. [Google Scholar] [CrossRef]

- Moffat, R.J. Describing the uncertainties in experimental results. Exp. Therm. Fluid Sci. 1988, 1, 3–17. [Google Scholar] [CrossRef]

- Ho, C.D.; Lin, C.S.; Chuang, Y.C.; Chao, C.C. Performance improvement of wire mesh packed double-pass solar air heaters with external recycle. Renew. Energy 2013, 57, 479–489. [Google Scholar] [CrossRef]

- Prasad, S.B.; Saini, J.S.; Singh, K.M. Investigation of heat transfer and friction characteristics of packed bed solar air heater using wire mesh as packing material. Sol. Energy 2009, 83, 773–783. [Google Scholar] [CrossRef]

- Bird, R.B.; Stewart, W.E.; Lightfoot, E.N. Transport Phenomena, 2nd ed.; Wiley: New York, NY, USA, 2007. [Google Scholar]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ho, C.-D.; Chang, H.; Lin, C.-S.; Chao, C.-C.; Tien, Y.-E. Device Performance Improvement of Double-Pass Wire Mesh Packed Solar Air Heaters under Recycling Operation Conditions. Energies 2016, 9, 68. https://doi.org/10.3390/en9020068

Ho C-D, Chang H, Lin C-S, Chao C-C, Tien Y-E. Device Performance Improvement of Double-Pass Wire Mesh Packed Solar Air Heaters under Recycling Operation Conditions. Energies. 2016; 9(2):68. https://doi.org/10.3390/en9020068

Chicago/Turabian StyleHo, Chii-Dong, Hsuan Chang, Chun-Sheng Lin, Chun-Chieh Chao, and Yi-En Tien. 2016. "Device Performance Improvement of Double-Pass Wire Mesh Packed Solar Air Heaters under Recycling Operation Conditions" Energies 9, no. 2: 68. https://doi.org/10.3390/en9020068