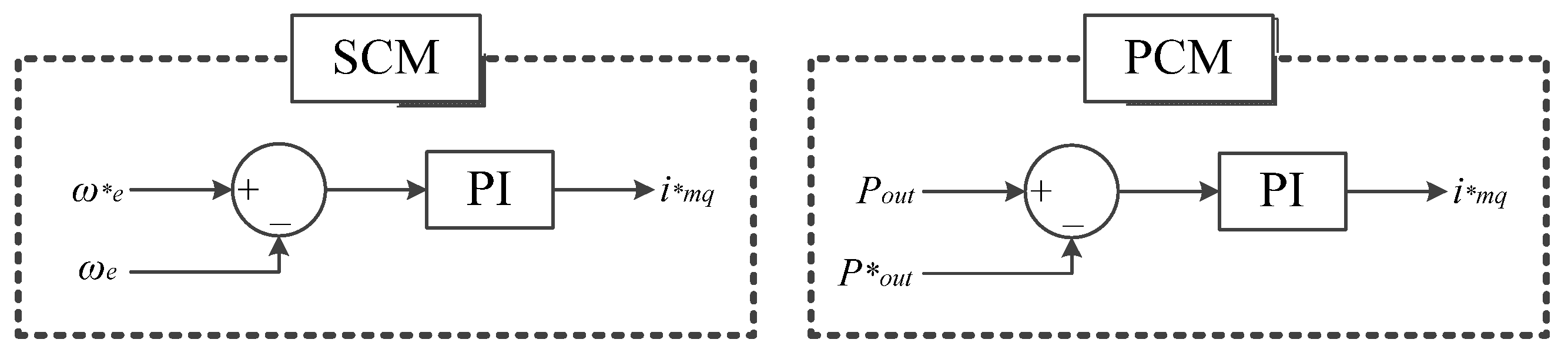

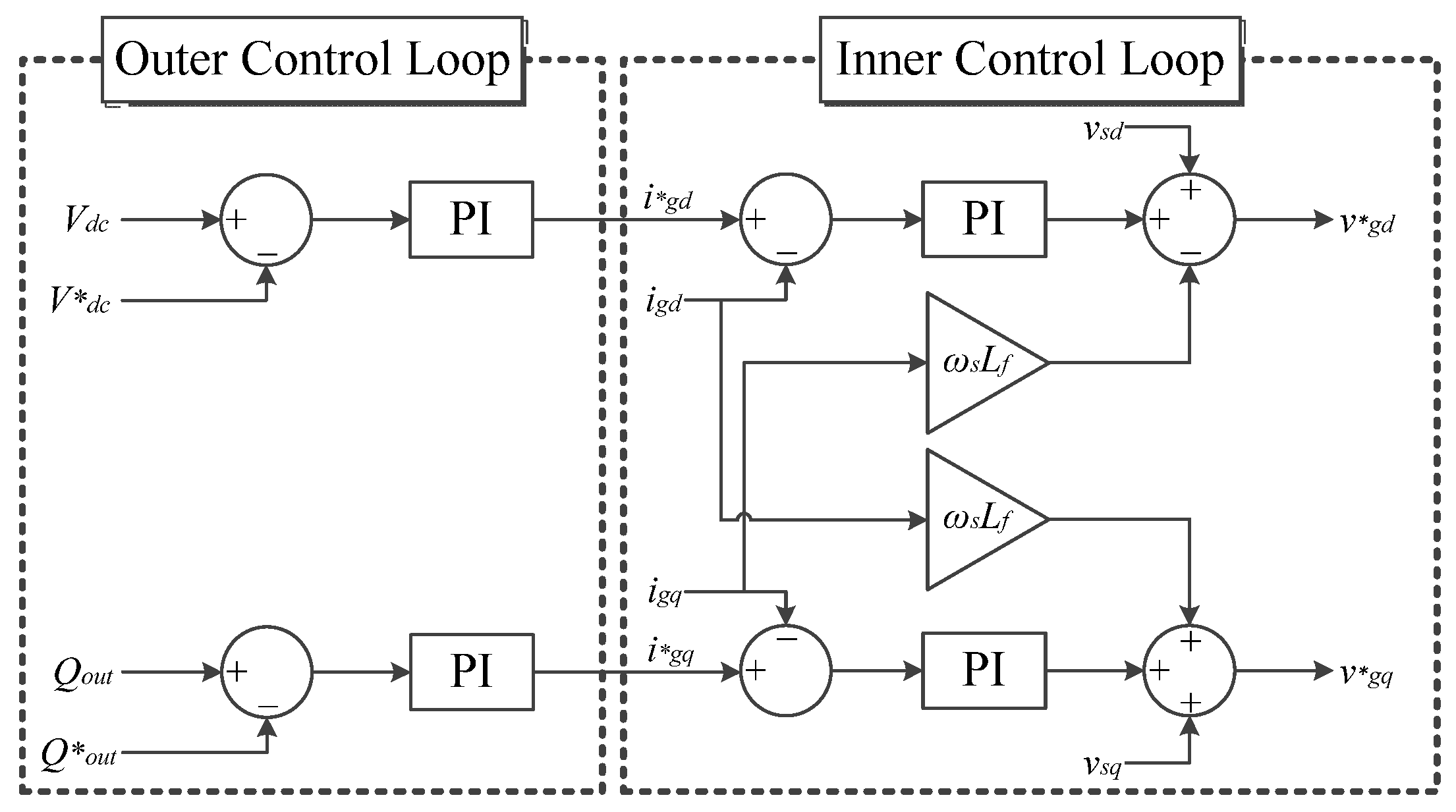

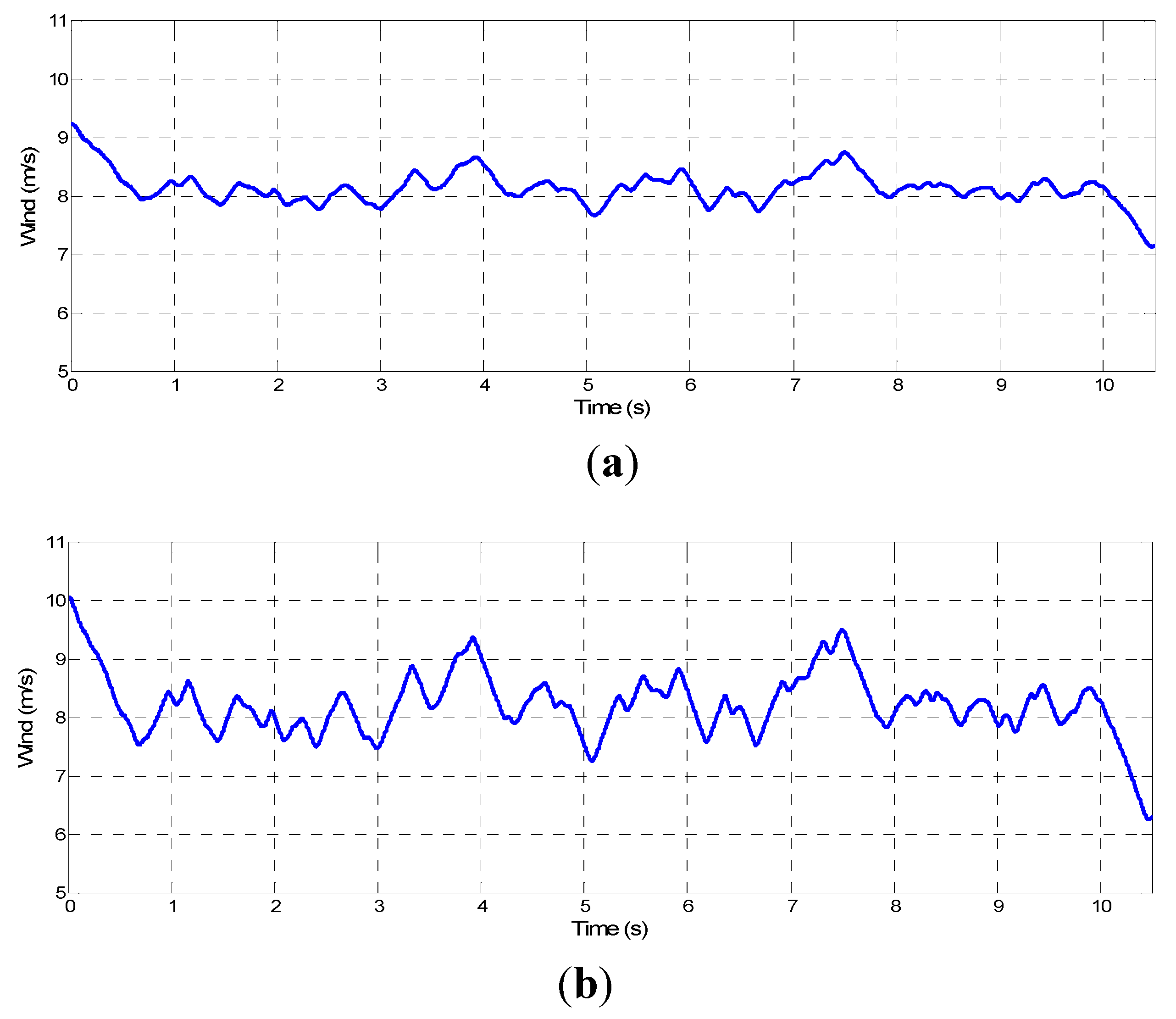

An analysis of the differences between SCM and PCM is described in this section. MPPT was used, since it is the most common method to control VSWTs. In theory, SCM and PCM are equivalent because they both control the active power. However, due to the differences in the time delays of the control loop, differences exist between applying SCM or PCM at the outer control loop of the MSC. These differences become greater as the wind-speed fluctuations become more severe. To illustrate this, two cases were investigated for both SCM and PCM. For each case, we used the same mean wind speed. However, the rate of change and the amount of change of the wind speed were varied, as shown in

Figure 7. Since it can be expected and obvious that there will be no differences between SCM and PCM when the wind speed is constant, a case of constant wind speed is disregarded in the case study.

