Water Invasion Law and Water Invasion Risk Identification Method for Deep Sea Bottom-Water Gas Reservoir

Abstract

:1. Introduction

2. Geological Characteristics of LS Gas Field

2.1. Reservoir Physical Characteristics

2.2. Water Characteristics

2.3. Development Characteristics

3. Horizontal Well Gas Production Profile Test

3.1. Experimental Purpose

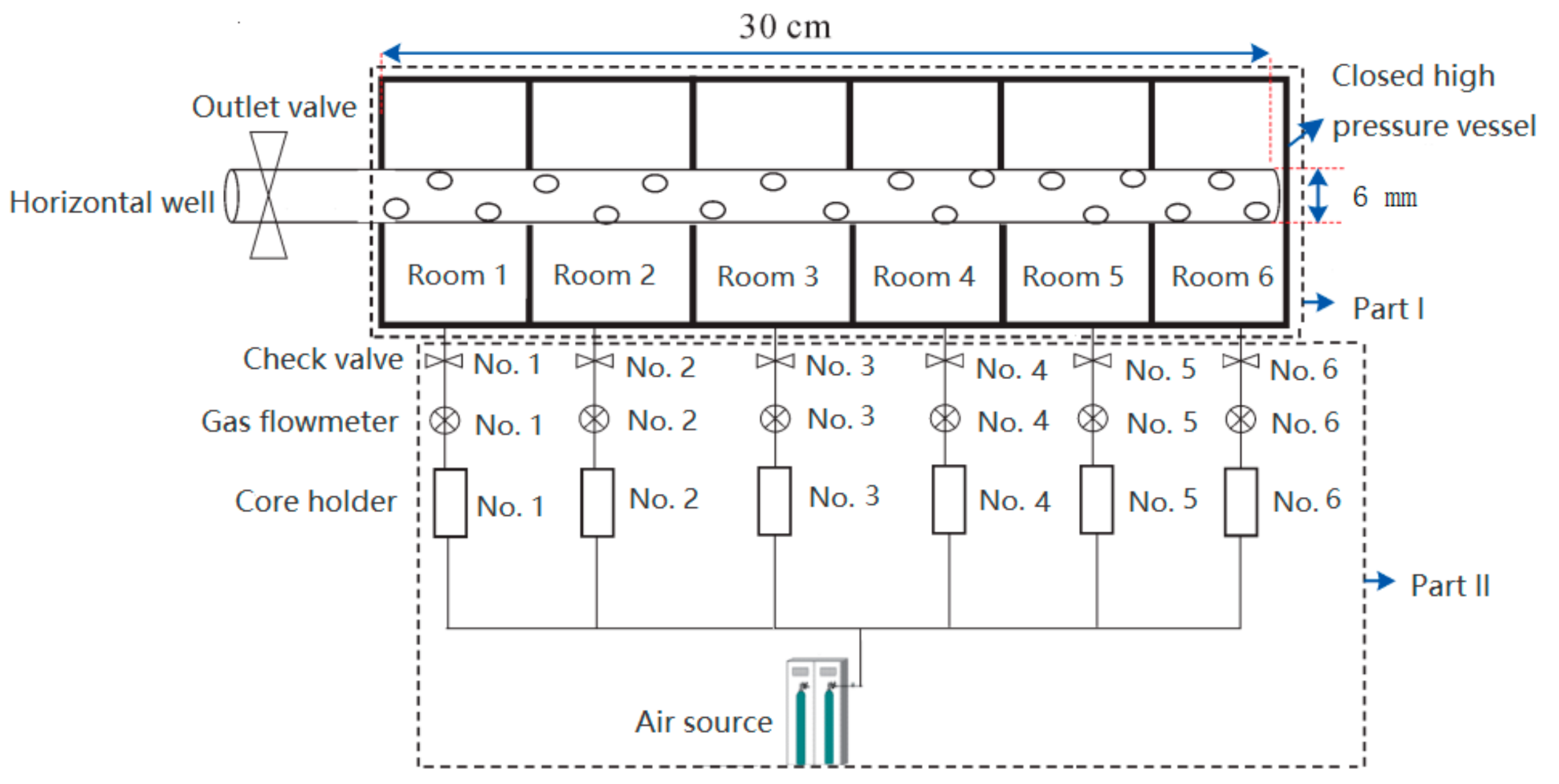

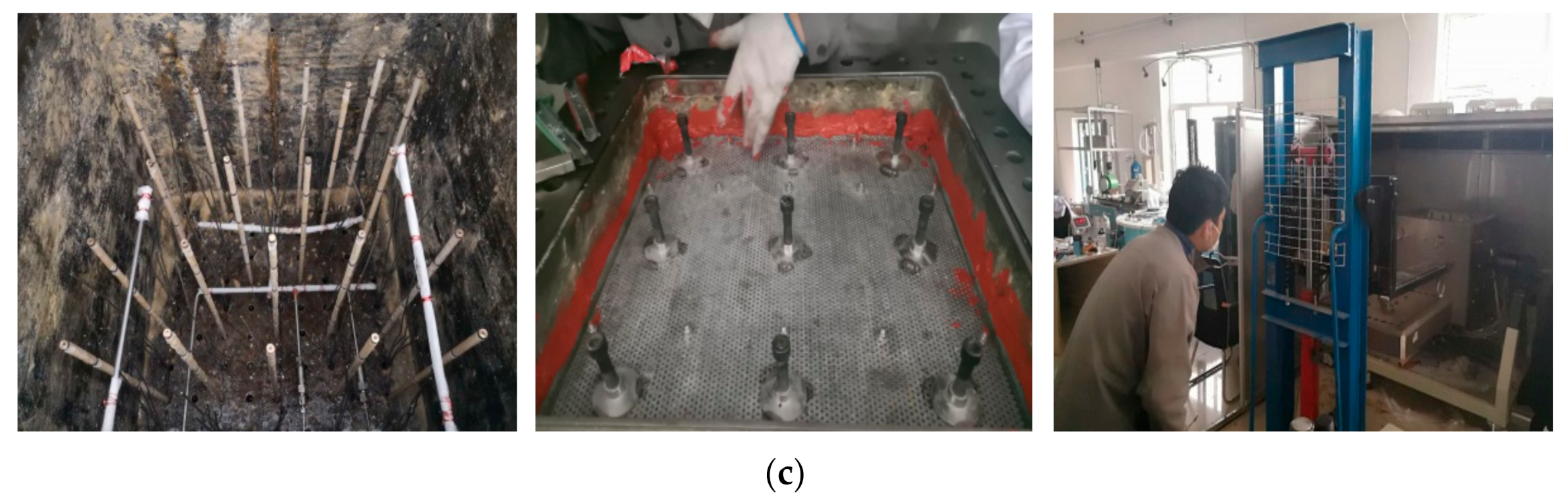

3.2. Experimental Steps and Scheme

3.3. Analysis of Experimental Results

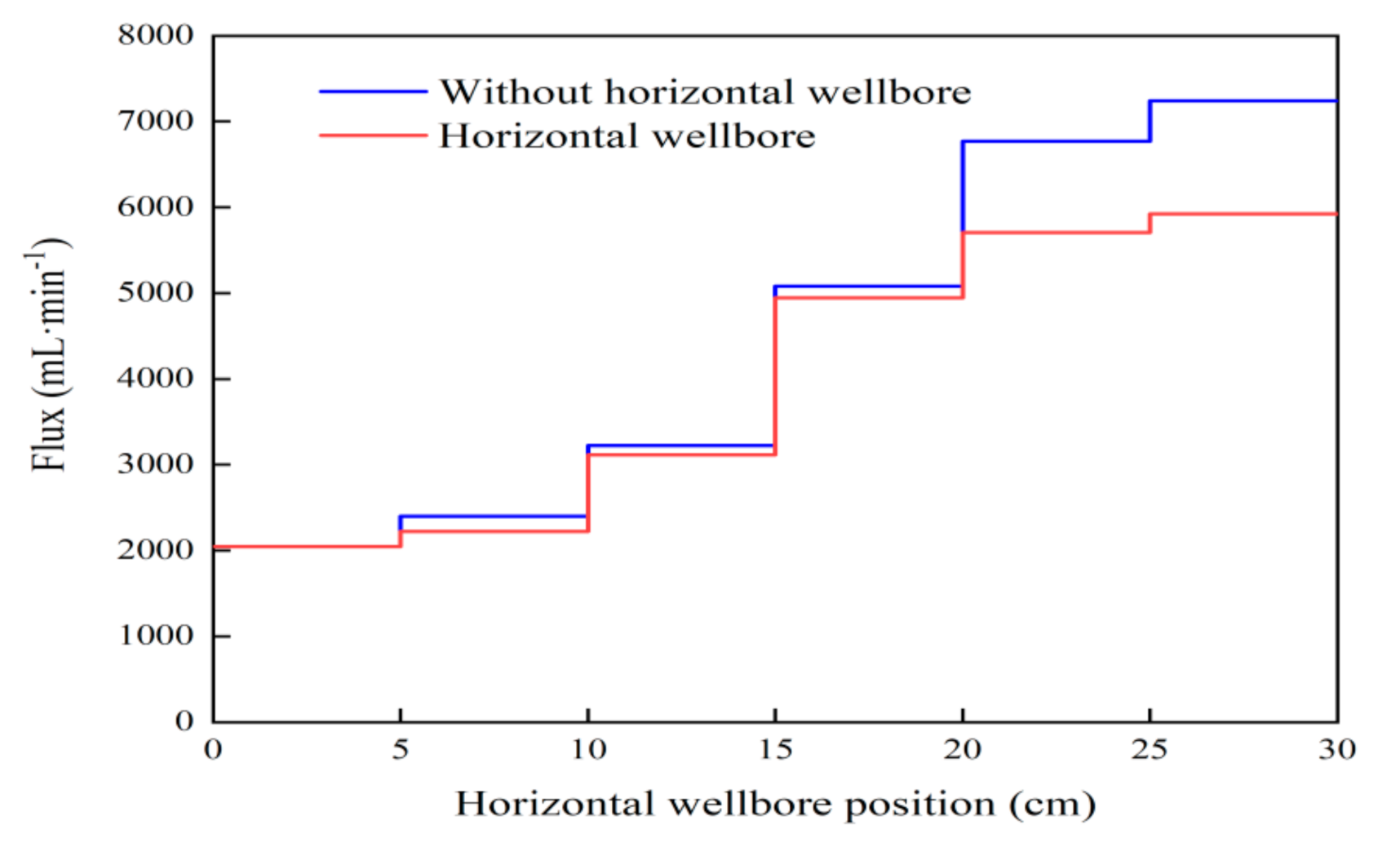

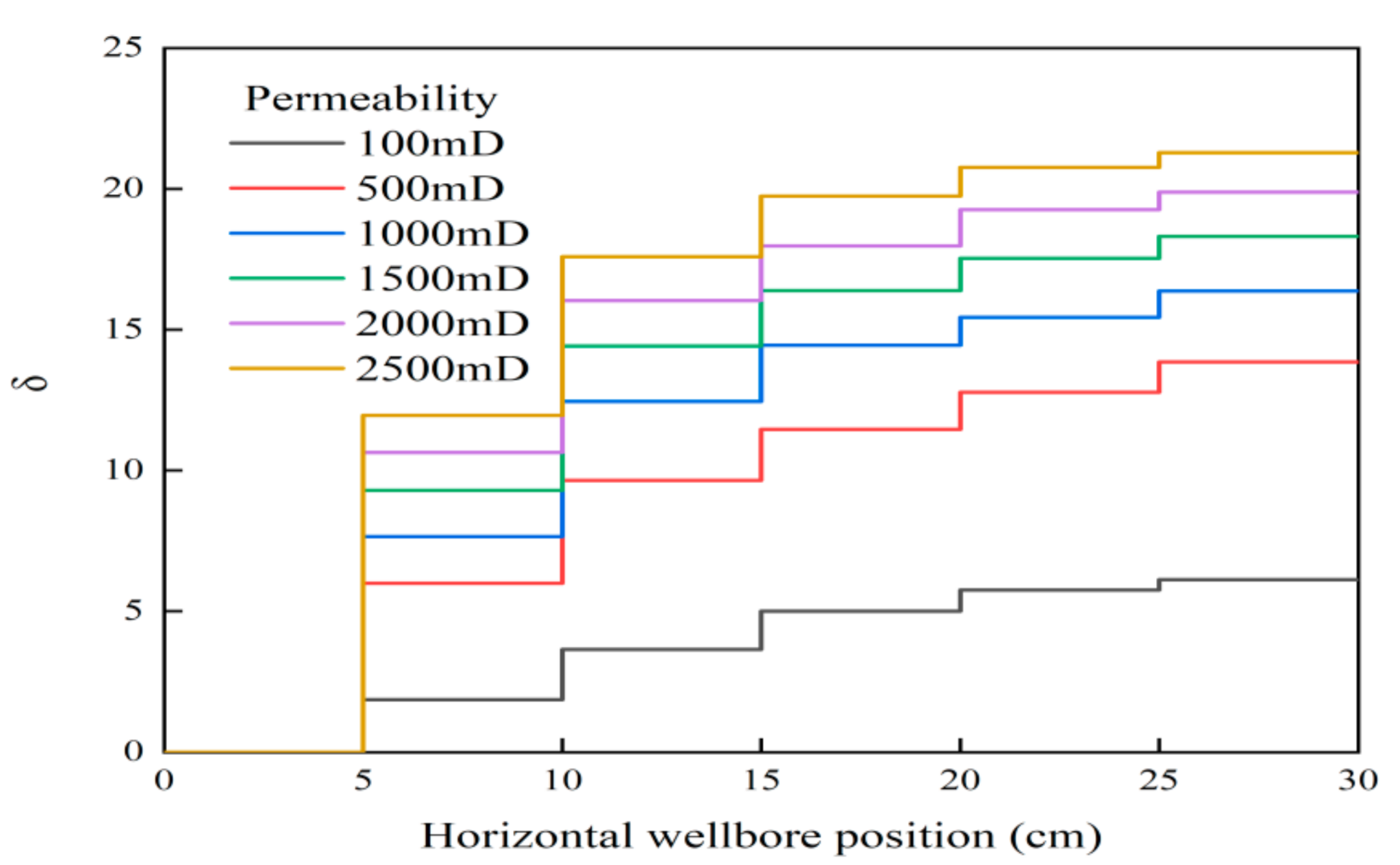

3.3.1. Influence of Reservoir Heterogeneity

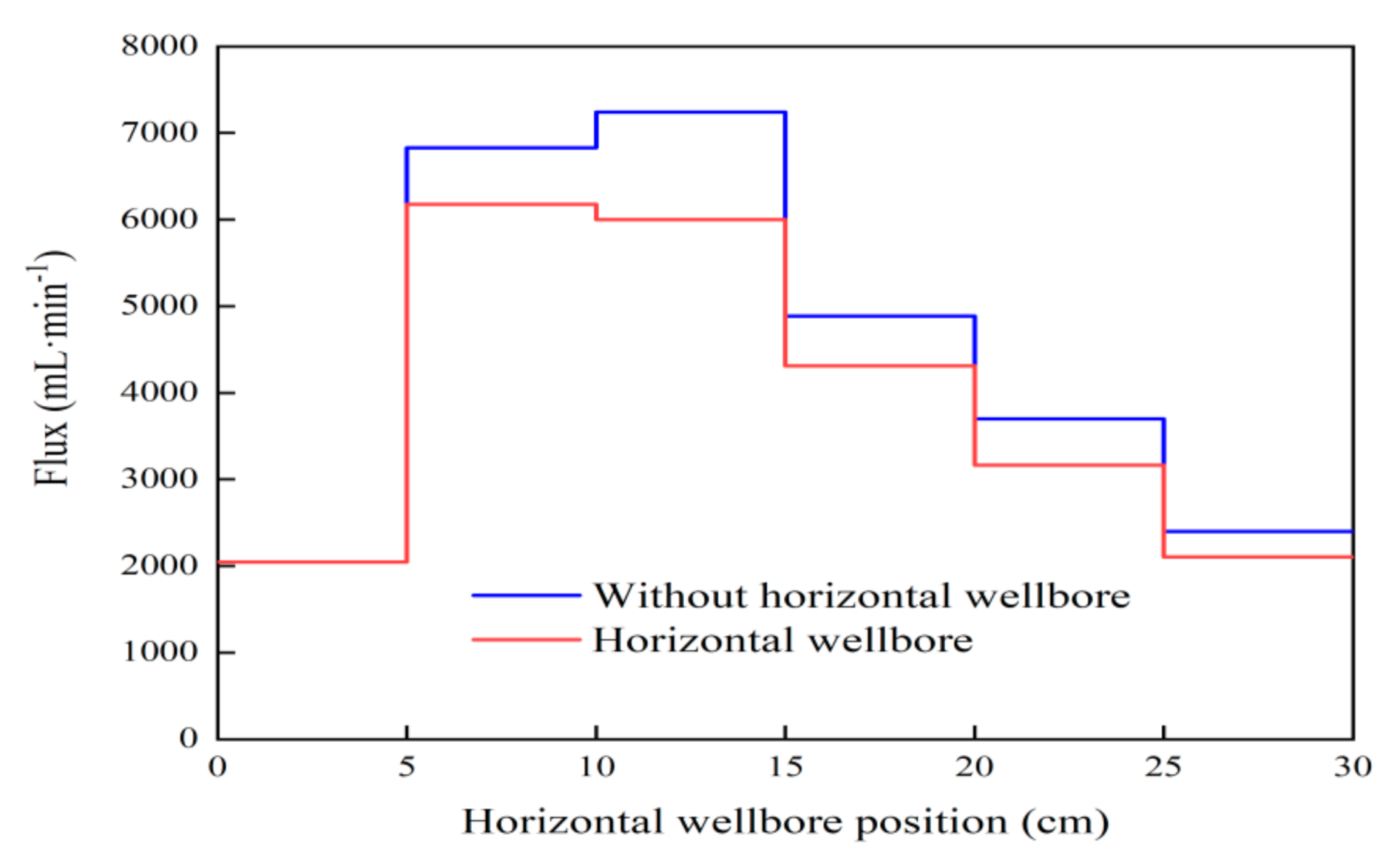

3.3.2. Influence of Heel–Toe Effect

3.3.3. Influence of Production Pressure Difference

3.3.4. Influence of Water Repellent Height

