Enhanced Gas Recovery for Tight Gas Reservoirs with Multiple-Fractured Horizontal Wells in the Late Stages of Exploitation: A Case Study in Changling Gas Field

Abstract

:1. Introduction

2. Detailed Description of Remaining Gas

2.1. Background of Gas Reservoir

2.2. Geological Model

2.3. Numerical Simulation Model

2.4. Splitting of Gas Production Rate

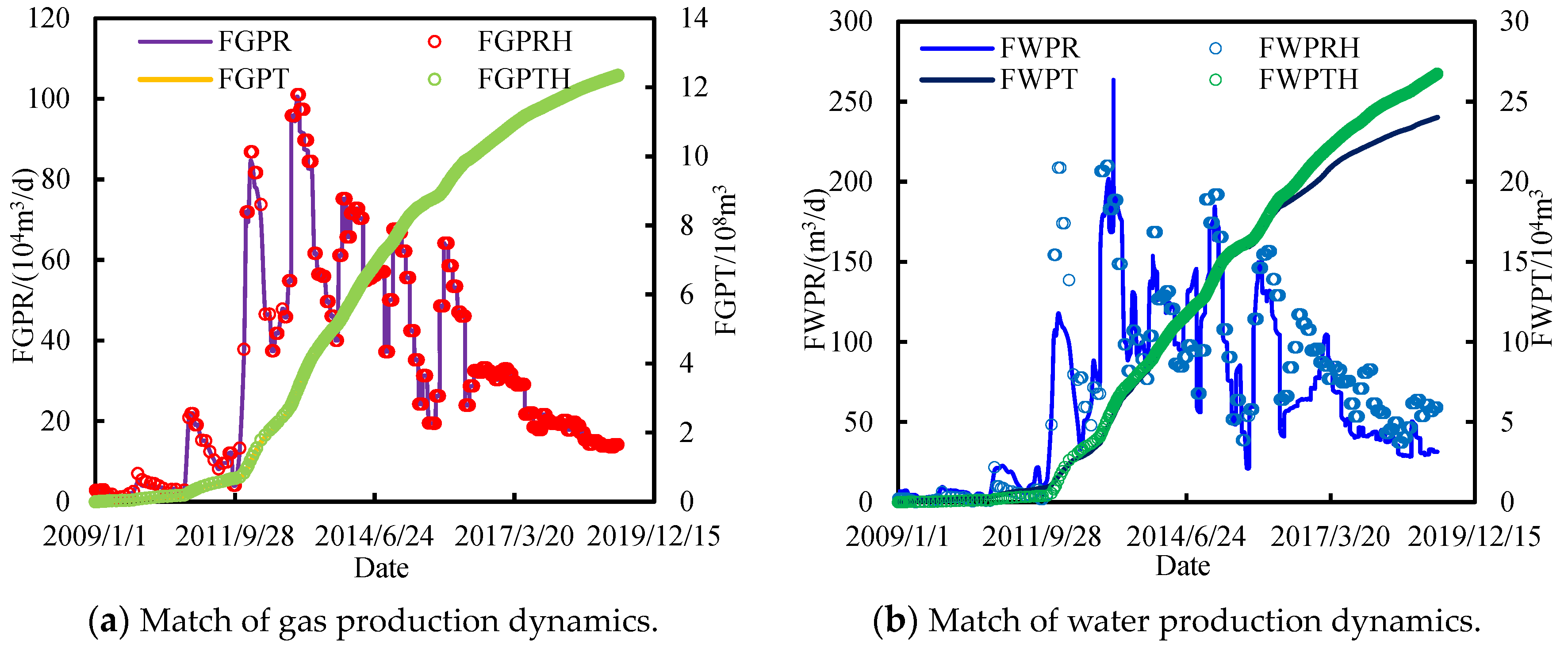

2.5. History Match

- (1)

- Match of gas reserve

- (2)

