Corn Stover and Wheat Straw Combustion in a 176-kW Boiler Adapted for Round Bales

Abstract

:1. Introduction

2. Material and Method

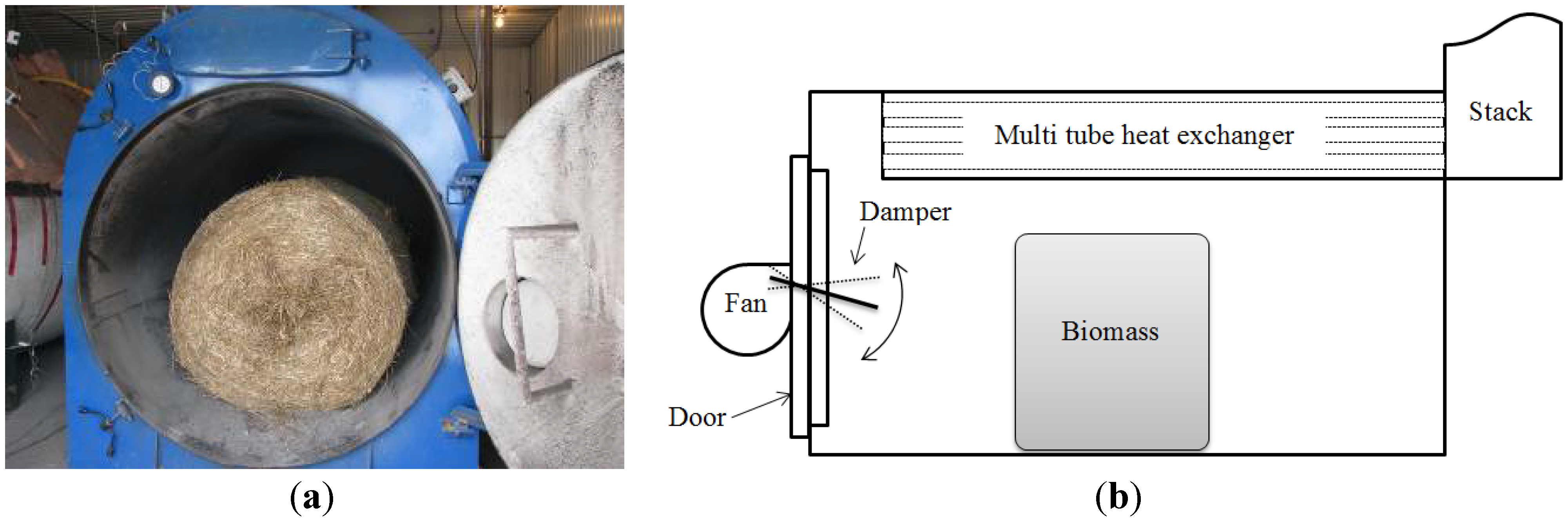

2.1. Biomass Boiler, Hydronics System and Barn Description

2.2. Monitoring Devices

2.3. Biomass Characterization Prior to Combustion

2.4. Combustion Procedure

2.5. Energy Balance Calculation

2.6. Combustion Validation Trials with CS

3. Results and Discussion

3.1. Biomass Characteristics

| Parameter | Unit | WS (six bales) | CS (twelve bales) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Ave. | S.D. | Min. | Max. | Ave. | S.D. | Min. | Max. | ||

| Moisture content | % | 14.6 | 0.7 | 13.6 | 15.5 | 13.6 | 1.4 | 12.7 | 17.7 |

| Bale mass | kg | 183.2 | 13.7 | 166.6 | 198.6 | 190.2 | 12.4 | 163.4 | 206.8 |

| kg DM | 156.5 | 11.9 | 144.0 | 170.7 | 164.5 | 12.5 | 134.5 | 180.4 | |

| Diameter | m | 1.47 | 0.03 | 1.43 | 1.52 | 1.32 | 0.04 | 1.25 | 1.39 |

| Width | m | 1.20 | 0.00 | 1.20 | 1.20 | 1.15 | 0.02 | 1.12 | 1.18 |

| Volume | m3 | 2.04 | 0.09 | 1.91 | 2.16 | 1.58 | 0.11 | 1.40 | 1.76 |

| Density | kg/m3 | 90.2 | 8.7 | 79.6 | 103.8 | 120.8 | 6.7 | 112.0 | 131.8 |

| kg DM/m3 | 77.1 | 7.6 | 68.8 | 89.2 | 104.5 | 6.3 | 96.1 | 114.2 | |

| Gross calorific value | MJ/kg d.b. | 18.91 | 0.33 | 18.55 | 19.47 | 17.04 | 0.87 | 15.90 | 18.72 |

