Evaporator Optimization of Refrigerator Systems Using Quality Analysis

Abstract

:1. Introduction

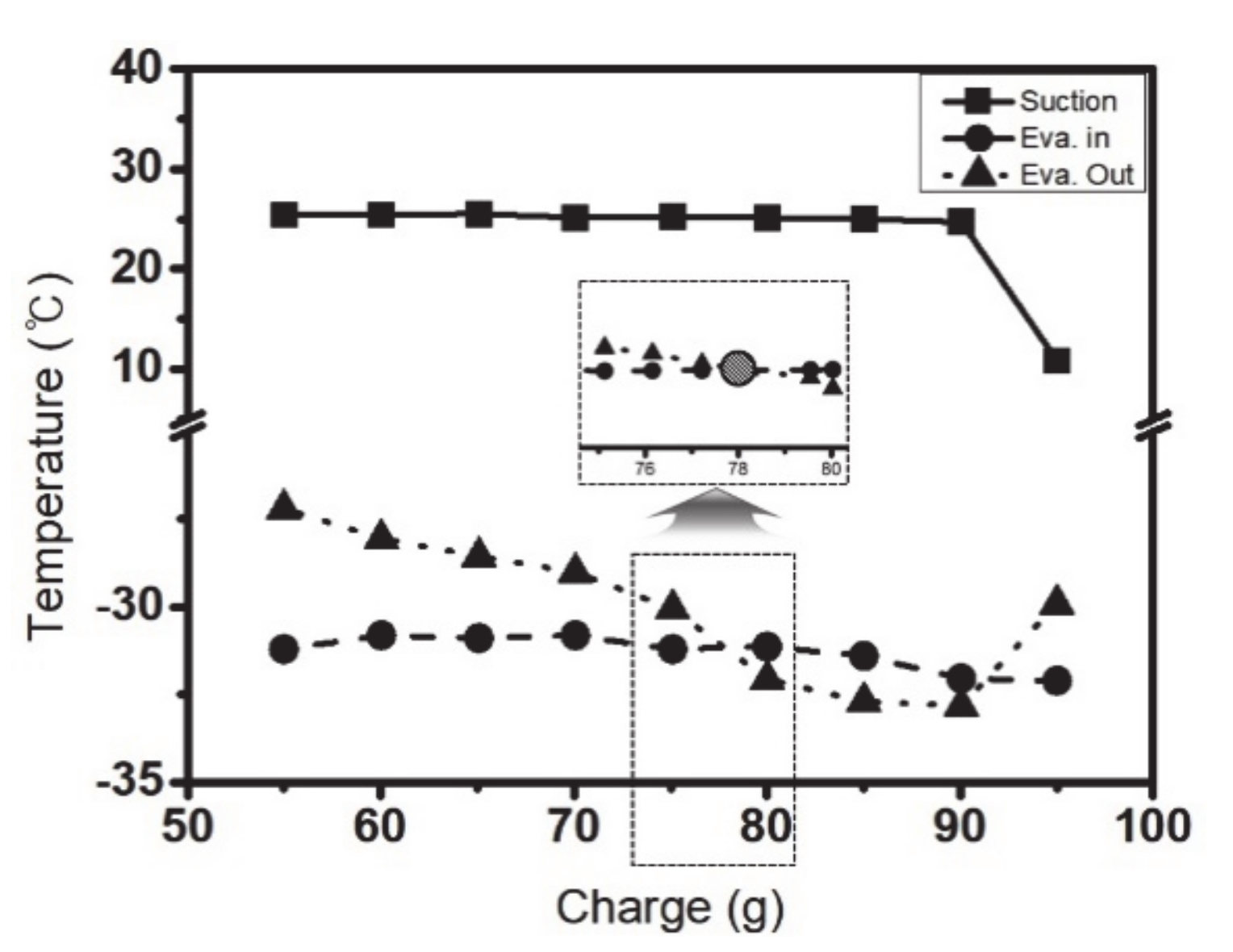

2. Experimental Setup

3. Evaluation of the Refrigerator System

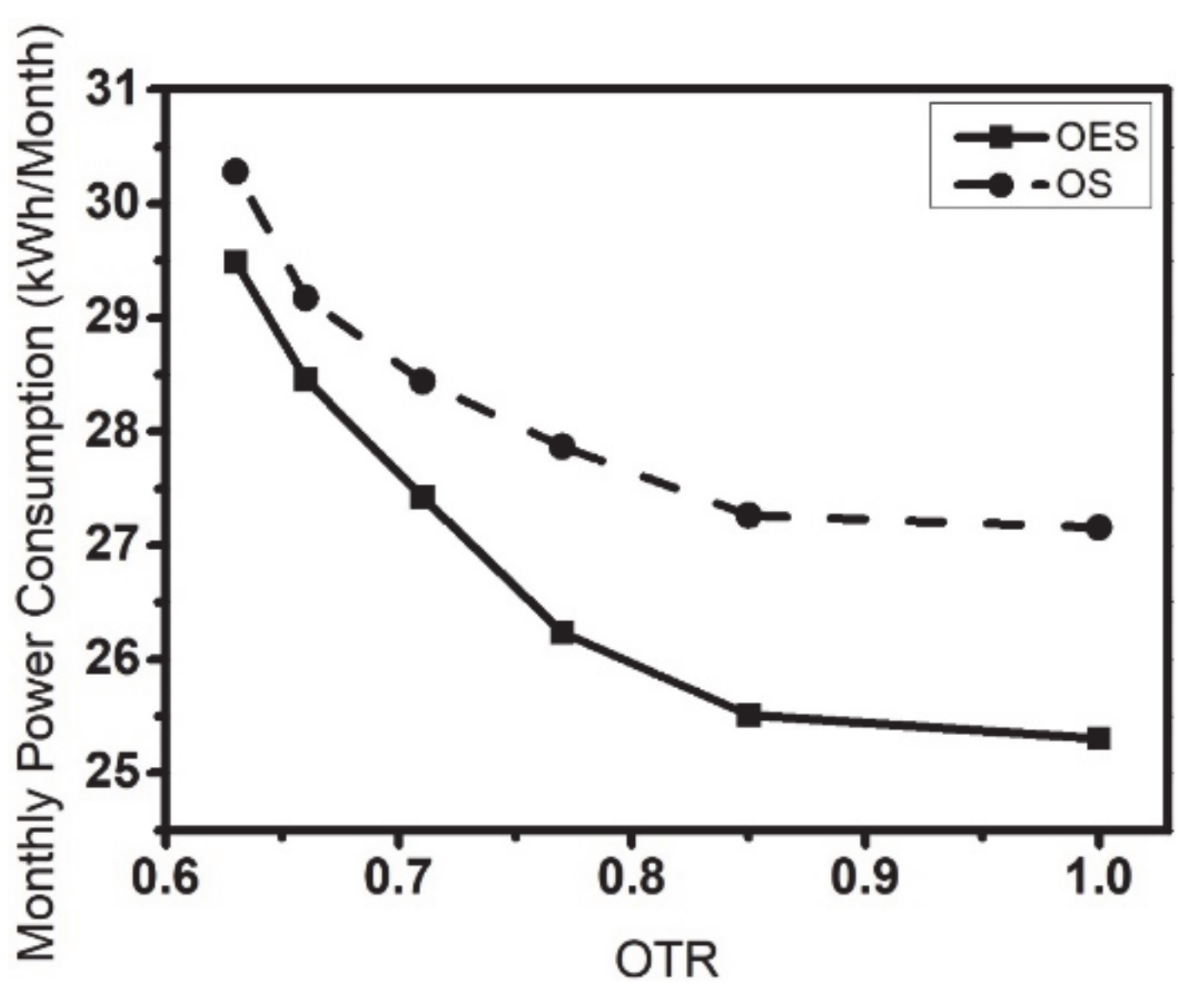

3.1. Monthly Power Consumption of Refrigeration System

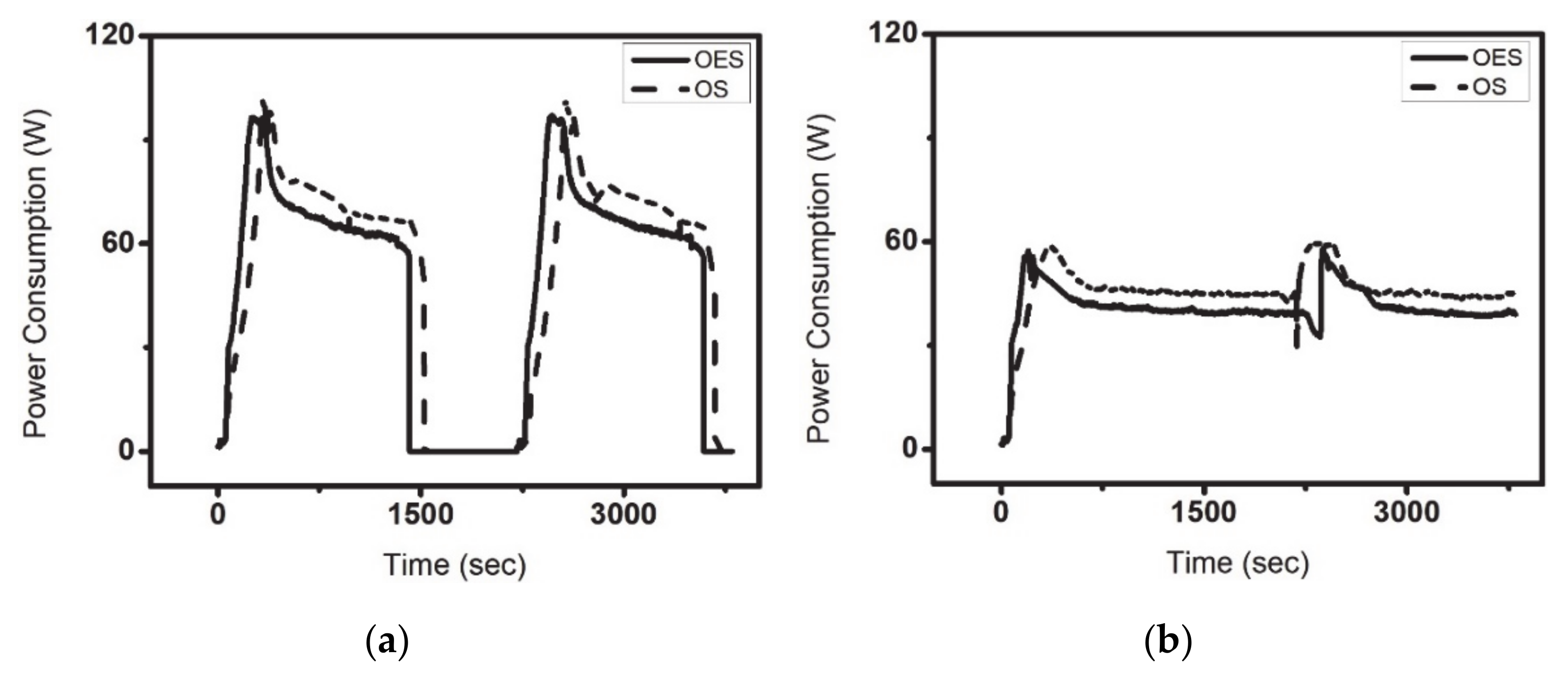

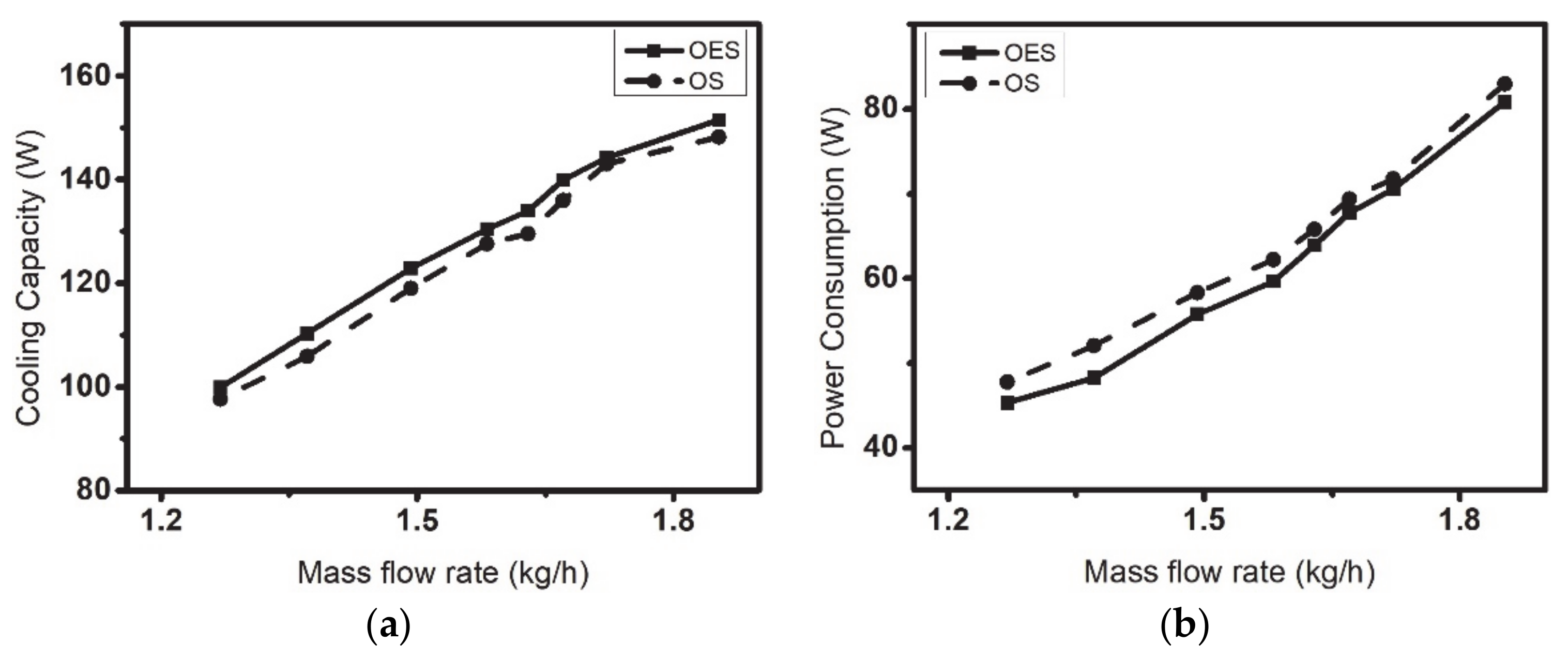