- Match of gas reservoir performance

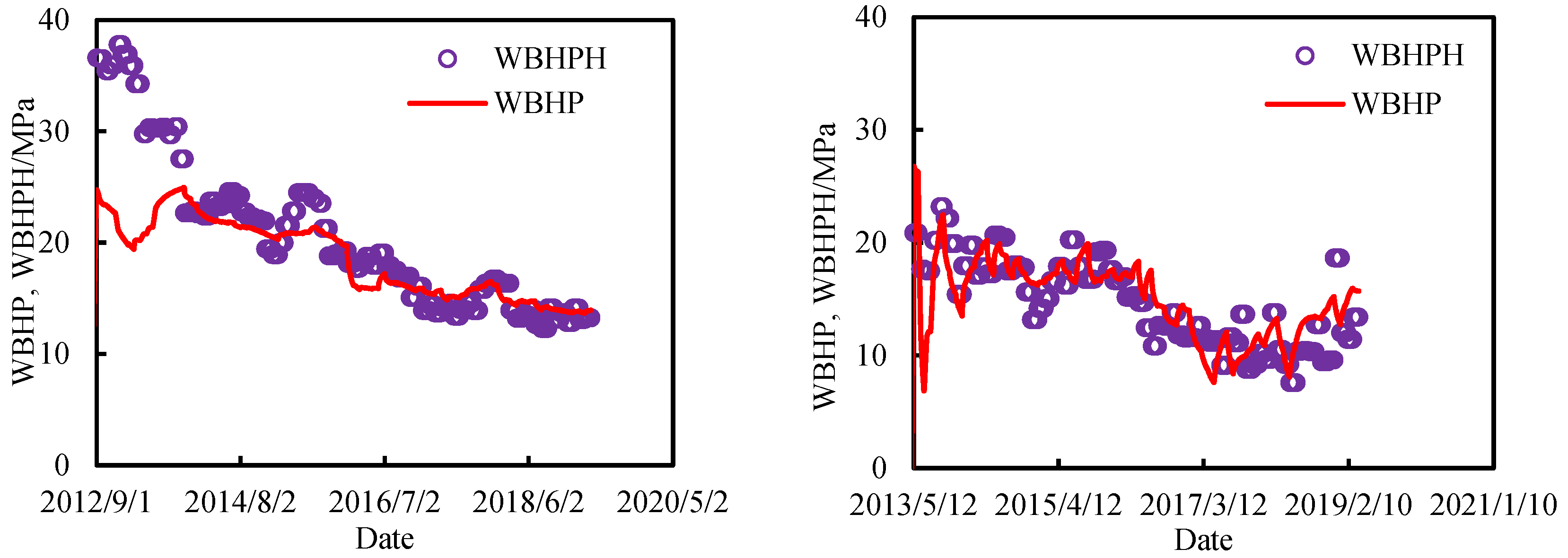

- (3)

- Match of well production performance

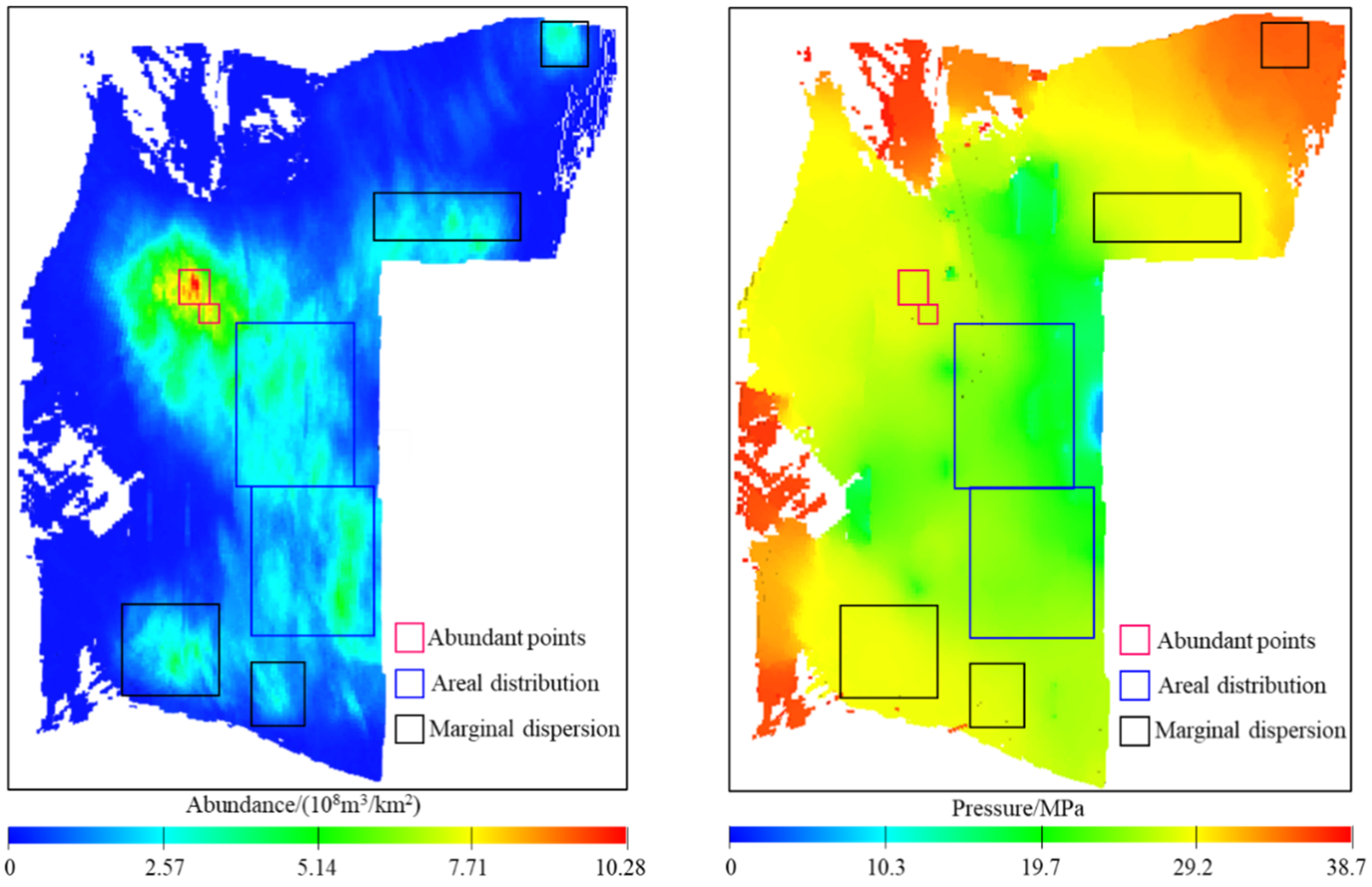

2.6. Division of Remaining Gas Types

- (1)

- The marginal dispersion type. This type of remaining gas is mainly located in the marginal area, and the distribution of effective sands is dispersed. Additionally, the net pay zone for these sands is relatively low, the physical properties and the gas abundance is usually low, that is, lower than 2.57 × 108 m3/km2. The proportion for this type of remaining gas is about 15.5%. Due to its poor properties, the wells in these locations are rare, and the controlled range by wells is small, which causes the pressure to be high and larger than 29 MPa. The productivity of MFHWs in these places is low, and due to the immature technology, there is no economic benefit. In the vertical direction, this type of remaining gas is primarily located in the sands of D1, D2 and the layer of D3-1, D3-2. For this type of remaining gas, it should not be seen as the primary objective for EGR, and it may be reasonable to adopt measures of patching holes and sidetracking for improving the gas production rate.

