Analysis of Operation Parameters in a Dual Fluidized Bed Biomass Gasifier Integrated with a Biomass Rotary Dryer: Development and Application of a System Model

Abstract

:1. Introduction

2. Model Development

2.1. Woody Biomass Characteristics

| Proximate Analysis wt% (od) | Ultimate Analysis, wt% (od) | ||

|---|---|---|---|

| H2O | 0 | C | 51.2 |

| Volatile | 84 | H | 6.1 |

| Fixed carbon | 15.6 | O | 42.3 |

| Ash | 0.4 | N | 0.2 |

| - | - | S | 0.02 |

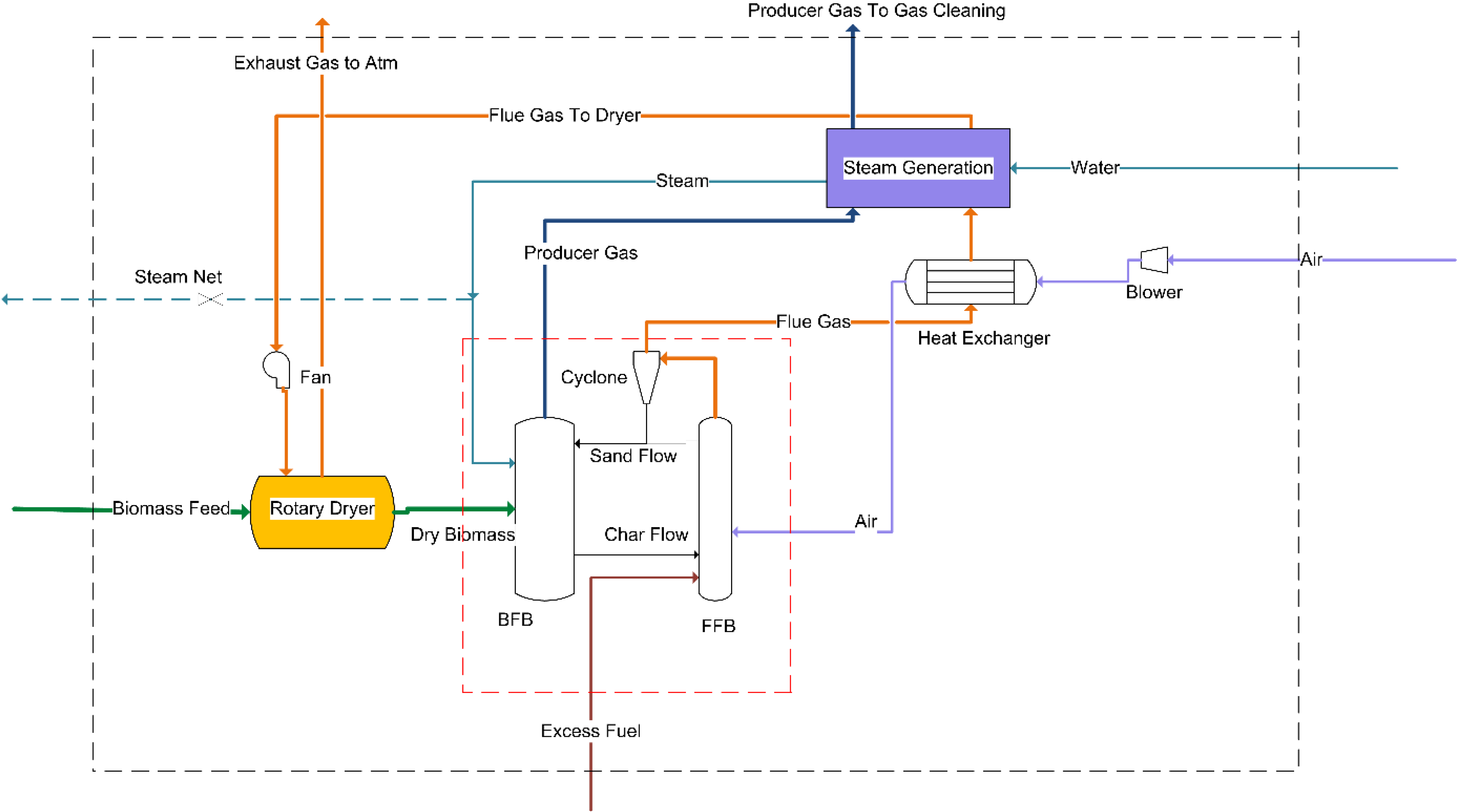

2.2. Process Configuration

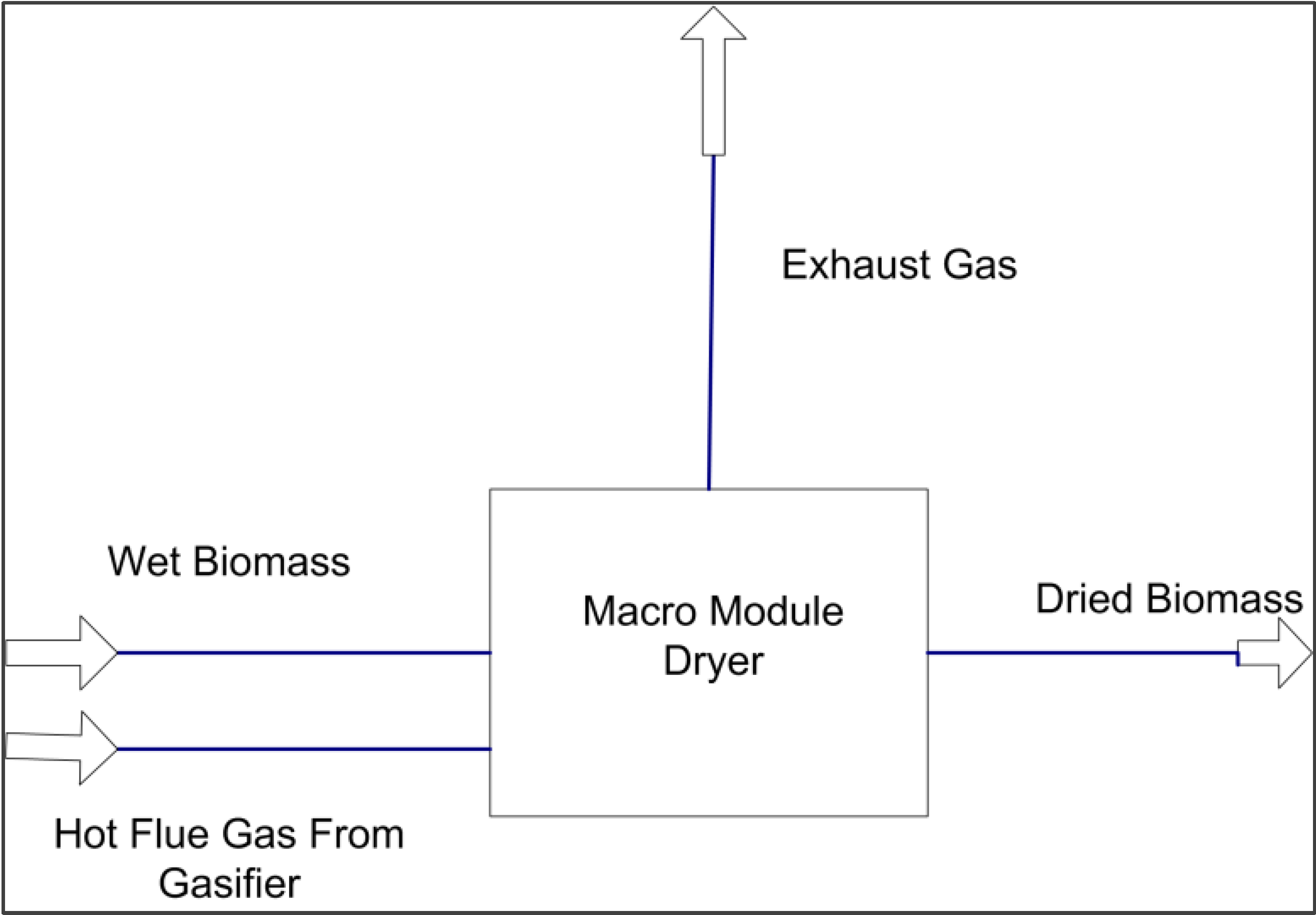

2.3. Modelling of the Rotary Drying

- The exhaust gas temperature is assumed to be always higher than wet-bulb temperature (70 °C).

- The heat of vaporization of water is kept constant during the drying using the average temperature between inlet and outlet temperatures.

- The heat loss of the dryer is assumed to be 15% based on the experimental results with a semi industrial rotary dryer [25]. It does not include the heat loss by the exhaust gas.

- The heat transfer coefficient between the drying medium and the biomass is calculated using the correlation proposed by Saeman and Mitchell [26].

