Energy Management of Hybrid DC Microgrid with Different Levels of DC Bus Voltage for Various Load Types

Abstract

:1. Introduction

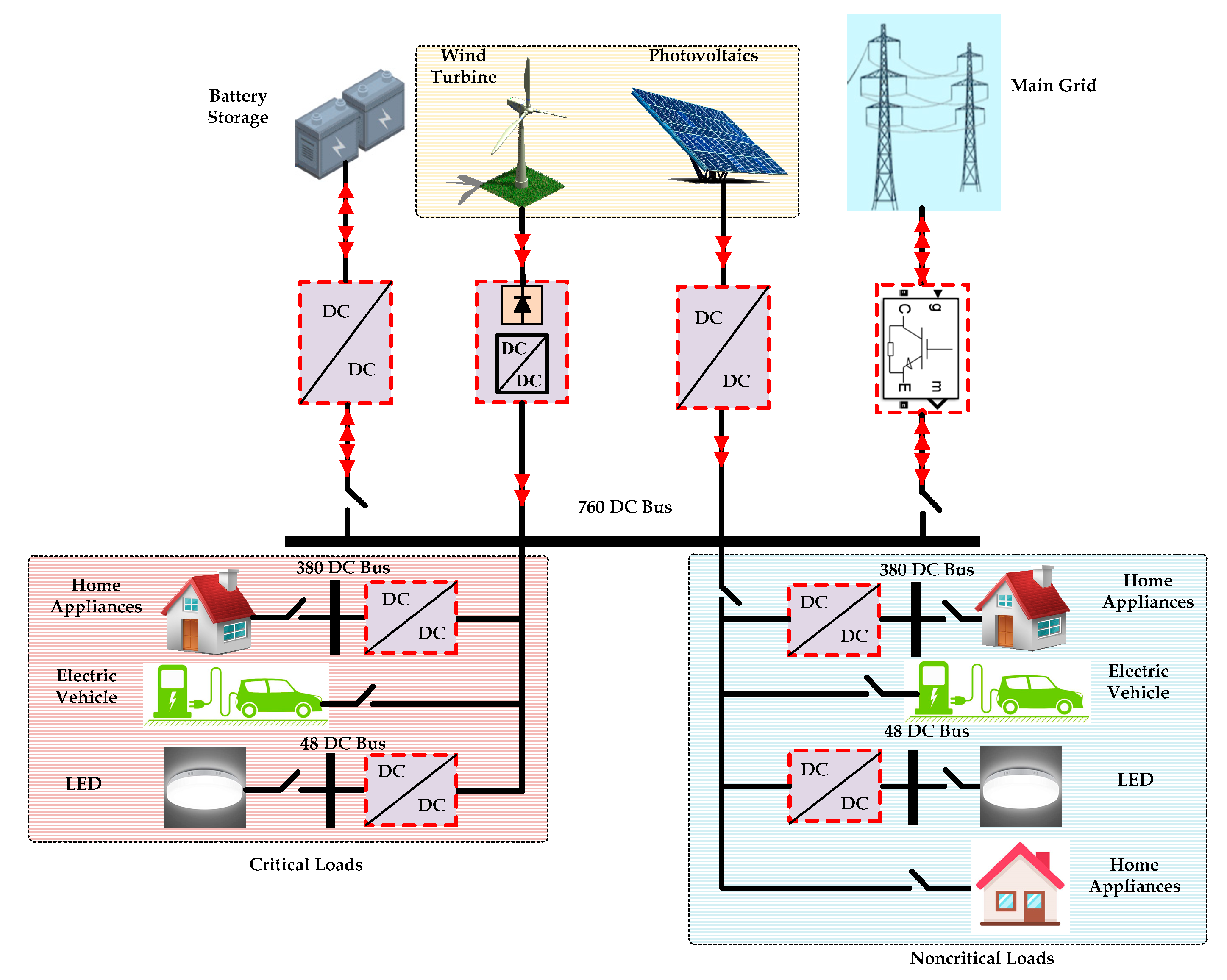

- A comprehensive model is established to generate the power from the PV system and the wind generating system as well as the characteristics of the MPPT.

- An adaptable architectural design to meet the electricity requirement.

- Three voltage buses primarily use the major bus (760 V) for fast-charging EVs, the secondary bus (380 V) to distribute power to each home appliance, and the third bus (48 V) for low-voltage appliances and LEDs.

- Instead of static switches, this development transfers power across buses using bidirectional power converters, making it feasible to set the buses’ voltages.

- Three levels of control algorithms are designed: (i) bidirectional inverter control for grid synchronization; (ii) a DC-DC algorithm for photovoltaic systems; and (iii) an AC-DC algorithm for wind energy generation.

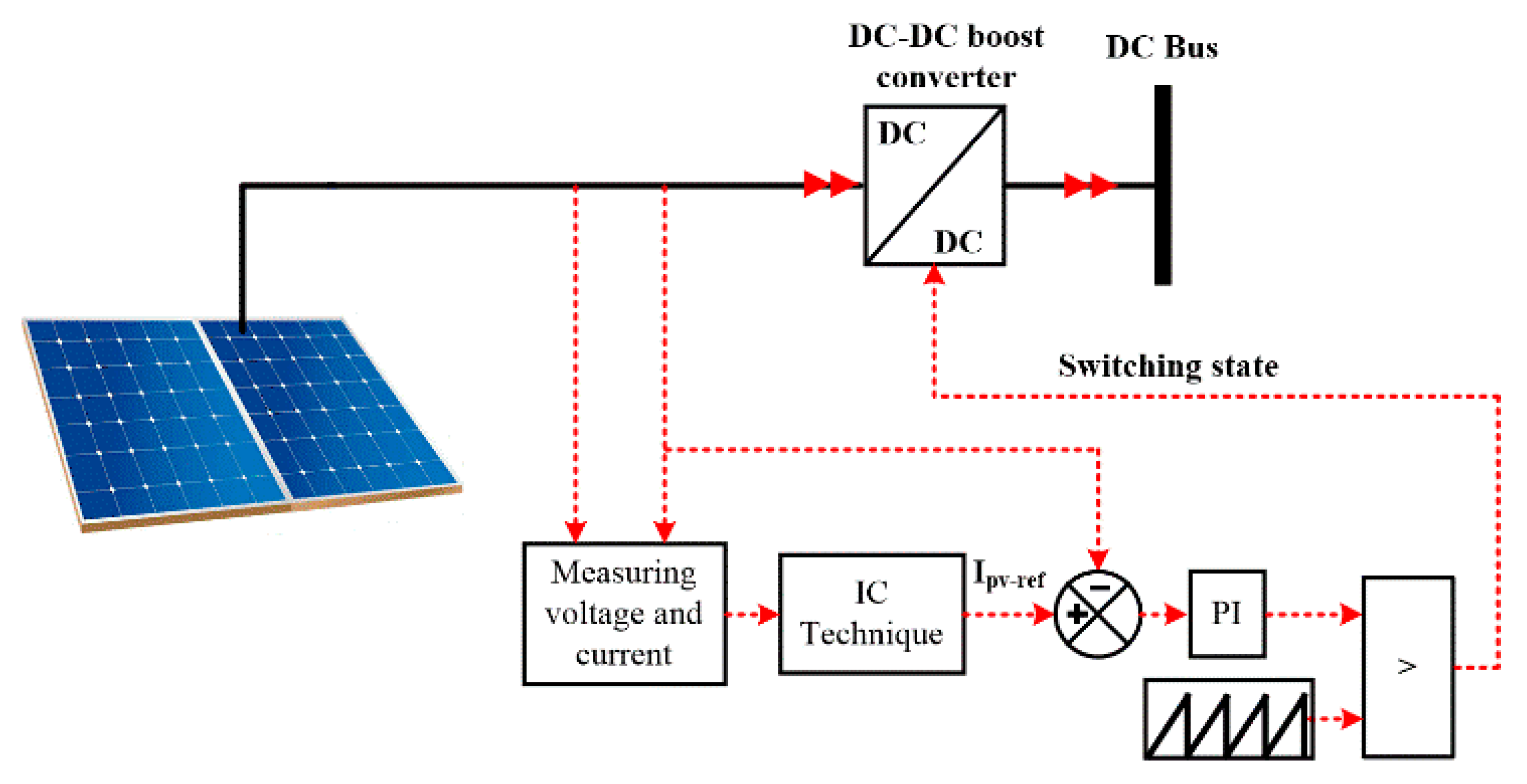

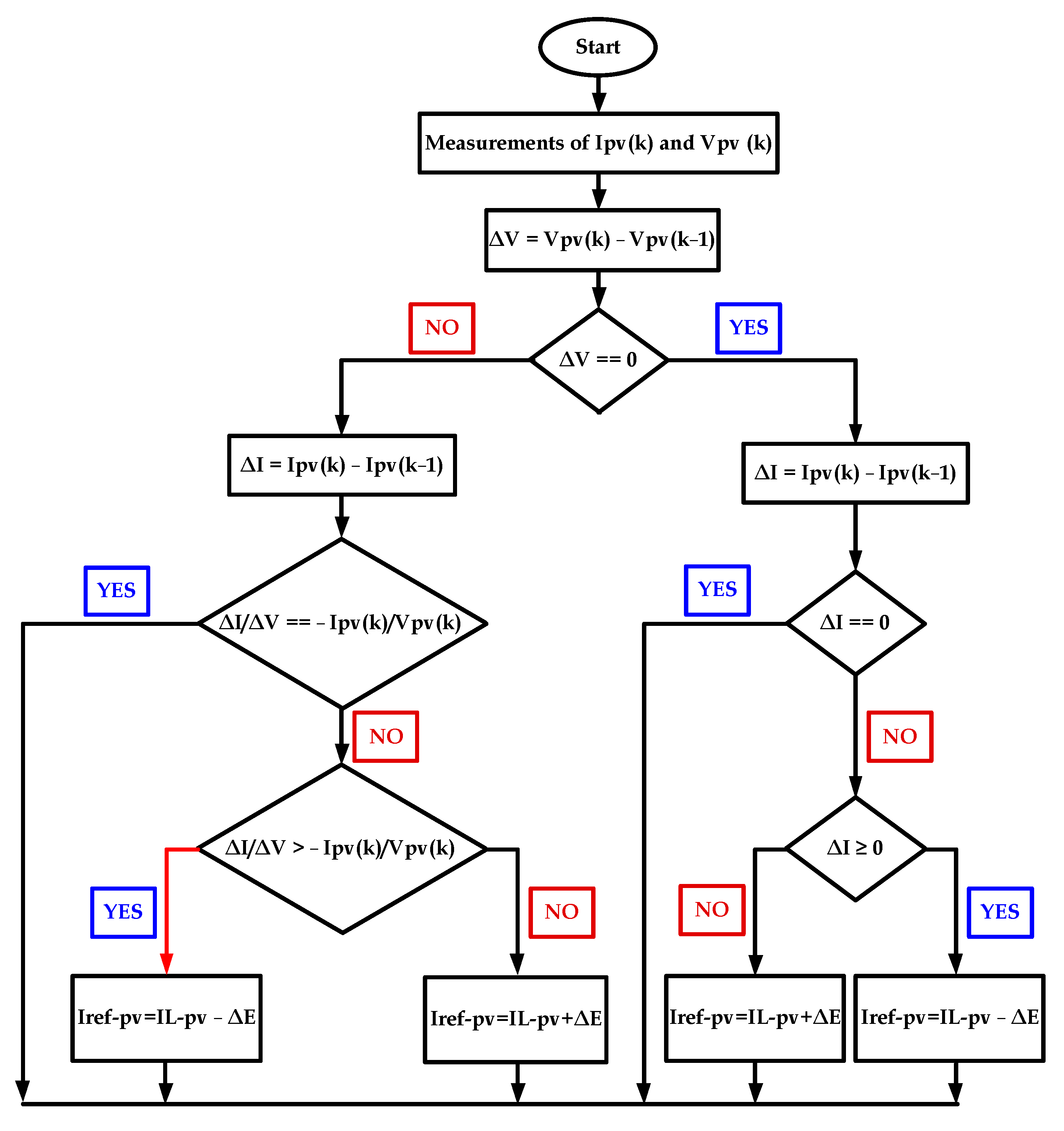

- The first level of control consists of the following components: (i) a DC-AC three-phase inverter with grid synchronization; (ii) a maximum power point tracking (MPPT) algorithm for the PV system that makes use of IC; and (iii) a diode front end (DFE) for the WGS generating system that uses the maximum power point algorithm using the PI controller.

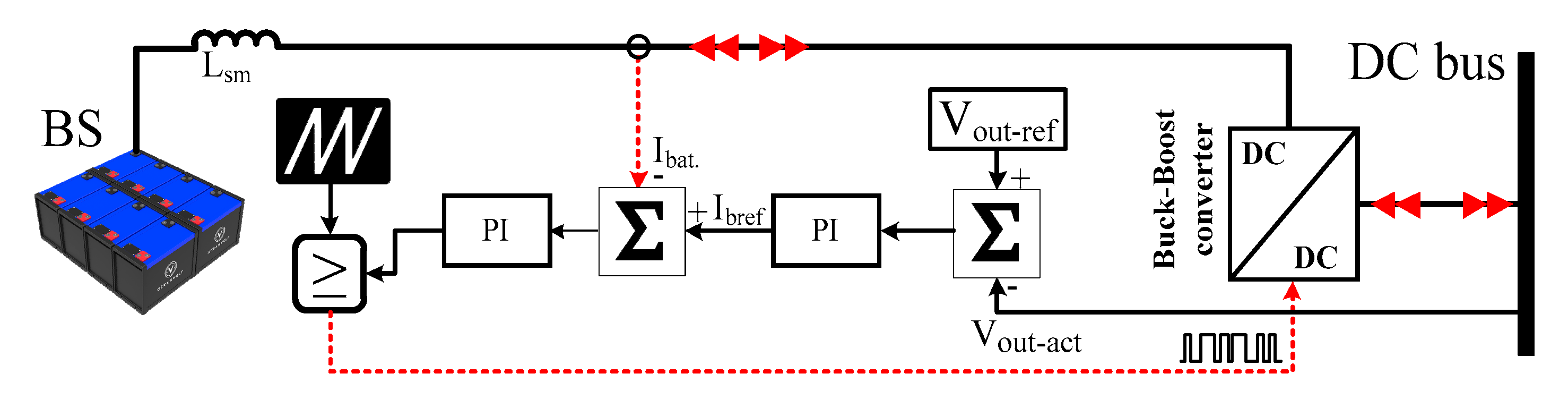

- A coordinated control technique is carried out to regulate the current and power as part of the second level of control.

- The third level of control utilizes an EMS method equipped with a user-friendly algorithm to determine the suitable set points for all power sources following their respective operational targets. In addition to being efficient in supplying the electrical power for both critical and noncritical DC loads where complex algorithms are avoided, it has a simple implementation in the hardware and it does not require high processing, as it is based on ON/OFF switching, assisting the control in regulating the DC bus voltage at the required levels, and improving the stability of the proposed system by injecting the excess power into the grid or absorbing the shortage power from the main grid.