- (2)

- The abundant points type. In the reservoir, this type is distributed as the local points, and the scale is small, which makes it difficult to form continuous distribution. Nevertheless, the thickness, formation properties and gas abundance are relatively large. The gas abundance for this type of remaining gas is larger than 7.71~10.28 × 108 m3/km2, and the formation pressure is greater than 29 Mpa. The proportion for this type of remaining gas is about 4.2%. Due to the initial immature recognition for the effective formation, there are no wells that dominate this area. This type of remaining gas is mainly distributed in unexploited sand and layers, which are D2, D3-1, D3-2 and D5-2. It is necessary to evaluate the distribution range, and the infilling vertical/horizontal wells or sidetracking of old wells can be used to EGR for the type of remaining gas.

- (3)

- The areal distribution type. This type of remaining gas is mainly distributed in the main body of the gas reservoir, which is continuous in the horizontal direction. The thickness and physical properties are stable in the plane, and the gas abundance of the reservoir is 2.57~5.14 × 108 m3/km2. Due to the highly controlled extent of MFHWs and after a long period of exploitation, the formation pressure is lower than the other types of remaining gas, and is about 19.7 Mpa. The proportion is 80.3%, which is the largest of the three types of remaining gas. Vertically, it locates primarily in the sands of D4, D6 and the layers of D3-3, D3-4 and D5-2. This type of remaining gas is the main objective of EGR, and with consideration of the existing well patterns, it is suitable for optimizing the infilling well type to improve the gas production and gas recovery factor.

