Numerical Models for Viscoelastic Liquid Atomization Spray

Abstract

:1. Introduction

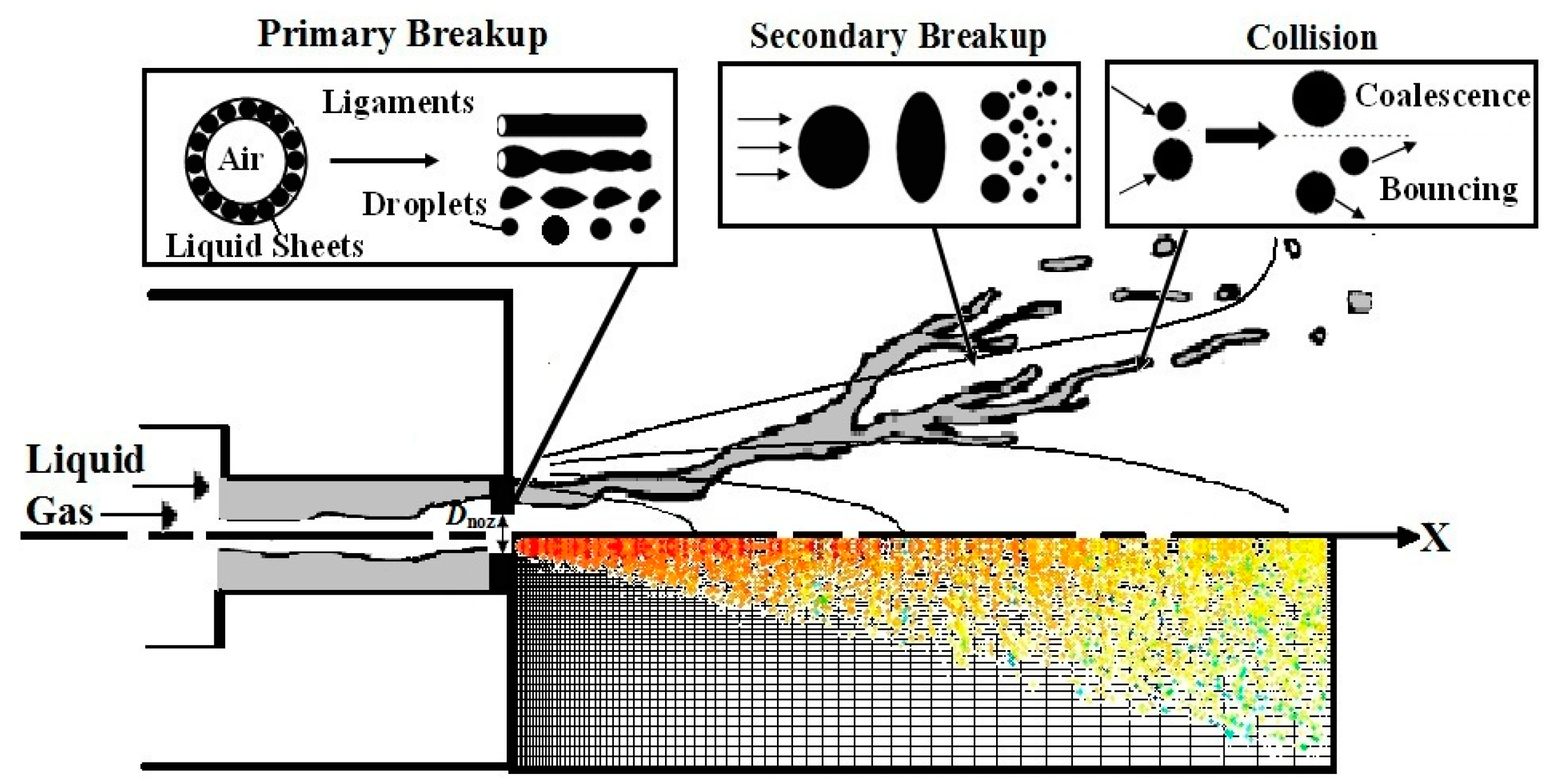

2. Mathematical Models

2.1. Sub-Model of Primary Atomization