Figure 7.

Time dependence of the wind speed for (a) case 1 and (b) case 2.

3.1. Simulation Results

Simulations were developed using MATLAB/SimPowerSystems to investigate these two cases using both SCM and PCM. The characteristics of the modeled wind turbine are summarized in

Table 1.

Table 1.

Characteristics of the wind turbine used in the simulations.

Table 1.

Characteristics of the wind turbine used in the simulations.

| Parameters | Value | Unit |

|---|

| Rated power | 7.35 | MW |

| Rotor radius | 83.5 | m |

| Nominal wind turbine rotor speed | 0.936 | rad/s |

| Gearbox ratio | 30 | - |

| Number of pole pairs | 9 | - |

Since voltage and frequency at the PCC are affected by characteristics of the transformer and the infinite bus, and hence the simulation results which contain performances of the power quality are related to them, it is useful to provide characteristics of the transformer and the infinite bus. They are shown in

Table 2 and

Table 3, respectively.

Table 2.

Characteristics of the transformer used in the simulations.

Table 2.

Characteristics of the transformer used in the simulations.

| Parameters | Value | Unit |

|---|

| Nominal power | 7.35 | MVA |

| Nominal primary/secondary voltage | 3.3/22.9 | kV |

| Primary and secondary resistance/inductance | 0.002/0.08 | p.u. |

Table 3.

Characteristics of the infinite bus in the simulations.

Table 3.

Characteristics of the infinite bus in the simulations.

| Parameters | Value | Unit |

|---|

| 3-phase short-circuit level at base voltage | 100 | MVA |

| Base voltage | 22.9 | kV |

| X/R ratio | 7 | - |

To determine whether the electrical rotor speed properly tracks the optimal electrical rotor speed, the rotor speeds for SCM and PCM were measured. The power coefficient was measured to compare the efficiencies of SCM and PCM. To analyze the relative power quality between SCM and PCM, the active power output, frequency, and root mean square (RMS) voltage were measured. The subscripts SCM and PCM are used to denote which mode was used for controlling the active power of the wind turbine.