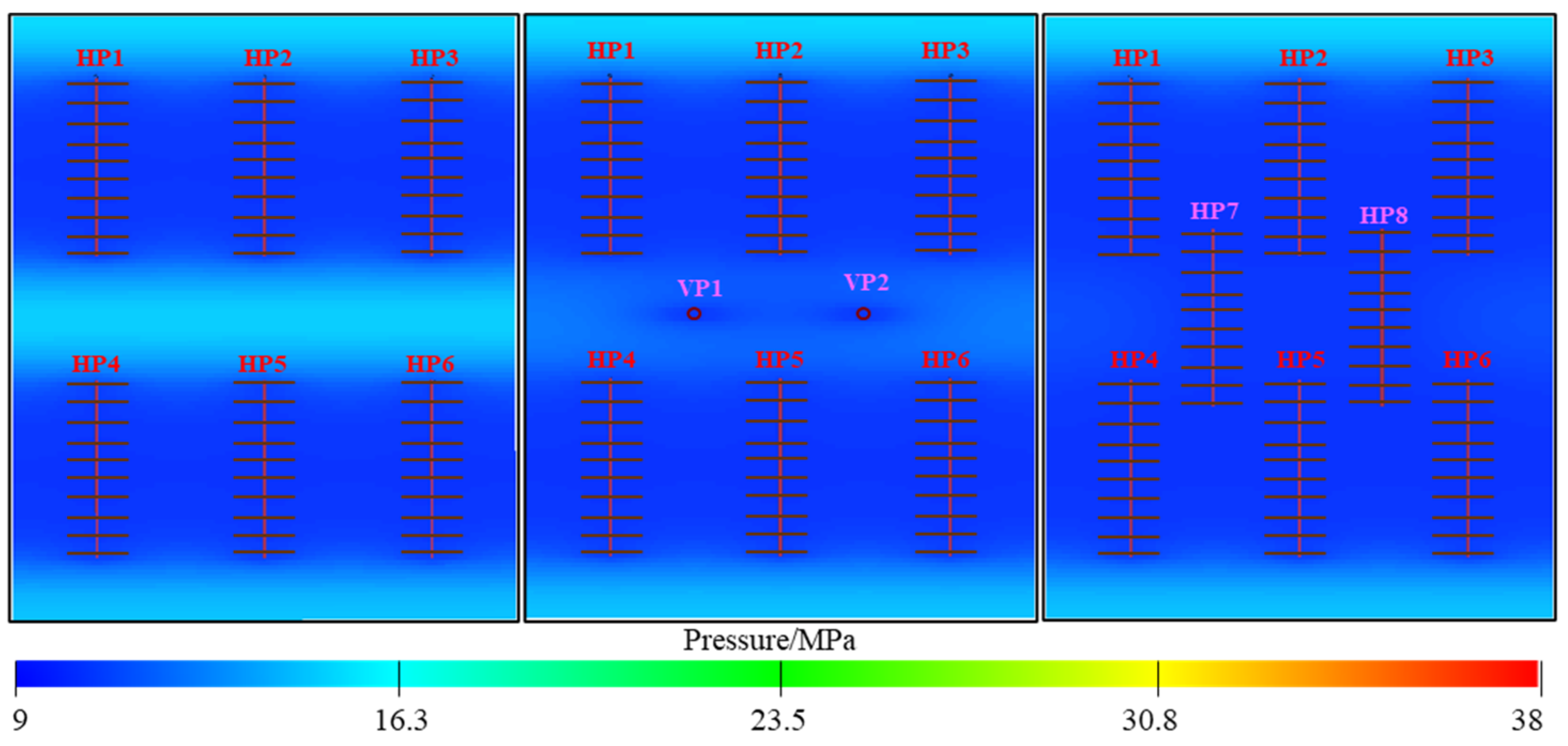

3. Optimization of Infilling Well Types

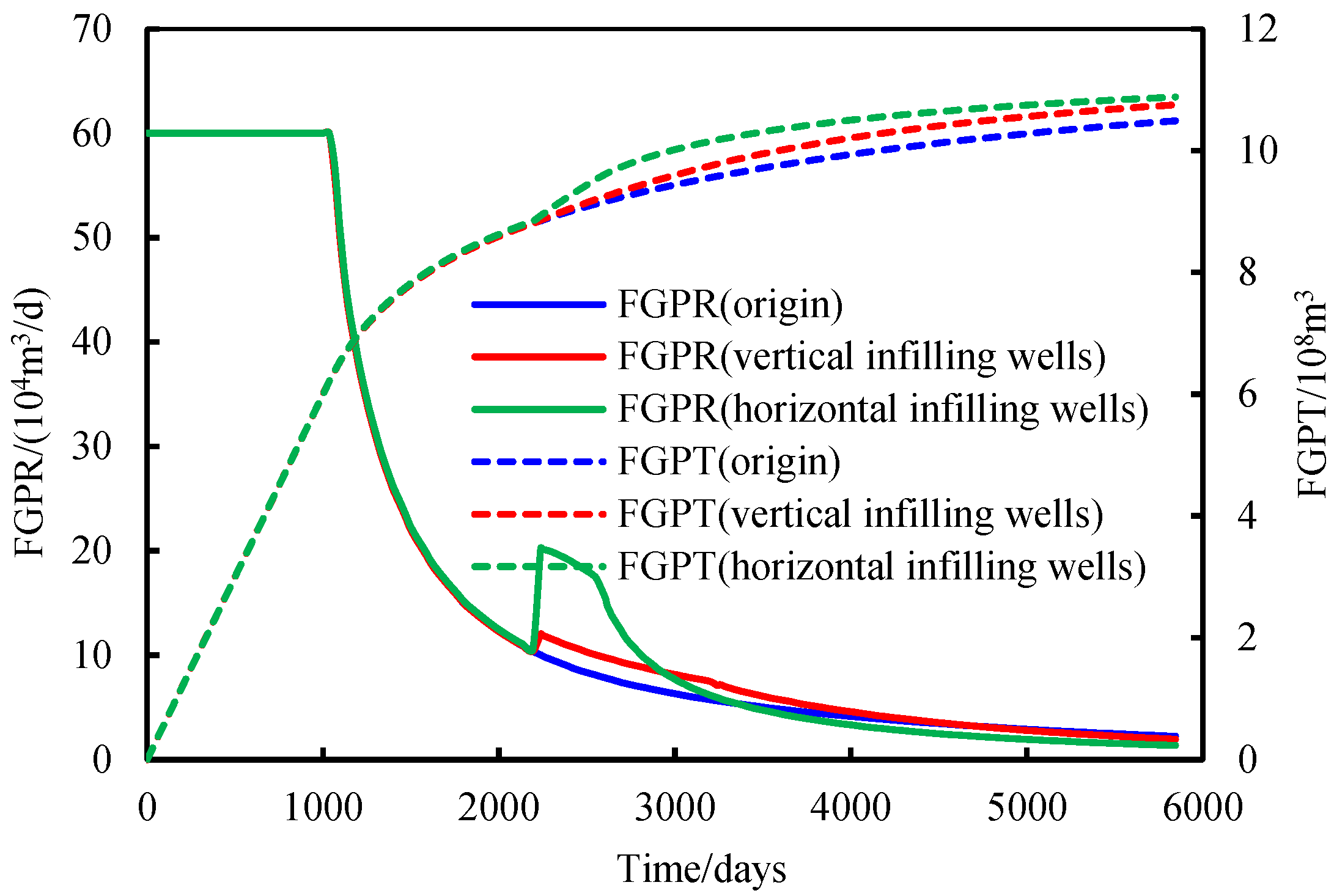

3.1. Parallel Pattern with MFHWs

3.2. Zipper Pattern with MFHWs

4. Design and Optimization of Adjustment Schemes

4.1. Design of Adjustment Schemes

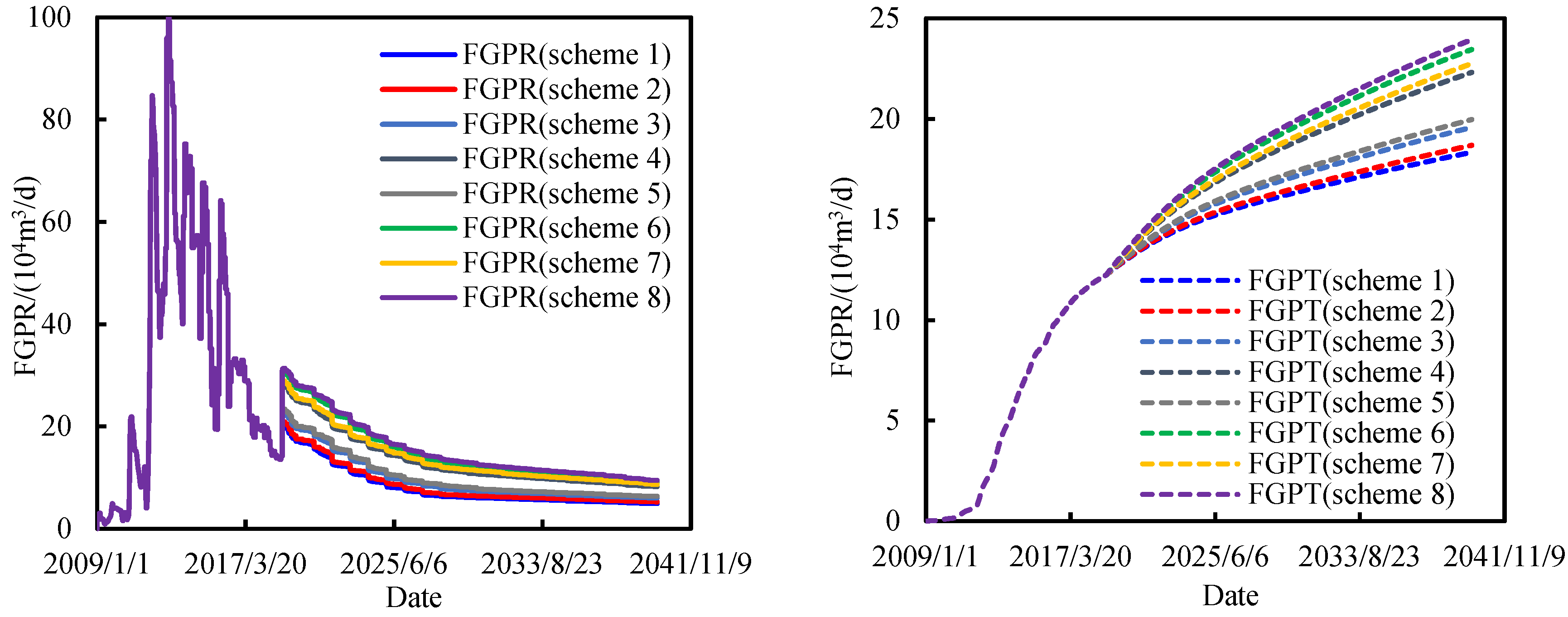

4.2. Comparison and Optimization for Adjustment Schemes

- (1)

- Introduction of economical indices

- (2)

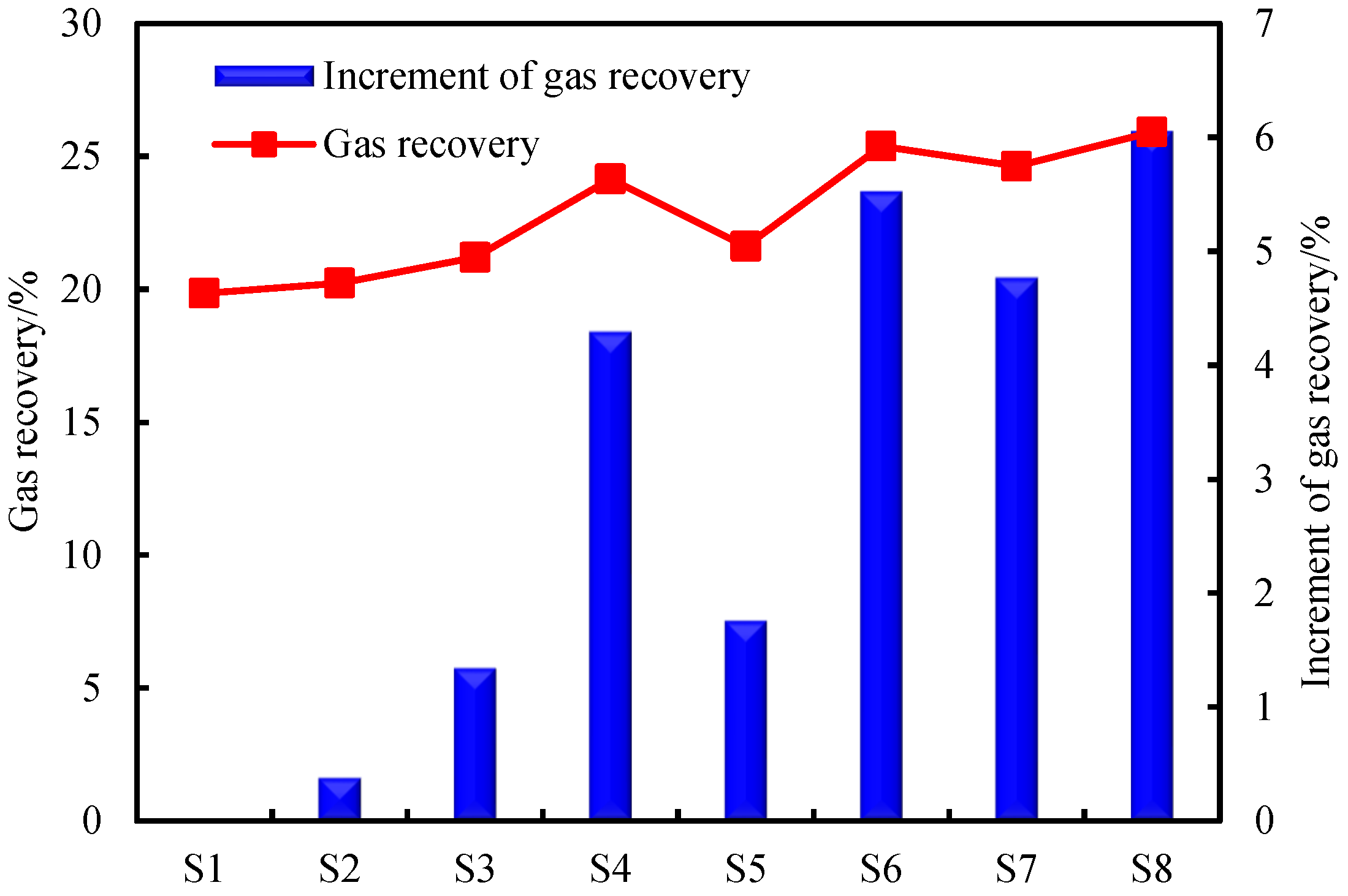

- Comparison and optimization of adjustment schemes

5. Conclusions

- (1)

- This paper presented a comprehensive workflow for the adjustment of development schemes, which includes the establishment of geological and numerical simulation models, the match of reservoir and well production performance, the analysis for the remaining gas, and the design and optimization of adjustment schemes.

- (2)

- Based on the numerical simulation technology for gas reservoirs, according to the distribution, scale and origin for the remaining gas reserve, the remaining gas can be classified into three types, which are marginal dispersion, abundant points and areal distribution, and the ratios for these three types are 80.3%, 4.2% and 15.5%, respectively. The type of areal distribution is the largest, and is the main objective for EGR.