3.4. Discussion of Experimental Results

- (1)

- Reservoir heterogeneity results in small δ, small energy loss, and strong gas flow along the high permeability zone of the wellbore, resulting in a fast bottom-water ridge speed, which is the main seepage channel for water intrusion. Reservoir heterogeneity and uneven distribution of the production pressure profile in the wellbore are the root causes of uneven advances of a bottom-water front between units and in the region. Eliminating heterogeneity and maintaining the pressure balance in the wellbore are at the core of controlling the water body ridge in advance [15,16,17];

- (2)

- The heel–toe effect has a great influence on horizontal wellbore δ. The main reason is that after the wellbore pipe flow of the horizontal well forms a coupled flow with the reservoir seepage, the additional acceleration resistance formed by the radial inflow of the horizontal downhole section increases the flow resistance in the process of the fluid from the upstream section to the downstream, resulting in the heel–toe effect in the development of the horizontal well and the imbalance of the production pressure profile along the wellbore. The funnel-shaped distribution of the pressure gradually decreases from toe to heel [18,19,20];

- (3)

- The unreasonable setting of the production system (production differential pressure) leads to the aggravation of the horizontal well along the wellbore δ, affecting the migration rate of the water ridge interface. The pressure drop rate of the gas layer is greater than the pressure supplement rate of the bottom-water layer, resulting in the increase in the real ridge advance pressure difference between the bottom-water layer and the gas layer and the gradual aggravation of the bottom-water invasion. A reasonable production pressure difference is the key point of controlling the water body ridge;

- (4)

- The effect and impact of water avoidance height on δ along the wellbore is small, but it will have a great impact on the productivity of horizontal wells. For a bottom-water drive gas reservoir, the flow capacity of the gas phase is much stronger than that of the water phase. If the height of avoiding water is insufficient and the water body reaches the horizontal wellbore, a large amount of gas has not been produced on both wings of the gas reservoir, and the water body enters the wellbore, which will seriously affect the productivity of gas wells.

