2.1. Heating System Design

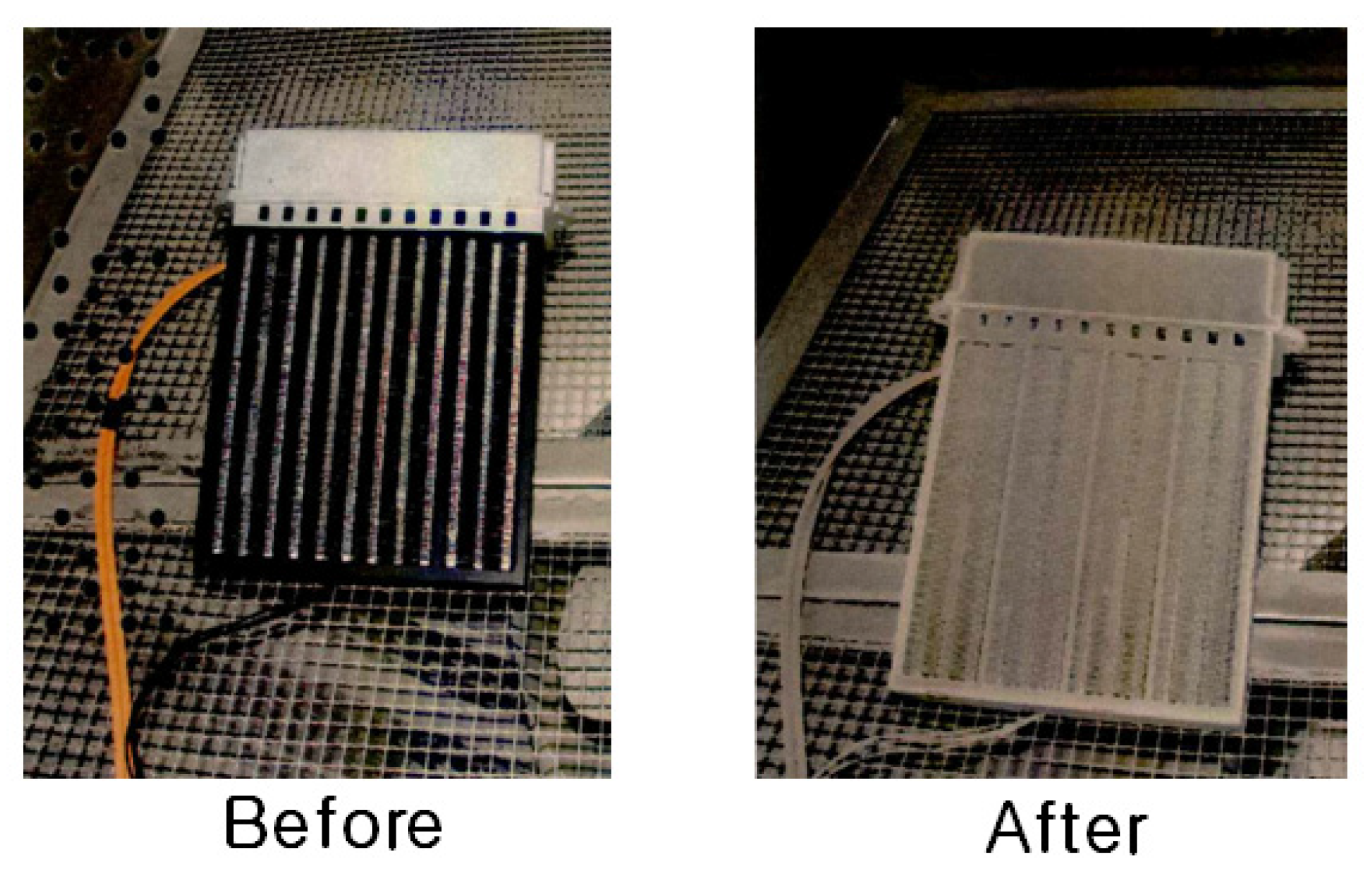

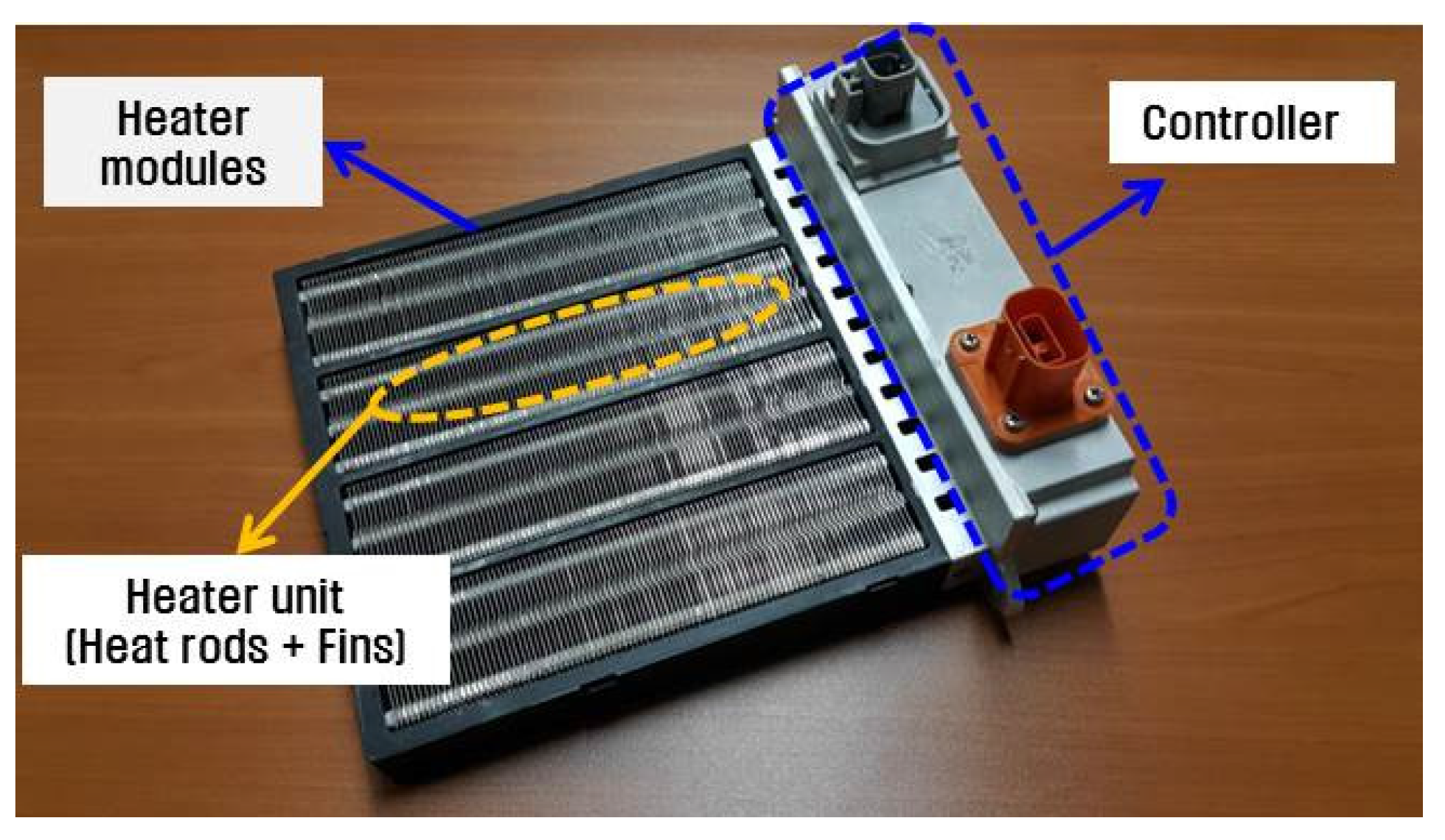

We designed and fabricated a high-voltage modularized and integrated heating system. The system contains four heater modules—with each unit comprising heating rods and radiation fins—and an integrated controller, which is used to regulate the power input and operate the heater. The system is shown in

Figure 1 and the specifications are presented in

Table 1. The main feature of the system is its proactive production response with respect to the heating capacity, which is afforded by the modular design. Compared to a conventional heating system, in which the heater and controller are separately configured, the developed system is 20% lighter. It also has the advantage of less high-voltage cable work between the controller and heater for its installation inside a vehicle.

Figure 1.

Modularized and integrated high-voltage heating system.

Figure 1.

Modularized and integrated high-voltage heating system.

Table 1.

Specifications of the high-voltage heating system.

Table 1.

Specifications of the high-voltage heating system.

