Retrofitting Domestic Hot Water Heaters for Solar Water Heating Systems in Single-Family Houses in a Cold Climate: A Theoretical Analysis

Abstract

:1. Introduction

- To theoretically investigate different system configurations and control strategies in retrofitting conventional domestic water heaters for SWH systems in single-family houses in the Swedish climate;

- To compare the performance of the retrofitted systems with the performance of a standard solar thermal system for the same reference conditions.

2. Methodology

2.1. Existing Domestic Hot Water Heaters in Swedish Single-Family Houses

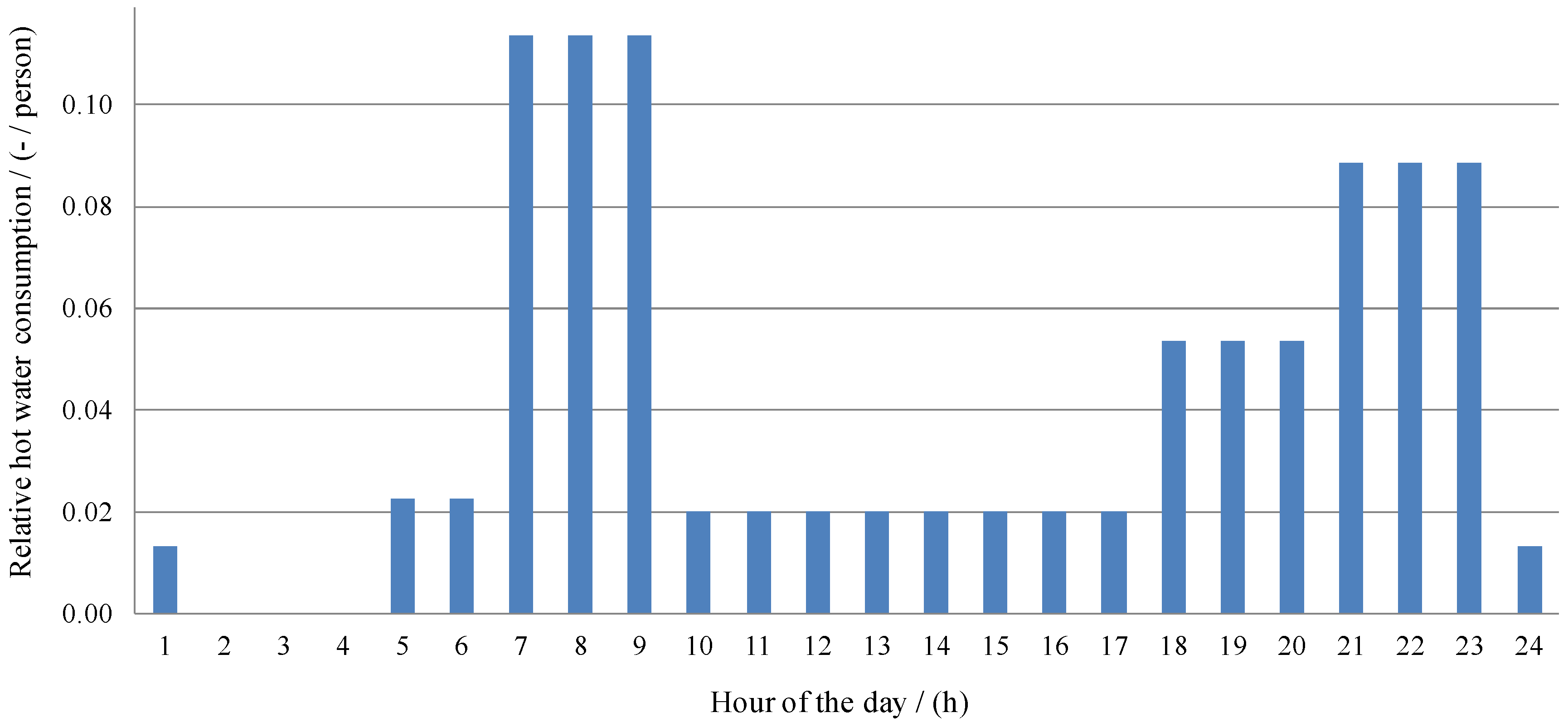

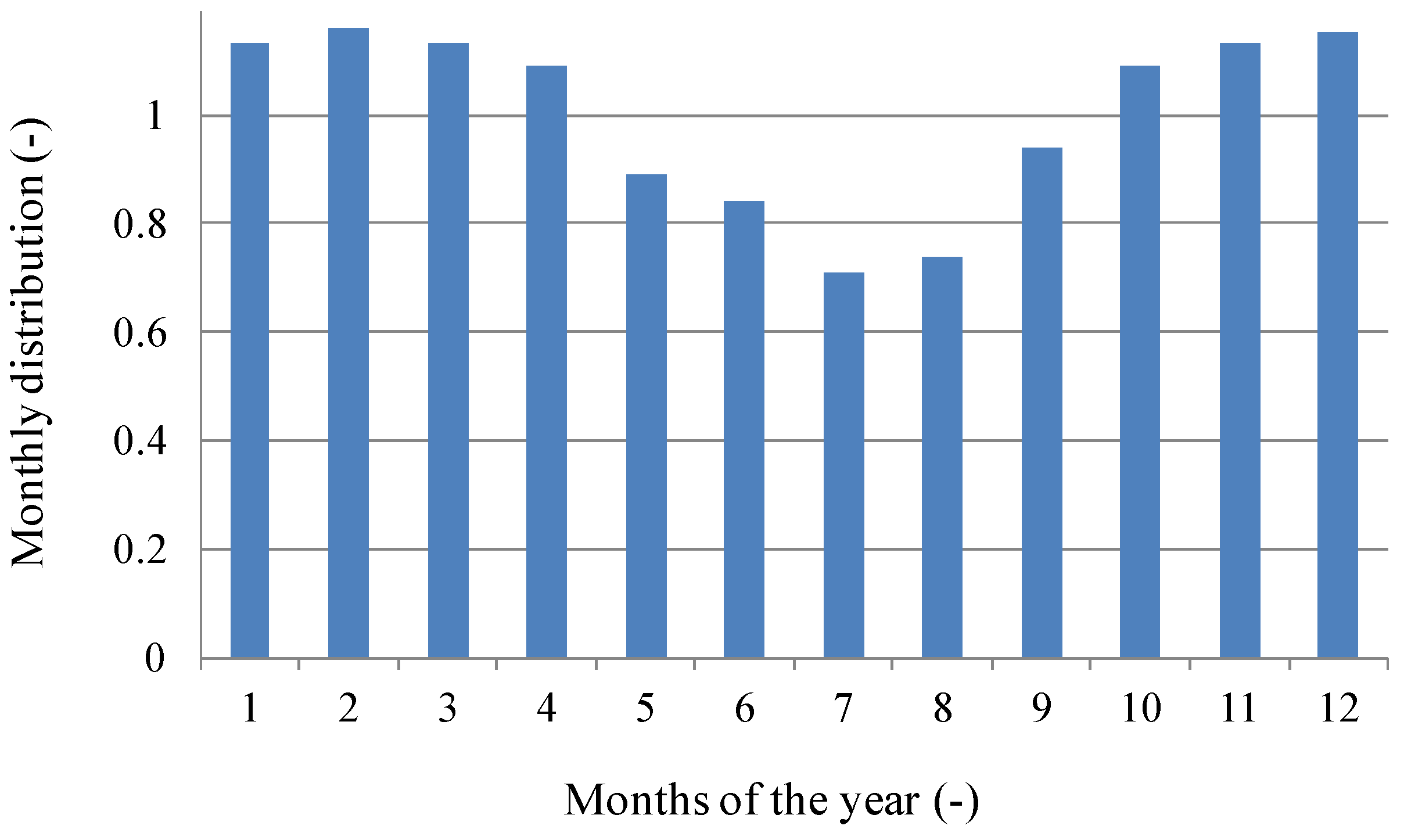

2.2. Domestic Hot Water Load in Swedish Single-Family Houses

2.3. Regulations Regarding Water Heating Systems and Legionella Growth

- Auxiliary heater volume kept at 60 °C;

- Hot water temperature available at the higher than 50 °C and lower than 60 °C;

- Heating up the whole storage volume to 60 °C during 20 min if the temperature of the retrofitted tank was below 60 °C during a period of one week;

- As a design guideline, the domestic hot water system should, during a maximal period of six hours, be able to heat up 10 °C cold water and deliver two times 140 litres of 40 °C water in one hour. This is the equivalent to being able to provide, every six hours, 9.75 kWh during one hour.

