The Influence of Photovoltaic Cell Coverage Rate on the Thermal and Electric Performance of Semi-Transparent Crystalline Silicon Photovoltaic Windows Based on the Dynamic Power Coupling Model

Abstract

:1. Introduction

2. Numerical Model of ST-PVW

- 1.

- The outer glass layer,

- 2.

- The outer EVA layer,

- 3.

- The photovoltaic cell layer,

- 4.

- The inner EVA layer,

- 5.

- The inner glass layer,

3. Numerical Simulation Process and Experimental Verification

3.1. Numerical Calculation Process

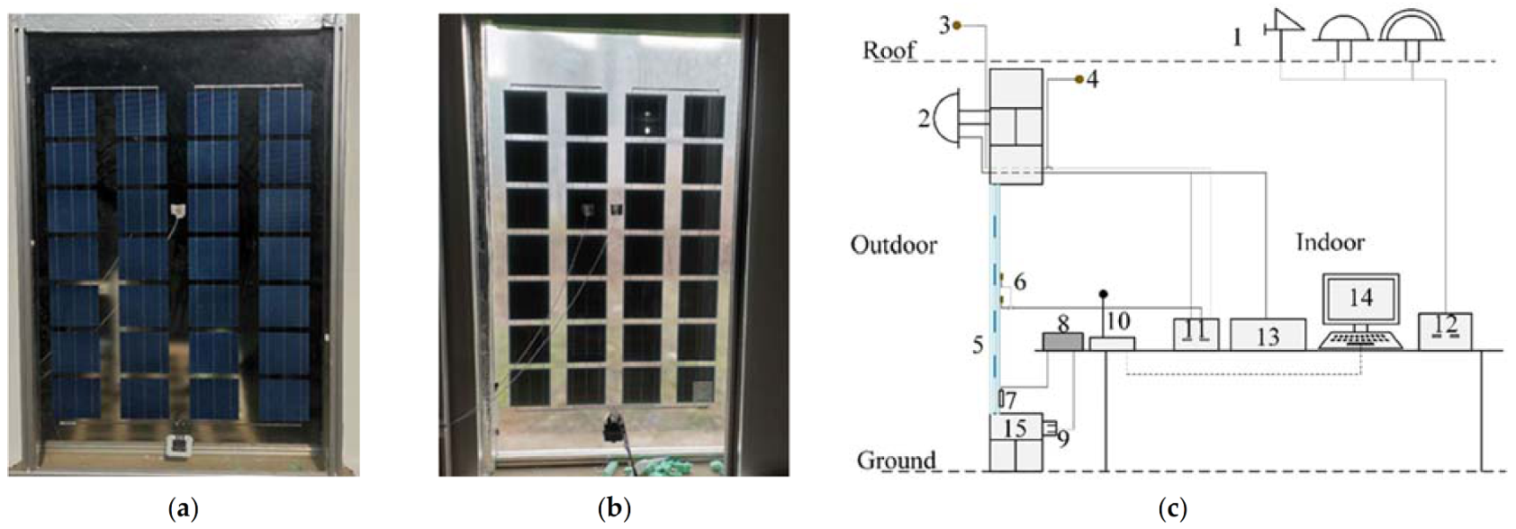

3.2. System Experiment Platform

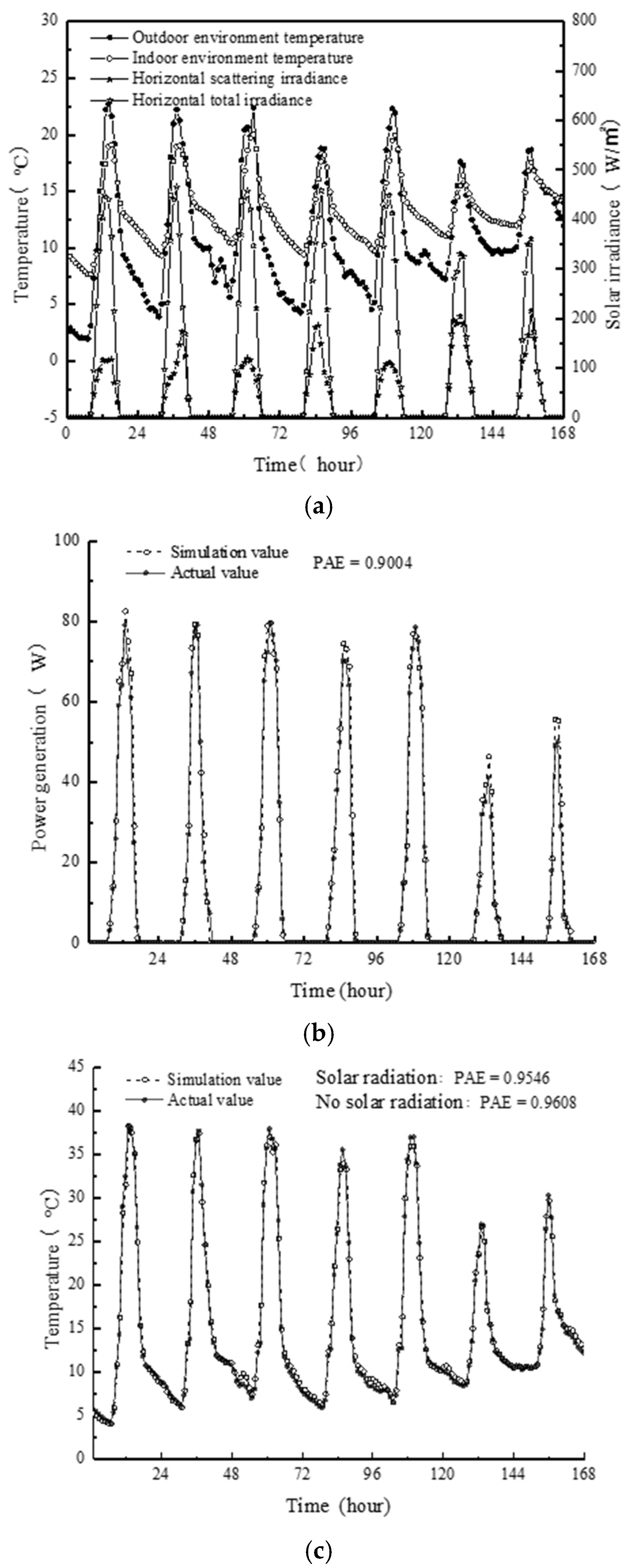

3.3. Experimental Verification and Error Analysis

4. Effect of PVR on the Performance of ST-PVW

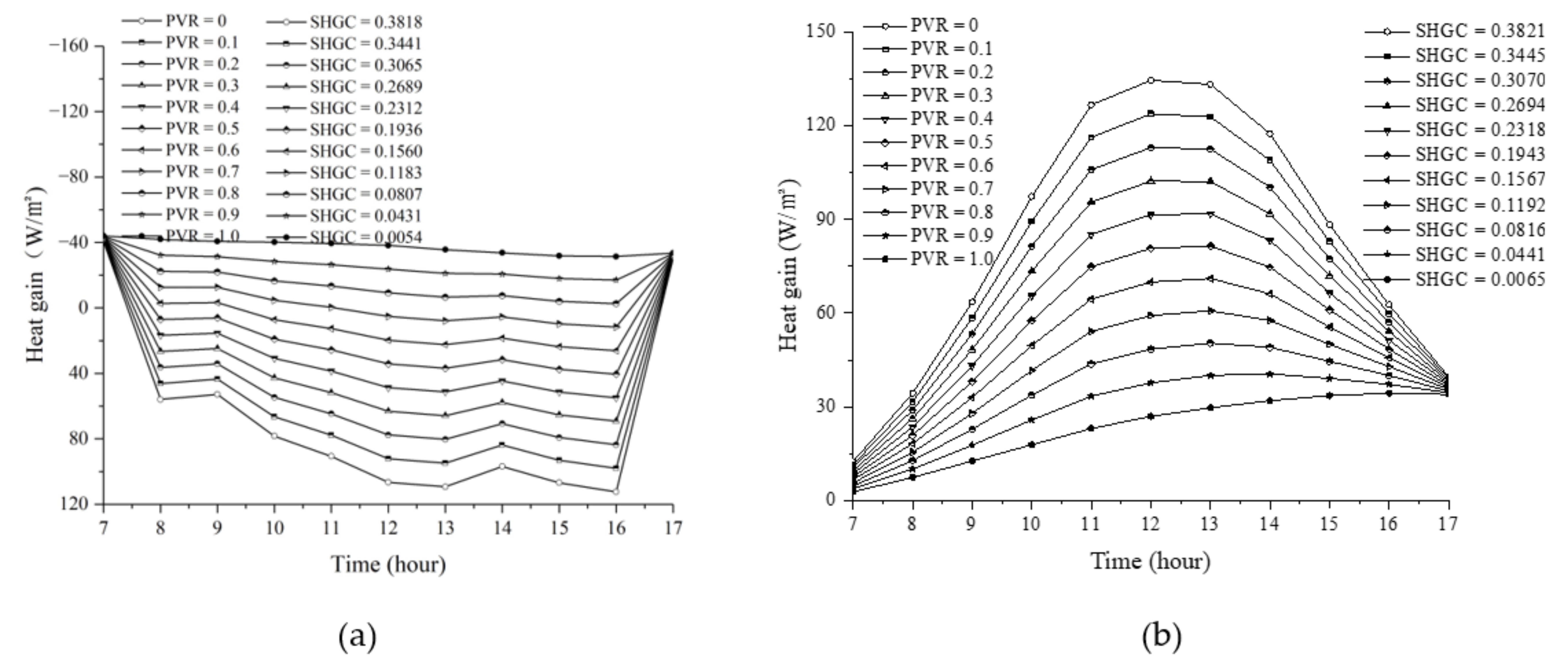

4.1. Effect of PVR on Thermal Performance of ST-PVW

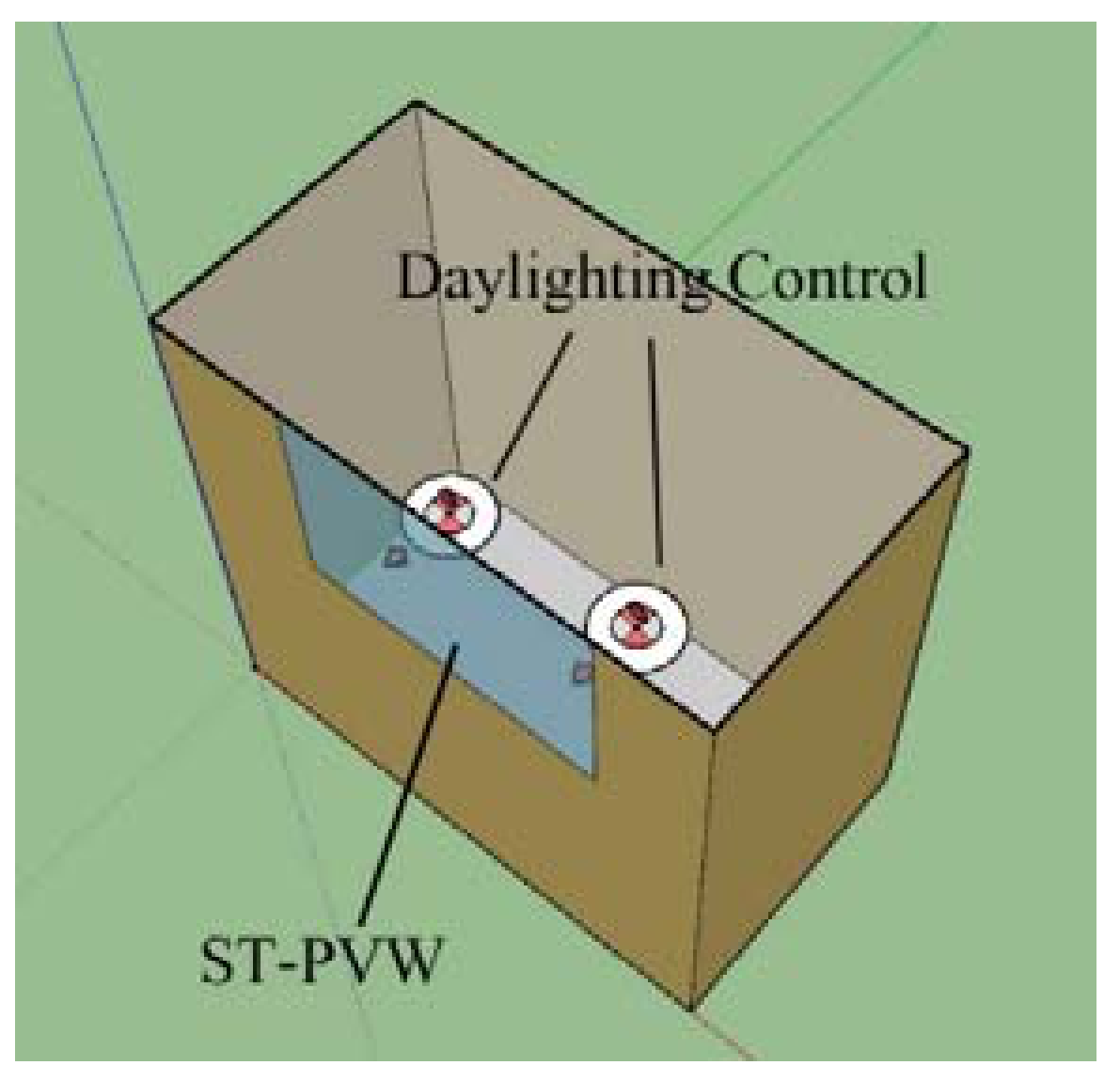

4.2. Effect of PVR on Building Energy Consumption

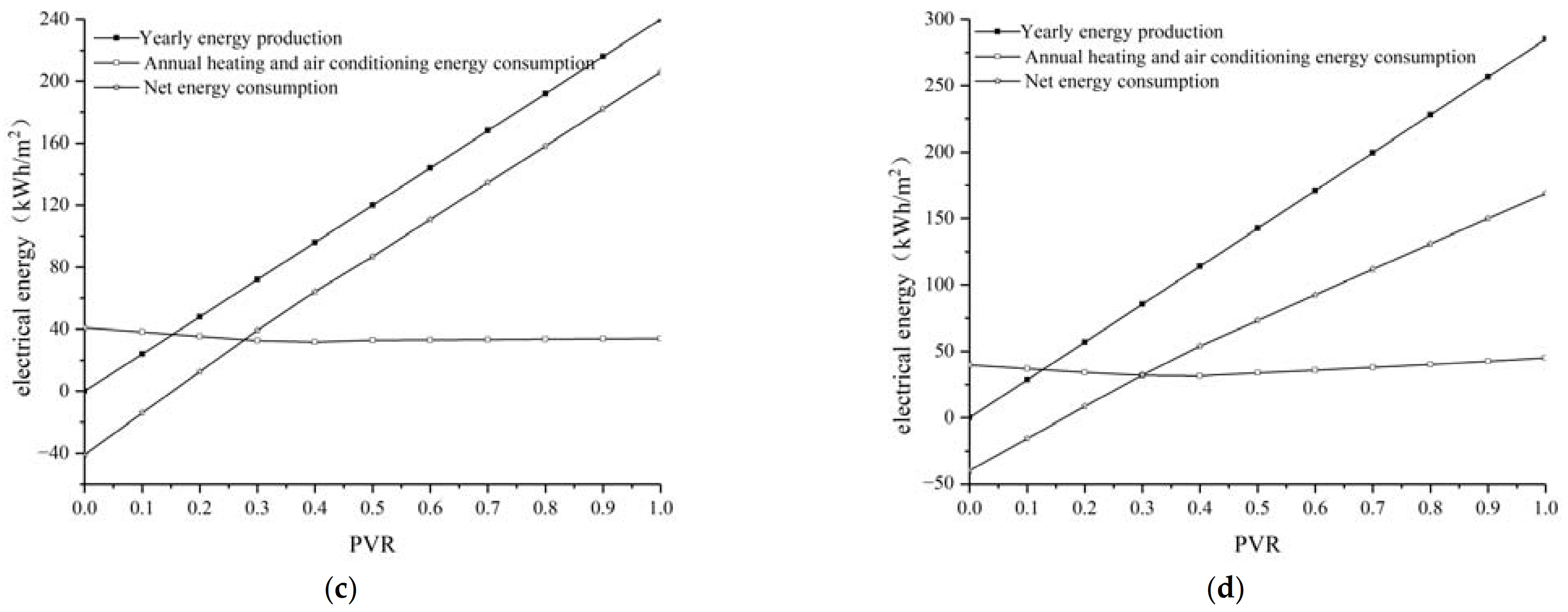

4.3. Analysis of the Impact of PVR in Different Regions

5. Conclusions