4. Large-Scale 3D Physical Simulation Experiment of Water Invasion in Bottom-Water Gas Reservoir

4.1. Experimental Purpose

4.2. Experimental Methods and Steps

4.3. Experimental Scheme

4.4. Experimental Results

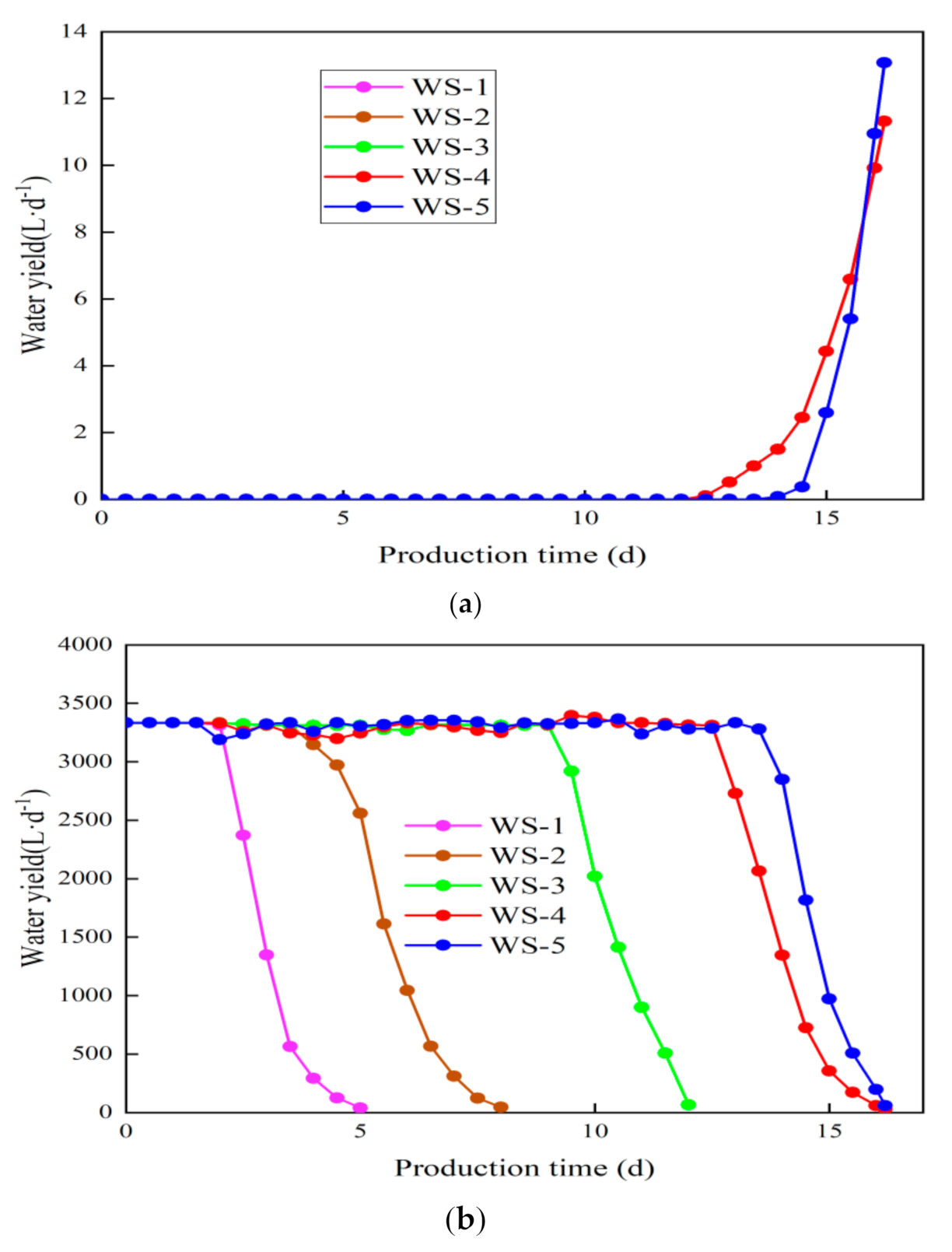

4.4.1. Homogeneous Reservoir

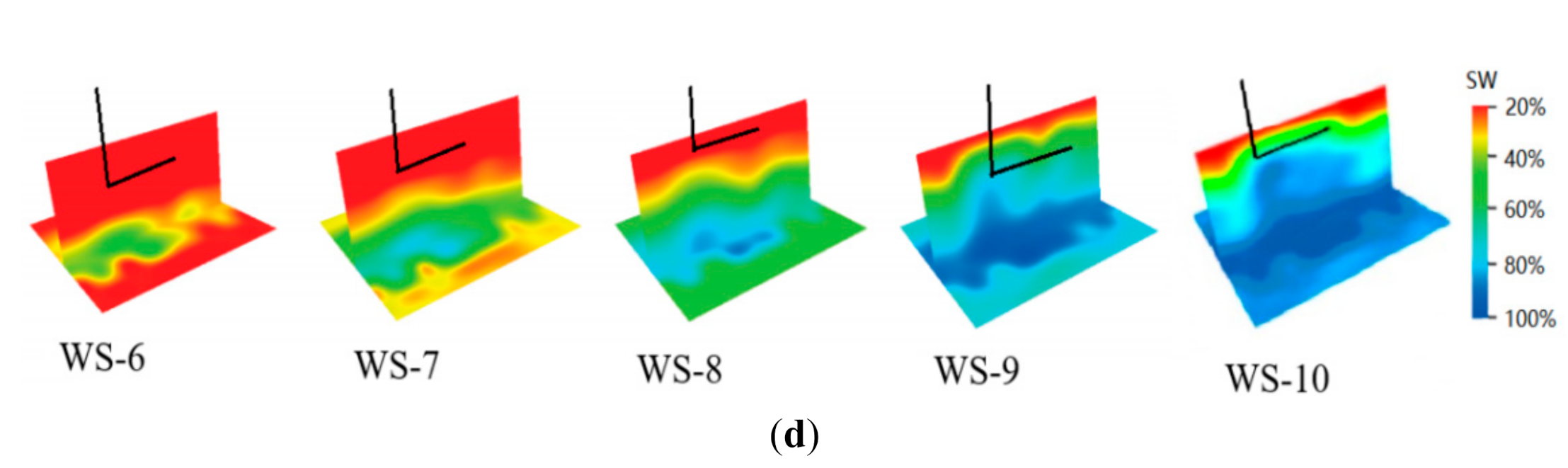

4.4.2. Heterogeneous Reservoir

5. Water Control Development Strategy for Bottom-Water Gas Reservoir

6. Conclusions

- (1)

- During the development of bottom-water gas reservoirs, water ridging is mainly affected by reservoir heterogeneity, the production system and the heel–toe effect of horizontal wellbores, and the influence degree of the above three factors on water influx decreases successively.