2.3.1. Mass Balance of Water

2.3.2. Energy Balance

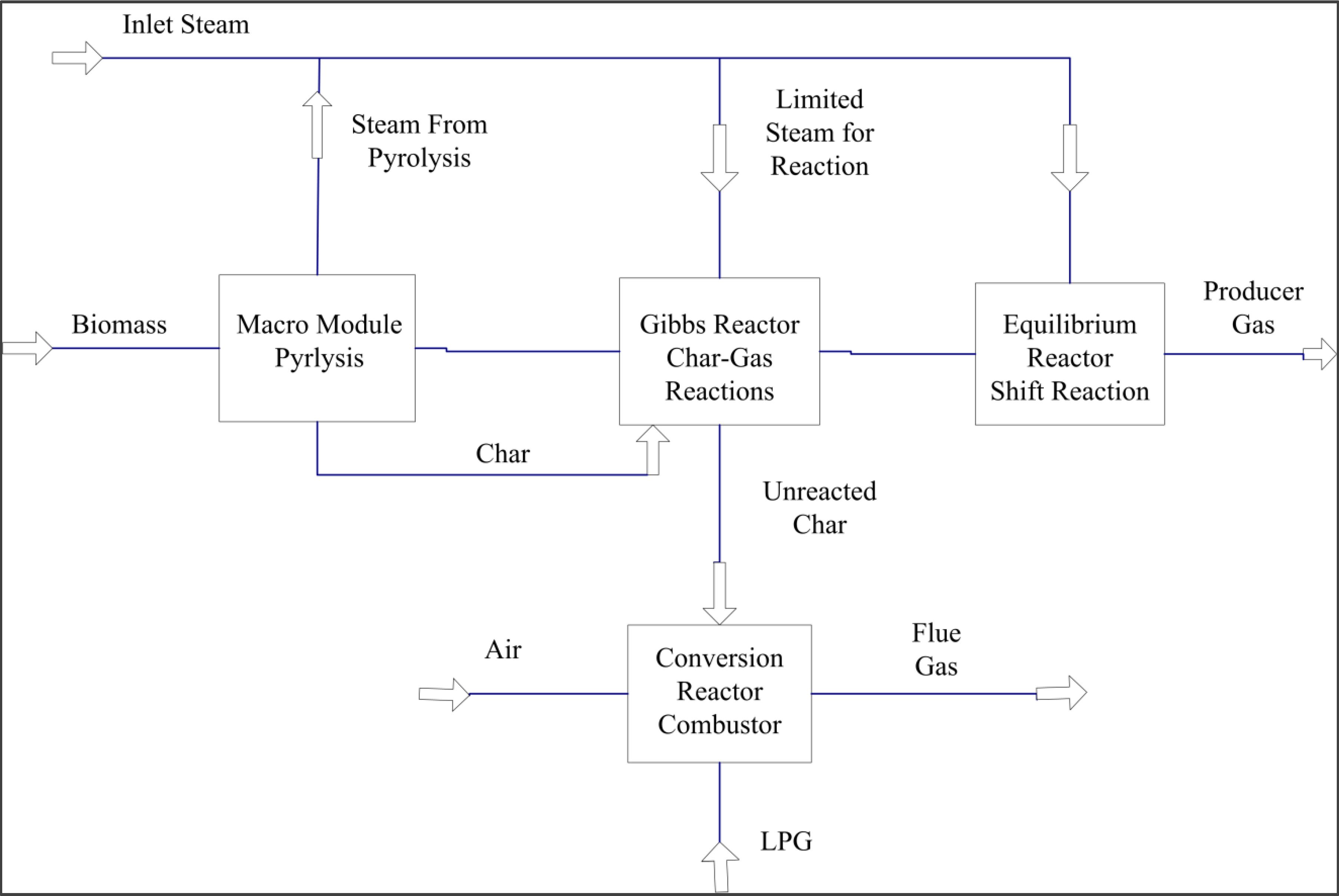

2.4. Modelling of the Gasification System

2.4.1. Modeling of the Pyrolysis Step

are determined by the following correlations as a function of temperature:

are determined by the following correlations as a function of temperature:

2.4.2. Modeling of the Char-gas Reactions and Reactions among Gases

- Boudouard: C+CO2→2CO

- Primary steam-gas reaction: C+H2O→CO+H2

- Secondary steam-gas reaction: C+2H2O→CO2+2H2

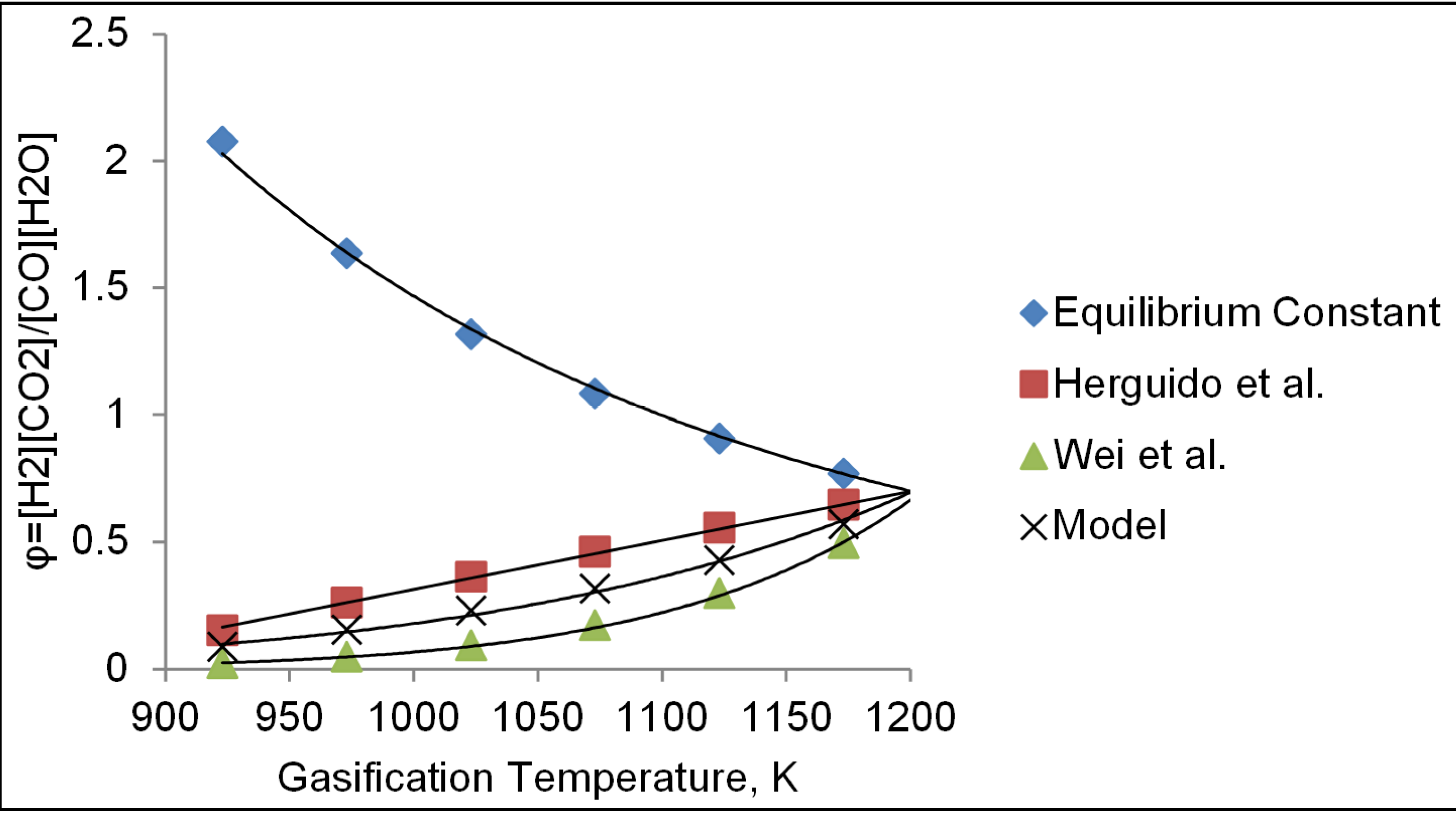

- Steam-gas shift reaction: CO+H2O→CO2+H2

is the total moles of steam in the system, nH2O,con is the moles of steam that contributes to the reactions and Tg is the gasification temperature (K).

is the total moles of steam in the system, nH2O,con is the moles of steam that contributes to the reactions and Tg is the gasification temperature (K).

