Detailed Analysis of the Effects of Biodiesel Fraction Increase on the Combustion Stability and Characteristics of a Reactivity-Controlled Compression Ignition Diesel-Biodiesel/Natural Gas Engine

Abstract

:1. Introduction

2. Experimental Setup

3. Experiment Procedure

4. Uncertainty Analysis

5. Results and Discussion

5.1. Engine Performance

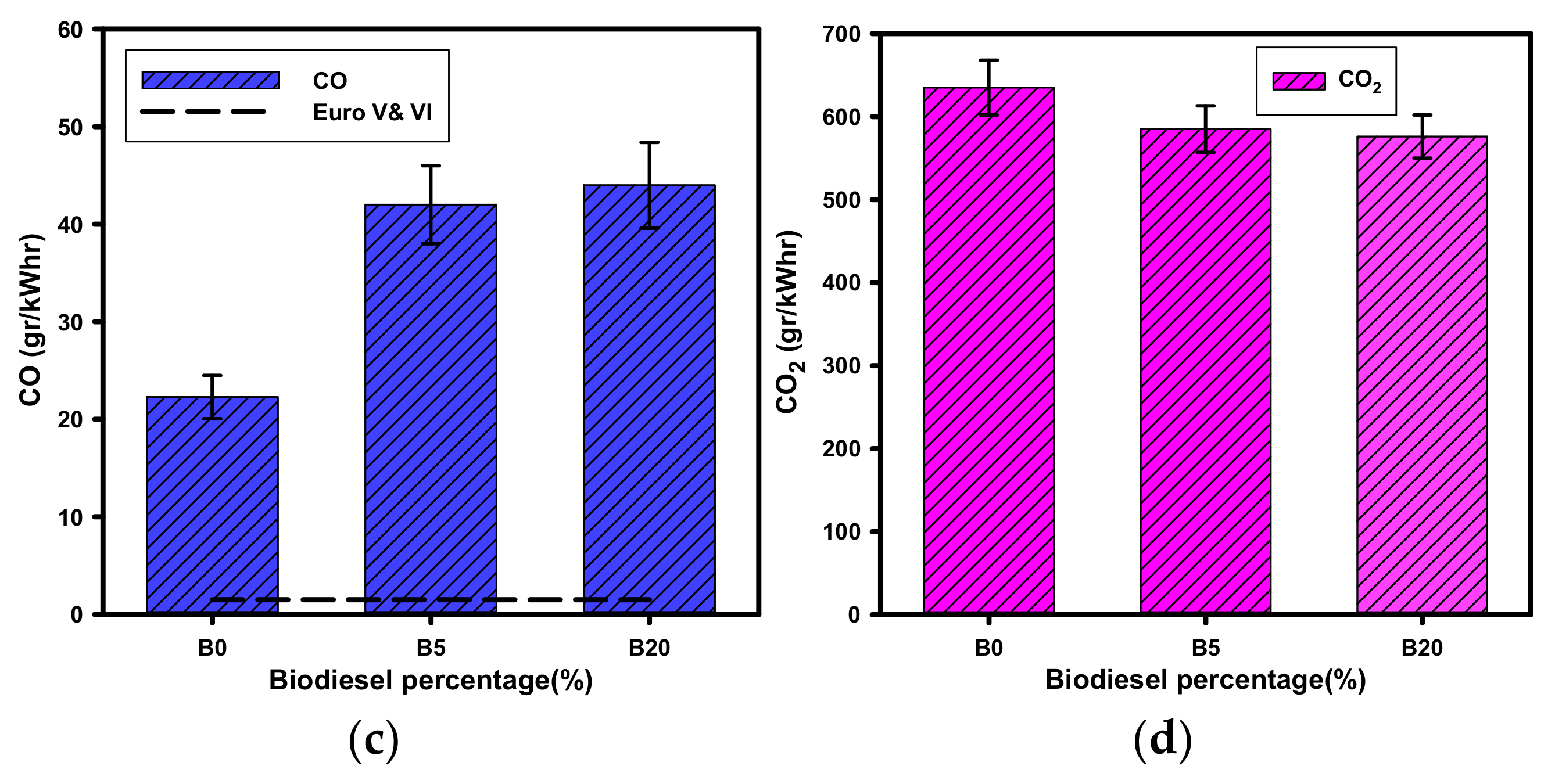

5.2. Engine-Out Emissions

5.3. Combustion Stability

5.3.1. Cyclic Variations in the Combustion Parameters

5.3.2. Misfire and Knocking Analysis

5.3.3. Combustion Cyclic Historical Dependency

6. Conclusions

- Increasing the biodiesel fraction from B0 to B5 and B20 reduced NOx emissions by 71.3% and 74.1%, respectively. NOx emissions were reduced to values below the Euro VI limit of a stationary diesel engine with no after-treatment technology;