3.2. Steady-State Energy Test

4. Quality Analysis of the Evaporator

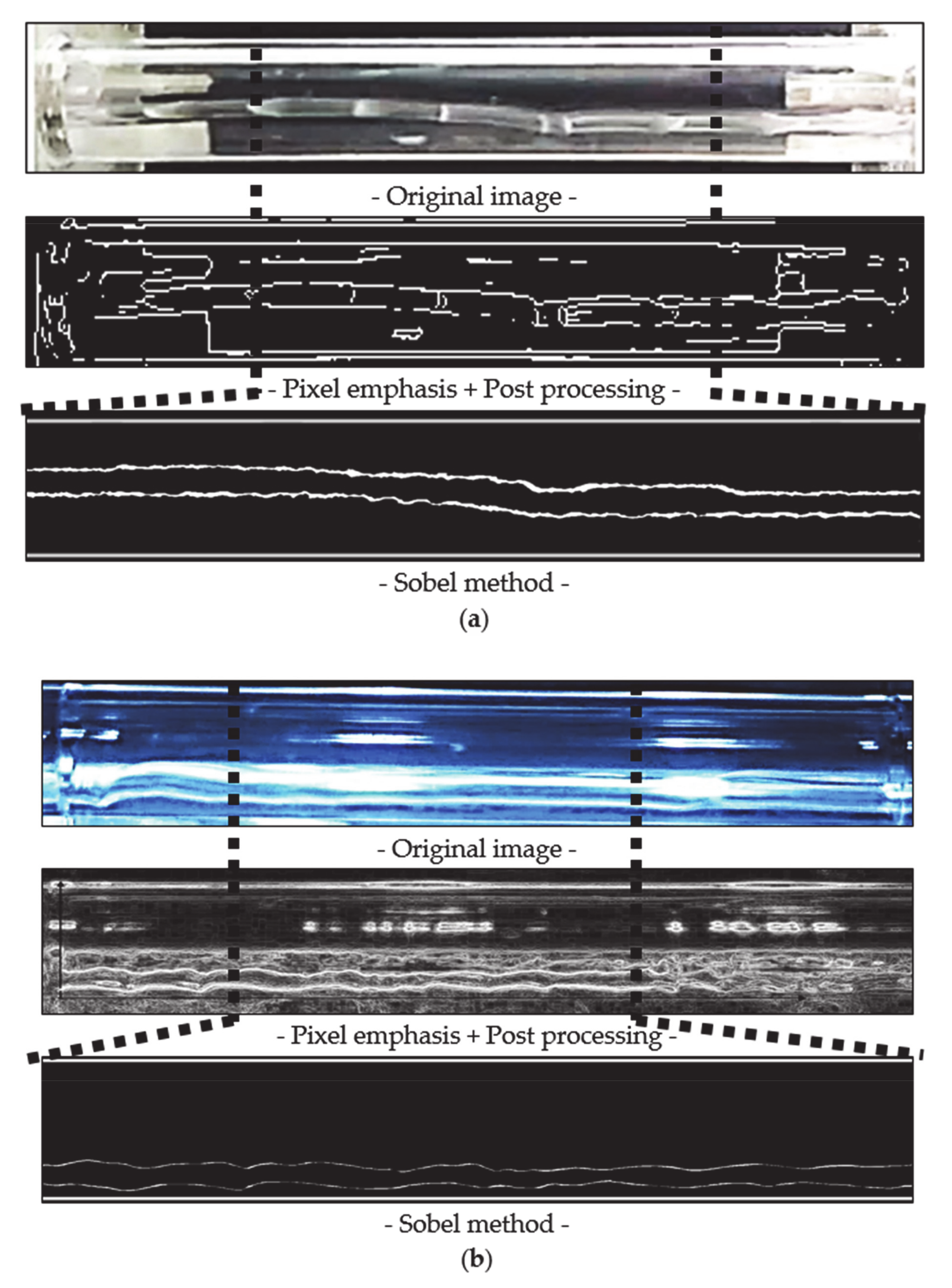

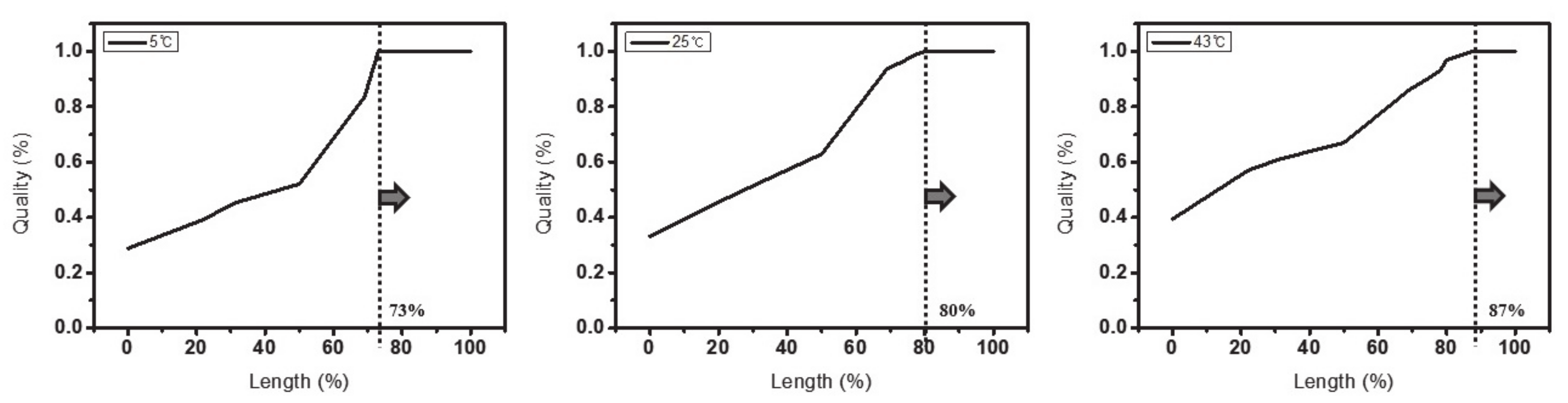

4.1. Quality Analysis through Visualization Method

4.2. Simulation Results of Evaporator Quality

5. Conclusions

- When the OTR varies from 0.6 to 1, the monthly power consumption of the OES is about 2.6% less than for the OS. In the case where the OTR is 1, the monthly power consumption of the OES is lower by about 6.8% compared to the OS. This is because the additional power consumption to overcome the equalization pressure, occurs in the OS and the heat transfer capability of the evaporator has been improved by eliminating oil in the OES.

- -

- When the OTR is 1, the cooling capacity of the OES was an average 2.6% higher, at various mass flow rate conditions. When considering the power consumption, OES is lower, by an average of 3.6%, compared to the OS. This is because the power loss attributable to the oil film inside the evaporator was removed and heat transfer capacity improved. COP, the ratio of the cooling capacity and power consumption, of the OES is higher by an average of 6.2% at various mass flow rate conditions.