2.2. Sub-Model of Droplet-Gas Two-Phase Flow

2.2.1. Gas Phase

2.2.2. Liquid Phase

Secondary Atomization

Droplets Collision

3. Numerical Setup

4. Results and Discussion

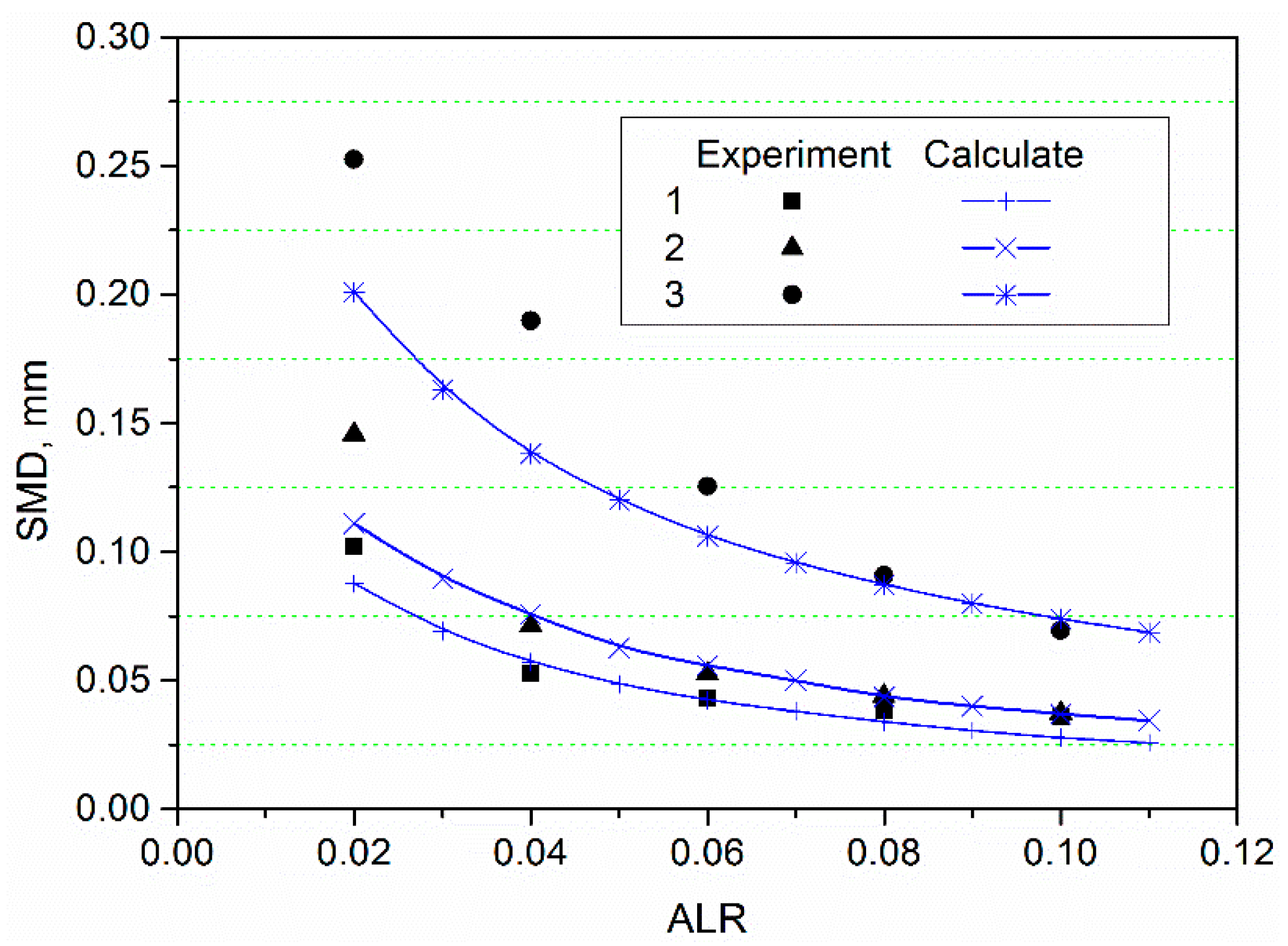