- RCCI baseline combustion had high UHCs and CO. Increasing the biodiesel fraction further increased these emissions.

- Using B5 and B20 instead of B0 led to an increase of 18% and 13.5% in UHCs and an increase of 88.5% and 97% in CO emissions, respectively. Increasing the biodiesel fraction to B5 and B20 prolonged the ignition delay by 48.5 and 50.7 CAD from 47 CAD of the baseline engine;

- The maximum in-cylinder pressure was reduced by 3% for B5 and 10.2% for B20 in comparison to B0;

- By increasing the biodiesel fraction, the combustion stability decreased. Using COV IMEP as an indicator of combustion variability, it increased from 1.8% for B0 to 4.2% for B5 and 4.8 for B20. The cyclic variations of IMEP, combustion duration, and start of combustion indicated that the addition of biodiesel to DFI increased the standard deviation and generally made the combustion more unstable;

- The tendency to knock was decreased by increasing the fraction of biodiesel in DFI. The knocking tendency decreased from 13.7% for the baseline case (B0) to 4.3% for B20;

- The baseline case (B0) had no misfiring cycle, and the B5 case had some misfiring cycles, but no knocking cycle was observed.

- This study shows that the addition of sunflower methyl ester as an additive to diesel direct fuel injection leads to more cyclic variations of RCCI combustion under low loads conditions. In other words, it makes combustion more unstable. The use of other biodiesel or biofuels with different physical and chemical properties and investigation of their impacts on combustion characteristics, stability, and engine-out emissions is the subject of future research. Moreover, numerical studies will provide an insightful perspective on the use of various biodiesels in RCCI combustion.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| aTDC | After top dead center | IMEP | Indicated mean effective pressure |

| CA10 | Crank angle due to 10% heat release | iTH | Indicated thermal efficiency |

| CA50 | Crank angle due to 50% heat release | LHV | Lower heating value |

| CA90 | Crank angle due to 90% heat release | LTC | Low temperature combustion |

| CAD | Crank angle degree | NG | Natural gas |

| CD | Combustion duration | NGEF | Natural gas energy fraction |

| CO | Carbon monoxide | NOx | Nitrogen oxides |

| CO2 | Carbon dioxide | PFI | Port fuel injection |

| COV | Coefficient of variance | PPC | Partially premixed charge |

| DFI | Direct fuel injection | RCCI | Reactivity controlled compression ignition |

| H2 | Hydrogen | rpm | Revolution per minute |

| HCCI | Homogeneous charge compression ignition | SOI | Start of injection |

| HRR | Heat release rate | UHC | Unburned hydrocarbon |

| ID | Ignition delay |

References

- Sanjeevannavar, M.B.; Banapurmath, N.R.; Soudagar, M.E.M.; Atgur, V.; Hossain, N.; Mujtaba, M.A.; Yunus Khan, T.M.; Nageswar Rao, B.; Ismail, K.A.; Elfasakhany, A. Performance indicators for the optimal BTE of biodiesels with additives through engine testing by the Taguchi approach. Chemosphere 2022, 288, 132450. [Google Scholar] [CrossRef] [PubMed]

- Tompkins, B.T.; Jacobs, T.J. Low-temperature combustion with biodiesel: Its enabling features in improving efficiency and emissions. Energy Fuels 2013, 27, 2794–2803. [Google Scholar] [CrossRef]