- (2)

- The horizontal/vertical ratio of the well area determines whether the gas well productivity is affected by water invasion, and the heterogeneity of the reservoir will affect the identification limit of water invasion risk. The stronger the reservoir heterogeneity, the smaller the horizontal/vertical ratio safety limit value. When the permeability level difference is 1, 5, 10, 20 and 30, the safety limit value of the horizontal/vertical ratio is 43.52, 32.86, 22.75, 13.08 and 6.44, respectively.

- (3)

- Based on the established relationship curve between permeability level difference and the safety limit value of the transverse/longitudinal ratio in the well area, the reservoir plane permeability level difference and transverse/longitudinal ratio of well N1H are 30 and 77.13, which are far greater than the safety limit value of the transverse/longitudinal ratio (6.44). The well is subject to a high risk of water invasion and must be controlled by water development.

- (4)

- Water control development strategies for deepwater bottom-water gas reservoirs include: (1) Reducing the heel–toe effect of the horizontal wellbore and the influence of reservoir heterogeneity to inhibit the uneven inflow of bottom-water. The corresponding water control measures are the annular multi-stage artificial bottom hole technology and variable density screen technology suitable for horizontal wells; (2) the exploitation system should be regulated to prevent the formation of uneven water invasion, and the corresponding water control measures should be periodic gas recovery technologies; (3) a water-blocking barrier was established near the bottom of the well to suppress the ridge of the front water head, and the corresponding measures were filling the horizontal well with permeability and water-blocking gravel technology; (4) the comprehensive technology of water control and development for deepwater and bottom-water gas reservoirs is formed, in which each stage complements and accommodates each other.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, K.; Lu, R.; Zhang, L.; Zhang, X.; Yao, J.; Li, R.; Zhao, H. A two-stage efficient history matching procedure of non-Gaussian fields. J. Pet. Sci. Eng. 2016, 138, 189–200. [Google Scholar] [CrossRef]

- Han, J.F.; Zhang, H.Z.; Yu, H.F.; Ji, Y.G.; Dong, R.X. Hydrocarbon accumulation characteristic and exploration on large marine carbonate condensate field in Tazhong Uplift. Acta Petrol. Sin. 2012, 28, 769–782. [Google Scholar]

- Liu, Y.; Wang, H.; Meng, W.; Zhang, C.; Zhi, J.; Shen, A. Stimulation experiment of horizontal wells filled with permeable and water-blocking gravel in deepsea bottom-water gas reservoirs. Nat. Gas Ind. 2020, 40, 61–68. [Google Scholar] [CrossRef]

- Fang, F.F.; Li, X.Z.; Gao, S.S.; Xue, H.; Zhu, W.Q.; Liu, H.X.; An, W.G.; Li, C.H. Visual simulation experimental study on water invasion rules of gas reservoir with edge and bottom water. Nat. Gas Geosci. 2016, 27, 2246–2252. [Google Scholar]

- Zubarev, D.; Nnebocha, E.; Vasper, A. Feasibility study and selection process for ICD applications in an offshore Niger Delta Field. In Proceedings of the SPE Nigeria Annual International Conference and Exhibition, Lagos, Nigeria, 6–8 August 2018. [Google Scholar] [CrossRef]

- Guo, C.F.; Li, H.B.; Tao, Y.; Lang, L.Y.; Niu, Z.X. Water invasion and remaining gas distribution in carbonate gas reservoirs using core displacement and NMR. J. Cent. South Univ. 2020, 27, 531–541. [Google Scholar] [CrossRef]

- Sheng, R.; Li, X. Influences of gas recovery rate and aquifer size on production of sandstone water-drive gas reservoirs. Pet. Explor. Dev. 2005, 32, 94–97. [Google Scholar]

- Huaxun, L.; Dong, R.; Shusheng, G.; Zhiming, H.; Liyou, Y.; Xia, L. Water influx mechanism and development strategy of gas reservoirs with edge and bottom water. Nat. Gas Ind. 2015, 35, 47–53. [Google Scholar]

- Xu, C.; Tao, J.; Wang, J.; He, F.; Zhang, Q.; Zhou, G. A quantitative recognition method on water-invasion direction in edge-water gas reservoirs: An example from bioreef gas reservoirs of Changxing Formation, Huanglongchang structure, eastern Sichuan Basin. Nat. Gas Explor. Dev. 2019, 42, 90–96. [Google Scholar]

- Deng, C.; Li, J.; Chai, X.; Chen, F.; Yang, X.; Wang, H. Early identification methods of water invasion in weak water drive gas reservoirs in Sebei gas field, Qaidam Basin. Lithol. Reserv. 2020, 32, 128–134. [Google Scholar]

- Li, Y.; Zhang, J.; Li, B. New method of aquifer influx risk classification for wells in gas reservoir with aquifer support. Nat. Gas Geosci. 2016, 27, 128–133. [Google Scholar]

- Shen, W.J.; Li, X.Z.; Liu, X.H.; Lu, J.L.; Jiao, C.Y. Physical simulation of water influx mechanism in fractured gas reservoirs. J. Cent. South Univ. (Sci. Technol.) 2014, 45, 3283–3287. [Google Scholar]

