Operation of Steam Turbines under Blade Failures during the Summer Peak Load Periods

Abstract

:1. Introduction

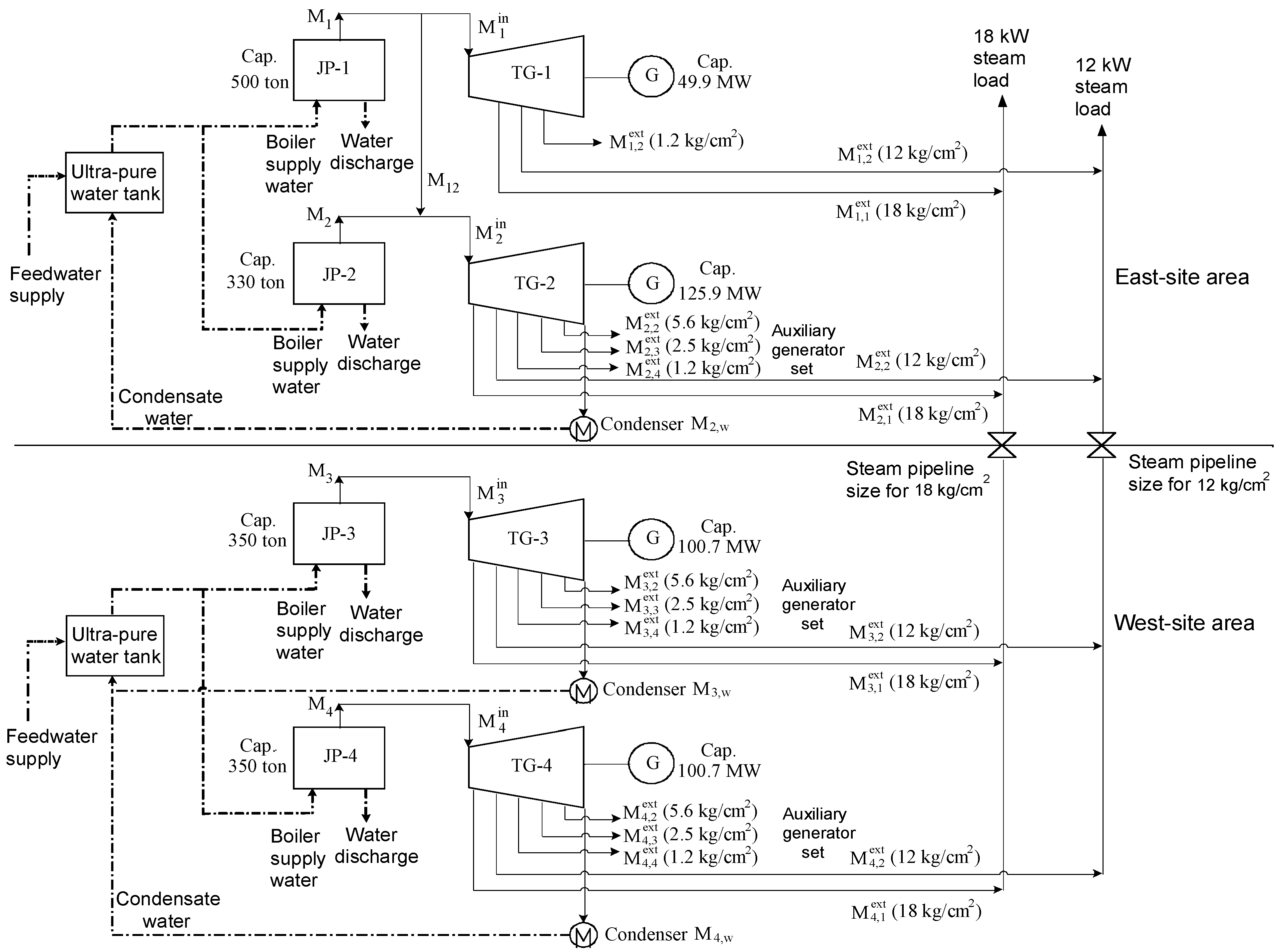

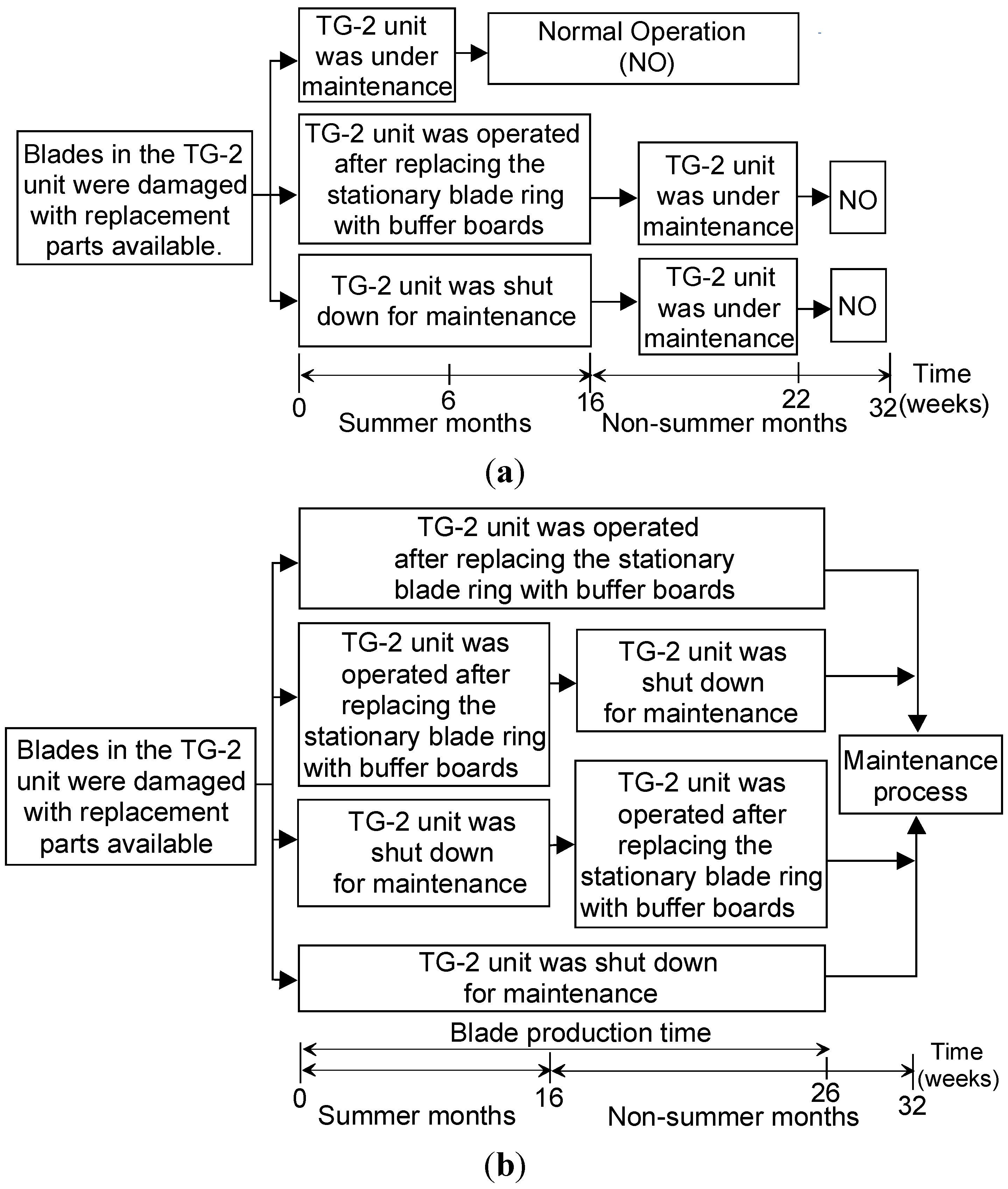

2. Strategic Decision-Making and Problem Formulation

- Case Y1:

- A complete inspection and overhaul of the TG-2 unit has been performed within six weeks and the unit continues to be operated normally for 22 weeks.

- Case Y2:

- The TG-2 unit has been operated for 16 weeks within summer electricity rate after an 80-h of replacing the stationary blade ring with buffer boards, and the unit resumes operation after carrying out a complete overhaul during non-summer months.

- Case Y3:

- The TG-2 unit has been shut down for maintenance during summer months, and the unit resumes operation after carrying out a complete overhaul during non-summer months.

- Case N1:

- The TG-2 unit has been operated abnormally for 16 weeks within summer electricity rate and for 10 weeks within non-summer electricity rate after replacing the stationary blade ring with buffer boards. Then, a complete overhaul on the unit is performed.

- Case N2:

- The TG-2 unit has been operated abnormally for 16 weeks within summer electricity rate and has been shut down for 10 weeks of repairs during non-summer months. Then, a complete overhaul on the unit is performed.

- Case N2:

- The TG-2 unit has been shut down for maintenance during summer months and operated abnormally for 10 weeks within non-summer electricity rate after replacing the stationary blade ring with buffer boards. Then, a complete overhaul of the unit is performed.

- Case N2:

- The TG-2 unit has been shut down for maintenance during summer and non-summer months, and a complete overhaul of the unit is performed. This case assumes the TG-2 unit will return to a normal efficiency after the full overhaul.

- (1)

- I/O curve for each generating unit: To analyze the operating data and an isentropic effect of the steam boilers, it will help to determine the optimal operating points, the generating units’ efficiency characteristics and the performance of operational effectiveness.

- (2)

- Time-frame for the repair: Since the TOU rate varies by season, the cost of power consumption exceeding the contract capacity, due to a temporary failure, does vary. Moreover, the damaged unit operated at a lower efficiency may cause more fuel to be used, affecting the profits greatly.

- (3)

- The satisfaction of energy and steam needed in the manufacturing process: This factor takes into account ensuring that an adequate supply of steam and electricity is available to meet all manufacturing processes.