| Parameter | Value |

|---|

| Core size (mm3) | 200 × 210 × 28 |

| Weight (g) | 2200 |

| Input voltage (V) | 330 |

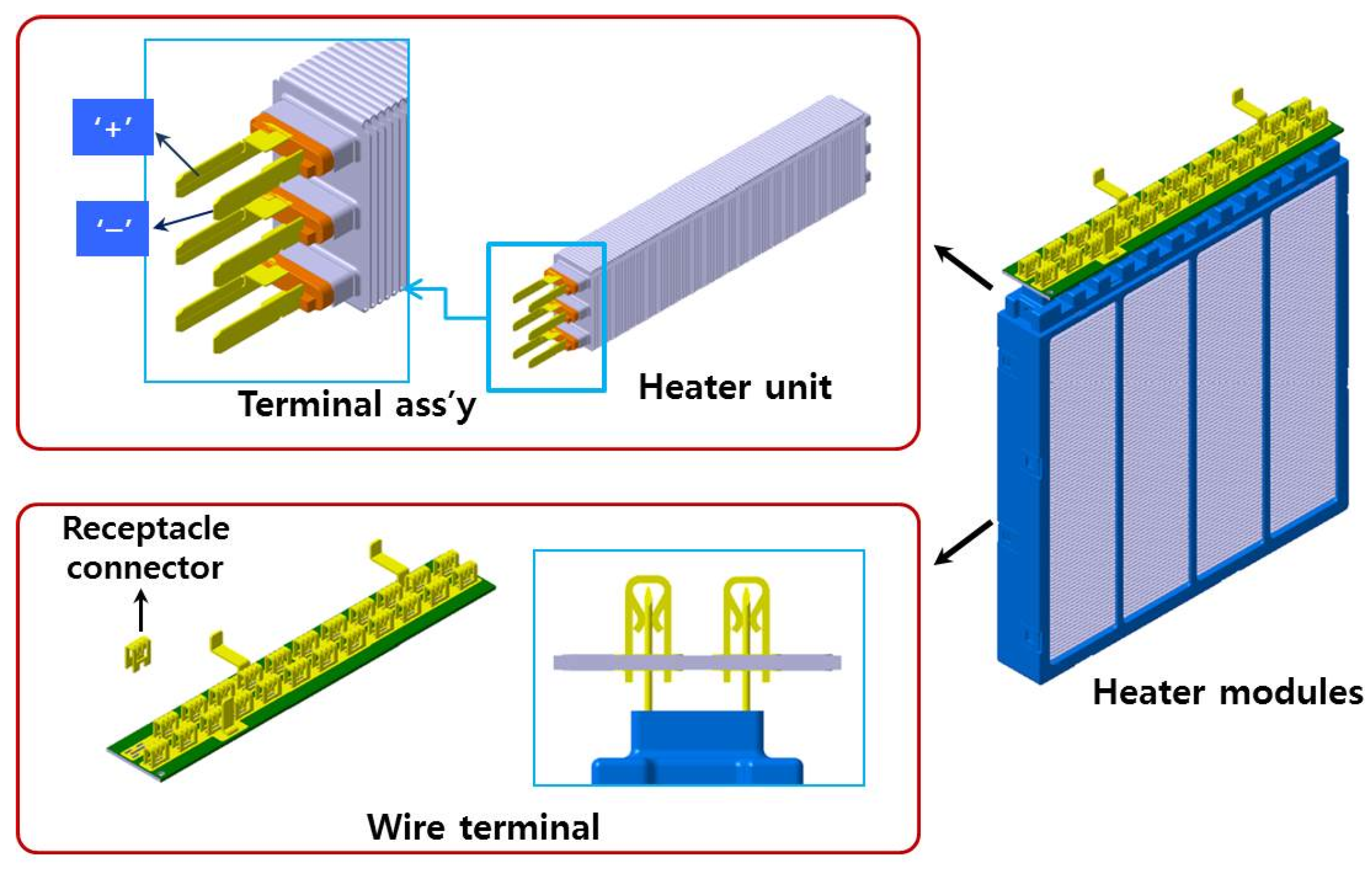

Each of the heating rods, which are core components of each heater module unit, consists of a PTC thermistor, terminal assembly, insulator, and heat rod cover, as shown in

Figure 2. The configuration of the power terminal structure is based on the shape of the heating rod and fins, as shown in

Figure 3. The adopted structure improves the insulation and water resistance of the external surface of the heater, and the positive and negative terminals of the power supply are inserted into the cover of the heating rod. To further improve the assembly and enable smooth connection to the controller, receptacle connectors are employed in the power supply section of the heater module.

Figure 2.

Schematic diagram of a heating rod.

Figure 2.

Schematic diagram of a heating rod.

Figure 3.

Schematic diagram of the heating unit and modules.

Figure 3.

Schematic diagram of the heating unit and modules.

The heater module unit directly affects the heating performance of the system. Therefore, to achieve higher performance, the heating rods and fins of the heater modules were varied as indicated in

Table 2 and

Table 3, respectively, and the corresponding performances of the heating system, which contained four heater modules, compared. The heating performance of a heater module was evaluated based on the maximum temperature of the PTC thermistor and the conductivity of the insulator. The fins served as heat exchangers with the environment, and the heater module performance was also examined for various thickness and shapes of the fins, as indicated in

Table 3.

Table 2.

Experimental results of the heater module performance for varying properties of heating rod.

Table 2.

