1. Introduction

As the number of vehicles increases globally, the energy crisis and environmental pollution have become drastic issues which restrict the development of the world auto industry. Undoubtedly, electric vehicles (EVs) with clean and low energy consumption are one of the best solutions of these problems and have received attention from all around the world. As the key part of EVs, different driveline types have been tried in EVs. Especially, the direct driveline with in-wheel machine is generating more and more interest. It can omit the clutch, the reduction gear and the differential gear. Because in-wheel machines are aimed to provide the traction of EVs directly, they should have high power density, high efficiency and perfect torque characteristic.

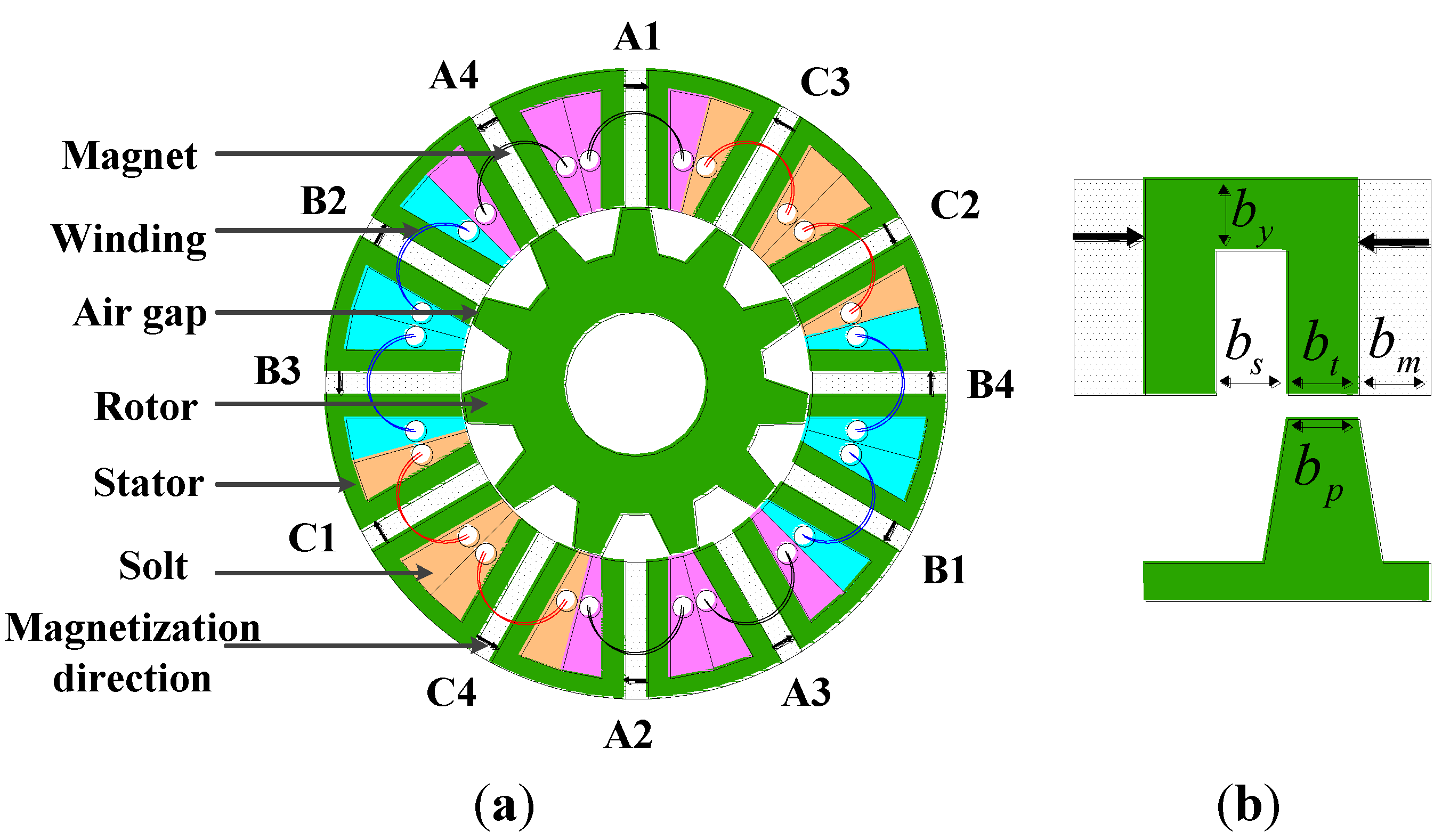

The flux switching permanent magnet (FSPM) machine is a potential candidate for the in-wheel machine. It can generate sufficient torque and power density, especially under starting and climbing conditions [

1,

2,

3]. Its high power density characteristics are similar to those of permanent magnet (PM) machines [

4,

5,

6,

7,

8]. Both windings and PMs are installed on the stator. This structure can avoid both the influence of centrifugal force on PMs and the problem of PM demagnetization caused by heat dissipation issues. As the waveform of the back electromotive force (EMF) is a sine wave, it is preferable to drive the FSPM machine in the brushless alternating current mode. Magnet accumulation effect is generated by neighboring PMs with opposite directions, which can reduce the volume of the machine, lessen the number of the PMs and decrease the machine cost. Different from common PM machines having PMs and armature windings magnetically in series, FSPM machines having PMs and armature windings magnetically in parallel lead to high flux weak capability, which is suitable for a wide speed range [

9,

10]. In particular, after hybrid excitation flux-switching machines were proposed, the flux linked in the armature windings per phase can be increased or reduced according to the operational status requests, which makes the magnetic field easily adjusted [

11,

12,

13]. The fault-tolerant capability of FSPM machines has also been a hot topic in recent years, FSPM machines with fault-tolerant capability can continue to operate under open circuit and short circuit fault conditions [

14,

15,

16,

17]. To sum up, because of the FSPM machine’s simple structure, good controllability, high power density and fault-tolerant performance, it is a good selection for driving EVs.