2. The Proposed DC Microgrid System Mathematical Modeling

2.1. Mathematical Representation of the WGS

| Ca = 0.51760 | Cb = 116.0 | Cc = 5.0 |

| Cd = 0.40 | Cf = 21.0 | Cg = 0.00680 |

2.2. The Mathematical Model of the PV System

2.3. The Mathematical Model of the PV System

2.4. Mathematical Representation of the LED

| a1 = −88.72 | b1 = 19.98 | c1 = 1.929 |

| a2 = −0.05488 | b2 = 15.49 | c2 = 0.8177 |

| a3 = 0 | b3 = 0.2712 | c3 = 2.239 |

| a4 = 98.00 | b4 = 20.12 | c4 = 2.017 |

| a5 = −0.02065 | b5 = 17.28 | c5 = 0.3815 |

| a6 = −0.01613 | b6 = 16.80 | c6 = 0.4395 |

2.5. Mathematical Representation of the AC Grid

3. Proposed Control Techniques for the Suggested HDCMG

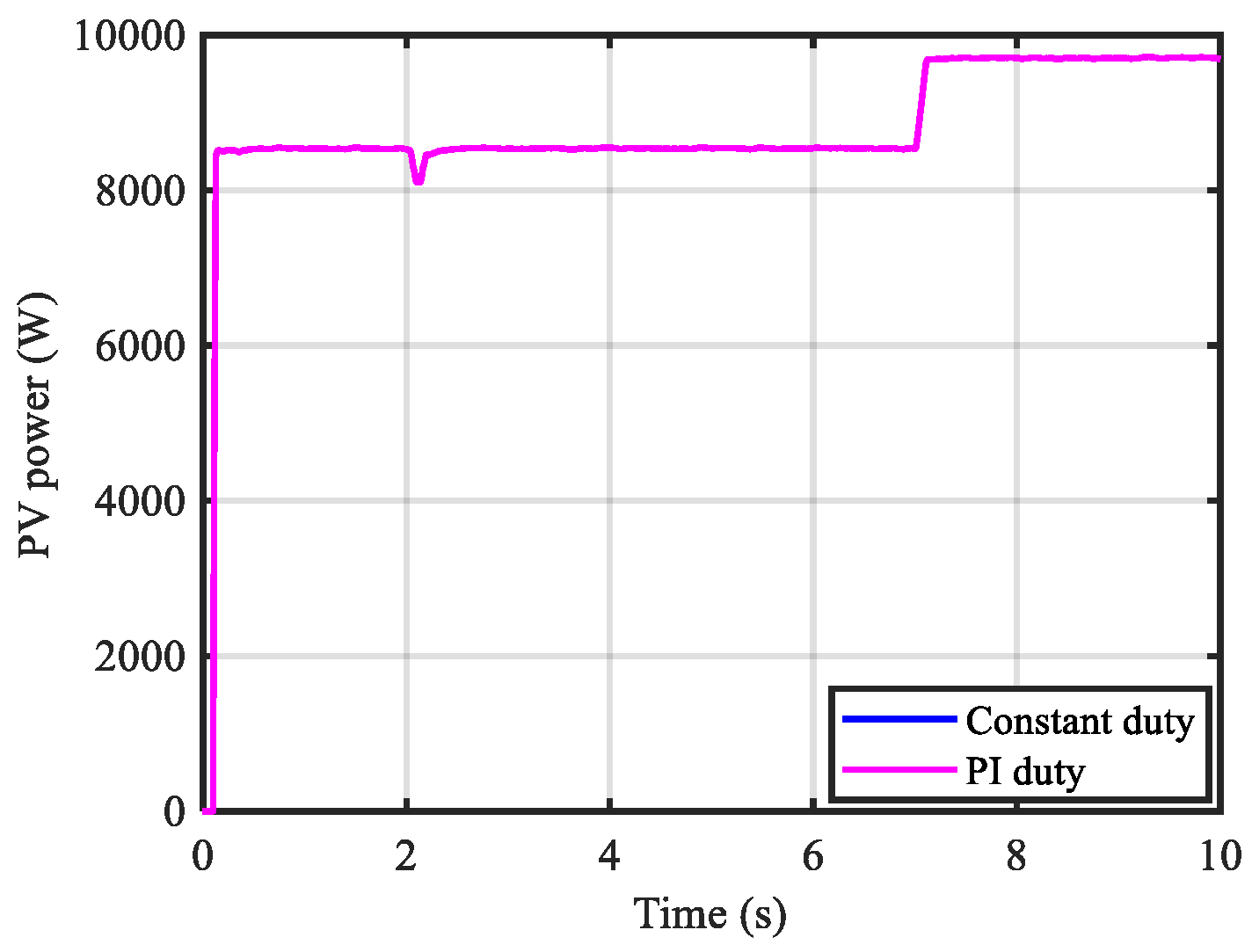

3.1. Extracting the Maximum Power from the PV System

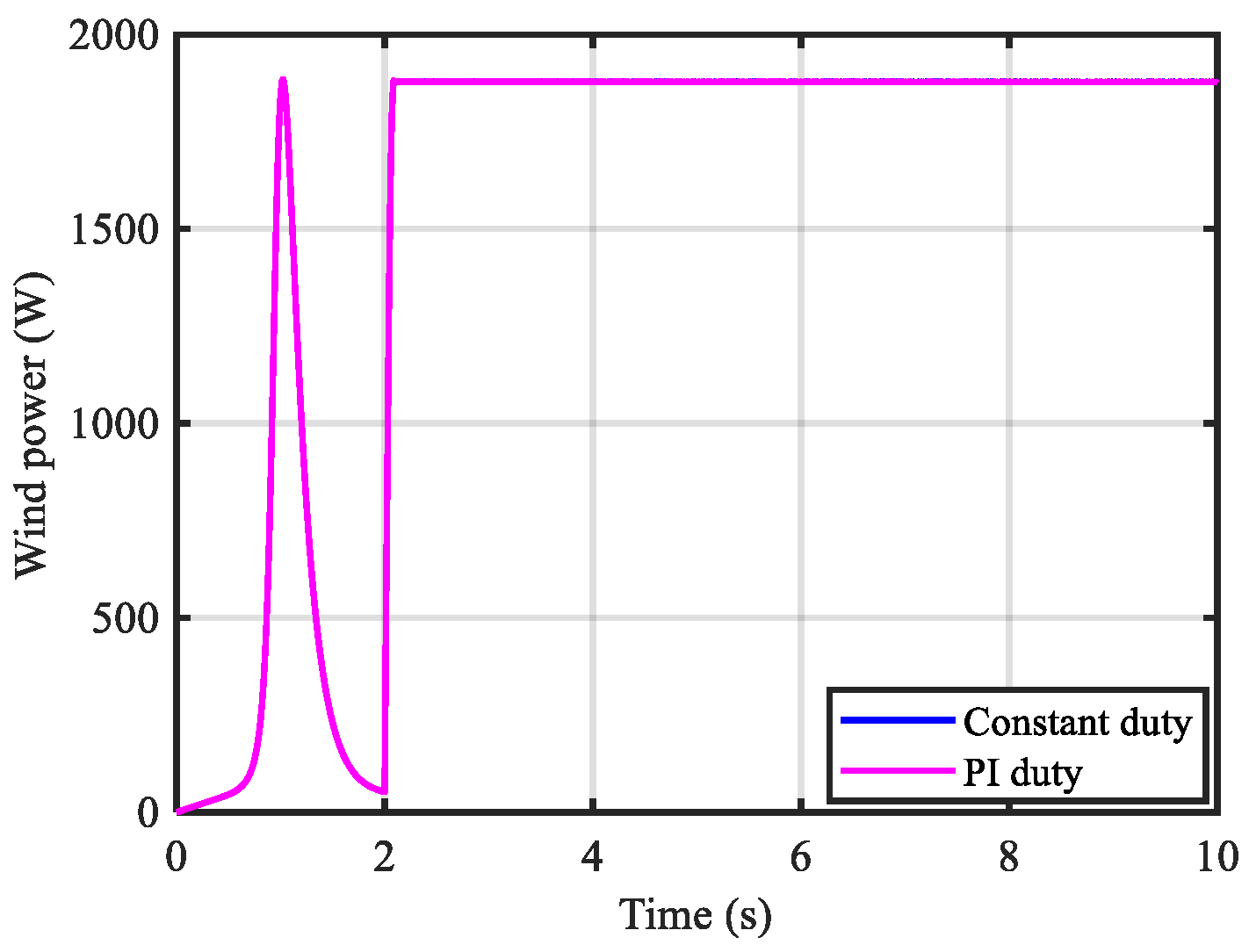

3.2. Extracting the Maximum Power from the WGS