- The thermal-electric coupling calculation model based on dynamic power proposed in this paper is used to accurately simulate the thermal and electrical properties of the ST-PVW;

- The thermal performance of ST-PVW in summer and winter mainly depends on the PVR of ST-PVW. In summer, the heat gain of ST-PVW decreases with the increase of PVR, while in winter, the heat loss of ST-PVW increases with the increase of PVR. On typical summer days, ST-PVW is in a heat-gaining state. In typical winter days, when the PVR is greater than 0.8, the ST-PVW is in a state of heat loss in the daytime. When the PVR is less than 0.5, the ST-PVW is in heat-gaining state from 8:00 to 16:00;

- PVR will affect the energy consumption of heating and cooling and indoor lighting. In Nanjing, if the lighting energy consumption is considered, the building energy consumption reaches the minimum when PVR is 0.6, and the total energy consumption is 15.63 kWh/m2;

- For different regions, climate conditions and solar energy resources are different, and the PVR will have great differences in the thermal and electrical properties of ST-PVW. According to the simulation results, for Guangzhou, Nanjing, Beijing and Harbin, when the PVR is 1.00, 0.60–0.64, 0.28–0.32 and 0.26–0.30, the annual air conditioning power consumption reaches the minimum, and when the PVR is 0.16–0.17, 0.24–0.25, 0.22–0.23 and 0.19–0.20, the power generation of ST-PVW can just offset the air conditioning power consumption in the daytime.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| PV | photovoltaic |