2.1. I/O Cost Curve Construction

| Time (h) | JP-1 | JP-2 | JP-3 | JP-4 | ||||

|---|---|---|---|---|---|---|---|---|

| Mass of Steam Produced (tonne/h) | Mass of Coal Utilized (tonne/h) | Mass of Steam Produced (tonne/h) | Mass of Coal Utilized (tonne/h) | Mass of Steam Produced (tonne/h) | Mass of Coal Utilized (tonne/h) | Mass of Steam Produced (tonne/h) | Mass of Coal Utilized (tonne/h) | |

| 1 | 415 | 47.2 | 235 | 23.4 | 302 | 37.5 | 273.9 | 33 |

| 2 | 411.8 | 48 | 240 | 24 | 264.1 | 33.3 | 261.1 | 31 |

| 3 | 415.1 | 48 | 242 | 24.2 | 265.2 | 33.8 | 260 | 31 |

| 4 | 416.2 | 48.1 | 235 | 23.6 | 266.5 | 33.2 | 260.4 | 31 |

| 5 | 413.7 | 48.1 | 233 | 23 | 266.6 | 33.5 | 260.9 | 30.9 |

| 6 | 414 | 48 | 229 | 22.8 | 267.6 | 33.1 | 260.3 | 30.8 |

| 7 | 414.1 | 48 | 230 | 22.6 | 265.9 | 33.4 | 260.8 | 30.9 |

| 8 | 421.1 | 47.6 | 238 | 23.1 | 268.6 | 33.4 | 260.2 | 30.7 |

| 9 | 409.4 | 47.6 | 238 | 22.9 | 268 | 32.8 | 260.5 | 30.7 |

| 10 | 411 | 47.6 | 235 | 21.8 | 268.6 | 33.3 | 260.4 | 30.8 |

| 11 | 408.9 | 47.2 | 226 | 21.5 | 268.6 | 32.9 | 260 | 30.5 |

| 12 | 400.1 | 46.4 | 243 | 26.7 | 268.1 | 32.6 | 260.7 | 30.6 |

| 13 | 401.7 | 46.4 | 244 | 26.8 | 269 | 32.9 | 260.9 | 30.7 |

| 14 | 402.1 | 46.6 | 246 | 27 | 269 | 33.4 | 260.5 | 30.6 |

| 15 | 399 | 46.4 | 244 | 26.8 | 266.7 | 32.8 | 261.1 | 30.5 |

| 16 | 398 | 46.7 | 242 | 26.6 | 269.6 | 33.1 | 261.2 | 30.6 |

| 17 | 401 | 46.7 | 240 | 26.4 | 267.4 | 33.2 | 261.1 | 30.8 |

| 18 | 405 | 46.9 | 242 | 26.6 | 269.4 | 33.4 | 270.4 | 31.6 |

| 19 | 411 | 46.7 | 242 | 26.6 | 267.6 | 33.3 | 270.9 | 31.8 |

| 20 | 407 | 46.7 | 244 | 26.8 | 267.8 | 33.3 | 270.8 | 31.7 |

| 21 | 404 | 46.8 | 243 | 26.7 | 269 | 33.3 | 270.5 | 32 |

| 22 | 407.4 | 46.6 | 242 | 26.6 | 268 | 33.1 | 270.1 | 31.8 |

| 23 | 406.8 | 46.8 | 244 | 26.8 | 267 | 32.5 | 270.1 | 31.9 |

| 24 | 405.2 | 46.7 | 230 | 21.5 | 266.8 | 32.3 | 270.5 | 31.8 |

| Boilers No. | Coefficients | ||

|---|---|---|---|

| ai,0 (tonne/h) | ai,1 (dimensionless) | ai,2 (h/tonne) | |

| JP-1 | −10.30 | 0.1691 | −0.000068 |

| JP-2 | −14.21 | 0.2291 | −0.000250 |

| JP-3 | −38.53 | 0.3843 | −0.000443 |

| JP-4 | 56.00 | −0.2871 | 0.000724 |

| Generating units | Coefficients | |||||||

|---|---|---|---|---|---|---|---|---|

| bj,0 | bj,1 | bj,2 | bj,3 | bj,4 | bj,5 | bj,6 | ||

| TG-1 | 8.77 | 0.00062 | 0.00105 | 0.00072 | 0 | 0 | 0 | |

| TG-2 | Abnormal | −12.80 | 0 | −0.00097 | 0.00580 | 0.00222 | 0.02610 | −0.00021 |

| Normal | −18.12 | −0.0014 | 0.00145 | 0.00016 | 0.00294 | 0.00167 | 0.00152 | |

