Convolutional Neural Network-Based Stator Current Data-Driven Incipient Stator Fault Diagnosis of Inverter-Fed Induction Motor

Abstract

1. Introduction

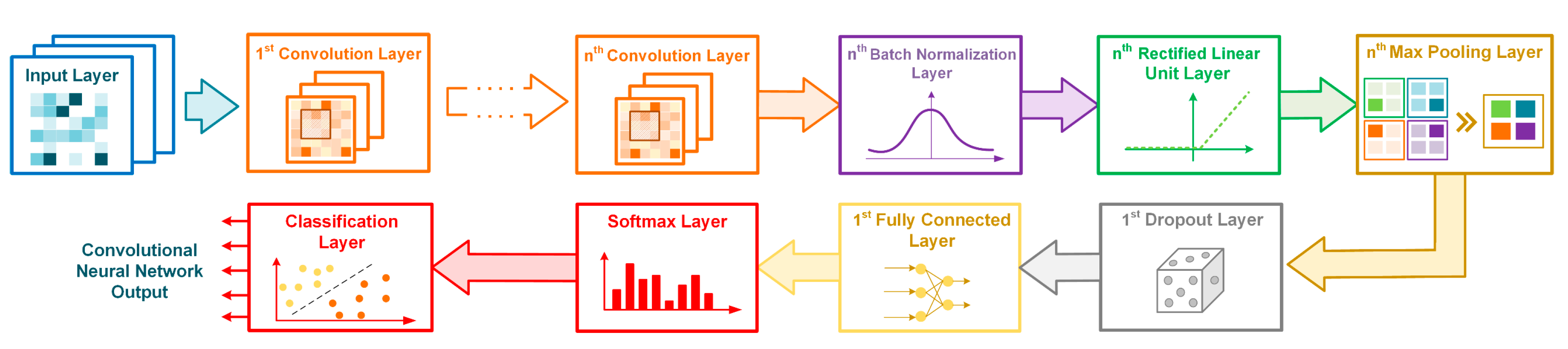

2. General Description of Convolutional Neural Network Used in the Research

2.1. Structure of the Convolutional Network

2.2. Training of the Convolutional Network

3. Description of the Experimental Implementation of the CNN-Based Detector of Inter-Turn Short Circuits

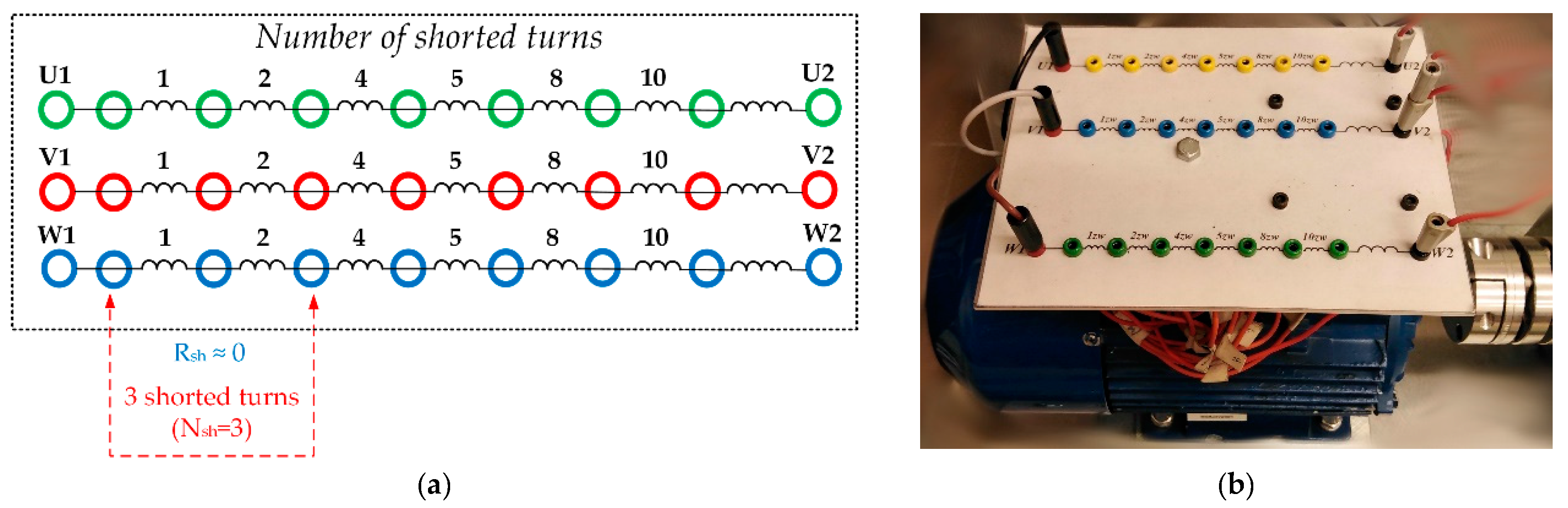