2.5. Energy and Exergy Efficiencies of an Integrated System

| Item | Eẋa | Eẋu |

|---|---|---|

| Biomass Drying | Eẋfg,in − Eẋfg,out | 0 |

| Air Preheating | Eẋfg,in − Eẋfg,out | Eẋair,out − Eẋair,in |

| Steam Generation | (Eẋfg,in + Eẋpg,in) − (Eẋfg,out + Eẋfg,out) | Eẋsteam,gen |

| DFB Gasification | Eẋbiom + Eẋfuel | (Eẋpg + Eẋfg) − (Eẋair + Eẋsteam,con) |

| Blower | Elpower | Eẋair,out − Eẋair,in |

| Fan | Elpower | Eẋfg,out − Eẋfg,in |

(1 − T0 / T)

(1 − T0 / T)

= Ṁsteam(h − h0)

= Ṁsteam(h − h0)

3. Results and Discussion

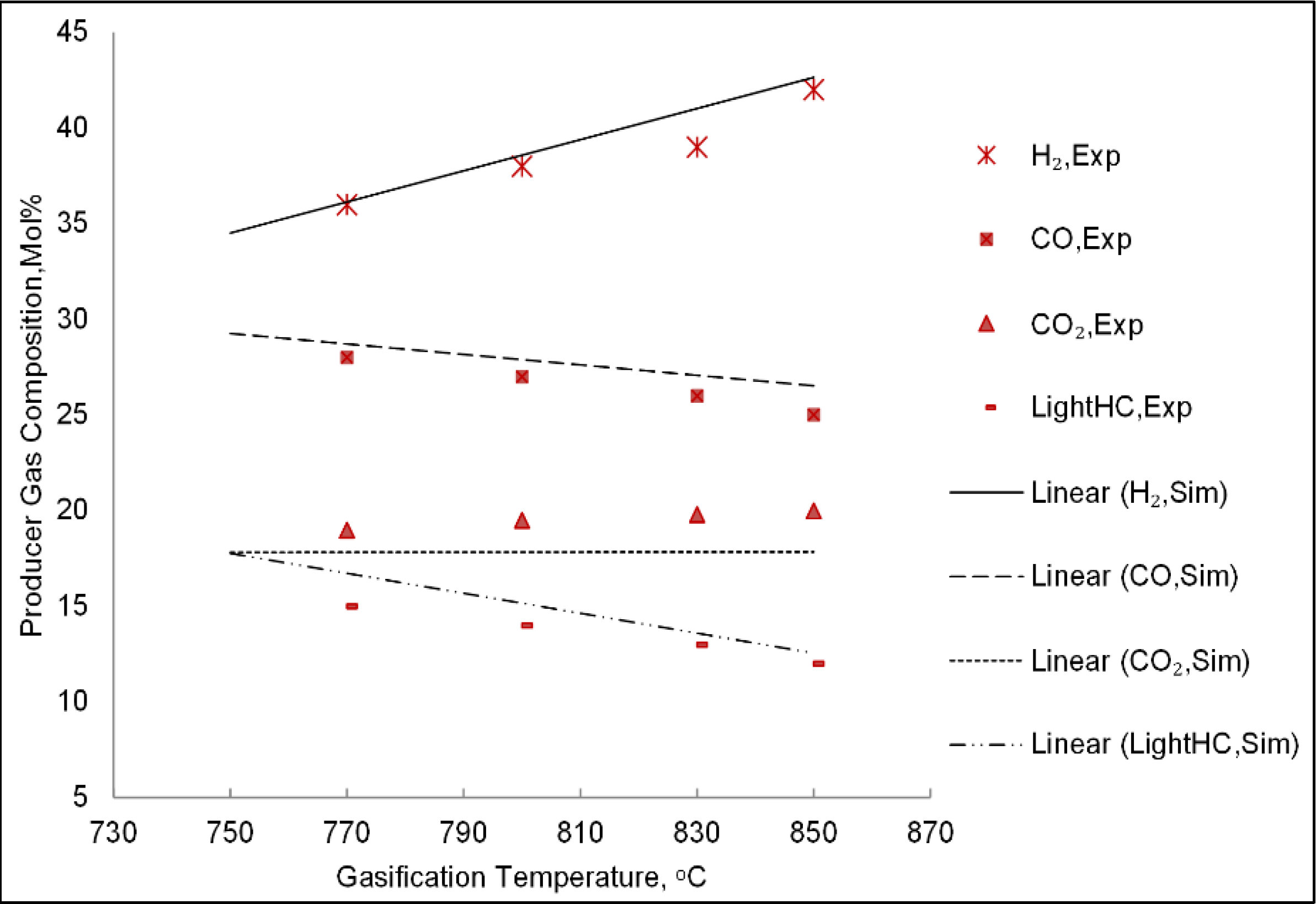

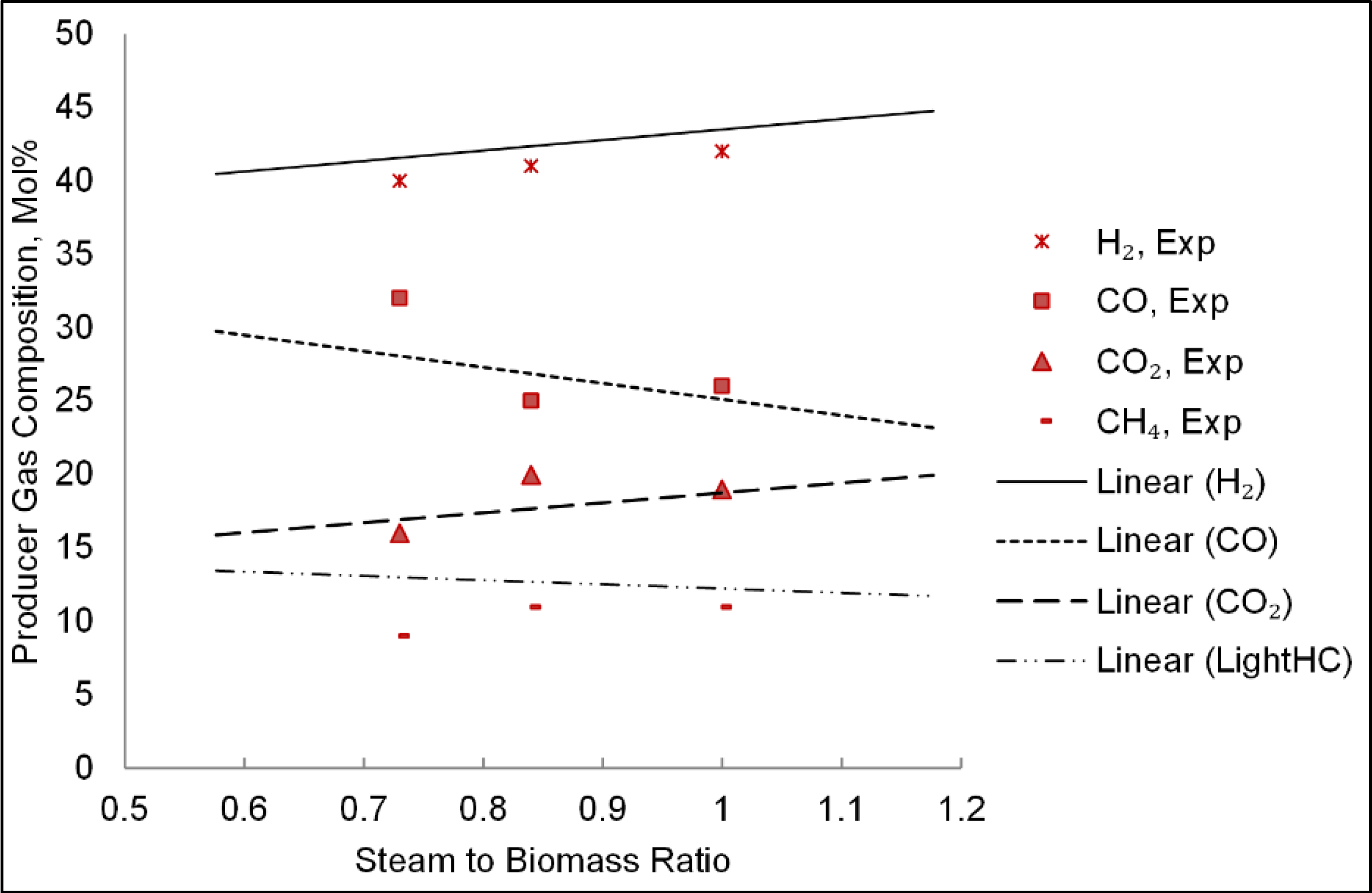

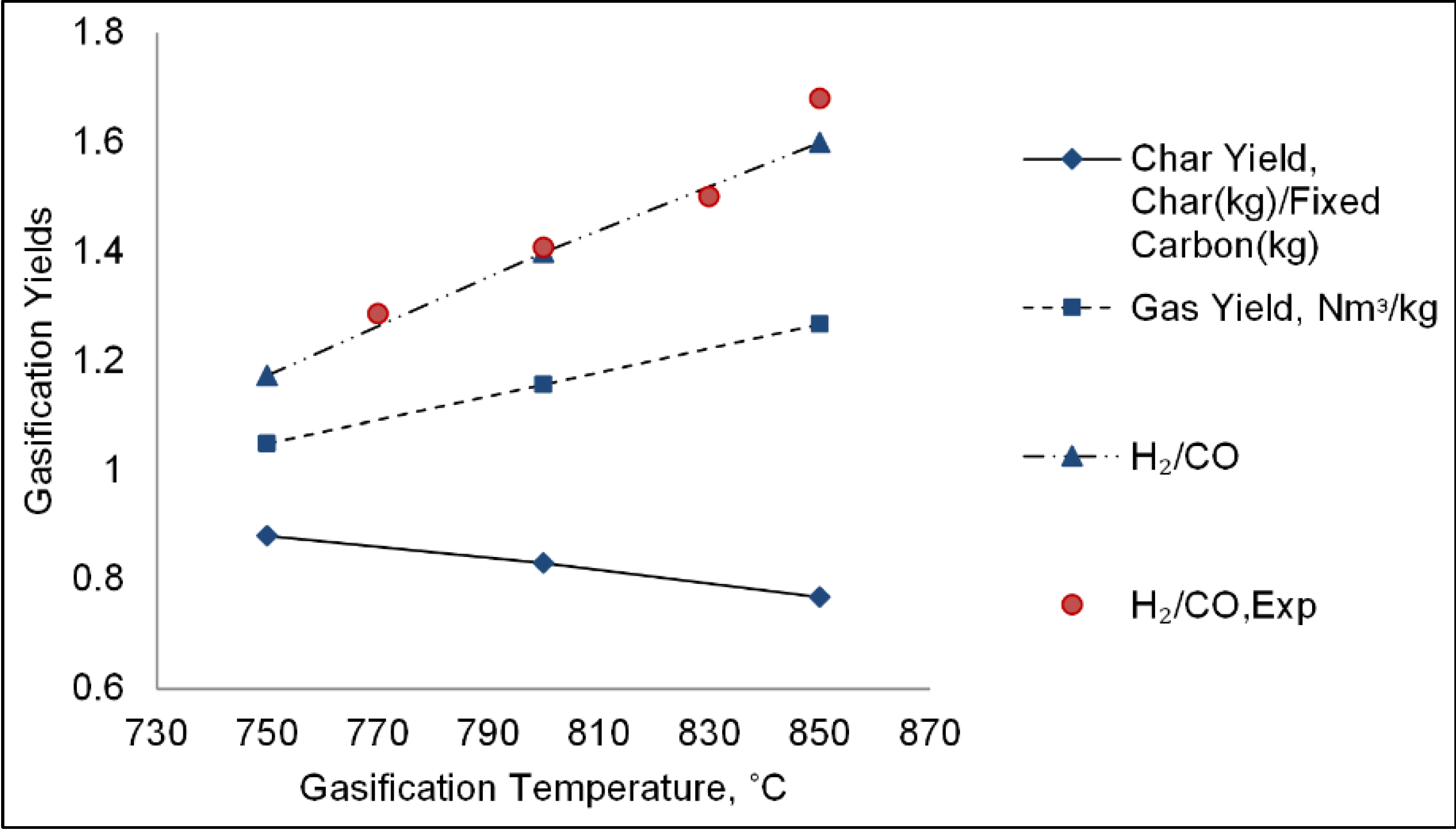

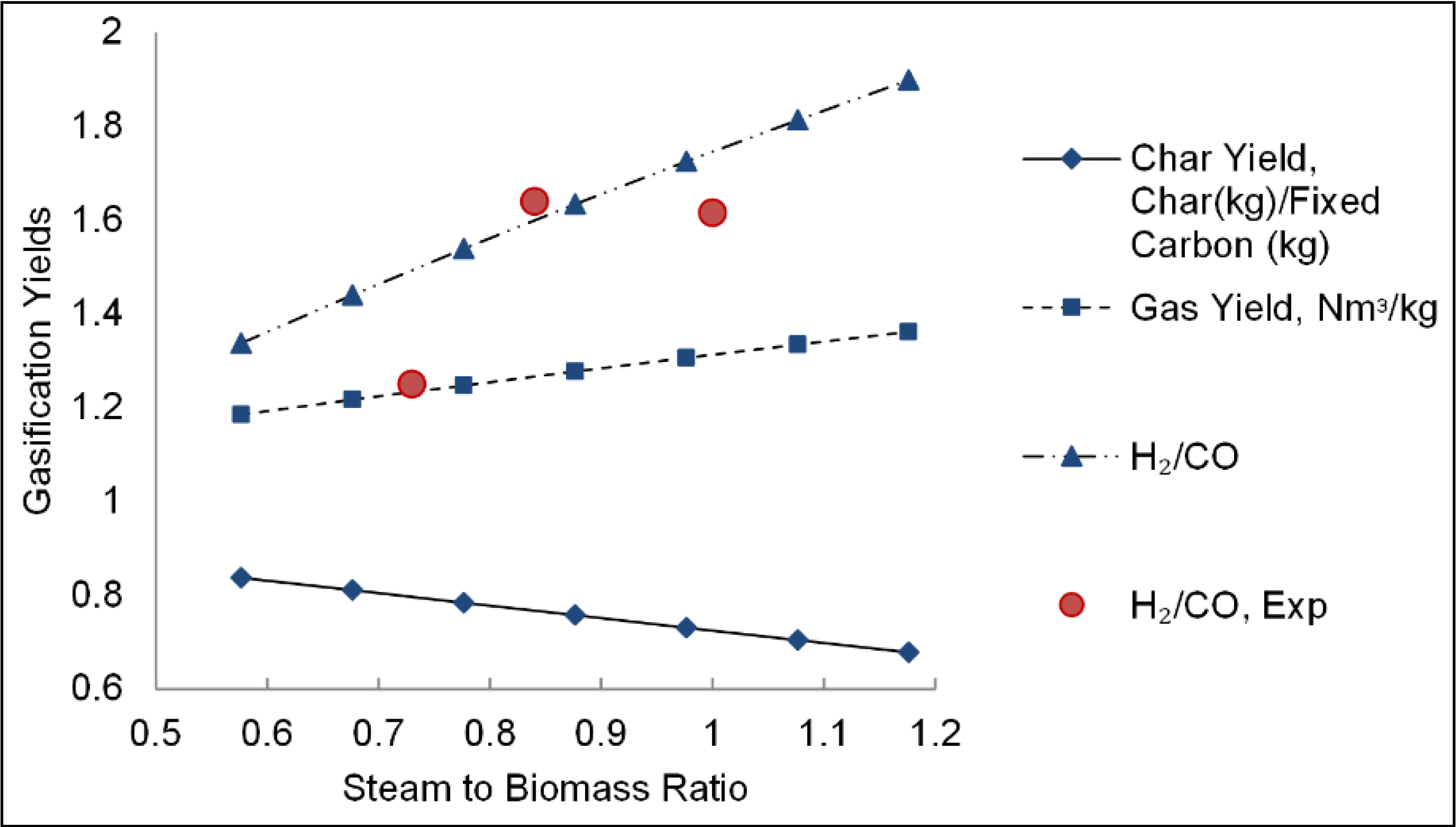

3.1. The Simulation and Model Validation of DFB Biomass Gasification