4.1. Validation of Primary Atomization

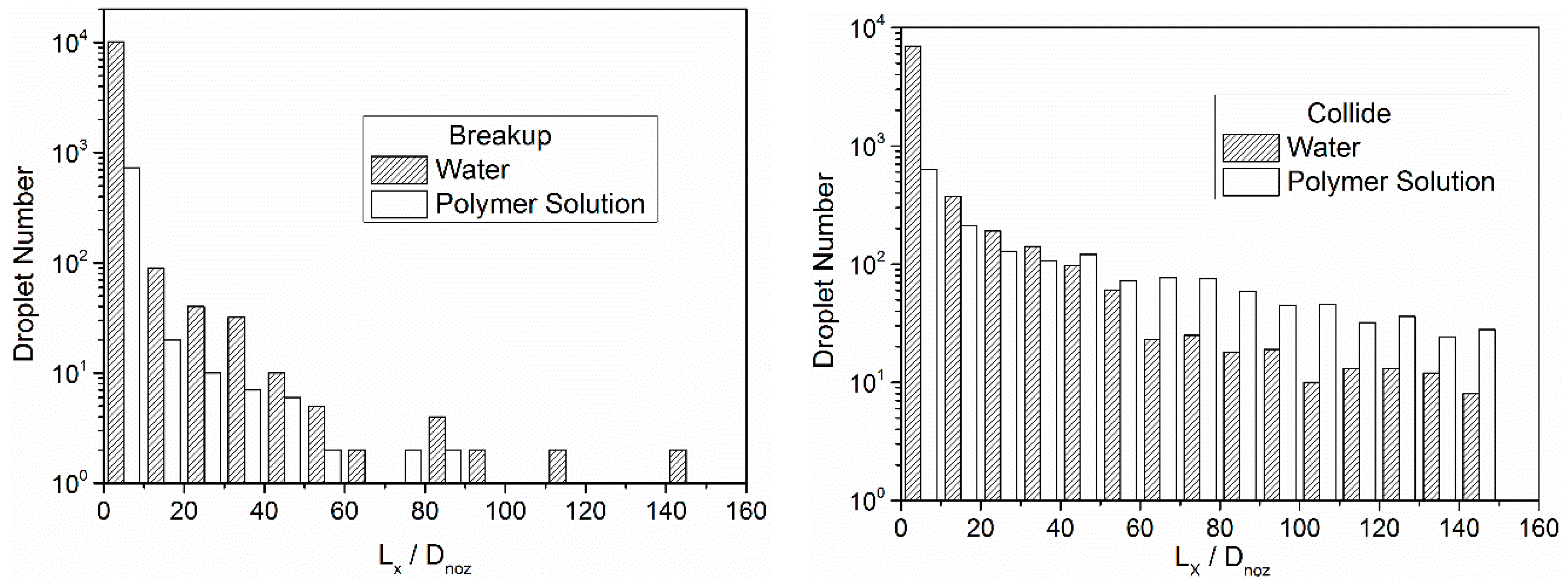

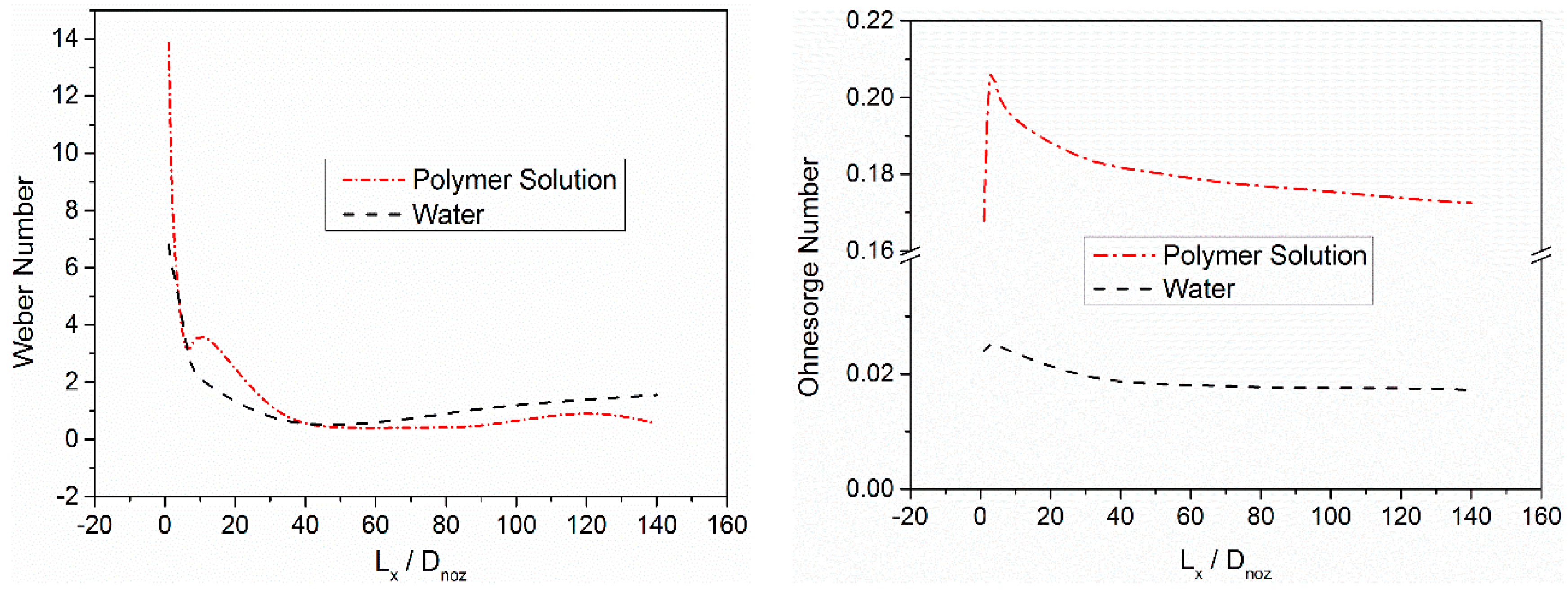

4.2. Evolution of Spray Field

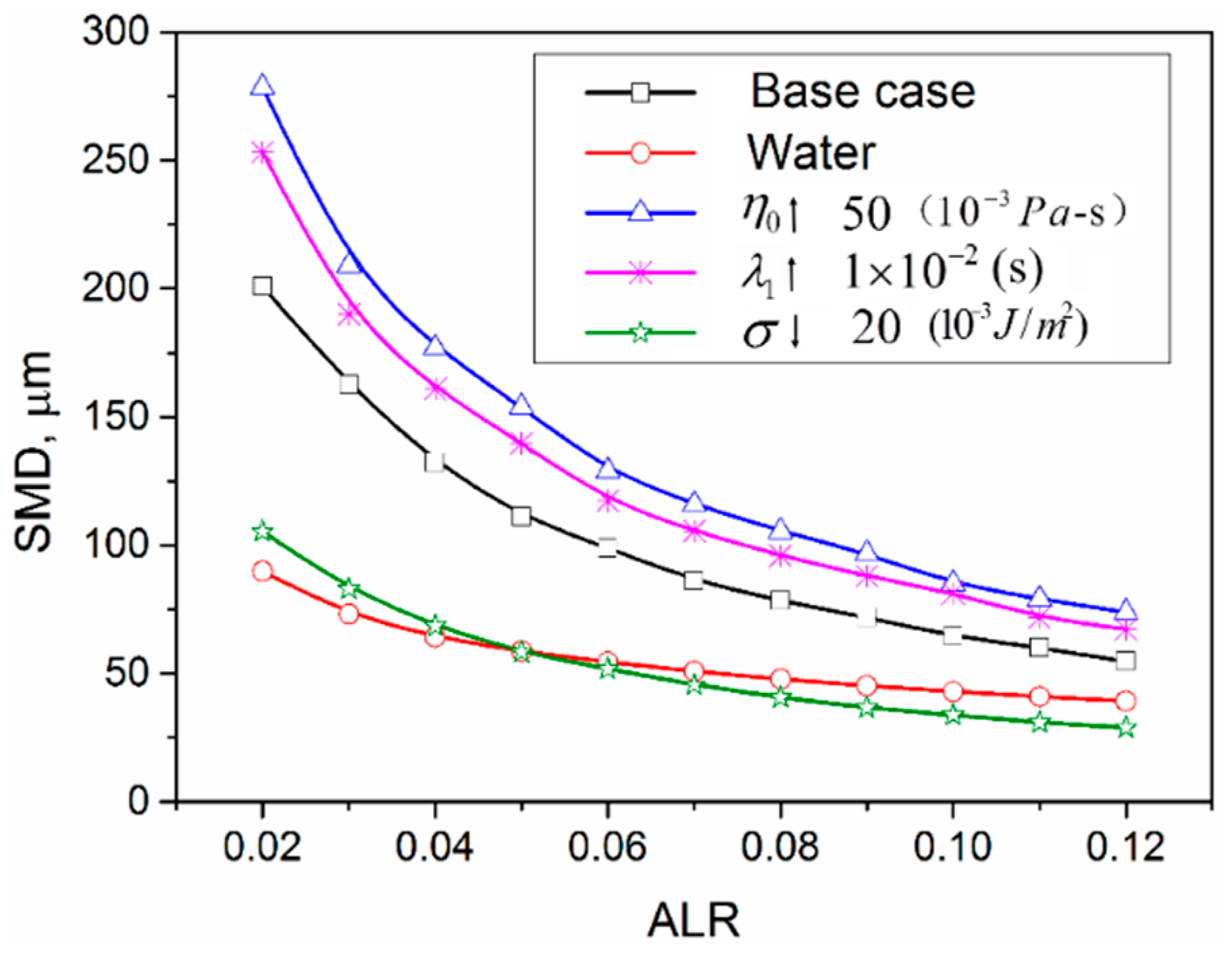