- (3)

- The remaining gas and production performance for parallel and zipper well patterns in columns are identical, which represents high potential for infilling. The vertical well is the optimal infilling well type. However, the FGPT for these two well patterns is lower than the zipper well patterns in rows, while the infilling potential for this well pattern is lower.

- (4)

- Through the comprehensive consideration of gas production and economic benefits, scheme 6 with patching holes, sidetracking and infilling is the optimal adjustment scheme for the Denglouku gas reservoir. At the end of the production period, the gas recovery factor is 25.4%, which is larger than 5.5% compared with the basic scheme. The IPR for the optimal scheme is 15.6%, and the pay-back period is 6.1 years. With the increase in IPR, the advantages for the scheme become greater.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhu, H.Y.; Xu, X.; Gao, Y.; Hu, Y.; An, L.Z.; Guo, C.M. Occurrence characteristics of tight sandstone pore water and its influence on gas seepage: A case study from the Denglouku gas reservoir in the Changling Gas Field, southern Songliao Basin. Nat. Gas Ind. 2014, 34, 54–58. [Google Scholar]

- Guo, S.C. Changling Denglouku Group Gas Reservoir Horizontal Well Overall Development Technology and the Evaluation of the Effect. Ph.D. Thesis, Northeast Petroleum University, Daqing, China, 2015. [Google Scholar]

- Jia, A.L.; Wang, G.T.; Meng, D.W.; Guo, Z.; Ji, G.; Cheng, L.H. Well pattern infilling strategy to enhance oil recovery of giant low-permeability tight gasfield a case study of Sulige gasfield, Ordos Basin. Acta Pet. Sin. 2018, 39, 802–813. [Google Scholar]

- Ji, G.; Jia, A.L.; Meng, D.W.; Guo, Z.; Wang, G.; Cheng, L.; Zhao, X. Technical strategies for effective development and gas recovery enhancement of a large tight gas field: A case study of Sulige gas field, Ordos Basin, NW China. Pet. Explor. Dev. 2019, 46, 602–612. [Google Scholar] [CrossRef]

- Guo, J.L.; Guo, Z.; Cui, Y.P.; Meng, D.W.; Wang, G.T.; Ji, G.; Cheng, L.H.; Sun, Y.Y.; Jia, C.Y. Recovery factor calculation method of giant tight sandstone gas field. Acta Pet. Sin. 2018, 39, 1389–1396. [Google Scholar]

- Guo, Z.; Jia, A.L.; Ji, G.; Ning, B.; Wang, G.T.; Meng, D.W. Reserve classification and well pattern infilling method of tight sandstone gasfield: A case study of Sulige gasfield. Acta Pet. Sin. 2017, 38, 1299–1309. [Google Scholar]

- Dong, S.; Guo, J.L.; Guo, Z.; Meng, D.W.; Ji, G.; Cheng, L.H. Evaluation of remaining reserves and strategies of enhanced oil recovery for Su 6 Block. Fault-Block Oil Gas Field 2020, 27, 74–79. [Google Scholar]

- Wu, K.L.; Zhu, Q.Y.; Chen, Z.X.; Li, J.; Feng, D.; Wang, M.Y.; Guo, S.Q.; Guo, Y.C. Microscopic gas displacement efficiency of enhanced gas recovery in carbonate gas reservoirs with edge and bottom water. Nat. Gas Ind. B 2023, 10, 372–382. [Google Scholar] [CrossRef]

- Guo, P.; Zhou, R.; Tian, Z.K.; Wang, Y.; Yang, L.H.; Zhao, J.F. Gas and water distribution characteristics of water-driven gas process in tight sandstone gas reservoirs: A microscale study by molecular simulation and experiment. Energy Rep. 2022, 8, 7025–7036. [Google Scholar] [CrossRef]

- Ma, X.H.; He, D.G.; Wei, Y.H.; Guo, J.L.; Jia, C.Y. Enhanced gas recovery: Theory, technology, and prospects. Nat. Gas Ind. B 2023, 10, 393–405. [Google Scholar] [CrossRef]

- Hasan, M.; Eliebid, M.; Mahmoud, M.; Elkatatny, S.; Shawabkeh, R.; King Fahd University of Petroleum & Minerals. Enhanced Gas Recovery (EGR) Methods and Production Enhancement Techniques for Shale & Tight Gas Reservoirs. In Proceedings of the SPE Kingdom of Saudi Arabia Annual Technical Symposium and Exhibition, Dammam, Saudi Arabia, 24–27 April 2017. [Google Scholar]

- Li, G.X.; Tian, J.; Duan, X.W.; Yang, H.J.; Tang, Y.L.; Bi, H.B.; Zhang, C.Z.; Xian, C.G.; Liu, H. Research and Practice on Enhancing Recovery of Tight Sandstone Gas Reservoirs in Kelasu Gas Field, Tarim Basin. In Proceedings of the SPE/AAPG/SEG Asia Pacific Unconventional Resources Technology Conference, Virtual, 16–18 November 2021. [Google Scholar]

- He, D.B.; Jia, A.L.; Ji, G.; Wei, Y.S.; Tang, H.F. Well type and pattern optimization technology for large scale tight sand gas, Sulige gas field. Pet. Explor. Dev. 2012, 39, 458–464. [Google Scholar] [CrossRef]

- Gao, S.S.; Liu, H.X.; Ye, L.Y.; Wen, Z.J.; Zhu, W.Q.; Zhang, C. A new method for well pattern density optimization and recovery factor evaluation of tight sandstone gas reservoirs. Nat. Gas Ind. 2019, 39, 58–65. [Google Scholar]