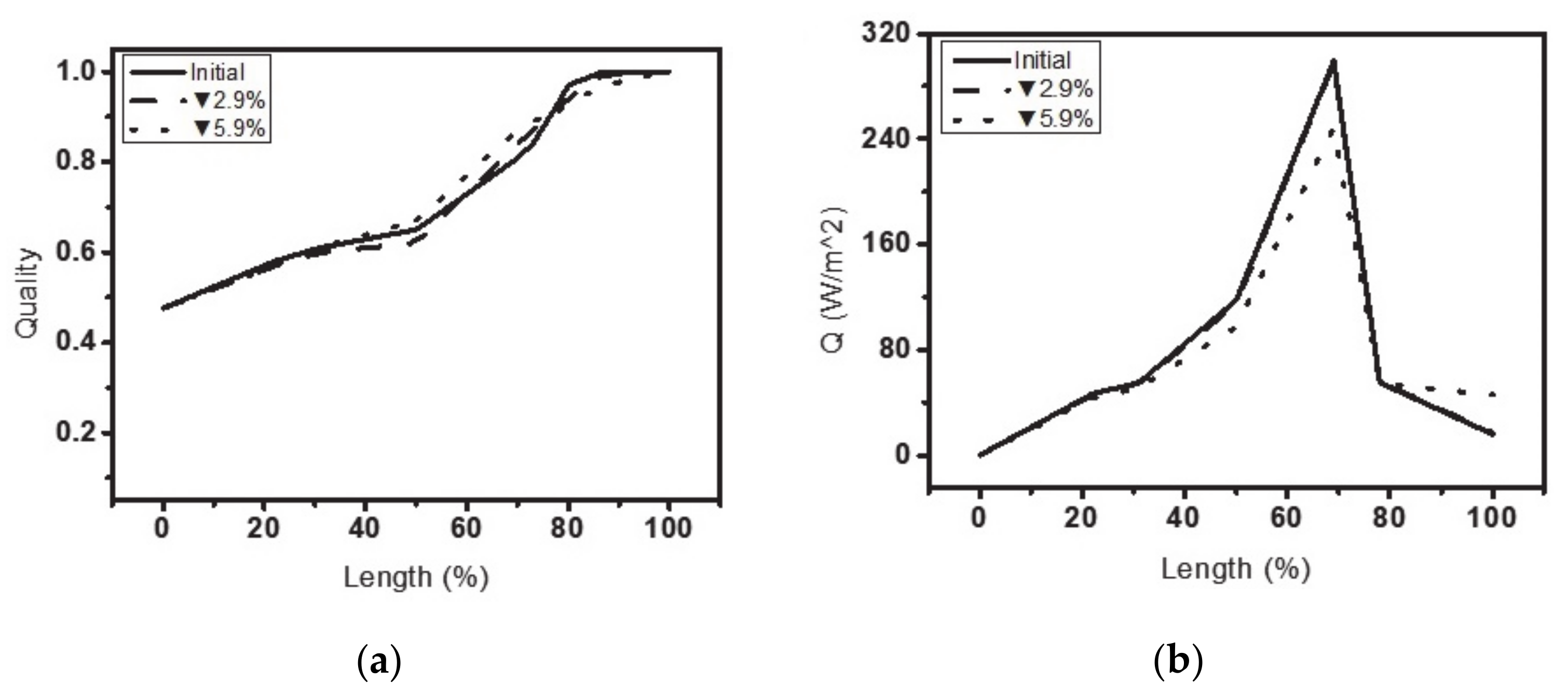

- To optimize the evaporator of the refrigerator, visualization experiments and simulations were conducted under the optimal operating conditions (OES and OTR are 1). The size of the evaporator can be reduced by about 2.9%. The details and results of the visualization experiments and simulations follow in the text bellow:

- -

- To evaluate the quality of the refrigerant in the evaporator, the visualization experiments were conducted at three different ambient temperature conditions. The quality of the refrigerants was calculated using numerical models based on the visualization results. The visualization results of the evaporator inlet part were compared to the sensing value to evaluate the visualization experiments. The maximum error of the visualization results is 3.43% when the ambient temperature is 43 °C. In the case of the visualization results of the evaporator middle part, the results compared to simulation results to evaluate the simulation accuracy and the maximum error of the simulation is 4.61% when the ambient temperature is 5 °C condition.

- -

- To minimize the evaporator of the refrigerator, quality simulations were conducted at all regions of the evaporator. The amount of heat transfer per unit area, 2.9% for the case of the minimized evaporator a similar amount of heat transfer was observed when compared to the conventional evaporator size. If it is reduced by more than 2.9%, the heat transfer amount per unit area is lower than the conventional evaporator performance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

Nomenclature

| COP | Coefficient of performance |

| CFD | Computational fluid dynamics |

| MFM | Mass flow meter |

| R room | Refrigerator room |

| F room | Freezer room |

| ISO | International organization for standardization |

| τ | On-Time Ratio(OTR) |