| TG-3 | 5.46 | 0 | 0.00009 | 0.00697 | 0.00111 | 0.01760 | 0.00004 | |

| TG-4 | −2.44 | 0 | 0.00206 | 0.01060 | 0.00224 | 0.00282 | 0.00045 | |

2.2. Mathematical Model

2.2.1. Unit Commitment

2.2.2. Economic Operation Cost

2.2.3. The Start-up Cost of Each Unit

| Start-up time (h) | Start-up costs (NT$) | |||

|---|---|---|---|---|

| JP-1&TG-1 | JP-2&TG-2 | JP-3&TG-3 | JP-4&TG-4 | |

| 2 | 1,332,900 | 1,332,900 | 1,332,900 | 1,332,900 |

| 3 | 1,354,350 | 1,354,350 | 1,354,350 | 1,354,350 |

| 4 | 1,375,800 | 1,375,800 | 1,375,800 | 1,375,800 |

| 5 | 1,397,250 | 1,397,250 | 1,397,250 | 1,397,250 |

| 6 | 1,418,700 | 1,418,700 | 1,418,700 | 1,418,700 |

| 7 | 1,440,150 | 1,440,150 | 1,440,150 | 1,440,150 |

| 8 | 1,461,600 | 1,461,600 | 1,461,600 | 1,461,600 |

| 9 | 1,483,050 | - | - | - |

2.2.4. Equality and Inequality Constraints

- (a)

- Power balance:

- (b)

| Unit No. | Steam input source | Electricity output of each generator (MW) | Boilers No. | Boiler steam production (tonne/h) | ||

|---|---|---|---|---|---|---|

| Pj,min | Pj,max | Mi,min | Mi,max | |||

| TG-1 | JP-1 | 10 | 49.9 | JP-1 | 170 | 500 |

| TG-2 | JP-1, JP-2 | 10 | 125.9 | JP-2 | 110 | 330 |

| TG-3 | JP-3 | 22 | 100.7 | JP-3 | 150 | 350 |

| TG-4 | JP-4 | 22 | 100.7 | JP-4 | 150 | 350 |

- (c)

- Flow conservation constraints:

- (d)

- Steam flow capacity constraints of the j-th turbine:

- (e)

- Steam balance:

- (f)

- Capacity limit of steam connecting pipe:

- (g)

- Spinning reserve:

- (h)

- Minimum up-time/down-time limit of units:

| Boile/Turbine | Hot start (h) | Warm start (h) | Cold start (h) | Low load/Shutdown (h) |

|---|---|---|---|---|

| P-1/TG-1 | 2/1 | 5/1 | 9/2 | 3/1 |

| JP-2/TG-2 | 2/1 | 4/1 | 8/2 | 3/1 |

| JP-3/TG-3 | 2/1 | 4/1 | 8/2 | 3/1 |

| JP-4/TG-4 | 2/1 | 4/1 | 8/2 | 3/1 |

3. Simulation Results

3.1. Case Description

- (1)

- The capacity price with contracts signed in 2006 is listed in Table 7.

- (2)

- (3)

- The assumed coal purchase price and fuel oil price are 2.004 NT$/kg and 12.9 NT$/L, respectively.

- (4)

- The operating cost of boiler make-up water is 30 NT$/tonne and the boiler blowdown rate is 3%.

- (5)

- The sale prices of the steam pressures at 18 and 12 kg/cm2 are assumed to be 471 and 424 NT$/tonne, respectively.

- (6)

- The coal/steam ratio of JP-1, JP-2, JP-3 and JP-4 boilers are equal to the mass (in tonne/h) of coal utilized divided by the mass (tonne/h) of steam produced which are 116.050, 99.414, 120.131 and 116.409, respectively.

| Items | Summer peak | Summer off-peak | |

|---|---|---|---|

| Basic electricity price (NT$) | Annual contract | 217.3 | 160.6 |

| Semi-peak contract | 160.6 | 160.6 | |

| Saturday semi-peak and off-peak contract | 43.4 | 32.1 | |

| Items | TOU rate (NT$/kW·h) | |||

|---|---|---|---|---|

| Summer months | Non-summer months | |||

| Weekday | On-peak | 10:00–12:00 | 3.29 | - |

| 13:00–17:00 | ||||

| Semi-peak | 07:30–10:00 | 1.9 | - | |

| 12:00–13:00 | ||||

| 17:00–22:30 | ||||

| 07:30–22:30 | - | 1.85 | ||

| Off-peak | 00:00–07:30 | 0.78 | 0.73 | |

| 22:30–24:00 | ||||

| Saturday | Semi-peak | 07:30–22:30 | 1.08 | 1.02 |

| Off-peak | All day | 0.78 | 0.73 | |

| Sunday | Off-peak | All day | 0.78 | 0.73 |

| Items | Within the 20% installed capacity | Over the 20% installed capacity | ||||

