Evaluation of Structural Changes in the Coal Specimen Heating Process and UCG Model Experiments for Developing Efficient UCG Systems

Abstract

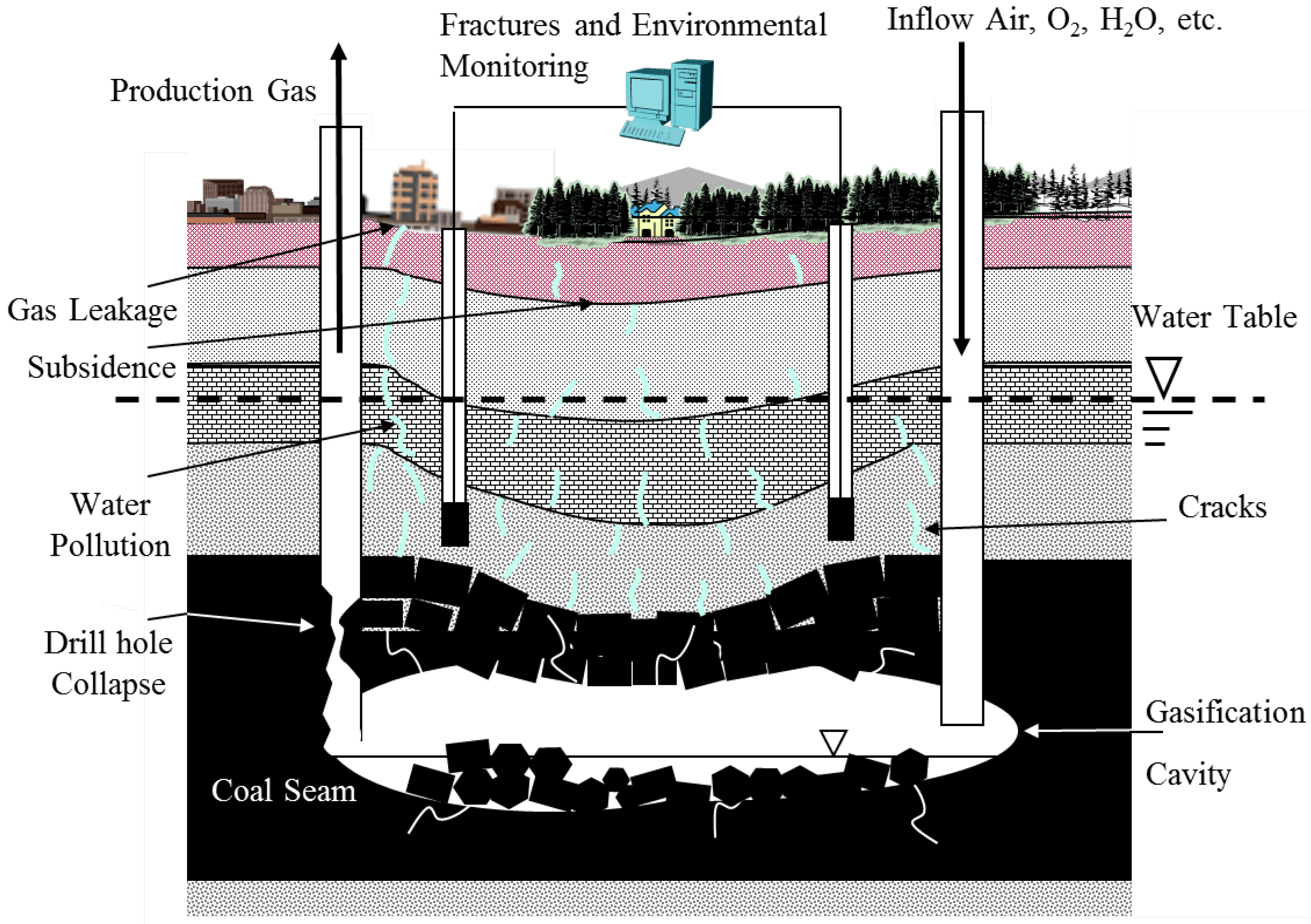

:1. Introduction

2. Structural Change Estimation in Coal Specimen

2.1. Experimental Apparatus and Procedure

| No. | Parameter | Kushiro coal |

|---|---|---|

| Proximate analysis (%) | ||

| 1 | Fixed moisture | 5.30 |

| 2 | Ash content | 15.40 |

| 3 | Volatile matter | 40.10 |

| 4 | Fixed carbon | 39.20 |

| 5 | Total sulfur | 0.23 |

| Ultimate analysis (%) | ||

| 6 | Carbon | 65.70 |

| 7 | Hydrogen | 5.99 |

| 8 | Nitrogen | 1.12 |

| 9 | Oxygen | 10.89 |

| No. | Coal types | Shape | Direction of stratified plane | Operation time (min) | Geometrical parameters (mm) | ||

|---|---|---|---|---|---|---|---|

| high | wide | thick | |||||

| P1 | Kushiro | Plate-shaped | vertical | 127 | 40 | 20 | 5 |

| P2 | Kushiro | Plate-shaped | vertical | 55 | 40 | 20 | 5 |

| P3 | Kushiro | Plate-shaped | horizontal | 55 | 40 | 20 | 5 |

| C1 | Canada | Cylindrical | vertical | 135 | 20 | 10 (diameter) | |

| C2 | Canada | Cylindrical | vertical | 45 | 20 | 10 (diameter) | |

| Specification | Description |

|---|---|

| Spatial resolution | voxel size (6–30 μm), low-contrast resolution (10 μm) |

| X-ray Source | Sealed air-cooled x-ray tubes 20–50 kV, 40 W |

| X-ray Detector | 1.3 M pixels (1280 × 1024), 12 bit CCD |

| Sample maximum size | Diameter (5–30 mm), Length (50 mm), Height (50 mm) |

| Reconstruction Algorithm | Feldkamp algorithm with volumetric (cone-beam) geometry |

| Installation requirements | Temperature (18–25 °C), no condensation, <85% humidity |