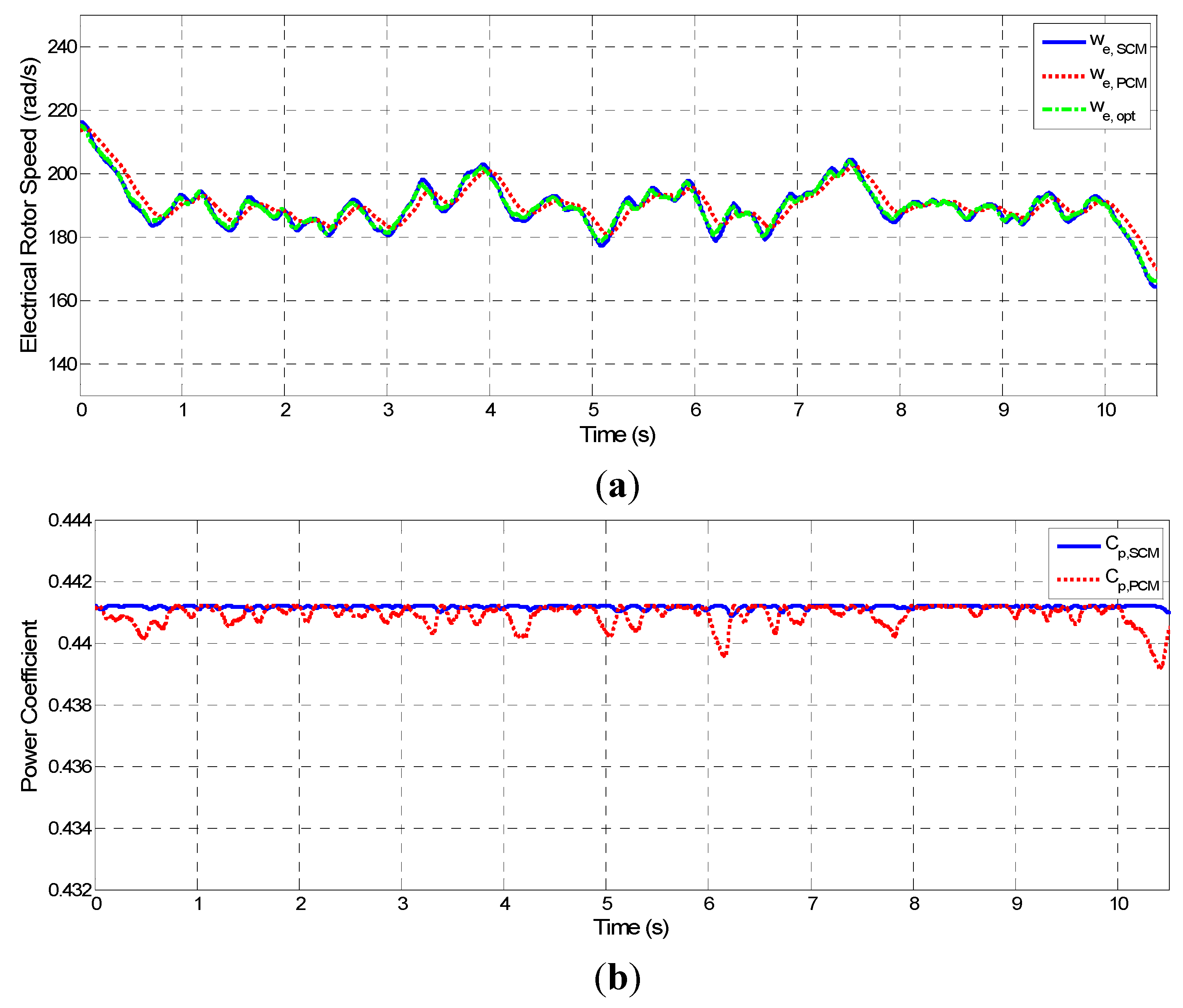

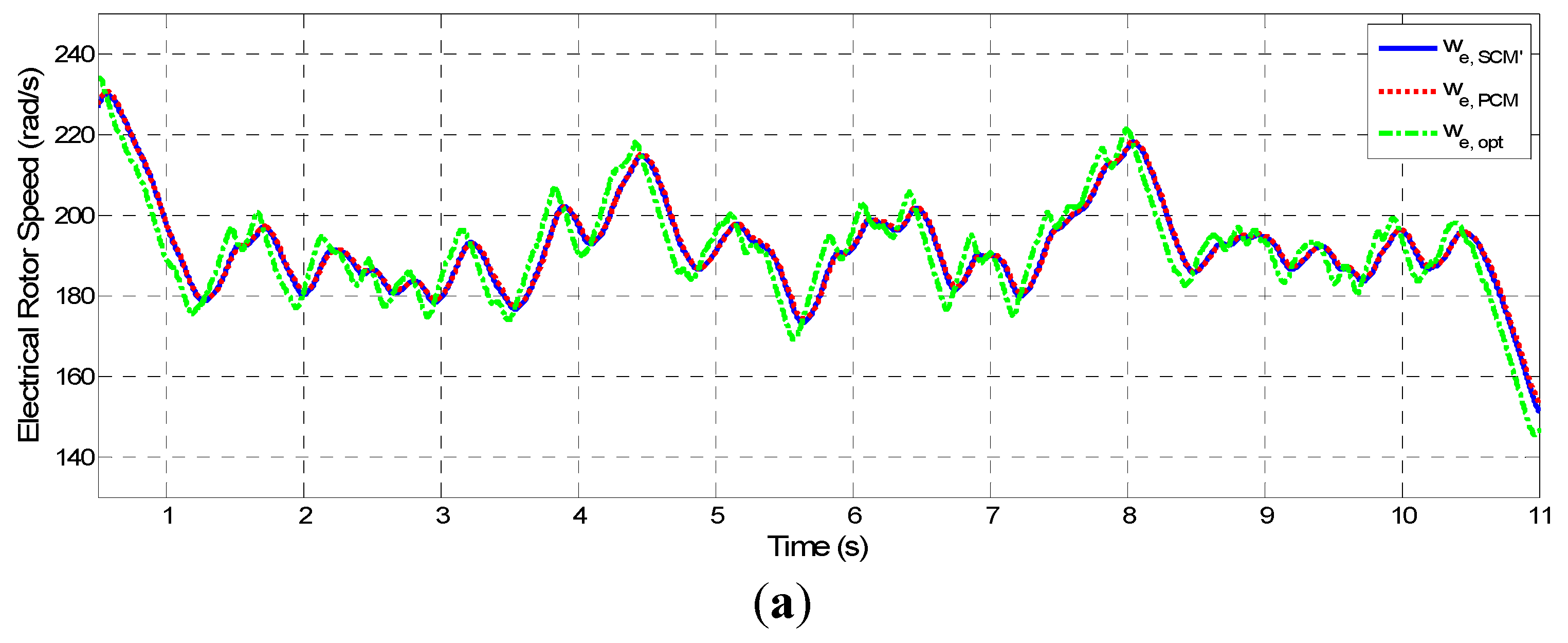

The simulated data for case 1 are shown in

Figure 8. The power coefficient and power quality of SCM and PCM were slightly different when the wind-speed fluctuation was weak.

Figure 8a shows

,

, and

for case 1;

followed

slightly faster than

did.

Figure 8.

Simulated data for case 1. (a) Electrical rotor speed; (b) power coefficient; (c) active power output at the PCC; (d) frequency at the PCC; and (e) RMS voltage at the PCC.

Figure 8.

Simulated data for case 1. (a) Electrical rotor speed; (b) power coefficient; (c) active power output at the PCC; (d) frequency at the PCC; and (e) RMS voltage at the PCC.

This means that SCM exhibited better performance than PCM in terms of efficiency, which can be verified from

Figure 8b. However, from the power quality and system stability point of view, PCM exhibited more steady operation than SCM.