2.4. System Model

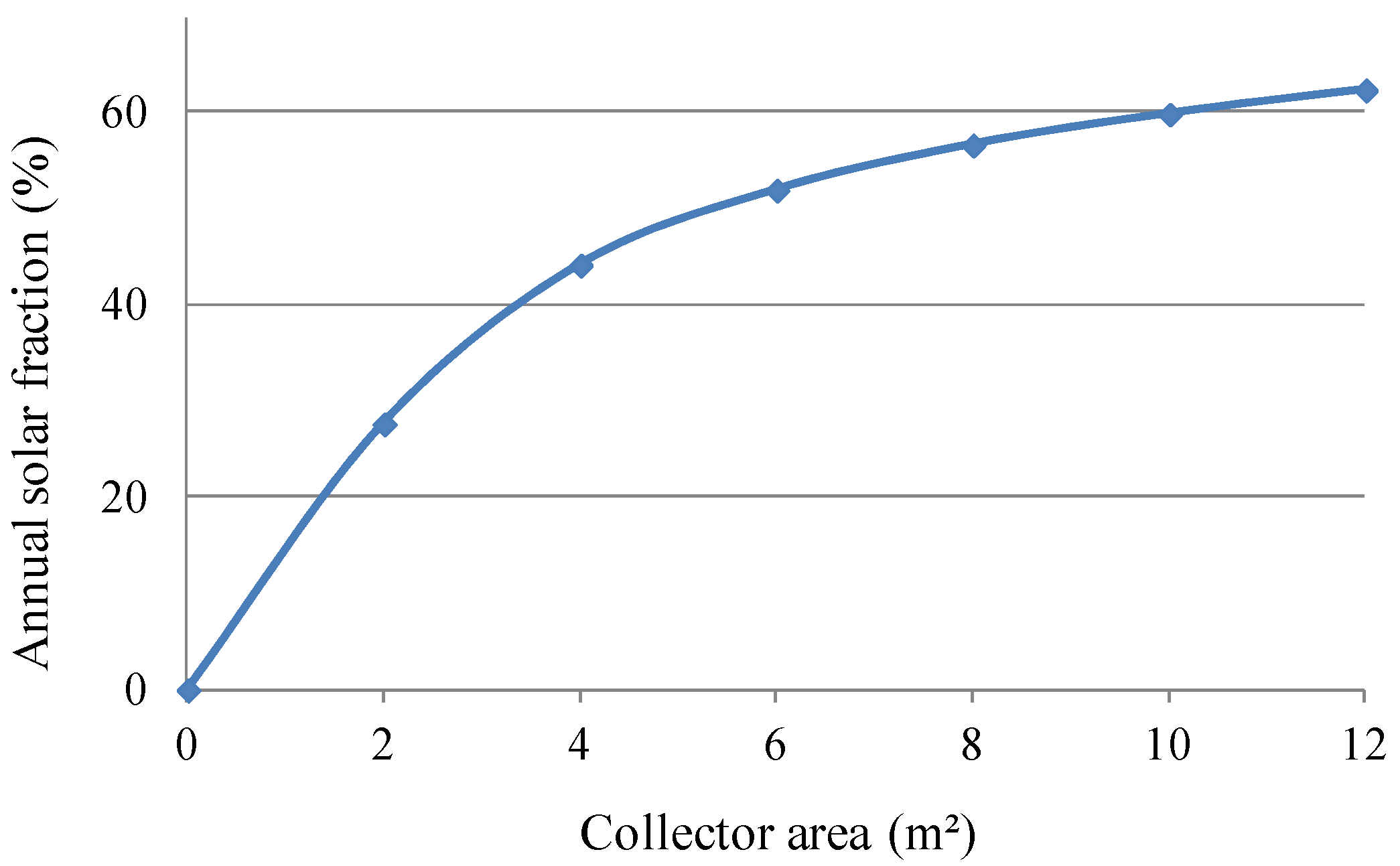

- Thermal collector—type 537 from TESS TRSYS library [44]. This solar collector model operates like a conventional flat plate collector but makes it possible to regulate a variable speed for the pump in the collector loop in order to keep the outlet temperature, Tout, at a user-specified value. The parameters used to describe the collector were considered to be reasonable for flat plate collectors used in a cold climate [18,24]. These are 0.8 for F’(τα)n, −3.6 for F’U0, −0.014 for F’U1 and −0.2 for b0 based on average collector temperature and tested flow rate of 30 kg/h. The dependence of parameter kb(θ) on b0 is described by Equation (1) [19]. A sensitivity analysis was performed regarding the size of the collector and the corresponding annual solar fraction in the range 0–12 m2.