| Net calorific value | MJ/kg w.b. | 14.77 | 0.23 | 14.54 | 15.07 | 13.35 | 0.74 | 12.51 | 14.98 |

| Total gross energy | MJ/bale | 2955.9 | 188.7 | 2731.6 | 3167.5 | 2800.5 | 227.5 | 2422.1 | 3226.1 |

| Total net energy | MJ/bale | 2702.7 | 169.9 | 2503.4 | 2894.4 | 2540.1 | 216.6 | 2189.9 | 2957.9 |

| Ash content | % d.b. | 1.82 | 0.22 | 1.59 | 2.14 | 11.70 | 5.32 | 5.09 | 22.14 |

3.2. Combustion Trials

| Bale ID | MC (%) | Mass (kg) | Mass (kg DM) | Start date and time | End date and time | Duration (min) | Burning rate (kg DM /h) | Ext. temp. (°C) |

|---|---|---|---|---|---|---|---|---|

| WS | ||||||||

| S1 | 14.4 | 193.2 | 165.4 | 01/23 15:40 | 01/23 18:55 | 195 | 50.88 | 0.1 |

| S2 | 14.0 | 198.6 | 170.7 | 01/23 19:00 | 01/23 23:15 | 255 | 40.17 | 2.0 |

| S3 | 13.6 | 166.6 | 144.0 | 01/23 23:15 | 01/24 09:35 | 620 | 29.93 | 5.5 |

| S21 | 15.0 | 194.4 | 165.2 | Dual burning with S3 | ||||

| S4 | 15.1 | 174.0 | 147.8 | 01/24 09:40 | 01/24 13:45 | 245 | 36.19 | 11.2 |

| S5 | 15.5 | 172.2 | 145.6 | 01/24 13:50 | 01/24 19:55 | 365 | 23.93 | 8.3 |

| Ave. | 14.6 | 183.2 | 156.5 | - | - | 280 a | 33.52 | 5.4 |

| Sum | - | 1099.0 | 938.7 | - | - | 1680 | - | - |

| CS | ||||||||

| C6 | 13.1 | 198.2 | 172.3 | 01/24 20:00 | 01/24 23:30 | 210 | 49.22 | 5.8 |

| C7 | 13.7 | 168.6 | 145.5 | 01/24 23:35 | 01/25 06:25 | 410 | 21.30 | 3.4 |

| C8 | 12.8 | 190.0 | 165.7 | 01/25 06:30 | 01/25 10:55 | 265 | 37.52 | 3.3 |

| C9 | 13.8 | 191.6 | 165.2 | 01/25 11:00 | 01/25 14:55 | 235 | 42.18 | 4.1 |

| C10 | 12.9 | 195.2 | 170.0 | 01/25 15:00 | 01/25 18:20 | 200 | 50.99 | 1.7 |

| C11 | 12.8 | 206.8 | 180.4 | 01/25 18:25 | 01/25 22:40 | 255 | 42.44 | −0.4 |

| C12 | 13.9 | 199.0 | 171.3 | 01/25 22:45 | 01/26 03:55 | 310 | 33.15 | −0.5 |

| C13 | 13.8 | 190.4 | 165.2 | 01/26 04:00 | 01/26 07:45 | 225 | 43.79 | −3.3 |

| C14 | 12.8 | 191.6 | 166.1 | 01/26 07:50 | 01/26 11:40 | 230 | 43.61 | −1.7 |

| C15 | 12.7 | 197.4 | 172.4 | 01/26 11:45 | 01/26 15:35 | 230 | 44.97 | 0.0 |

| C16 | 12.9 | 190.4 | 165.9 | 01/26 15:40 | 01/26 20:40 | 300 | 33.18 | −6.0 |

| C17 | 17.7 | 163.4 | 134.5 | 01/26 20:45 | 01/26 23:55 | 190 | 42.46 | −6.4 |

| Ave. | 13.6 | 190.2 | 164.5 | - | - | 255 | 38.69 | 0.0 |

| Sum | - | 2282.6 | 1974.4 | - | - | 3060 | - | - |

| Biomass | Bales burned | Mass burned | Accumulation period | Ash and unburned content | Ash production rate | |