| ton | Compressor operating time [s] |

| toff | Compressor off time [s] |

| ε | Void fraction |

| x | Quality |

| ρG | Gas phase density of refrigerant [kg/m3] |

| ρL | Liquid phase density of refrigerant [kg/m3] |

| C0 | Distribution parameter |

| UGU | Drift velocity [m/s] |

| G | Total mass flux of gas and liquid [kg/m2] |

| σ | Surface tension [N/m] |

| g | Acceleration of gravity [9.81 m/s2] |

References

- Elarem, R.; Mellouli, S.; Abhilash, E.; Jemni, A. Performance analysis of a household refrigerator integrating a PCM heat exchanger. Appl. Therm. Eng. 2017, 125, 1320–1333. [Google Scholar] [CrossRef]

- Simard, A.; Lacroix, M. Study of the thermal behavior of a latent heat cold storage unit operating under frosting conditions. Energy Convers. Manag. 2003, 44, 1605–1624. [Google Scholar] [CrossRef]

- Coulomb, D.; Dupont, J.L.; Pichard, A. The Role of refrigeration in the Global Economy—29th Informatory Note on Refrigeration Technologies; International Institute of Refrigeration: Paris, France, 2015. [Google Scholar]

- Kim, J.K.; Roh, C.G.; Kim, H.; Jeong, J.H. An experimental and numerical study on an inherent capacity modulated linear compressor for home refrigerators. Int. J. Refrig. 2011, 34, 1415–1423. [Google Scholar] [CrossRef]

- Chun, T.-W.; Ahn, J.-R.; Lee, H.-H.; Kim, H.-G.; Nho, E.-C. A Novel Strategy of Efficiency Control for a Linear Compressor System Driven by a PWM Inverter. IEEE Trans. Ind. Electron. 2008, 55, 296–301. [Google Scholar] [CrossRef]

- Na, S.; Shin, M.; Choi, G.; Min, B. Effect of pressure ratio and oil viscosity on rotary compressor efficiency. J. Mech. Sci. Technol. 2018, 32, 4971–4981. [Google Scholar] [CrossRef]

- Aprea, C.; Mastrullo, R.; Renno, C. Determination of the compressor optimal working conditions. Appl. Therm. Eng. 2009, 29, 1991–1997. [Google Scholar] [CrossRef] [Green Version]