Experimental results of the heater module performance for varying properties of heating rod.

| Varying Properties of Heating Rod | Heating Capacity of Heater Modules (kW) |

|---|

| Maximum temperature of the PTC thermistor (°C) @ plate fin thickness of 0.3 mm | 160 | 5.1 |

| 170 | 5.2 |

| 180 | 5.4 |

| Conductivity of the insulator (W/m·K) @ plate fin thickness of 0.4 mm | 1.2 | 4.9 |

| 1.5 | 5.0 |

| 3.0 | 5.4 |

The radiation fins of the PTC heater module are the key parts of the heating system that radiate heat directly into the air. The design parameters of a fin are important for achieving lightweight and high PTC heater energy efficiency. As shown in

Table 3, heater modules using 0.3- and 0.4-mm-thick comparison models, with the shape fixed as plate, yielded heating capacities of 5.2 and 5.4 kW, respectively. The heat outputs of the heater modules using plate and embossed fin models, with thickness fixed at 0.3 mm, were 5.2 and 5.4 kW, respectively. Therefore, the optimized design parameter for a radiation fin for the PTC heater was determined to be a thickness of 0.3 m, given the advantage of the 0.3 m model over the 0.4 m model in the tradeoff between weight and capacity, and the embossed type because of the turbulent effect of the emboss.

Table 3.

Experimental results of the heater module performance for varying fin geometry.

Table 3.

Experimental results of the heater module performance for varying fin geometry.

| Varying Fin Geometry | Heating Capacity of Heater Modules (kW) |

|---|

| Thickness of plate fin (mm) | 0.3 | 5.2 |

| 0.4 | 5.4 |

| Shape of fin @ fin thickness of 0.3 mm | ![Energies 09 00018 i001]() Plate Plate | 5.2 |

![Energies 09 00018 i002]() Emboss Emboss | 5.4 |

The printed circuit board (PCB) of the heating system’s controller and other components were configured as shown in

Figure 4. The specifications are given in

Table 4. Compared to the conventional separated-type heating system, the integrated structure of the developed system and the arrangement of its components afforded compactness.

Figure 4.

PCB of the controller and other components of the heating system.

Figure 4.

PCB of the controller and other components of the heating system.

Table 4.

Specifications of the controller of the high-voltage heating system.

Table 4.

Specifications of the controller of the high-voltage heating system.