| PVR | photovoltaic cell coverage rate |

| ST-PVW | Semi-transparent Crystalline Silicon Photovoltaic Windows |

| PAE | accuracy rate |

| SHGC | solar heat gain coefficient |

| EVA | ethylene-vinyl acetate |

| TEC | the total energy consumption |

| T | temperature, ℃ |

| h | heat transfer quantity, W/(m2·K) |

| ε | surface emissivity, W/m2 |

| α | radiant heat absorption coefficient |

| τ | radiation penetration coefficient |

| λ | thermal conductivity, W/ (m · K) |

| d | thickness, m |

| E | power generation, W/m2 |

| I | current, A |

| a | curve fitting factor |

| R | resistance, Ω |

| ν | wind speed, m/s |

| σ | Stefan–Boltzmann constant, W/(m2·K4) |

| U | U-value |

| pvgla1 | the outer glass layer |

| pvgla2 | the inner glass layer |

| o | the outer surface |

| i | the inner surface |

| e | outdoor environment |

| room | indoor |

| c | convective |

| r | radiation |

| gla1 | the outer surface of the ST-PVW |

| gla2 | the inner surface of the ST-PVW |

| eva1 | the outer EVA sandwich |

| eva2 | the inner EVA sandwich |

| s | the equivalent circuit |

References

- China Association of Building Efficiency (CABEE). Research Report on Building Energy Consumption in China. Constr. Archit. 2020, 7, 30–39. [Google Scholar]

- Peng, J.; Lin, L. Investigation on the Development Potential of Rooftop PV System in Hong Kong and its Environmental Benefits. Renew. Sustain. Energy Rev. 2013, 27, 149–162. [Google Scholar] [CrossRef]

- Hou, G.; Honghang, S.; Ziying, J.; Ziqiang, P.; Yibo, W.; Xiaodan, Z.; Ying, Z.; Qiang, Y. Life Cycle Assessment of Grid-Connected Photovoltaic Power Generation from Crystalline Silicon Solar Modules in China. Appl. Energy 2016, 164, 882–890. [Google Scholar] [CrossRef]

- Rezaei, S.D.; Santiranjan, S.; Seeram, R. A Review of Conventional, Advanced, and Smart Glazing Technologies and Materials for Improving Indoor Environment. Sol. Energy Mater. Sol. Cells 2017, 159, 26–51. [Google Scholar] [CrossRef]

- Kou, R.; Zhong, Y.; Wang, Q.; Kim, J.; Chen, R.; Qiao, Y. Improved Window Energy Efficiency with Thermal Insulating Polymer-Air Multilayer. Appl. Therm. Eng. 2021, 191, 116890. [Google Scholar] [CrossRef]

- Sun, Y.; Wu, Y.; Wilson, R. A Review of Thermal and Optical Characterisation of Complex Window Systems and their Building Performance Prediction. Appl. Energy 2018, 222, 729–747. [Google Scholar] [CrossRef]

- Barman, S.; Chowdhury, A.; Mathur, S.; Mathur, J. Assessment of the Efficiency of Window Integrated CdTe Based Semi-Transparent Photovoltaic Module. Sustain. Cities Soc. 2018, 37, 250–262. [Google Scholar] [CrossRef]

- Ye, H.; Long, L.; Zhang, H.; Gao, Y. The Energy Saving Index and the Performance Evaluation of Thermochromic Windows in Passive Buildings. Renew. Energy 2014, 66, 215–221. [Google Scholar] [CrossRef]

- Lu, L.; Law, K.M. Overall Energy Performance of Semi-Transparent Single-Glazed Photovoltaic (PV) Window for a Typical Office in Hong Kong. Renew. Energy 2013, 49, 250–254. [Google Scholar] [CrossRef]

- Peng, J.; Lu, L.; Yang, H.; Ma, T. Comparative Study of the Thermal and Power Performances of a Semi-Transparent Photovoltaic Facade under Different Ventilation Modes. Appl. Energy 2015, 138, 572–583. [Google Scholar] [CrossRef]

- Alrashidi, H.; Ghosh, A.; Issa, W.; Sellami, N.; Mallick, T.K.; Sundaram, S. Thermal Performance of Semitransparent CdTe BIPV Window at Temperate Climate. Sol. Energy 2020, 195, 536–543. [Google Scholar] [CrossRef]

- Leite, D.; Evelise, L.; Wagner, A. Semi-Transparent PV Windows: A Study for Office Buildings in Brazil. Energy Build. 2013, 67, 136–142. [Google Scholar] [CrossRef]