- Zhang, J.J.; Wei, Y.; Fang, Z. Ozone pollution: A major health hazard worldwide. Front. Immunol. 2019, 10, 2518. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Valavanidis, A.; Vlachogianni, T.; Fiotakis, K.; Loridas, S. Pulmonary oxidative stress, inflammation and cancer: Respirable particulate matter, fibrous dusts and ozone as major causes of lung carcinogenesis through reactive oxygen species mechanisms. Int. J. Environ. Res. Public Health 2013, 10, 3886–3907. [Google Scholar] [CrossRef]

- Kulkarni, P.C. Reducing Green House Effect Caused by Soot via Oxidation Using Modified LaFe1-xCuxO3 Catalysts. In Global Warming and Climate Change; IntechOpen: London, UK, 2019. [Google Scholar]

- Xu, G.; Jia, M.; Li, Y.; Chang, Y.; Wang, T. Potential of reactivity controlled compression ignition (RCCI) combustion coupled with variable valve timing (VVT) strategy for meeting Euro 6 emission regulations and high fuel efficiency in a heavy-duty diesel engine. Energy Convers. Manag. 2018, 171, 683–698. [Google Scholar] [CrossRef]

- Duraisamy, G.; Rangasamy, M.; Ramasankaran, A.P. Statistical and experimental investigation of single fuel reactivity controlled compression ignition combustion on a non-road diesel engine. Energy Convers. Manag. 2019, 199, 112025. [Google Scholar] [CrossRef]

- Benajes, J.; García, A.; Monsalve-Serrano, J.; Villalta, D. Benefits of E85 versus gasoline as low reactivity fuel for an automotive diesel engine operating in reactivity controlled compression ignition combustion mode. Energy Convers. Manag. 2018, 159, 85–95. [Google Scholar] [CrossRef]

- Kousheshi, N.; Yari, M.; Paykani, A.; Saberi Mehr, A.; de la Fuente, G.F. Effect of syngas composition on the combustion and emissions characteristics of a syngas/diesel RCCI engine. Energies 2020, 13, 212. [Google Scholar] [CrossRef] [Green Version]

- Muniappan, K.; Sheshadri, S.; Duvvuri, P.P. Numerical Analysis of the Effects of Direct Dual Fuel Injection on the Compression Ignition Engine. ACS Omega 2020, 5, 30047–30058. [Google Scholar] [CrossRef]

- Wenming, Y.; Meng, Y. Phi-T map analysis on RCCI engine fueled by methanol and biodiesel. Energy 2019, 187, 115958. [Google Scholar] [CrossRef]

- Zheng, Z.; Xia, M.; Liu, H.; Shang, R.; Ma, G.; Yao, M. Experimental study on combustion and emissions of n-butanol/biodiesel under both blended fuel mode and dual fuel RCCI mode. Fuel 2018, 226, 240–251. [Google Scholar] [CrossRef]

- Harari, P.; Banapurmath, N.; Yaliwal, V.; Khan, T.; Badruddin, I.A.; Kamangar, S.; Mahlia, T.M.I. Effect of Injection Timing and Injection Duration of Manifold Injected Fuels in Reactivity Controlled Compression Ignition Engine Operated with Renewable Fuels. Energies 2021, 14, 4621. [Google Scholar] [CrossRef]

- Li, R.; Liu, Z.; Han, Y.; Cai, Y.; Wang, X.; Zheng, J.; Tan, M.; Xu, Y.; Tian, J.; Meng, X. Target-Oriented Fuel Design for the Homogeneous Charge Autoignition Combustion Mode: A Case Study of an-Heptane–PODE3–Ethanol Mixture. 1. A Pathway To Increase the Combustion Efficiency and Reduce Pollutant Emissions. Energy Fuels 2018, 33, 16–30. [Google Scholar] [CrossRef]

- Sun, C.; Kang, D.; Bohac, S.V.; Boehman, A.L. impact of fuel and injection timing on partially premixed charge compression ignition combustion. Energy Fuels 2016, 30, 4331–4345. [Google Scholar] [CrossRef]

- Benajes, J.; García, A.; Monsalve-Serrano, J.; Sari, R.L. Experimental investigation on the efficiency of a diesel oxidation catalyst in a medium-duty multi-cylinder RCCI engine. Energy Convers. Manag. 2018, 176, 1–10. [Google Scholar] [CrossRef]