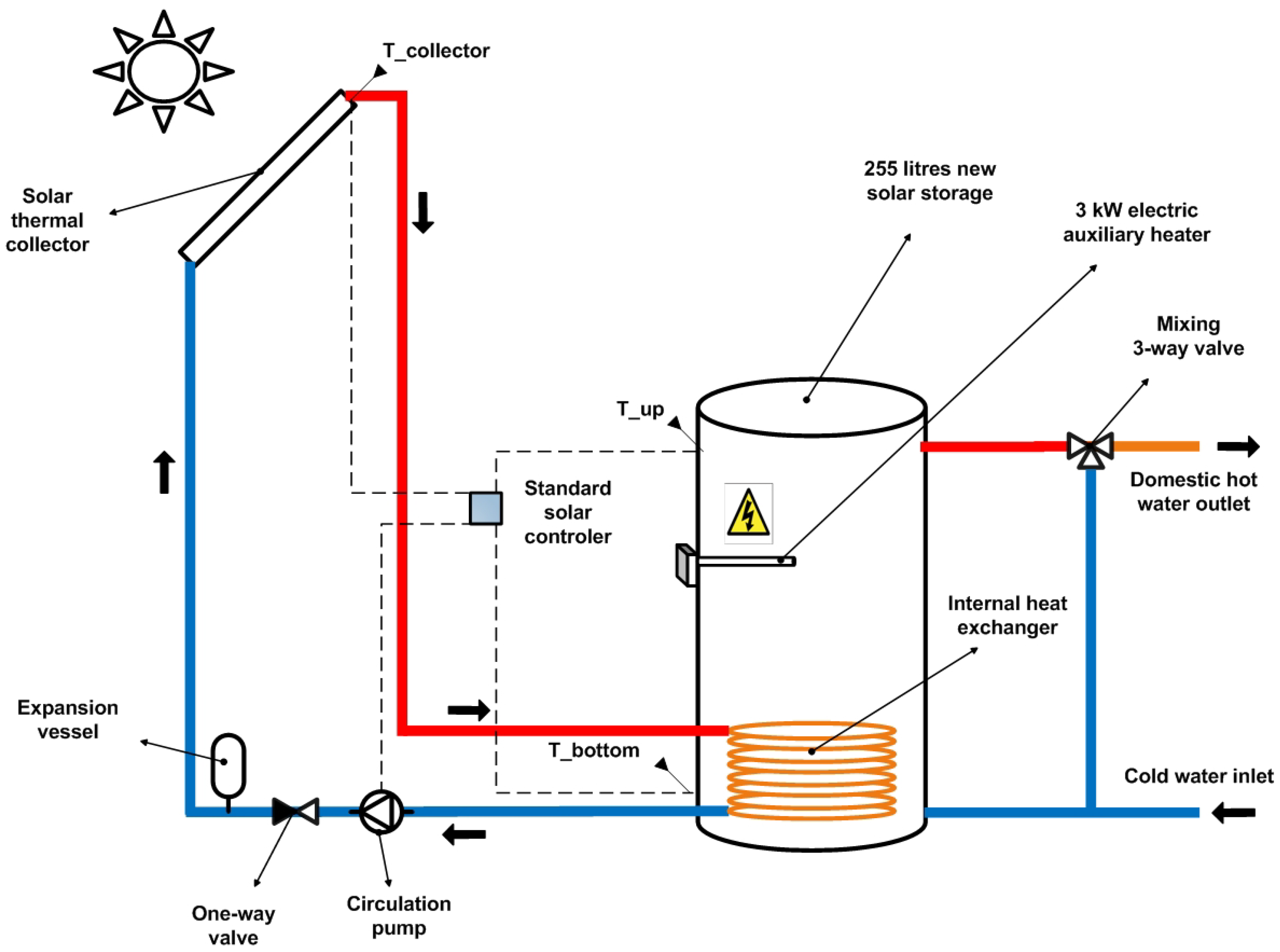

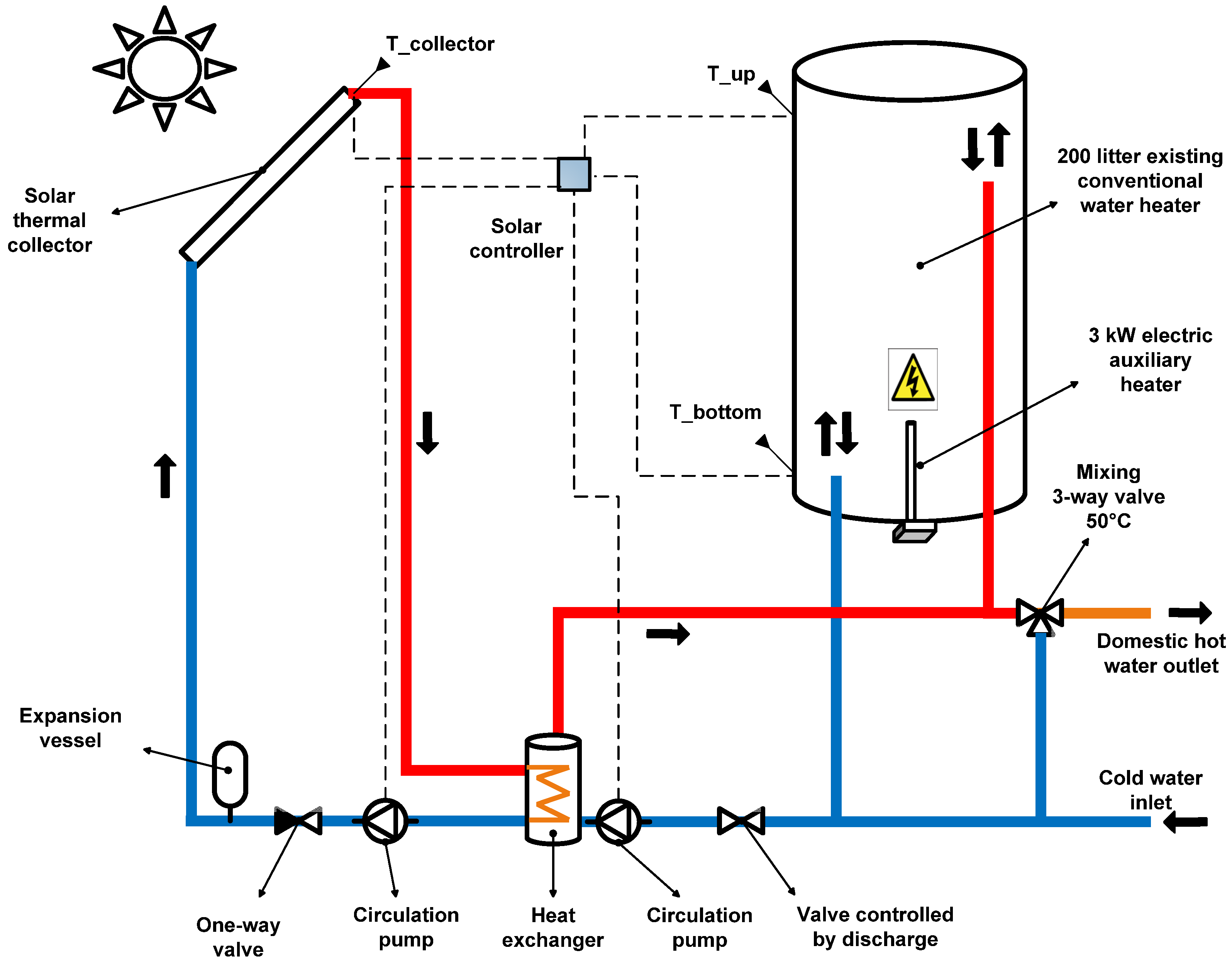

- Fully stratified standard storage tank (6 nodes)—type 534 from TESS TRNSYS library. This model represents a common type of storage tank in standard SWH systems for domestic hot water production. The model divides the tank into isothermal nodes that thermally interact with the ones above, below and with the tank wall. It models a vertical cylindrical tank with a total volume of 255 litres and 1.60 m high. The coil heat exchanger was placed in the lower third of the tank according to the manufacturer’s specifications. A 3 kW electric auxiliary heater was fitted horizontally at 0.5 m from the top with a set-point temperature, Tset, of 60 °C (Figure 3). As shown by Cruickshank and Harrison [45], calculating the heat loss factor of the storage based on its insulation characteristics and materials can lead to significant errors. The number and type of inlet and outlet connections and poor insulation at the tank bottom are examples of factors that lead to such inaccuracies. Thus, the U-values were then based on the experimental results with common storages in standard SWH systems [45]. These were assumed to be 1 W/m2 °C for the top and middle of the storage, Utop, Uside and 2.5 W/m2 °C for the bottom, Ubottom;