|---|---|---|---|---|---|---|

| - | - | kg DM | h | kg | % d.b. | kg/h |

| PCT WS | 48 | 7517 | 240 | 127.6 | 1.70 | 0.53 |

| WS | 6 | 938.7 | 28 | 24.0 | 2.55 | 0.86 |

| CS | 12 | 1974.4 | 52 | 181.0 | 9.17 | 3.48 |

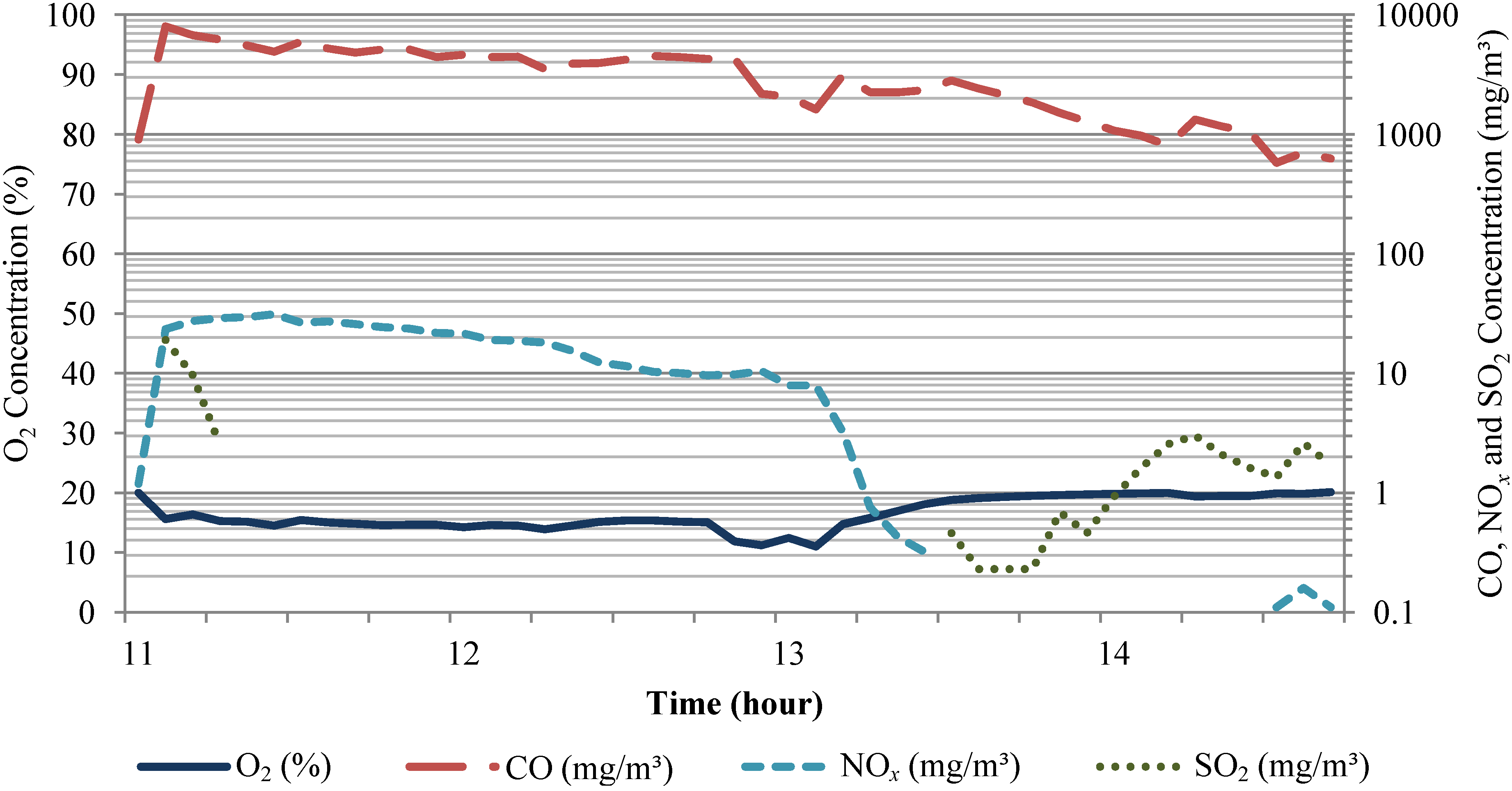

3.3. Flue Gas Emissions

| Bale ID | Stack Temp. (°C) | Intake Temp. (°C) | Mass air flow (kg/s) | Eff. (%) | Excess air ratio (%) | O2 (%) | CO2 (%) | CO (mg/m3) | NOx (mg/m3) | SO2 (mg/m3) | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| - | Ave. | Ave. | Ave. | Ave. | Ave. | Ave. | Ave. | Ave. | Max. | Ave. | Max. | Ave. | Max. |

| WS | |||||||||||||

| S1 | 275.0 | 27.1 | 0.30 | 68.9 | 181 | 13.7 | 7.4 | 3533 | 7148 | 108.8 | 179.0 | 7.9 | 76.3 |

| S2 | 249.3 | 30.8 | 0.27 | 70.2 | 110 | 15.1 | 10.0 | 1644 | 4622 | 58.3 | 121.4 | 1.8 | 6.9 |

| S3–S21 | 181.6 | 34.3 | 0.26 | 70.8 | 135 | 17.0 | 9.5 | 2357 | 8999 | 11.3 | 91.4 | 8.0 | 24.3 |

| S22 | 181.8 | 22.8 | 0.24 | 67.4 | 178 | 16.8 | 7.5 | 1719 | 3604 | 6.1 | 17.3 | 0.7 | 3.0 |