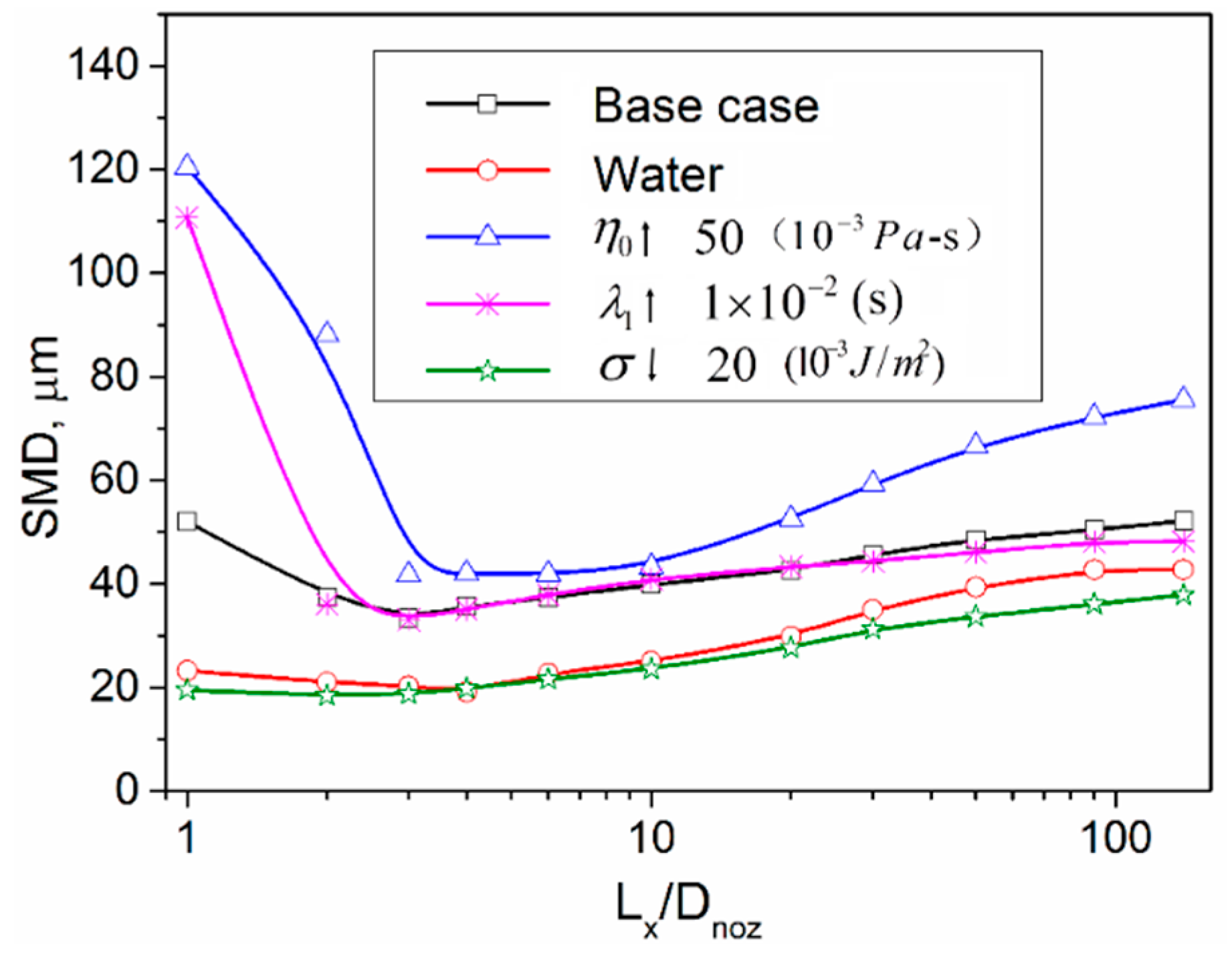

4.3. Effects of Viscoelastic Parameters

5. Conclusions

- (1)

- Based on the comparison with experimental data and the predicted results of other dispersion relation, the primary model using Joseph’s relation effectively captured the influence of rheological properties on the breakup process of polymer solution and to quantitatively predict the resulting droplet sizes.