|---|---|---|---|---|---|---|

| Summer peak | Summer off-peak | Summer peak | Summer off-peak | |||

| Basic electricity price | Per kW | 207 | 153 | 202.86 | 149.94 | |

| TOU rate | On-peak | Per kW·h | 3.04 | - | 3.0237 | - |

| Semi-peak | Per kW·h | 1.83 | 1.77 | 1.6432 | 1.5861 | |

| Saturday semi-peak | Per kW·h | 1.00 | 0.94 | 0.8142 | 0.757 | |

| Off-peak | Per kW·h | 0.69 | 0.64 | 0.5194 | 0.471 | |

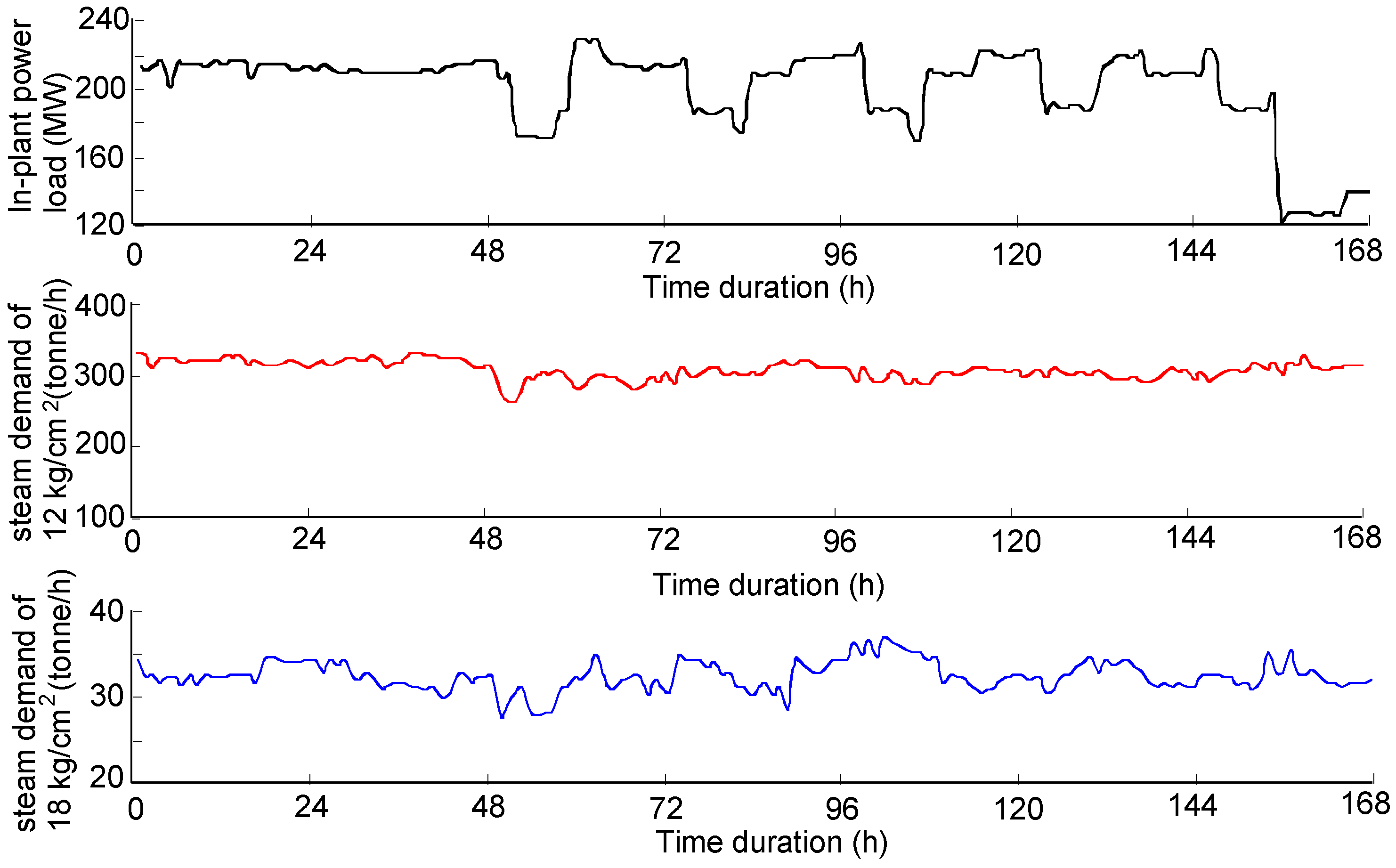

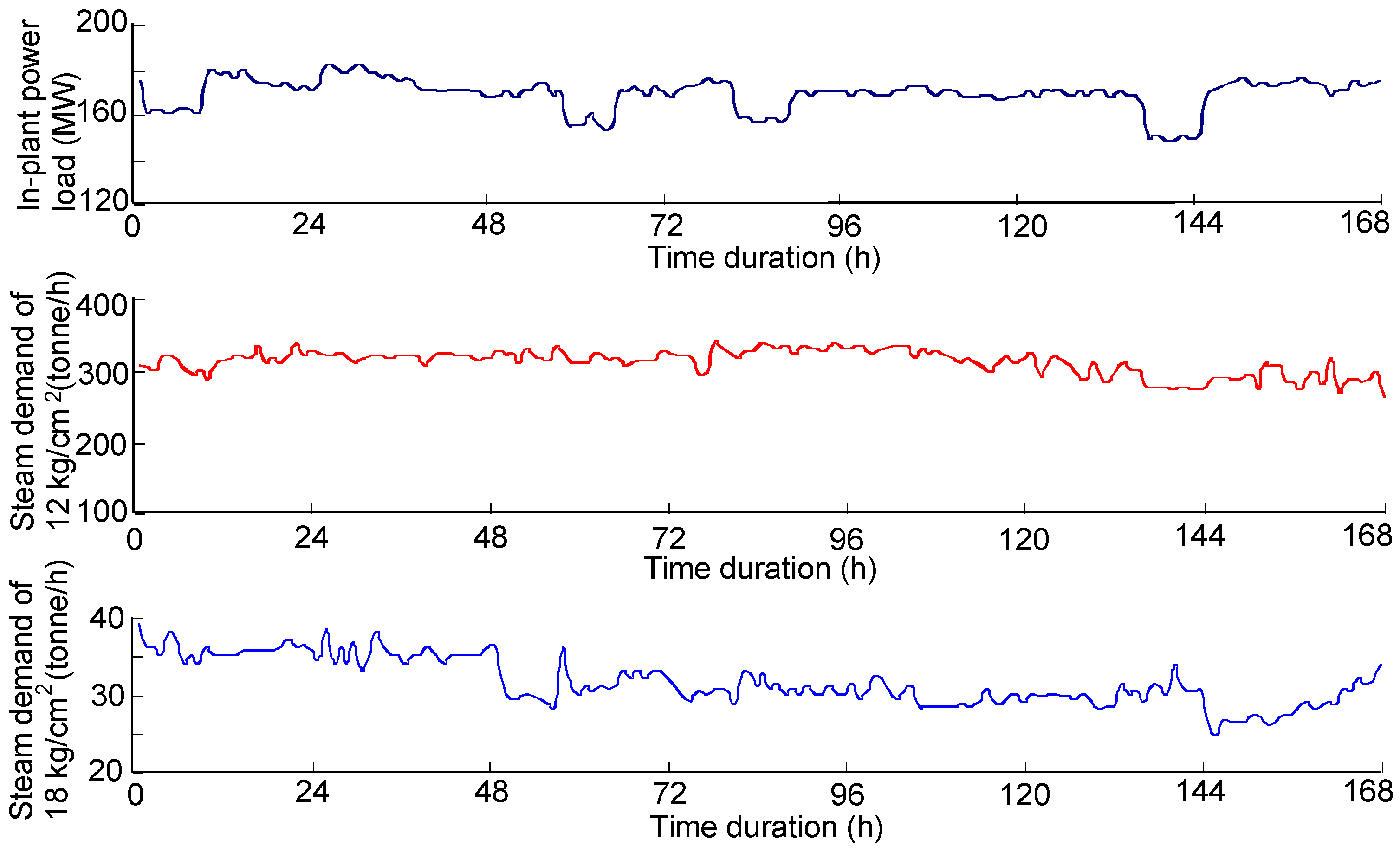

3.2. Considering the Time-of-Use Rate into Decision-Making

3.2.1. During the Summer Months

3.2.2. During the Non-Summer Months

| TOU rates | Operating conditions of the TG-2 turbine | Total costs (NT$/week) |

|---|---|---|

| Summer months | Actual recording | 15,303,200 |

| Case Y1 | 12,254,394 | |

| Case Y2 | 14,379,317 | |

| Case Y3 | 20,308,900 | |

| Non-summer months | Actual recording | 15,796,623 |

| Case Y1 | 13,771,791 | |

| Case Y2 | 15,119,318 | |

| Case Y3 | 19,121,263 |

3.3. Maintenance Strategies Decision Making