- Ooi, K.; Wong, T. A computer simulation of a rotary compressor for household refrigerators. Appl. Therm. Eng. 1997, 17, 65–78. [Google Scholar] [CrossRef]

- Tuhovcak, J.; Hejcik, J.; Jicha, M. Comparison of heat transfer models for reciprocating compressor. Appl. Therm. Eng. 2016, 103, 607–615. [Google Scholar] [CrossRef]

- Cai, D.; Qiu, C.; Pan, J.; Yang, X.; He, G.; Tetsuhide, Y.; Chen, X.; Li, H. Leakage characteristics and an updated volumetric efficiency prediction model of rolling piston type rotary compressor for small capacity air-conditioner and heat pump applications. Appl. Therm. Eng. 2017, 121, 1080–1094. [Google Scholar] [CrossRef]

- Mohseni, S.; Akhavan-Behabadi, M. Flow pattern visualization and heat transfer characteristics of R-134a during evaporation inside a smooth tube with different tube inclinations. Int. Commun. Heat Mass Transf. 2014, 59, 39–45. [Google Scholar] [CrossRef]

- Zhang, Q.; Lin, G.; Shen, X.; Bai, L.; Wen, D. Visualization study on the heat and mass transfer in the evaporator-compensation chamber of a loop heat pipe. Appl. Therm. Eng. 2020, 164, 114472. [Google Scholar] [CrossRef]

- Tosun, T.; Tosun, M. Heat exchanger optimization of a domestic refrigerator with separate cooling circuits. Appl. Therm. Eng. 2020, 168, 114810. [Google Scholar] [CrossRef]

- Söylemez, E.; Alpman, E.; Onat, A.; Hartomacıoğlu, S. CFD analysis for predicting cooling time of a domestic refrigerator with thermoelectric cooling system. Int. J. Refrig. 2021, 123, 138–149. [Google Scholar] [CrossRef]

- Zhu, Z.; Liang, K.; Li, Z.; Jiang, H.; Meng, Z. Thermal-economic-environmental analysis on household refrigerator using a variable displacement compressor and low-GWP refrigerants. Int. J. Refrig. 2021, 123, 189–197. [Google Scholar] [CrossRef]

- Hermes, C.J.; Melo, C.; Knabben, F.T. Alternative test method to assess the energy performance of frost-free refrigerating appliances. Appl. Therm. Eng. 2013, 50, 1029–1034. [Google Scholar] [CrossRef]

- Thome, J.R. Encyclopedia of Two-Phase Heat Transfer and Flow IV: Modeling Methodologies-Boiling of CO2 and Micro Two-Phase Cooling; World Scientific Publishing: Singapore, 2018. [Google Scholar]

- Zuber, N.; Findlay, J.A. Average Volumetric Concentration in Two-Phase Flow Systems. J. Heat Transf. 1965, 87, 453–468. [Google Scholar] [CrossRef]

- Wallis, G.B. One-Dimensional Two-Phase Flow; McGraw Hill: New York, NY, USA, 1969. [Google Scholar]

- Hibiki, T.; Ishii, M. One-dimensional drift-flux model and constitutive equations for relative motion between phases in various two-phase flow regimes. Int. J. Heat Mass Transf. 2003, 46, 4935–4948. [Google Scholar] [CrossRef] [Green Version]

- Godbole, P.V.; Tang, C.C.; Ghajar, A.J. Comparison of Void Fraction Correlations for Different Flow Patterns in Upward Vertical Two-Phase Flow. Heat Transf. Eng. 2011, 32, 843–860. [Google Scholar] [CrossRef]

- Woldesemayat, M.A.; Ghajar, A.J. Comparison of void fraction correlations for different flow patterns in horizontal and upward inclined pipes. Int. J. Multiph. Flow 2007, 33, 347–370. [Google Scholar] [CrossRef]

- Coddington, P.; Macian, R. A study of the performance of void fraction correlations used in the context of drift-flux two-phase flow models. Nucl. Eng. Des. 2002, 215, 199–216. [Google Scholar] [CrossRef]

- Kim, G.; Lee, J.; Park, J.; Song, S. Flow visualization and noise measurement of R410A two-phase flow near electric expansion valve for heating cycle of multi-split air-source heat pump. Appl. Therm. Eng. 2019, 157, 113712. [Google Scholar] [CrossRef]

- Rouhani, S.; Axelsson, E. Calculation of void volume fraction in the subcooled and quality boiling regions. Int. J. Heat Mass Transf. 1970, 13, 383–393. [Google Scholar] [CrossRef]

- Steiner, D. VDI-Gesellshaft Verfahrenstechnik und Chemieingenieurwesen (GVC); Springer: Berlin/Heidelberg, Germany, 1993. [Google Scholar]

- Gao, W.; Zhang, X.; Yang, L.; Liu, H. An improved Sobel edge detection. In Proceedings of the 2010 3rd International conference on computer science and information technology, Chengdu, China, 9–11 July 2010; Volume 5, pp. 67–71. [Google Scholar]

