Comparative Simulation Study of Pump System Efficiency Driven by Induction and Synchronous Reluctance Motors

Abstract

:1. Introduction

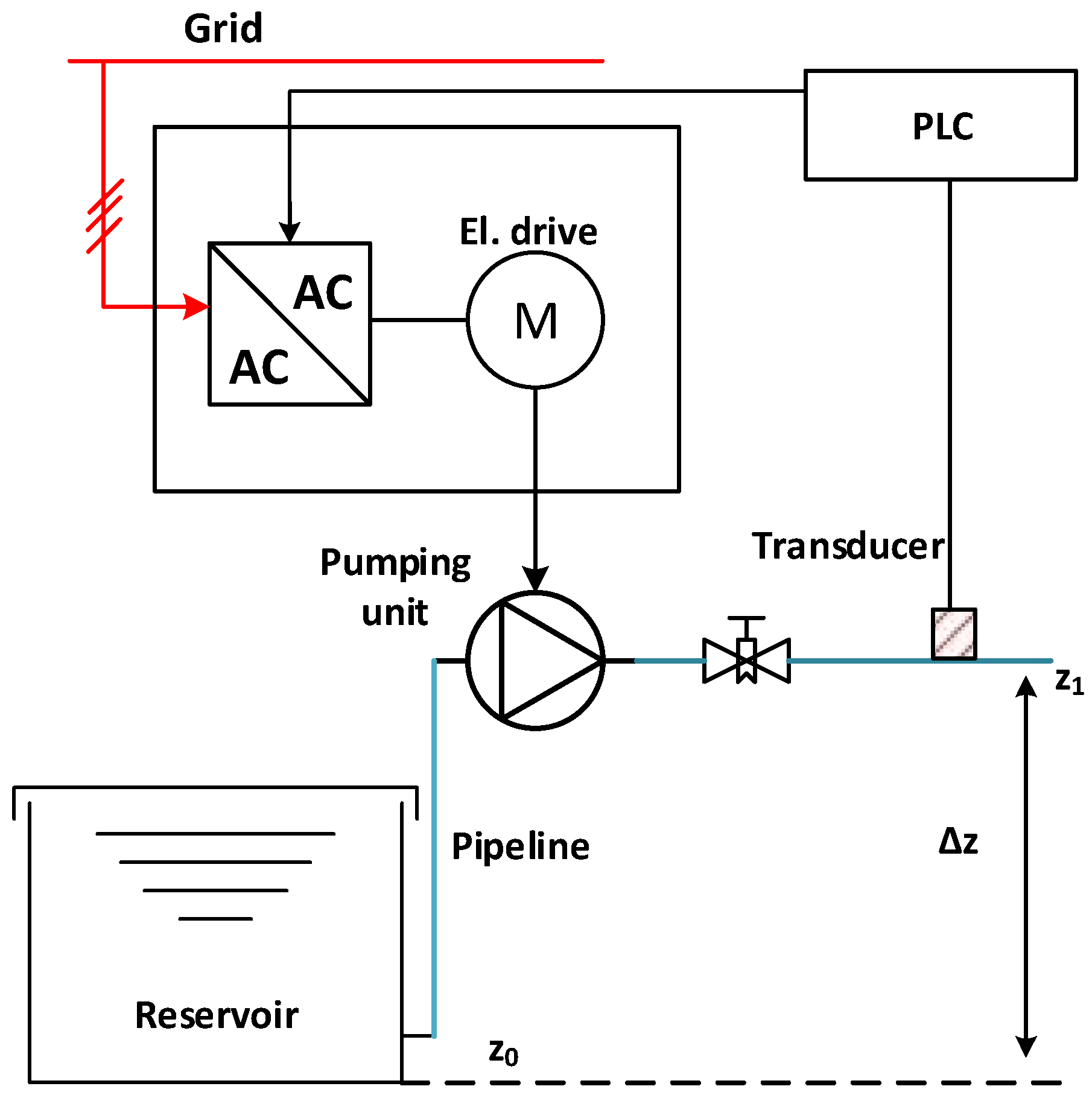

2. Efficiency-Oriented Control of a Pump

3. Simulation Approach for Pumping Plant’s Efficiency Calculation

- In1, In2—the reference speed input for flow and head calculation of a system curve;

