Prediction of Wall and Indoor Hygrothermal Properties of Rammed Earth Folk House in Northwest Sichuan

Abstract

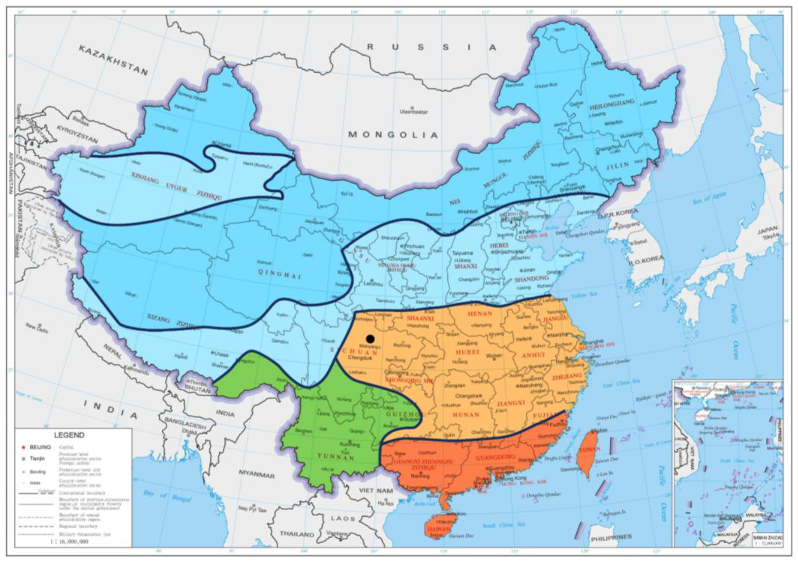

:1. Introduction

2. Mathematical Models

2.1. Hygrothermal Model of the Rammed Earth Wall

2.2. Heat and Moisture Balance of Indoor Air

2.2.1. Heat Balance of Indoor Air

2.2.2. Moisture Balance of Indoor Air

3. Numerical Validation

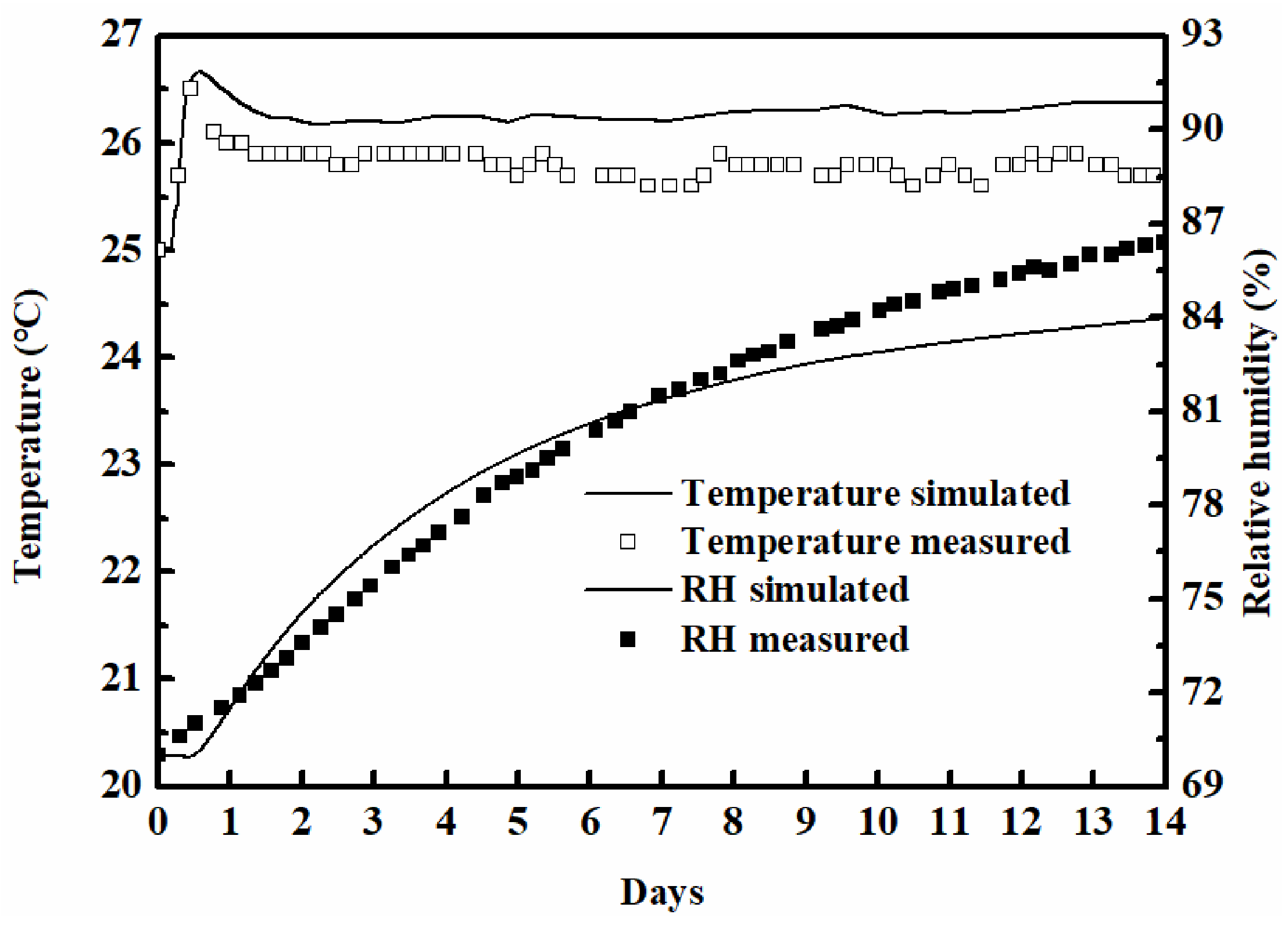

3.1. Validation of Wall Temperature and Relative Humidity

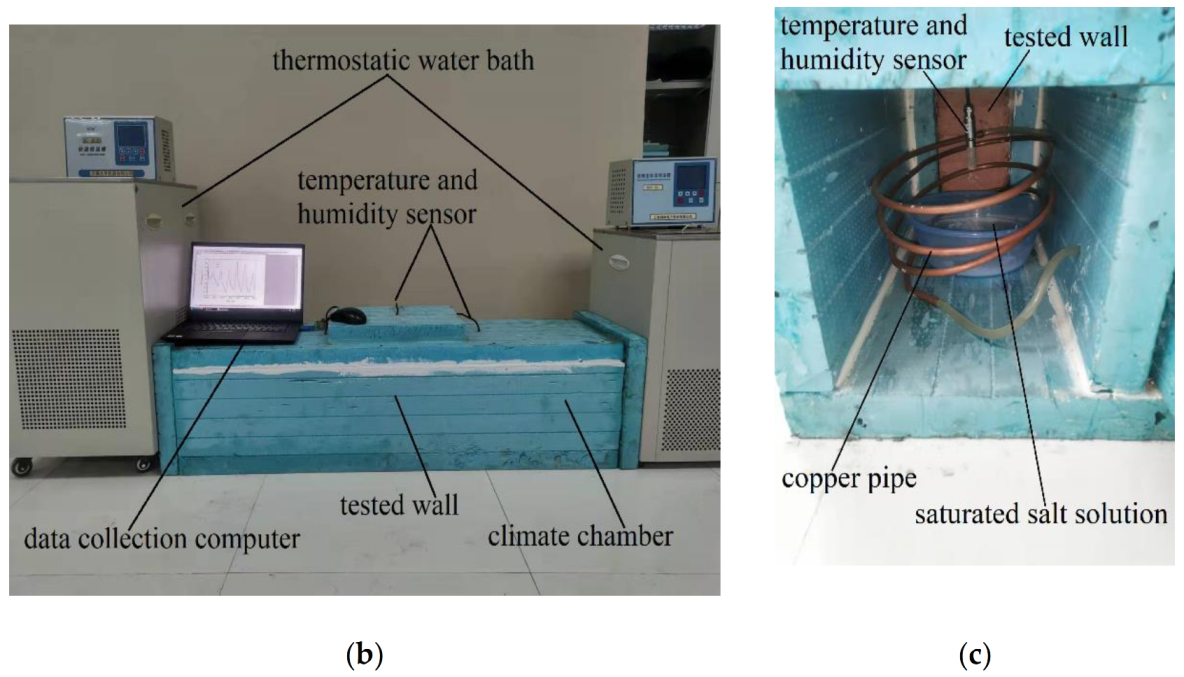

3.1.1. Experimental Equipment Setup