| Items | Unit 1 | Unit 2 | Unit 3 | Unit 4 | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Years | Years | Years | Years | |||||||||||||

| 2004 | 2005 | 2006 | 2007 | 2004 | 2005 | 2006 | 2007 | 2004 | 2005 | 2006 | 2007 | 2004 | 2005 | 2006 | 2007 | |

| Number of abnormal situations | 0 | 0 | 0 | 1 | 1 | 2 | 3 | 2 | 1 | 2 | 3 | 3 | 1 | 2 | 3 | 1 |

| Total shutdown hour (h) | 0 | 0 | 0 | 4 | 3 | 8 | 166 | 35 | 37 | 42 | 26 | 23 | 3 | 8 | 16.5 | 4 |

| Actual operating hours (h) | 8,760 | 34,080 | 34,080 | 34,080 | ||||||||||||

| Probability of occurring faults | 0.0457% | 0.6221% | 0.3756% | 0.0924% | ||||||||||||

- (a)

- The penal charges for exceeding the contract demand, CP: it is written to be 2 × (the maximum exceeded power consumption is less than 10% of the contract demand × basic tariff) + 3 × (the maximum exceeded power consumption is more than 10% of the contract demand × basic tariff).

- (b)

- The loss of profits, CL: It means the cost of purchasing energy from the utility instead of selling that energy during the maintenance period, which is calculated by multiplying the purchase price of energy by the TOU rate.