- In3, In4, In4—the reference flow input that determines the position of a system curve;

- Out1—the reference value of total head corresponding to the reference flow;

- Out2—the flow value corresponding to the reference speed and system curve position;

- Out3—the mechanical power of the pumping unit, which is estimated in line with mathematical expression (3).

4. Simulation and Experimental Results

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- European Commission. Study on Improving the Energy Efficiency of Pumps. 2001. Available online: http://www.jakob-albertsen.dk/komposit/Darmstadtrapport.pdf (accessed on 2 February 2020).

- Karassik, I.J.; McGuire, T. Centrifugal Pumps; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012; p. 780. [Google Scholar]

- Nelik, L. Centrifugal and Rotary Pumps. Fundamentals with Applications; CRC Press: Boca Raton, FL, USA, 1999; p. 152. [Google Scholar]

- Finnemore, E.; Franzini, J.B. Fluid Mechanics with Engineering Applications; McGraw Hill Inc.: New York, NY, USA, 2002; p. 500. [Google Scholar]

- Gevorkov, L.; Šmídl, V.; Sirový, M. Model for Pump Driven Heating System in Domestic Application. In Proceedings of the 2019 IEEE 2nd Ukraine Conference on Electrical and Computer Engineering (UKRCON), Lviv, Ukraine, 2–6 July 2019; pp. 610–614. [Google Scholar]

- Guan, D.; Cong, X.; Li, J.; Niu, Z. Experimental test and theoretical modeling on the working characteristics of spherical water pump, Flow Measurement and Instrumentation. Flow Meas. Instrum. 2022, 85, 102162. [Google Scholar] [CrossRef]

- Oshurbekov, S.; Kazakbaev, V.; Prakht, V.; Dmitrievskii, V.; Gevorkov, L. Energy Consumption Comparison of a Single Variable-Speed Pump and a System of Two Pumps: Variable-Speed and Fixed-Speed. Appl. Sci. 2020, 10, 8820. [Google Scholar] [CrossRef]

- Oshurbekov, S.; Kazakbaev, V.; Prakht, V.; Dmitrievskii, V.; Gevorkov, L. Extending Pump Unit Service Life Using Combined Pump Control. In Proceedings of the 28th International Workshop on Electric Drives: Improving Reliability of Electric Drives (IWED), Moscow, Russia, 27–29 January 2021; pp. 1–6. [Google Scholar]

- Ahonen, T. Monitoring of Centrifugal Pump Operation by a Frequency Converter. Ph.D. Thesis, Lappeenranta University of Technology, Lappeenranta, Finland, May 2011. [Google Scholar]

- Chen, Y.C.; Coulbeck, B. Optimized operation of water supply systems containing a mixture of fixed and variable speed pumps. In Proceedings of the 1991 International Conference on Control, Edinburgh, UK, 25–28 March 1991; Volume 2, pp. 1200–1205. [Google Scholar]

- Zhang, Y.; Wang, X.; Pu, W. The Relationship Between the Maximum Efficiency and the Flow of Centrifugal Pumps in Parallel Operation. J. Press. Vessel. Technol. 2010, 132, 1–2. [Google Scholar] [CrossRef]

- Rauschenbach, T. Modeling, Control and Optimization of Water Systems: Systems Engineering Methods for Control and Decision Making Tasks; Springer: Berlin/Heidelberg, Germany, 2015; p. 303. [Google Scholar]

- Goman, V.; Prakht, V.; Kazakbaev, V.; Dmitrievskii, V. Comparative Study of Energy Consumption and CO2 Emissions of Variable-Speed Electric Drives with Induction and Synchronous Reluctance Motors in Pump Units. Mathematics 2021, 9, 2679. [Google Scholar] [CrossRef]