- Yu, G.; Yang, H.; Luo, D.; Cheng, X.; Ansah, M.K. A Review on Developments and Researches of Building Integrated Photovoltaic (BIPV) Windows and Shading Blinds. Renew. Sustain. Energy Rev. 2021, 149, 111355. [Google Scholar] [CrossRef]

- Li, D.H.; Lam, T.N.; Chan, W.W.; Mak, A.H. Energy and Cost Analysis of Semi-Transparent Photovoltaic in Office Buildings. Appl. Energy 2009, 86, 722–729. [Google Scholar] [CrossRef]

- Fung, T.Y.Y.; Yang, H. Study on Thermal Performance of Semi-Transparent Building-Integrated Photovoltaic Glazings. Energy Build. 2008, 40, 341–350. [Google Scholar] [CrossRef]

- Liao, W.; Xu, S. Energy Performance Comparison among See-Through Amorphous-Silicon PV (Photovoltaic) Glazings and Traditional Glazings Under Different Architectural Conditions in China. Energy 2015, 83, 267–275. [Google Scholar] [CrossRef]

- Jia, J.; Gao, F.; Cheng, Y.; Wang, P.; EI-Ghetany, H.H.; Han, J. A Comparative Study on Thermoelectric Performances and Energy Savings of Double-Skin Photovoltaic Windows in Cold Regions of China. Sol. Energy 2020, 206, 464–472. [Google Scholar] [CrossRef]

- Guo, W.W.; Qiu, Z.Z.; Li, P.; He, J.; Zhang, Y.; Li, Q.M. Application of PV Window for Office Building in Hot Summer and Cold Winter Zone of China. Adv. Mater. Res. 2012, 347, 81–88. [Google Scholar] [CrossRef]

- Skandalos, N.; Karamanis, D. Investigation of Thermal Performance of Semi-Transparent PV Technologies. Energy Build. 2016, 124, 19–34. [Google Scholar] [CrossRef]

- Ghosh, A.; Sundaram, S.; Mallick, T.K. Investigation of Thermal and Electrical Performances of a Combined Semi-Transparent PV-vacuum Glazing. Appl. Energy 2018, 228, 1591–1600. [Google Scholar] [CrossRef]

- Wysocki, J.J.; Rappaport, P. Effect of Temperature on Photovoltaic Solar Energy Conversion. J. Appl. Phys. 1960, 31, 571–578. [Google Scholar] [CrossRef]

- Agathokleous, R.A.; Kalogirou, S.A. Double Skin Facades (DSF) and Building Integrated Photovoltaics (BIPV): A Review of Configurations and Heat Transfer Characteristics. Renew. Energy 2016, 89, 743–756. [Google Scholar] [CrossRef]

- Ma, M.; Liu, H.; Zhang, Z.; Yun, P.; Liu, F. Rapid diagnosis of hot spot failure of crystalline silicon PV module based on I-V curve. Microelectron. Reliab. 2019, 100-101, 113402. [Google Scholar] [CrossRef]

- Liao, W. Investigation of Overall Energy Performance of Transparent mono Crystalline Silicon Glazing in Architecture Application. Huazhong Univ. Sci. Technol. 2015, 92. [Google Scholar]

- Chen, F.; Wittkopf, S.K.; Ng, P.K.; Du, H. Solar Heat Gain Coefficient Measurement of Semi-Transparent Photovoltaic Modules with Indoor Calorimetric Hot Box and Solar Simulator. Energy Build. 2012, 53, 74–84. [Google Scholar] [CrossRef]

- Cuce, E.; Young, C.-H.; Riffat, S.B. Thermal Performance Investigation of Heat Insulation Solar Glass: A Comparative Experimental Study. Energy Build. 2015, 86, 595–600. [Google Scholar] [CrossRef]

- Peng, J.; Lu, L.; Yang, H. An Experimental Study of the Thermal Performance of a Novel Photovoltaic Double-Skin Facade in Hong Kong. Sol. Energy 2013, 97, 293–304. [Google Scholar] [CrossRef]