| Item | Specification |

|---|

| Operating voltage (V) | High voltage: 220–460/Low voltage: 9–16 |

| Communication | CAN 2.0 |

| Output | PWM (Pulse Width Modulation) |

| Protection | Over current protection |

| Over/under voltage protection |

| Command fail |

| Interlock detection |

| Soft start |

| Maximum power consumption |

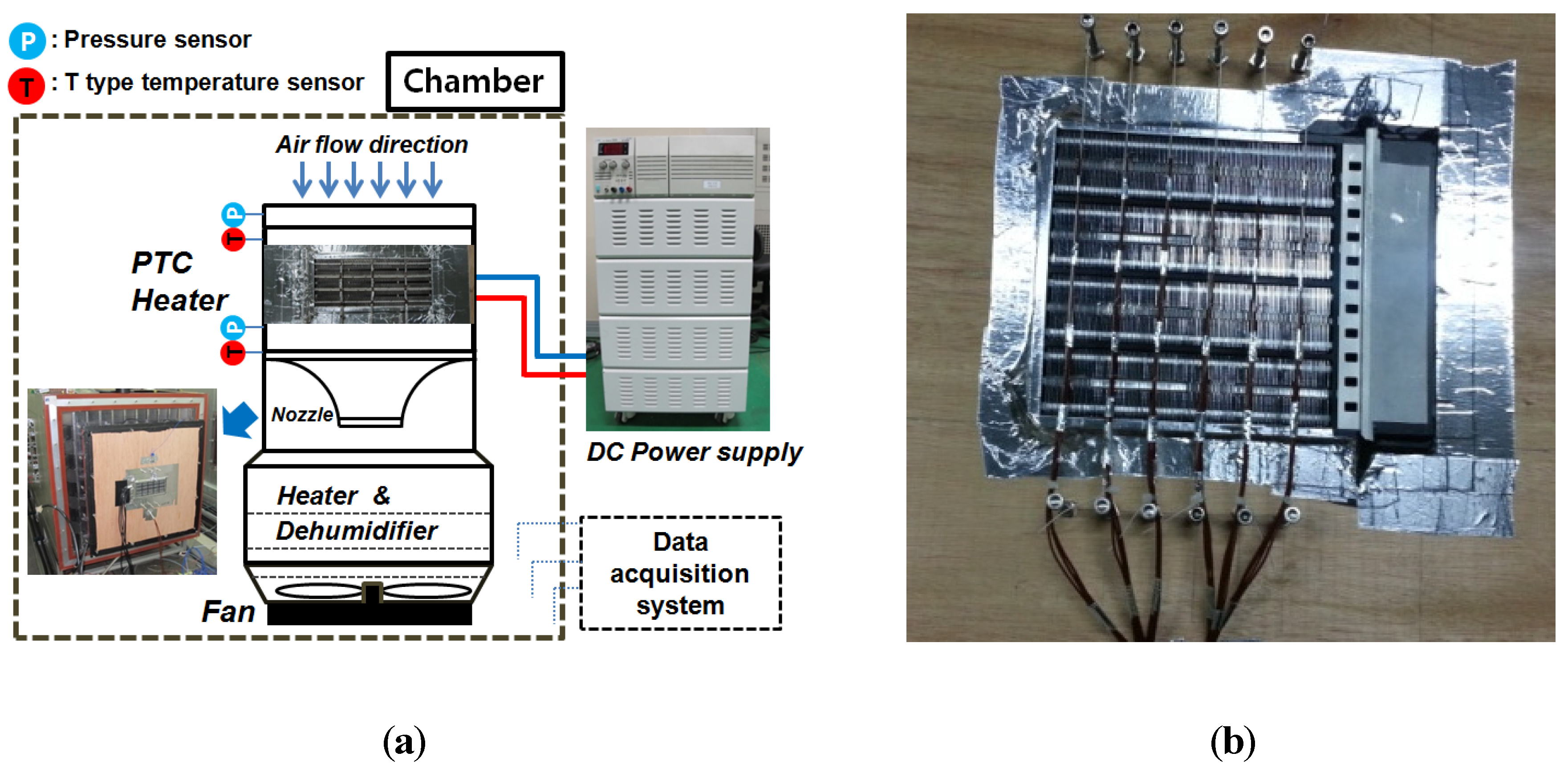

2.2. Heater Module Analysis

Assuming a symmetrical shape with respect to the PTC heater cross-section, we applied a 1/16 model and ignored the heat radiation error stemming from the power source terminal. The boundary conditions used to analyze the heating performance of the PTC heater consisted of an inlet air flow of 500 kg/h, inlet air temperature of 0 °C, and heating capacity of the PTC element of 312.2 W. The heat value of the PTC element was calculated by applying a PTC heater module heating capacity of 5 kW to the analysis model. A thermal analysis of the heater was also performed by substituting the property values for each component into the model. The number of mesh is about ten million and the computational time required to produce a converged solution was about 1 or 2 days on average. The analysis program that was used in this study utilizes the grid-quality check method, and its analysis involves a method that checks the convergence for each iteration, confirming that the grid independency is highly reliable.

The mass, momentum, and energy conservation equations were used as the governing equations for the simulation of the heater. The turbulence model was used to calculate the turbulent flow with constants obtained via empirical and theoretical methods. The modified production (MP) k-ε equation known as the Kato-Launder modification was used for the turbulence model [

14]. The heat flow analysis was performed using SC-tetra built on a node-based finite-volume discretization method, a commercial analysis program [

15], and the analysis results were organized with respect to the heater’s temperature distribution using a pressure drop to below a value corresponding to an air flow of 500 kg/h, which was the maximum flow of the blower. The cross-sectional temperature distribution around the heating rods and fins of the PTC heater is shown in

Figure 5a. The distribution reflects the pertinent air flow and is shown in a manner that enables comparison of the different heat transfer paths from the PTC element to the fins. In the heat transfer path from the PTC element surface to the fins, the heat resistance of the radiation pad, which serves as an insulator, accounted for about 75% of the total heat resistance.

Figure 5b shows the pressure distribution in the fin at the same position of the temperature distribution shown in

Figure 5a. A relatively high flow resistance was observed at the point where the heat rods and fins of the PTC heater curve. The temperature and pressure of each component of the PTC heater determined by the analysis can be used to improve the fin design.

Figure 5.

Temperature and pressure distribution of the high-voltage PTC heater modules. (a) Temperature distribution (°C); (b) Pressure distribution (Pa).

Figure 5.

Temperature and pressure distribution of the high-voltage PTC heater modules. (a) Temperature distribution (°C); (b) Pressure distribution (Pa).