- Xu, Z.; Jia, M.; Xu, G.; Li, Y.; Zhao, L.; Xu, L.; Lu, X. Potential for reducing emissions in reactivity-controlled compression ignition engines by fueling syngas and diesel. Energy Fuels 2018, 32, 3869–3882. [Google Scholar] [CrossRef]

- Yousefi, A.; Guo, H.; Birouk, M.; Liko, B. On greenhouse gas emissions and thermal efficiency of natural gas/diesel dual-fuel engine at low load conditions: Coupled effect of injector rail pressure and split injection. Appl. Energy 2019, 242, 216–231. [Google Scholar] [CrossRef]

- Yousefi, A.; Guo, H.; Birouk, M. Effect of diesel injection timing on the combustion of natural gas/diesel dual-fuel engine at low-high load and low-high speed conditions. Fuel 2019, 235, 838–846. [Google Scholar] [CrossRef]

- García, A.; Monsalve-Serrano, J.; Roso, V.R.; Martins, M.E.S. Evaluating the emissions and performance of two dual-mode RCCI combustion strategies under the World Harmonized Vehicle Cycle (WHVC). Energy Convers. Manag. 2017, 149, 263–274. [Google Scholar] [CrossRef]

- Karczewski, M.; Chojnowski, J.; Szamrej, G. A Review of Low-CO2 Emission Fuels for a Dual-Fuel RCCI Engine. Energies 2021, 14, 5067. [Google Scholar] [CrossRef]

- Ogunkunle, O.; Ahmed, N.A. A review of global current scenario of biodiesel adoption and combustion in vehicular diesel engines. Energy Rep. 2019, 5, 1560–1579. [Google Scholar] [CrossRef]

- Gashaw, A.; Teshita, A. Production of biodiesel from waste cooking oil and factors affecting its formation: A review. Int. J. Renew. Sustain. Energy 2014, 3, 92–98. [Google Scholar]

- Yaqoob, H.; Teoh, Y.H.; Sher, F.; Farooq, M.U.; Jamil, M.A.; Kausar, Z.; Sabah, N.U.; Shah, M.F.; Rehman, H.Z.U.; Rehman, A.U. Potential of Waste Cooking Oil Biodiesel as Renewable Fuel in Combustion Engines: A Review. Energies 2021, 14, 2565. [Google Scholar] [CrossRef]

- Firoz, S. A review: Advantages and disadvantages of biodiesel. Int. Res. J. Eng. Technol. 2017, 4, 530–533. [Google Scholar]

- Lin, L.; Cunshan, Z.; Vittayapadung, S.; Xiangqian, S.; Mingdong, D. Opportunities and challenges for biodiesel fuel. Appl. Energy 2011, 88, 1020–1031. [Google Scholar] [CrossRef]

- Khan, H.; Soudagar, M.E.M.; Kumar, R.H.; Safaei, M.R.; Farooq, M.; Khidmatgar, A.; Banapurmath, N.R.; Farade, R.A.; Abbas, M.M.; Afzal, A. Effect of nano-graphene oxide and n-butanol fuel additives blended with diesel—Nigella sativa biodiesel fuel emulsion on diesel engine characteristics. Symmetry 2020, 12, 961. [Google Scholar] [CrossRef]

- Soudagar, M.E.M.; Banapurmath, N.; Afzal, A.; Hossain, N.; Abbas, M.M.; Haniffa, M.A.C.M.; Naik, B.; Ahmed, W.; Nizamuddin, S.; Mubarak, N. Study of diesel engine characteristics by adding nanosized zinc oxide and diethyl ether additives in Mahua biodiesel–diesel fuel blend. Sci. Rep. 2020, 10, 15326. [Google Scholar] [CrossRef]

- Jeswani, H.K.; Azapagic, A. Life Cycle Sustainability Assessment of Second Generation Biodiesel. In Advances in Biodiesel Production; Elsevier: Amsterdam, The Netherlands, 2012; pp. 13–31. [Google Scholar]

- Du, H.; Huque, Z.; Kommalapati, R.R. Impacts of Biodiesel Applied to the Transportation Fleets in the Greater Houston Area. J. Renew. Energy 2018, 2018, 7350715. [Google Scholar] [CrossRef] [Green Version]

- Diesel Vehicles Using Biodiesel. 2018. Available online: https://afdc.energy.gov/vehicles/diesel.html (accessed on 20 December 2021).