3.1.2. Boundary Conditions and Initial Conditions

3.1.3. Experimental Test Process

3.1.4. Numerical Simulation Setup and Results

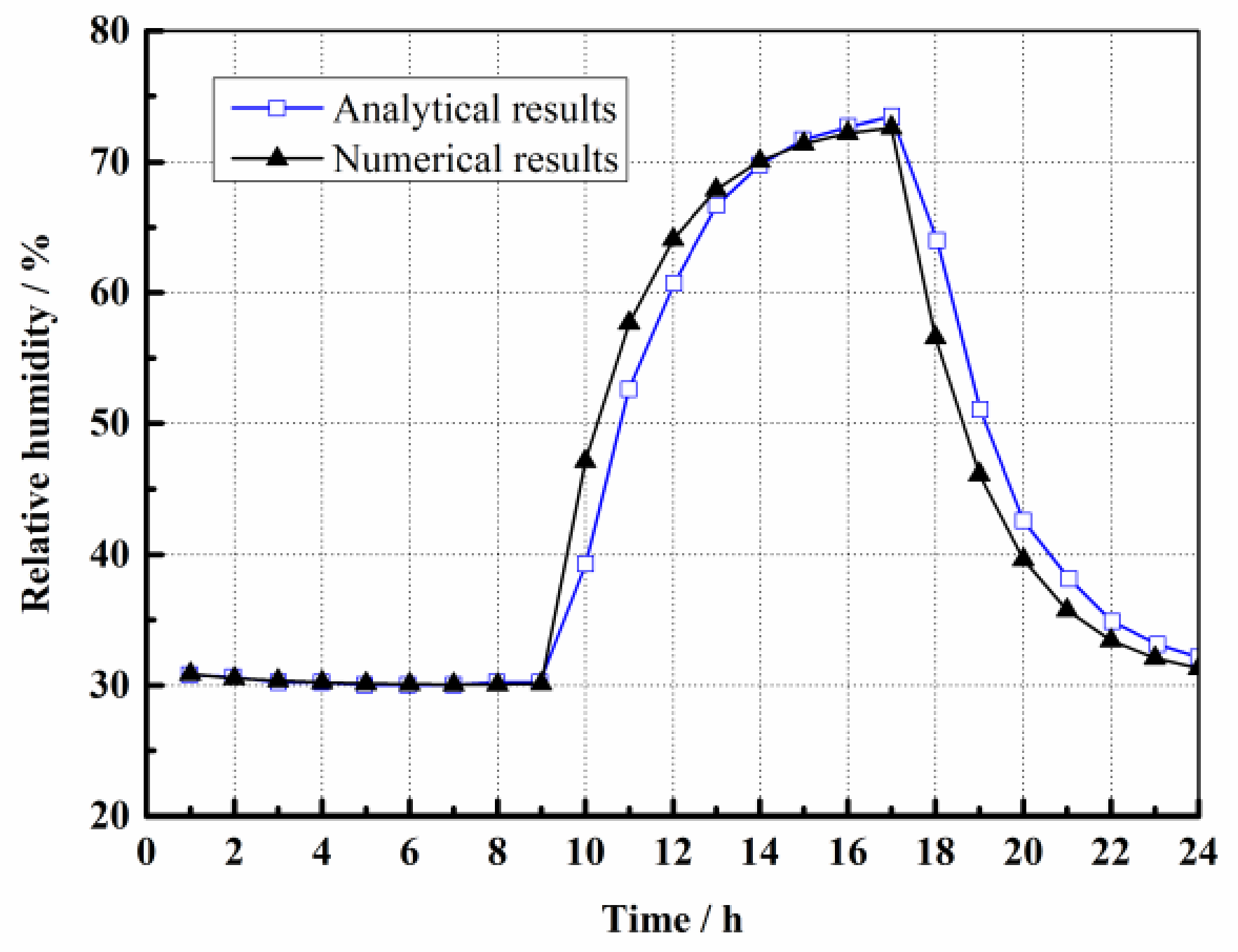

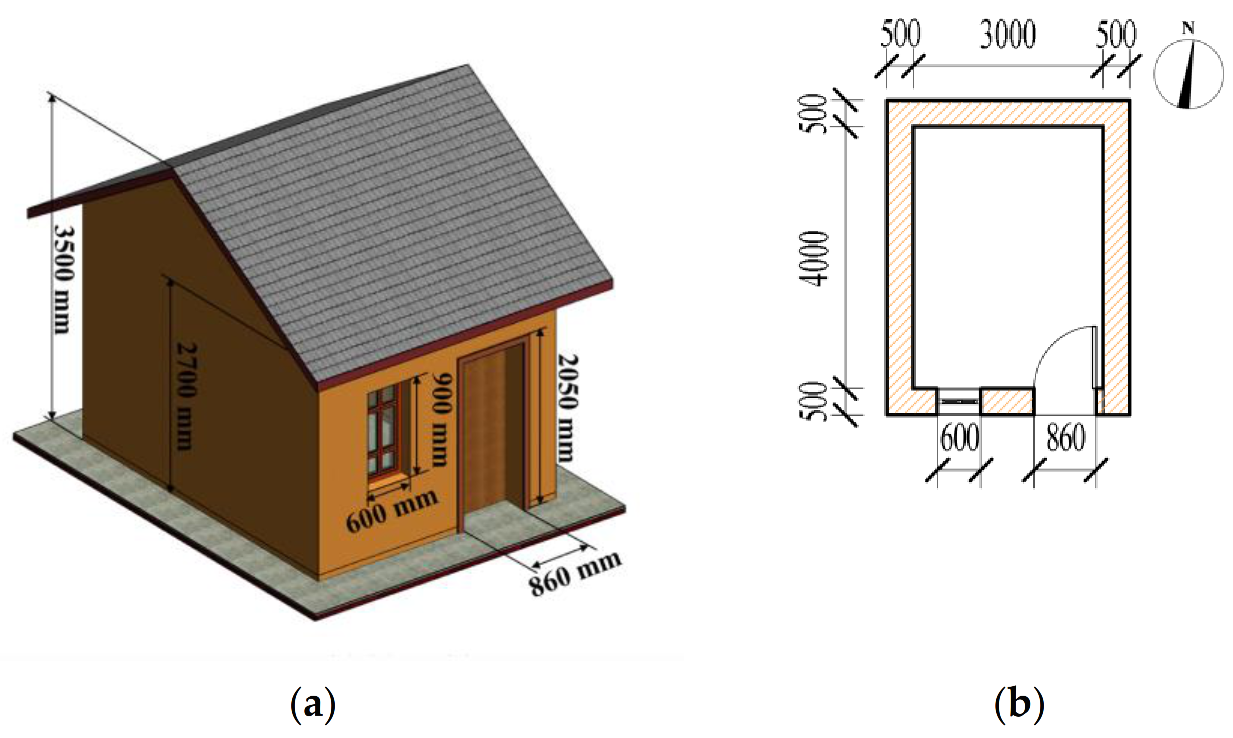

3.2. Validation of Indoor Temperature and Relative Humidity

4. Discussion

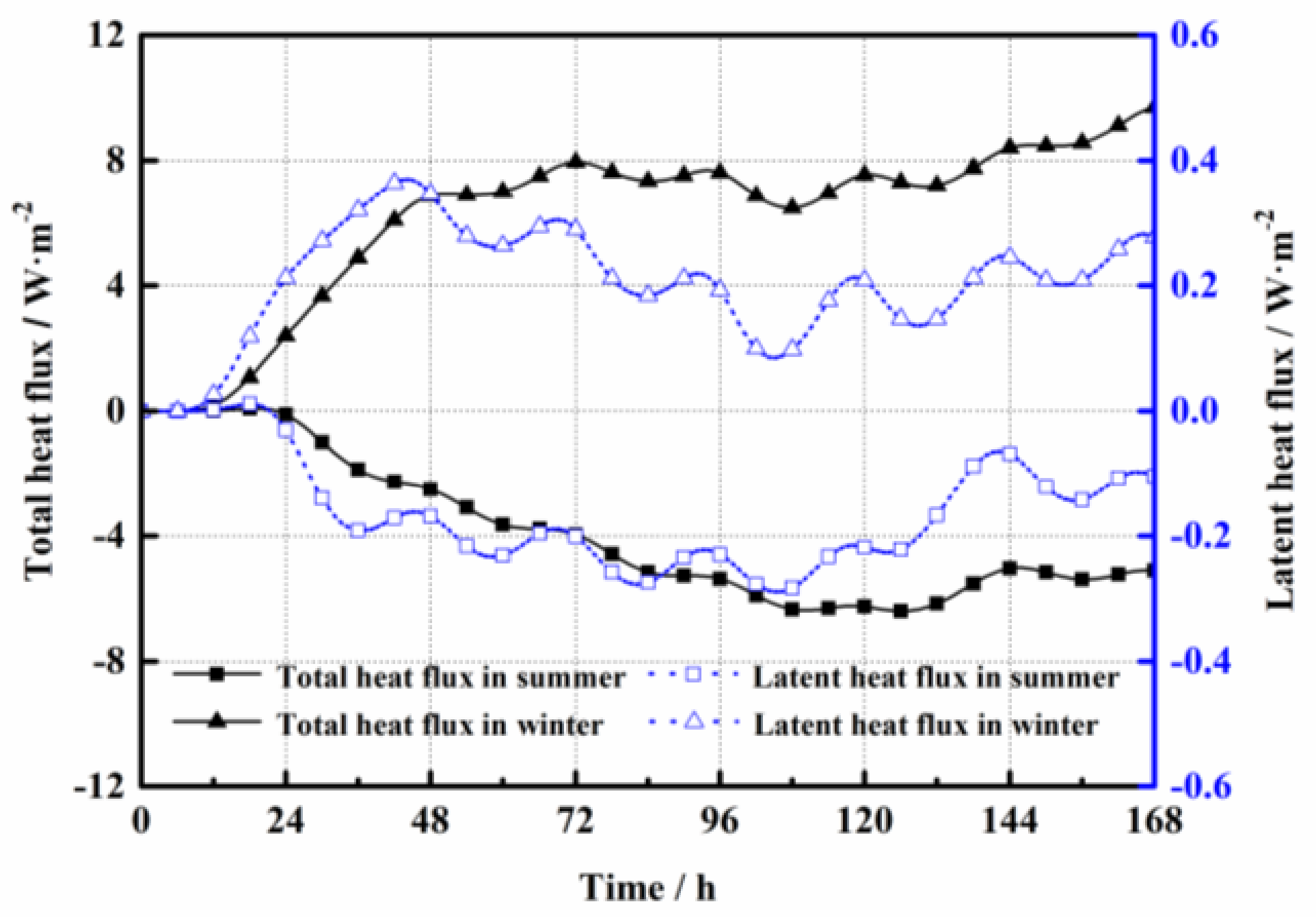

4.1. Thermal and Moisture Properties of The Rammed Earth Wall

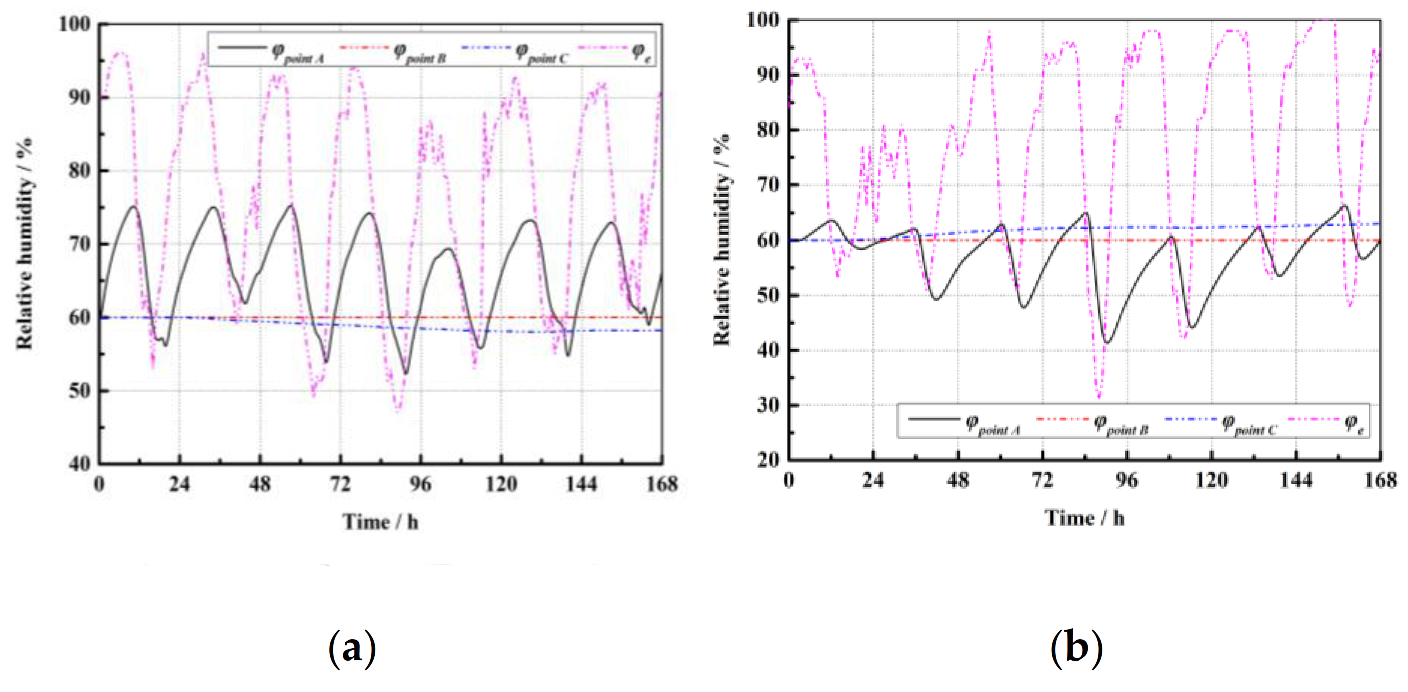

4.2. Indoor Thermal and Humid Environment

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ness, D.A.; Xing, K. Toward a Resource-Efficient Built Environment: A