2.3. Heat Interference Analysis of the Controller

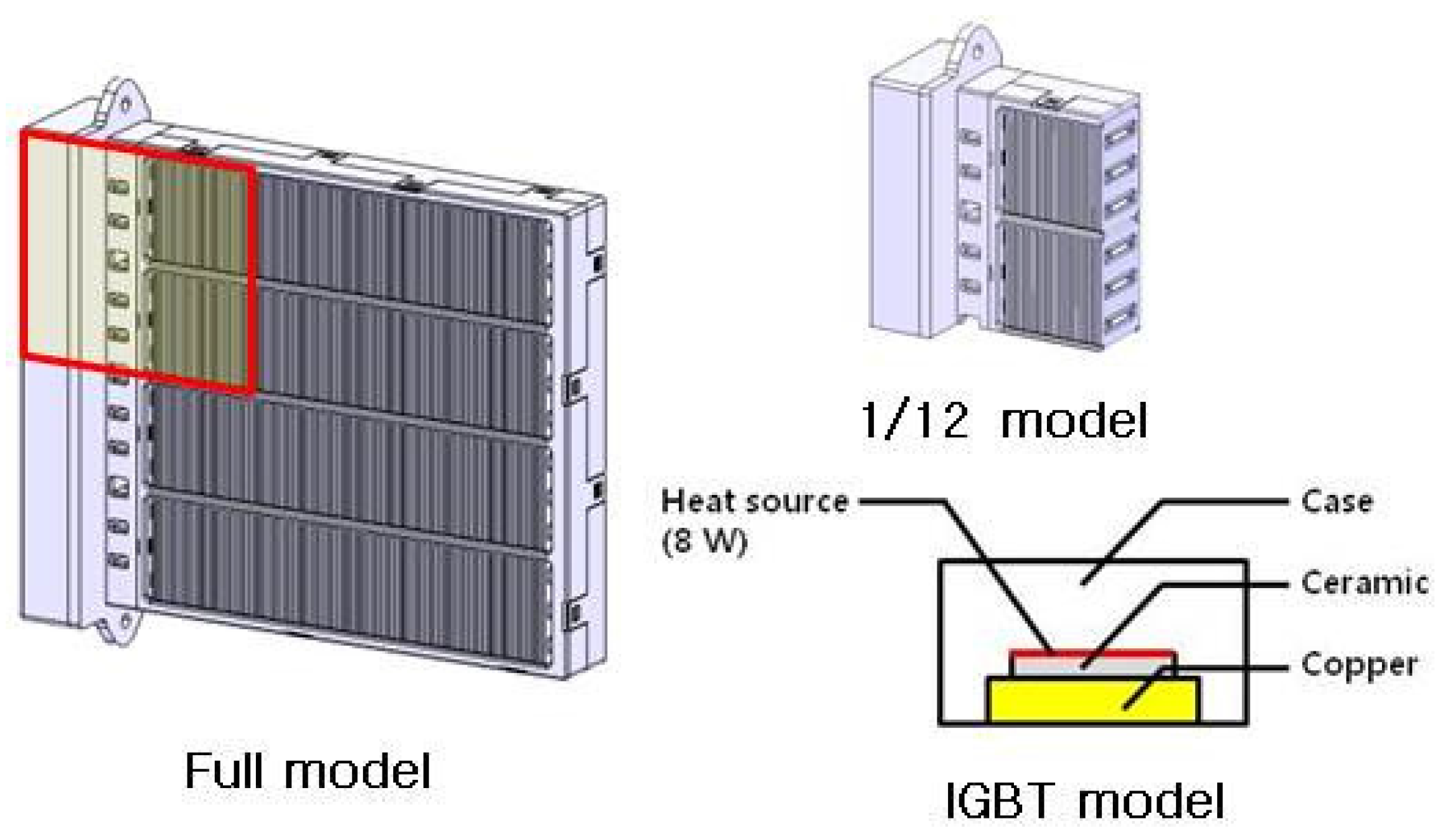

The integration of the controller and the heater modules, which are conventionally separated, causes the radiation performance of the controller to decline due to heat interference with the heater in the limited space. By a heat flow analysis, we considered possible design alternatives for addressing this issue. The employed analysis model of the controller-integrated PTC heating system is shown in

Figure 6. The model contains an insulated gate bipolar mode transistor (IGBT), which serves as a heat source and is a core component of the controller. It was developed using a scale of 1/12. The flow region of the analysis was set to ensure flux uniformity.

The boundary conditions were divided into basic and severe conditions as indicated in

Table 5 to compare the radiation performance of the controller with respect to the operation condition of the system. The analysis was performed by switching between operation and non-operation of the heater and various flow conditions of the blower. The basic flow condition was 300 kg/h and the severe condition corresponded to reduction of the air flow by about 2/3, which constitutes a severe operation environment for the controller in a real vehicle environment [

16]. The physical property value for each component including the IGBT was used for the analysis.

Figure 6.

Analysis model of the heat interference with the controller.

Figure 6.

Analysis model of the heat interference with the controller.

Table 5.

Boundary conditions for heat flow analysis of the controller-integrated high-voltage PTC heating system.

Table 5.