| S23 | 206.0 | 26.2 | 0.28 | 63.1 | 220 | 17.3 | 6.4 | 1799 | 4366 | 17.4 | 36.5 | 0.1 | 1.4 |

| Ave. | 218.7 | 28.2 | 0.30 | 68.1 | 165 | 16.0 | 8.2 | 2210 | - | 40.4 | - | 3.7 | - |

| CS | |||||||||||||

| C7 | 139.0 | 34.9 | 0.21 | 69.6 | 235 | 18.5 | 6.7 | 1724 | 7604 | 2.3 | 12.5 | 4.7 | 10.4 |

| C8 | 195.9 | 24.0 | 0.27 | 68.5 | 241 | 16.6 | 6.7 | 3132 | 7782 | 10.2 | 29.3 | 2.6 | 33.1 |

| C9 | 200.5 | 24.0 | 0.28 | 69.0 | 203 | 15.4 | 7.0 | 3564 | 7915 | 3.2 | 11.3 | 1.1 | 13.0 |

| C14 | 212.4 | 19.1 | 0.28 | 67.6 | 219 | 15.5 | 6.5 | 3592 | 8571 | 16.8 | 36.2 | 3.6 | 95.0 |

| C15 | 194.9 | 28.5 | 0.25 | 68.5 | 227 | 16.4 | 6.3 | 3238 | 8005 | 10.6 | 31.3 | 1.2 | 19.0 |

| C16 | 195.1 | 23.0 | 0.23 | 67.9 | 166 | 16.4 | 8.0 | 1774 | 6023 | 6.7 | 17.3 | 0.8 | 4.6 |

| C17 | 213.8 | 25.9 | 0.27 | 63.9 | 218 | 17.0 | 6.6 | 2053 | 6939 | 19.1 | 44.7 | 0.7 | 11.2 |

| Ave. | 193.1 | 25.6 | 0.26 | 67.8 | 215 | 16.6 | 6.8 | 2725 | - | 9.8 | - | 2.1 | - |