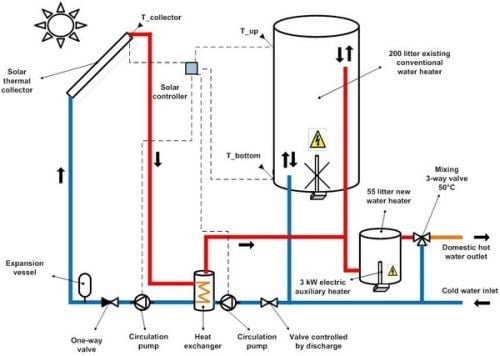

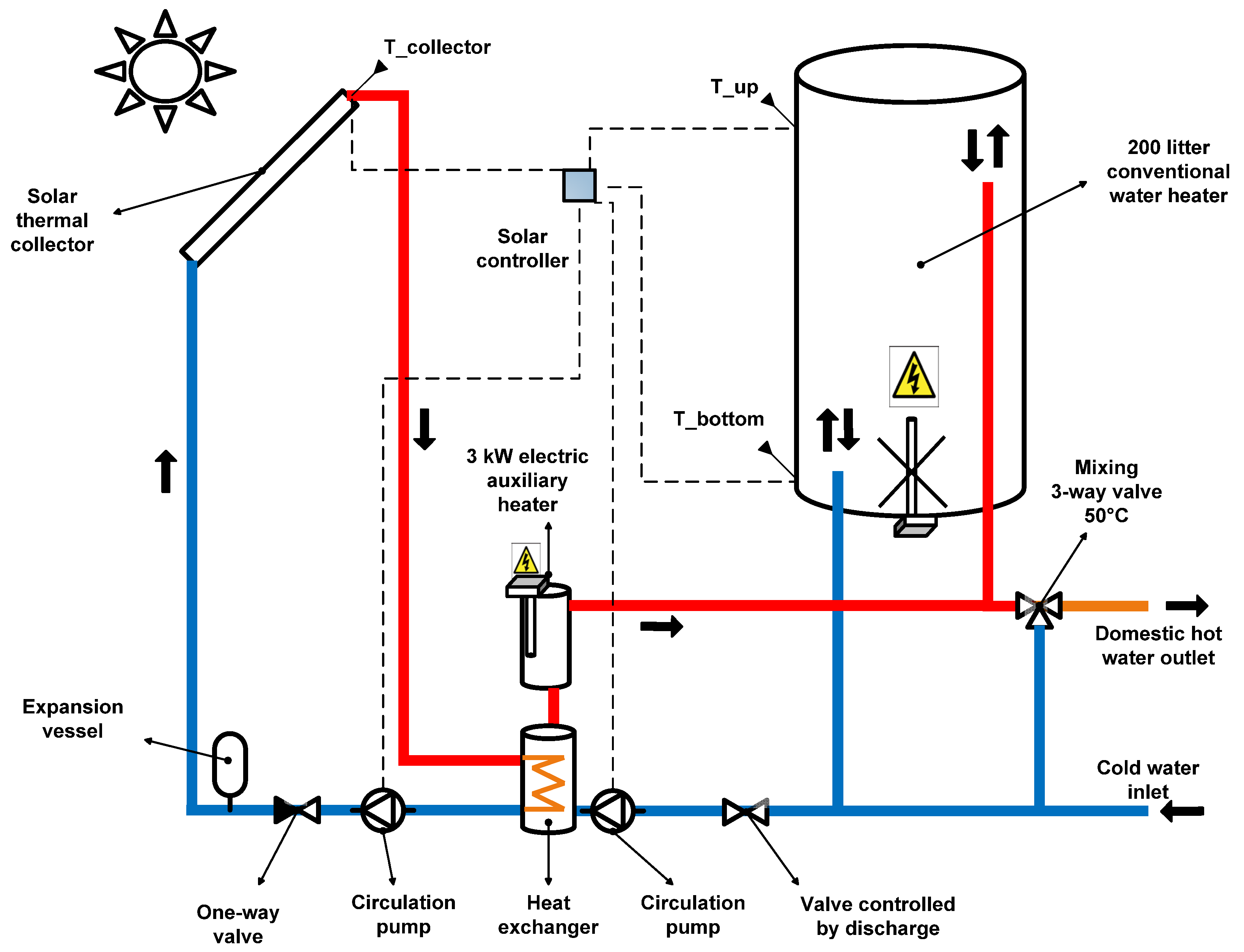

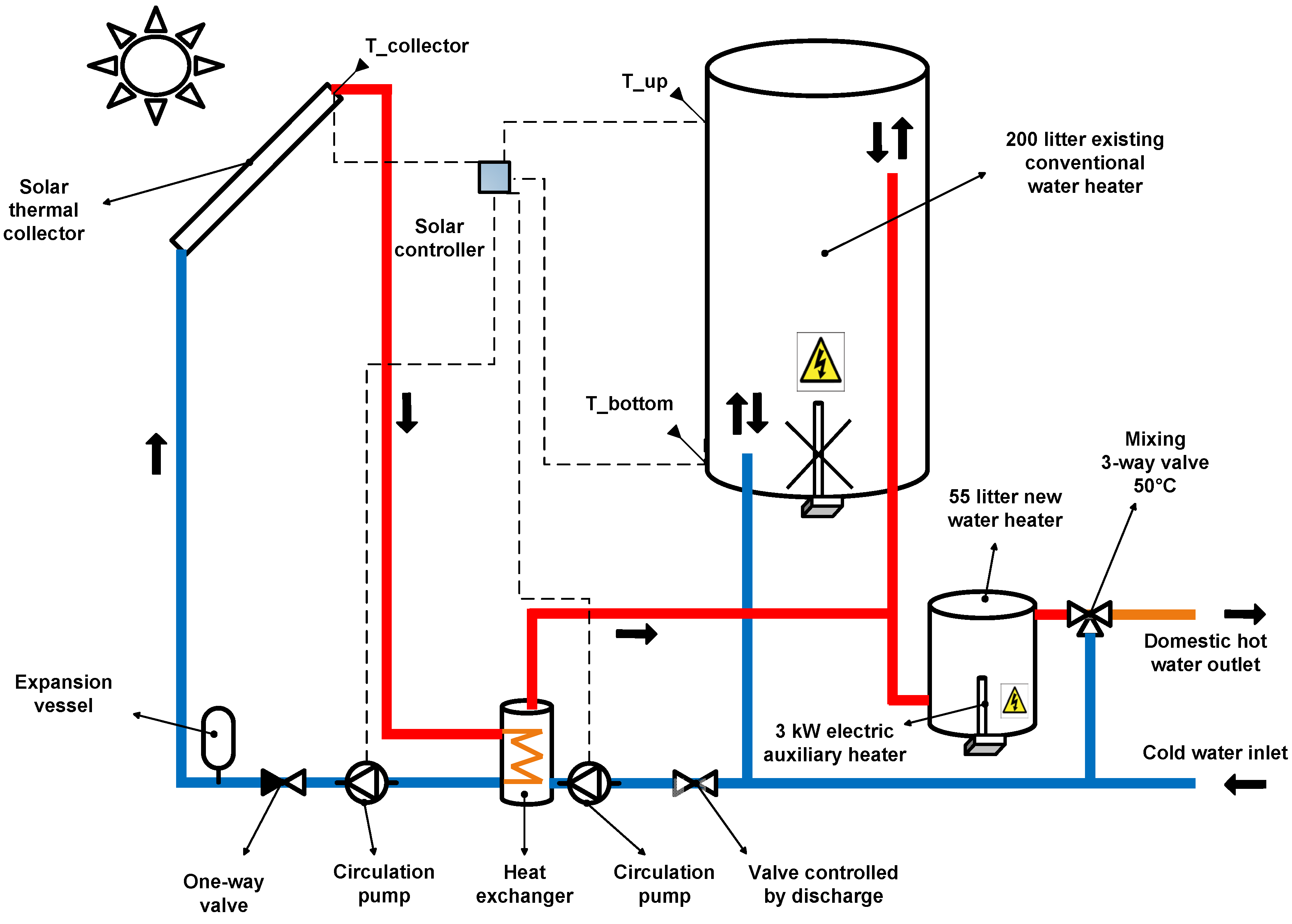

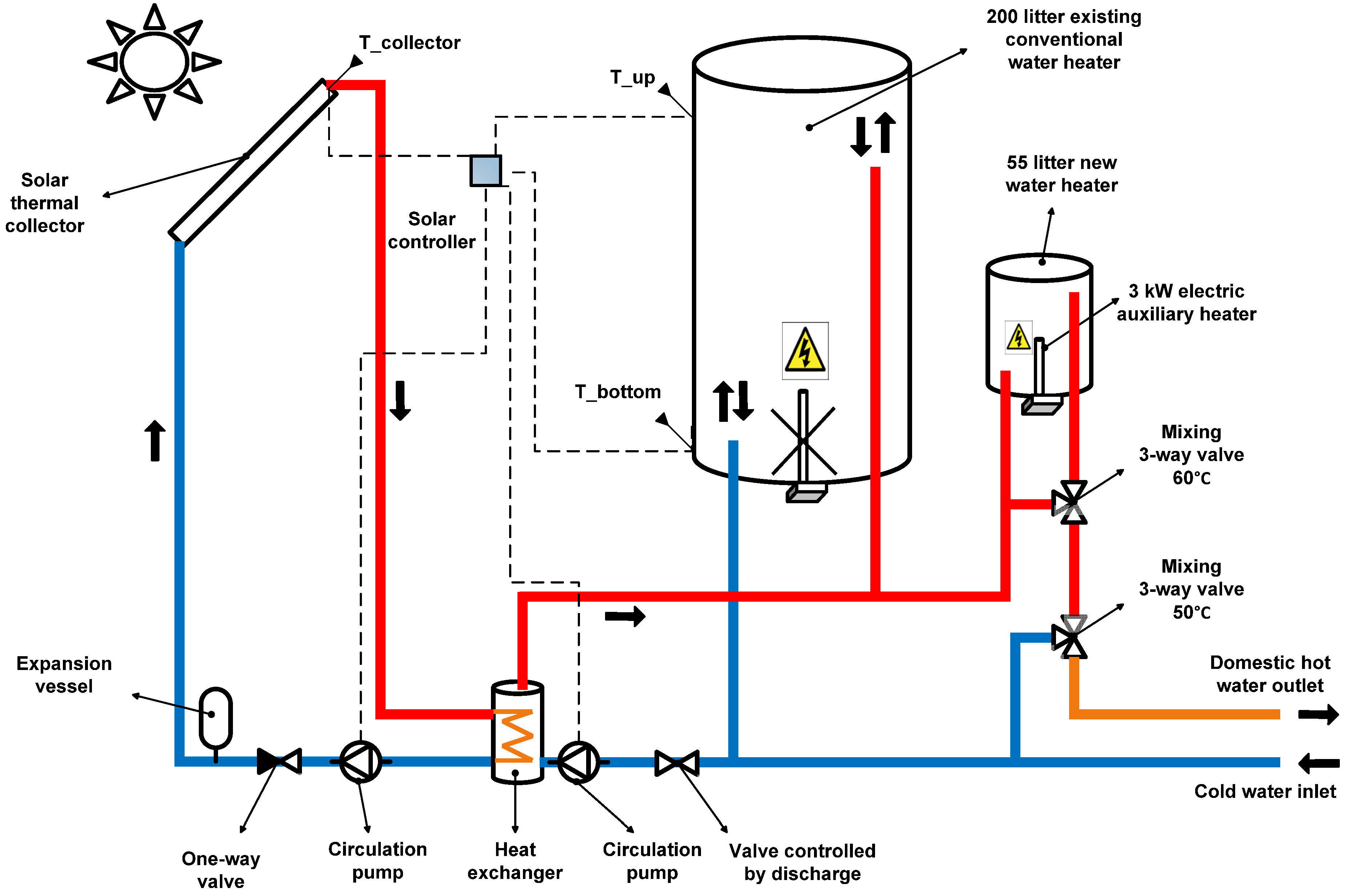

- Fully stratified retrofitted storage tank (6 nodes)—type 534 from TESS TRNSYS library. This storage was modelled with the same principles as the standard storage for SWH systems. However, the total volume was set to 200 litres, the height was assumed to be 1.40 m, the connections are placed at the top and bottom of the tank (Figure 4, Figure 5, Figure 6 and Figure 7) and there is no internal heat exchanger. Only retrofitted system 2 uses the auxiliary heater placed at the bottom (Figure 4). In all the other systems this heater is disabled. The same U-values described above were also used for this storage;