- Dlala, E.; Belahcen, A.; Pippuri, J.; Arkkio, A. Interdependence of Hysteresis and Eddy-Current Losses in Laminated Magnetic Cores of Electrical Machines. IEEE Trans. Magn. 2010, 46, 306–309. [Google Scholar] [CrossRef]

- Gevorkov, L.; Vodovozov, V.; Lehtla, T.; Bakman, I. PLC-based flow rate control system for centrifugal pumps. In Proceedings of the 56th International Scientific Conference on Power and Electrical Engineering of Riga Technical University (RTUCON), Riga, Latvia, 14 October 2015; pp. 1–5. [Google Scholar]

- Gallicchio, G.; Di Nardo, M.; Palmieri, M.; Marfoli, A.; Degano, M.; Gerada, C.; Cupertino, F. High Speed Synchronous Reluctance Machines: Modeling, Design and Limits. IEEE Trans. Energy Convers. 2021, 37, 585–597. [Google Scholar] [CrossRef]

- Degano, M.; Murataliyev, M.; Shuo, W.; Barater, D.; Buticchi, G.; Jara, W.; Bianchi, N.; Galea, M.; Gerada, C. Optimised Design of Permanent Magnet Assisted Synchronous Reluctance Machines for Household Appliances. IEEE Trans. Energy Convers. 2021, 36, 3084–3095. [Google Scholar] [CrossRef]

- Gokdag, M. Modulated Predictive Control to Improve the Steady-State Performance of NSI-Based Electrification Systems. Energies 2022, 15, 2043. [Google Scholar] [CrossRef]

- Gulbudak, O.; Gokdag, M. Predictive dual-induction machine control using nine-switch inverter for multi-drive systems. In Proceedings of the IEEE 12th International Conference on Compatibility, Power Electronics and Power Engineering (CPE-POWERENG 2018), Doha, Qatar, 10–12 April 2018; pp. 1–6. [Google Scholar]

- Urschel, S.; Dolgirev, J. Energy–and resource saving synchronous reluctance machine for the use in circulation pumps. In Proceedings of the 2017 IEEE 3rd International Future Energy Electronics Conference and ECCE Asia (IFEEC 2017–ECCE Asia), Kaohsiung, Taiwan, 3–7 June 2017; pp. 2139–21441. [Google Scholar]

- Gevorkov, L.; Vodovozov, V. Study of the Centrifugal Pump Efficiency at Throttling and Speed Control. In Proceedings of the 2016 15th Biennial Baltic Electronics Conference (BEC), Tallinn, Estonia, 3–5 October 2016; pp. 199–202. [Google Scholar]

- Vodovozov, V.; Lehtla, T.; Bakman, I.; Raud, Z.; Gevorkov, L. Energy-efficient predictive control of centrifugal multi-pump stations. In Proceedings of the Electric Power Quality and Supply Reliability (PQ), Tallinn, Estonia, 29–31 August 2016; pp. 233–2381. [Google Scholar]

- Shankar, A.; Umashankar, V.K.; Paramasivam, S.; Hanigovszki, S. A comprehensive review on energy efficiency enhancement initiatives in centrifugal pumping system. Appl. Energy 2016, 181, 495–5131. [Google Scholar] [CrossRef]

- Gevorkov, L.; Šmídl, V.; Sirový, M. Model of Hybrid Speed and Throttle Control for Centrifugal Pump System Enhancement. In Proceedings of the 2019 IEEE 28th International Symposium on Industrial Electronics (ISIE), Vancouver, BC, Canada, 12–14 June 2019; pp. 563–568. [Google Scholar]

- Boglietti, A.; Cavagnino, A.; Pastorelli, M.; Vagati, A. Experimental comparison of induction and synchronous reluctance motors performance. In Proceedings of the Fourtieth IAS Annual Meeting. Conference Record of the 2005, Hong Kong, China, 2–6 October 2005; Volume 1, pp. 474–479. [Google Scholar]