- Zou, W.; Yao, Y.; Wang, Q. Study on influential factors of water cresting morphology in horizontal well of bottom water reservoirs. Pet. Geol. Recovery Effic. 2017, 24, 70–77. [Google Scholar]

- Kabir, C.S. Predicting gas well performance coning water in bottom-water-drive reservoirs. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Francisco, CA, USA, 5–8 October 1983. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, J.; Li, B.; Jiang, W.; Wang, X. Study on water production characteristics of Dixi 18 volcanic gas reservoir. Nat. Gas Explor. Dev. 2013, 36, 48–52. [Google Scholar]

- Shen, W.J.; Liu, X.H.; Li, X.Z.; Lu, J.L. Water coning mechanism in Tarim fractured sandstone gas reservoirs. J. Cent. South Univ. 2015, 22, 344–349. [Google Scholar] [CrossRef]

- Zendehboudi, S.; Elkamel, A.; Chatzis, I.; Ahmadi, M.A.; Bahadori, A.; Lohi, A. Estimation of breakthrough time for water coning in fractured systems: Experimental study and connectionist modeling. AICHE J. 2014, 60, 1905–1919. [Google Scholar] [CrossRef]

- Tan, Y.; Li, H.; Jiang, B.; Wang, Y.; Nan, Z. A non-steady state model of gas reservoir and horizontal wellbore coupling based on volume source. Reserv. Eval. Dev. 2018, 8, 24–29. [Google Scholar] [CrossRef]

- Yong, L.I.; Jing, Y.A. Water-cut rising patterns and optimal water injection techniques of horizontal wells in thin carbonate reservoir with bottom water. Lithol. Reserv. 2019, 31, 135–144. [Google Scholar]

- Guo, D. The Water Cone Problem of a Horizontal Well in Bottom Water Reservoir. J. Southwest Pet. Univ. (Sci. Technol. Ed.) 1995, 17, 119–123. [Google Scholar]

- Fang, F.; Shen, W.; Gao, S.; Liu, H.; Wang, Q.; Li, Y. Experimental Study on the Physical Simulation of Water Invasion in Carbonate Gas Reservoirs. Appl. Sci. 2017, 7, 697. [Google Scholar] [CrossRef] [Green Version]

- Fang, F.; Shen, W.; Li, X.; Gao, S.; Liu, H.; Li, J. Experimental study on water invasion mechanism of fractured carbonate gas reservoirs in Longwangmiao Formation, Moxi block, Sichuan Basin. Environ. Earth Sci. 2019, 78, 1–11. [Google Scholar] [CrossRef]

- Zhou, M.; Li, X.; Hu, Y.; Xu, X.; Jiang, L.; Li, Y. Physical Simulation Experimental Technology and Mechanism of Water Invasion in Fractured-Porous Gas Reservoir: A Review. Energies 2021, 14, 3918. [Google Scholar] [CrossRef]

- Hu, Y.; Li, X.; Shen, W.; Guo, C.; Jiao, C.; Xu, X.; Jia, Y. Study on the Water Invasion and Its Effect on the Production from Multilayer Unconsolidated Sandstone Gas Reservoirs. Geofluids 2021, 2021, 5135159. [Google Scholar] [CrossRef]

- Shen, W.; Li, X.; Lu, J. Similarity theory of physical simulation in the development of abnormal pressure gas reservoirs. Sci. Technol. Eng. 2013, 13, 10460–10465. [Google Scholar]

- Cao, P.; Chang, S.; Ai, C.D.; Luo, X.; Zhao, J. Review of water cresting of horizontal well in bottom water driving reservoirs. J. Chongqing Univ. Sci. Technol. (Nat. Sci. Ed.) 2014, 63–66. [Google Scholar] [CrossRef]

- Yu, G.; Li, H.; Chen, Y.; Liu, L.; Zhang, D. Risk Decision-Making Technology in Gas Reservoir Development at Sichuan Basin. Shock Vib. 2021, 2021, 4890871. [Google Scholar] [CrossRef]

- Huang, X.; Guo, X.; Zhou, X.; Shen, C.; Lu, X.; Qi, Z.; Xiao, Q.; Yan, W. Effects of water invasion law on gas wells in high temperature and high pressure gas reservoir with a large accumulation of water-soluble gas. J. Nat. Gas Sci. Eng. 2019, 62, 62–78. [Google Scholar] [CrossRef]

- Feng, X.; Zhong, B.; Yang, X.; Deng, H. Effective water influx control in gas reservoir development: Problems and countermeasures. Nat. Gas Ind. 2015, 35, 35–40. [Google Scholar] [CrossRef] [Green Version]

- Xu, X.; Li, X.; Hu, Y.; Mei, Q.; Shi, Y.; Jiao, C. Physical simulation for water invasion and water control optimization in water drive gas reservoirs. Sci. Rep. 2021, 11, 6301. [Google Scholar] [CrossRef]

- Li, X.; Guo, Z.; Hu, Y.; Luo, R.; Su, Y.; Sun, H.; Liu, X.; Wan, Y.; Zahng, Y.; Li, L. Efficient development strategies for large ultra-deep structural gas fields in China. Pet. Explor. Dev. 2018, 45, 118–126. [Google Scholar] [CrossRef]