Literature Review and Conceptual Model. J. Ind. Ecol. 2017, 21, 572–592. [Google Scholar] [CrossRef]

- Jannat, N.; Hussien, A.; Abdullah, B.; Cotgrave, A. Application of agro and non-agro waste materials for unfired earth blocks construction: A review. Constr. Build. Mater. 2020, 254, 119346. [Google Scholar] [CrossRef]

- Mateus, R.; Fernandes, J.; Teixeira, E.R. Environmental Life Cycle Analysis of Earthen Building Materials. In Encyclopedia of Renewable and Sustainable Materials; Hashmi, S., Choudhury, I.A., Eds.; Elsevier: Oxford, UK, 2020; pp. 63–68. [Google Scholar]

- Burroughs, S. Recommendations for the Selection, Stabilization, and Compaction of Soil for Rammed Earth Wall Construction. J. Green Build. 2010, 5, 101–114. [Google Scholar] [CrossRef]

- Gandreau, D.; Ensag, C.R.; Delboy, L. UNESCO World Heritage Inventory of Earthen Architecture, 2012; CRATerre: Villefontaine, France; ENSAG: Grenbole, France, 2012. [Google Scholar]

- Giuffrida, G.; Detommaso, M.; Nocera, F.; Caponetto, R. Design Optimisation Strategies for Solid Rammed Earth Walls in Mediterranean Climates. Energies 2021, 14, 325. [Google Scholar] [CrossRef]