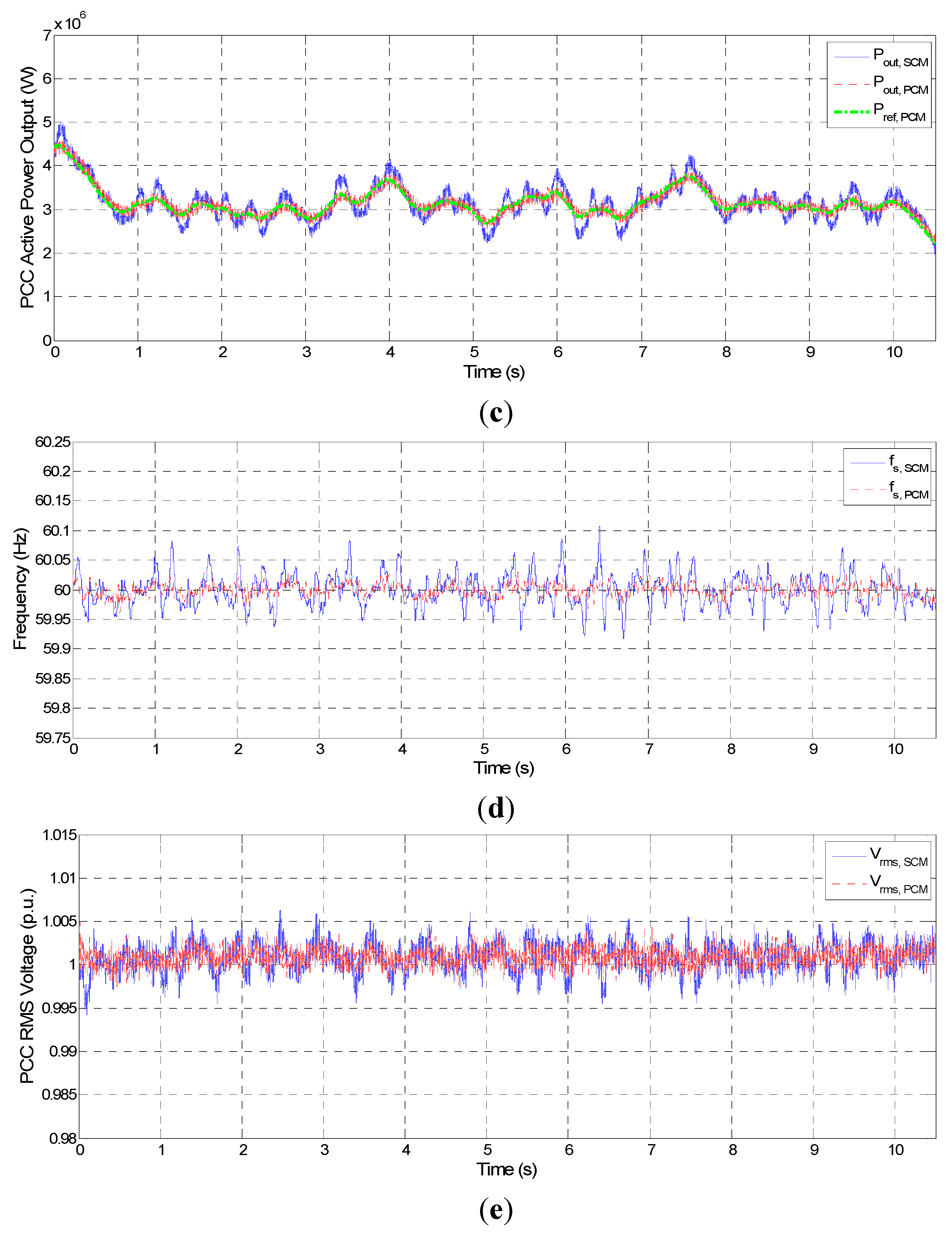

These differences between the two modes became more obvious as the wind-speed fluctuations increased.

Figure 9a shows that as the rate and magnitude of the changes in wind speed became larger, the corresponding optimal rotor speed changed more rapidly. This became too fast for PCM to adjust

in response to

due to the time delay of the PCM controller, while SCM adjusted

in response to changes in

despite the intensified wind-speed fluctuations. Consequently, the efficiency gap between the two control modes increased. On the other hand, the power fluctuations, frequency deviation, and voltage deviation were more significant with SCM than with PCM. Thus, PCM is preferable from a power quality and system stability perspective.

Figure 9.

Simulated data for case 2. (a) Electrical rotor speed; (b) power coefficient; (c) active power output at the PCC; (d) frequency at the PCC; and (e) RMS voltage at the PCC.

Figure 9.

Simulated data for case 2. (a) Electrical rotor speed; (b) power coefficient; (c) active power output at the PCC; (d) frequency at the PCC; and (e) RMS voltage at the PCC.

3.2. Discussion

Table 4 shows the average of

and

as well as the maximum deviation from

and

, for each case to provide a numerical analysis of the relative efficiencies of SCM and PCM.