- Li, Y.G.; Xu, W.; Xiao, F.; Liu, L.L.; Liu, S.X.; Zhang, W. Development well pattern optimization based on dynamic characteristics: A case study from the Sulige tight sandstone gas field with great heterogeneity. Nat. Gas Ind. 2014, 34, 56–61. [Google Scholar]

- Zhou, Y.; King, M.J.; Du, S. A simulation-free approach for well placement in tight gas reservoirs. In Proceedings of the Intermational Peroleum Technology Conference, Beijing, China, 26–26 March 2013. [Google Scholar]

- Cheng, Y.; McVay, D.A.; Lee, J.W. Optimal infill drilling design for marginal gas reservoirs using a simulation-based inversion approach. In Proceedings of the SPE Eastern Regional Meeting, Canton, OH, USA, 11–13 October 2006. [Google Scholar]

- Luo, S.; Kelkar, M. Infill-Drilling Potential in Tight Gas Reservoirs. Soc. Pet. Eng. 2013, 135, 19–22. [Google Scholar] [CrossRef]

- Tison, J.K.; Agarwal, R.G.; Rosepiler, M.J.; Schlottman, B.W. A Method for Selecting Potential Infill Locations in the East Texas Cotton Valley Tight Gas Play. In Proceedings of the 57th Annual Fall Technical Conference and Exhibition of the Society of Petroleum Engineers of AlME, New Orleans, LA, USA, 26–29 September 1982. [Google Scholar]

- Hinn, R.L., Jr.; Glenn, J.M.; McNichol, K.C. Case history: Use of a multiwell model to optimize infill development of a tight-gas-sand reservoir. J. Pet. Technol. 1988, 40, 881–886. [Google Scholar] [CrossRef]

- Li, Q.; Li, Y.X.; Gao, S.H.; Liu, H.X.; Ye, L.Y.; Wu, H.H.; Zhu, W.Q.; An, W.G. Well network optimization and recovery evaluation of tight sandstone gas reservoirs. J. Pet. Sci. Eng. 2021, 196, 107705. [Google Scholar] [CrossRef]

- Zhang, T.L.; Wang, X.Z.; Yan, Y.K.; Qiao, X.Y.; Ma, C.; Lei, K.Y.; Tang, P.Z.; Feng, D.; Zhao, W. Efficient mobilization method of stereoscopic well patterm in low-permeability complex superimposed tight reservoir: A case study of Yan’an gasfield. Acta Pet. Sin. 2018, 39, 1279–1291. [Google Scholar]

- Lu, T.; Liu, Y.X.; Wu, L.C.; Wang, X.W. Challenges to and countermeasures for the production stabilization of tight sandstone gas reservoirs of the Sulige Gasfield, Ordos Basin. Nat. Gas Ind. 2015, 35, 43–52. [Google Scholar] [CrossRef]

- Tan, Z.Z.; Lu, T.; Liu, Y.X.; Wu, L.C.; Yang, Y. Technical ideas of recovery enhancement in the Sulige Gas field during the 13th Five-Year Plan. Nat. Gas Ind. 2016, 36, 30–40. [Google Scholar]

- Zhang, J.W.; Wang, G.Y.; He, K.; Ye, C.L. Practice and understanding of sidetracking horizontal drilling technology in old wells in Sulige Gas Field. Pet. Explor. Dev. 2019, 46, 370–377. [Google Scholar] [CrossRef]

- Guo, P.; Jing, S.S.; Peng, C.Z. Technology and countermeasures for gas recovery enhancement. Nat. Gas Ind. 2014, 34, 48–55. [Google Scholar]

- Jukić, L.; Vulin, D.; Lukić, M.; Sedlar, D.K. Enhanced gas recovery and storability in a high CO2 content gas reservoir. Int. J. Greenh. Gas Control 2022, 117, 103662. [Google Scholar] [CrossRef]

- Zhang, K.Q.; Jin, Z.J.; Li, G.S.; Liu, Q.Y.; Tian, L. Gas adsorptions of geological carbon storage with enhanced gas recovery. Sep. Purif. Technol. 2023, 311, 123260. [Google Scholar] [CrossRef]

- Omari, A.; Wang, C.; Li, Y.; Xu, X.G. The progress of enhanced gas recovery (EGR) in shale gas reservoirs: A review of theory, experiments, and simulations. J. Pet. Sci. Eng. 2022, 213, 110461. [Google Scholar] [CrossRef]

- Ding, J.C.; Yan, C.H.; He, Y.M.; Wang, C.C. Supercritical CO2 sequestration and enhanced gas recovery in tight gas reservoirs: Feasibility and factors that influence efficiency. Int. J. Greenh. Gas Control 2021, 105, 103234. [Google Scholar] [CrossRef]

- Kokal, S.; Sayegh, S. Enhanced Gas Recovery: Prospects and Technology. In Proceedings of the CIM 1993 Annual Technical Conference, Calgary, AB, Canada, 9–12 May 1993. [Google Scholar]

- Jia, Y.; Shi, Y.Q.; Yan, J. The feasibility appraisal for CO2 enhanced gas recovery of tight gas reservoir: Case analysis and economic evaluation. In Proceedings of the International Petroleum Technology Conference, Virtual, 23–25 March 2021. [Google Scholar]

- Zhang, L.H.; Xiong, Y.; Zhao, Y.L.; Tang, H.M.; Guo, J.L.; Jia, C.S.; Lei, Q.; Wang, B.H. A reservoir drying method for enhancing recovery of tight gas. Pet. Explor. Dev. 2022, 49, 144–155. [Google Scholar] [CrossRef]

- Deng, F.C.; Huang, B.; Li, X.S.; Liu, J.W.; Li, G.; Xu, Y.T.; Yin, B. Review of sand control and sand production in a gas hydrate reservoir. Energy Fuels 2022, 36, 11712–11723. [Google Scholar] [CrossRef]