Boundary conditions for heat flow analysis of the controller-integrated high-voltage PTC heating system.

| Operating Condition | Heater Not Operated | Heater Operated |

|---|

| Basic Conditions | Basic Conditions | Severe Conditions |

|---|

| Inlet air flow (kg/h) | 35.9 (300 kg/h at full mode) | 12.0 (100 kg/h at full mode) |

| Air temperature (°C) | - | 0 |

| Heat value of IGBT (W) | - | 8 |

| Heat value of PTC (W) | 0 | 416.7 (Heating capacity of 5 kW) | 250 (Heating capacity of 3 kW) |

Table 6 summarizes the temperatures attained by the components as determined by the analysis. The temperature of the IGBT under operation conditions without the heater was determined to be about 59.6 °C, while the operation of the heater increased it to about 77.9 °C. Under the severe condition involving decreased air flow, the temperature increased to a maximum of 101.4 °C. Because this was within the allowed range for the controller, the radiation design was determined to be appropriate.

Table 6.

Results of the heat flow analysis of the controller-integrated high-voltage PTC heating system.

Table 6.

Results of the heat flow analysis of the controller-integrated high-voltage PTC heating system.

| Component | Heater Not Operated | Heater Operated |

|---|

| Basic Condition | Basic Condition | Severe Condition |

|---|

| IGBT (°C) | 59.5 | 77.9 | 101.4 |

| PTC element (°C) | - | 92.8 | 113.2 |

| Radiation fin (°C) | - | 80.0 | 105.6 |

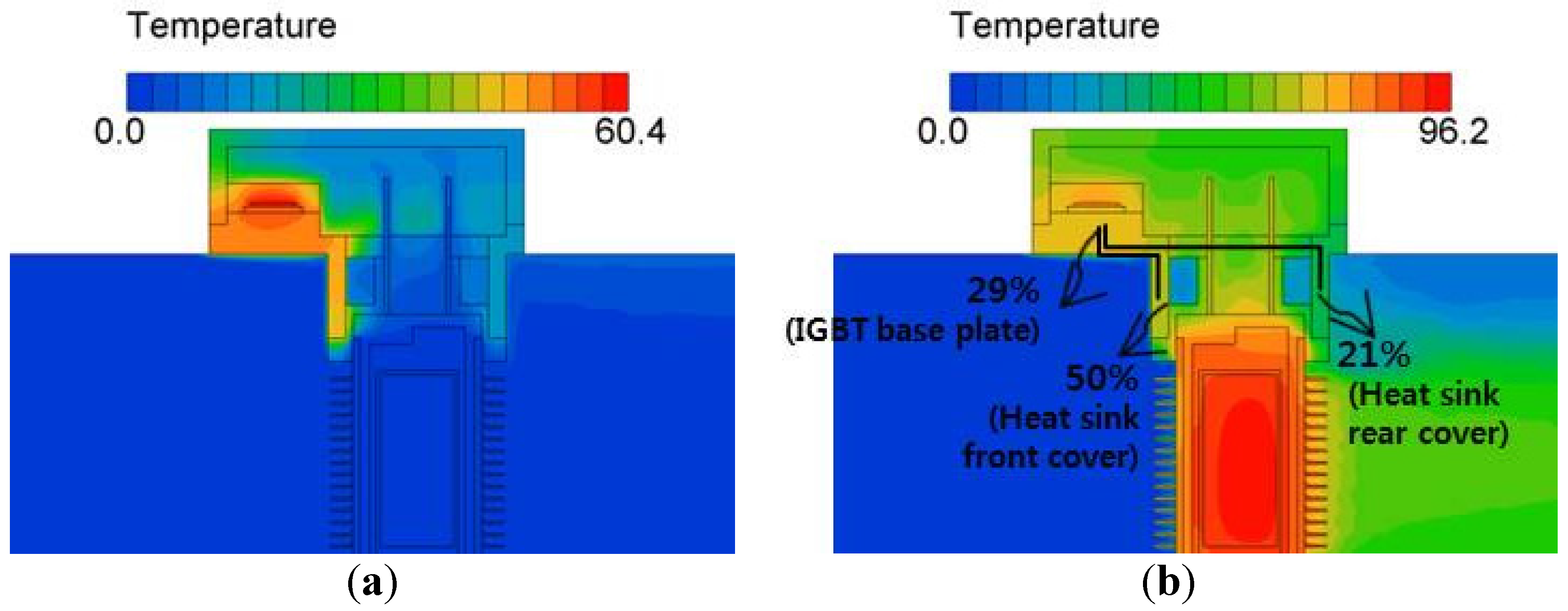

Figure 7 compares the cross-sectional temperature distributions of the PTC heater with and without operation of the heat source under the basic operation condition, and also quantitatively shows the heat transfer paths through the IGBT components. Radiation apparently constitutes a considerable portion of the heat produced in the IGBT; about 71% of the heat is transferred to the controller housing cover, which functions as a heat sink.