- Li, X.; Gao, S.; Wan, Y.; Liu, X.; Zhang, M.; Xie, W.; Su, Y.; Hu, Y.; Feng, J.; Yang, B.; et al. Geological characteristics and development strategies for Cambrian Longwangmiao Formation gas reservoir in Anyue gas field, Sichuan Basin, SW China. Pet. Explor. Dev. 2017, 44, 428–436. [Google Scholar] [CrossRef]

- Li, M.; Li, T.; Jiang, Q.; Yang, H.; Liu, S.C. The gas recovery of water-drive gas reservoirs. J. Hydrodyn. 2015, 27, 530–541. [Google Scholar] [CrossRef]

- Wang, H.; Liu, Y. Horizontal well completion with multiple artifificial bottom holes improves production performance in bottom water reservoir. Math. Probl. Eng. 2020, 6, 1–11. [Google Scholar]

| Horizontal Location of Reservoir (m) | Average Permeability (mD) |

|---|---|

| 0~100 | 250 |

| 100~150 | 2500 |

| 150~250 | 500 |

| 250~300 | 1500 |

| Well | Length (km) | Width (km) | Area (km2) | Water Type | Multiple Water | Distance to Water Body (m) | Geological Reserves (108 m3) |

|---|---|---|---|---|---|---|---|

| N1H | 6.55 | 4.84 | 26.5 | Bottom-water | 4.1 | 66.8 | 178 |

| N2 | 15.07 | 3.97 | 44.8 | Edge water | 2.8 | 376 | 264 |

| N3H | 11.22 | 2.43 | 16.2 | Bottom-water | 1.7 | 44.1 | 116 |

| N4 | 6.15 | 4.25 | 17.5 | Bottom-water | 7.3 | 543 | 76 |

| N5 | 16.54 | 8.11 | 33.7 | Bottom-water | 10.7 | 57.5 | 213 |

| N6H | 15.42 | 4.03 | 40.3 | Bottom-water | 5.3 | 30.4 | 143 |

| N7H | 7.12 | 1.94 | 8.13 | Bottom-water | 2.8 | 12.2 | 86 |

| Package Number | Horizontal Well | Permeability (mD) | |||||

|---|---|---|---|---|---|---|---|

| Number 1 Core | Number 2 Core | Number 3 Core | Number 4 Core | Number 5 Core | Number 6 Core | ||

| 1 | Yes | 100 | 500 | 1000 | 1500 | 2000 | 2500 |

| 2 | No | 100 | 500 | 1000 | 1500 | 2000 | 2500 |

| 3 | Yes | 100 | 2000 | 2500 | 1500 | 1000 | 500 |

| 4 | Yes | 100 | 100 | 100 | 100 | 100 | 100 |

| 5 | Yes | 500 | 500 | 500 | 500 | 500 | 500 |

| 6 | Yes | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 |

| 7 | Yes | 2000 | 2000 | 2000 | 2000 | 2000 | 2000 |

| 8 | Yes | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 |

| Permeability Ratio | Deviation Degree of Gas Production |

|---|---|

| 1 | 0 |

| 2 | 72.34% |

| 4 | 161.1% |

| 5 | 193.5% |

| 10 | 276.3% |

| Serial Number | Permeability (mD) | Wellblock Length (cm) | Horizontal and Longitudinal Ratio of Well Area | External Air Storage (m3) |

|---|---|---|---|---|

| WS-1 | 500 | 300 | 10 | 0.058 |

| WS-2 | 500 | 600 | 20 | 0.116 |

| WS-3 | 500 | 1200 | 40 | 0.231 |

| WS-4 | 500 | 1800 | 60 | 0.347 |

| WS-5 | 500 | 2310 | 77 | 0.445 |

| WS-6 | 2500/250 | 300 | 10 | 0.058 |

| WS-7 | 2500/250 | 600 | 20 | 0.116 |

| WS-8 | 2500/250 | 1200 | 40 | 0.231 |

| WS-9 | 2500/250 | 1800 | 60 | 0.347 |

| WS-10 | 2500/250 | 2310 | 77 | 0.445 |

| WS-11 | 5000/250 | 300 | 10 | 0.058 |

| WS-12 | 5000/250 | 600 | 20 | 0.116 |

| WS-13 | 5000/250 | 1200 | 40 | 0.231 |

| WS-14 | 5000/250 | 2310 | 77 | 0.445 |

| WS-15 | 7500/250 | 300 | 10 | 0.058 |

| WS-16 | 7500/250 | 600 | 20 | 0.116 |

| WS-17 | 7500/250 | 1200 | 40 | 0.231 |

| WS-18 | 7500/250 | 2310 | 77 | 0.445 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhi, J.; Bo, L.; Qu, G.; Jiang, N.; Zhang, R. Water Invasion Law and Water Invasion Risk Identification Method for Deep Sea Bottom-Water Gas Reservoir. Energies 2022, 15, 1937. https://doi.org/10.3390/en15051937

Zhi J, Bo L, Qu G, Jiang N, Zhang R. Water Invasion Law and Water Invasion Risk Identification Method for Deep Sea Bottom-Water Gas Reservoir. Energies. 2022; 15(5):1937. https://doi.org/10.3390/en15051937

Chicago/Turabian StyleZhi, Jiqiang, Lifeng Bo, Guohui Qu, Nan Jiang, and Rongzhou Zhang. 2022. "Water Invasion Law and Water Invasion Risk Identification Method for Deep Sea Bottom-Water Gas Reservoir" Energies 15, no. 5: 1937. https://doi.org/10.3390/en15051937