- Deng, F.C.; Yin, B.; Li, X.S.; Wang, Y.; Xu, Y.T. Analysis of the scaling mechanism and characteristics of a double-defects screen based on data from Hafaya oilfield. J. Pet. Sci. Eng. 2022, 216, 110729. [Google Scholar] [CrossRef]

- Deng, F.C.; Deng, Z.Q.; He, L.; Wang, L.H.; Hu, H.T.; Xu, Y. Life prediction of slotted screen based on back-propagation neural network. Eng. Fail. Anal. 2021, 119, 104909. [Google Scholar] [CrossRef]

- Deng, F.C.; Li, X.R.; He, L.; Feng, Y.C. Experimental evaluation of metal foam for sand control. J. Pet. Sci. Eng. 2019, 176, 1152–1160. [Google Scholar] [CrossRef]

- Deng, F.C.; Yan, C.L.; Jia, S.P.; Chen, S.H.; Wang, L.H.; He, L. Influence of sand production in an unconsolidated sandstone reservoir in a deepwater gas field. J. Energy Resour. Technol. 2019, 141, 092904–092911. [Google Scholar] [CrossRef]

- Eclipse Industry-Reference Reservoir Simulator Page. Available online: https://www.software.slb.com/products/eclipse (accessed on 28 November 2023).

- Hagedorn, A.R.; Brown, K.E. Experimental study of pressure gradients occurring during continuous two-phase flow in small diameter vertical conduits. J. Pet. Technol. 1965, 17, 475–484. [Google Scholar] [CrossRef]

- Islam, J.; Rahaman, M.S.A.; Vasant, P.M.; Negash, B.M.; Hoqe, A.; Khalifa Alhitmi, H.; Watada, J. A modified niching crow search approach to well placement optimization. Energies 2021, 14, 857. [Google Scholar] [CrossRef]

- Zhou, J.; Wang, H.; Xiao, C.; Zhang, S. Hierarchical Surrogate-Assisted Evolutionary Algorithm for Integrated Multi-Objective Optimization of Well Placement and Hydraulic Fracture Parameters in Unconventional Shale Gas Reservoir. Energies 2023, 16, 303. [Google Scholar] [CrossRef]

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Formation length/m | 2025 | X grid size/m | 15 |

| Formation width/m | 3300 | Y grid size/m | 25 |

| Formation thickness/m | 21 | Z grid size/m | 3 |

| Length of horizontal wells/m | 1000 | Fracture conductivity/(mD) | 150 |

| Spacing of fractures/m | 675 | Gas production rate/(m3/d) | 100,000 |

| Row spacing/m | 650 | Minimum BHP/Mpa | 10 |

| Porosity/% | 6.55 | Fracture half-length/m | 112.5 |

| Permeability/mD | 0.151 | Formation pressure/Mpa | 38.86 |

| Depth of top face/m | 3900 | Fracturing stages | 10 |

| No | Measures | Description | Wells | FGPR/ 104 m3/d | Investment/ USD Million |

|---|---|---|---|---|---|

| 1 | Basic | No measures | 39 | 20 | 0 |

| 2 | Pressure boost | WTHP is set to be 1.5 MPa and 4.5 MPa for wells with low and high CO2 mole fraction | 39 | 20 | 4.1 |

| 3 | Patching holes, side tracking | Patching holes for 11 wells, and sidetracking for 3 wells | 39 | 20 | 2.9 |

| 4 | Infilling | Add of 8 infill wells | 47 | 28 | 20.0 |

| 5 | Patching holes, side tracking, pressure boost | Patching holes for 11 wells, and sidetracking for 3 wells, and WTHP is 1.5 MPa and 4.5 MPa for wells with low and high CO2 mole fraction | 39 | 20 | 7.0 |

| 6 | Patching holes, side tracking, infilling | Patching holes for 11 wells, and sidetracking for 3 wells, addition of 8 infill wells | 47 | 28 | 22.9 |

| 7 | Infilling, pressure boost | Addition of 8 infill wells, and WTHP is 1.5 MPa and 4.5 MPa for wells with low and high CO2 mole fraction | 47 | 20 | 24.1 |

| 8 | Patching holes, side tracking, infilling, infilling, pressure boost | Patching holes for 11 wells, and sidetracking for 3 wells, addition of 8 infill wells and WTHP is 1.5 MPa and 4.5 MPa for wells with low and high CO2 mole fraction | 47 | 28 | 27.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ning, B.; Li, J.; Zhong, T.; Guo, J.; Liu, Y.; Fu, N.; Bie, K.; Meng, F. Enhanced Gas Recovery for Tight Gas Reservoirs with Multiple-Fractured Horizontal Wells in the Late Stages of Exploitation: A Case Study in Changling Gas Field. Energies 2023, 16, 7918. https://doi.org/10.3390/en16247918

Ning B, Li J, Zhong T, Guo J, Liu Y, Fu N, Bie K, Meng F. Enhanced Gas Recovery for Tight Gas Reservoirs with Multiple-Fractured Horizontal Wells in the Late Stages of Exploitation: A Case Study in Changling Gas Field. Energies. 2023; 16(24):7918. https://doi.org/10.3390/en16247918

Chicago/Turabian StyleNing, Bo, Junjian Li, Taixian Zhong, Jianlin Guo, Yuyang Liu, Ninghai Fu, Kang Bie, and Fankun Meng. 2023. "Enhanced Gas Recovery for Tight Gas Reservoirs with Multiple-Fractured Horizontal Wells in the Late Stages of Exploitation: A Case Study in Changling Gas Field" Energies 16, no. 24: 7918. https://doi.org/10.3390/en16247918