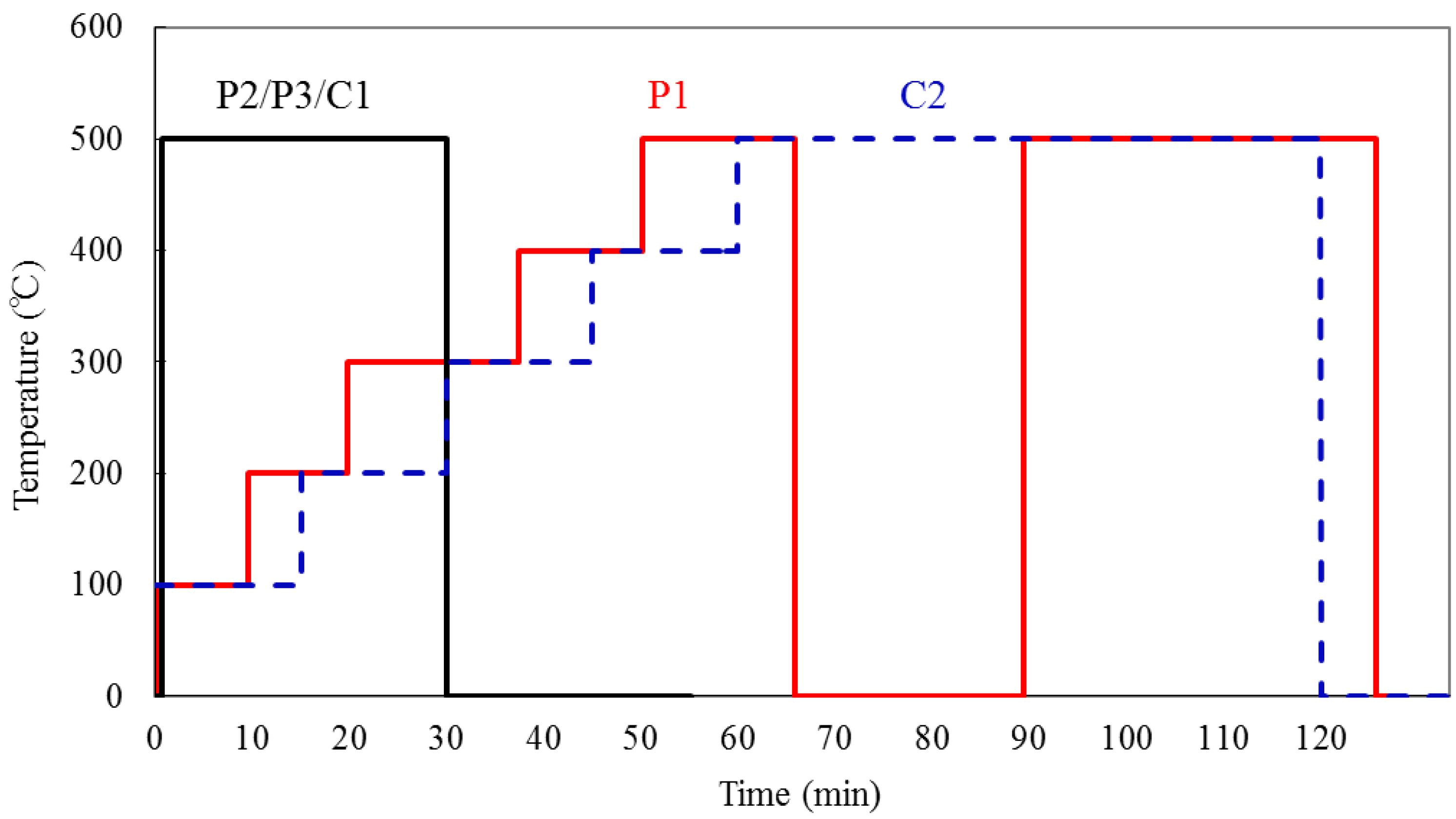

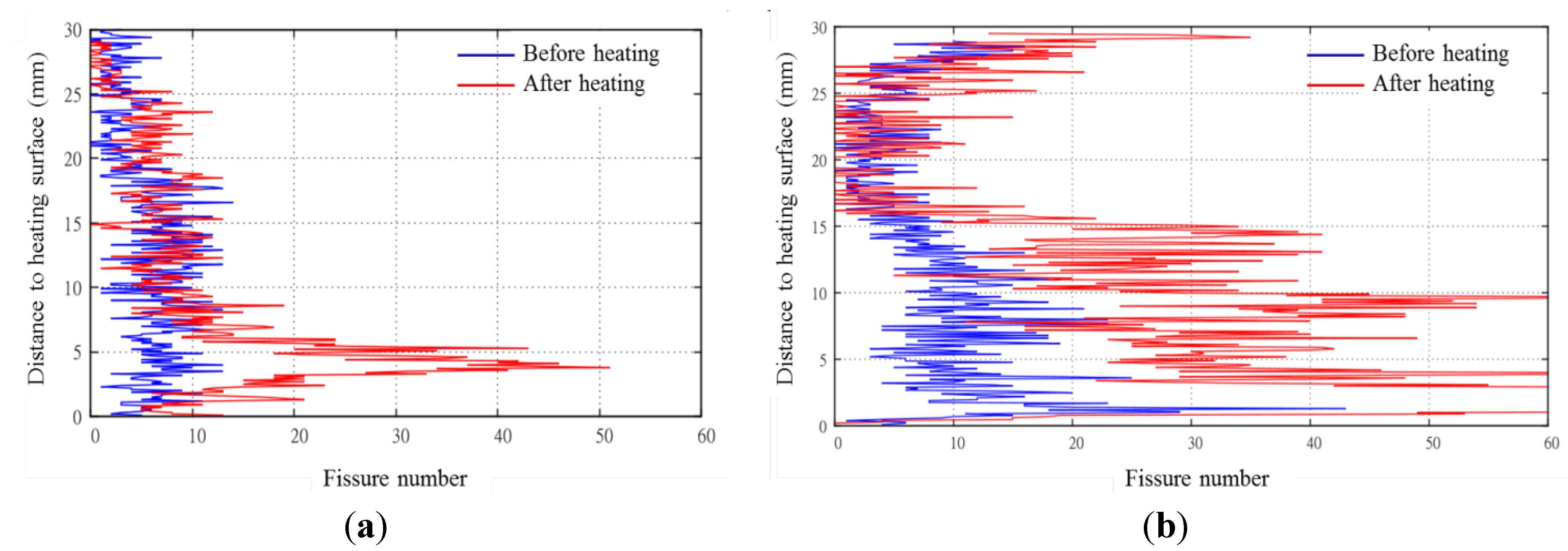

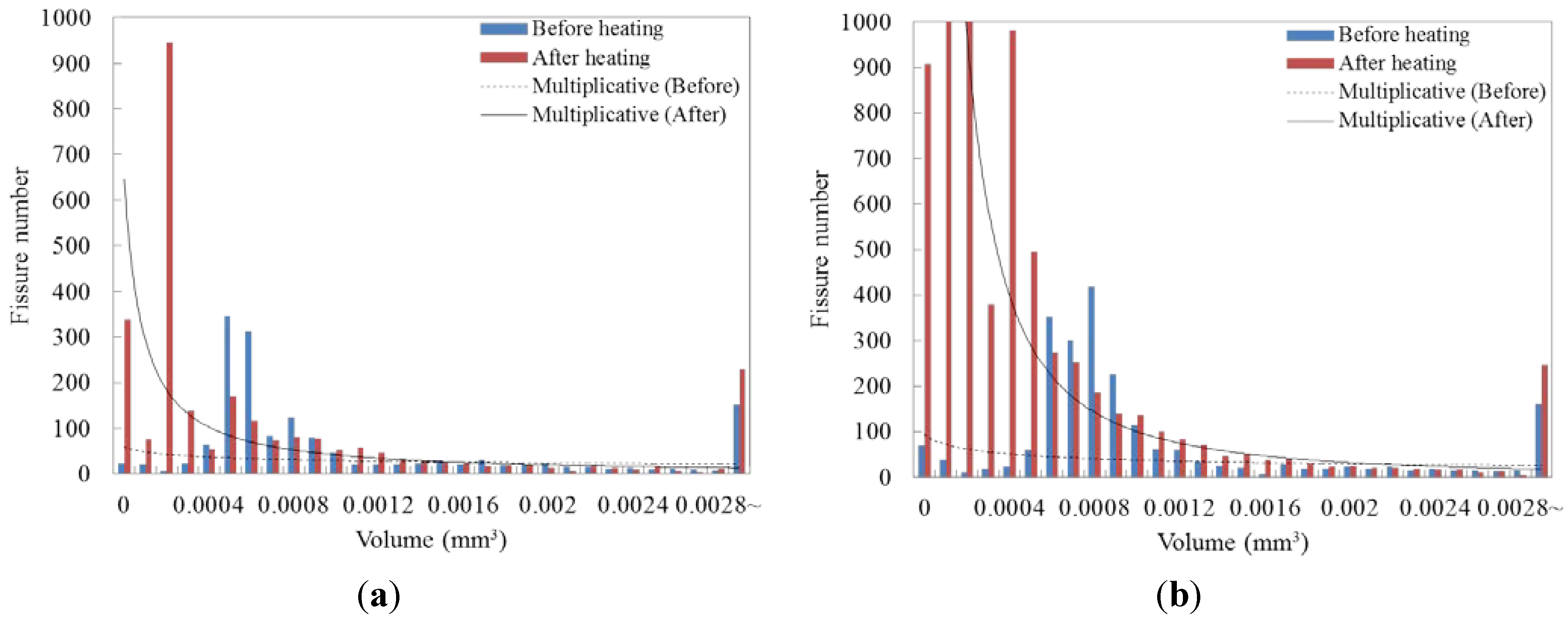

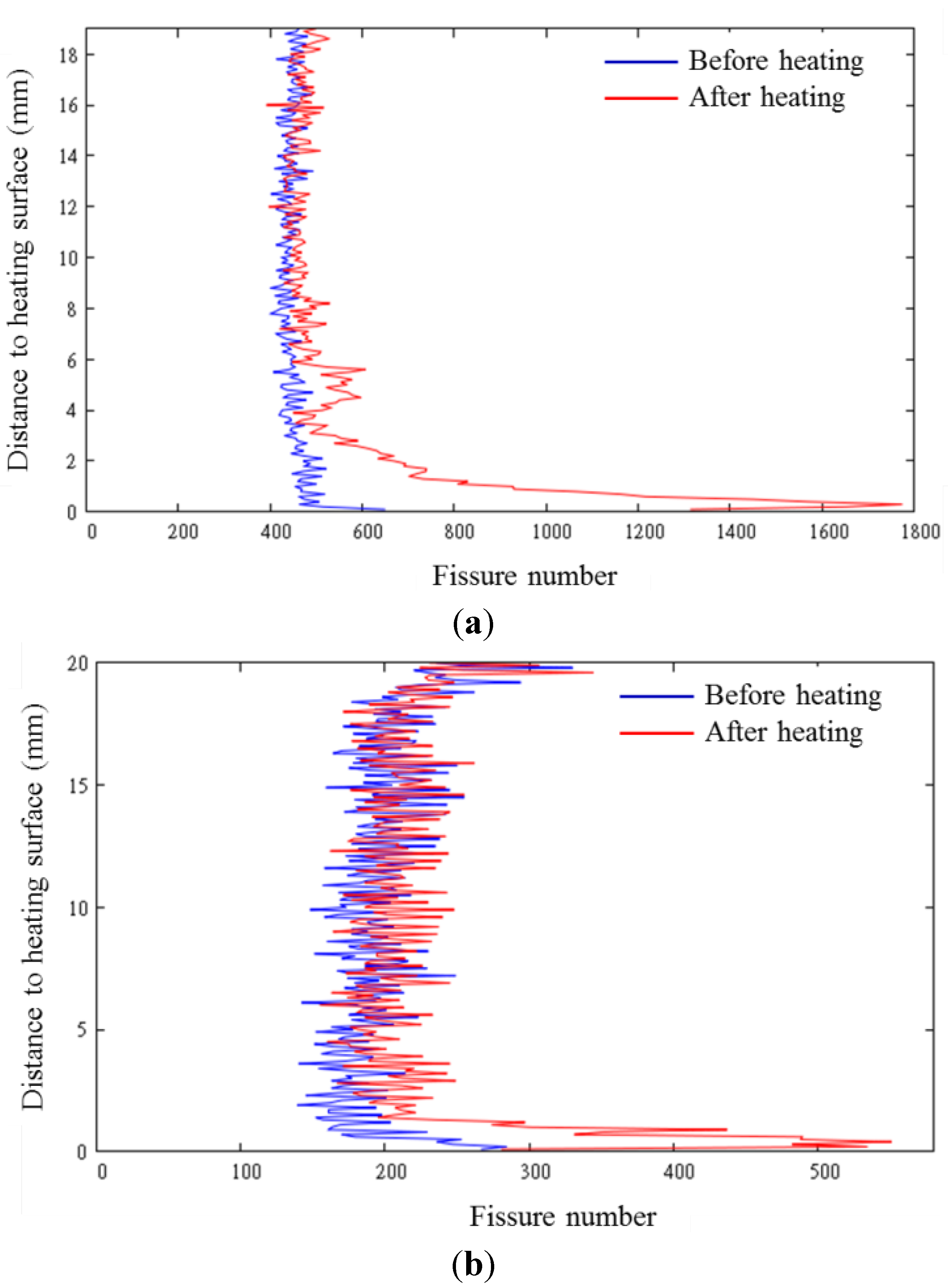

2.2. Heating Experiments of Plate-Shaped and Cylindrical Specimens

3. UCG Model Experiments

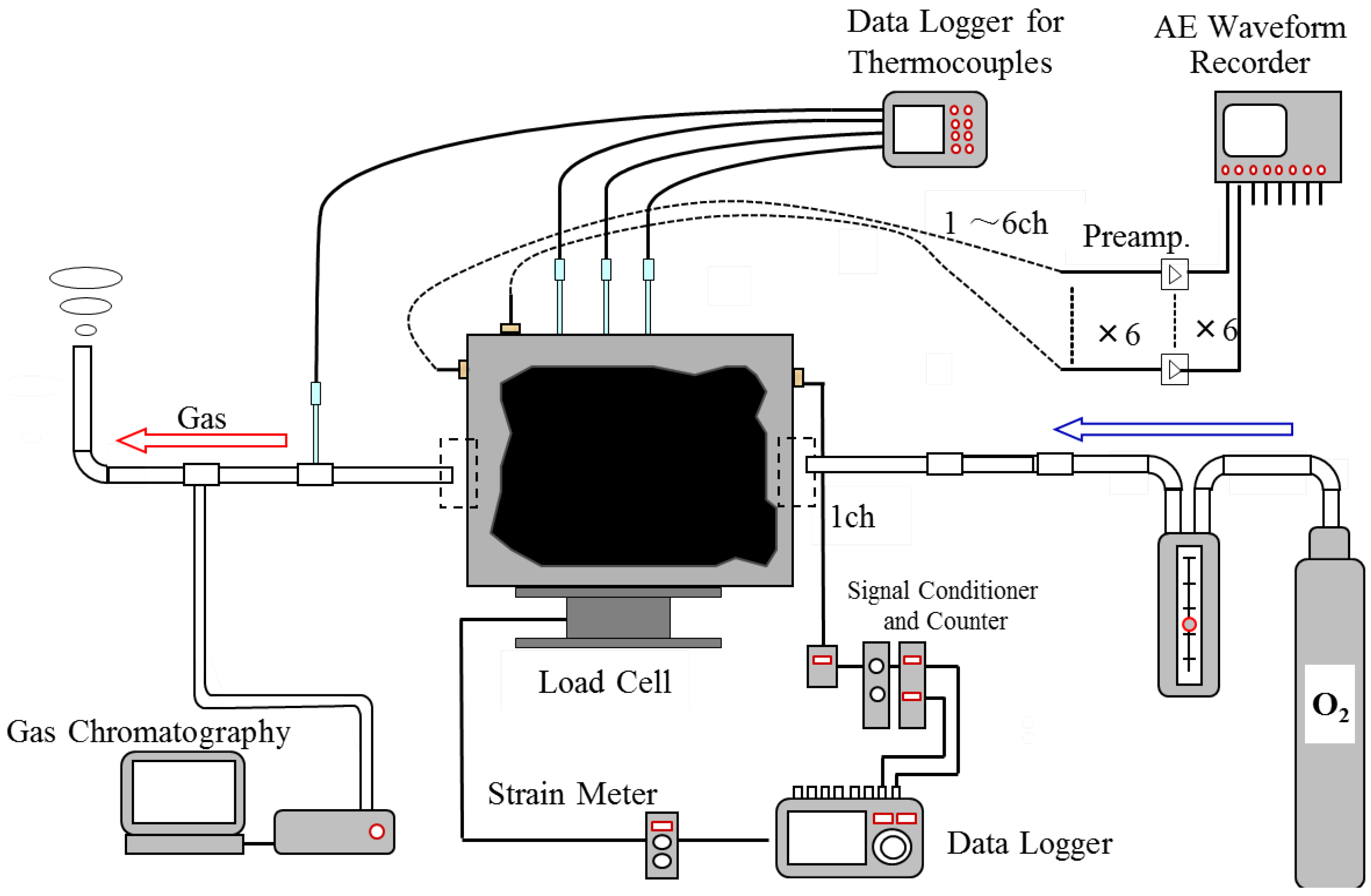

3.1. Experimental Design