- Small heater storage tank (1 node)—type 534 from TESS TRNSYS library. The total volume was set to 55 litres and the height to 0.60 m. The connections are also placed at the top and bottom of the tank (Figure 5, Figure 6 and Figure 7). An auxiliary heater of 3 kW was used in all models since this is the most common and a higher power could create problems with the installed capacity in such houses. The auxiliary heater keeps the temperature of the storage volume at least at 60 °C to avoid legionella problems [46]. The average U-value used for this storage was 0.5 W/m2 °C based on preliminary measurements on an existing tank. A sensitivity analysis concerning the impact on the annual solar fraction of the variation in the auxiliary heater volume and temperature was performed;

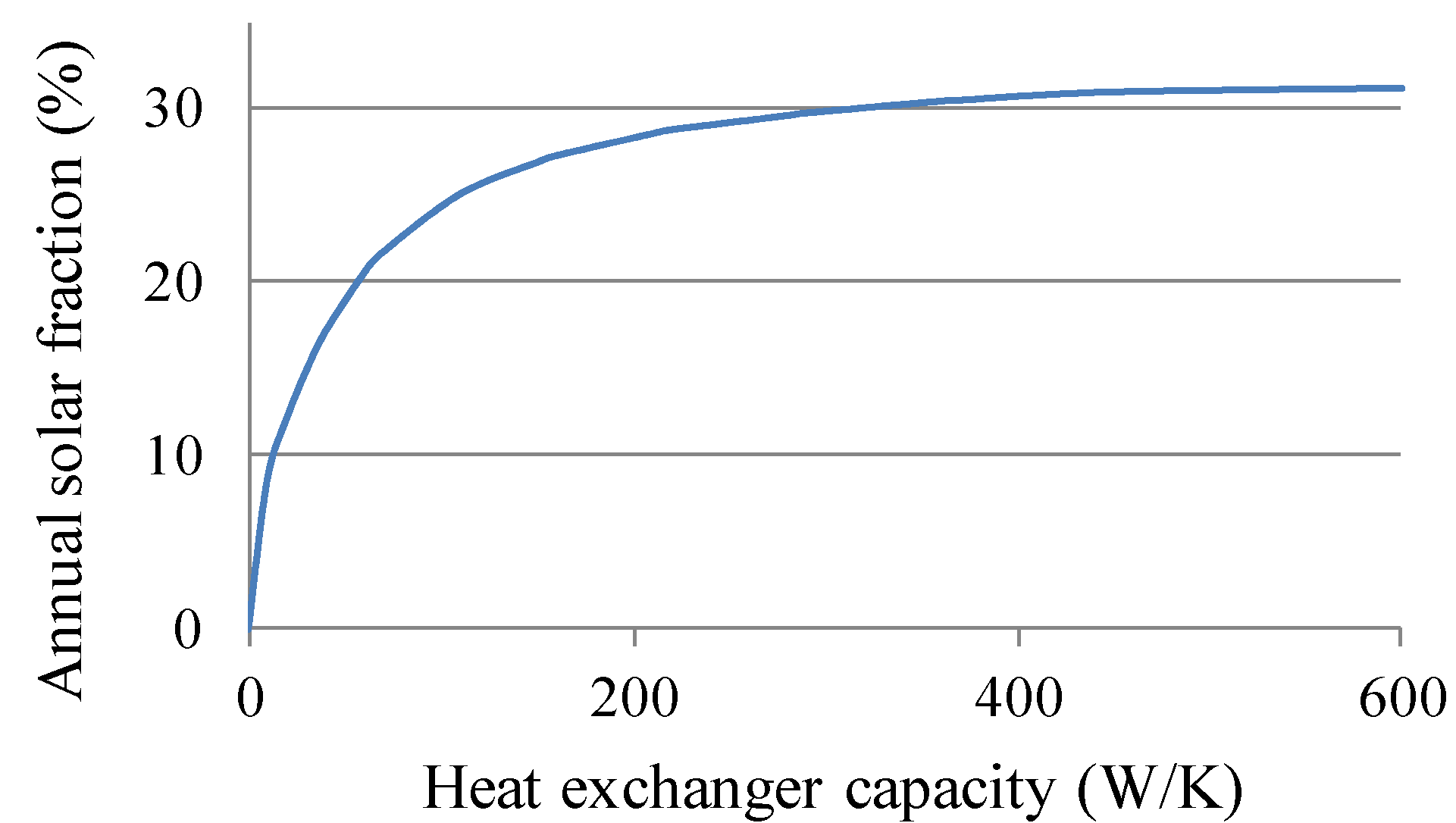

- External heat exchanger—type 5b, counter flow (Figure 4, Figure 5, Figure 6 and Figure 7). A sensitivity analysis was performed to investigate the influence of the heat exchanger capacity on the annual solar fraction in the interval 0–600 W/K. Since the effect of glycol percentage in the anti-freeze solution of the collector circuit was previously shown to have small impact on the annual solar fraction [18], the Cp of water, 4.19 kJ/kg K, was used instead. The flow speed was set equal on both sides of the heat exchanger;