- (2)

- The evolutionary trend of droplet mean diameter, Weber number and Ohnesorge number of viscoelastic liquids along with axial direction were qualitatively similar to that of Newtonian liquids. The SMD for the case of polymer solutions were obviously larger than that of water throughout the spray field. While, the gap of SMD between water and polymer solution became shorten along with the development of the jet. This phenomenon indicated that the mean size of polymer solution increased more gently than that of water at the axial distance , which benefited the stable control of the desirable size in the applications.

- (3)

- The changes of Weber and Ohnesorge number for polymer solution were more dramatic than that of water, since the viscosity of the viscoelastic liquid was influenced by the relative velocity of gas and droplets. Besides, the distribution range of water was about 40% larger than that of polymer solution in present study, which indicated the spray angle became narrow for the viscoelastic liquids.

- (4)

- In primary atomization, the surface tension was the dominating physical property for viscoelastic liquid rather than relaxation time and zero shear viscosity. When the finer atomization effects were desirable, it was important to select solvents with lower surface tension for the polymer solutions, while, concerning the evolution of atomization spray, larger relaxation time and zero shear viscosity increased droplet SMD significantly. The zero shear viscosity was effective throughout the jet region, while the effect of relaxation time became weaken at the downstream of the spray field.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Mallory, J.A. Jet Impingement and Primary Atomization of Non-Newtonian Liquids. Ph.D. Thesis, Purdue University, West Lafayette, IN, USA, 2012. [Google Scholar]

- Yoo, H.; Kim, C. Generation of inkjet droplet of non-Newtonian fluid. Rheol. Acta 2013, 52, 313–325. [Google Scholar] [CrossRef]

- Hoath, S.D.; Vadillo, D.C.; Harlen, O.G.; Mcllroy, C.; Morrison, N.F.; Hsiao, W.; Tuladhar, T.R.; Jung, S.; Martin, G.D.; Hutchings, I.M. Inkjet printing of weakly elastic polymer solution. J. Non-Newton. Fluid Mech. 2014, 205, 1–10. [Google Scholar] [CrossRef]

- Petersen, F.J.; Wørts, O.; Schæfer, T.; Sojka, P.E. Effervescent atomization of aqueous polymer solutions and dispersions. Pharm. Dev. Technol. 2001, 6, 201–210. [Google Scholar] [CrossRef] [PubMed]

- Pawlowski, L. Suspension and solution thermal spray coatings. Surf. Coat. Technol. 2009, 203, 2807–2829. [Google Scholar] [CrossRef]

- Bartolo, D.; Boudaoud, A.; Narcy, G.; Bonn, D. Dynamics of non-newtonian droplets. Phys. Rev. Lett. 2007, 99, 174502. [Google Scholar] [CrossRef] [PubMed]

- Schowalter, W.R. Mechanics of Non-Newtonian Fluids; Pergamon Press: Oxford, UK, 1978. [Google Scholar]

- Oldroyd, O.G. Non-Newtonian effects in steady motion of some idealized elastic viscous fluids. Proc. R. Soc. 1958, 279, A245. [Google Scholar]

- Li, L.K.B.; Dressler, D.M.; Green, S.I.; Davy, M.H.; Eadie, D.T. Experiments on air-blast atomization of viscoelastic liquids, Part 1: Quiescent conditions. At. Sprays 2009, 19, 157–190. [Google Scholar] [CrossRef]

- Dumouchel, C. On the experimental investigation on primary atomization of liquid streams. Exp. Fluids 2008, 45, 371–422. [Google Scholar] [CrossRef]

- Aliseda, A.; Hopfinger, E.J.; Lasheras, J.C.; Kremer, D.M.; Berchielli, A.; Connolly, E.K. Atomization of viscous and non-newtonian liquids by a coaxial, high-speed gas jet: Experiments and droplet size modeling. Int. J. Multiph. Flow 2008, 34, 161–175. [Google Scholar] [CrossRef]

- Harrison, G.M.; Mun, R.P.; Cooper, G.; Boger, D.V. A note on the effect of polymer rigidity and concentration on spray atomization. J. Non-Newton. Fluid Mech. 1999, 85, 93–104. [Google Scholar] [CrossRef]

- Chao, K.K.; Child, C.A.; Grens, E.A., II; Williams, M.C. Anti-misting action of polymeric additives in jet fuels. AIChE J. 1984, 30, 111–120. [Google Scholar] [CrossRef]