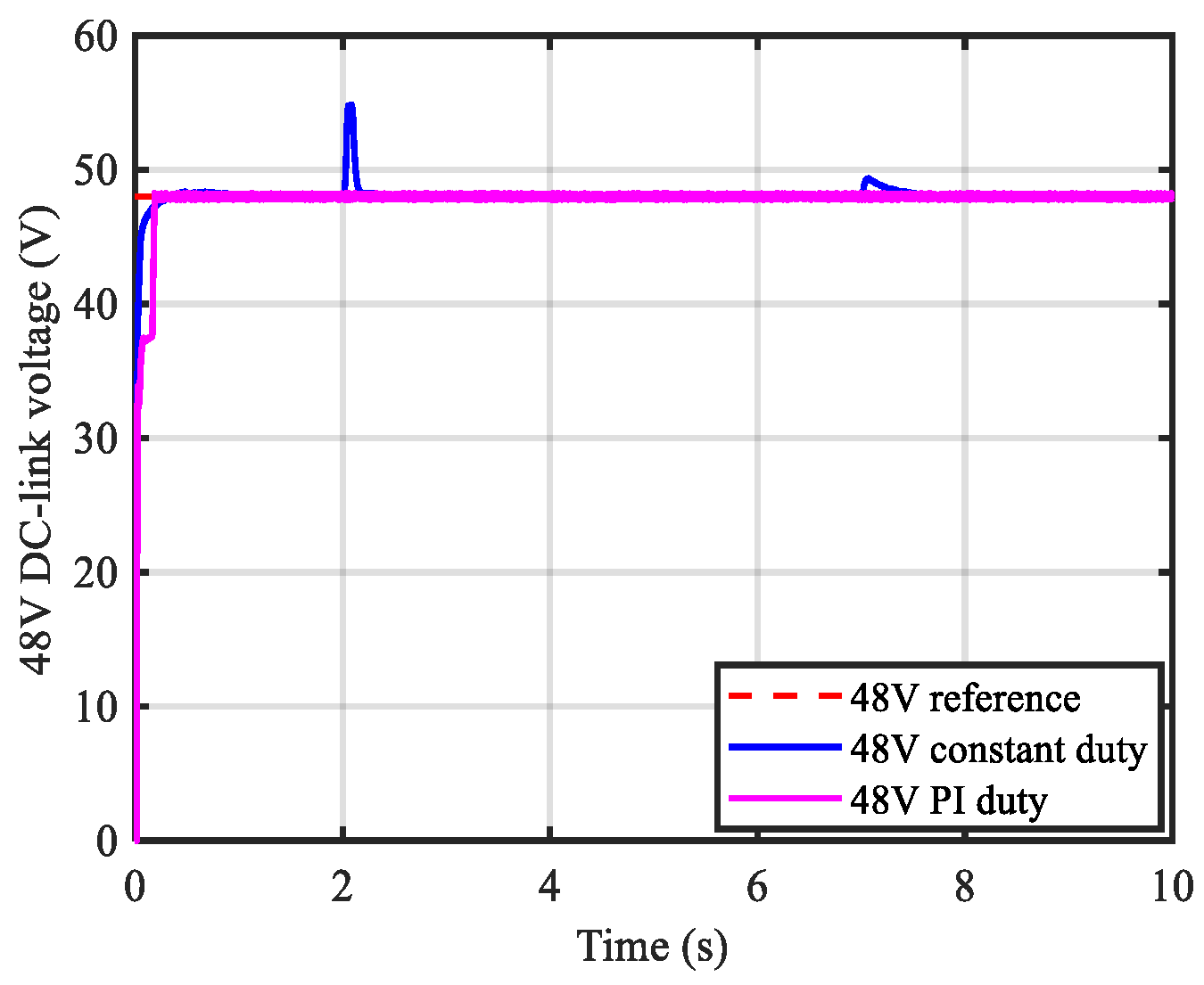

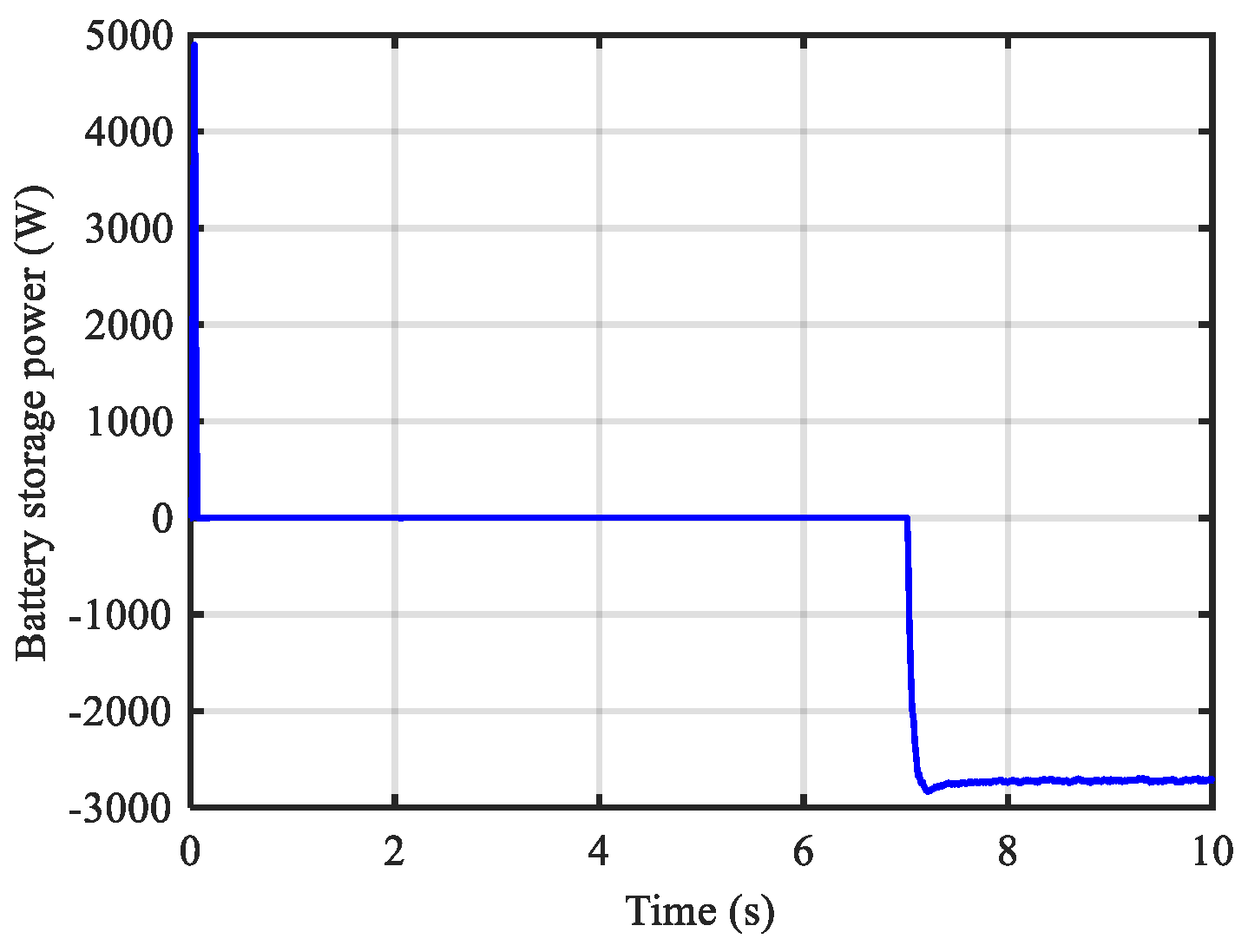

3.3. DC Bus Control Based on BES

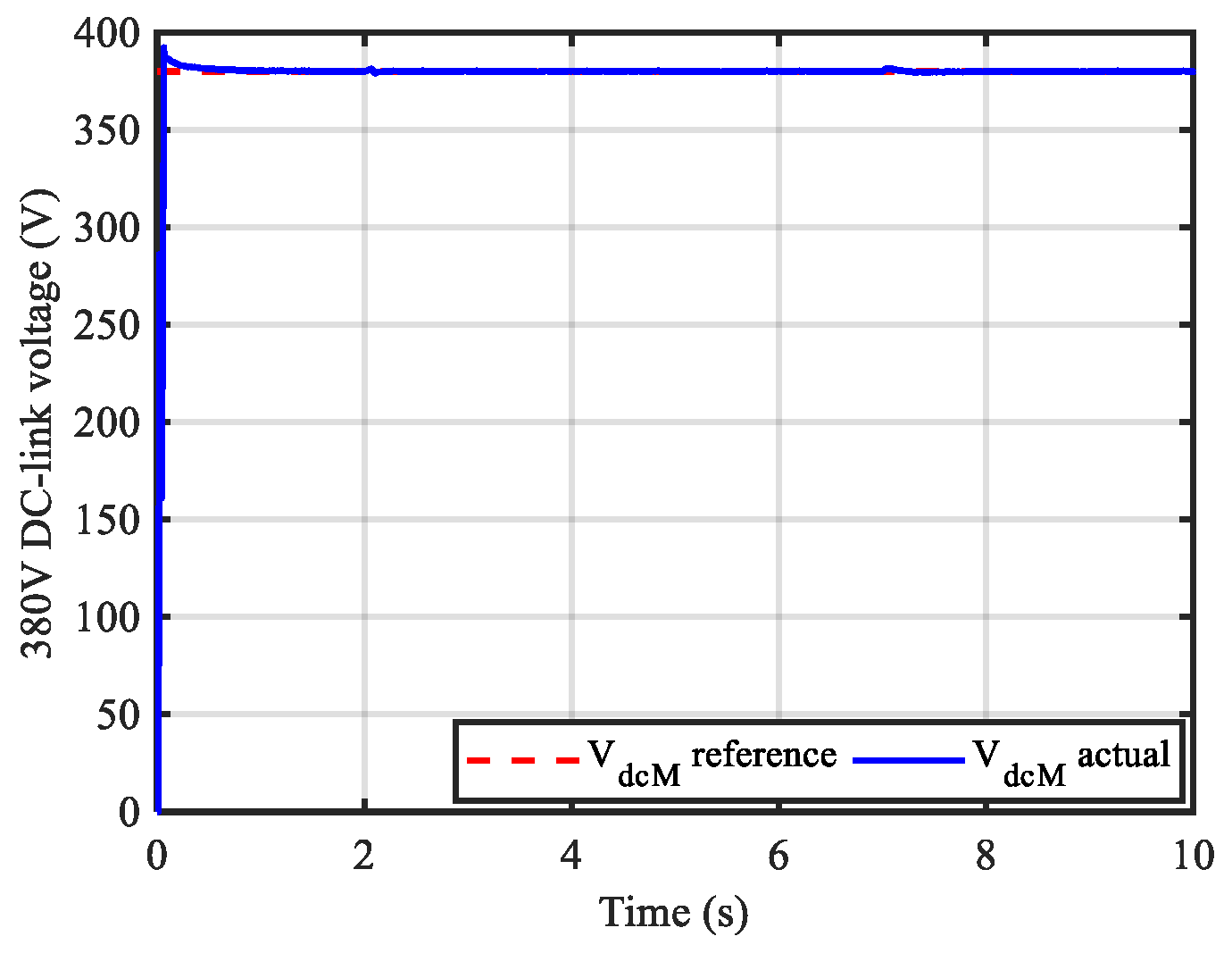

3.4. DC Bus Control Based on the Main Grid

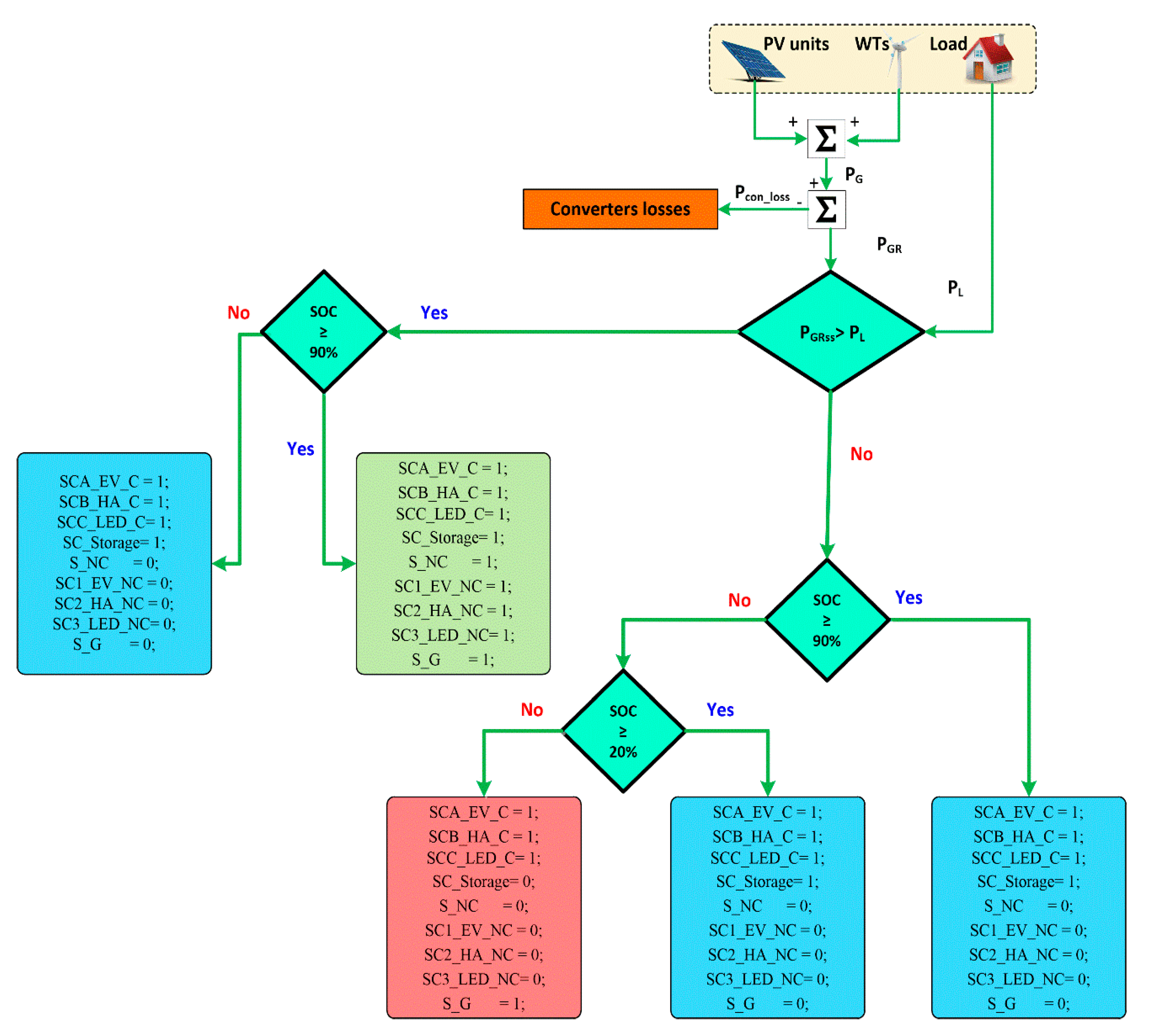

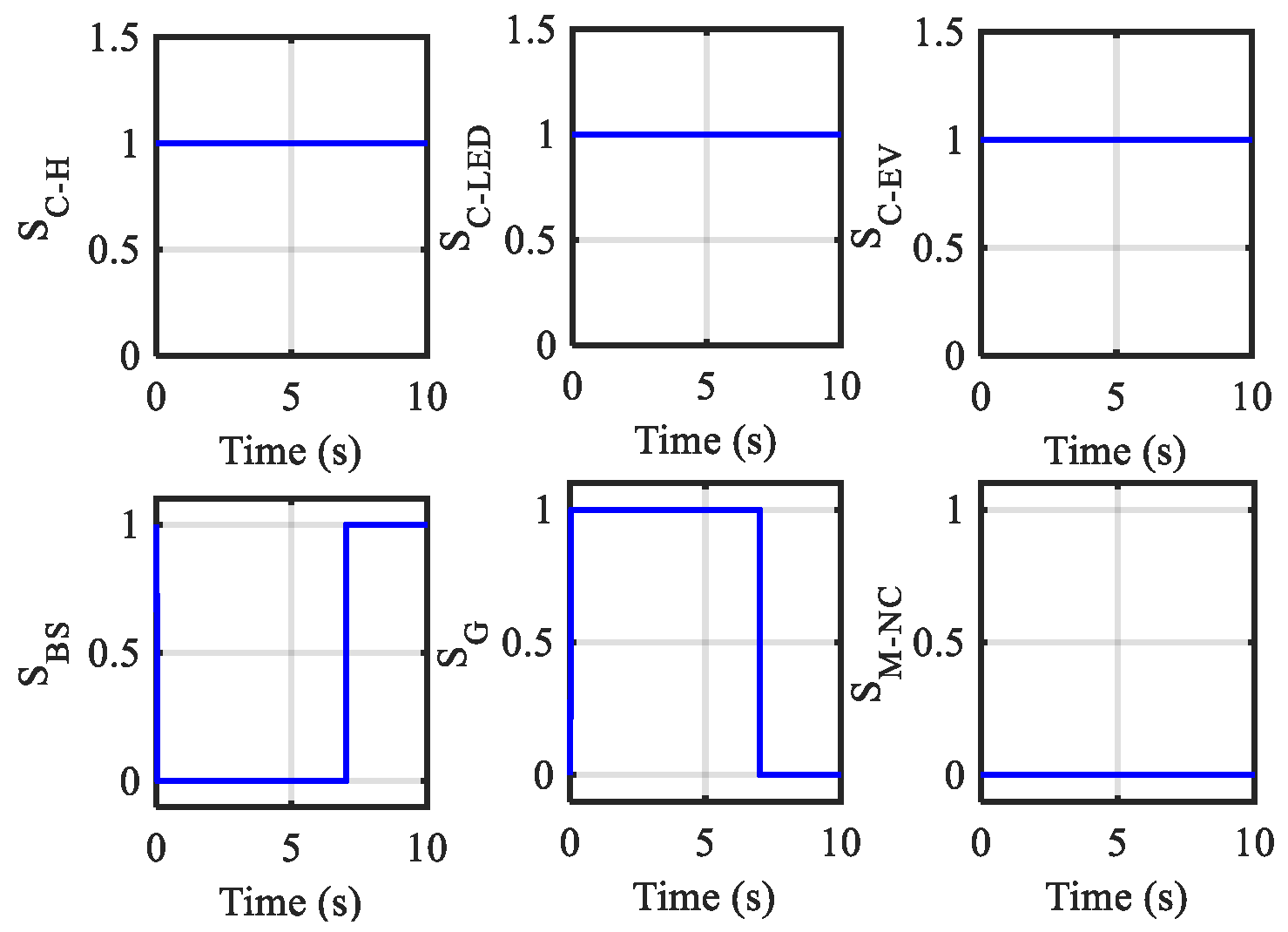

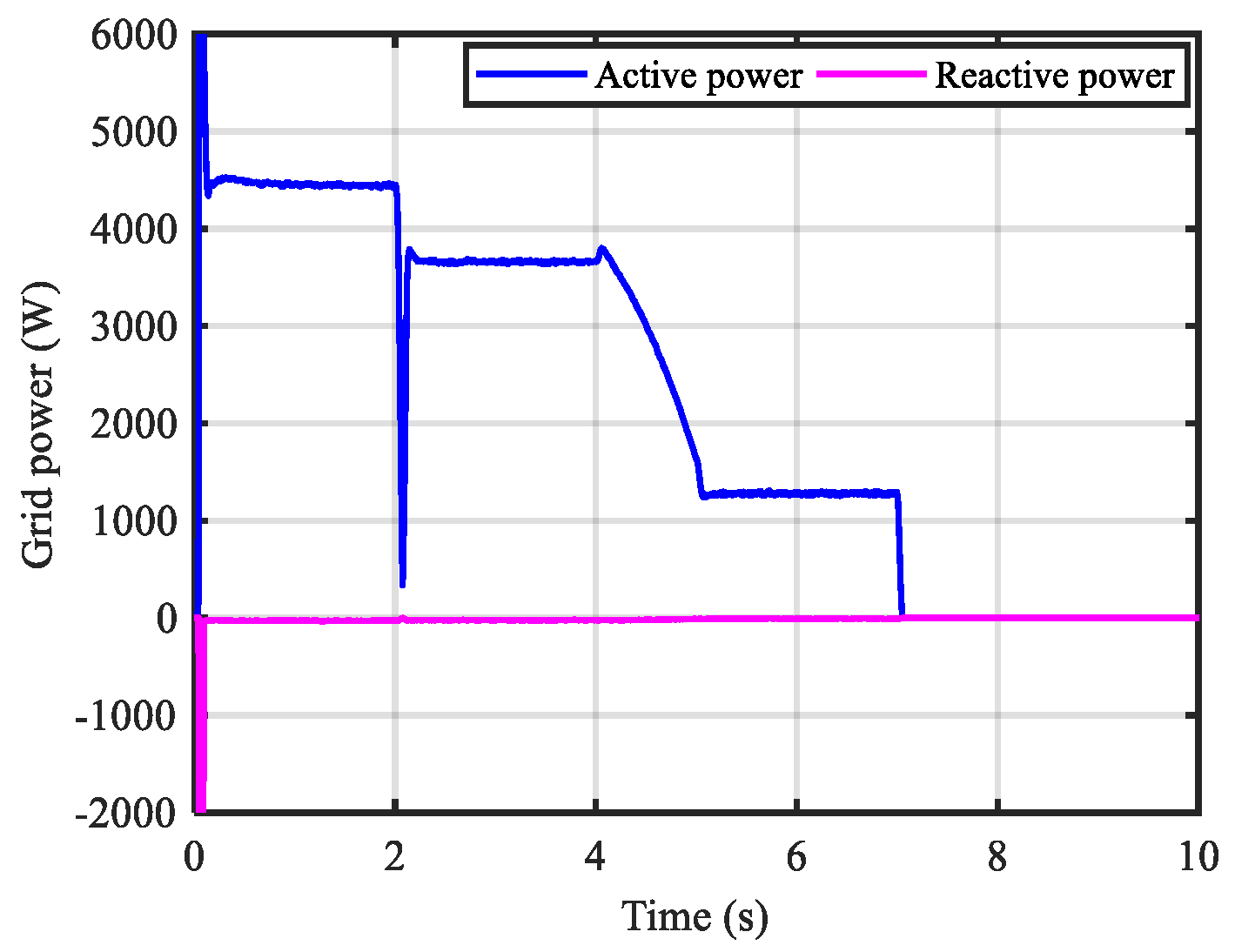

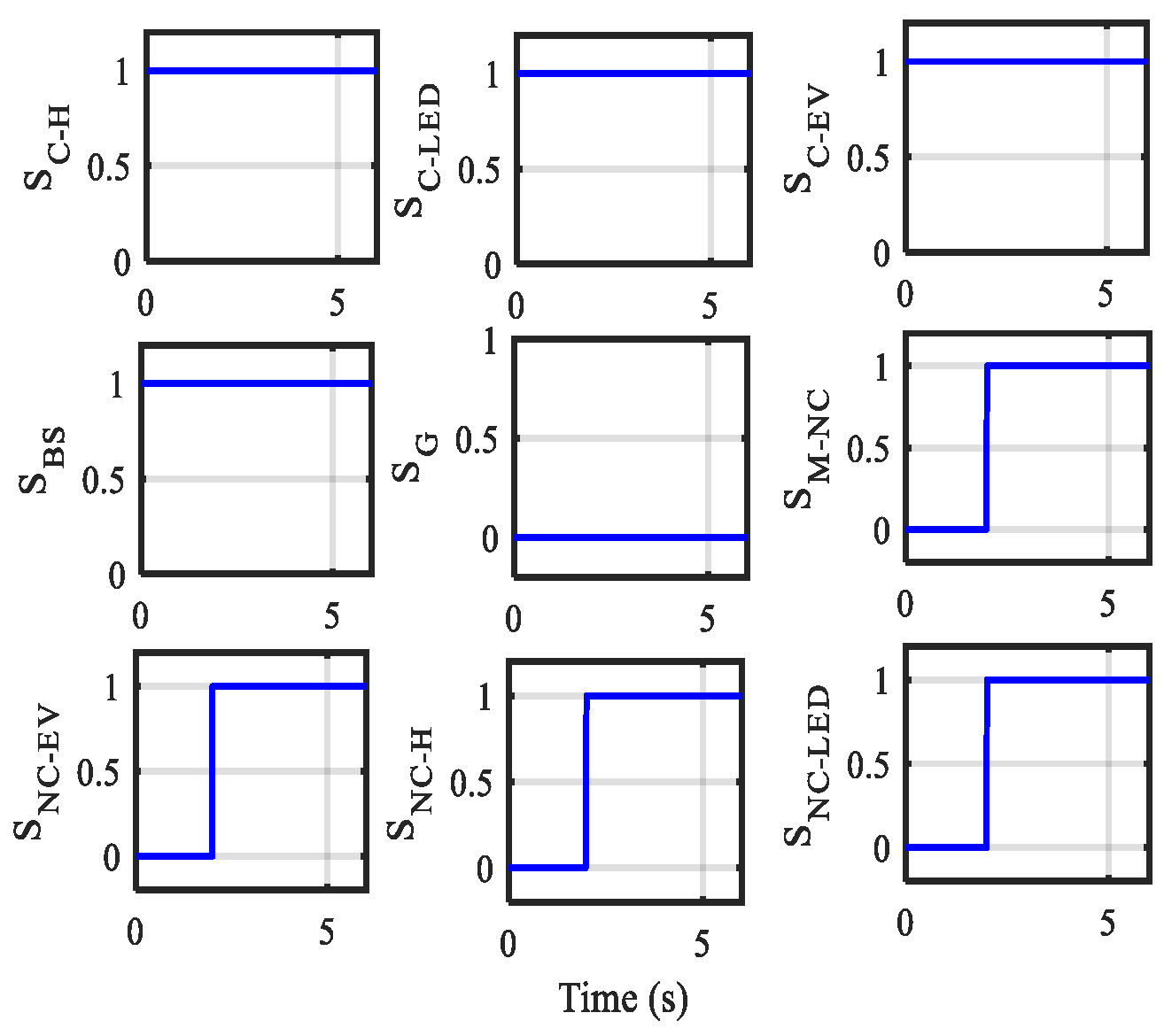

4. Suggested Energy Management Strategy

- Managing the total generated power across all generating sources.

- Supplying both critical and noncritical loads with the most power possible from each generating unit using MPPT techniques.

- Assisting in stabilizing the DC bus voltage under different working conditions.

- Giving the priority to the critical loads and the battery storage system.

- Connecting or disconnecting the grid during extreme working cases to ensure the system is safe and stable.