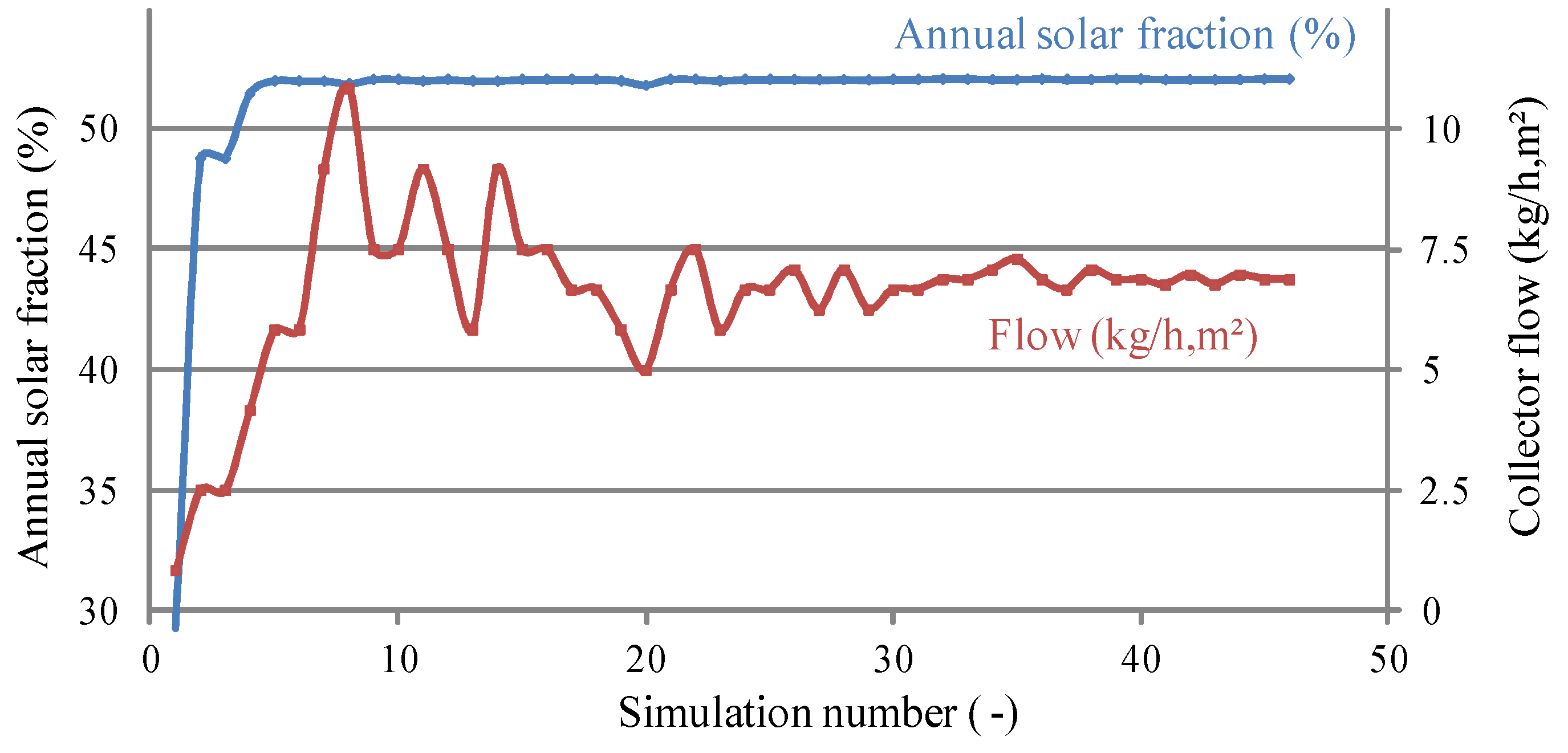

- Circulation pumps—type 3b, single speed. In all the systems the flow was optimized in order to maximise the annual solar fraction;

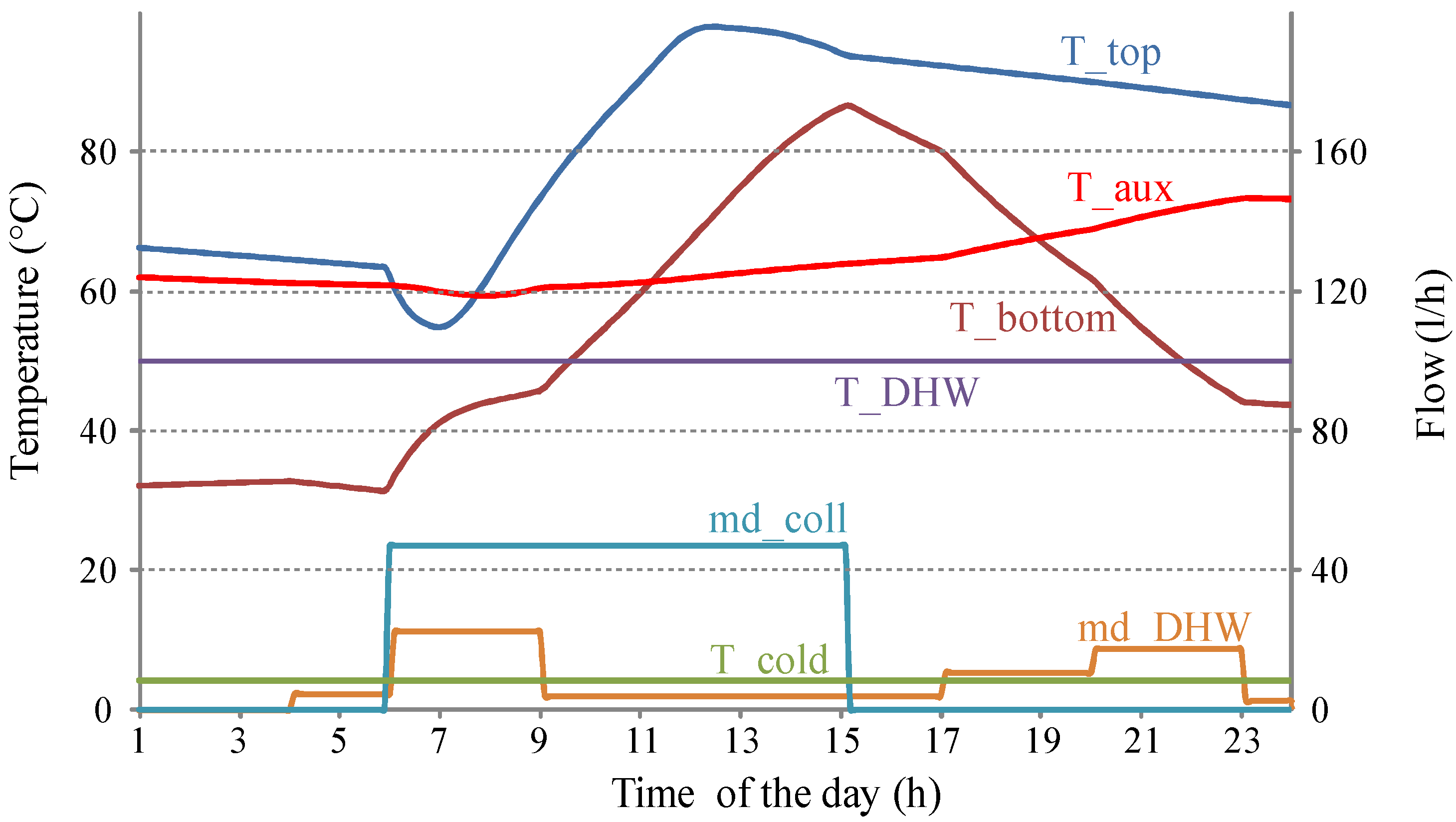

- Controller—type 2b, ON/OFF differential controller. The controller turns ON both the pumps when the difference between the outlet collector temperatures, Tout, and the bottom tank temperature, Tbottom, is higher than 10 °C. The charging process is ceased when this difference is lower than 3 °C. The charging is also stopped if the temperature at the top of the tank, Ttop, reaches 100 °C.

- Radiation processor—type 109-TMY2 used to compute the radiation and weather data for Lund, Sweden (latitude 55°44'N, longitude 13°12'E);

- Domestic hot water load profile—type 14 used to generate the daily load profile (Figure 1);

- Energy balance check—type 28 with energy balance check based on Buckles and Klein [17] for every simulation time-step, t, of six min.

| Parameter | Value |

|---|---|

| Ac | 0–12 m2 |

| F’(τα)n | 0.8 (−) |

| F’U0 | −3.6 W/m2 K |

| F’U1 | −0.014 W/m2 K2 |

| b0 | 0.2 (−) |

| β | 40 ° |

| 0–11 kg/h m2 | |

| Ppump | 60 W |

| Upipe | 0.8 W/m2 K |

| lout | 8 m |

| lin | 8 m |

| HXcapacity | 0–600 W/K |

| Tset | 60–90 °C |

| Vaux | 55–75 L |

| Utop | 1 W/m2 K |

| Uside | 1 W/m2 K |

| Ubottom | 2.5 W/m2 K |

2.4.1. Solar Collectors and Flow Control

2.4.2. Standard System

2.4.3. Retrofitted System 1

2.4.4. Retrofitted System 2

2.4.5. Retrofitted System 3

2.4.6. Retrofitted System 4

3. Results and Discussion

3.1. Standard System

3.1.1. Collector Area

3.1.2. Mass Flow Rate

3.2. Retrofitted System 1

3.2.1. Heat Exchanger Capacity

3.3. Retrofitted System 2

3.4. Retrofitted System 3

| Vaux (L) | Qaux-nonsolar (kWh/y) | Qaux-solar (kWh/y) | Qpumps(kWh/y) | Qlosses-retrofit (kWh/y) | Qlosses-aux (kWh/y) | Annual Solar Fraction (%) |

|---|---|---|---|---|---|---|

| 55 | 2037 | 877 | 131 | 447 | 148 | 50.5 |

| 65 | 2053 | 885 | 131 | 445 | 163 | 50.5 |

| 75 | 2070 | 901 | 131 | 446 | 179 | 50.1 |

| Tset (°C) | Qaux-nonsolar (kWh/y) | Qaux-solar (kWh/y) | Qpumps (kWh/y) | Qlosses-retrofit (kWh/y) | Qlosses-aux (kWh/y) | Annual Solar Fraction (%) |

|---|---|---|---|---|---|---|

| 60 | 2037 | 877 | 131 | 447 | 148 | 50.5 |

| 70 | 2088 | 1007 | 127 | 477 | 176 | 45.7 |

| 80 | 2138 | 1148 | 122 | 508 | 208 | 40.6 |

| 90 | 2188 | 1296 | 118 | 538 | 244 | 35.4 |

3.5. Retrofitted System 4

| Tset (°C) | Qaux-nonsolar (kWh/y) | Qaux-solar (kWh/y) | Qpumps (kWh/y) | Qlosses-retrofit (kWh/y) | Qlosses-aux (kWh/y) | Annual Solar Fraction (%) |