- (c)

- The restart cost, CS: It can be obtained based on calculating the cold start-up cost.

| Items | TOU rate during summer months | TOU rate during non-summer months | ||||

|---|---|---|---|---|---|---|

| Shutdown maintenance | Abnormal operation | Normal operation | Shutdown maintenance | Abnormal operation | Normal operation | |

| Operational cost | 20,308,900 | 14,379,317 | 12,254,394 | 19,121,263 | 15,119,319 | 13,771,791 |

| Expected loss of unit 1 | 328,967 | 78,586 | 93,028 | 88,257 | 68,149 | 90,308 |

| Expected loss of unit 2 | 0 | 3,428,981 | 5,021,015 | 0 | 1,263,816 | 4,348,737 |

| Expected loss of unit 3 | 13,783,512 | 4,623,253 | 4,212,521 | 13,112,259 | 3,929,824 | 2,775,196 |

| Expected loss of unit 4 | 2,766,203 | 886,020 | 838,635 | 884,982 | 954,645 | 513,873 |

| Total expected loss | 16,878,682 | 9,016,840 | 10,165,198 | 14,085,498 | 6,216,433 | 7,728,114 |

3.3.1. Replacement Blades Are Readily Available

| Items | During summer months | During non-summer months | ||||||

|---|---|---|---|---|---|---|---|---|

| With Extra Blades | Without Extra Blades | With Extra Blades | Without Extra Blades | |||||

| Shutdown maintenance | Abnormal operation | Shutdown without maintenance | Abnormal operation | Shutdown without maintenance | Shutdown maintenance | Shutdown maintenance | Abnormal operation | |

| Average operating cost | 90,922 | 85,591 | 120,886 | 85,591 | 120,886 | 93,916 | 113,817 | 98,929 |

| Expected loss | 75,493 | 53,672 | 100,468 | 53,672 | 100,468 | 60,191 | 83,842 | 54,567 |

| Abnormal operating cost | 0 | 80,000 | 0 | 80,000 | 0 | 0 | 0 | 0 |

| Total costs | 166,414 | 219,263 | 221,355 | 219,263 | 221,355 | 154,107 | 197,659 | 153,496 |

3.3.2. Replacement Blades Are Not Readily Available

4. Results and Discussion

5. Conclusions

Abbreviations and Symbols

| ai.n | The coefficients of boilers’ I/O cost curves, n = 0–2 |

| bj,m | The coefficients of turbines’ characteristic, m = 0–6 |

| C | The total overall operation cost (NT$; 1 USD = 30 NT$) |

| CH12,max | The upper limit on the delivered steam at pressure 12 kg/cm2 in the connecting pipe (tonne/h) |

| CH18,max | The upper limit on the delivered steam at pressure 18 kg/cm2 in the connecting pipe (tonne/h) |

| Et | The economic operation cost at the t-th hour (NT$) |

| Fi | The quantity of fuel consumed by the i-th boiler (oil: kL/h, coal: tonne/h) |

| FCi | The unit price of fuel (oil: NT$/kL, coal: NT$/tonne) |

| H | The number of hours in study period (h) |

The enthalpy of steam at turbine inlet (kcal/kg) | |

The enthalpy in the k-th extraction stage on a turbine (kcal/kg) | |

| hj,w | The enthalpy in the condensing stage on a turbine (kcal/kg) |

| M12 | The flow supplied from JP-1 to TG-2 with the maximum capacity of 170 (tonne/h) |

| Mi | The flow of steam produced by the i-th boiler (tonne/h) |

The inlet steam flow of the j-th turbine (tonne/h) | |

| Mj,12 | The 12 kg/cm2 extraction flow of the j-th turbine (tonne/h) |

| Mj,18 | The 18 kg/cm2 extraction flow of the j-th turbine (tonne/h) |

| Mj,W | The exhaust flow of the j-th turbine (tonne/h) |

The steam flow in the k-th extraction stage of the j-th turbine (tonne/h) | |

| Mj,p2 | The extraction flow for heating the high-pressure make-up water of the j-th turbine (tonne/h) |

| Mj,p3 | The extraction flow for heating the deaerator of the j-th turbine (tonne/h) |

| Mj,p4 | The extraction flow for heating the low-pressure make-up water of the j-th turbine (tonne/h) |

| MM | The flow of make-up water (tonne/h) |

| M18 | The 18 kg/cm2 flow of steam (tonne/h) |

| MDTi | The minimum down time of the i-th boiler (h) |

| MDTj | The minimum down time of the j-th turbine (h) |

| MUTi | The minimum up time of the i-th boiler (h) |

| MUTj | The minimum up time of the j-th turbine (h) |

| Nb | The number of boilers |

| Ntg | The number of turbine generators |

| PD,t | System demand at hour t (MW) |

| Pj,t | The power output of the j-th turbine generator at hour t (MW) |

| Plant12 | The flow of steam at pressure 12 kg/cm2 used inside the plant (tonne/h) |

| Plant18 | The flow of steam at pressure 18 kg/cm2 used inside the plant (tonne/h) |