- Zhou, S.; Zhao, J. Comparative Analysis of Energy Efficiency in Air-Conditioning System with GSHP, Electricity-Driven Refrigerating Unit and Direct-Fired Li-Br Absorption Refrigerating and Heating Unit. Energy Procedia 2012, 16, 673–678. [Google Scholar] [CrossRef] [Green Version]

- Wang, M.; Peng, J.; Li, N.; Yang, H.; Wang, C.; Li, X.; Lu, T. Comparison of Energy Performance Between PV Double Skin FacaDes and PV Insulating Glass Units. Appl. Energy 2017, 194, 148–160. [Google Scholar] [CrossRef]

- Hu, J.; Kwok, G.; Xuan, W.; Williams, J.H.; Kahrl, F. Using Natural Gas Generation to Improve Power System Efficiency in China. Energy Policy 2013, 60, 116–121. [Google Scholar] [CrossRef]

| Parameter Name | Value | Parameter Name | Value |

|---|---|---|---|

| Short-circuit current /A | 8.88 | Thermal radiation absorption coefficient of external and internal glass | 0.25 |

| Open circuit voltage /V | 21.3 | Thermal radiation penetration coefficients of external and internal glass | 0.65 |

| Maximum power point current /A | 8.38 | Thermal conductivity of outer and inner glass /(W/(m·K)) | 1.09 |

| Maximum power point voltage /V | 17.9 | Thickness of external and internal glass /m | 0.003 |

| Current temperature coefficient | −0.06% | EVA thermal radiation absorption coefficient | 0.1 |

| Peak power /W | 150 | EVA thermal radiation penetration coefficient | 0.9 |

| Photovoltaic window area /m2 | 1.49 | Thermal conductivity of EVA adhesive /(W/(m·K)) | 0.116 |

| Photovoltaic cell area / m2 | 0.69 | EVA adhesive thickness /m | 0.0008 |

| PVR | Heating Energy Consumption /(kWh/m2) | Cooling Energy Consumption /(kWh/m2) | Lighting Energy Consumption /(kWh/m2) | PV Power Generation /(kWh/m2) | TEC /(kWh/m2) |

|---|---|---|---|---|---|

| 0 | 3.38 | 58.50 | 41.39 | 0.00 | 103.27 |

| 0.2 | 3.51 | 50.04 | 41.69 | 21.78 | 73.46 |

| 0.4 | 3.51 | 41.58 | 41.98 | 43.56 | 43.51 |

| 0.6 | 3.92 | 33.30 | 43.73 | 65.31 | 15.63 |

| 0.8 | 8.78 | 24.84 | 71.30 | 87.09 | 17.83 |

| 1 | 19.85 | 16.38 | 104.94 | 108.87 | 32.30 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, W.; Liu, K.; Ma, S.; Gong, T.; Zhao, Y. The Influence of Photovoltaic Cell Coverage Rate on the Thermal and Electric Performance of Semi-Transparent Crystalline Silicon Photovoltaic Windows Based on the Dynamic Power Coupling Model. Energies 2021, 14, 7117. https://doi.org/10.3390/en14217117

Zhang W, Liu K, Ma S, Gong T, Zhao Y. The Influence of Photovoltaic Cell Coverage Rate on the Thermal and Electric Performance of Semi-Transparent Crystalline Silicon Photovoltaic Windows Based on the Dynamic Power Coupling Model. Energies. 2021; 14(21):7117. https://doi.org/10.3390/en14217117

Chicago/Turabian StyleZhang, Wenjie, Kangyong Liu, Shengbin Ma, Tongdan Gong, and Yingbo Zhao. 2021. "The Influence of Photovoltaic Cell Coverage Rate on the Thermal and Electric Performance of Semi-Transparent Crystalline Silicon Photovoltaic Windows Based on the Dynamic Power Coupling Model" Energies 14, no. 21: 7117. https://doi.org/10.3390/en14217117