|---|---|---|---|---|---|---|

| 60 | 2042 | 930 | 129 | 461 | 135 | 48.2 |

| 70 | 2081 | 992 | 128 | 470 | 171 | 46.2 |

| 80 | 2120 | 1030 | 128 | 470 | 208 | 45.4 |

| 90 | 2161 | 1068 | 128 | 470 | 244 | 44.6 |

3.6. Standard and Retrofitted Systems

| System name | Qaux-nonsolar (kWh/y) | Qaux-solar (kWh/y) | Qpumps (kWh/y) | Qlosses-retrofit/Qlosses-stnd (kWh/y) | Qlosses-aux (kWh/y) | Annual Solar Fraction (%) |

|---|---|---|---|---|---|---|

| Standard system (a) | 2397 | 1238 | 92 | 648 | (-) | 44.5 |

| Standard system (b) | 2397 | 1090 | 60 | 779 | (-) | 52.0 |

| Retrofitted system 1 (b) | 3105 | 2134 | 75 | 973 | (-) | 28.9 |

| Retrofitted system 2 (a) | 3507 | 2002 | 286 | 886 | (-) | 34.8 |

| Retrofitted system 2 (b) | 3507 | 1945 | 243 | 904 | (-) | 37.6 |

| Retrofitted system 3 (a) | 2037 | 1074 | 187 | 369 | 145 | 38.1 |

| Retrofitted system 3 (b) | 2037 | 877 | 131 | 447 | 148 | 50.5 |

| Retrofitted system 4 (a) | 2042 | 1108 | 181 | 392 | 135 | 36.9 |

| Retrofitted system 4 (b) | 2042 | 930 | 129 | 461 | 135 | 48.2 |

| Retrofitted system 4 (c) | 2042 | 914 | 129 | 461 | 123 | 49.0 |

4. Conclusions

Acknowledgments

Nomenclature

| Tset | Temperature setting of the auxiliary heater (°C) |

| Tout | Collector outlet temperature (°C) |

| Ttop | Solar hot water temperature in the upper part of the retrofitted tank (°C) |

| Vaux | Volume of the auxiliary heater storage (L) |

| β | Collector slope from horizontal (°) |

| F’(τα)n | Zero loss efficiency of the collector (-) |

| F’U0 | Heat loss factor (W/m2 K) |

| F’U1 | Temperature dependence of the heat loss factor (W/m2 K2) |

| F’U | Total heat loss factor (W/m2 K) |

| kb(θ) | Beam incidence angle modifier as a function of θ(-) |

| b0 | Calibration factor for kb(θ) |

| θ | Angle of incidence on the collector normal (°) |

| t | Simulation time-step (h) |

| Utop | Average heat loss factor for the top of the storage (W/m2 °C) |

| Uside | Average heat loss factor for the edges of the storage (W/m2 °C) |

| Ubottom | Average heat loss factor for the bottom of the storage (W/m2 °C) |

| Upipe | Average heat loss factor for the piping (W/m2 °C) |

| lout | Total length of the pipes exposed to outdoor temperature (m) |

| lin | Total length of the pipes exposed to indoor temperature of 20 °C (m) |

| Cp | Specific heat of water (J/kg K) |

| HXcapacity | Capacity of the heat exchanger (W/K) |

| Ppump | Maximum pump power (W) |

Mass flow rate (kg/h) | |

| Ac | Collector area (m2) |

| Qaux-nonsolar | Required auxiliary energy to meet the load without solar collectors (kWh/y) |

| Qaux-solar | Required auxiliary energy to meet the load with solar collectors (kWh/y) |

| Qpumps | Required energy to run all the pumps in the system (kWh/y) |

| Qlosses-retrofit | Thermal losses from the retrofitted storage (kWh/y) |

| Qlosses-aux | Thermal losses from the auxiliary storage (kWh/y) |

| Qlosses-stnd | Thermal losses from the standard solar storage (kWh/y) |

| T_top | Temperature at the top of the retrofitted storage (°C) |

| T_bottom | Temperature at the bottom of the retrofitted storage (°C) |

| T_aux | Temperature at the new auxiliary heater storage (°C) |

| T_DHW | Temperature of the domestic hot water provided to the user (°C) |

| T_cold | Temperature of the cold water from the main (°C) |

| md_coll | Mass flow rate at the solar collector circuit (L/h) |

| md_DHW | Mass flow rate of the domestic hot water provided to the user (L/h) |

References

- Hang, Y.; Qu, M.; Zhao, F. Economic and environmental life cycle analysis of solar hot water systems in the United States. Energy Build. 2012, 45, 181–188. [Google Scholar] [CrossRef]

- Dayan, M. High Performance in Low Flow Solar Domestic Hot Water Systems. Master’s Thesis, University of Winsconsin, Madison, MI, USA, 1997. [Google Scholar]

- Tsilingiris, P.T. Design and performance of large low-cost solar water heating systems. Renew. Energy 1996, 9, 617–621. [Google Scholar] [CrossRef]

- Eicker, U.; Pietruschka, D. Design and performance of solar powered absorption cooling systems in office buildings. Energy Build. 2009, 41, 81–91. [Google Scholar] [CrossRef]

- Swedish Energy Agency. Energy Statistics for Single-Family Houses; Swedish Energy Agency: Stockholm, Sweden, 2010.

- Cruickshank, C.A.; Harrison, S.J. Analysis of a Modular Thermal Storage for Solar Heating systems. In Proceedings of the Joint Conference of the Canadian Solar Buildings Research Network and Solar Energy Society of Canada Inc. (SESCI), Montreal, Canada, 2004.

- Cruickshank, C.A.; Harrison, S.J. Experimental Characterization of a Natural Convection Heat Exchanger for Solar Domestic Hot Water Systems. ASME Conf. Proc. 2006, 425–431. [Google Scholar]

- Cruickshank, C.A.; Harrison, S.J. Thermal response of a series- and parallel-connected solar energy storage to multi-day charge sequences. Sol. Energy 2011, 85, 180–187. [Google Scholar] [CrossRef]

- Qin, L. Analysys, modeling and optimum design of solar domestic hot water systems. Ph.D. Thesis, Danish Technical University, Copenhagen, Danmark, 1998. [Google Scholar]

- Fraser, K.F.; Hollands, K.G.T.; Brunger, A.P. An empirical model for natural convection heat exchangers in SDHW systems. Sol. Energy 1995, 55, 75–84. [Google Scholar] [CrossRef]

- Morrison, G.L.; Tran, H.N. Simulation of the long term performance of thermosyphon solar water heaters. Sol. Energy 1984, 33, 515–526. [Google Scholar] [CrossRef]

- Ogueke, N.V.; Anyanwu, E.E.; Ekechukwu, O.V. A review of solar water heating systems. J. Renew. Sustain. Energy 2009, 1, 106–121. [Google Scholar] [CrossRef]

- Abdul-Jabbar, N.K. Forced versus natural circulation solar water heaters: A comparative performance study. Renew. Energy 1998, 14, 77–82. [Google Scholar] [CrossRef]

- Davidson, J.; Liu, W. Comparison of natural convection heat exchangers for solar water heating systems; University of Minesota: Minneapolis, MN, USA, 1998. [Google Scholar]

- Wongsuwan, W.; Kumar, S. Forced circulation solar water heater performance prediction by TRNSYS and ANN. Int. J. Sustain. Energy 2005, 24, 69–86. [Google Scholar] [CrossRef]

- Klein, S.A. TRNSYS—Official Website. Available online: http://sel.me.wisc.edu/trnsys (accessed on 1 July 2010).