5. Comparison between the Proposed System and the Literature on the DC Microgrid Systems

6. Evaluation of the Proposed HDCMG

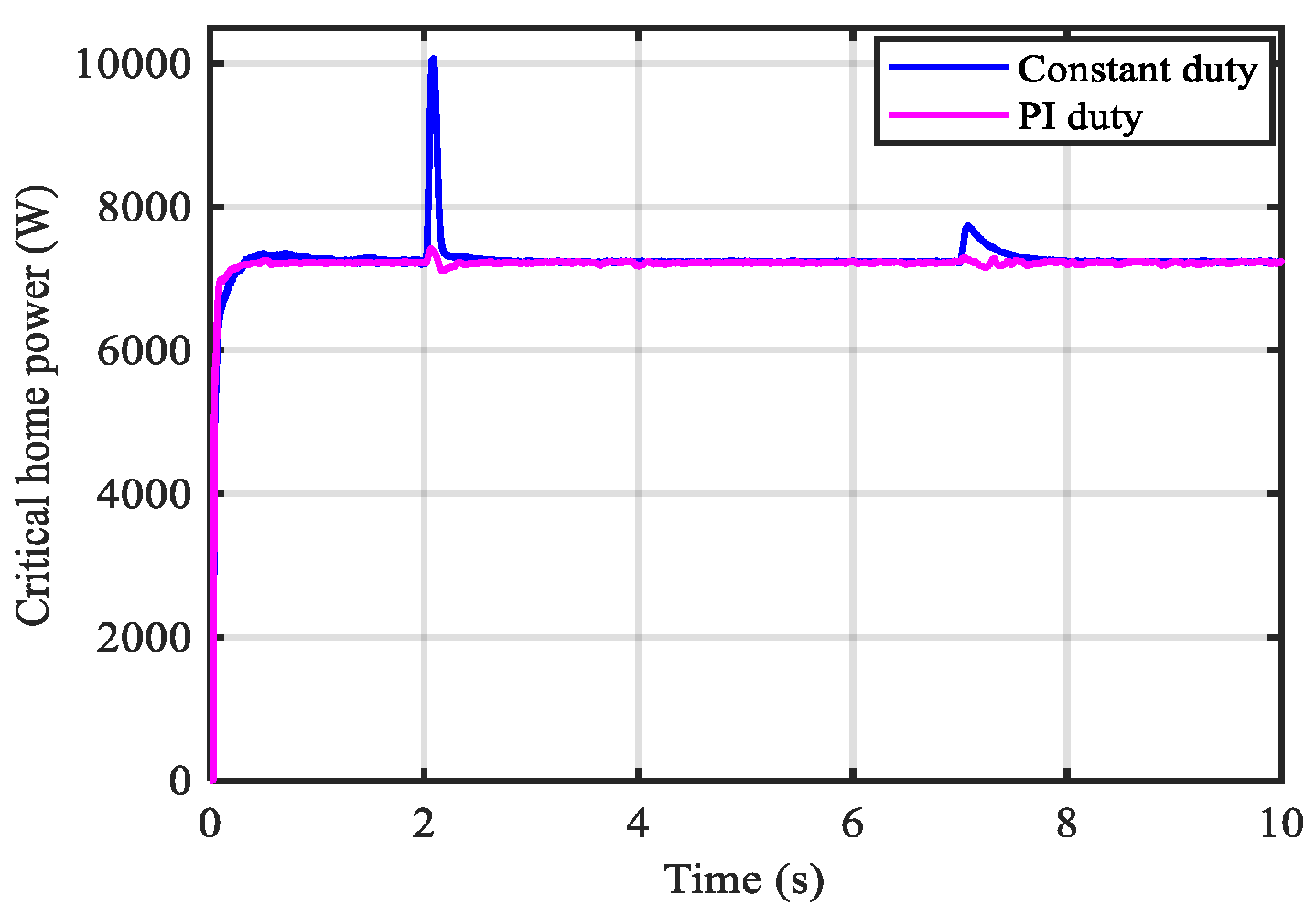

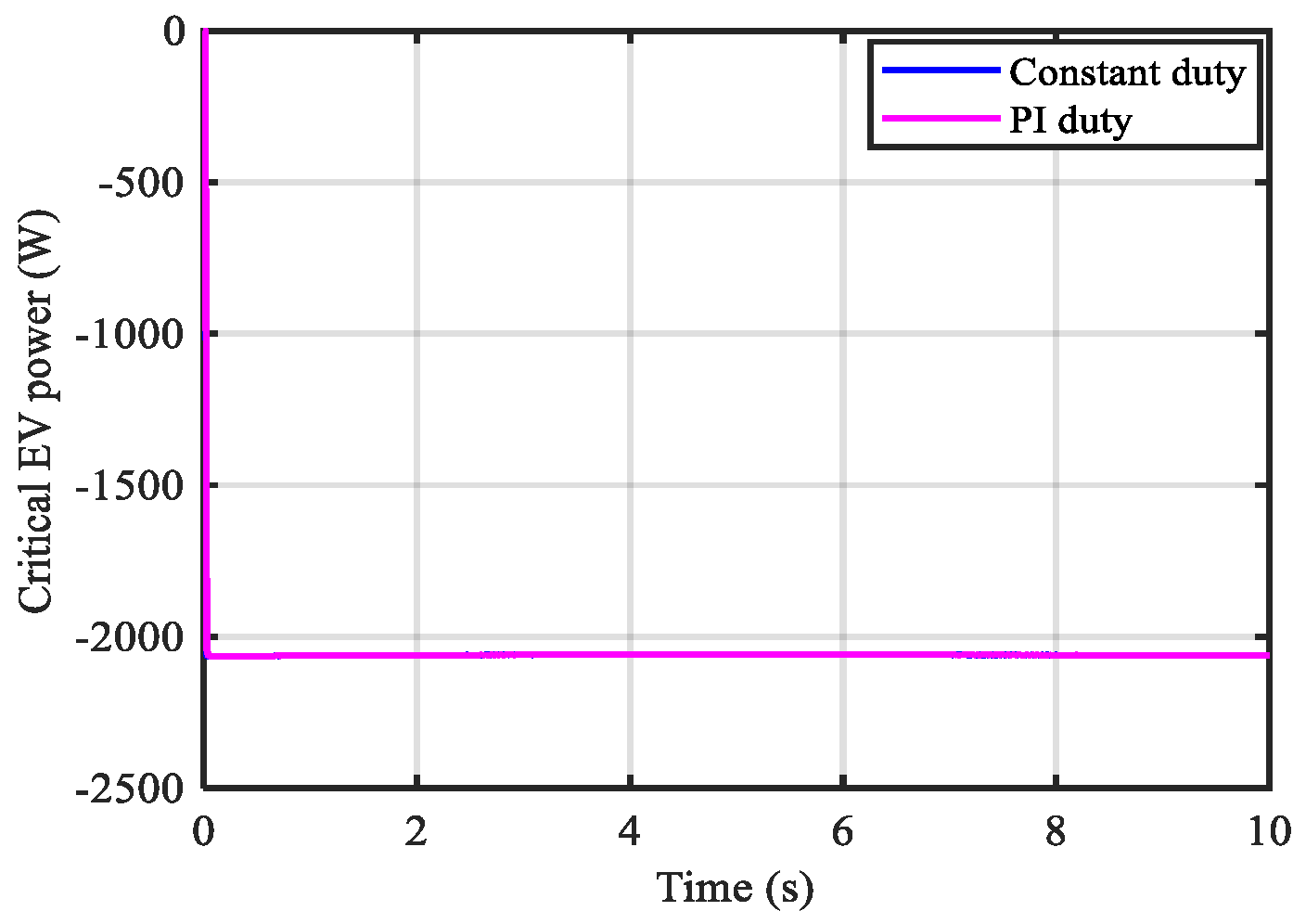

6.1. Comparison between the Use of PI Controller and Constant Value for the Duty Cycle

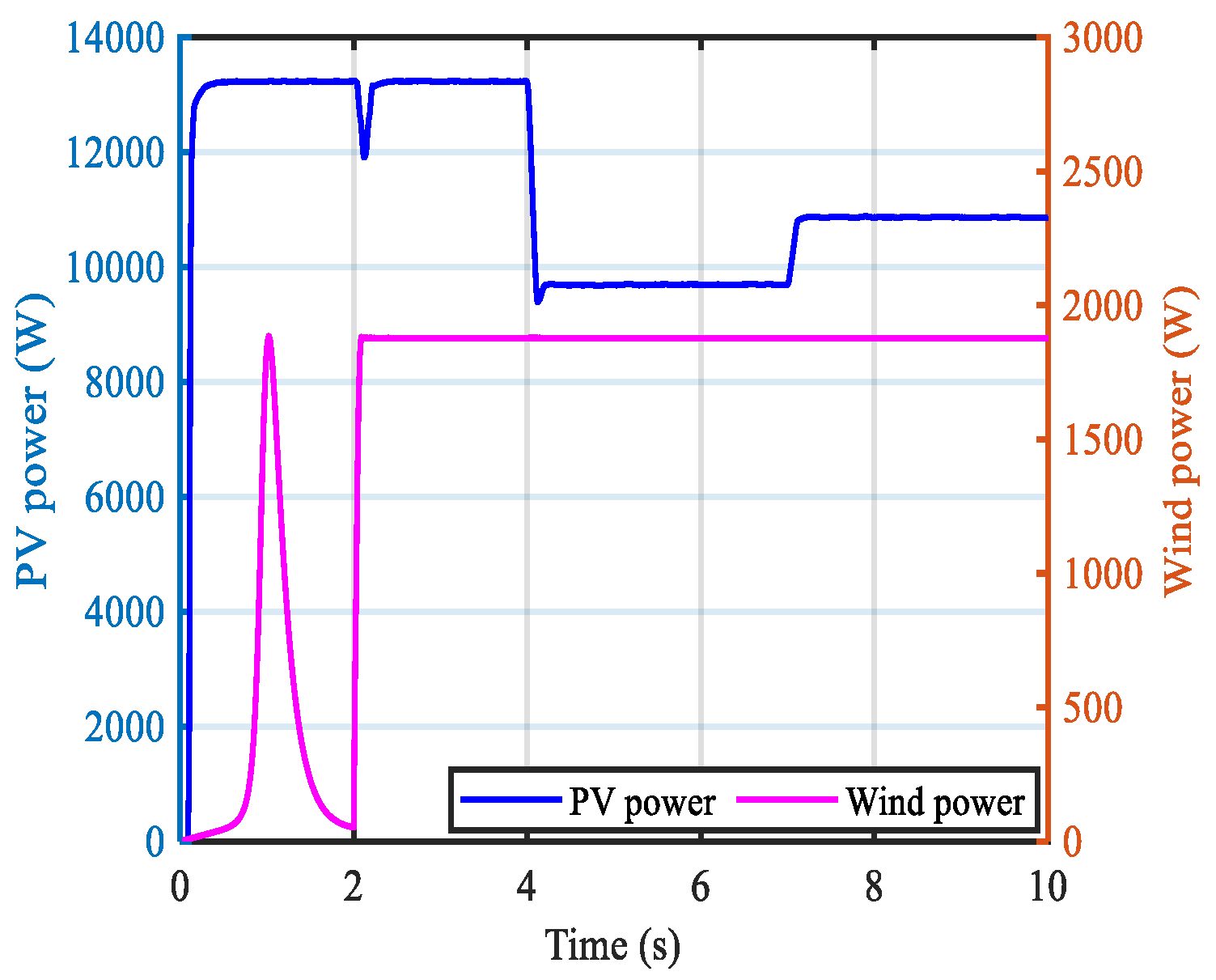

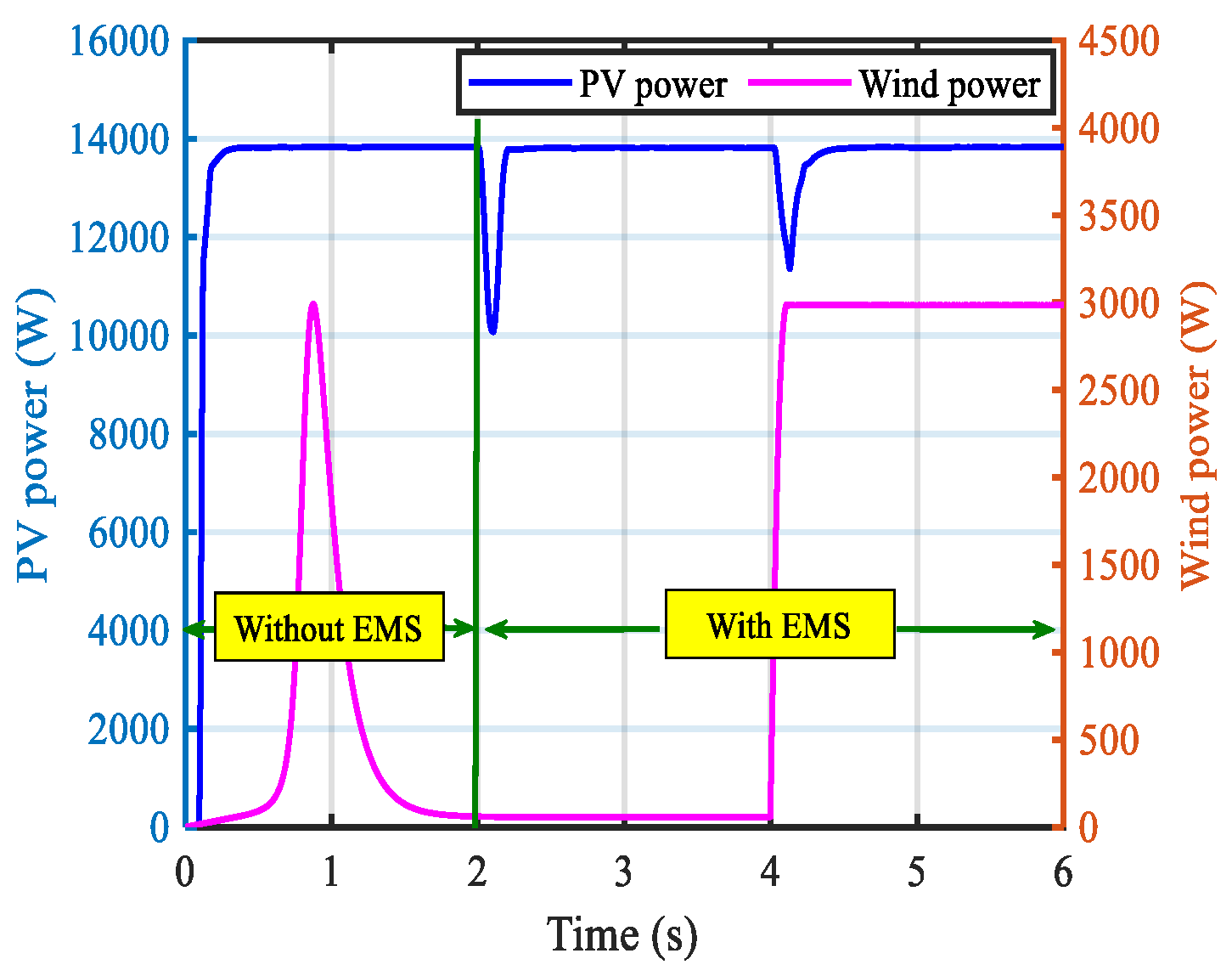