Table 4.

Numerical comparison of the power coefficients of the three cases.

Table 4.

Numerical comparison of the power coefficients of the three cases.

| Control Mode | Case 1 | Case 2 |

|---|

| | | |

|---|

| SCM | 0.4412 | 0.0003 | 0.4410 | 0.0012 |

| PCM | 0.4409 | 0.002 | 0.4400 | 0.0085 |

For case 1, if wind-speed fluctuations occur, of SCM is maintained close to . On the other hand, with PCM, fell below to 0.4409. This means that if PCM is used as the active power-control mode of a VSWT, an average active power loss of 0.453% will occur relative to the optimal value, while SCM maintains the optimal output power. In case 2, the average active power losses of SCM and PCM were 0.272% and 1.927%, respectively. Thus, SCM is preferable to PCM in terms of efficiency, and the gap between the two modes increases when the wind-power fluctuations are more significant.

It appears that SCM offers significantly better performance than PCM if efficiency is the only concern. However, from a system stability and power quality perspective, PCM is superior to SCM, as indicated by the data listed in

Table 5 and

Table 6. The maximum frequency deviation,

, from the nominal value is shown in

Table 5; in case 2, this was approximately two times larger than in case 1 when the VSWT was controlled using SCM. In contrast, when using PCM, the difference in

was less than a factor of two between cases 1 and 2. Moreover,

, the maximum RMS voltage deviation from the nominal value, changed little for the two cases when the VSWT was controlled by PCM, while it changed dramatically when the VSWT was controlled using SCM.

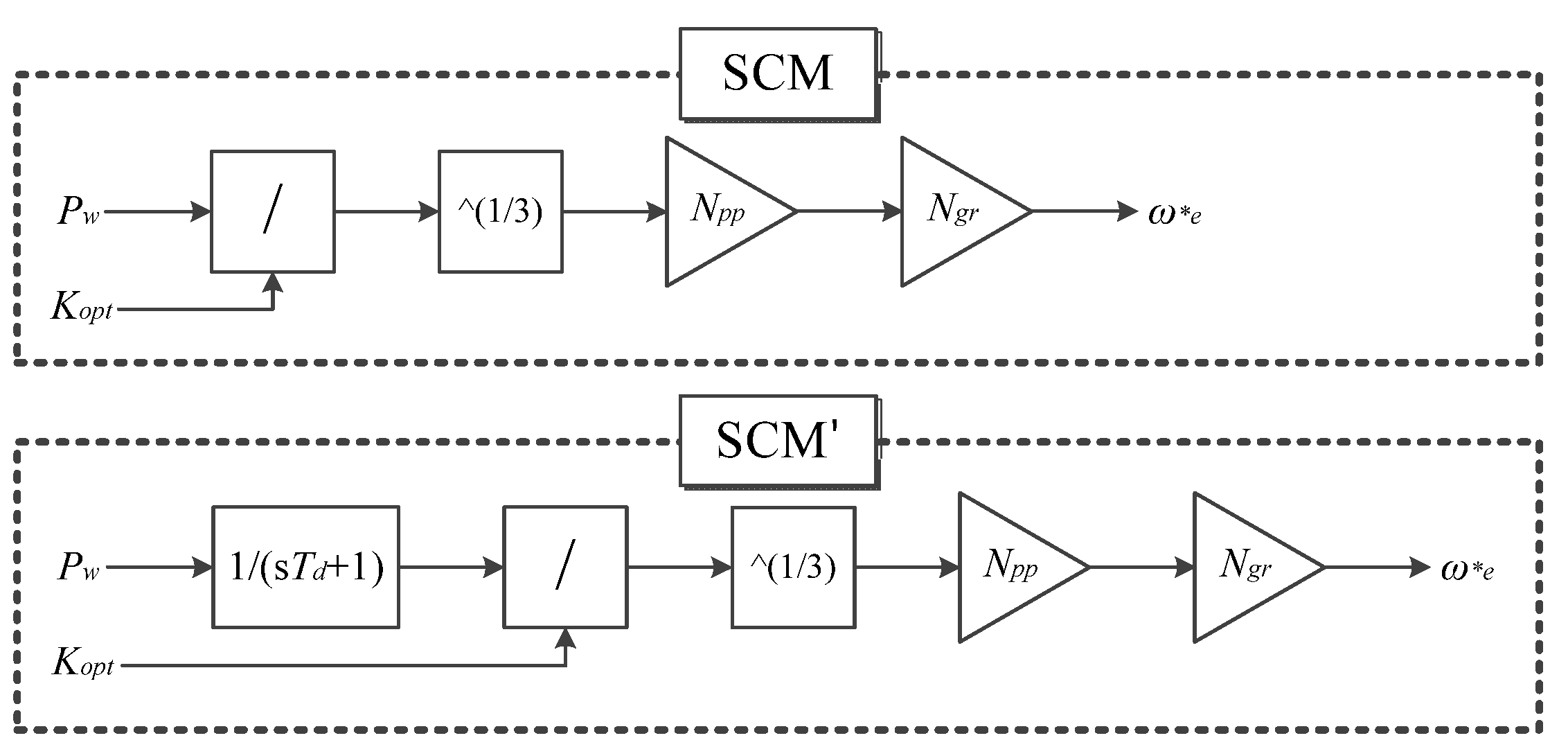

However, it may be arguable in the point of view that SCM can be controlled as similar as PCM in power quality perspective. For instance, it can be implemented by using time delay function before

of SCM as shown in

Figure 10, where

is the time constant of the time delay function.