- Buckles, W.E.; Klein, S.A. Analysis of solar domestic hot water heaters. Sol. Energy 1980, 25, 417–424. [Google Scholar] [CrossRef]

- Hobbi, A.; Siddiqui, K. Optimal design of a forced circulation solar water heating system for a residential unit in cold climate using TRNSYS. Sol. Energy 2009, 83, 700–714. [Google Scholar] [CrossRef]

- Duffie, J.A.; Beckman, W.A. Solar Engineering of the Thermal Processes, 3rd ed.; John Wiley & Sons Inc.: New York, NY, USA, 2006. [Google Scholar]

- Fanney, A.H.; Klein, S.A. Thermal performance comparisons for solar hot water systems subjected to various collector and heat exchanger flow rates. Sol. Energy 1988, 40, 1–11. [Google Scholar] [CrossRef]

- Michaelides, I.M.; Wilson, D.R. Simulation studies of the position of the auxiliary heater in thermosyphon solar water heating systems. Renew. Energy 1997, 10, 35–42. [Google Scholar] [CrossRef]

- Mills, D.; Morrison, G.L. Optimisation of minimum backup solar water heating system. Sol. Energy 2003, 74, 505–511. [Google Scholar] [CrossRef]

- Furbo, S.; Vejen, N.K.; Shah, L.J. Thermal Performance of a Large Low Flow Solar Heating System With a Highly Thermally Stratified Tank. J. Sol. Energy Eng. 2005, 127, 15–20. [Google Scholar] [CrossRef]

- Bernardo, L.R.; Davidsson, H.; Karlsson, B. Performance Evaluation of a High Solar Fraction CPC-Collector System. Jpn. Soc. Mech. Eng. J. Environ. Eng. 2011, 6, 680–692. [Google Scholar]

- Sophie, T. Advanced and Sustainable Housing Rennovation Handbook, a guide for designers and planners. Available online: http://www.iea-shc.org/publications/task.aspx?Task=37 (accessed on 1 November 2010).

- Home page of Conergy Australia. Available online: http://www.conergy.com.au (accessed on 1 February 2009).

- Thermo Dynamics Ltd. Solar Water Heating, Solar Pumps. Available online: http://www.thermo-dynamics.com (accessed on 1 May 2009).

- Enerworks, Solar Thermal Solutions. Available online: http://enerworks.com (accessed on 1 July 2009).

- Widén, J.; Lundh, M.; Vassileva, I.; Dahlquist, E.; Ellegård, K.; Wäckelgård, E. Constructing load profiles for household electricity and hot water from time-use data—Modelling approach and validation. Energy Build. 2009, 41, 753–768. [Google Scholar] [CrossRef]

- Swedish Energy Agency. Measurments of Cold and Hot Water Usage in 44 Single-Family Houses in Sweden; Swedish Energy Agency: Stockholm, Sweden, 2009.

- Swedish Energy Agency. Guidelines for Low Energy Houses; Report Number EBD-R--09/26; Lund University of Technology: Lund, Sweden, 2009.

- Swedish Statistics. Housing and Housing Expenses; Swedish Statistics: Stockholm, Sweden, 2006. [Google Scholar]

- Swedish Energy Agency. Measurements of Cold and Hot Water Usage in 10 Single-Family Houses; Swedish Energy Agency: Stockholm, Sweden, 2008.

- Werner, W. IEA-SHC, Task 26, Publications & Outcomes. In Proceedings of the Industry Workshop, Solar Combisystems, London, UK, 2011; Available online: http://www.iea-shc.org/publications/task.aspx?Task=26 (accessed on 1 February 2012).

- Kim, B.R.; Anderson, J.E.; Mueller, S.A.; Gaines, W.A.; Kendall, A.M. Literature review—Efficacy of various disinfectants against Legionella in water systems. Water Res. 2002, 36, 4433–4444. [Google Scholar] [CrossRef] [PubMed]

- WHO. Legionella and the prevention of legionellosis. Available online: http://www.who.int/water_sanitation_health/emerging/legionella/en/index.html (accessed on 1 January 2012).

- Warmedan, J.; Caris, R. Workshop Legionella. In Proceedings of International Energy Agency, Solar and Cooling Program, Delft, The Netherlands, 4–5 October 2001; Available online: http://www.iea-shc.org/publications/category.aspx?CategoryID=57 (accessed on 1 February 2012).

- Darelid, J.; Löfgren, S.; Malmvall, B.E. Control of nosocomial Legionnaires’ disease by keeping the circulating hot water temperature above 55 °C: Experience from a 10-year surveillance programme in a district general hospital. J. Hosp. Infect. 2002, 50, 213–219. [Google Scholar] [CrossRef] [PubMed]

- Marchesi, I.; Marchegiano, P.; Bargellini, A.; Cencetti, S.; Frezza, G.; Miselli, M.; Borella, P. Effectiveness of different methods to control legionella in the water supply: Ten-year experience in an Italian university hospital. J. Hosp. Infect. 2011, 77, 47–51. [Google Scholar] [CrossRef] [PubMed]

- Cabeza, L. Legionella in Combisystems Tanks. Available online: http://www.iea-shc.org/publications/task.aspx?Task=32 (accessed on 1 February 2012).

- Health, Safety Executive, U.K. The Control of Legionella Bacteria in Water Systems, Approved Code of Practice and guidance. Available online: http://www.hse.gov.uk/pubns/books/l8.htm (accessed on 1 March 2012).

- Swedish Building Regulations, Statute-book of the Swedish Building Regulations. Available online: http://www.boverket.se/Lag-ratt/Boverkets-forfattningssamling/BFS-efter-forkortning/BBR/ (accessed on 1 December 2011).

- Safe water installation. Swedish branch rules. Available online: http://www.sakervatten.se/Branschregler (accessed on 1 March 2012).

- TESS Libraries. Thermal Energy System Specialists TESS Component Library Package. TRNSYS: Transient System Simulation Tool. Available online: http://www.trnsys.com/tess-libraries (accessed on 1 May 2011).

- Cruickshank, C.A.; Harrison, S.J. Heat loss characteristics for a typical solar domestic hot water storage. Energy Build. 2010, 42, 1703–1710. [Google Scholar] [CrossRef]

- Swedish Energy Agency. Hot Water Circulation. Available online: http://energimyndigheten.se/sv/Siteseeker/?q=legionella+sjukdom&defst=True&uaid=5E2A3C27CEB0B04C50EECEBB3DDE489B:3139322E3136382E31312E35:5246323862601135320 (accessed on 1 December 2011).

- Bernardo, L.R.; Perers, B.; Håkansson, H.; Karlsson, B. Performance evaluation of low concentrating photovoltaic/thermal systems: A case study from Sweden. Sol. Energy 2011, 85, 1499–1510. [Google Scholar] [CrossRef]

- Lawrence Berkeley National Laboratory in University of California GenOpt—Generic Optimization Program. Available online: http://gundog.lbl.gov/GO (accessed on 1 June 2011).

- Wetter, M. Generic Optimization Program Manual 3-0-2; Simulation Research Group, Lawrence Berkeley National Laboratory: Berkeley, UC, USA, 2009; Available online: http://engine4.org/g/genopt-generic-optimization-program-user-manual-w316-pdf.pdf (accessed on 1 April 2011).

- Hollands, K.G.T.; Lightstone, M.F. A review of low-flow, stratified-tank solar water heating systems. Sol. Energy 1989, 43, 97–105. [Google Scholar] [CrossRef]

- International Energy Agency. Publications & Outcomes. Available online: http://www.iea-shc.org/publications/task.aspx?Task=14 (accessed on 1 January 2012).

- Wuestling, M.D.; Klein, S.A.; Duffie, J.A. Promising control alternatives for solar water heating systems. J. Sol. Energy Eng. 1985, 107, 215–221. [Google Scholar] [CrossRef]

- Swedish Technical Research Centre. Annual solar fraction for solar water heating systems. Available online: http://www.sp.se/sv/index/services/solar/water/list/Sidor/default.aspx (accessed on 1 March 2012).

© 2012 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Bernardo, L.R.; Davidsson, H.; Karlsson, B. Retrofitting Domestic Hot Water Heaters for Solar Water Heating Systems in Single-Family Houses in a Cold Climate: A Theoretical Analysis. Energies 2012, 5, 4110-4131. https://doi.org/10.3390/en5104110

Bernardo LR, Davidsson H, Karlsson B. Retrofitting Domestic Hot Water Heaters for Solar Water Heating Systems in Single-Family Houses in a Cold Climate: A Theoretical Analysis. Energies. 2012; 5(10):4110-4131. https://doi.org/10.3390/en5104110

Chicago/Turabian StyleBernardo, Luis R., Henrik Davidsson, and Björn Karlsson. 2012. "Retrofitting Domestic Hot Water Heaters for Solar Water Heating Systems in Single-Family Houses in a Cold Climate: A Theoretical Analysis" Energies 5, no. 10: 4110-4131. https://doi.org/10.3390/en5104110