6.2. Constant Wind SPEED and Variable Solar Radiation

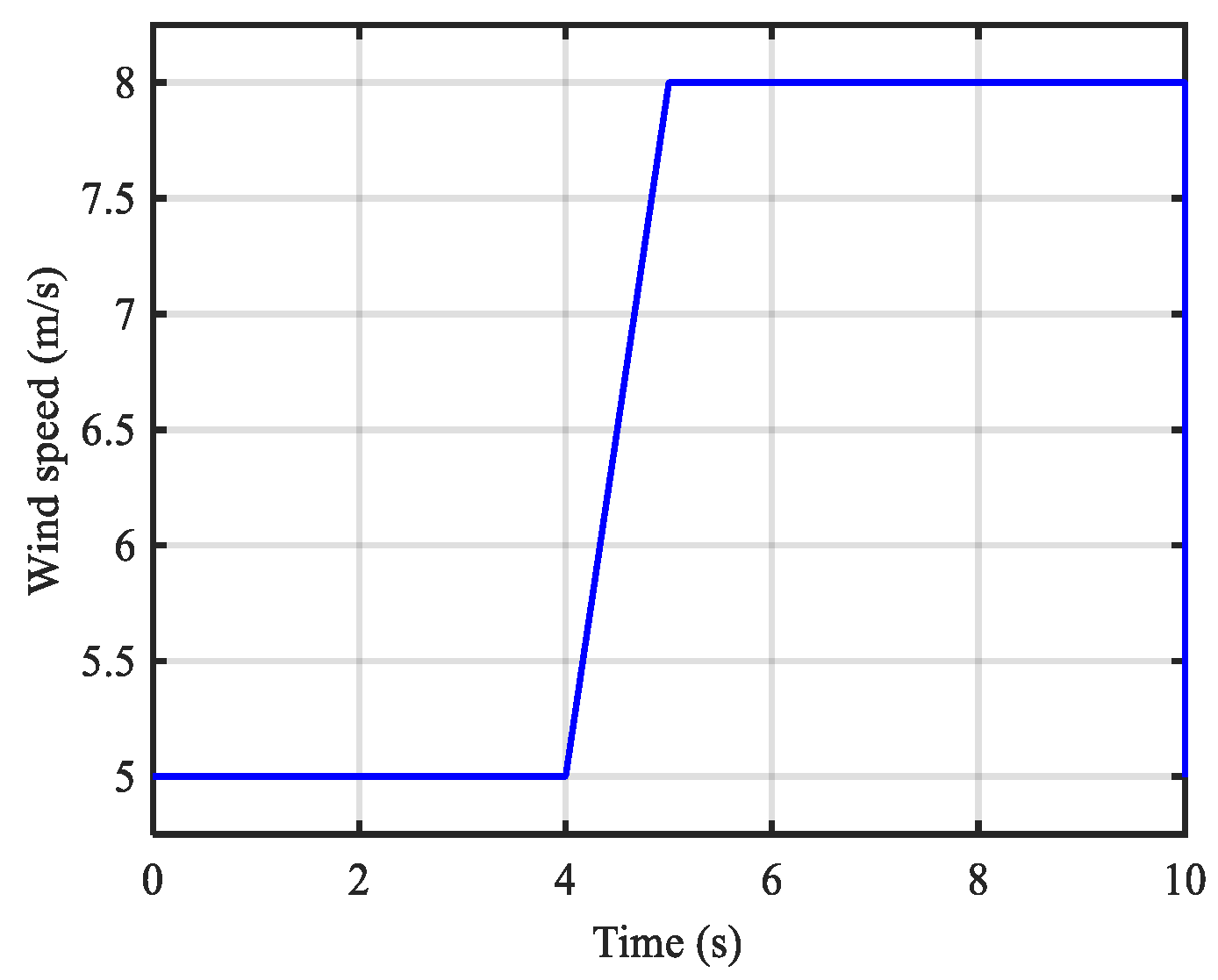

6.3. Variable Wind Speed as Well as Solar Irradiance

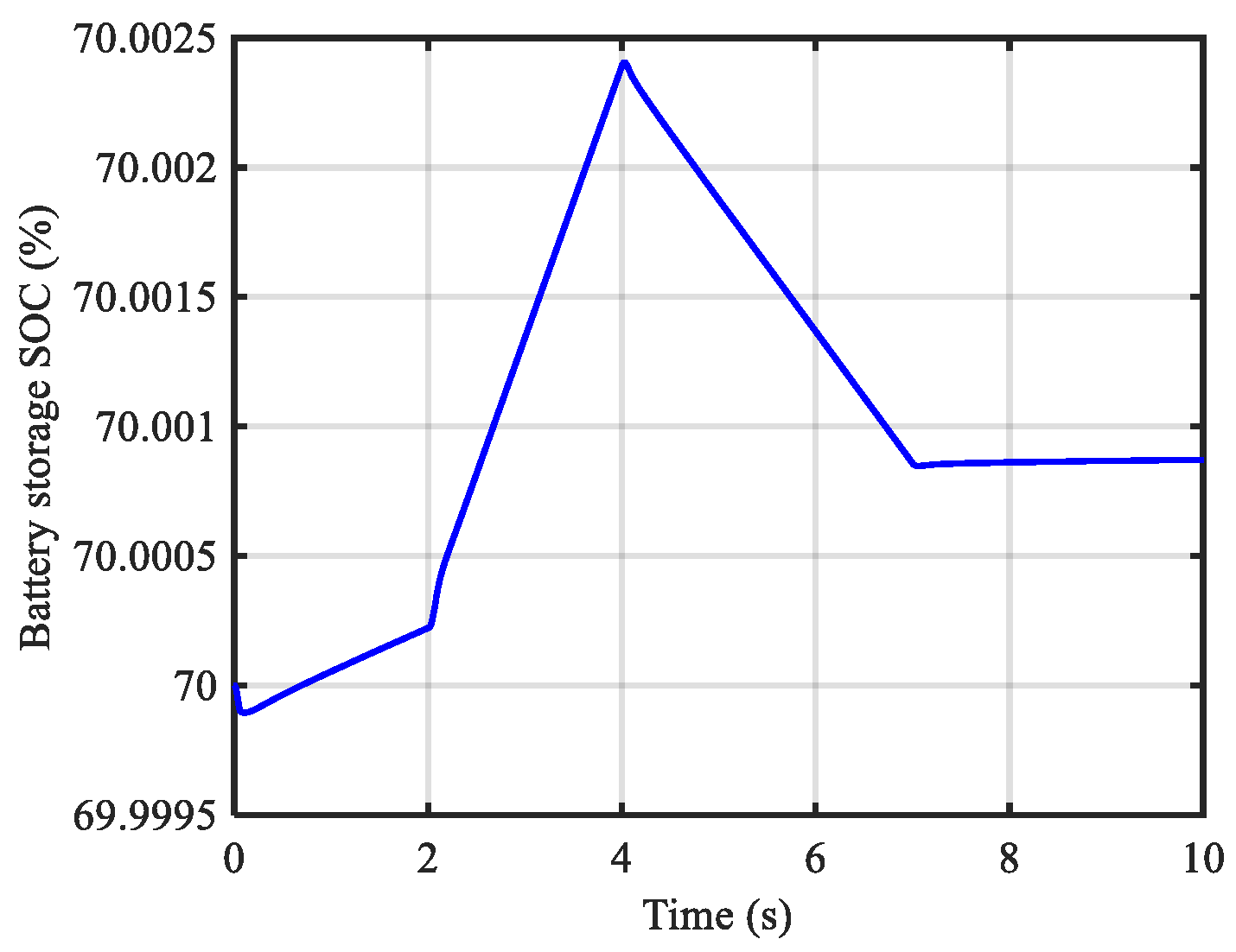

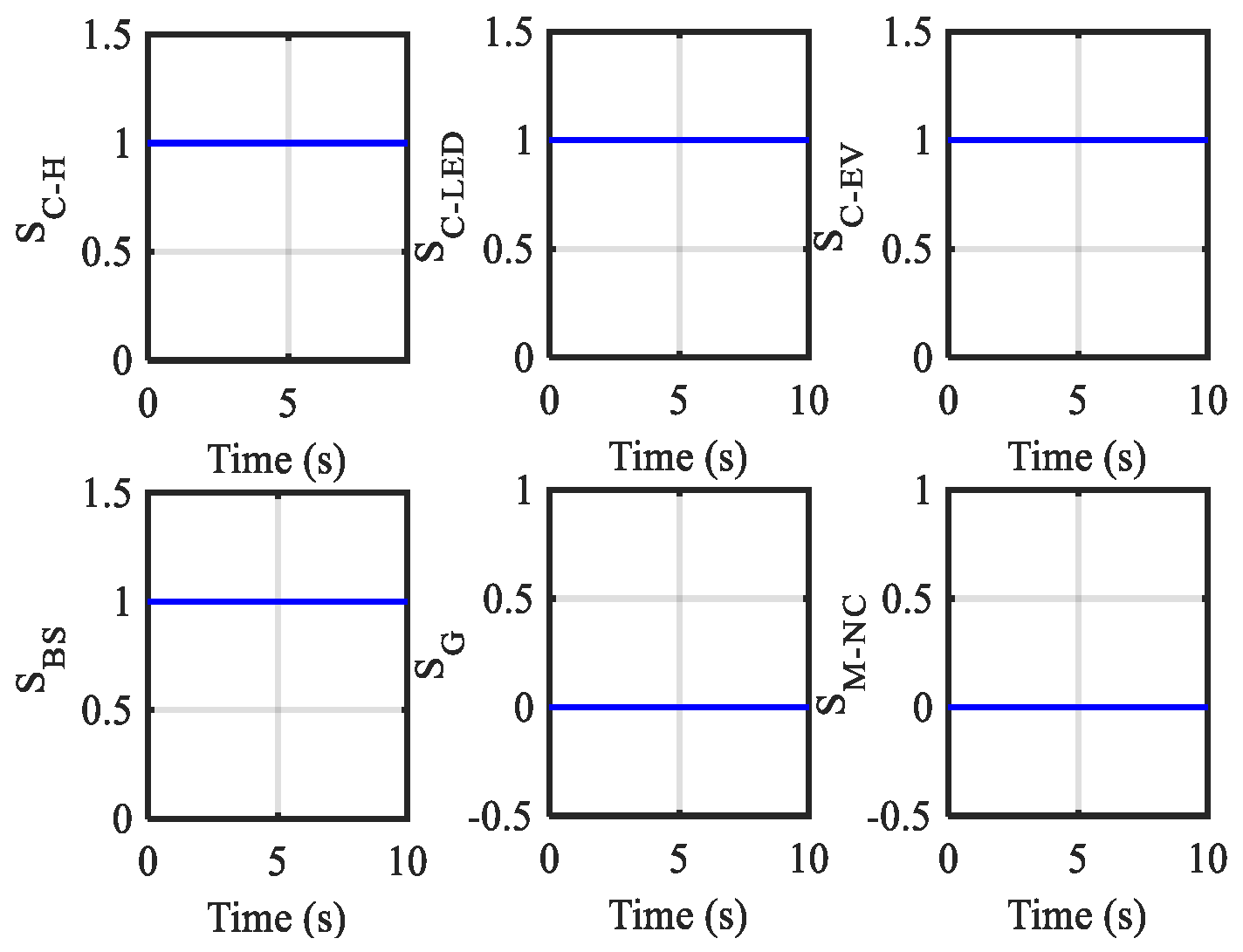

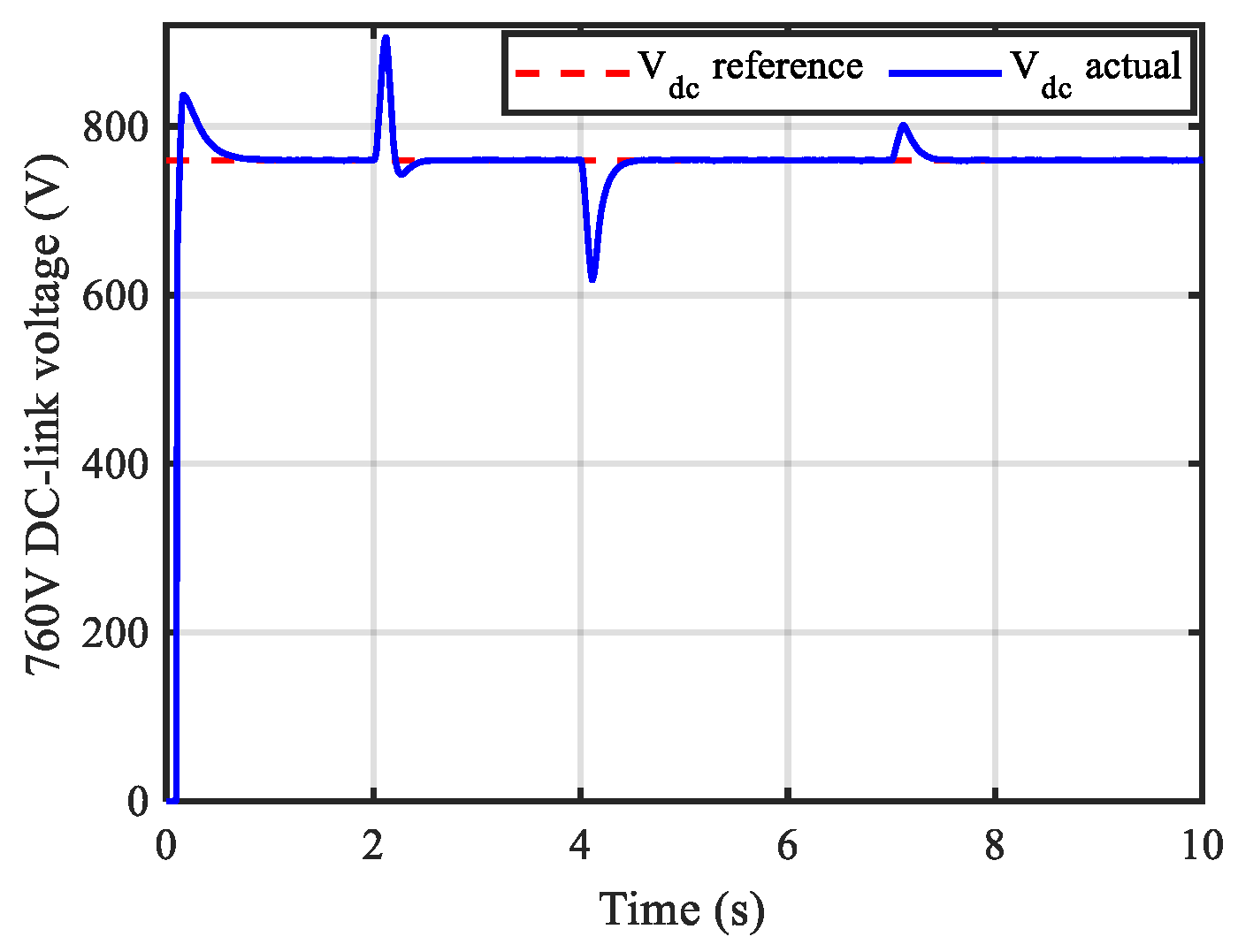

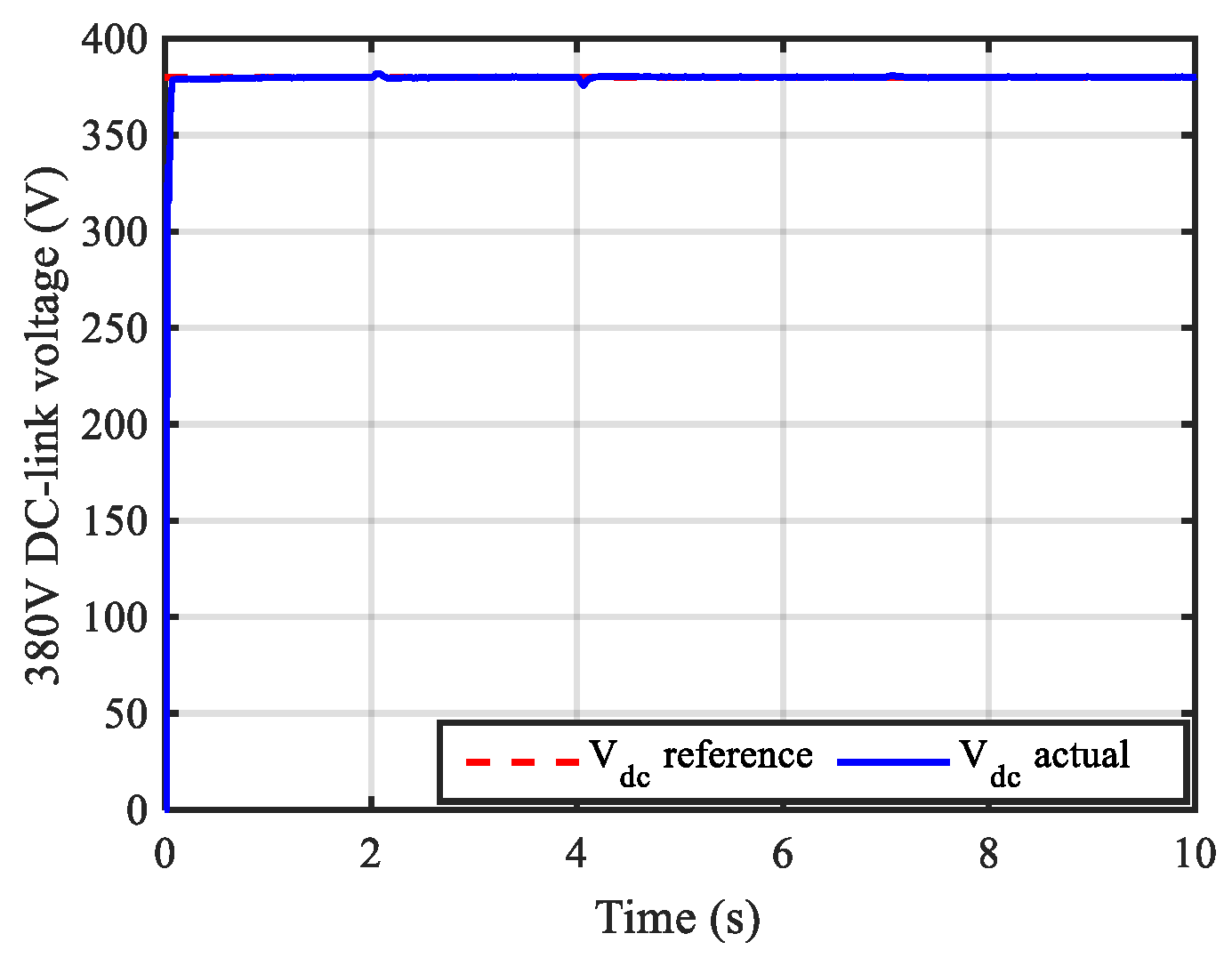

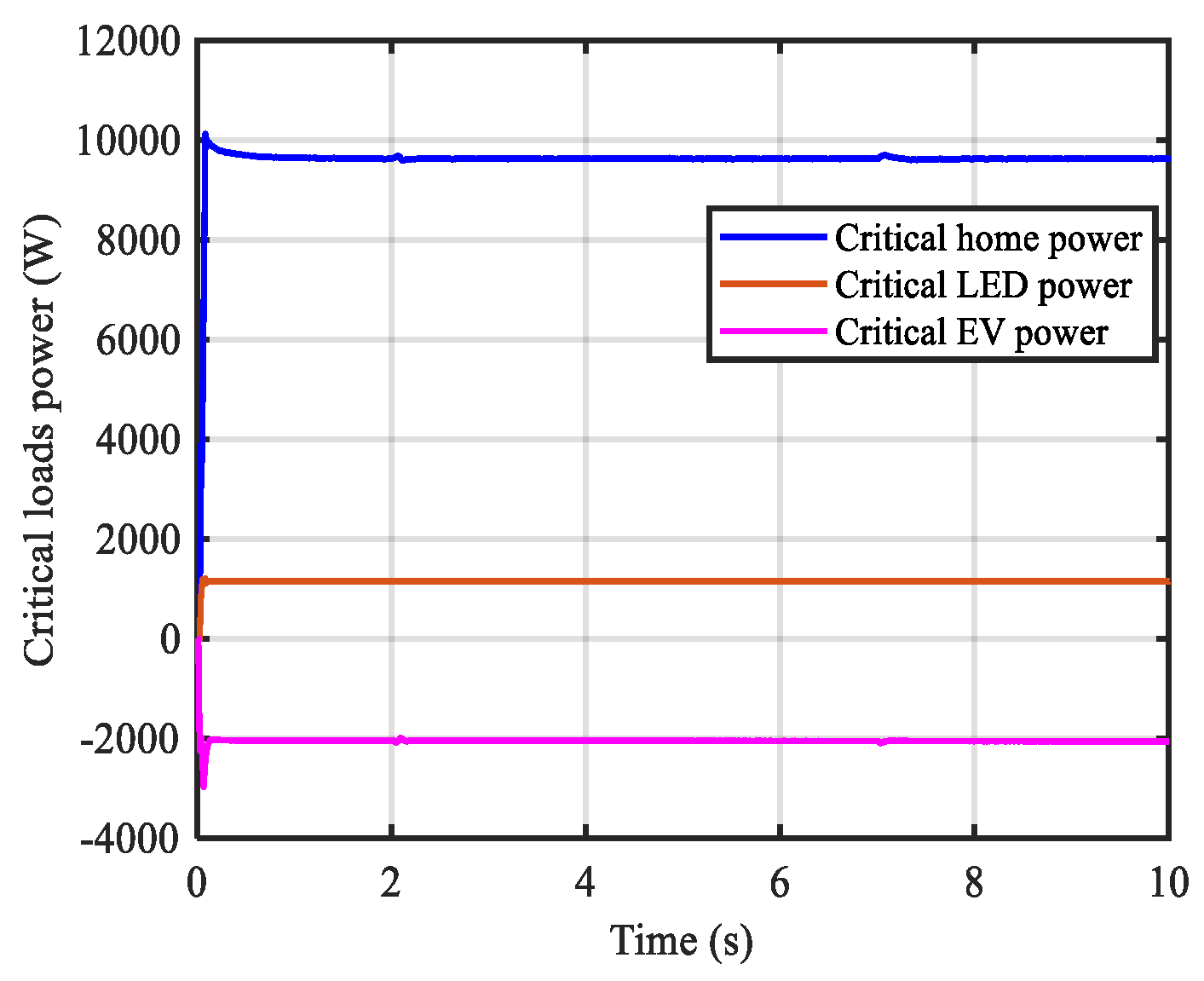