3.4. Energy Balance

| Biomass type | Biomass | Boiler | Tank | Total losses | Thermal | |

|---|---|---|---|---|---|---|

| NCV (MJ) | Accumulated (MJ) | Output (MJ) | Accumulated (MJ) | (By difference) (MJ) | Efficiency (%) | |

| WS | 16,216 | 117.7 | 9,509 | 1,400 | 5,190 | 68.0 |

| CS | 30,481 | 72.8 | 13,332 | −960 | 18,036 | 40.8 |

3.5. Combustion Validation Trials Results

| Trial | MC | Bale mass | Start date | End date | Duration | Burning rate | Ext. temp. | |

|---|---|---|---|---|---|---|---|---|

| % | kg | kg DM | min/bale | kg DM/h | °C | |||

| 1 | 13.3 | 182.4 | 158.1 | 2013-01-30 | 2013-02-08 | 412 | 23.0 | −4.7 |

| 2a | 12.4 | 176.4 | 154.5 | 2013-02-17 | 2013-03-23 | 624 | 14.8 | −2.3 |

| 3 | 11.7 | 167.5 | 147.9 | 2013-04-12 | 2013-04-23 | 537 | 16.5 | 6.1 |

| Ave. | 12.5 | 175.4 | 153.5 | - | - | 524 | 17.6 | −0.3 |

| Trial | Bales burned | Total mass burned | Accumulation period | Ash content | Ash production rate | |

|---|---|---|---|---|---|---|

| kg DM | h | kg | % d.b. | kg/h | ||

| 1 | 30 | 4,743.2 | 206.2 | 374.6 | 7.90 | 1.82 |

| 2 | 30 | 4,634.0 | 312.2 | 266.4 | 5.75 | 0.85 |

| 3 | 30 | 4,437.9 | 268.3 | 219.0 | 4.93 | 0.82 |

| Ave. | 30 | 4,605.0 | 262.2 | 286.7 | 6.19 | 1.09 |

| Sum | 90 | 13,815.0 | 786.7 | 860.0 | - | - |

4. Conclusions

Acknowledgments

Conflicts of Interest

References

- Agriculture and Agri-Food Canada. Canada: Outlook for Principal Field Crops. Available online: http://www.agr.gc.ca/pol/mad-dam/index_e.php?s1=pubs&s2=fco-ppc&s3=php&page=fco-ppc_2013-04-17 (accessed on 17 April 2013).

- Lal, R. The role of residue management in sustainable agricultural systems. J. Sustain. Agric. 1995, 5, 51–78. [Google Scholar] [CrossRef]

- Wilhelm, W.W.; Johnson, J.M.E.; Karlen, D.L.; Lightle, D.T. Corn stover to sustain soil organic carbon further constrains biomass supply. Agron. J. 2007, 99, 1665–1667. [Google Scholar] [CrossRef]

- Lockeretz, W. Crop residues for energy: Comparative costs and benefits for the farmer, the energy facility, and the public. Energy Agric. 1982, 1, 71–89. [Google Scholar] [CrossRef]

- English, A.; Tyner, W.E.; Sesmero, J.; Owens, P.; Muth, D.J. Environmental tradeoffs of stover removal and erosion in Indiana. Biofuels Bioprod. Bioref. 2013, 7, 78–88. [Google Scholar] [CrossRef]

- Kludze, H.; Deen, B.; Weersink, A.; van Acker, R.; Janovicek, K.; De Laporte, A.; McDonald, I. Estimating sustainable crop residue removal rates and costs based on soil organic matter dynamics and rotational complexity. Biomass Bioenergy 2013, 56, 607–618. [Google Scholar] [CrossRef]

- Taheripour, F.; Tyner, W.E.; Fiegel, J. Development of Corn Stover Biofuel: Impacts on Corn and Soybean Markets and Land Rotation. In Proceedings of the Agricultural & Applied Economics Association’s AAEA & CAES Joint Annual Meeting, Washington, DC, USA, 4–6 August 2013.

- Bennett, A.S.; Bern, C.J.; Richard, T.L.; Anex, R.P. Corn grain drying using corn stover combustion and CHP systems. Trans. ASABE 2007, 50, 2161–2170. [Google Scholar] [CrossRef]

- Villeneuve, J.; Palacios, J.H.; Savoie, P.; Godbout, S. A critical review of emission standards and regulations regarding biomass combustion in small scale units (<3 MW). Bioresour. Technol. 2012, 111, 1–11. [Google Scholar]

- Leino, T.J.; Aho, M.J.; Gynther, S.J.; Ruuskanen, T.A.; Häkkinen, M.H. Experiences from a novel sensor for fireside corrosion monitoring during grate combustion of corn stover/wood chip blends. Energy Fuels 2013, 27, 5653–5662. [Google Scholar] [CrossRef]