3.2. Effect of Gasification Conditions on Gasification Performance

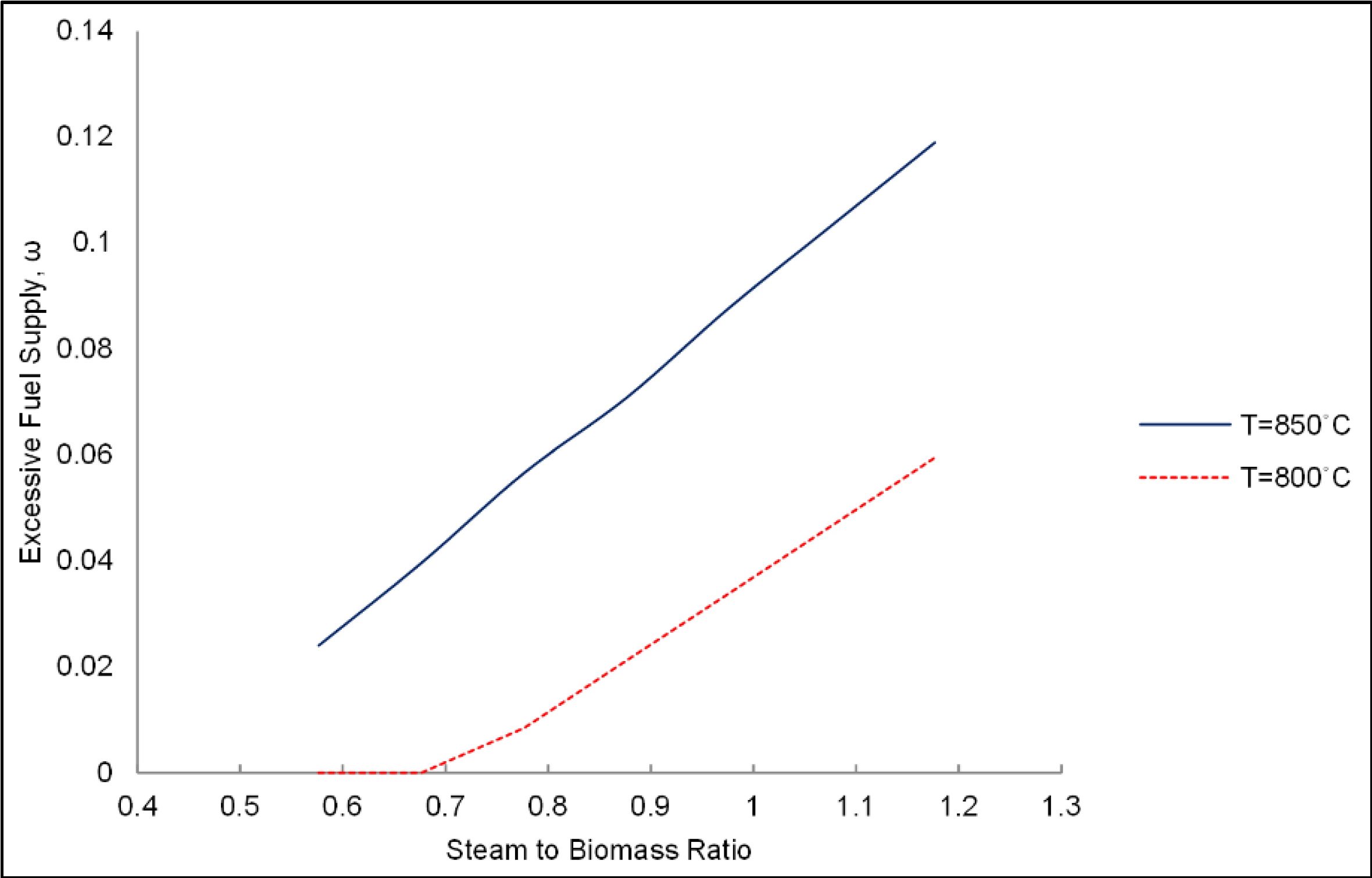

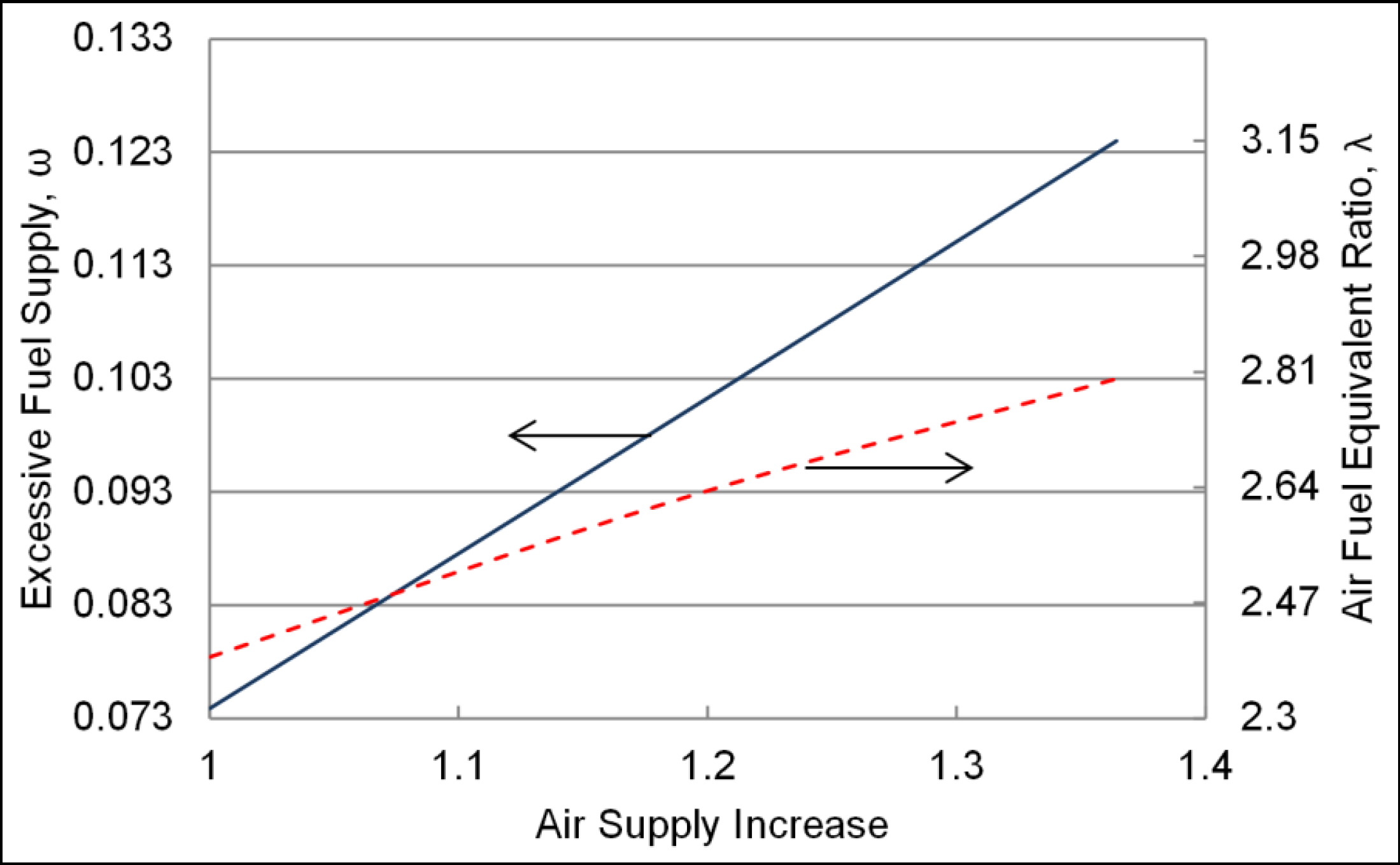

3.3. Effect of Excessive Fuel and Air Supply

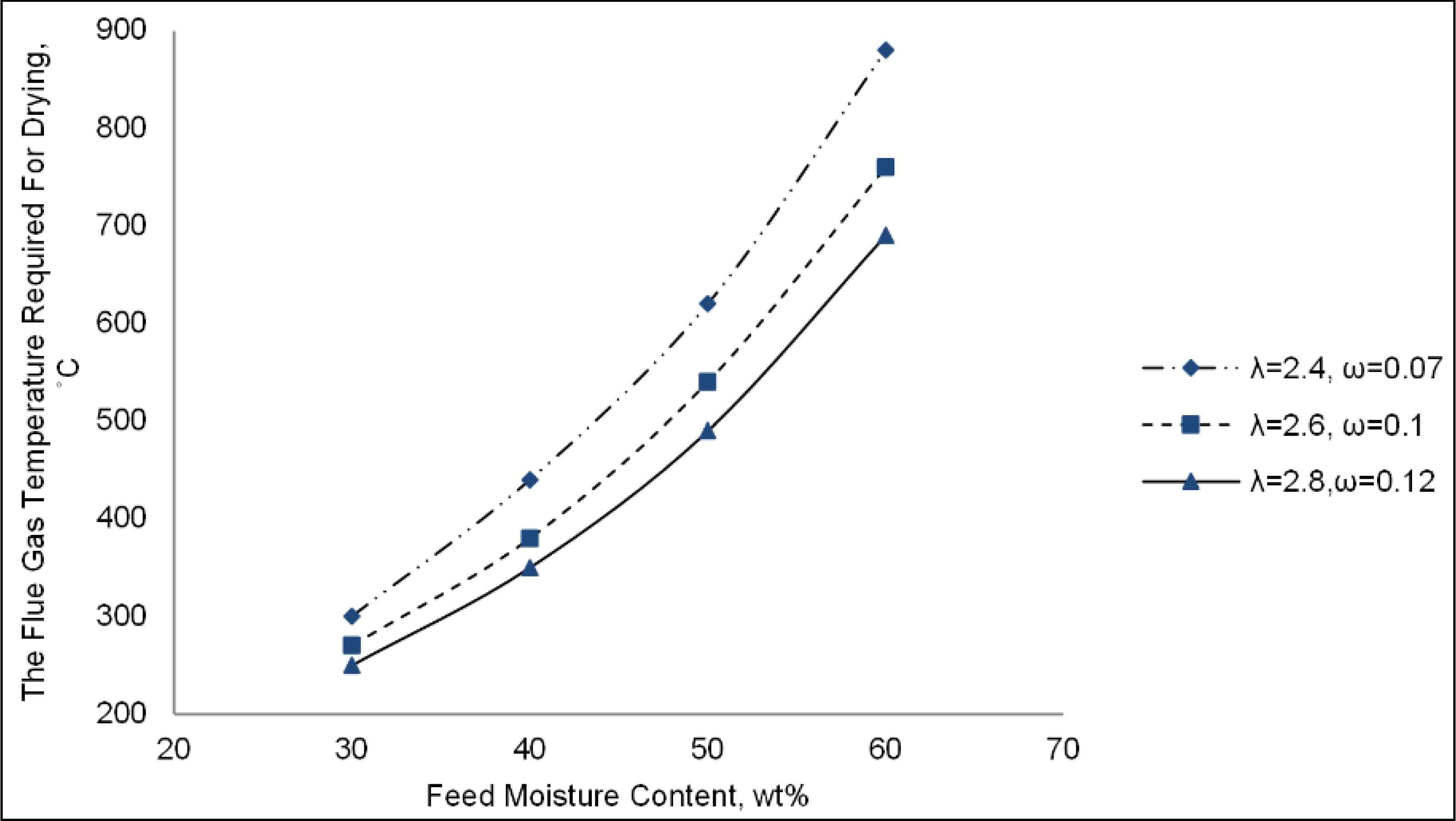

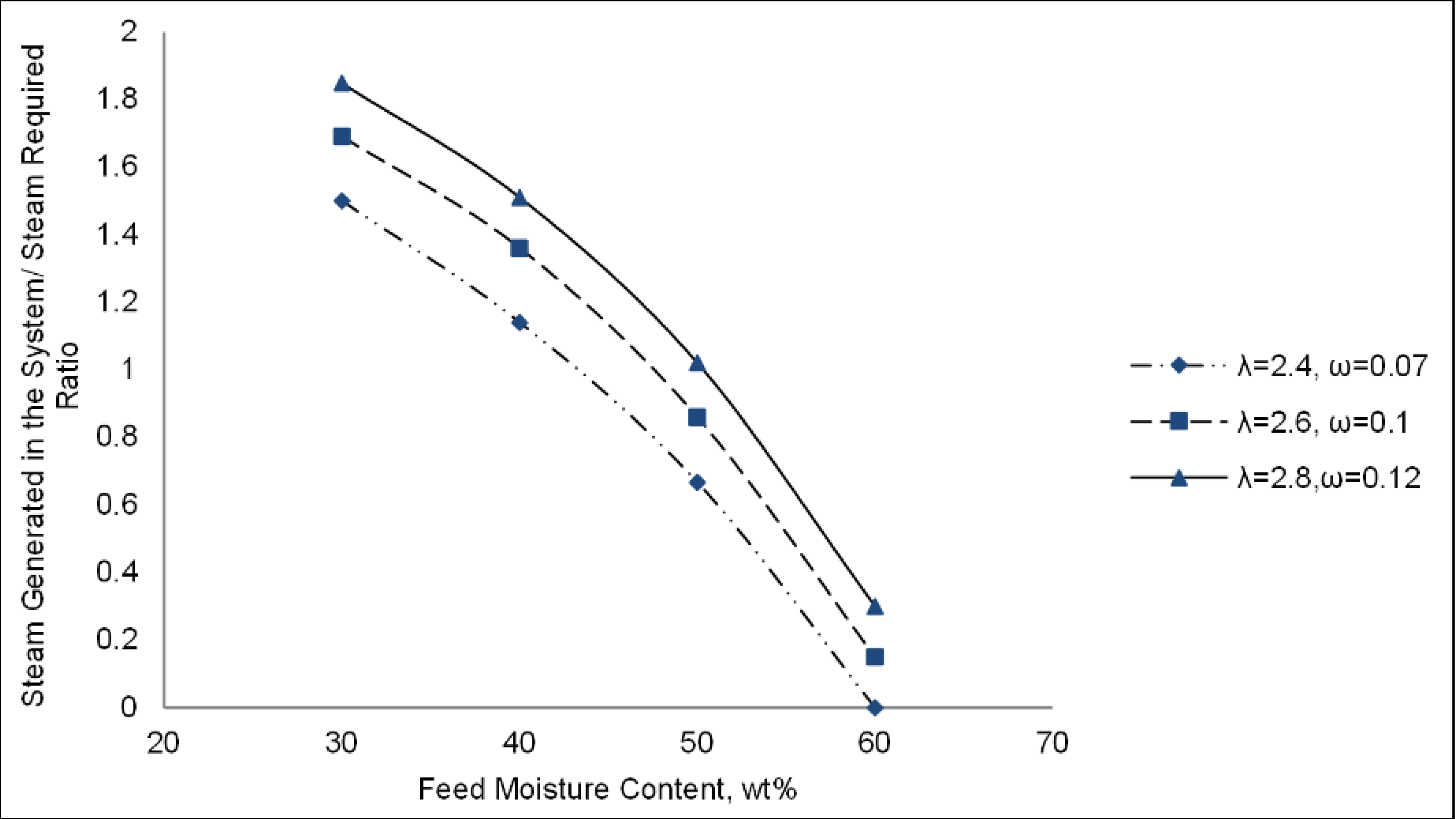

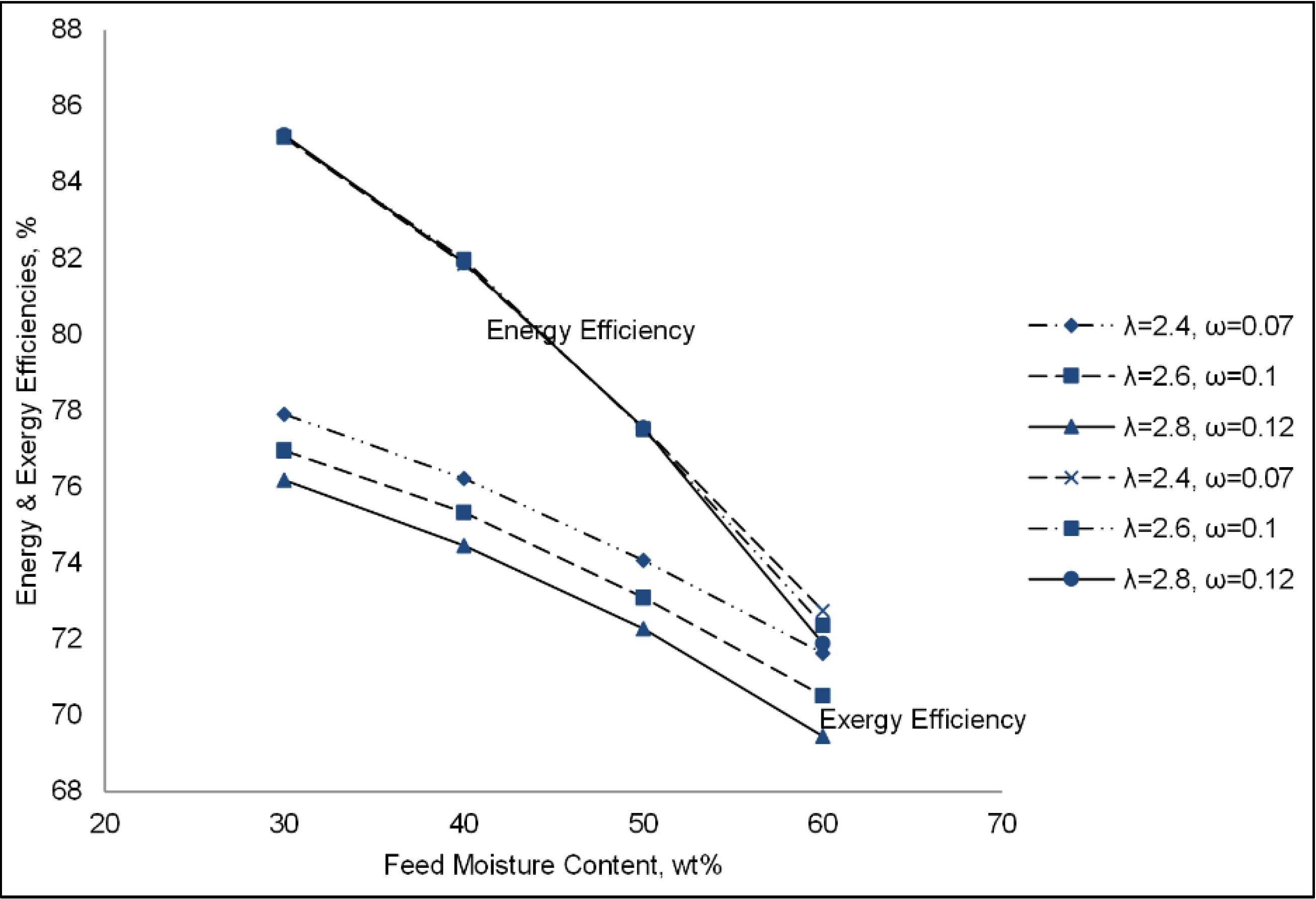

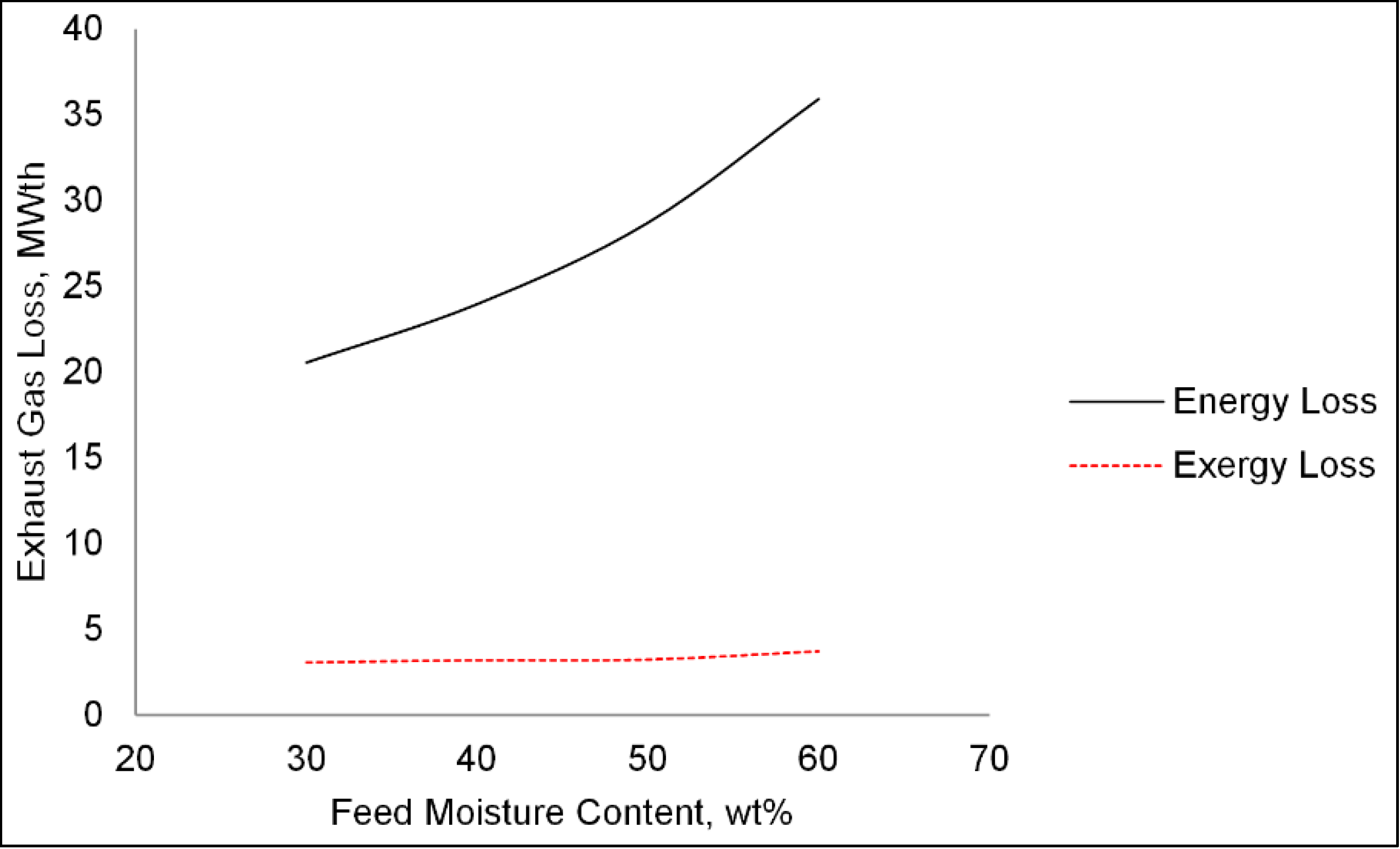

3.4. The Effect of Feed Biomass Moisture Content on System Performance

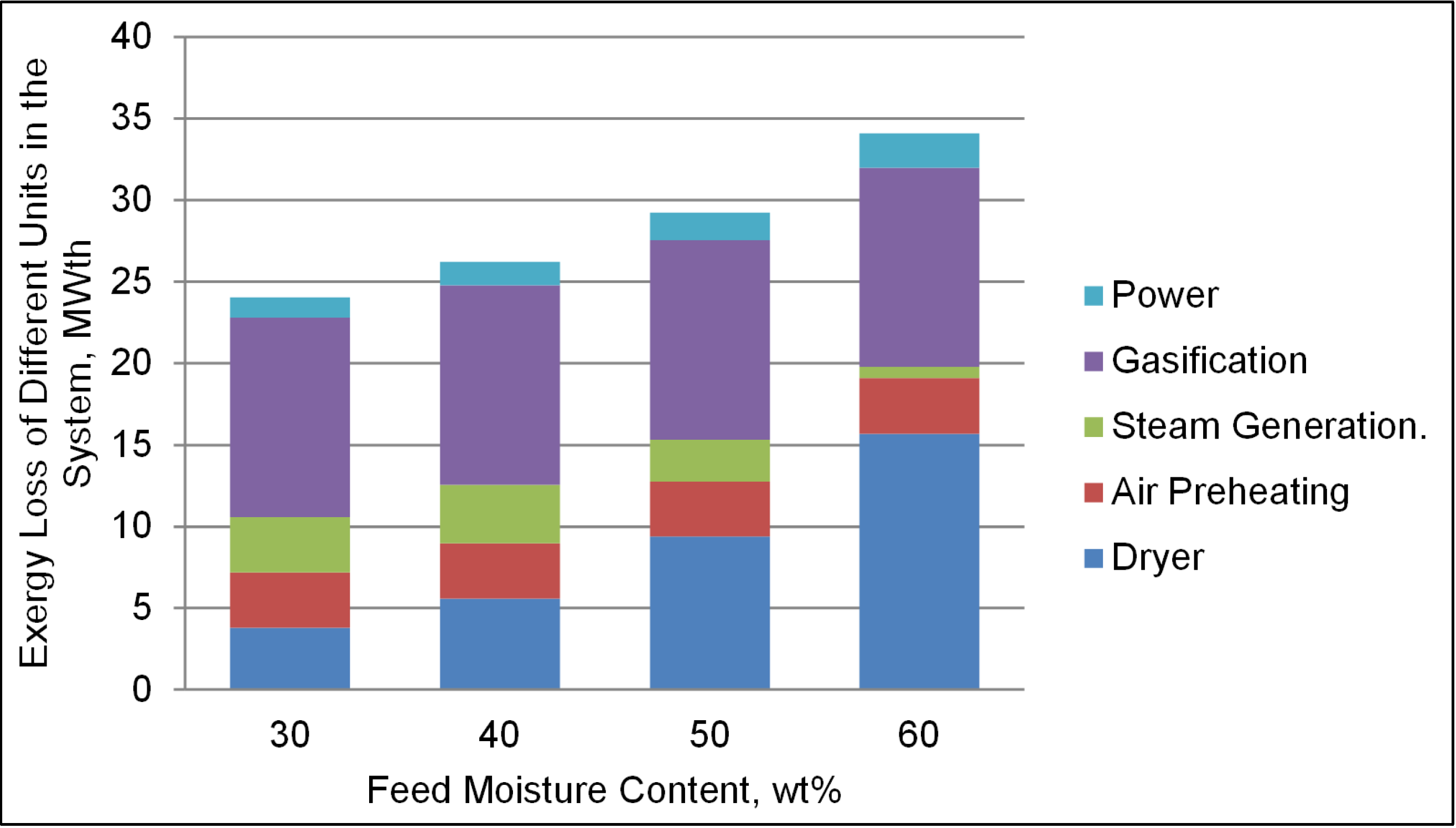

3.5. The Energy and Exergy Analysis of the System

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Saw, W.; Pang, S. Influence of mean gas residence time in the bubbling fluidised bed on the performance of a 100-kW dual fluidised bed steam gasifier. Biomass Convers. Bioref. 2012, 2, 197–205. [Google Scholar]