Table 5.

Numerical comparison of the system frequencies of the three cases.

Table 5.

Numerical comparison of the system frequencies of the three cases.

| Control Mode | Case 1 (Hz) | Case 2 (Hz) |

|---|

| | | | | |

|---|

| SCM | 59.9170 | 60.1070 | 0.1070 | 59.8377 | 60.2199 | 0.2199 |

| PCM | 59.9613 | 60.0301 | 0.0387 | 59.9457 | 60.0469 | 0.0543 |

Table 6.

Numerical comparison of the RMS voltages of the three cases.

Table 6.

Numerical comparison of the RMS voltages of the three cases.

| Control Mode | Case 1 (p.u.) | Case 2 (p.u.) |

|---|

| | | | | |

|---|

| SCM | 0.9942 | 1.0063 | 0.0063 | 0.9838 | 1.0095 | 0.0162 |

| PCM | 0.9974 | 1.0050 | 0.0050 | 0.9958 | 1.0045 | 0.0045 |

Figure 10.

Methods of giving signal to speed controller.

Figure 10.

Methods of giving signal to speed controller.

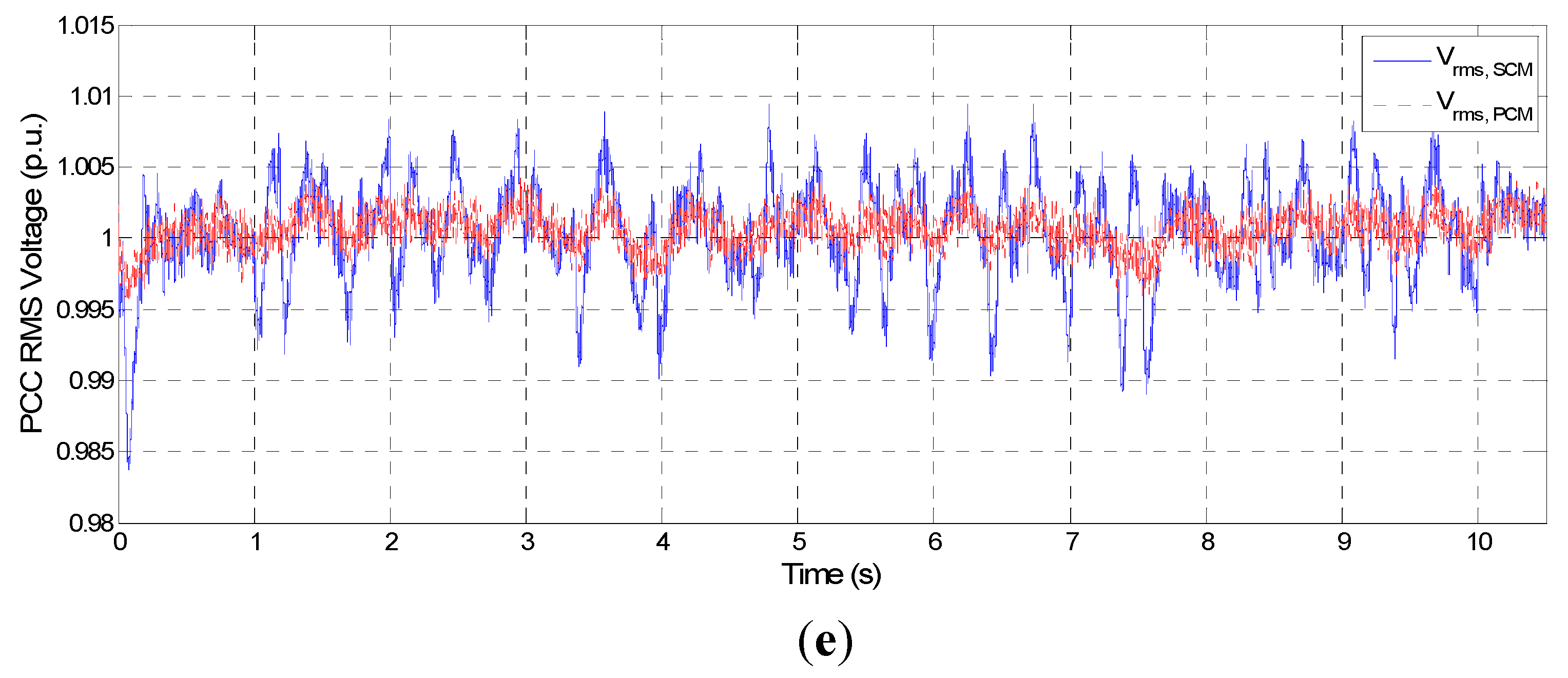

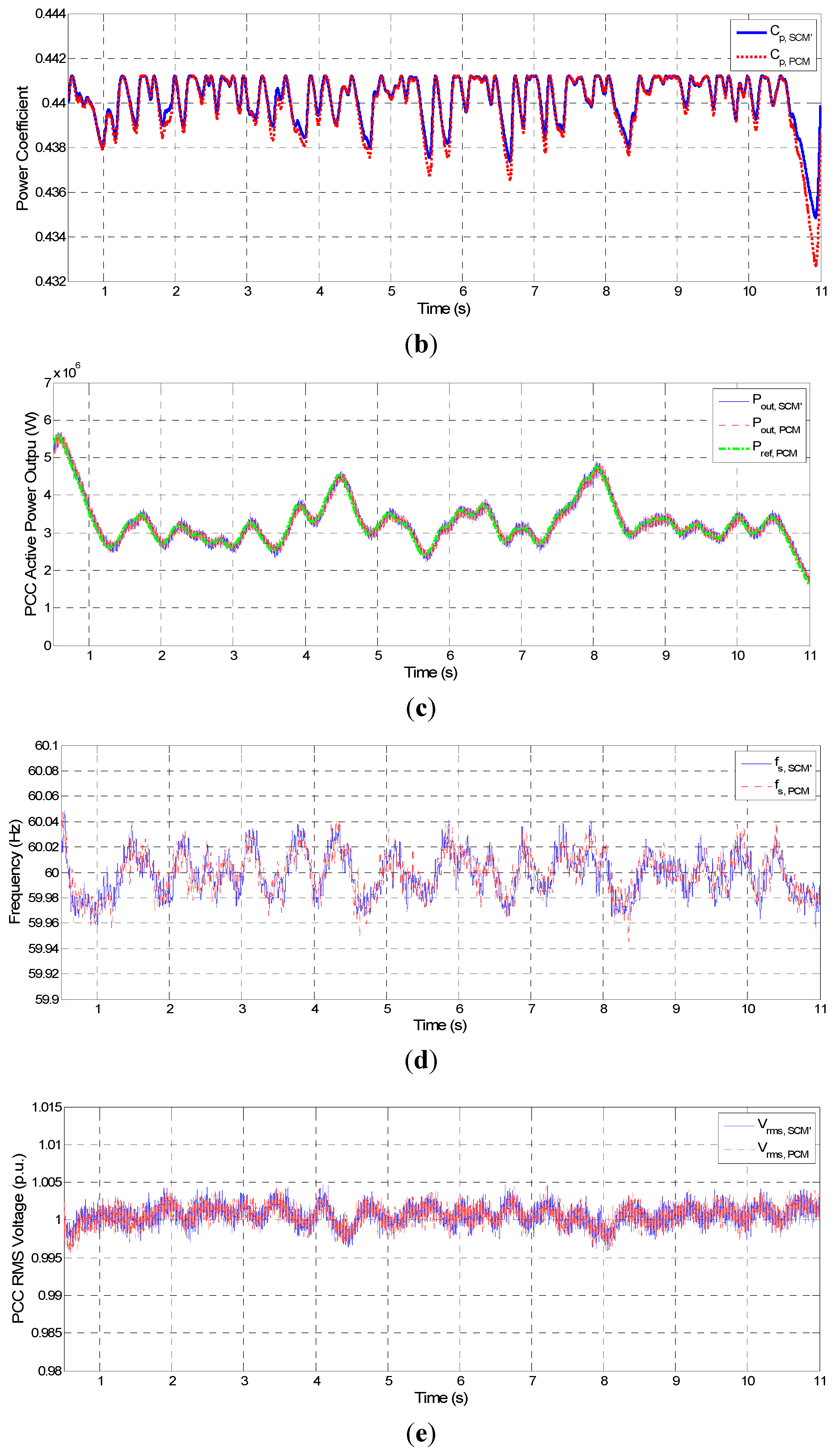

Since SCM′ is suggested to improve power quality, it may be compared with PCM as shown in

Figure 11.

is given as 0.1 s. From

Figure 11a, it can be noticed that

of both SCM′ and PCM are slightly deviated from

, and as a result, power coefficients of both methods are deviated from

. Besides, power quality of SCM′ is similar to that of PCM as shown by

Figure 11c–e. This proves that SCM can be controlled as similar as PCM in power quality point of view. However, it is hard to determine the value of

to make performance of electrical signals of SCM as same as those of PCM, and still, SCM′ is slightly superior to PCM in power coefficient perspective as can be shown in

Figure 11b.

Figure 11.

Comparison between SCM′ and PCM. (a) Electrical rotor speed; (b) power coefficient; (c) active power output at the PCC; (d) frequency at the PCC; and (e) RMS voltage at the PCC.

Figure 11.

Comparison between SCM′ and PCM. (a) Electrical rotor speed; (b) power coefficient; (c) active power output at the PCC; (d) frequency at the PCC; and (e) RMS voltage at the PCC.