- Leiser, S.; Cieplik, M.K.; Smit, R. Slagging behavior of straw and corn stover and the fate of potassium under entrained-flow gasification conditions. Energy Fuels 2012, 27, 318–326. [Google Scholar] [CrossRef]

- Lizotte, P.-L.; Savoie, P. Spring harvest of corn stover. Appl. Eng. Agric. 2011, 27, 697–703. [Google Scholar] [CrossRef]

- Sumner, H.R.; Sumner, P.E.; Hammond, W.C.; Monroe, G.E. Indirect-fired biomass furnace test and bomb calorimeter determinations. Trans. ASAE 1983, 26, 238–241. [Google Scholar] [CrossRef]

- Teisen Products Ltd. Farm 2000. Available online: http://www.farm2000.co.uk (accessed on 1 May 2013).

- Lizotte, P.-L.; Savoie, P. Spring harvest of corn stover for animal bedding with a self-loading wagon. Appl. Eng. Agric. 2013, 29, 25–31. [Google Scholar] [CrossRef]

- Solid Biofuels. Determination of Calorific Value; Standard Number BS EN 14918:2009; British Standards Institution: London, UK, 2010.

- Standard Test Methods for Proximate Analysis of Coal and Coke by Macro Thermogravimetric Analysis; ASTM D7582-10; ASTM International: West Conshohocken, PA, USA, 2010.

- Van Loo, S.; Koppejan, J. The Handbook of Biomass Combustion and Co-firing; Earthscan: London, UK, 2008. [Google Scholar]

- BIOBIB—A Database for Biofuels. Available online: http://cdmaster2.vt.tuwien.ac.at/biobib/biobib.html (accessed on 20 March 2012).

- Schmidt, A.; Zschetzsche, A.; Hantsch-Linhart, W. Analyse von biogenen Brennstoffen; TU Wien, Institut für Verfahrens-, Brennstoff- und Umwelttechnik: Vienna, Austria, 1993. [Google Scholar]

- Morissette, R.; Savoie, P.; Villeneuve, J. Combustion of corn stover bales in a small 146-kW boiler. Energies 2011, 4, 1102–1111. [Google Scholar] [CrossRef]

- Xiong, S.; Burvall, J.; Orberg, H.; Kalen, G.; Thyrel, M.; Ohman, M.; Boström, D. Slagging characteristics during combustion of corn stovers with and without kaolin and calcite. Energy Fuels 2008, 22, 3465–3470. [Google Scholar] [CrossRef]

- Beauchemin, P.A.; Tampier, M. Emissions from Wood-Fired Combustion Equipment; Envirochem Services Inc: North Vancouver, BC, Canada, 2008. [Google Scholar]

- Basu, P.; Cen, K.F.; Jestin, L. Boilers and Burners; Springer: New York, NY, USA, 2000. [Google Scholar]

- Guide to Low-Emission Boiler and Combustion Equipment Selection; ORNL/TM-2002/19; Oak Ridge National Laboratory (ORNL): Oak Ridge, TN, USA, 2002.

- Biedermann, F.; Obernberger, I. Ash-Related Problems during Biomass Combustion and Possibilities for a Sustainable Ash Utilization; Elsevier Ltd.: Oxford, UK, 2005. [Google Scholar]

- Cleaver-Brooks. Boiler Efficiency Guide. Available online: http://www.cleaver-brooks.com/uploadedFiles/Internet_Content/Reference_Center/Insights/Boiler%20Efficiency%20Guide.pdf (accessed on 14 October 2013).

© 2013 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Morissette, R.; Savoie, P.; Villeneuve, J. Corn Stover and Wheat Straw Combustion in a 176-kW Boiler Adapted for Round Bales. Energies 2013, 6, 5760-5774. https://doi.org/10.3390/en6115760

Morissette R, Savoie P, Villeneuve J. Corn Stover and Wheat Straw Combustion in a 176-kW Boiler Adapted for Round Bales. Energies. 2013; 6(11):5760-5774. https://doi.org/10.3390/en6115760

Chicago/Turabian StyleMorissette, René, Philippe Savoie, and Joey Villeneuve. 2013. "Corn Stover and Wheat Straw Combustion in a 176-kW Boiler Adapted for Round Bales" Energies 6, no. 11: 5760-5774. https://doi.org/10.3390/en6115760