However, the FSPM machine suffers from great slot effects and serious partial saturation due to its own double salient structure, which causes high cogging torque and torque ripple. Numerous methods have been researched for reducing cogging torque and torque ripple considering either the machine design or control aspects. In the machine design aspect, pole and slot matching is a common method to improve the torque performance of machines and it can be directly used in FSPM machines [

18,

19]. Both finite-element method (FEM) results and experimental tests show that the rotors with odd numbers have lower torque ripple than the rotors with even numbers when the stator structures are the same. Optimization of PM shape is a typical method to improve the torque characteristics of traditional PM machines [

20,

21]. However, because the PMs are inserted into stator teeth, optimizing the PM shape is not a suitable approach for FSPM machines. Optimizing the rotor structure is however a favorable method for FSPM machines. Rotors with stepped skew were adopted in [

22,

23] to reduce the cogging torque and torque ripple under various load conditions. Various kinds of notching schemes and their influence on cogging torque are evaluated in [

24,

25]. It is revealed that the notches effectively reduce torque ripples, but the average torque decreases as well. In order to have a maximum average torque with minimum ripple content, notches with exponential variation profile are imposed [

25]. The multi-tooth structure is able to diminish the reluctance of magnetic circuit, which can improve the average torque, reduce the cogging torque and torque ripple [

26,

27]. The new laminated structure proposed in [

28] can decrease magnetic saturation at the edges of stators and rotor teeth and lead to lower cogging torque and higher torque density. In the control aspect, injecting harmonic current or adjusting the current of normal phases can compensate torque ripple [

29,

30,

31], but a sensitive and reliable sensor is needed to confirm the amplitude and angle of the current, and hence the complexity of the entire control system is increased. Optimizing the machine structure can either reduce the cogging torque or reduce the total harmonic distortion (THD) and hence torque ripple, so the machine design method is usually better than the control method.