- Bui, Q.-B.; Morel, J.-C. Assessing the anisotropy of rammed earth. Constr. Build. Mater. 2009, 23, 3005–3011. [Google Scholar] [CrossRef]

- Beckett, C.T.S.; Cardell-Oliver, R.; Ciancio, D.; Huebner, C. Measured and simulated thermal behaviour in rammed earth houses in a hot-arid climate. Part A: Structural behaviour. J. Build. Eng. 2018, 15, 243–251. [Google Scholar] [CrossRef] [Green Version]

- Kosarimovahhed, M.; Toufigh, V. Sustainable usage of waste materials as stabilizer in rammed earth structures. J. Clean. Prod. 2020, 277, 123279. [Google Scholar] [CrossRef]

- Arrigoni, A.; Pelosato, R.; Dotelli, G.; Beckett, C.T.S.; Ciancio, D. Weathering’s beneficial effect on waste-stabilised rammed earth: A chemical and microstructural investigation. Constr. Build. Mater. 2017, 140, 157–166. [Google Scholar] [CrossRef] [Green Version]

- Abhilash, H.N.; Morel, J.-C.; Champiré, F.; Fabbri, A. A novel experimental study to investigate the interface properties of rammed earth. Constr. Mater. 2020, 1–9. [Google Scholar] [CrossRef]

- Giuffrida, G.; Caponetto, R.; Nocera, F. Hygrothermal Properties of Raw Earth Materials: A Literature Review. Sustainability 2019, 11, 5342. [Google Scholar]