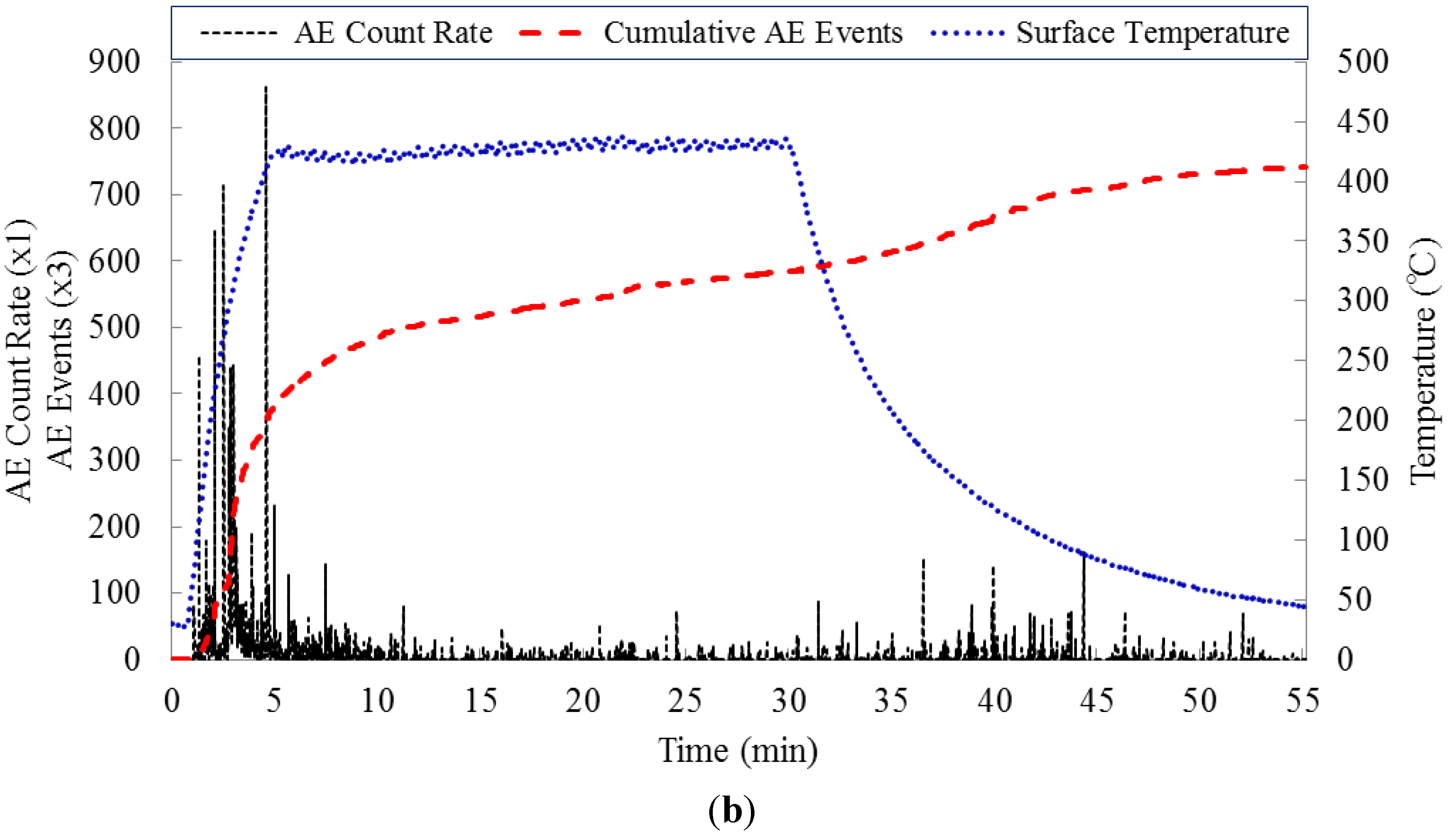

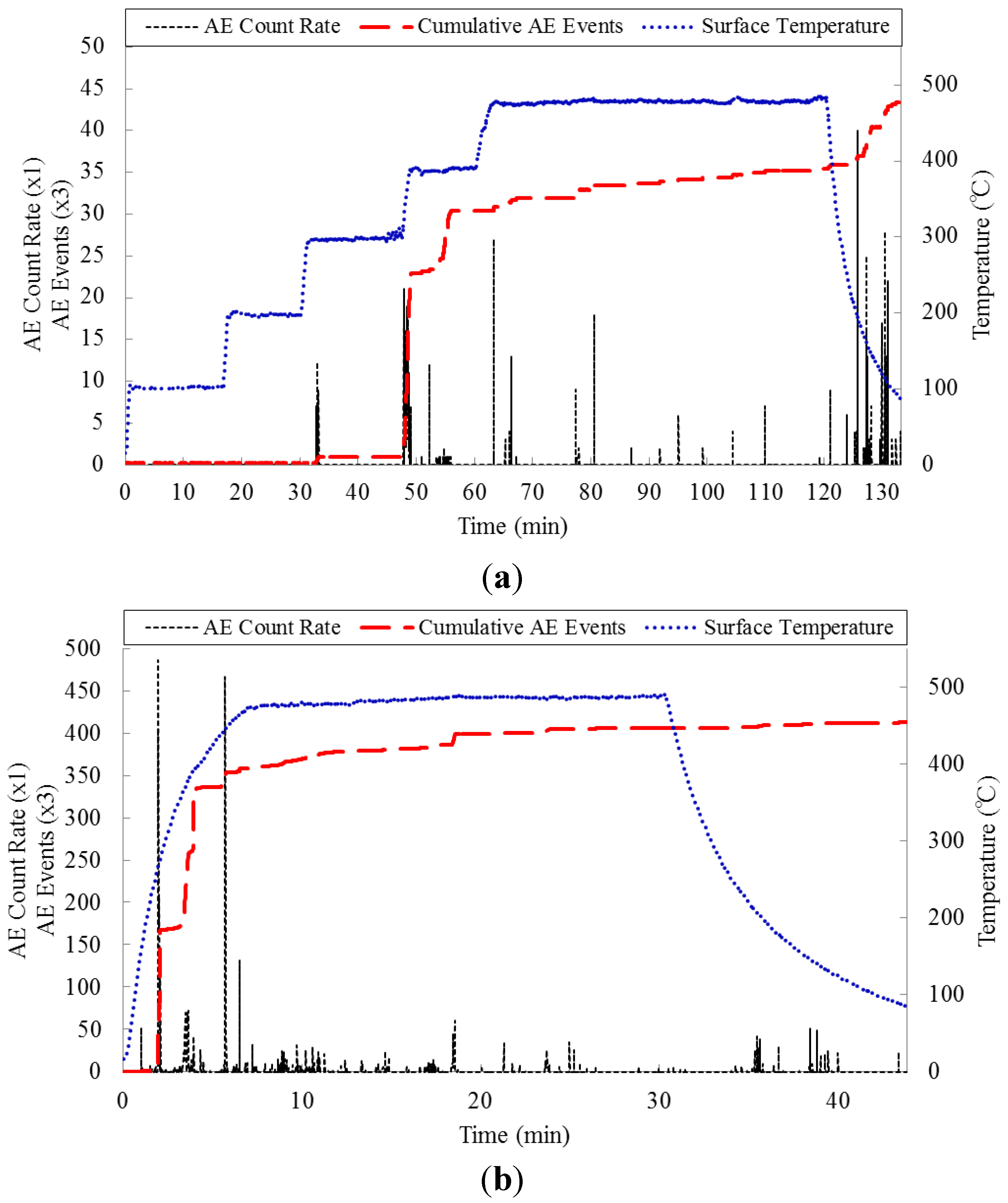

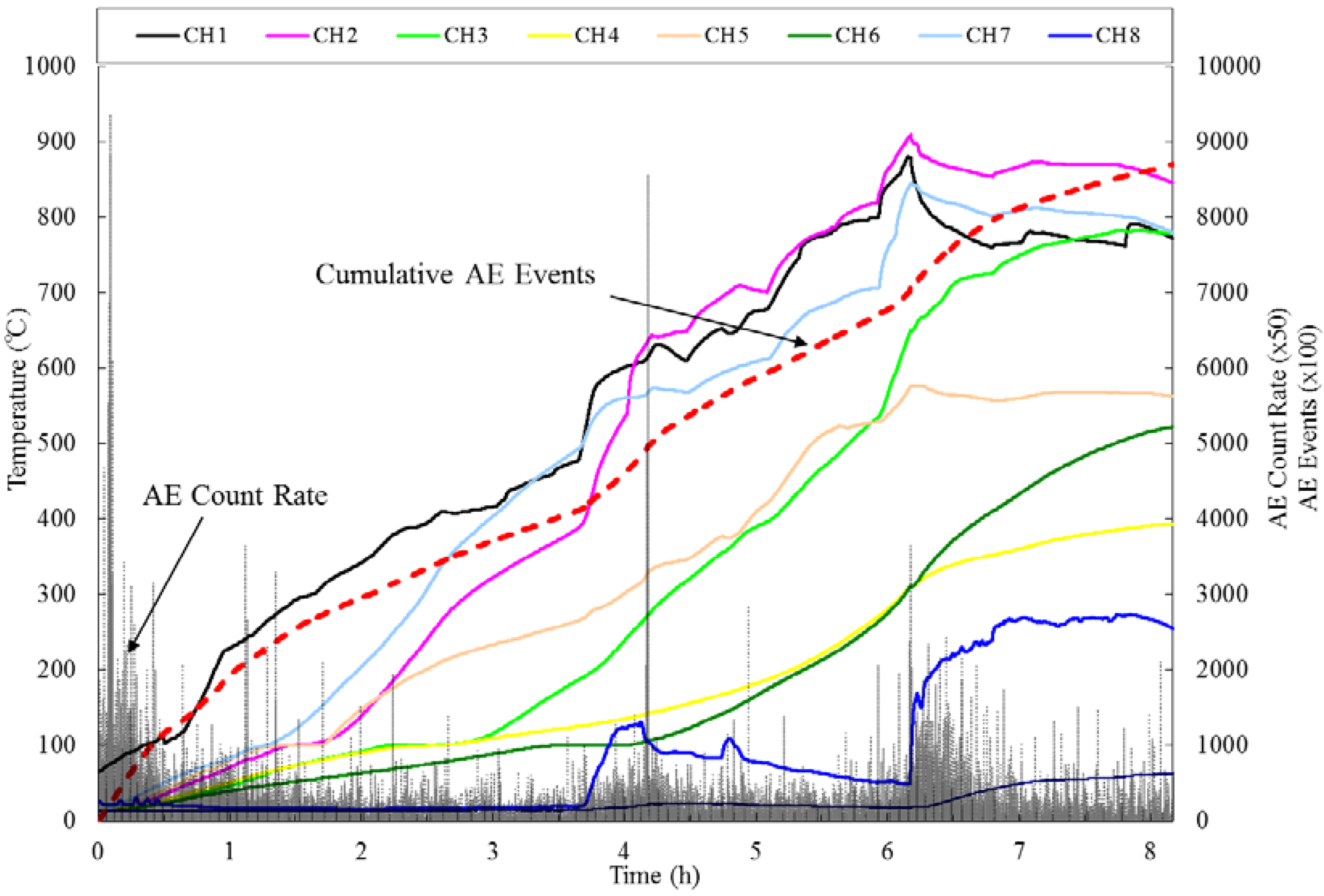

3.2. Monitoring of the AE Activities and Temperature Profile

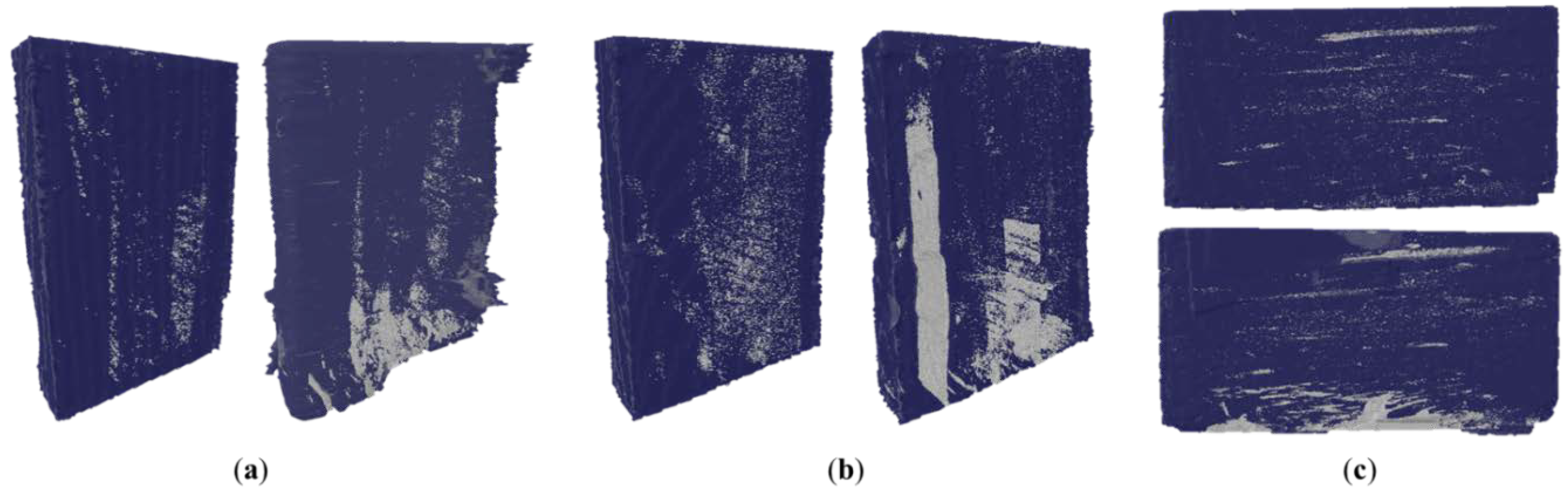

3.3. Construction of the Simulated Seam with Coal Block

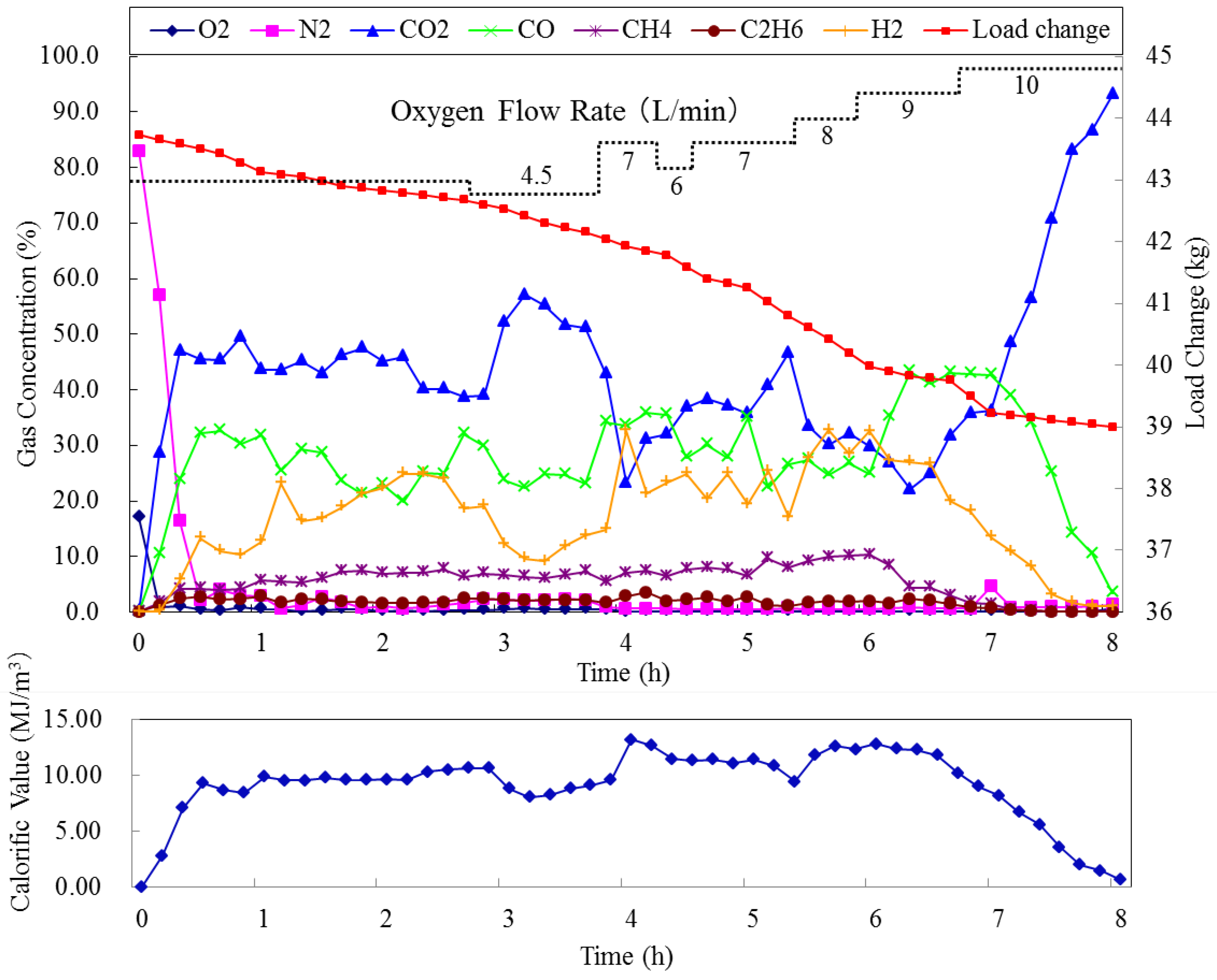

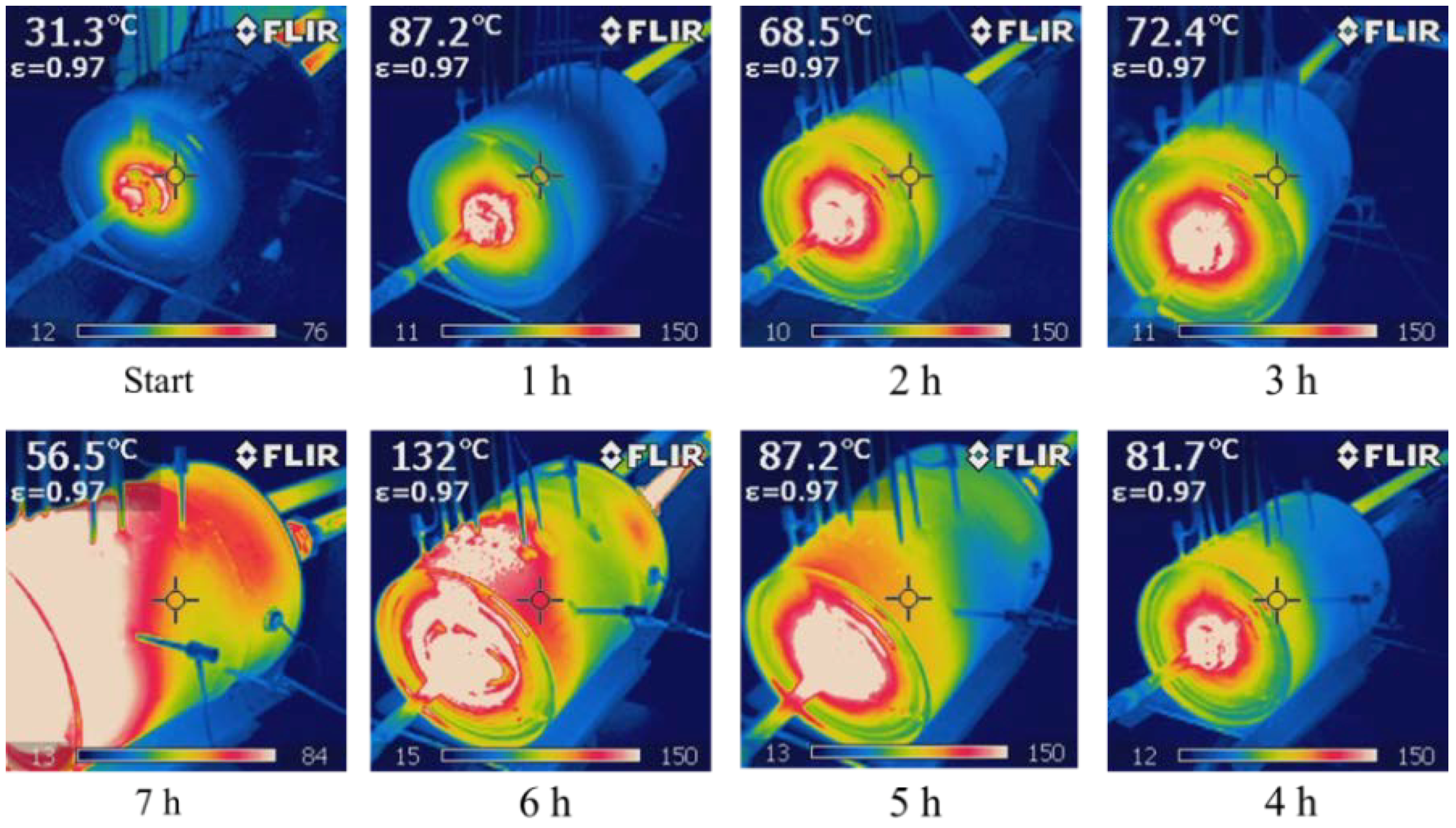