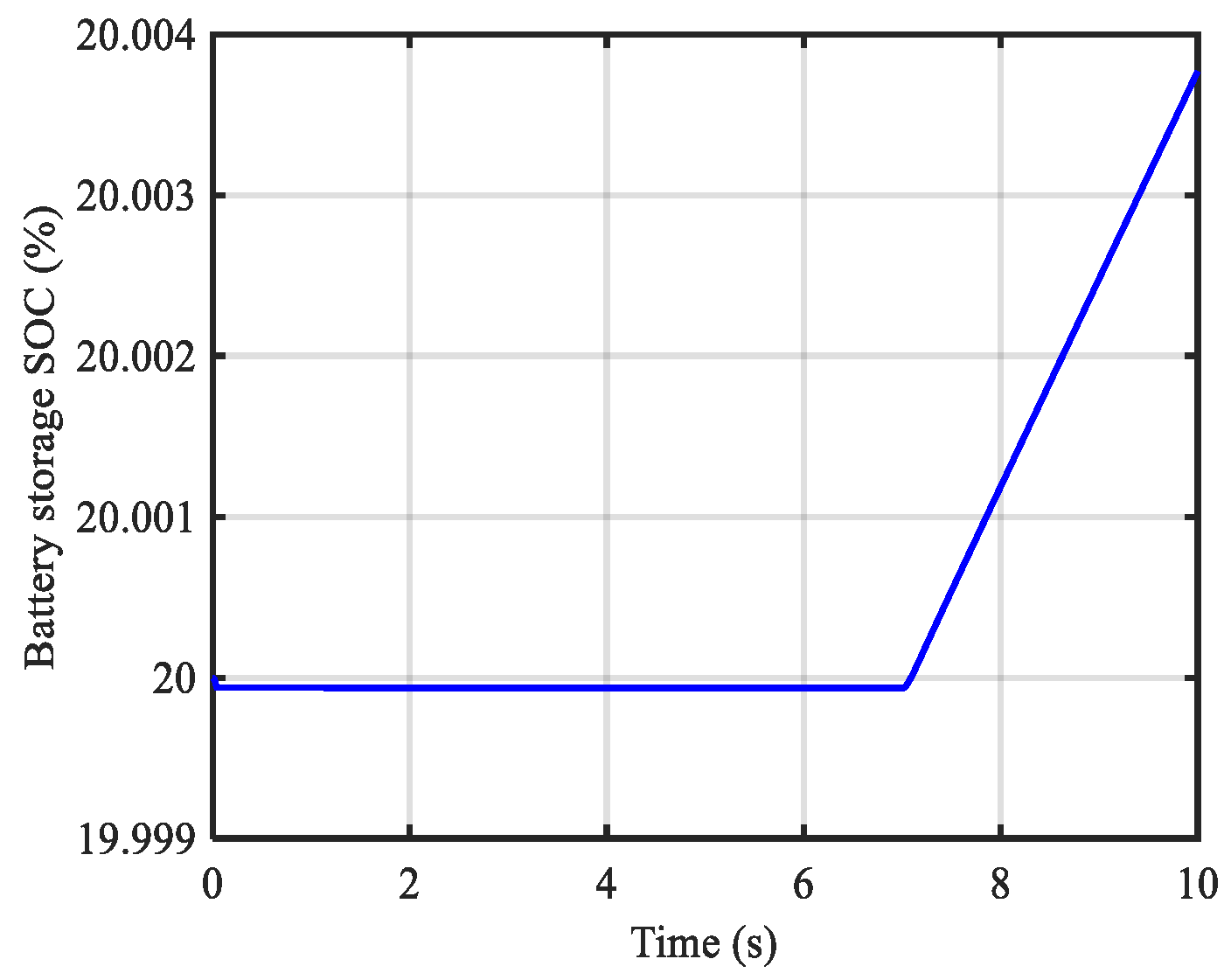

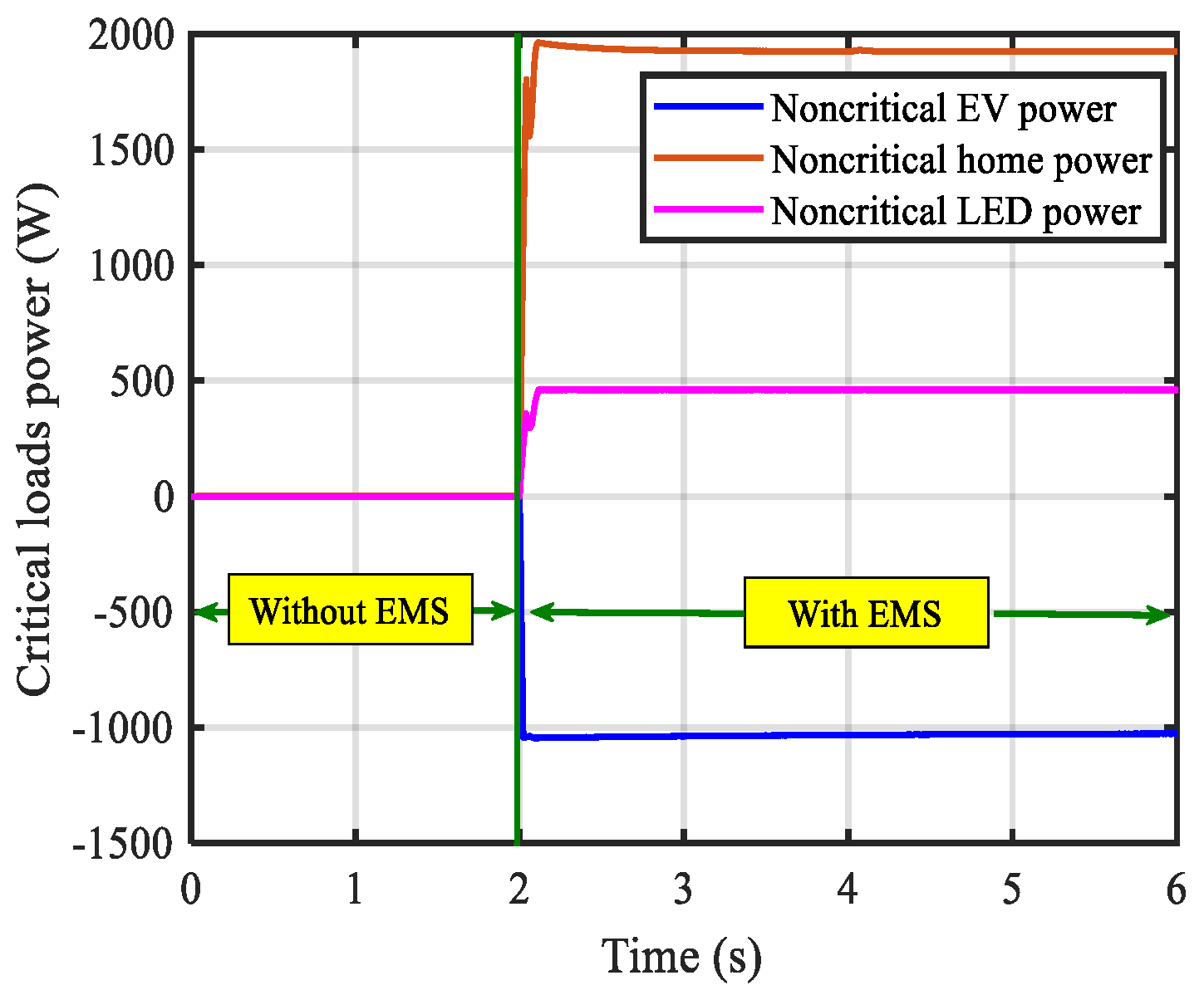

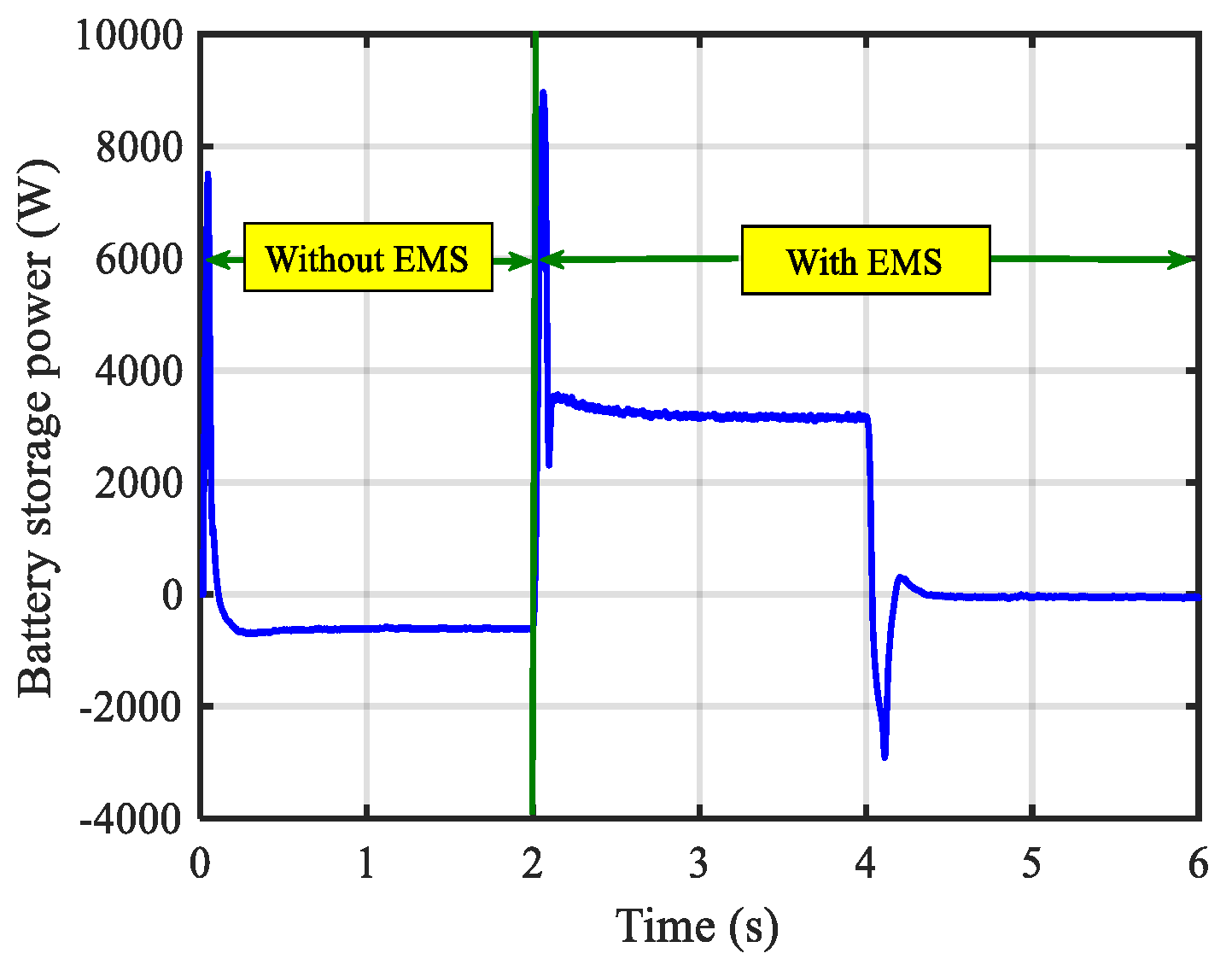

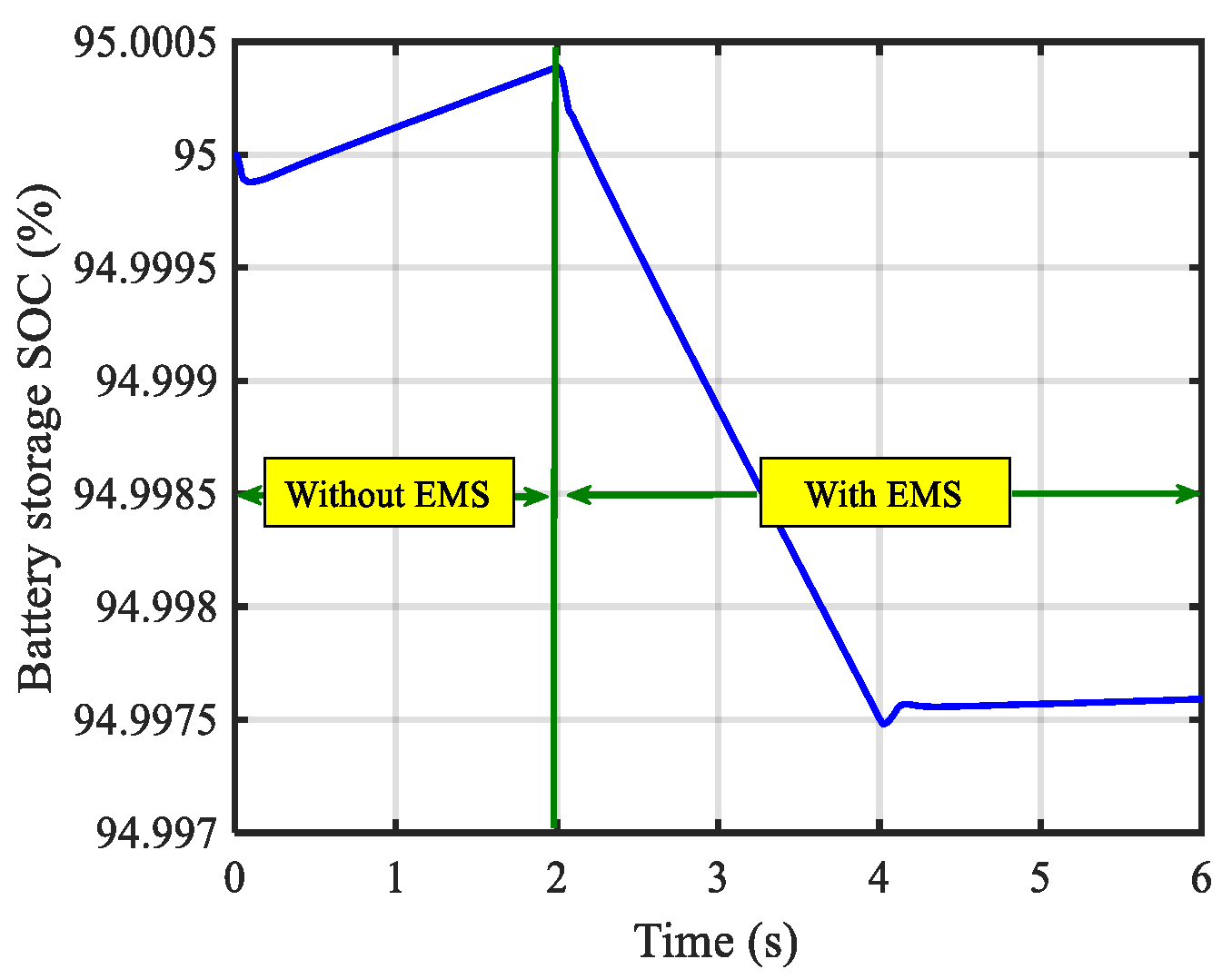

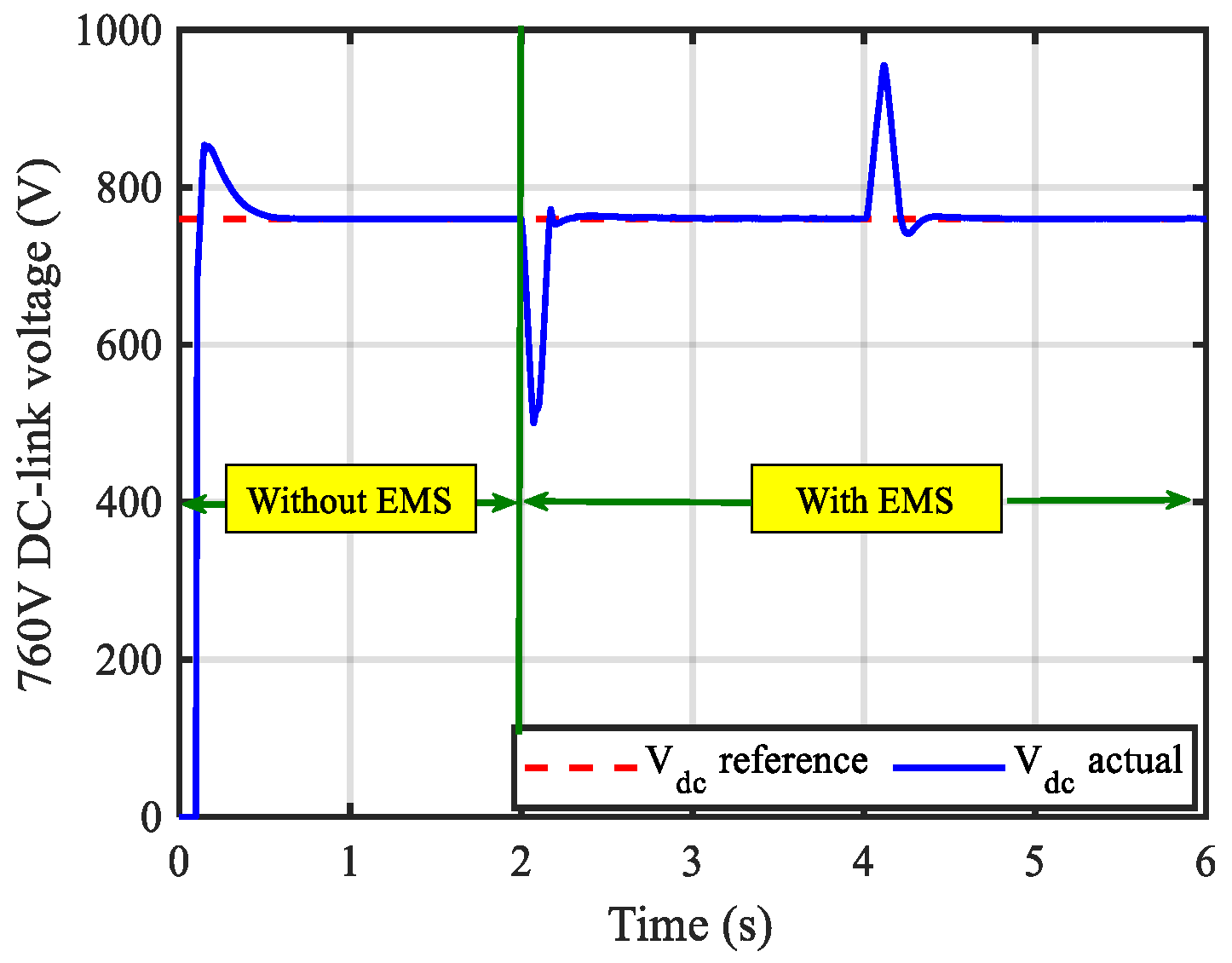

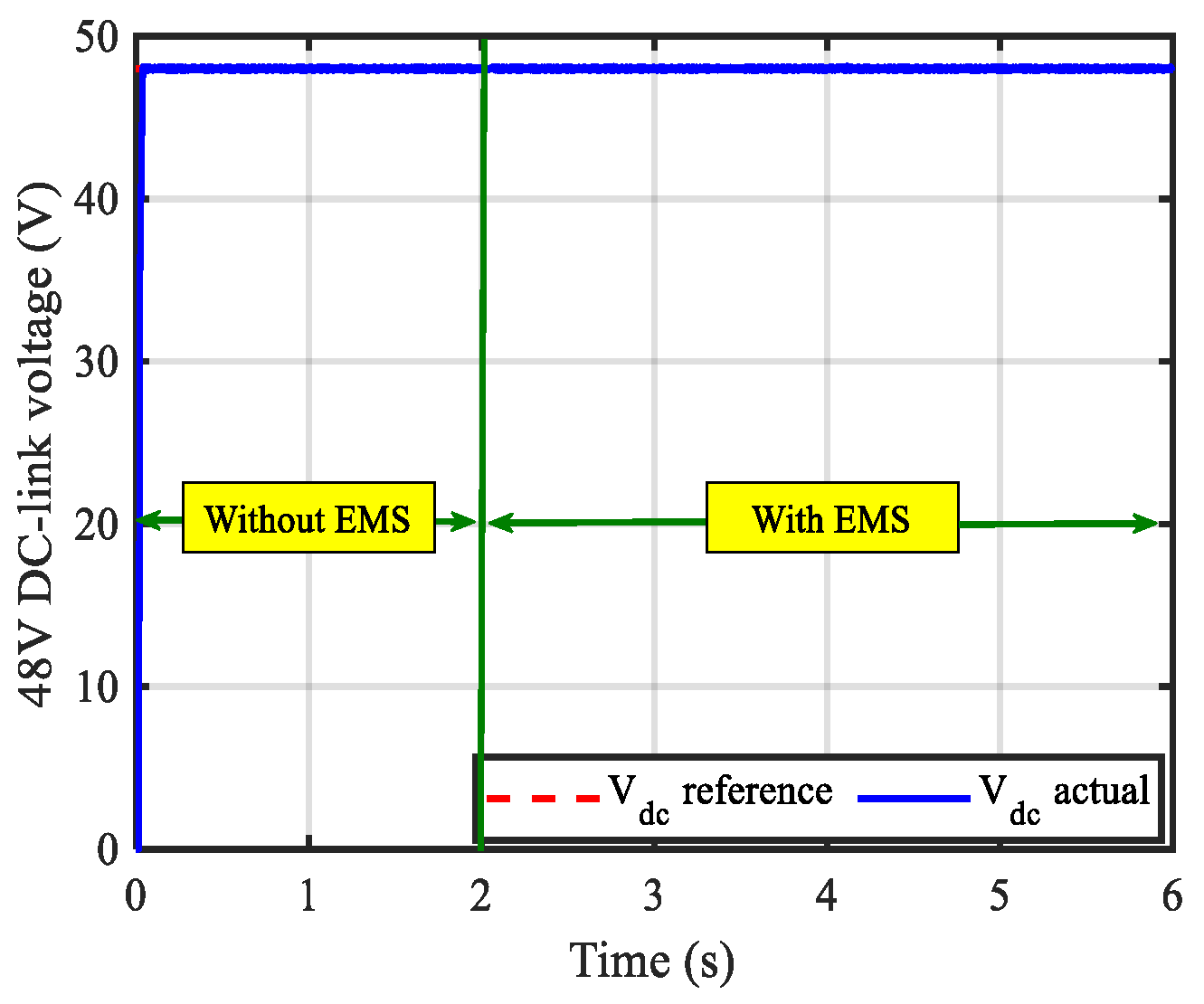

6.4. Effect of the Proposed PEMS

7. Conclusions

- Applying sliding mode control techniques for regulating the DC bus voltage.