- Fernandes, J.; Mateus, R.; Gervásio, H.; Silva, S.M.; Bragança, L. Passive strategies used in Southern Portugal vernacular rammed earth buildings and their influence in thermal performance. Renew. Energy 2019, 142, 345–363. [Google Scholar] [CrossRef] [Green Version]

- Serrano, S.; Rincón, L.; González, B.; Navarro, A.; Bosch, M.; Cabeza, L.F. Rammed earth walls in Mediterranean climate: Material characterization and thermal behaviour. Int. J. Low Carbon Technol. 2016, 12, 281–288. [Google Scholar] [CrossRef] [Green Version]

- Serrano, S.; de Gracia, A.; Cabeza, L.F. Adaptation of rammed earth to modern construction systems: Comparative study of thermal behavior under summer conditions. Appl. Energy 2016, 175, 180–188. [Google Scholar] [CrossRef] [Green Version]

- Teixeira, E.R.; Machado, G.; Adilson, P., Jr.; Guarnier, C.; Fernandes, J.; Silva, S.M.; Mateus, R. Mechanical and Thermal Performance Characterisation of Compressed Earth Blocks. Energies 2020, 13, 2978. [Google Scholar] [CrossRef]

- Nshimiyimana, P.; Messan, A.; Courard, L. Physico-Mechanical and Hygro-Thermal Properties of Compressed Earth Blocks Stabilized with Industrial and Agro By-Product Binders. Materials 2020, 13, 3769. [Google Scholar] [CrossRef]

- Bogas, J.A.; Silva, M.; Glória Gomes, M. Unstabilized and stabilized compressed earth blocks with partial incorporation of recycled aggregates. Int. J. Archit. Herit. 2019, 13, 569–584. [Google Scholar] [CrossRef]

- Hall, M.; Allinson, D. Analysis of the hygrothermal functional properties of stabilised rammed earth materials. Build. Environ. 2009, 44, 1935–1942. [Google Scholar] [CrossRef] [Green Version]

- Liuzzi, S.; Hall, M.R.; Stefanizzi, P.; Casey, S.P. Hygrothermal behaviour and relative humidity buffering of unfired and hydrated lime-stabilised clay composites in a Mediterranean climate. Build. Environ. 2013, 61, 82–92. [Google Scholar] [CrossRef]

- Soudani, L.; Fabbri, A.; Morel, J.-C.; Woloszyn, M.; Chabriac, P.-A.; Wong, H.; Grillet, A.-C. Assessment of the validity of some common assumptions in hygrothermal modeling of earth based materials. Energy Build. 2016, 116, 498–511. [Google Scholar] [CrossRef]

- Zhang, L.; Yang, L.; Jelle, B.P.; Wang, Y.; Gustavsen, A. Hygrothermal properties of compressed earthen bricks. Constr. Build. Mater. 2018, 162, 576–583. [Google Scholar] [CrossRef]

- Desta, T.Z.; Langmans, J.; Roels, S. Experimental data set for validation of heat, air and moisture transport models of building envelopes. Build. Environ. 2011, 46, 1038–1046. [Google Scholar] [CrossRef]

- Abahri, K.; Belarbi, R.; Trabelsi, A. Contribution to analytical and numerical study of combined heat and moisture transfers in porous building materials. Build. Environ. 2011, 46, 1354–1360. [Google Scholar] [CrossRef]

- Juan, X.; Ziliang, L.; Weijun, G.; Mengsheng, Y.; Menglong, S. The comparative study on the climate adaptability based on indoor physical environment of traditional dwelling in Qinba mountainous areas, China. Energy Build. 2019, 197, 140–155. [Google Scholar] [CrossRef]

- Chandel, S.S.; Sharma, V.; Marwah, B.M. Review of energy efficient features in vernacular architecture for improving indoor thermal comfort conditions. Renew. Sustain. Energy Rev. 2016, 65, 459–477. [Google Scholar] [CrossRef]

- Fang, A.; Chen, Y.; Wu, L. Transient simulation of coupled heat and moisture transfer through multi-layer walls exposed to future climate in the hot and humid southern China area. Sustain. Cities Soc. 2020, 52, 101812. [Google Scholar] [CrossRef]