- Charitha, V.; Thirumalini, S.; Prasad, M.; Srihari, S. Investigation on performance and emissions of RCCI dual fuel combustion on diesel-bio diesel in a light duty engine. Renew. Energy 2019, 134, 1081–1088. [Google Scholar] [CrossRef]

- Zheng, Z.; Xia, M.; Liu, H.; Wang, X.; Yao, M. Experimental study on combustion and emissions of dual fuel RCCI mode fueled with biodiesel/n-butanol, biodiesel/2, 5-dimethylfuran and biodiesel/ethanol. Energy 2018, 148, 824–838. [Google Scholar] [CrossRef]

- Thomas, J.J.; Sabu, V.; Nagarajan, G.; Kumar, S.; Basrin, G. Influence of waste vegetable oil biodiesel and hexanol on a reactivity controlled compression ignition engine combustion and emissions. Energy 2020, 206, 118199. [Google Scholar] [CrossRef]

- Benajes, J.; García, A.; Monsalve-Serrano, J.; Balloul, I.; Pradel, G. An assessment of the dual-mode reactivity controlled compression ignition/conventional diesel combustion capabilities in a EURO VI medium-duty diesel engine fueled with an intermediate ethanol-gasoline blend and biodiesel. Energy Convers. Manag. 2016, 123, 381–391. [Google Scholar] [CrossRef]

- Agarwal, A.K.; Singh, A.P.; Maurya, R.K. Evolution, challenges and path forward for low temperature combustion engines. Prog. Energy Combust. Sci. 2017, 61, 1–56. [Google Scholar] [CrossRef]

- Ansari, E.; Menucci, T.; Shahbakhti, M.; Naber, J. Experimental investigation into effects of high reactive fuel on combustion and emission characteristics of the Diesel-Natural gas Reactivity Controlled Compression Ignition engine. Appl. Energy 2019, 239, 948–956. [Google Scholar] [CrossRef]

- Kakoee, A.; Bakhshan, Y.; Aval, S.M.; Gharehghani, A. An improvement of a lean burning condition of natural gas/diesel RCCI engine with a pre-chamber by using hydrogen. Energy Convers. Manag. 2018, 166, 489–499. [Google Scholar] [CrossRef]

- Kalsi, S.S.; Subramanian, K. Experimental investigations of effects of hydrogen blended CNG on performance, combustion and emissions characteristics of a biodiesel fueled reactivity controlled compression ignition engine (RCCI). Int. J. Hydrog. Energy 2017, 42, 4548–4560. [Google Scholar] [CrossRef]

- Harari, P.; Banapurmath, N.; Yaliwal, V.; Khan, T.Y.; Soudagar, M.E.M.; Sajjan, A. Experimental studies on performance and emission characteristics of reactivity controlled compression ignition (RCCI) engine operated with gasoline and Thevetia Peruviana biodiesel. Renew. Energy 2020, 160, 865–875. [Google Scholar] [CrossRef]

- Işik, M.Z.; Aydin, H. Investigation on the effects of gasoline reactivity controlled compression ignition application in a diesel generator in high loads using safflower biodiesel blends. Renew. Energy 2019, 133, 177–189. [Google Scholar] [CrossRef]

- Giakoumis, E.G.; Sarakatsanis, C.K. Estimation of biodiesel cetane number, density, kinematic viscosity and heating values from its fatty acid weight composition. Fuel 2018, 222, 574–585. [Google Scholar] [CrossRef]

- Duan, H.; Jia, M.; Chang, Y.; Liu, H. Experimental study on the influence of low-temperature combustion (LTC) mode and fuel properties on cyclic variations in a compression-ignition engine. Fuel 2019, 256, 115907. [Google Scholar] [CrossRef]

- Saxena, M.R.; Maurya, R.K. Effect of Diesel Injection Timing on Peak Pressure Rise Rate and Combustion Stability in RCCI Engine; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2018. [Google Scholar]

- Klos, D.T.; Kokjohn, S.L. Investigation of the effect of injection and control strategies on combustion instability in reactivity-controlled compression ignition engines. J. Eng. Gas Turbines Power 2016, 138, 011502. [Google Scholar] [CrossRef] [Green Version]