- Sirignano, W.A.; Mehring, C. Review of theory of distortion and disintegration of liquid streams. Prog. Energy Combust. Sci. 2000, 26, 609–655. [Google Scholar] [CrossRef]

- Middleman, S. Stability of a viscoelastic jet. Chem. Eng. Sci. 1965, 20, 1037–1040. [Google Scholar] [CrossRef]

- Goren, S.L.; Gorttlieb, M. Surface-tension driven breakup of viscoelastic liquid threads. J. Fluid Mech. 1982, 120, 245–266. [Google Scholar] [CrossRef]

- Joseph, G.E.; Funda, B.T. Rayleigh-Taylor instability of viscoelastic drops at high Weber number. J. Fluid Mech. 2002, 453, 109–132. [Google Scholar] [CrossRef]

- Yang, L.J.; Tong, M.X.; Fu, Q.F. Linear stability analysis of a three-dimensional viscoelastic liquid jet surrounded by a swirling air stream. J. Non-Newton. Fluid Mech. 2013, 191, 1–13. [Google Scholar] [CrossRef]

- Fuster, D.; Bagué, A.; Boeck, T.; Le Moyner, L.; Leboissetier, A.; Popinet, S.; Scardovelli, R.; Zaleski, S. Simulation of primary atomization with an octree adaptive mesh refinement and VOF method. Int. J. Multiph. Flow 2009, 35, 550–565. [Google Scholar] [CrossRef]

- Villermaux, E. Fragmentation. Annu. Rev. Fluid Mech. 2007, 39, 419–446. [Google Scholar] [CrossRef]

- Gorokhovski, M.; Herrmann, M. Modeling primary atomization. Annu. Rev. Fluid Mech. 2008, 40, 343–366. [Google Scholar] [CrossRef]

- Zhu, C.; Ertl, M.; Weigand, B. Numerical investigation on the primary breakup of an inelastic non-Newtonian liquid jet with inflow turbulence. Phys. Fluids 2013, 25, 083102. [Google Scholar] [CrossRef]

- Stelter, M.; Brenn, G.; Durst, F. The influence of viscoelastic fluid properties on spray formation from flat-fan and pressure-swirl atomizers. At. Sprays 2002, 12, 299–327. [Google Scholar] [CrossRef]

- Dexter, R.W. Measurement of extensional viscosity of polymer solutions and its effects on atomization from a spray nozzle. At. Sprays 1996, 6, 167–191. [Google Scholar] [CrossRef]

- Hartranft, T.J.; Settles, G.S. Sheet atomization of non-Newtonian liquids. At. Sprays 2003, 13, 191–221. [Google Scholar] [CrossRef]

- Mun, R.P.; Young, B.W.; Boger, D.V. Atomization of dilute polymer solutions in agricultural spray nozzles. J. Non-Newton. Fluid Mech. 1999, 83, 163–178. [Google Scholar] [CrossRef]

- Rivera, C.L. Secondary Breakup of Inelastic Non-Newtonian Liquid Drops. Ph.D. Thesis, Purdue University, West Lafayette, IN, USA, 2010. [Google Scholar]

- Dechelette, A.; Campanellab, O.; Corvalanc, C.; Sojka, P.E. An experimental investigation on the breakup of surfactant-laden non-Newtonian jets. Chem. Eng. Sci. 2011, 66, 6367–6374. [Google Scholar] [CrossRef]

- Ma, Y.; Bai, F.; Chang, Q.; Yi, J.; Jiao, K.; Du, Q. An experimental study on the atomization characteristics of impinging jets of power law fluid. J. Non-Newton. Fluid Mech. 2015, 217, 49–57. [Google Scholar] [CrossRef]

- Xue, Z.; Carlos, M.C.; Dravid, V.; Sojka, P.E. Breakup of shear-thinning liquid jets with surfactants. Chem. Eng. Sci. 2008, 63, 1842–1849. [Google Scholar] [CrossRef]

- Mallory, J.; Sojka, P.E. On the primary atomization of non-Newtonian imping jets: Volume II linear stability theory. At. Sprays 2014, 24, 525–554. [Google Scholar] [CrossRef]

- Ashgriz, N. Handbook of Atomization and Sprays: Theory and Applications; Springer: New York, NY, USA, 2011. [Google Scholar]

- Broniarz-Press, L.; Ochowiak, M.; Woziwodzki, S. Atomization of PEO aqueous solutions in effervescent atomizers. Int. J. Heat Fluid Flow 2010, 31, 651–658. [Google Scholar] [CrossRef]