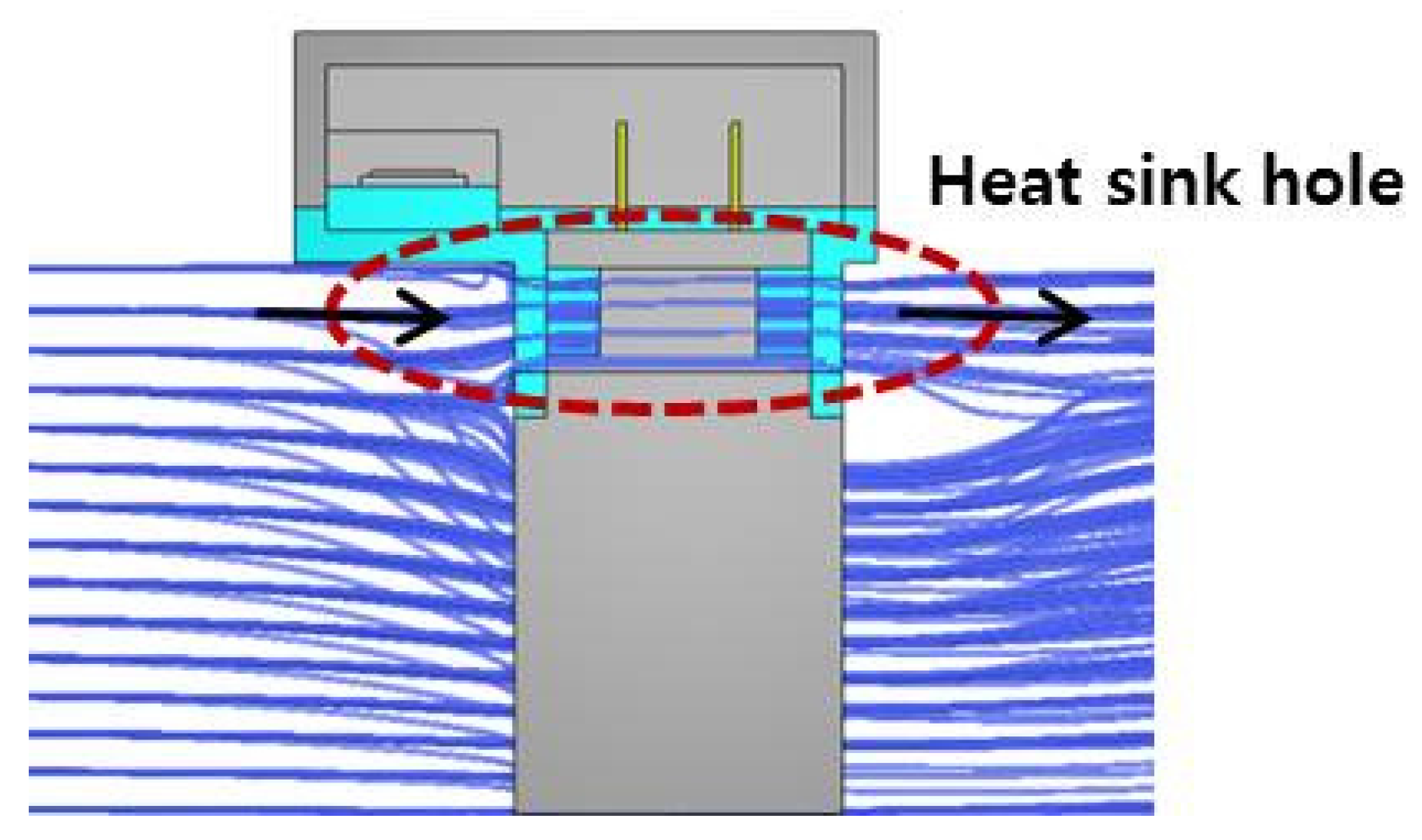

Figure 8 shows the air flow line through the heat sink of the controller. It was observed that about 5% of the total air flow into the radiator entered the cooling hole of the heat sink. This flow proportion indicates a correlation between the heating performance of the system and the heat interference with the controller.

Figure 7.

Comparison of the temperature distributions in the PTC heater under the basic condition with and without operation of the heater (°C). (a) Without operation of the heater; (b) With operation of the heater.

Figure 7.

Comparison of the temperature distributions in the PTC heater under the basic condition with and without operation of the heater (°C). (a) Without operation of the heater; (b) With operation of the heater.

Figure 8.

Flow line at the heat sink hole of the heating system controller.

Figure 8.

Flow line at the heat sink hole of the heating system controller.

Plate

Plate Emboss

Emboss