- Hofbauer, H.; Rauch, R.; Loeffler, G.; Kaiser, S.; Fercher, E.; Tremmel, H. Six years experience with the FICFB-Gasification process. In Proceedings of the 12th European Biomass Conference, Amsterdam, The Netherlands, 17–21 June 2002.

- Hofbauer, H.; Rauch, R.; Bosch, K.; Koch, R.; Aichernig, C. CHP Plant Güssing—A Success Story. In Pyrolysis and Gasification of Biomass and Waste; CPL Press: Newbury, NH, USA, 2003. [Google Scholar]

- Saw, W.; McKinnon, H.; Gilmour, I.; Pang, S. Production of hydrogen-rich syngas from steam gasification of blend of biosolids and wood using a dual fluidised bed gasifier. Fuel 2012, 93, 473–478. [Google Scholar] [CrossRef]

- Van der Drift, A.; van Doorn, J.; Vermeulen, J.W. Ten residual biomass fuels for circulating fluidized-bed gasification. Biomass Bioenergy 2001, 20, 45–56. [Google Scholar] [CrossRef]

- Pang, S.; Mujumdar, A.S. Drying of woody biomass: Drying technologies for an integrated bio-energy plant. Dry. Technol. 2010, 28, 690–801. [Google Scholar] [CrossRef]

- Xu, Q.; Pang, S. Mathematical modeling of rotary drying of woody biomass. Dry. Technol. 2008, 26, 1344–1350. [Google Scholar] [CrossRef]

- Begum, S.; Rasul, M.G.; Akbar, D.; Ramzan, N. Performance analysis of an integrated fixed bed gasifier model for different biomass feedstocks. Energies 2013, 6, 6508–6524. [Google Scholar] [CrossRef]

- Begum, S.; Rasul, M.G.; Akbar, D.; Cork, D. An experimental and numerical investigation of fluidized bed gasification of solid waste. Energies 2014, 7, 43–61. [Google Scholar]

- Holmberg, H.; Ahtila, P. Evaluation of energy efficiency in biofuel drying by means of energy and exergy analyses. Appl. Therm. Eng. 2005, 25, 3115–3128. [Google Scholar] [CrossRef]

- Vitasari, C.R.; Jurascik, M.; Ptasinski, K.J. Exergy analysis of biomass-to-synthetic natural gas (SNG) process via indirect gasification of various biomass feedstock. Energy 2011, 36, 3825–3837. [Google Scholar] [CrossRef]

- Aspen Process Flowsheet Simulation Model of a Battelle Biomass-Based Gasification, Fischer-Tropsch Liquefaction and Combined-Cycle Power Plant; Technical Report No. DE-AC22-93PC91029-16; Pittsburgh Energy Technology Center: Pittsburg, PA, USA, 1998.