3.4. Results and Discussion

| Gas compositions | O2 (%) | N2 (%) | CO2 (%) | CO (%) | CH4 (%) | C2H6 (%) | H2 (%) |

|---|---|---|---|---|---|---|---|

| Gas concentration | 0.6 | 4.4 | 43.0 | 27.5 | 5.5 | 1.7 | 17.2 |

| Calorific value | 9.1 MJ/m3 | ||||||

4. Conclusions

Acknowledgments

Conflict of Interest

References

- Energy Information Administration (EIA). International Energy Outlook 2009; EIA: Washington, DC, USA, 2009; pp. 49–60.

- Alexander, Y.K. Early ideas in underground coal gasification and their evolution. Energies 2009, 2, 456–476. [Google Scholar] [CrossRef]

- Olness, D.U.; Gregg, D.W. The Historical Development of Underground Coal Gasification; Technical Report UCRL-52283; California University, Lawrence Livermore Lab: Livermore, CA, USA, 1977. [Google Scholar]

- Betts, A.G. An Improved Process for Utilizing Unmined Coal. UK Patent 21674; filed 1909, issued 1910,

- Burton, E.; Friedmann, J.; Upadhye, R. Best Practices in Underground Coal Gasification; Lawrence Livermore National Laboratory: Livermore, CA, USA, 2006. [Google Scholar]

- Kreinin, E.B. Two-stage underground coal gasification. Coal Chem. Ind. 1993, 6, 61–63. [Google Scholar]

- Franke, F.H. Survey on Experiment Laboratory Work on UCG. In Proceedings of the 12th Annual Underground Coal Gasification Symposium, Washington, DC, USA, 21–28 August 1986; pp. 131–133.