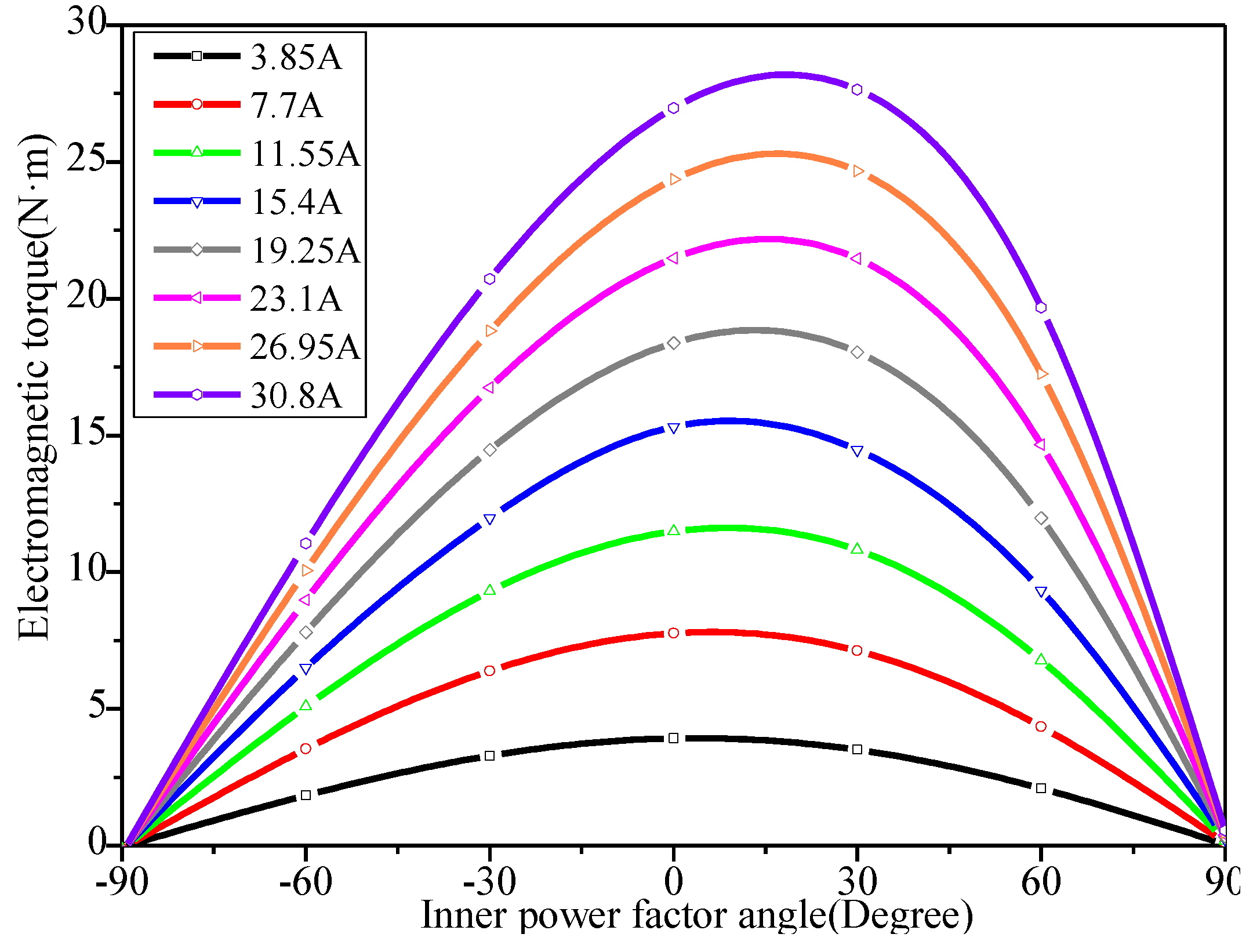

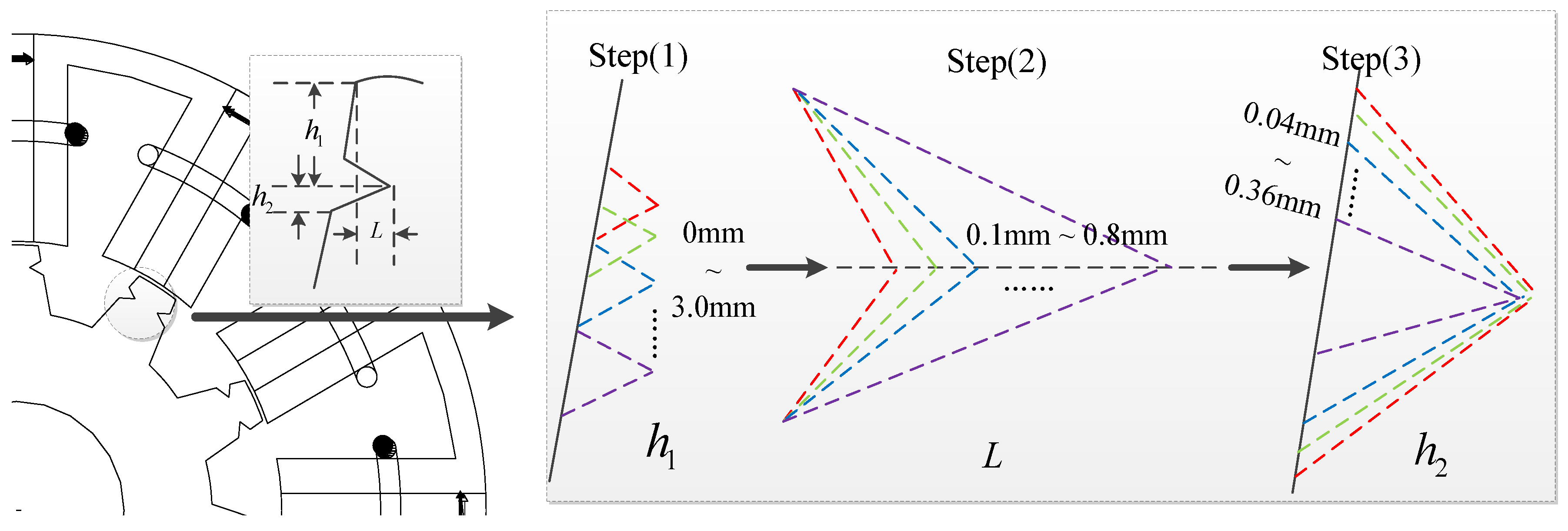

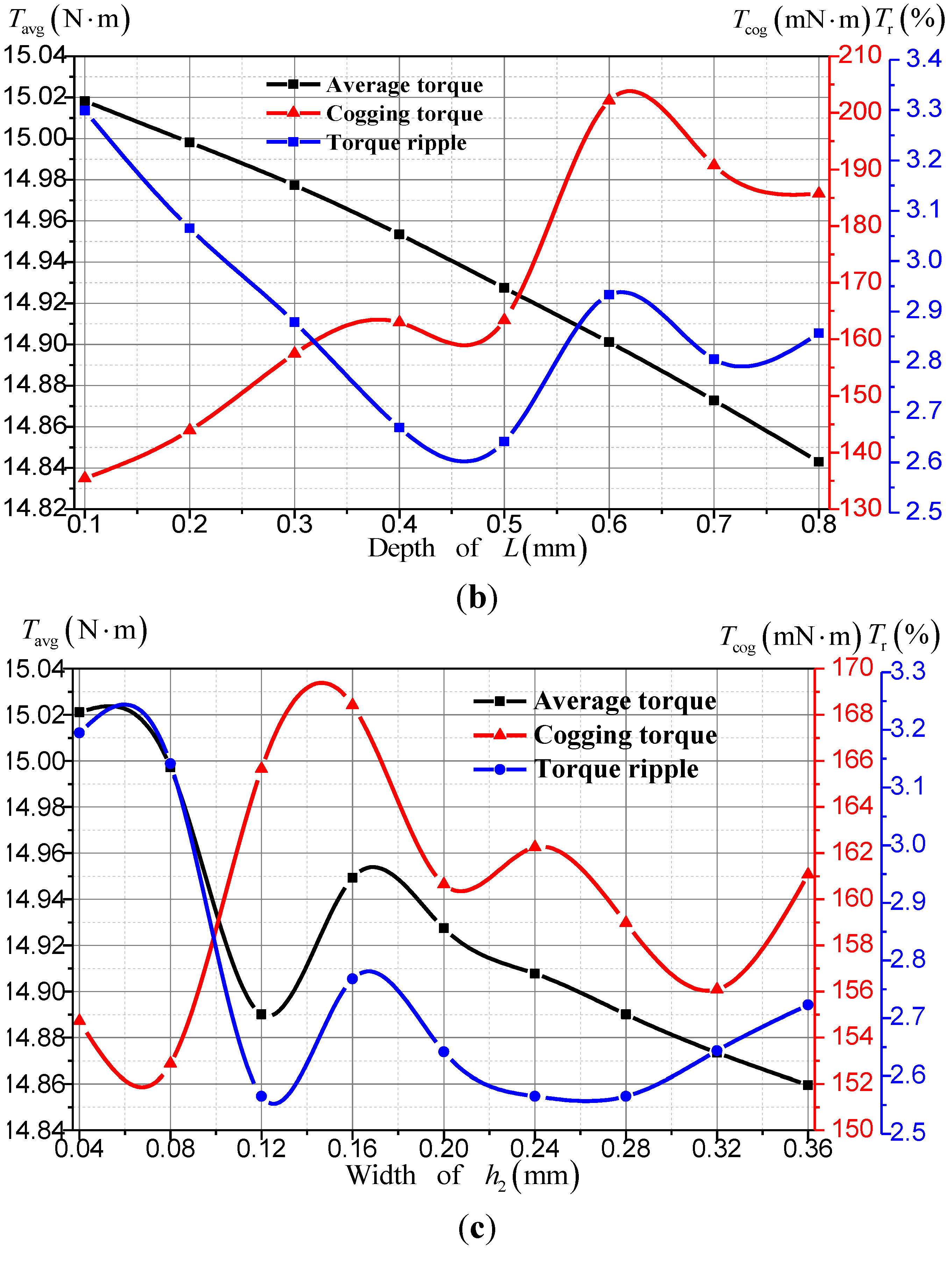

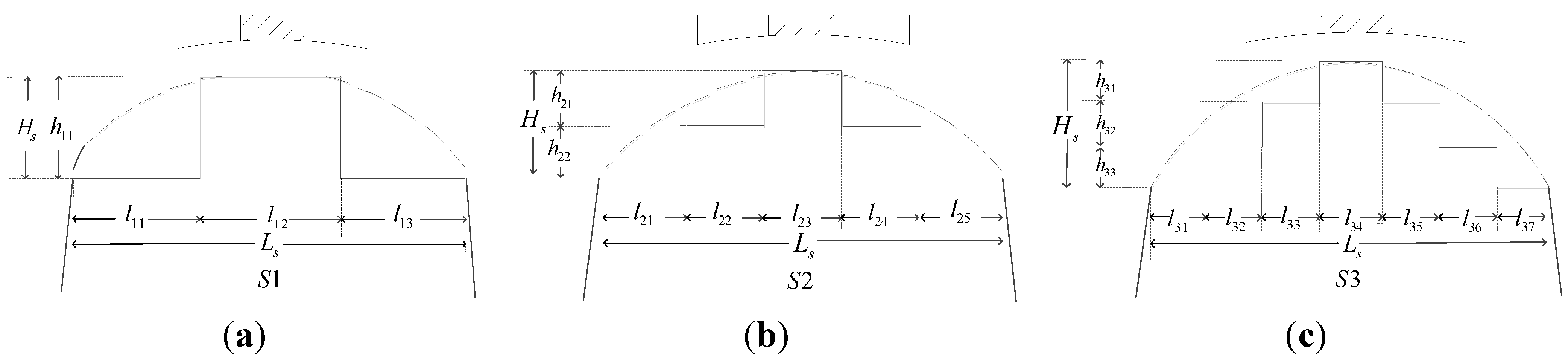

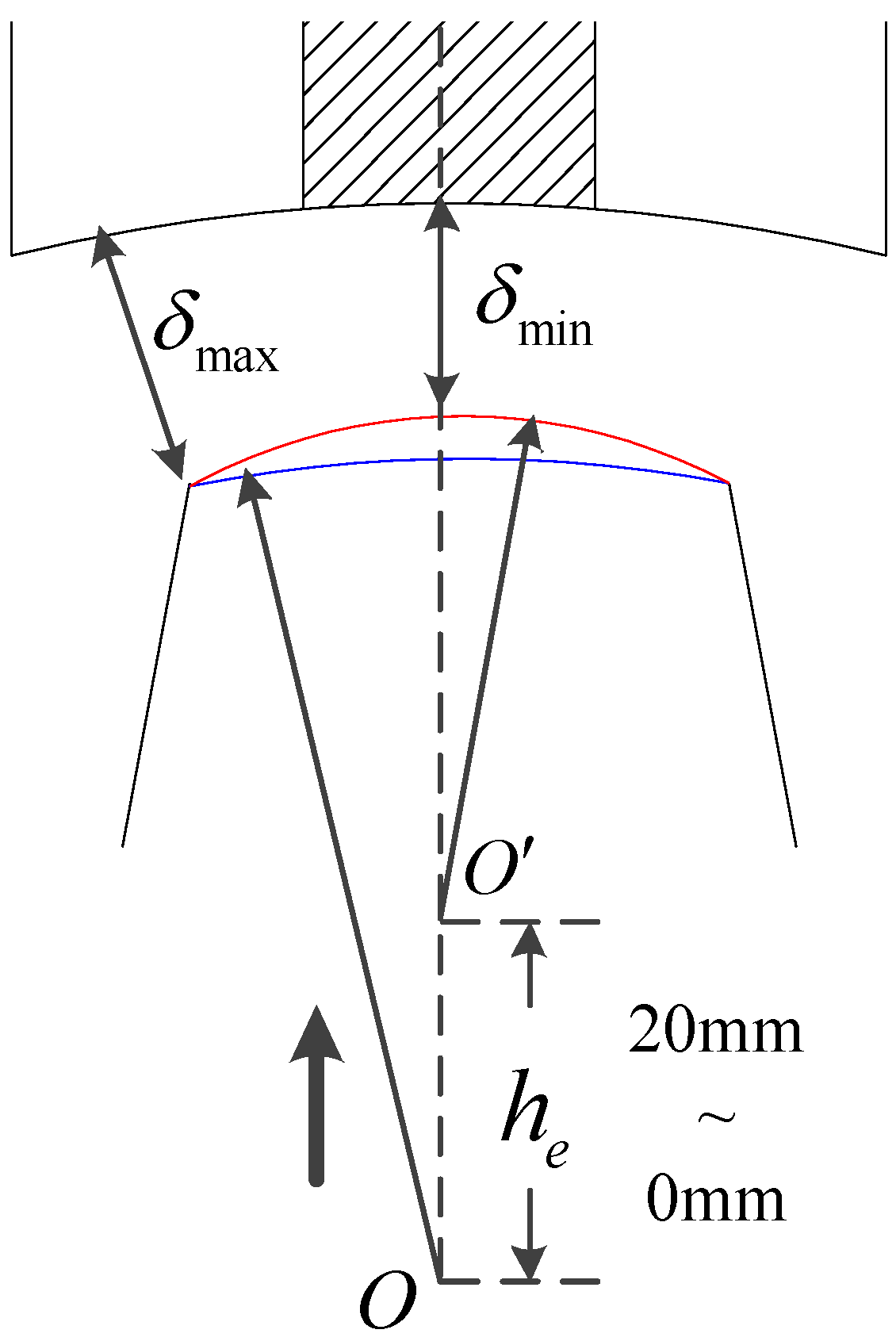

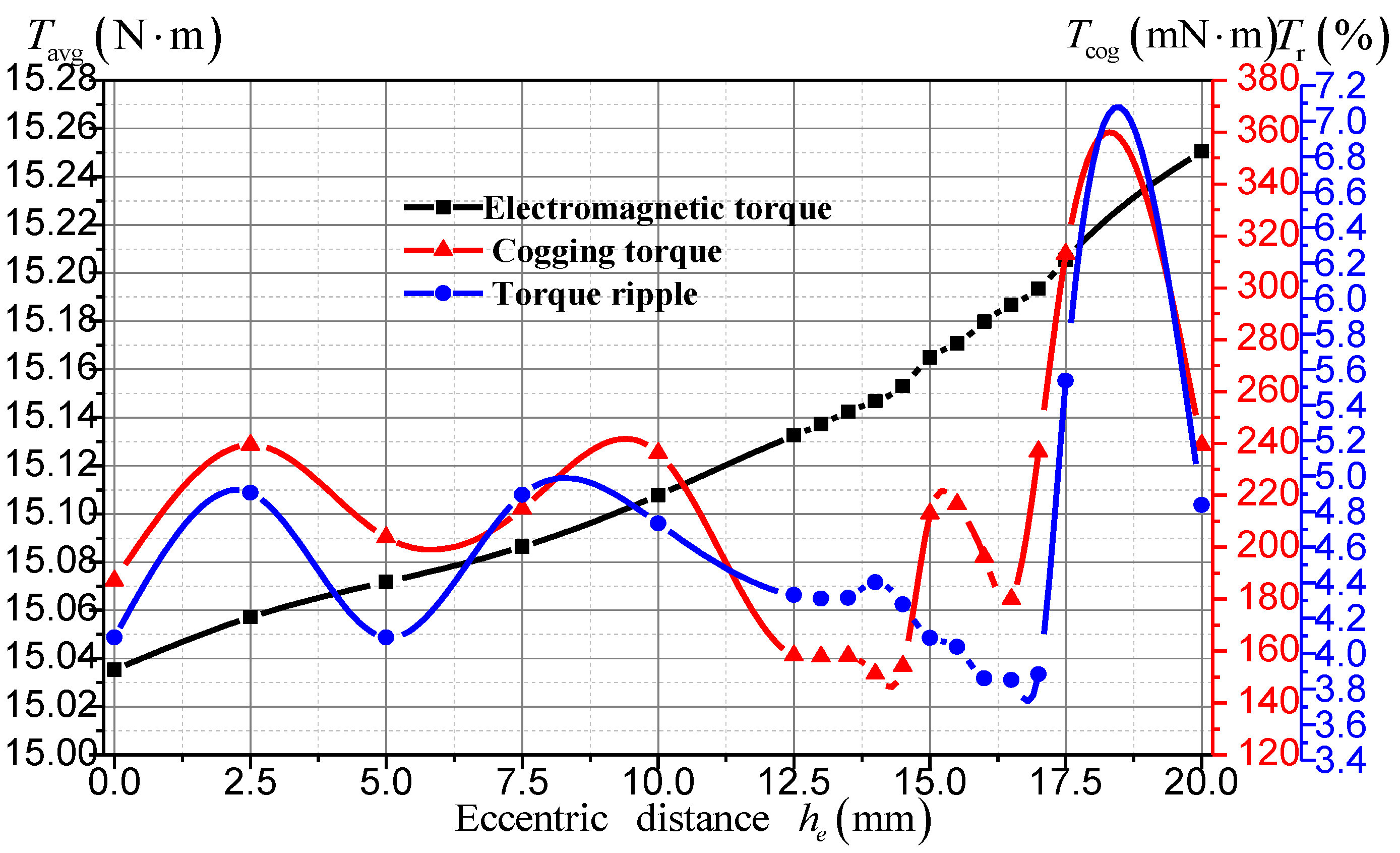

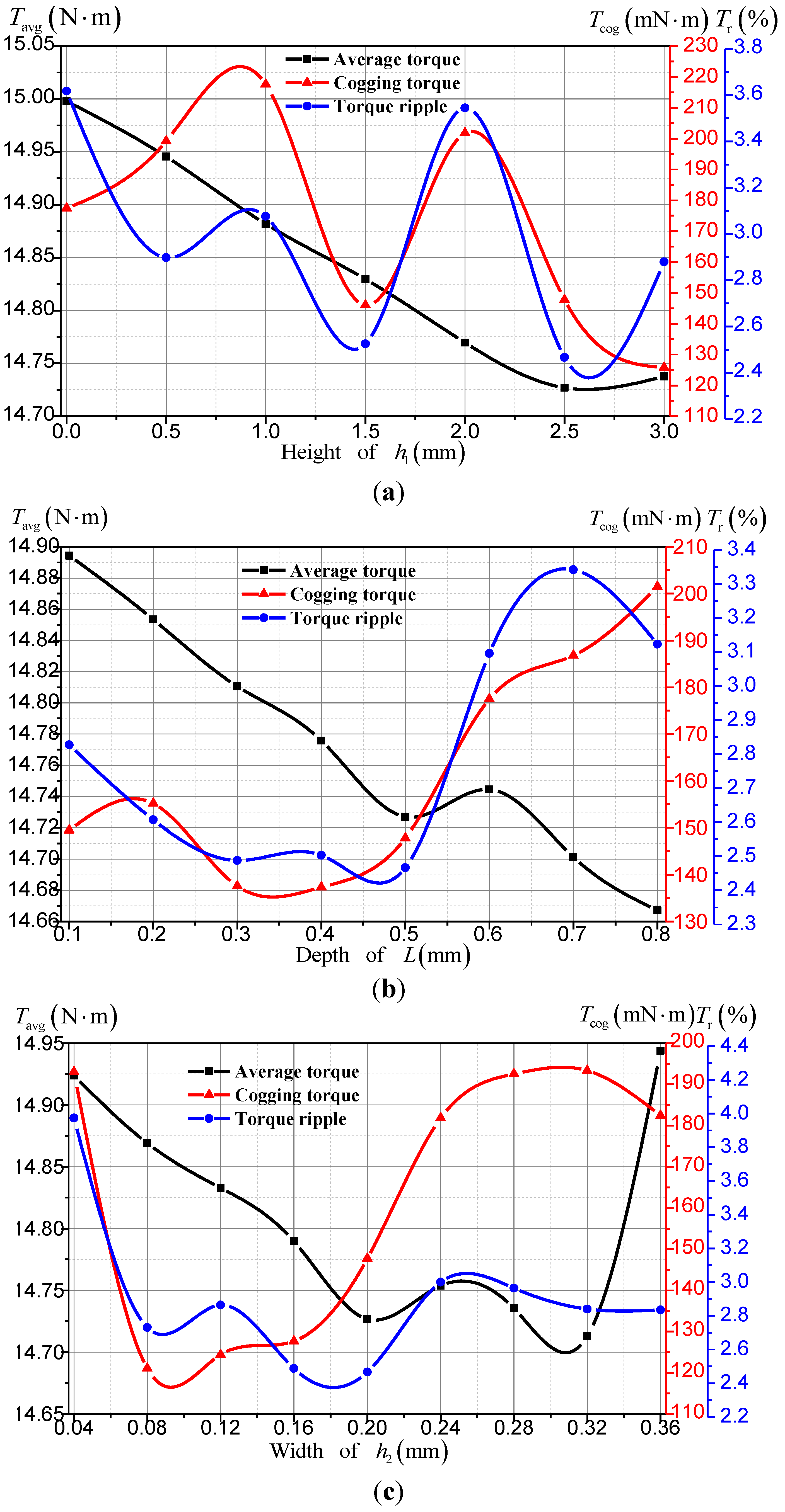

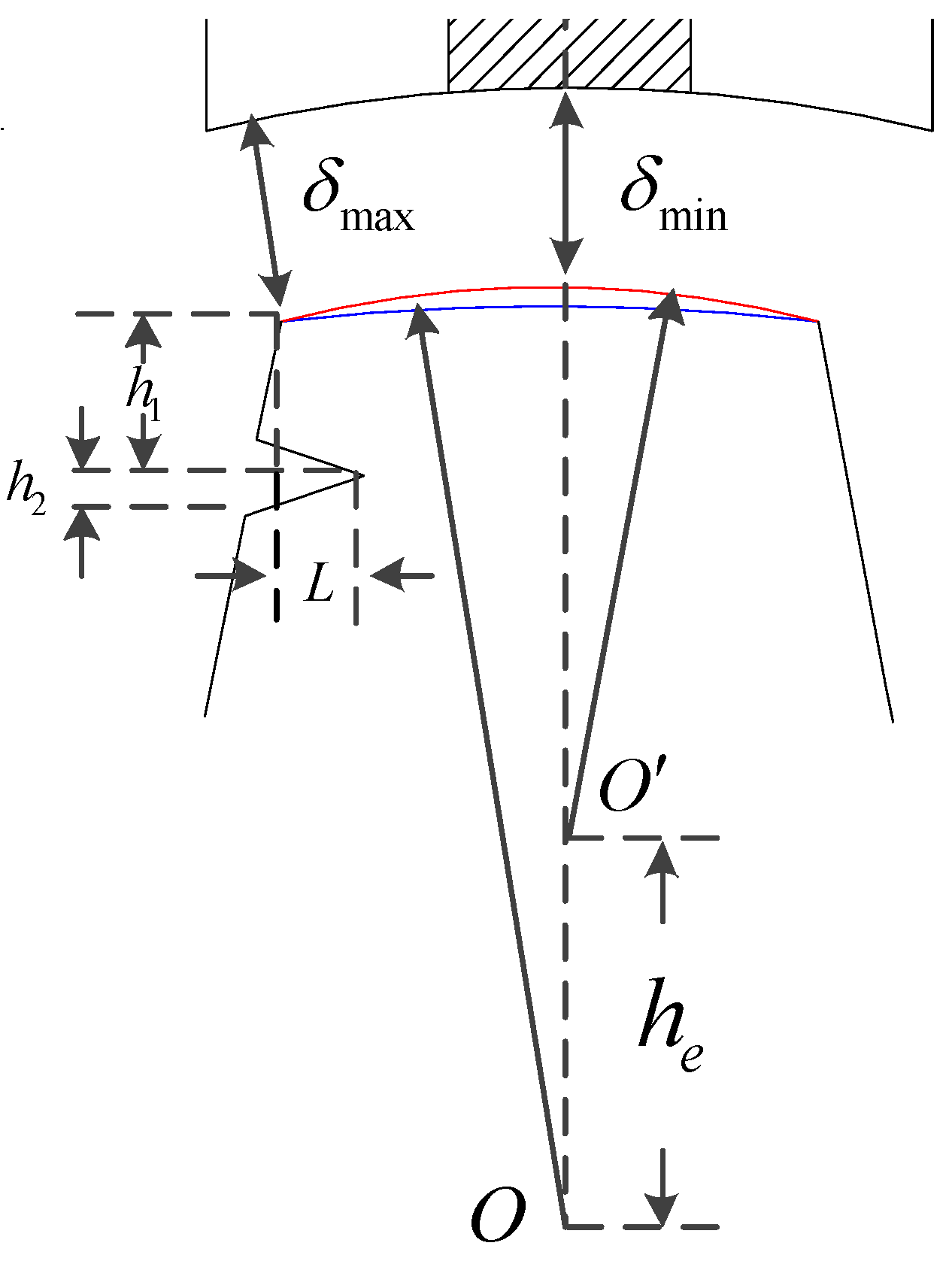

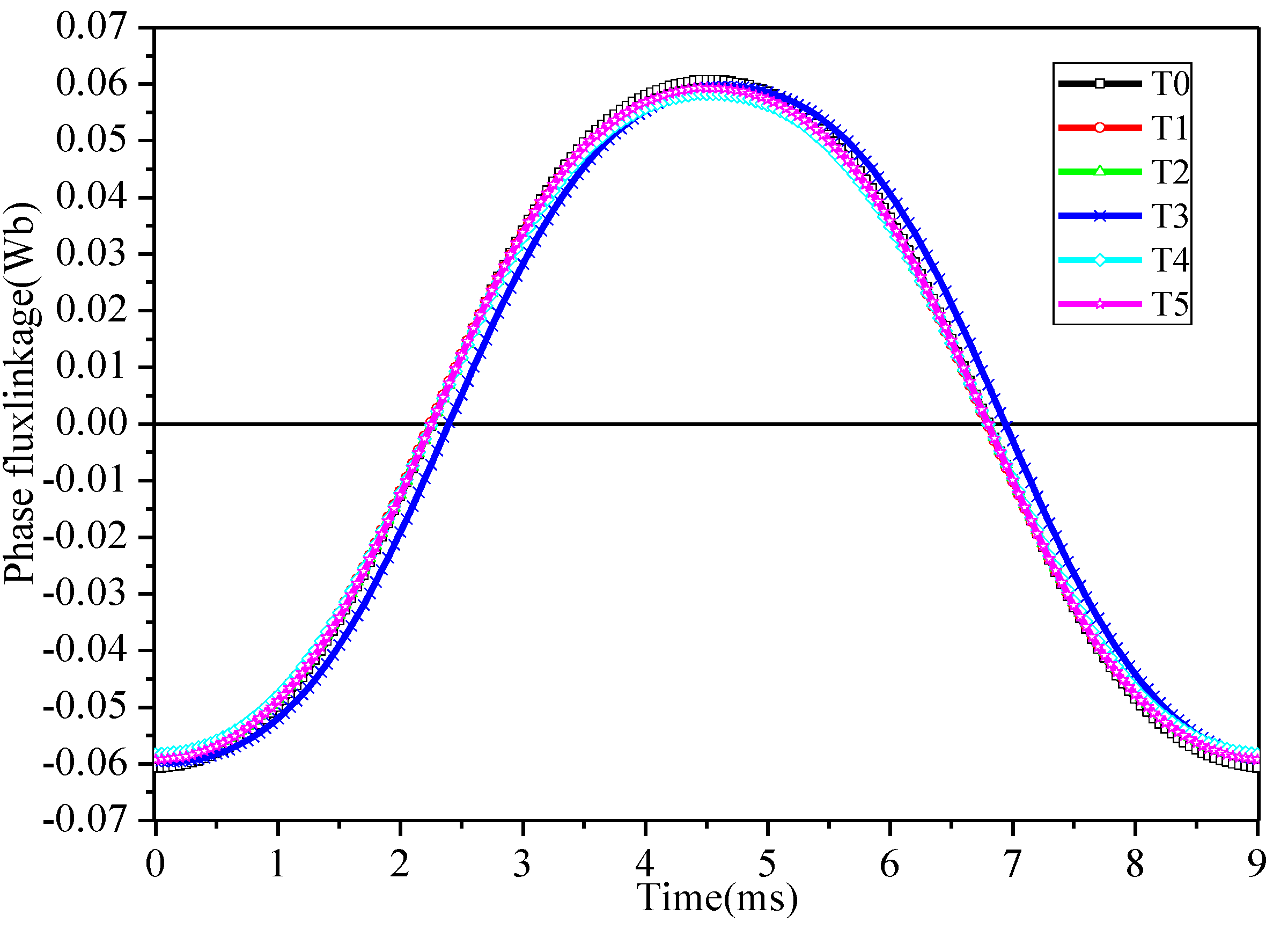

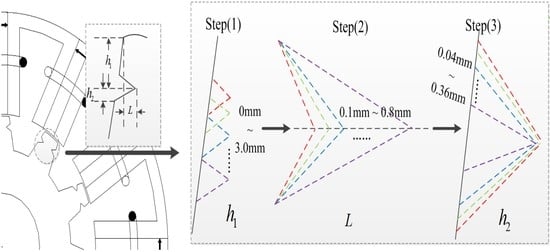