- Hong, T.; Chou, S.K.; Bong, T.Y. Building simulation: An overview of developments and information sources. Build. Environ. 2000, 35, 347–361. [Google Scholar] [CrossRef]

- Burch, D.M. An analysis of moisture accumulation in walls subjected to hot and humid climates. ASHRAE Trans. 1993, 99, 1013–1022. [Google Scholar]

- Mukhopadhyaya, P.; Kumaran, K.; Reenen, D.V. Vapour Barrier and Moisture Response of Wood-frame Stucco Wall-Results from Hygrothermal Simulation. In Proceedings of the CIB World Building Congress 2004, Toronto, ON, Canada, 2–7 May 2004; pp. 1–10. [Google Scholar]

- Hema, C.M.; Van Moeseke, G.; Evrad, A.; Courard, L.; Messan, A. Vernacular housing practices in Burkina Faso: Representative models of construction in Ouagadougou and walls hygrothermal efficiency. Energy Procedia 2017, 122, 535–540. [Google Scholar] [CrossRef]

- Ministry of Housing and Urban-Rural Development (MOHURD). GB 50176-2016; Code for Thermal Design of Civil Building; MOHURD: Beijing, China, 2016. [Google Scholar]

- Available online: http://bzdt.ch.mnr.gov.cn/index.html (accessed on 5 September 2019).

- Jiang, B.; Wu, T.; Xia, W.J.; Liang, J.H. Hygrothermal performance of rammed earth wall in Tibetan Autonomous Prefecture in Sichuan Province of China. Build. Environ. 2020, 181, 107128. [Google Scholar] [CrossRef]

- Tao, W. Heat Transfer, 5th ed.; Higher Education Press: Beijing, China, 2019. [Google Scholar]

- Li, L.P.; Wu, Z.G.; He, Y.L.; Lauriat, G.; Tao, W.Q. Optimization of the configuration of 290 × 140 × 90 hollow clay bricks with 3-D numerical simulation by finite volume method. Energy Build. 2008, 40, 1790–1798. [Google Scholar] [CrossRef]

- Yan, Z. Dynamic Modelling of the IndoorThermal and Humidity Environment in the Adobe Buildings. Ph.D. Thesis, Xi’an University of Architecture and Technology, Xi’an, China, 2003. [Google Scholar]

- Bednar, T.; Hagentoft, C.E. Analytical solution for moisture buffering effect Validation exercises for simulation tools. In Proceedings of the 7th Nordic Symposium on Building Physics, Reykjavik, Iceland, 13–15 June 2005. [Google Scholar]

| Molecular Formula | MgCl2 | K2CO3 | NaBr | NaCl | KCl | K2SO4 |

|---|---|---|---|---|---|---|

| Relative humidity | 33.07 ± 0.18 | 43.16 ± 0.33 | 59.14 ± 0.44 | 75.47 ± 0.14 | 85.11 ± 0.29 | 97.59 ± 0.53 |

| Physical Parameters | δp/s | ρm/kgm−3 | cp,m/J (kgK)−1 | λ/W (mK)−1 |

|---|---|---|---|---|

| Value | 3 × 10−11 | 650.00 | 840.00 | 0.18 |

| Name | SiO2 | Al2O3 | CaO | Fe2O3 | K2O | MgO | TiO2 | Na2O | P2O5 | MnO |

|---|---|---|---|---|---|---|---|---|---|---|

| wt.% | 56.52 | 18.39 | 10.23 | 6.70 | 3.72 | 2.46 | 0.90 | 0.54 | 0.17 | 0.11 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, Q.; Wu, T.; Liu, L.; Yao, Y.; Jiang, B. Prediction of Wall and Indoor Hygrothermal Properties of Rammed Earth Folk House in Northwest Sichuan. Energies 2022, 15, 1936. https://doi.org/10.3390/en15051936

Gao Q, Wu T, Liu L, Yao Y, Jiang B. Prediction of Wall and Indoor Hygrothermal Properties of Rammed Earth Folk House in Northwest Sichuan. Energies. 2022; 15(5):1936. https://doi.org/10.3390/en15051936

Chicago/Turabian StyleGao, Qinglong, Tao Wu, Lei Liu, Yong Yao, and Bin Jiang. 2022. "Prediction of Wall and Indoor Hygrothermal Properties of Rammed Earth Folk House in Northwest Sichuan" Energies 15, no. 5: 1936. https://doi.org/10.3390/en15051936