- Using different topologies of the DC-DC converters to achieve higher boosting or lower bucking compared to the traditional DC-DC converter.

- Adopting an AI technique for maximum power extraction from both PV and wind generating systems.

- Extending the system by adding AC loads.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| DFE | Diode front end |

| EMS | Energy management strategy |

| HESs | Hybrid energy systems |

| DC | Direct current |

| FC | Fuel cell |

| AC | Alternating current |

| MG | Microgrid |

| PI | Proportional integral |

| P&O | Perturb and observe |

| PLL | Phase-locked loop |

| PSF | Power signal feedback |

| RERs | Renewable energy resources |

| STC | Standard test conditions |

| TSR | Tip-speed ratio |

| VSI | Voltage source inverter |

| WS | Wind system |

| WT | Wind turbines |

| PV | Photovoltaic |

| SOC | State of charge |

| BES | Battery energy system |

| Abbreviations | |

| PWT | Wind power |

| A | Swept area |

| ρ | Air density |

| VWT | Wind speed |

| VC-in | Cut in wind speed |

| VR | Rated wind speed |

| VC-off | Cut off wind speed |

| R | Blade radius |

| ηWT | Wind turbine efficiency |

| TWT | Wind turbine torque |

| ωWT | Angular wind speed |

| λ | Tip-speed ratio |

| Cp | Wind power coefficient |

| Te | Generator torque |

| B | Generator friction |

| J | Moment of inertia |

| TPV | PV actual temperature |

| Tair | PV ambient temperature |

| TPV, STC | PV temperature at STC |

| TNOCT | PV operating temperature at nominal |

| GT | PV average hourly solar radiation at the working temperature |

| GT,STC | Solar radiation (SR) at STC (1 kW/m2) |

| EBS | Energy collected in the BS |

| NBS | Number of the BS |

| VBS | BS’ voltage in volts |

| CBS | BS’ rated capacity in Ahr |

| Pconv | power of PPC size in kW |

| ηDFE | efficiency of the DFE |

| ηB | efficiency of the boost converter |

| Lf | filter inductance |

| Rf | filter resistance |

| ωG | grid angular frequency |

Appendix A

| Parameters | Amount |

|---|---|

| Rated speed | 12 m/s |

| Rated power | 20 kW |

| Rated torque | 905 Nm |

| Radius | 2.5 m |

| Inertia | 0.2 kg·m2 |

| Stator resistance | 0.1764 Ω |

| Stator inductance | 4.48 mH |

| Parameters | Amount |

|---|---|

| Rated power | 305 W |

| Short circuits current | 5.96 A |

| Open circuits voltage | 64.2 V |

| Temperature coefficient | −0.386% |

| Capital cost | 1000 $/kW |

| Lifetime | 25 years |

References

- Ranjan, M.; Shankar, R. A literature survey on load frequency control considering renewable energy integration in power system: Recent trends and future prospects. J. Energy Storage 2022, 45, 103717. [Google Scholar] [CrossRef]

- Coban, H.H.; Rehman, A.; Mousa, M. Load Frequency Control of Microgrid System by Battery and Pumped-Hydro Energy Storage. Water 2022, 14, 1818. [Google Scholar] [CrossRef]

- Ali, S.; Zheng, Z.; Aillerie, M.; Sawicki, J.-P.; Péra, M.-C.; Hissel, D. A Review of DC Microgrid Energy Management Systems Dedicated to Residential Applications. Energies 2021, 14, 4308. [Google Scholar] [CrossRef]

- Faisal, M.; Hannan, M.A.; Ker, P.J.; Hussain, A.; Mansor, M.B.; Blaabjerg, F. Review of Energy Storage System Technologies in Microgrid Applications: Issues and Challenges. IEEE Access 2018, 6, 35143–35164. [Google Scholar] [CrossRef]

- Thirunavukkarasu, G.S.; Seyedmahmoudian, M.; Jamei, E.; Horan, B.; Mekhilef, S.; Stojcevski, A. Role of optimization techniques in microgrid energy management systems—A review. Energy Strat. Rev. 2022, 43, 100899. [Google Scholar] [CrossRef]

- Nehrir, M.H.; Wang, C.; Strunz, K.; Aki, H.; Ramakumar, R.; Bing, J.; Miao, Z.; Salameh, Z. A Review of Hybrid Renewable/Alternative Energy Systems for Electric Power Generation: Configurations, Control, and Applications. IEEE Trans. Sustain. Energy 2011, 2, 392–403. [Google Scholar] [CrossRef]

- Nejabatkhah, F.; Li, Y.W. Overview of Power Management Strategies of Hybrid AC/DC Microgrid. IEEE Trans. Power Electron. 2015, 30, 7072–7089. [Google Scholar] [CrossRef]

- Jin, C.; Wang, P.; Xiao, J.; Tang, Y.; Choo, F.H. Implementation of Hierarchical Control in DC Microgrids. IEEE Trans. Ind. Electron. 2014, 61, 4032–4042. [Google Scholar] [CrossRef]

- Chen, Y.-K.; Wu, Y.-C.; Song, C.-C.; Chen, Y.-S. Design and Implementation of Energy Management System with Fuzzy Control for DC Microgrid Systems. IEEE Trans. Power Electron. 2013, 28, 1563–1570. [Google Scholar] [CrossRef]

- Ahmed, M.; Kuriry, S.; Shafiullah, M.; Abido, M.A. DC Microgrid Energy Management with Hybrid Energy Storage Systems. In Proceedings of the 2019 23rd International Conference on Mechatronics Technology (ICMT), Salerno, Italy, 23–26 October 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Leskarac, D.; Moghimi, M.; Liu, J.; Water, W.; Lu, J.-W.; Stegen, S. Hybrid AC/DC Microgrid testing facility for energy management in commercial buildings. Energy Build. 2018, 174, 563–578. [Google Scholar] [CrossRef]

- Han, Y.; Chen, W.; Li, Q.; Yang, H.; Zare, F.; Zheng, Y. Two-level energy management strategy for PV-Fuel cell-battery-based DC microgrid. Int. J. Hydrogen Energy 2019, 44, 19395–19404. [Google Scholar] [CrossRef]

- Soliman, M.S.; Belkhier, Y.; Ullah, N.; Achour, A.; Alharbi, Y.M.; Al Alahmadi, A.A.; Abeida, H.; Khraisat, Y.S.H. Supervisory energy management of a hybrid battery/PV/tidal/wind sources integrated in DC-microgrid energy storage system. Energy Rep. 2021, 7, 7728–7740. [Google Scholar] [CrossRef]

- Mosa, M.A.; Ali, A. Energy management system of low voltage dc microgrid using mixed-integer nonlinear programing and a global optimization technique. Electr. Power Syst. Res. 2021, 192, 106971. [Google Scholar] [CrossRef]

- Katiraei, F.; Iravani, M.R. Power Management Strategies for a Microgrid with Multiple Distributed Generation Units. IEEE Trans. Power Syst. 2006, 21, 1821–1831. [Google Scholar] [CrossRef]

- Zakir, M.; Arshad, A.; Sher, H.A.; Lehtonen, M. An Optimal Power Management System Based on Load Demand and Resources Availability for PV Fed DC-Microgrid with Power-Sharing among Multiple Nanogrids. In Proceedings of the 2021 IEEE PES Innovative Smart Grid Technologies Europe (ISGT Europe), Espoo, Finland, 18–21 October 2021; pp. 1–5. [Google Scholar] [CrossRef]

- Xia, Y.; Wei, W.; Yu, M.; Wang, X.; Peng, Y. Power Management for a Hybrid AC/DC Microgrid with Multiple Subgrids. IEEE Trans. Power Electron. 2018, 33, 3520–3533. [Google Scholar] [CrossRef]

- Ali, S.U.; Waqar, A.; Aamir, M.; Qaisar, S.M.; Iqbal, J. Model Predictive Control of Consensus-Based Energy Management System for DC Microgrid. PLoS ONE 2023, 18, e0278110. [Google Scholar] [CrossRef]

- Wang, C.; Nehrir, M.H. Power Management of a Stand-Alone Wind/Photovoltaic/Fuel Cell Energy System. IEEE Trans. Energy Convers. 2008, 23, 957–967. [Google Scholar] [CrossRef]

- Zhang, X.; Huang, C.; Shen, J. Energy Optimal Management of Microgrid With High Photovoltaic Penetration. IEEE Trans. Ind. Appl. 2022, 59, 128–137. [Google Scholar] [CrossRef]

- Perez-Flores, A.C.; Antonio, J.D.M.; Olivares-Peregrino, V.H.; Jimenez-Grajales, H.R.; Claudio-Sanchez, A.; Ramirez, G.V.G. Microgrid Energy Management with Asynchronous Decentralized Particle Swarm Optimization. IEEE Access 2021, 9, 69588–69600. [Google Scholar] [CrossRef]

- Thirugnanam, K.; Kerk, S.K.; Yuen, C.; Liu, N.; Zhang, M. Energy Management for Renewable Microgrid in Reducing Diesel Generators Usage With Multiple Types of Battery. IEEE Trans. Ind. Electron. 2018, 65, 6772–6786. [Google Scholar] [CrossRef]

- Solanki, B.V.; Bhattacharya, K.; Canizares, C.A. A Sustainable Energy Management System for Isolated Microgrids. IEEE Trans. Sustain. Energy 2017, 8, 1507–1517. [Google Scholar] [CrossRef]

- Yu, J.; Dou, C.; Li, X. MAS-Based Energy Management Strategies for a Hybrid Energy Generation System. IEEE Trans. Ind. Electron. 2016, 63, 3756–3764. [Google Scholar] [CrossRef]

- Ma, J.; Geng, G.; Jiang, Q. Two-Time-Scale Coordinated Energy Management for Medium-Voltage DC Systems. IEEE Trans. Power Syst. 2016, 31, 3971–3983. [Google Scholar] [CrossRef]

- Samuel, O.; Javaid, N.; Khalid, A.; Khan, W.Z.; Aalsalem, M.Y.; Afzal, M.K.; Kim, B.-S. Towards Real-Time Energy Management of Multi-Microgrid Using a Deep Convolution Neural Network and Cooperative Game Approach. IEEE Access 2020, 8, 161377–161395. [Google Scholar] [CrossRef]

- Xu, Y.; Shen, X. Optimal Control Based Energy Management of Multiple Energy Storage Systems in a Microgrid. IEEE Access 2018, 6, 32925–32934. [Google Scholar] [CrossRef]

- Hussain, S.; El-Bayeh, C.Z.; Lai, C.; Eicker, U. Multi-Level Energy Management Systems Toward a Smarter Grid: A Review. IEEE Access 2021, 9, 71994–72016. [Google Scholar] [CrossRef]

- Xiao, J.; Wang, P.; Setyawan, L.; Xu, Q. Multi-Level Energy Management System for Real-Time Scheduling of DC Microgrids With Multiple Slack Terminals. IEEE Trans. Energy Convers. 2016, 31, 392–400. [Google Scholar] [CrossRef]

- Eddy, Y.S.F.; Gooi, H.B.; Chen, S.X. Multi-Agent System for Distributed Management of Microgrids. IEEE Trans. Power Syst. 2015, 30, 24–34. [Google Scholar] [CrossRef]

- Mao, M.; Jin, P.; Hatziargyriou, N.; Chang, L. Multiagent-Based Hybrid Energy Management System for Microgrids. IEEE Trans. Sustain. Energy 2014, 5, 938–946. [Google Scholar] [CrossRef]

- Nunna, H.S.V.S.K.; Doolla, S. Energy Management in Microgrids Using Demand Response and Distributed Storage—A Multiagent Approach. IEEE Trans. Power Deliv. 2013, 28, 939–947. [Google Scholar] [CrossRef]

- Lagorse, J.; Simoes, M.G.; Miraoui, A. A Multiagent Fuzzy-Logic-Based Energy Management of Hybrid Systems. IEEE Trans. Ind. Appl. 2009, 45, 2123–2129. [Google Scholar] [CrossRef]

- Wang, H.; Tian, J.; Yan, J.; Wang, F.; Zhuo, F. Definition and influencing factors of power quality in DC microgrids. In Proceedings of the 2021 IEEE 4th International Electrical and Energy Conference (CIEEC), Wuhan, China, 28–30 May 2021; pp. 1–5. [Google Scholar] [CrossRef]

- Jithin, K.; Haridev, P.P.; Mayadevi, N.; Kumar, R.H.; Mini, V.P. A Review on Challenges in DC Microgrid Planning and Implementation. J. Mod. Power Syst. Clean Energy 2022, 1–21. [Google Scholar] [CrossRef]

- Mahmood, H.; Michaelson, D.; Jiang, J. A Power Management Strategy for PV/Battery Hybrid Systems in Islanded Microgrids. IEEE J. Emerg. Sel. Top. Power Electron. 2014, 2, 870–882. [Google Scholar] [CrossRef]

- Mehrizi-Sani, A. Chapter 2—Distributed Control Techniques in Microgrids. In Microgrid: Advanced Control Methods and Renewable Energy System Integration; Mahmoud, M.S., Ed.; Butterworth-Heinemann: Oxford, UK, 2017; pp. 43–62. [Google Scholar]

- Alidrissi, Y.; Ouladsine, R.; Elmouatamid, A.; Bakhouya, M. An Energy Management Strategy for DC Microgrids with PV/Battery Systems. J. Electr. Eng. Technol. 2021, 16, 1285–1296. [Google Scholar] [CrossRef]

- Zhang, R.; Hredzak, B.; Morstyn, T. Distributed Control with Virtual Capacitance for the Voltage Restorations, State of Charge Balancing, and Load Allocations of Heterogeneous Energy Storages in a DC Datacenter Microgrid. IEEE Trans. Energy Convers. 2019, 34, 1296–1308. [Google Scholar] [CrossRef]

- Belal, E.K.; Yehia, D.M.; Azmy, A.M. Adaptive Droop Control for Balancing SOC of Distributed Batteries in DC Microgrids. IET Gener. Transm. Distrib. 2019, 13, 4667–4676. [Google Scholar] [CrossRef]

- Alam, S.; Al-Ismail, F.S.; Al-Sulaiman, F.A.; Abido, M.A. Energy management in DC microgrid with an efficient voltage compensation mechanism. Electr. Power Syst. Res. 2023, 214, 108842. [Google Scholar] [CrossRef]

- Available online: https://windenergysolutions.nl/ (accessed on 3 July 2023).

- Zhang, W.; Maleki, A.; Rosen, M.A. A heuristic-based approach for optimizing a small independent solar and wind hybrid power scheme incorporating load forecasting. J. Clean. Prod. 2019, 241, 117920. [Google Scholar] [CrossRef]

- Elmorshedy, M.F.; Allam, S.M.; Shobair, A.I.A.; Rashad, E.E. Voltage and frequency control of a stand-alone wind-energy conversion system based on PMSG. In Proceedings of the 2015 4th International Conference on Electric Power and Energy Conversion Systems (EPECS), Sharjah, United Arab Emirates, 24–26 November 2015. [Google Scholar] [CrossRef]

- Elmorshedy, M.F.; Habib, H.U.R.; Ali, M.M.; Sathik, M.J.; Almakhles, D.J. Improved Performance of Hybrid PV and Wind Generating System Connected to the Grid Using Finite-Set Model Predictive Control. IEEE Access 2022, 10, 110344–110361. [Google Scholar] [CrossRef]

- Available online: https://us.sunpower.com/ (accessed on 3 July 2023).