- Saxena, M.R.; Maurya, R.K. Experimental Investigation of Combustion Stability and Particle Emission from CNG/Diesel RCCI Engine; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2020. [Google Scholar]

- Tripathi, G.; Sharma, P.; Dhar, A. Effect of methane augmentation on combustion stability and unregulated emissions in compression ignition engine. Fuel 2020, 263, 116672. [Google Scholar] [CrossRef]

- Duraisamy, G.; Rangasamy, M.; Nagarajan, G. Effect of EGR and Premixed Mass Percentage on Cycle to Cycle Variation of Methanol/Diesel Dual Fuel RCCI Combustion; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2019. [Google Scholar]

- Ghaffarzadeh, S.; Toosi, A.N.; Hosseini, V. An experimental study on low temperature combustion in a light duty engine fueled with diesel/CNG and biodiesel/CNG. Fuel 2020, 262, 116495. [Google Scholar] [CrossRef]

- Noor, C.W.M.; Mamat, R.; Ali, O.; Najafi, G.; Mansor, W.N.D. Cyclic Variation Analysis of Palm Biodiesel Fuel in Low Compression Marine Diesel Engine. J. Adv. Res. Fluid Mech. Therm. Sci. 2020, 75, 43–58. [Google Scholar] [CrossRef]

- Santos, B.S.; Capareda, S.C.; Capunitan, J.A. Sunflower methyl ester as an engine fuel: Performance evaluation and emissions analysis. Int. Sch. Res. Not. 2013, 2013, 352024. [Google Scholar] [CrossRef] [Green Version]

- Hussain, F.; Soudagar ME, M.; Afzal, A.; Mujtaba, M.A.; Fattah, I.M.; Naik, B.; Mulla, M.H.; Badruddin, I.A.; Yunus Khan, T.M.; Raju, V.D.; et al. Enhancement in Combustion, Performance, and Emission Characteristics of a Diesel Engine Fueled with Ce-ZnO Nanoparticle Additive Added to Soybean Biodiesel Blends. Energies 2020, 13, 4578. [Google Scholar] [CrossRef]

- Ra, Y.; Reitz, R.D.; McFarlane, J.; Daw, C.S. Effects of fuel physical properties on diesel engine combustion using diesel and bio-diesel fuels. SAE Int. J. Fuels Lubr. 2009, 1, 703–718. [Google Scholar] [CrossRef]

- European Emission Standards. Available online: https://dieselnet.com/standards/eu/hd.php#stds (accessed on 20 December 2021).

- Wategave, S.; Banapurmath, N.; Sawant, M.; Soudagar, M.E.M.; Mujtaba, M.; Afzal, A.; Basha, J.S.; Alazwari, M.A.; Safaei, M.R.; Elfasakhany, A. Clean combustion and emissions strategy using reactivity controlled compression ignition (RCCI) mode engine powered with CNG-Karanja biodiesel. J. Taiwan Inst. Chem. Eng. 2021, 124, 116–131. [Google Scholar] [CrossRef]

- Reitz, R.D.; Duraisamy, G. Review of high efficiency and clean reactivity controlled compression ignition (RCCI) combustion in internal combustion engines. Prog. Energy Combust. Sci. 2015, 46, 12–71. [Google Scholar] [CrossRef] [Green Version]

- Singh, A.P.; Kumar, V.; Agarwal, A.K. Evaluation of comparative engine combustion, performance and emission characteristics of low temperature combustion (PCCI and RCCI) modes. Appl. Energy 2020, 278, 115644. [Google Scholar] [CrossRef]

- Uyumaz, A. An experimental investigation into combustion and performance characteristics of an HCCI gasoline engine fueled with n-heptane, isopropanol and n-butanol fuel blends at different inlet air temperatures. Energy Convers. Manag. 2015, 98, 199–207. [Google Scholar] [CrossRef]

- Valladolid, P.G.; Tunestål, P.; Monsalve-Serrano, J.; García, A.; Hyvönen, J. impact of diesel pilot distribution on the ignition process of a dual fuel medium speed marine engine. Energy Convers. Manag. 2017, 149, 192–205. [Google Scholar] [CrossRef] [Green Version]