Considering that the stator structure of a FSPM machine is more complex, a relatively simpler rotor is selected to implement the improvement of torque characteristics of the FSPM machine in this paper. Firstly, the main parameters of FSPM machine are introduced. Secondly, the torque characteristics are analyzed. Under the premise of unchanging the stator’s structure, five novel rotor teeth shapes are proposed. Thirdly, the influences of different rotor teeth shapes on cogging torque, torque ripple and electromagnetic torque are analyzed by 2-D FEM using a commercial software package, Ansoft Maxwell. Finally, the performances of FSPMs with different rotor teeth shapes are compared and discussed based on cogging torque, torque ripple, electromagnetic torque, flux linkage, back EMF, and so on. The effects of different rotor teeth shapes are evaluated.

5. Conclusions

As one of the key part of the EV driveline system, a 12-slot/11-pole FSPM machine used for EVs is researched in this paper. Considering the comparatively larger cogging torque and torque ripple caused by the doubly salient structure, five rotor teeth shapes, i.e., rotor with notched teeth, rotor with stepped teeth, rotor with eccentric teeth, rotor with the combination of stepped and notched teeth, rotor with the combination of eccentric and notched teeth, are investigated to improve the torque characteristics. The laws of torque characteristic changes with the variation of the key parameters in different schemes are obtained and analyzed. The performance with different rotor teeth shapes are compared and discussed comprehensively from the aspects of cogging torque, torque ripple, electromagnetic torque, flux linkage, back EMF, and so on. It is found that the rotor with the combination of stepped and notched teeth has the best effectiveness to reduce the cogging torque by 31.87% and torque ripple by 39.15% but with a slight average torque loss of 1.63%. However, these methods all lead to more or less increased manufacturing costa and some of them may lead to considerable acoustic noise, which will be studied in our future work.