- Maleki, A.; Hafeznia, H.; Rosen, M.A.; Pourfayaz, F. Optimization of a grid-connected hybrid solar-wind-hydrogen CHP system for residential applications by efficient metaheuristic approaches. Appl. Therm. Eng. 2017, 123, 1263–1277. [Google Scholar] [CrossRef]

- Kotb, K.M.; Elmorshedy, M.F.; Salama, H.S.; Dán, A. Enriching the stability of solar/wind DC microgrids using battery and superconducting magnetic energy storage based fuzzy logic control. J. Energy Storage 2022, 45, 103751. [Google Scholar] [CrossRef]

- Chauhan, A.; Saini, R. Discrete harmony search based size optimization of Integrated Renewable Energy System for remote rural areas of Uttarakhand state in India. Renew. Energy 2016, 94, 587–604. [Google Scholar] [CrossRef]

- Schubert, E.F. Light-Emitting Diodes, 2nd ed.; Cambridge University Press: Cambridge, UK, 2006. [Google Scholar]

- Haitz, R. Another Semiconductor Revolution: This Time It’s Lighting! In Advances in Solid State Physics; Kramer, B., Ed.; Springer: Berlin/Heidelberg, Germany, 2003; pp. 35–50. [Google Scholar]

- Narendran, N.; Gu, Y. Life of LED-based white light sources. J. Disp. Technol. 2005, 1, 167–171. [Google Scholar] [CrossRef]

- Wang, Y.; Alonso, J.M.; Ruan, X. A Review of LED Drivers and Related Technologies. IEEE Trans. Ind. Electron. 2017, 64, 5754–5765. [Google Scholar] [CrossRef]

- Zhang, J.; Jiang, T.; Wu, X. A High-Efficiency Quasi-Two-Stage LED Driver With Multichannel Outputs. IEEE Trans. Ind. Electron. 2017, 64, 5875–5882. [Google Scholar] [CrossRef]

- Qiu, D.; Liao, M.; Liao, Z.; Chen, Z.; Zhang, S. Compact modeling of electrical LED module for analysis of LED driver system. Optik 2018, 170, 548–554. [Google Scholar] [CrossRef]

- Dahiru, A.T.; Tan, C.W. Optimal sizing and techno-economic analysis of grid-connected nanogrid for tropical climates of the Savannah. Sustain. Cities Soc. 2020, 52, 101824. [Google Scholar] [CrossRef]

- Masoum, M.A.S.; Dehbonei, H.; Fuchs, E.F. Theoretical and experimental analyses of photovoltaic systems with voltageand current-based maximum power-point tracking. IEEE Trans. Energy Convers. 2002, 17, 514–522. [Google Scholar] [CrossRef] [Green Version]

- Bendib, B.; Belmili, H.; Krim, F. A survey of the most used MPPT methods: Conventional and advanced algorithms applied for photovoltaic systems. Renew. Sustain. Energy Rev. 2015, 45, 637–648. [Google Scholar] [CrossRef]

- Yilmaz, U.; Turksoy, O.; Teke, A. Improved MPPT method to increase accuracy and speed in photovoltaic systems under variable atmospheric conditions. Int. J. Electr. Power Energy Syst. 2019, 113, 634–651. [Google Scholar] [CrossRef]

- Safari, A.; Mekhilef, S. Simulation and Hardware Implementation of Incremental Conductance MPPT With Direct Control Method Using Cuk Converter. IEEE Trans. Ind. Electron. 2011, 58, 1154–1161. [Google Scholar] [CrossRef]

- Muyeen, S.M.; Al-Durra, A.; Tamura, J. Variable speed wind turbine generator system with current controlled voltage source inverter. Energy Convers. Manag. 2011, 52, 2688–2694. [Google Scholar] [CrossRef] [Green Version]

- Dahbi, A.; Nait-Said, N.; Nait-Said, M.-S. A novel combined MPPT-pitch angle control for wide range variable speed wind turbine based on neural network. Int. J. Hydrogen Energy 2016, 41, 9427–9442. [Google Scholar] [CrossRef]

- Karabacak, M. A new perturb and observe based higher order sliding mode MPPT control of wind turbines eliminating the rotor inertial effect. Renew. Energy 2019, 133, 807–827. [Google Scholar] [CrossRef]

- Fathabadi, H. Maximum mechanical power extraction from wind turbines using novel proposed high accuracy single-sensor-based maximum power point tracking technique. Energy 2016, 113, 1219–1230. [Google Scholar] [CrossRef]

- ELmorshedy, M.F.; Allam, S.M.; Rashad, E.M. Load voltage control and maximum power extraction of a stand-alone wind-driven PMSG including unbalanced operating conditions. In Proceedings of the 2016 Eighteenth International Middle East Power Systems Conference (MEPCON), Cairo, Egypt, 27–29 December 2016; pp. 552–559. [Google Scholar] [CrossRef]

- Allam, S.M.; Elmorshedy, M.F.; Rashad, E.M. Load power and state-of-charge management strategy with MPPT of wind-driven isolated PMSG. In Proceedings of the 2016 XXII International Conference on Electrical Machines (ICEM), Lausanne, Switzerland, 4–7 September 2016. [Google Scholar] [CrossRef]

- Liang, Y.; He, Y.; Niu, Y. Robust Errorless-Control-Targeted Technique Based on MPC for Microgrid with Uncertain Electric Vehicle Energy Storage Systems. Energies 2022, 15, 1398. [Google Scholar] [CrossRef]

- Moussa, S.; Ghorbal, M.J.B.; Slama-Belkhodja, I. Bus voltage level choice for standalone residential DC nanogrid. Sustain. Cities Soc. 2019, 46, 101431. [Google Scholar] [CrossRef]

- Manavalan, G.; Tania, H.M.; Patra, J.K.; Poongothai, M.G.; Prema, S. A closed loop system to stabilize a 24V solar DC Nano grid. In Proceedings of the 2017 International Conference on Smart grids, Power and Advanced Control Engineering (ICSPACE), Bangalore, India, 17–19 August 2017; pp. 177–182. [Google Scholar] [CrossRef]

- Noritake, M.; Yuasa, K.; Takeda, T.; Shimomachi, K.; Hara, R.; Kita, H.; Matsumura, T. Experimental study of a 400 V class DC microgrid for commercial buildings. In Proceedings of the 2015 9th International Conference on Power Electronics and ECCE Asia (ICPE-ECCE Asia), Seoul, Korea, 1–5 June 2015; pp. 1730–1735. [Google Scholar] [CrossRef]

- Lin, X.; Xue, Y.; Song, C.; Song, S.; Bin, L. An experiment and research platform for DC micro-grid. In Proceedings of the 2016 35th Chinese Control Conference (CCC), Chengdu, China, 27–29 July 2016; pp. 8588–8595. [Google Scholar] [CrossRef]

- Poorfakhraei, A.; Narimani, M.; Emadi, A. A review of multilevel inverter topologies in electric vehicles: Current status and future trends. IEEE Open J. Power Electron. 2021, 2, 155–170. [Google Scholar] [CrossRef]

- Saudi Standards SASO 2879; Technical Regulation for Degradable Plastic Products. Metrology and Quality Organization SASO: Riyadh, Saudi Arabia, 2021.

- Muthuvel, P.; Daniel, S.A.; Yazhini, D. Retrofitting domestic appliances for PV powered DC Nano-grid and its impact on net zero energy homes in rural India. Eng. Sci. Technol. Int. J. 2016, 19, 1836–1844. [Google Scholar] [CrossRef] [Green Version]

- Joseph, S.C.; Ashok, S.; Dhanesh, P.R. Low voltage direct current (LVDC) nanogrid for home application. In Proceedings of the 2017 IEEE Region 10 Symposium (TENSYMP), Cochin, India, 14–16 July 2017; pp. 1–5. [Google Scholar] [CrossRef]

- Bogno, B.; Sawicki, J.-P.; Petit, P.; Aillerie, M.; Charles, J.-P.; Hamandjoda, O.; Beda, T. 230 VDC elementary block in off-grid PV systems. Sustain. Energy Technol. Assess. 2018, 29, 1–11. [Google Scholar] [CrossRef]

- Sabry, A.H.; Shallal, A.H.; Hameed, H.S.; Ker, P.J. Compatibility of household appliances with DC microgrid for PV systems. Heliyon 2020, 6, e05699. [Google Scholar] [CrossRef] [PubMed]

- Al Alahmadi, A.A.; Belkhier, Y.; Ullah, N.; Abeida, H.; Soliman, M.S.; Khraisat, Y.S.H.; Alharbi, Y.M. Hybrid wind/PV/battery energy management-based intelligent non-integer control for smart DC-microgrid of smart university. IEEE Access 2021, 9, 98948–98961. [Google Scholar] [CrossRef]

- Abadi, S.A.G.K.; Habibi, S.I.; Khalili, T.; Bidram, A. A Model Predictive Control Strategy for Performance Improvement of Hybrid Energy Storage Systems in DC Microgrids. IEEE Access 2022, 10, 25400–25421. [Google Scholar] [CrossRef]

- Qais, M.; Loo, K.H.; Hasanien, H.M. Optimal Comfortable Load Schedule for Home Energy Management Including Photovoltaic and Battery Systems sustainability Optimal Comfortable Load Schedule for Home Energy Management Including Photovoltaic and Battery Systems. Sustainability 2023, 15, 9193. [Google Scholar] [CrossRef]

- Rodriguez-Estrada, H.; Rodriguez-Segura, E.; Orosco-Guerrero, R.; Gordillo-Tapia, C.; Martínez-Nolasco, J. Novel Multibus Multivoltage Concept for DC-Microgrids in Buildings: Modeling, Design and Local Control. Appl. Sci. 2023, 13, 2405. [Google Scholar] [CrossRef]

- Kamran, M.; Bilal, M.; Mudassar, M. DC Home Appliances for DC Distribution System. Mehran Univ. Res. J. Eng. Technol. 2017, 36, 881–890. [Google Scholar] [CrossRef]

- Lucia, O.; Cvetkovic, I.; Boroyevich, D.; Mattavelli, P.; Lee, F.C. Design of household appliances for a Dc-based nanogrid system: An induction heating cooktop study case. In Proceedings of the 2013 Twenty-Eighth Annual IEEE Applied Power Electronics Conference and Exposition (APEC), Long Beach, CA, USA, 17–21 March 2013; pp. 1576–1583. [Google Scholar] [CrossRef]

- Sasidharan, N.; Madhu, M.N.; Singh, J.G.; Ongsakul, W. An approach for an efficient hybrid AC/DC solar powered Homegrid system based on the load characteristics of home appliances. Energy Build. 2015, 108, 23–35. [Google Scholar] [CrossRef]

- Elangovan, D.; Archana, R.; Jayadeep, V.J.; Nithin, M.; Arunkumar, G. DC grid for home applications. IOP Conf. Ser. Mater. Sci. Eng. 2017, 263, 052005. [Google Scholar] [CrossRef]

- Dastgeer, F.; Gelani, H.E.; Anees, H.M.; Paracha, Z.J.; Kalam, A. Analyses of efficiency/energy-savings of DC power distribution systems/microgrids: Past, present and future. Int. J. Electr. Power Energy Syst. 2019, 104, 89–100. [Google Scholar] [CrossRef]

- Elmorshedy, M.F.; Algadair, B.S.; Almakhles, D. Model Predictive Control of Two-Tier Converter for Maximum Power Extraction from Photovoltaic System. In Proceedings of the IECON 2022—48th Annual Conference of the IEEE Industrial Electronics Society, Brussels, Belgium, 17–20 October 2022; pp. 1–6. [Google Scholar] [CrossRef]

- Ullah, Q.; Busarello, T.D.C.; Brandao, D.I.; Simões, M.G. Design and Performance Evaluation of SMC-Based DC–DC Converters for Microgrid Applications. Energies 2023, 16, 4212. [Google Scholar] [CrossRef]

| Parameter | Capacity |

|---|---|

| PV system | 20 kW |

| Wind energy conversion system | 6 kW |

| Battery storage system | 300 Ah or 6 kW |

| Critical home appliances | 10 kW |

| Critical electric vehicle | 3 kW |

| Critical LED | 1.5 kW |

| Noncritical home appliances | 6 kW |

| Noncritical electric vehicle | 3 kW |

| Noncritical LED | 1.5 kW |

| Main grid | Infinity |

| Charging Node | Voltage | Time for Recharging | Maximum Charging Power |

|---|---|---|---|

| Mode 1 | 230 V AC | 5 h | 3.7 kVA (3.3 kW) |

| Mode 2 | 400 V AC | 0.5 h | 44 kVA (3.3 kW) |

| Mode 3 | 300–1000 VDC | 6 min | 40–350 kWh |

| Ref. | PV | Wind | Battery | Grid | Different Voltage Levels | DC Electric Vehicles | DC Home Appliances | DC LED | Year |

|---|---|---|---|---|---|---|---|---|---|

| [74] | √ | x | x | x | x | x | √ | x | 2016 |

| [69] | √ | x | x | x | x | x | √ | √ | 2017 |

| [75] | √ | x | √ | x | x | x | √ | √ | 2017 |

| [76] | √ | x | √ | x | x | x | √ | x | 2018 |

| [68] | √ | √ | √ | x | x | x | √ | √ | 2019 |

| [77] | √ | x | √ | √ | x | x | √ | √ | 2020 |

| [13] | √ | √ | √ | x | x | √ | x | x | 2021 |

| [78] | √ | √ | √ | x | x | x | √ | √ | 2021 |

| [14] | √ | √ | √ | √ | x | x | √ | √ | 2021 |

| [48] | √ | √ | √ | x | x | x | x | x | 2022 |

| [79] | √ | x | √ | x | x | x | x | x | 2022 |

| [80] | √ | x | √ | √ | x | √ | x | x | 2023 |

| [81] | √ | x | √ | √ | √ | x | √ | √ | 2023 |

| Proposed system | √ | √ | √ | √ | √ | √ | √ | 2023 |

| Appliance | Rated Voltage | Power Range | ||||

|---|---|---|---|---|---|---|

| 12 V | 24 V | 48 V | 380 V | 760 V | ||

| LED lamp | √ | √ | √ | 3–50 W | ||

| Fan | √ | √ | √ | 3–36 W | ||

| Refrigerator | √ | √ | √ | 40–150 W | ||

| Microwave | √ | 660–1100 W | ||||

| Coffee maker | √ | √ | 900–1200 W | |||

| Computer | √ | √ | 21–300 W | |||

| Television | √ | √ | √ | 65–120 W | ||

| Washing machine | √ | √ | 70–360 W | |||

| Iron | √ | 130–1200 W | ||||

| Rice cooker | √ | √ | 600 W | |||

| Water heater | √ | √ | √ | 1000 W | ||

| Electric kettle | √ | √ | √ | 1500 W | ||

| Air conditioner | √ | √ | 444–1300 W | |||

| Electric vehicle | √ | √ | √ | 3–350 kW | ||

| Ref. | Applications | DC Output Voltages | Remarks | Year |

|---|---|---|---|---|

| [83] | Induction heating cooktop | 380 V | Although the scientists obtained much higher efficiency when the supply voltage was 380 V DC rather than 230 V AC, the study only evaluated induction heating. | 2013 |

| [84] | Lights, chargers | 48 V | Although the authors obtained a considerable reduction in THD when the supply was 48 V DC rather than 220 V AC, the DC appliances in the study were fed via a DC-DC converter. | 2015 |

| [74] | The wet-grinder and the dough-maker for net-zero energy Homes (NZEH). | 5, 48, and 120 V | Two different types of appliances have been modified for improved performance with DC. | 2016 |

| [82] | Air conditioner, microwave oven, DC fan, cloth washer, refrigerator, air cooler, water pump, electronic appliances | 48 V | The use of BLDC (brushless DC) motors is suggested for 48 V DC rotary appliances in place of universal and induction motors, by means of a DC-DC converter. | 2017 |

| [85] | DC fan, mobile charger, laptop, LED light | 48, 5, 19, and 72 V | A DC-DC converter was employed to supply the DC appliances in the study; the authors found that the efficiency was substantially higher when the supply was DC than 240 V AC. | 2018 |

| [86] | Space heating, water heating, space cooling, lighting, refrigeration, electronics, wet cleaning, cooking, computers | 24, 48, 170 and 380 V | Only a summary of recent initiatives in the area of DC power distribution system energy/efficiency. | 2019 |

| [87] | Electronic loads | 200 V | In order to provide a DC load with the necessary voltage values, this work employed a newly built DC-DC converter, the so-called two-tier converter (TTC), in the photovoltaic (PV) system. | 2022 |

| [88] | DC fan, mobile charger, laptop, LED light | 48 V | The modeling and control of non-isolated, non-inverting four-switch buck-boost (FSBB) synchronous converters, which connect to a variety of low-power electronic appliances, are expanded upon in this work. | 2023 |

| [81] | Electronic loads in every office; lighting system of the place; driver LEDs for specific area lighting. | 48, 190, and 380 V | In order to distribute power in DC using a variety of buses at various voltage levels, the multibus functionality has been upgraded. The idea is thought to be validated by a building housing the offices of instructors that also contains a charging station for electric vehicles (EVs). The system uses different topologies of power electronics converters (PECs) to perform particular jobs and provide isolation between bus and end loads. | 2023 |

| Proposed system | DC fan, mobile charger, laptop, LED light, refrigerator, washing machine, fast charger for electric vehicles | 48, 380, and 760 V | The author proposes three different levels of DC voltage to cover all kinds of DC applications. Moreover, the connection of the EV to the high DC bus voltage level for faster charging is proposed. Finally, a power management strategy to supply the critical load and noncritical load is suggested. | 2023 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Elmorshedy, M.F.; Subramaniam, U.; Mohamed Ali, J.S.; Almakhles, D. Energy Management of Hybrid DC Microgrid with Different Levels of DC Bus Voltage for Various Load Types. Energies 2023, 16, 5438. https://doi.org/10.3390/en16145438

Elmorshedy MF, Subramaniam U, Mohamed Ali JS, Almakhles D. Energy Management of Hybrid DC Microgrid with Different Levels of DC Bus Voltage for Various Load Types. Energies. 2023; 16(14):5438. https://doi.org/10.3390/en16145438

Chicago/Turabian StyleElmorshedy, Mahmoud F., Umashankar Subramaniam, Jagabar Sathik Mohamed Ali, and Dhafer Almakhles. 2023. "Energy Management of Hybrid DC Microgrid with Different Levels of DC Bus Voltage for Various Load Types" Energies 16, no. 14: 5438. https://doi.org/10.3390/en16145438