- Tijmensen, M.J.A.; Faaij, A.P.C.; Hamelinck, C.N.; van Hardeveld, M.R.M. Exploration of the possibilities for production of Fischer Tropsch liquids and power via biomass gasification. Biomass Bioenergy 2002, 23, 129–152. [Google Scholar] [CrossRef]

- Swanson, R.M.; Platon, A.; Satrio, J.A.; Brown, R.C. Techno-economic analysis of biomass-to-liquids production based on gasification. Fuel 2010, 89, S11–S19. [Google Scholar] [CrossRef]

- Marinos-Kouris, D.; Maroulis, Z.B.; Kiranoudis, C.T. Modeling, simulation and design of convective industrial dryers. Dry. Technol. 1998, 16, 993–1026. [Google Scholar] [CrossRef]

- Schuster, G.; Löffler, G.; Weigl, K.; Hofbauer, H. Biomass steam gasification, An extensive parametric modeling study. Bioresour. Technol. 2001, 77, 71–79. [Google Scholar] [CrossRef]

- Rutherford, J. Heat and Power Applications of Advanced Biomass Gasifiers in New Zealand’s Wood Industry. Master’s Thesis, University of Canterbury, Christchurch, New Zealand, 2006; p. 114. [Google Scholar]

- Jarungthammachote, S.; Dutta, A. Thermodynamic equilibrium model and second law analysis of a downdraft waste gasifier. Energy 2007, 32, 1660–1669. [Google Scholar] [CrossRef]

- Ngo, S.I.; Nguyena, T.D.B.; Lim, Y.; Song, B.-H.; Lee, U.-D.; Choi, Y.-T.; Song, J.-H. Performance evaluation for dual circulating fluidized-bed steam gasifier of biomass using quasi-equilibrium three-stage gasification model. Appl. Energy 2011, 88, 5208–5220. [Google Scholar] [CrossRef]

- Nguyen, T.D.B.; Ngoa, S.I.; Lim, Y.-I.; Lee, J.W.; Lee, U.-D.; Song, B.-H. Three-stage steady-state model for biomass gasification in a dual circulating fluidized-bed. Energy Convers. Manag. 2012, 54, 100–112. [Google Scholar] [CrossRef]

- Proll, T.; Hofbauer, H. H2 rich syngas by selective CO2 removal from biomass gasification in a dual fluidized bed system—Process modelling approach. Fuel Process. Technol. 2008, 89, 1207–1217. [Google Scholar] [CrossRef]

- Glass, S.V.; Zelinka, S.L. Moisture relations and physical properties of wood. In Handbook of Wood: Wood as an Engineering Material; Forest Products Laboratory: Madison, WI, USA, 1999. [Google Scholar]

- Boerrigter, H.; Calis, H.P.; Slort, D.J.; Bodenstaff, H. Gas cleaning for integrated biomass gasification and Fischer-Tropsch systems. Experimental demonstration of two BG-FT systems. In proceedings of the 2nd Word Conference and Technology Exhibition on Biomass for Energy and Climate Protection, Rome, Italy, 10–14 May 2014.

- Iguaz, A.; Esnoz, A.; Martínez, G.; López, A.; Vírseda, P. Mathematical modelling and simulation for the drying process of vegetable wholesale by-products in a rotary dryer. J. Food Eng. 2003, 59, 151–160. [Google Scholar] [CrossRef]

- Meza, J.; Gil, A.; Cortés, C.; González, A. Drying costs of woody biomass in a semi-industrial experimental rotary dryer. In Proceedings of the 16th European Conference & Exhibition on Biomass for Energy, Biomass Resources, Valecia, Spain, 2–6 June 2008.

- Saeman, W.C.; Mitchell, T.R. Analysis of Rotary Dryer a Cooler Performance. Chem. Eng. Prog. 1954, 50, 467–475. [Google Scholar]

- McCabe, W.L.; Smith, J.C.; Harriott, P. Solid drying. In Unit Opeartions of Chemical Engineering; McGraw-Hill: Boston, MA, USA, 2001. [Google Scholar]

- Franco, C.; Pinto, F.; Gulyurtlu, I.; Cabrita, I. The study of reactions influencing the biomass steam gasification process. Fuel 2003, 82, 835–842. [Google Scholar] [CrossRef]

- Sadaka, S.S.; Ghaly, A.E.; Sabbah, M.A. Two phase biomass air-steam gasification model for fluidized bed reactors: Part I—model development. Biomass Bioenergy 2002, 22, 439–462. [Google Scholar] [CrossRef]

- Fagbemi, L.; Khezami, L.; Capart, R. Pyrolysis products from different biomasses: Application to the thermal cracking of tar. Appl. Energy 2001, 69, 293–306. [Google Scholar] [CrossRef]

- Aigner, I.; Wolfesberger, U.; Hofbauer, H. Tar content and composition in producer gas of fluidized bed gasification and low temperature pyrolysis of straw and wood–influence of temperature. In Proceedings of the International Conference on Polygeneration Strategies, Vienna, Austria, 3–5 September 2013.

- Koppatz, S.; Pfeifer, C.; Hofbauer, H. Comparison of the performance behaviour of silica sand and olivine in a dual fluidised bed reactor system for steam gasification of biomass at pilot plant scale. Chem. Eng. J. 2011, 175, 468–483. [Google Scholar] [CrossRef]

- Yoshida, H.; Kiyono, F.; Tajima, H.; Yamasaki, A.; Ogasawara, K.; Masuyama, T. Two-stage equilibrium model for a coal gasifier to predict the accurate carbon conversion in hydrogen production. Fuel 2008, 87, 2186–2193. [Google Scholar]

- Nguyen, T.D.B.; Lim, Y.-I.; Song, B.-H.; Kim, S.-M.; Joo, Y.-J.; Ahn, D.-H. Two-stage equilibrium model applicable to the wide range of operating conditions in entrained-flow coal gasifiers. Fuel 2010, 89, 3901–3910. [Google Scholar] [CrossRef]

- Herguido, J.; Corella, J.; Gonzalez-Saiz, J. Steam gasification of lignocellulosic residues in a fluidized bed at a small pilot scale. Effect of the type of feedstock. Ind. Eng. Chem. Res. 1992, 31, 1274–1282. [Google Scholar] [CrossRef]

- Wei, L.; Xu, S.; Zhang, L.; Liu, C.; Zhu, H.; Liu, S. Steam gasification of biomass for hydrogen-rich gas in a free-fall reactor. Int. J. Hydrog. Energy 2007, 32, 24–31. [Google Scholar] [CrossRef]

- Sohel, M.I.; Jack, M.W. Thermodynamic analysis of lignocellulosic biofuel production via a biochemical process: Guiding technology selection and research focus. Bioresour. Technol. 2011, 102, 2617–2622. [Google Scholar] [CrossRef]

- Nikulshin, V.; Wu, C.; Nikulshina, V. Exergy Efficiency Calculation of Energy Intensive Systems by Graphs. Exergy Int. J. 2002, 2, 78–86. [Google Scholar] [CrossRef]

- Prins, M.J.; Ptasinski, K.J.; Janssen, F.J.J.G. Exergetic optimisation of a production process of Fischer-Tropsch fuels from biomass. Fuel Process. Technol. 2005, 86, 375–389. [Google Scholar] [CrossRef]

- Szargut, J. Exergy Method: Technical and Ecological Applications; WIT Press: Sothhampton, UK, 2005. [Google Scholar]

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Puadian, N.; Li, J.; Pang, S. Analysis of Operation Parameters in a Dual Fluidized Bed Biomass Gasifier Integrated with a Biomass Rotary Dryer: Development and Application of a System Model. Energies 2014, 7, 4342-4363. https://doi.org/10.3390/en7074342

Puadian N, Li J, Pang S. Analysis of Operation Parameters in a Dual Fluidized Bed Biomass Gasifier Integrated with a Biomass Rotary Dryer: Development and Application of a System Model. Energies. 2014; 7(7):4342-4363. https://doi.org/10.3390/en7074342

Chicago/Turabian StylePuadian, Nargess, Jingge Li, and Shusheng Pang. 2014. "Analysis of Operation Parameters in a Dual Fluidized Bed Biomass Gasifier Integrated with a Biomass Rotary Dryer: Development and Application of a System Model" Energies 7, no. 7: 4342-4363. https://doi.org/10.3390/en7074342