- Bahri, B.; Aziz, A.A.; Shahbakhti, M.; Said, M.F.M. Understanding and detecting misfire in an HCCI engine fuelled with ethanol. Appl. Energy 2013, 108, 24–33. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Number of Cylinders | 1 |

| Cooling System | Water-cooled |

| Maximum Power | 4.7 kW at 3000 rpm |

| Maximum Speed (rpm) | 3600 |

| Maximum Torque | 16.7 Nm at 2400 rpm |

| Displacement Volume (cm3) | 290 |

| Bore (mm) | 82 |

| Stroke (mm) | 55 |

| Compression Ratio | 18:1 |

| Parameter | Value |

|---|---|

| Number of holes | 8 |

| Hole diameter | 120 |

| Spray Angle (measured vertically) | 120 |

| Injection Pressure (bar) | 400 |

| Number of injections per cycle | 1 |

| Property | Biodiesel | Diesel | NG |

|---|---|---|---|

| Density at 15 °C (kg/m3) | 0.883 | 0.83 | - |

| Kinematic viscosity (mm2/s) at 40 °C | 4.53 | 2.3 | - |

| LHV (MJ/kg) | 37.75 | 43.7 | 48 |

| Cloud point temperature (°C) | 2 | −35 | - |

| Flash point temperature (°C) | 192 | 128 | - |

| Cetane number (-) | 49.5 | 51 |

| # | - |

| Speed(rpm) | 1800 |

| DFI pressure (bar) | 400 |

| PFI pressure(bar) | 3 |

| PFI energy fraction (%) | 70 |

| PFI duration (ms) | 4.88 |

| DFI duration (µs) | 768 (B0), 770 (B5), and (775) |

| Volumetric percentage of biodiesel in DFI | 0, 5, and 20 |

| Port fuel mass (kg/h) | 0.256 |

| Direct fuel mass (kg/h) | 0.12(B0), 0.121 (B5), and 0.123 (B20) |

| Total fuel energy (J/cycle) | 325 |

| Inlet air temperature (°C) | 37 |

| Inlet air gauge pressure (bar) | 0.4 |

| Cooling water temperature (°C) | 60 |

| PFI | Natural gas |

| DFI | Diesel and biodiesel |

| SOI timing | −51 CAD aTDC |

| Case # | IMEP Range | Number of Cycles | % | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Number (of 300 Cycles) | % | Number (of 300 Cycles) | % | Number (of 300 Cycles) | % | ||||

| B0 | 205 | 68.3 | 86 | 28.7 | 9 | 3 | 3.9–4.1 | 283 | 94.3 |

| B5 | 203 | 67.7 | 81 | 27 | 14 | 5.3 | 3.1–3.6 | 287 | 95.7 |

| B20 | 211 | 70.4 | 67 | 22.3 | 22 | 7.3 | 3.1–3.7 | 288 | 96 |

| Case # | ||||

|---|---|---|---|---|

| Number (of 275 Cycles) | % | Number (of 300 Cycles) | % | |

| B0 | 0 | 0 | 41 | 13.7 |

| B5 | 51 | 18.5 | 0 | 0 |

| B20 | 96 | 34.9 | 13 | 4.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zarrinkolah, M.T.; Hosseini, V. Detailed Analysis of the Effects of Biodiesel Fraction Increase on the Combustion Stability and Characteristics of a Reactivity-Controlled Compression Ignition Diesel-Biodiesel/Natural Gas Engine. Energies 2022, 15, 1094. https://doi.org/10.3390/en15031094

Zarrinkolah MT, Hosseini V. Detailed Analysis of the Effects of Biodiesel Fraction Increase on the Combustion Stability and Characteristics of a Reactivity-Controlled Compression Ignition Diesel-Biodiesel/Natural Gas Engine. Energies. 2022; 15(3):1094. https://doi.org/10.3390/en15031094

Chicago/Turabian StyleZarrinkolah, Mohammad Taghi, and Vahid Hosseini. 2022. "Detailed Analysis of the Effects of Biodiesel Fraction Increase on the Combustion Stability and Characteristics of a Reactivity-Controlled Compression Ignition Diesel-Biodiesel/Natural Gas Engine" Energies 15, no. 3: 1094. https://doi.org/10.3390/en15031094