- Wang, Y.; Ionel, D.M.; Staton, D. Ultrafast Steady-State Multiphysics Model for PM and Synchronous Reluctance Machines. IEEE Trans. Ind. Appl. 2015, 51, 3639–3646. [Google Scholar] [CrossRef]

- Pi, A.J.; Xu, L. Comparison of apparent power consumption in Synchronous Reluctance and Induction Motor under vector control. In Proceedings of the Transportation Electrification Conference and Expo (ITEC), Dearborn, MI, USA, 14–17 June 2015; pp. 1–6. [Google Scholar]

- Gevorkov, L.; Šmídl, V.; Sirový, M.; Rassõlkin, A.; Kallaste, A.; Vaimann, T. Model for Torque Estimation of Pump System with Horizontal Pipe Network. In Proceedings of the 2019 26th International Workshop on Electric Drives: Improvement in Efficiency of Electric Drives (IWED), Moscow, Russia, 30 January–2 February 2019; pp. 1–5. [Google Scholar]

- Victoria, M.; Querin, O.M.; Díaz, C.; Martí, P. liteITD a MATLAB Graphical User Interface (GUI) program for topology design of continuum structures. Adv. Eng. Softw. 2016, 100, 126–147. [Google Scholar] [CrossRef]

- Centrifugal Pumps SE Series for Waste Water Applications. Available online: https://pdf.directindustry.com/pdf/grundfos/grundfos-se-sl-ranges/5420-488575.html (accessed on 31 May 2022).

- Autsou, S.; Rassõlkin, A.; Gevorkov, L.; Saroka, V.; Karpovich, D.; Vaimann, T.; Kallaste, A.; Belahcen, A. Comparative Study of Field-Orinted Contol Model in Application for Induction and Synchronous Reluctance Motors for Lifecycle Analysis. In Proceedings of the 25th International Workshop on Electric Drives: Optimization in Control of Electric Drives IWED, Moscow, Russia, 31 January–2 February 2019; pp. 1–6. [Google Scholar]

- Ikeda, K. Hysteretic Rotating Characteristics of an HTS Induction/Synchronous Motor. IEEE Trans. Appl. Supercond. 2017, 27, 1–5. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Pump type | SE |

| Impeller type | S-tube impeller |

| Pump free passage, mm | 85 |

| Housing type | Cast iron |

| Pump discharge, mm | 150 |

| Output power, kW | 9 |

| Pressure range type | High |

| Application | Water/wastewater |

| Parameter | IM | SynRM |

|---|---|---|

| Frame size | 132 MA | 132 MA |

| Nominal power, kW | 9.5 | 10.5 |

| Nominal current, A | 19.3 | 25.3 |

| Nominal speed, rpm | 1460 | 1500 |

| cosϕ | 0.7 | 0.6 |

| Moment of inertia, kgm2 | 0.02 | 0.02 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gevorkov, L.; Domínguez-García, J.L.; Rassõlkin, A.; Vaimann, T. Comparative Simulation Study of Pump System Efficiency Driven by Induction and Synchronous Reluctance Motors. Energies 2022, 15, 4068. https://doi.org/10.3390/en15114068

Gevorkov L, Domínguez-García JL, Rassõlkin A, Vaimann T. Comparative Simulation Study of Pump System Efficiency Driven by Induction and Synchronous Reluctance Motors. Energies. 2022; 15(11):4068. https://doi.org/10.3390/en15114068

Chicago/Turabian StyleGevorkov, Levon, José Luis Domínguez-García, Anton Rassõlkin, and Toomas Vaimann. 2022. "Comparative Simulation Study of Pump System Efficiency Driven by Induction and Synchronous Reluctance Motors" Energies 15, no. 11: 4068. https://doi.org/10.3390/en15114068