- Lund, M.T.; Jian, C.Q. The influence of atomizing gas molecular weight on low mass flow-rate effervescent atomization performance. J. Fluids Eng. 1998, 120, 750–754. [Google Scholar] [CrossRef]

- Bird, R.B. Useful non-Newtonian models. Annu. Rev. Fluid Mech. 1976, 8, 13–34. [Google Scholar] [CrossRef]

- Amsden, A.A.; O’Rourke, P.J.; Butler, T.D. KIVA-II: A Computer Program for Chemically Reactive Flows with Sprays; Technical Report LA-11560-MS; Los Alamos National Laboratory: Los Alamos, NM, USA, 1980. [Google Scholar]

- Denn, M.M. Issues in viscoelastic fluid mechanics. Annu. Rev. Fluid Mech. 1999, 22, 13–32. [Google Scholar] [CrossRef]

- Brodkey, R.S. The Phenomena of Fluid Motions, Addison-Wesley Series in Chemical Engineering; Addison-Wesley: New York, NY, USA, 1967. [Google Scholar]

- Xiong, H.B.; Lin, J.Z.; Zhu, Z.F. Three-dimensional simulation of effervescent atomization spray. At. Sprays 2009, 19, 1–16. [Google Scholar] [CrossRef]

- Lin, J.Z.; Qian, L.J.; Xiong, H.B.; Chan, T.L. Effects of operating conditions on droplet deposition onto surface of atomization impinging spray. Surf. Coat. Technol. 2009, 203, 1733–1740. [Google Scholar] [CrossRef]

- Lefebvre, A.H. Atomization and Sprays; Hemisphere Publishing Corporation: Carlbad, CA, USA, 1989. [Google Scholar]

- Geckler, S.C.; Sojka, P.E. Effervescent atomization of viscoelastic liquids: Experiments and modeling. J. Fluids Eng. 2008, 130, 061303. [Google Scholar] [CrossRef]

- Liu, L.S. Experimental and Theoretical Investigation on the Characteristics and Two-Phase Spray Flow Field of Effervescent Atomizers. Ph.D. Thesis, Tianjing University, Tianjin, China, 2001. [Google Scholar]

- Mansour, A.; Chigier, N. Air-Blast atomization of Non-Newtonian liquids. J. Non-Newton. Fluid Mech. 1995, 58, 161–194. [Google Scholar] [CrossRef]

| Type | Location | Conditions | |

|---|---|---|---|

| Open | 1 | Line BC | : , , are assigned the same as that in ambient |

| : , () | |||

| 2 | Line CD | : , , are assigned the same as that in ambient | |

| : , | |||

| 3 | Line DE | : , , are assigned the same as that in ambient | |

| : , | |||

| Wall | Line AB | ; ; turbulent wall function | |

| Inlet | Line OA | Data from primary breakup sub-model | |

| Axis | x = 0 | (, : at from the centerline); | |

| Periodic | θ = 2π | Circular direction: periodic boundary conditions | |

| Code | Polymer Concentration | Zero Shear Viscosity | Relaxation Time | Surface Tension |

|---|---|---|---|---|

| mPa·s | s | 10−3 J/m2 | ||

| 1 | 0.001% | 11 | 2.8 × 10−7 | 65.1 |

| 2 | 0.01% | 11.1 | 1.4 × 10−5 | 62.6 |

| 3 | 0.15% | 15.4 | 2.06 × 10−4 | 62.6 |

| Parameters | Value | Parameters | Value |

|---|---|---|---|

| 1 | 15 | ||

| 65 | 10 | ||

| 0.06 | 2.0 × 10-6 | ||

| 10 | 0.35 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qian, L.; Lin, J.; Bao, F. Numerical Models for Viscoelastic Liquid Atomization Spray. Energies 2016, 9, 1079. https://doi.org/10.3390/en9121079

Qian L, Lin J, Bao F. Numerical Models for Viscoelastic Liquid Atomization Spray. Energies. 2016; 9(12):1079. https://doi.org/10.3390/en9121079

Chicago/Turabian StyleQian, Lijuan, Jianzhong Lin, and Fubing Bao. 2016. "Numerical Models for Viscoelastic Liquid Atomization Spray" Energies 9, no. 12: 1079. https://doi.org/10.3390/en9121079

APA StyleQian, L., Lin, J., & Bao, F. (2016). Numerical Models for Viscoelastic Liquid Atomization Spray. Energies, 9(12), 1079. https://doi.org/10.3390/en9121079