- Malik, J.; Sainarayanan, G.; Dahiya, R. Min Max Threshold Range (MMTR) based approach in palmprint authentication by sobel code method. Procedia Comput. Sci. 2010, 2, 149–158. [Google Scholar] [CrossRef] [Green Version]

- Tanaka, K.; Higashi, Y. Measurements of the surface tension for R290, R600a and R290/R600a mixture. Int. J. Refrig. 2007, 30, 1368–1373. [Google Scholar] [CrossRef]

- Sharifian, A.; Siang, J.T. Impacts of Room Temperature on the Performance of a Portable Propane Air Conditioner. Int. J. Air-Conditioning Refrig. 2015, 23, 1550015. [Google Scholar] [CrossRef]

- Ameel, B.; Huisseune, H.; DeGroote, J.; T’Joen, C.; De Jaeger, P.; Vierendeels, J.; De Paepe, M. On fin efficiency in interrupted fin and tube heat exchangers. Int. J. Heat Mass Transf. 2013, 60, 557–566. [Google Scholar] [CrossRef]

- Wang, C.-C.; Chi, K.-Y.; Chang, C.-J. Heat transfer and friction characteristics of plain fin-and-tube heat exchangers, part II: Correlation. Int. J. Heat Mass Transf. 2000, 43, 2693–2700. [Google Scholar] [CrossRef]

- Dittus, F.; Boelter, L. Heat transfer in automobile radiators of the tubular type. Int. Commun. Heat Mass Transf. 1985, 12, 3–22. [Google Scholar] [CrossRef]

- Wojtan, L.; Ursenbacher, T.; Thome, J.R. Investigation of flow boiling in horizontal tubes: Part II—Development of a new heat transfer model for stratified-wavy, dryout and mist flow regimes. Int. J. Heat Mass Transf. 2005, 48, 2970–2985. [Google Scholar] [CrossRef]

- Incropera, F.P.; Dewitt, D.P. Introduction to Heat Transfer, 3rd ed.; WILEY: New York, NY, USA, 1996. [Google Scholar]

| Condition | Year | Domains | Ambient Temp. | Fresh Food Temp. | Freezer Temp. |

|---|---|---|---|---|---|

| ISO 62552 | 2007 | International | 25 °C or 32 °C | 5.0 °C | −6.0 °C or −12.0 °C or −18.0 °C |

| Ambient Temp. | Humidity | Inlet Part x | Middle Part x |

|---|---|---|---|

| 5°C | 50% | 0.288 | 0.521 |

| 25°C | 0.332 | 0.629 | |

| 43°C | 0.394 | 0.670 |

| Ambient Temperature | Humidity | Experimental Results | Sensing Results | Error (%) |

|---|---|---|---|---|

| 5 °C | 50% | 0.288 | 0.291 | 1.03 |

| 25 °C | 0.332 | 0.343 | 3.21 | |

| 43 °C | 0.394 | 0.408 | 3.43 |

| Refrigerants State | Numerical Model | |

|---|---|---|

| Fin efficiency correlations | Schmidt correlation [31] | |

| Air side heat transfer | Wang Chi Chang plate fin model [32] | |

| Refrigerant side heat transfer | Liquid-phase | Dittus Boelter model [33] |

| Two-phase | Thome TP evapo flow pattern-map [34] | |

| Vapor-phase | Dittus Boelter model [33] | |

| Air side pressure drop | Wang Chi Chang plate fin model [32] | |

| Refrigerant side pressure drop | Liquid-phase | Blasius type model [35] |

| Two-phase | Thome TP evapo flow pattern-map [34] | |

| Vapor-phase | Blasius type model [35] |

| Ambient Temperature | Experimental Results | Simulation Results | Error (%) |

|---|---|---|---|

| 5 °C | 0.521 | 0.545 | 4.61 |

| 25 °C | 0.629 | 0.647 | 2.86 |

| 43 °C | 0.670 | 0.680 | 1.50 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Na, S.; Song, S.; Lee, S.; Lee, J.; Kim, H.; Lee, S.; Choi, G.; Ahn, S. Evaporator Optimization of Refrigerator Systems Using Quality Analysis. Energies 2021, 14, 555. https://doi.org/10.3390/en14030555

Na S, Song S, Lee S, Lee J, Kim H, Lee S, Choi G, Ahn S. Evaporator Optimization of Refrigerator Systems Using Quality Analysis. Energies. 2021; 14(3):555. https://doi.org/10.3390/en14030555

Chicago/Turabian StyleNa, Sangkyung, Sanghun Song, Seunghyuk Lee, Jehwan Lee, Hyun Kim, Sungwoo Lee, Gyungmin Choi, and Seongyool Ahn. 2021. "Evaporator Optimization of Refrigerator Systems Using Quality Analysis" Energies 14, no. 3: 555. https://doi.org/10.3390/en14030555