| Ptie,t | The quantity of power sold or purchased at hour t (“+”: sold, “−”: purchased) (MW) |

| Sp,12 | The unit price of sold steam at pressure 12 kg/cm2 (NT$/tonne) |

| Sp,18 | The unit price of sold steam at pressure 18 kg/cm2 (NT$/tonne) |

| SS12 | The flow of sold steam at pressure 12 kg/cm2 (tonne/h) |

| SS18 | The flow of sold steam at pressure 18 kg/cm2 (tonne/h) |

| STi,t | The start cost for the i-th boiler (NT$) |

| STj,t | The start cost for the j-th turbine generator (NT$) |

| Ti,on | The duration started hours of the i-th boiler (h) |

| Tj,on | The during started hours of the j-th turbine (h) |

| Ti,off | The duration off hours of the i-th boiler (h) |

| Tj,off | The duration off hours of the j-th turbine (h) |

| TOU | The time-of-use rate (NT$/kW·h) |

| Uj,t | The status of unit j at hour t (1: on-line, 0: off-line) |

| Wp | The unit price of make-up water (NT$/tonne) |

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Li, T.; Shahidehpour, M. Price based unit commitment: A case of Lagrangian relaxation versus mixed integer programming. IEEE Trans. Power Syst. 2005, 20, 2015–2025. [Google Scholar] [CrossRef]

- Senjyo, T.; Shimabukuro, K.; Uezato, K.; Funabashi, T. A fast technique for unit commitment problem by extended priority list. IEEE Trans. Power Syst. 2003, 18, 882–888. [Google Scholar] [CrossRef]

- Venkatesh, B.N.; Chankong, V. Decision models for management of cogeneration plants. IEEE Trans. Power Syst. 1995, 10, 1250–1256. [Google Scholar] [CrossRef]

- Ashok, S.; Banerjee, R. Optimal operation of industrial cogeneration for load management. IEEE Trans. Power Syst. 2003, 18, 931–937. [Google Scholar] [CrossRef]

- Casolino, G.M.; Losi, A.; Russo, C. Design choices for combined cycle units and profit-based unit commitment. Int. J. Electr. Power Energy Syst. 2012, 42, 693–700. [Google Scholar]

- Basu, M. Artifical immune system for combined heat and power economic dispatch. Int. J. Electr. Power Energy Syst. 2012, 43, 1–5. [Google Scholar] [CrossRef]

- Basu, M. Combined heat and power economic emission dispatch using nondominated sorting genetic algorithm-II. Int. J. Electr. Power Energy Syst. 2013, 53, 135–141. [Google Scholar] [CrossRef]

- Peik-Herfeh, M.; Seifi, H.; Sheikh-El-Eslami, M.K. Decision making of a virtual power plant under uncertainties for bidding in a day-ahead market using point estimate method. Int. J. Electr. Power Energy Syst. 2013, 44, 88–98. [Google Scholar] [CrossRef]

- Kazarlis, S.A.; Bakirtizis, A.G.; Petridis, V. A genetic algorithm solution to the unit commitment problem. IEEE Trans. Power Syst. 1996, 11, 83–92. [Google Scholar] [CrossRef]

- Swarup, K.S.; Yamashiro, S. Unit commitment solution methodology using genetic algorithm. IEEE Trans. Power Syst. 2002, 17, 87–91. [Google Scholar] [CrossRef]

- Lu, B.; Shahidehpour, M. Unit commitment with flexible generating units. IEEE Trans. Power Syst. 2005, 20, 1022–1034. [Google Scholar] [CrossRef]

- Duff, M.C.; Price, W.G., Jr.; Davis, A.N.; Manuel, E.H., Jr. Cogen3: A Computer Model for Design, Costing, and Economic Operation of Cogeneration Projects; EPRI-EA-3995; EPRI (Electric Power Research Institute): Palo Alto, CA, USA, 1985. [Google Scholar]

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, C.-H.; Huang, S.-C.; Chang, C.-A.; Chen, B.-K. Operation of Steam Turbines under Blade Failures during the Summer Peak Load Periods. Energies 2014, 7, 7415-7433. https://doi.org/10.3390/en7117415

Lee C-H, Huang S-C, Chang C-A, Chen B-K. Operation of Steam Turbines under Blade Failures during the Summer Peak Load Periods. Energies. 2014; 7(11):7415-7433. https://doi.org/10.3390/en7117415

Chicago/Turabian StyleLee, Chien-Hsing, Shih-Cheng Huang, Chia-An Chang, and Bin-Kwie Chen. 2014. "Operation of Steam Turbines under Blade Failures during the Summer Peak Load Periods" Energies 7, no. 11: 7415-7433. https://doi.org/10.3390/en7117415

APA StyleLee, C.-H., Huang, S.-C., Chang, C.-A., & Chen, B.-K. (2014). Operation of Steam Turbines under Blade Failures during the Summer Peak Load Periods. Energies, 7(11), 7415-7433. https://doi.org/10.3390/en7117415