- Yang, L.H.; Liu, S.Q.; Yu, L.; Liang, J. Experimental study of shaftless underground gasification in thin high-angle coal seams. Energy Fuels 2007, 21, 2390–2397. [Google Scholar] [CrossRef]

- Thorsness, C.B.; Britten, J.A. Analysis of Material and Energy Balances for the Rocky Mountain-1 UCG Field Test; Report No. 44–49; Lawrence Livermore National Laboratory: Livermore, CA, USA, 1984. [Google Scholar]

- Debelle, B.; Malmendier, M. Modeling of flow at Thulin underground coal gasification experiments. Fuel 1992, 71, 95–104. [Google Scholar] [CrossRef]

- Edgar, T.F. Research and development on underground gasification of Texas lignite. ACS Symp. Ser. 1983, 79, 66–76. [Google Scholar]

- Chandelle, V. The pushing through project of the gasification channel in Tulin coal field. Min. Technol. 1992, 13, 5–7. [Google Scholar]

- Hossein, N.; Mohammad, K.; Zhang, C.; Jalal, A. Simulation study of underground coal gasification in Alberta reservoirs: Geological structure and process modeling. Energy Fuels 2010, 24, 3540–3550. [Google Scholar] [CrossRef]

- Alexander, P.; Coots, T.; David, B. Comparative study on the measuring methods adopted in the gasification of horizontal and steep coal layers. Min. Technol. 1985, 5, 107–115. [Google Scholar]

- Collot, A.G. Prospects for Hydrogen from Coal; IEA Clean Coal Centre: London, UK, 2003. [Google Scholar]

- Stanńczyk, K.; Kapusta, K.; Wiatowski, M.; Świądrowski, J.; Smoliński, A.; Rogut, J.; Kotyrba, A. Experimental simulation of hard coal underground gasification for hydrogen production. Fuel 2012, 91, 40–50. [Google Scholar] [CrossRef]

- Barbir, F. International Association for Hydrogen Energy; Martinus Nijhoff Publishers: Leiden, The Netherlands, 2009; pp. 275–285. [Google Scholar]

- Liang, J.; Liu, S.Q.; Yu, L. Method of stably controlling the process of underground coal gasification. J. China Univ. Min. Technol. 2002, 31, 358–361. [Google Scholar]

- Khadse, A.; Qayyumi, P.; Mahajani, S.; Aghalayam, P. Underground coal gasification: A new clean coal utilization technique for India. Energy 2007, 32, 2061–2071. [Google Scholar] [CrossRef]

- Kapusta, K.; Stanńczyk, K. Development conditions and limitations of the underground coal gasification in Poland. Chem. Rev. 2009, 88, 331–338. [Google Scholar]

- Su, F.Q.; Itakura, K.; Deguchi, G.; Ohga, K.; Goto, T.; Yoshida, Y. UCG Laboratory Experiments for Evaluation of Fracturing Activity around Coal Gasification Area. In Proceedings of MMIJ2011, Fall Convention of Mining and Materials Processing Institute, Sakai, Japan, 26–29 September 2011.

- Buscheck, T.A.; Hao, Y.; Morris, J.P.; Burton, E.A. Thermal–Hydrological Sensitivity Analysis of Underground Coal Gasification. In Proceedings of the 2009 International Pittsburgh Coal Conference, Pittsburgh, PA, USA, 20–23 September 2009.

- Watanabe, Y.; Itakura, K.; Sato, K.; Fujii, Y.; Balusu, R.; Guo, H.; Luo, X. A Modeling method on fractal distribution of cracks in rocks using AE Monitoring. J. Acoustic Emiss. 2005, 23, 119–128. [Google Scholar]

- Thompson, P.N. Gasifying coal underground. Endeavour 1978, 2, 2–93. [Google Scholar] [CrossRef]

- Blinderman, M.S.; Saulov, D.N.; Klimenko, A.Y. Forward and reverse combustion linking in underground coal gasification. Energy 2008, 33–446. [Google Scholar] [CrossRef]

- Gregg, D.W. Relative merits of alternate linking techniques for underground coal gasification and their system design implications. In Situ 1980, 4, 207–236. [Google Scholar]

- Betts, A.G. Lead Refining by Electrolysis; Wiley: New York, NY, USA, 1908. [Google Scholar]

- UCG Association. How UCG Works. Available online: http://www.ucgassociation.org/index.php/home (accessed on 26 March 2013).

- Hill, R.W. The Centralia Partial-Seam CRIP Test; Lawrence Livermore National Laboratory: Livermore, CA, USA, 1983. [Google Scholar]

- Hill, R.W. Review of the CRIP Process. In Proceedings of the Twelfth Annual Underground Coal Gasification Symposium, Saarbrücken, Germany, 21–28 August 1986.

- Ergo Exergy Technology Incorporated Website. Available online: http://www.ergoexergy.com (accessed on 27 March 2013).

- Thorsness, C.B.; Creighton, J.R. Review of Underground Coal Gasification Experiments at Hoe Creek; Report UCRL-87662; Lawrence Livermore National Laboratory: Livermore, CA, USA, 1982. [Google Scholar]

- Reginald Hardy, H., Jr. Acoustic Emission/Microseismic Activity; Taylor & Francis: Leiden, The Netherlands, 2003. [Google Scholar]

© 2013 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Su, F.; Nakanowataru, T.; Itakura, K.-i.; Ohga, K.; Deguchi, G. Evaluation of Structural Changes in the Coal Specimen Heating Process and UCG Model Experiments for Developing Efficient UCG Systems. Energies 2013, 6, 2386-2406. https://doi.org/10.3390/en6052386

Su F, Nakanowataru T, Itakura K-i, Ohga K, Deguchi G. Evaluation of Structural Changes in the Coal Specimen Heating Process and UCG Model Experiments for Developing Efficient UCG Systems. Energies. 2013; 6(5):2386-2406. https://doi.org/10.3390/en6052386

Chicago/Turabian StyleSu, Faqiang, Takuya Nakanowataru, Ken-ichi Itakura, Koutarou Ohga, and Gota Deguchi. 2013. "Evaluation of Structural Changes in the Coal Specimen Heating Process and UCG Model Experiments for Developing Efficient UCG Systems" Energies 6, no. 5: 2386-2406. https://doi.org/10.3390/en6052386

APA StyleSu, F., Nakanowataru, T., Itakura, K.-i., Ohga, K., & Deguchi, G. (2013). Evaluation of Structural Changes in the Coal Specimen Heating Process and UCG Model Experiments for Developing Efficient UCG Systems. Energies, 6(5), 2386-2406. https://doi.org/10.3390/en6052386