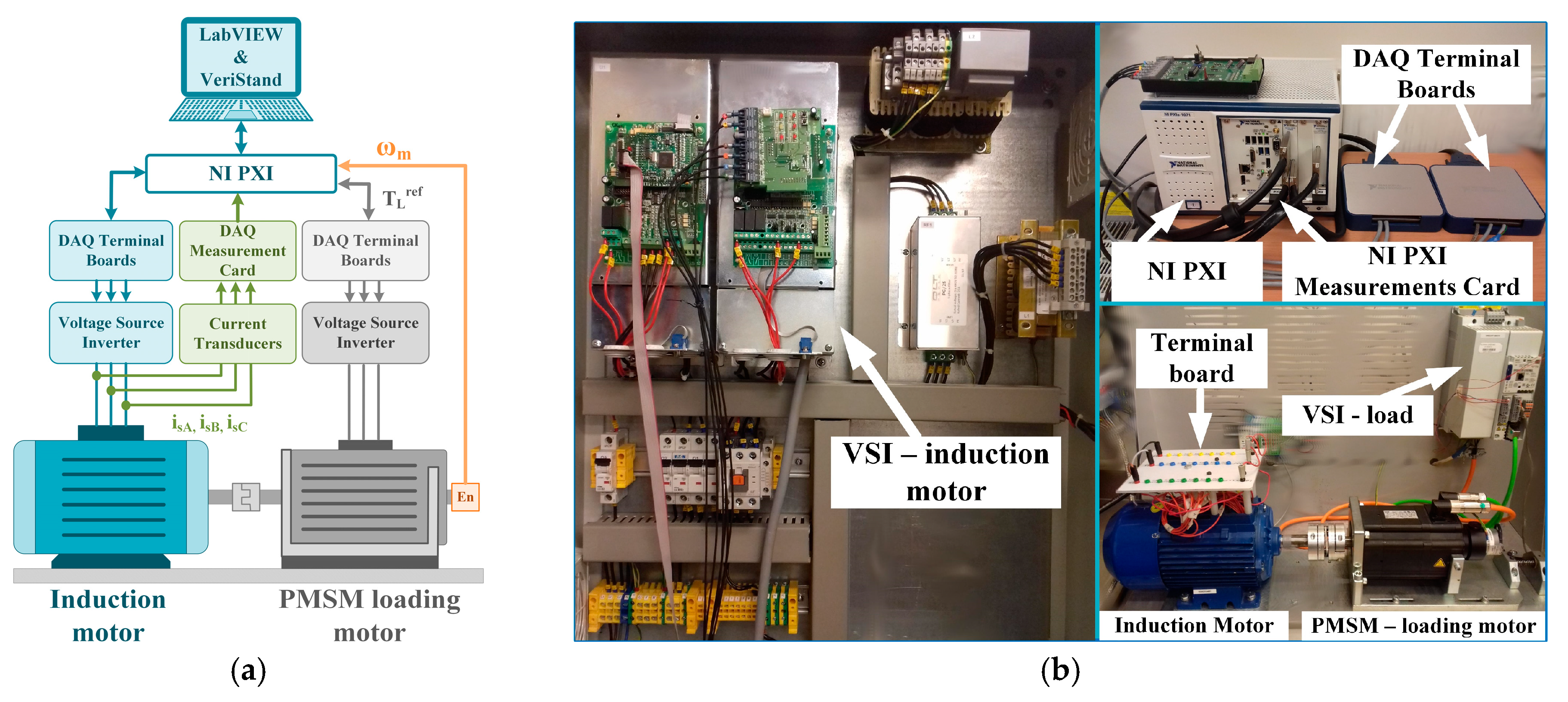

3.1. Short Description of the Laboratory Set-Up

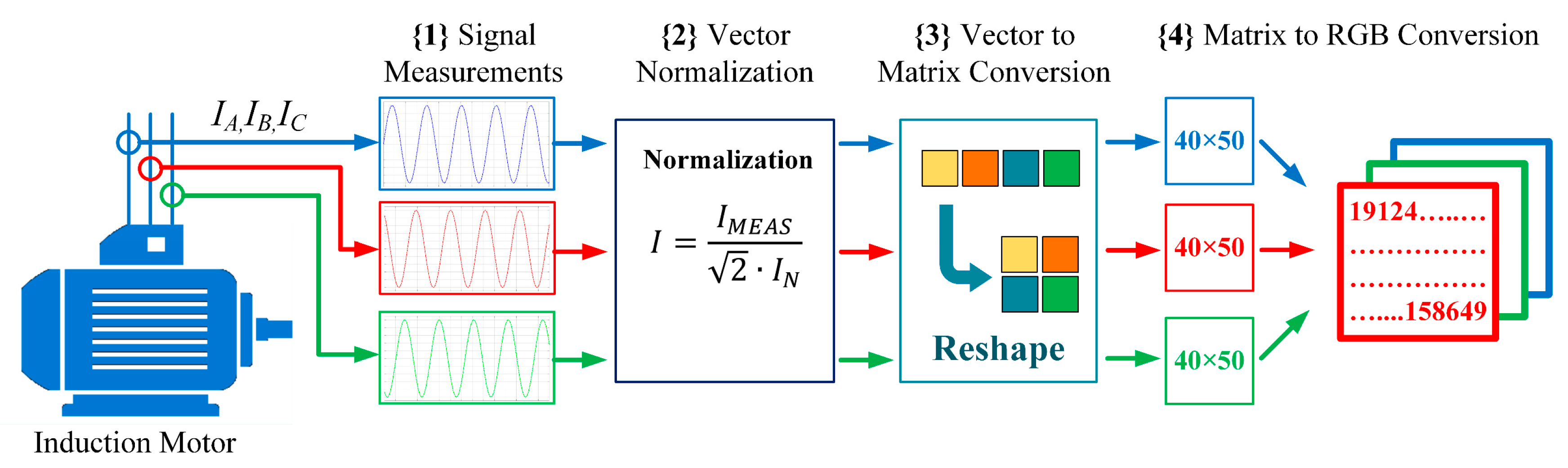

3.2. Description of the Input Data Preprocessing for the Developed CNNs

3.3. Description of the Structure and Tasks of the Developed CNN-Base Fault Detectors

- analysis of the assessment effectiveness of the degree of damage to a single stator phase of the IM—CNN-1,

- analysis of the assessment effectiveness of the degree of damage in three phases of the stator the IM—CNN-2,

- examination of the impact of CNNs’ learning process parameters on the effectiveness of the IM damage assessment,

- analysis of the impact of CNNs’ structure on the effectiveness of the IM damage assessment.

- The analysis of the results is presented below and in the next section of the paper.

4. Analysis of Experimental Results of the CNN-Based Stator Winding Fault Detectors Working On-Line

5. Impact of the CNN Structure and Training Method Parameters to the Fault Diagnosis

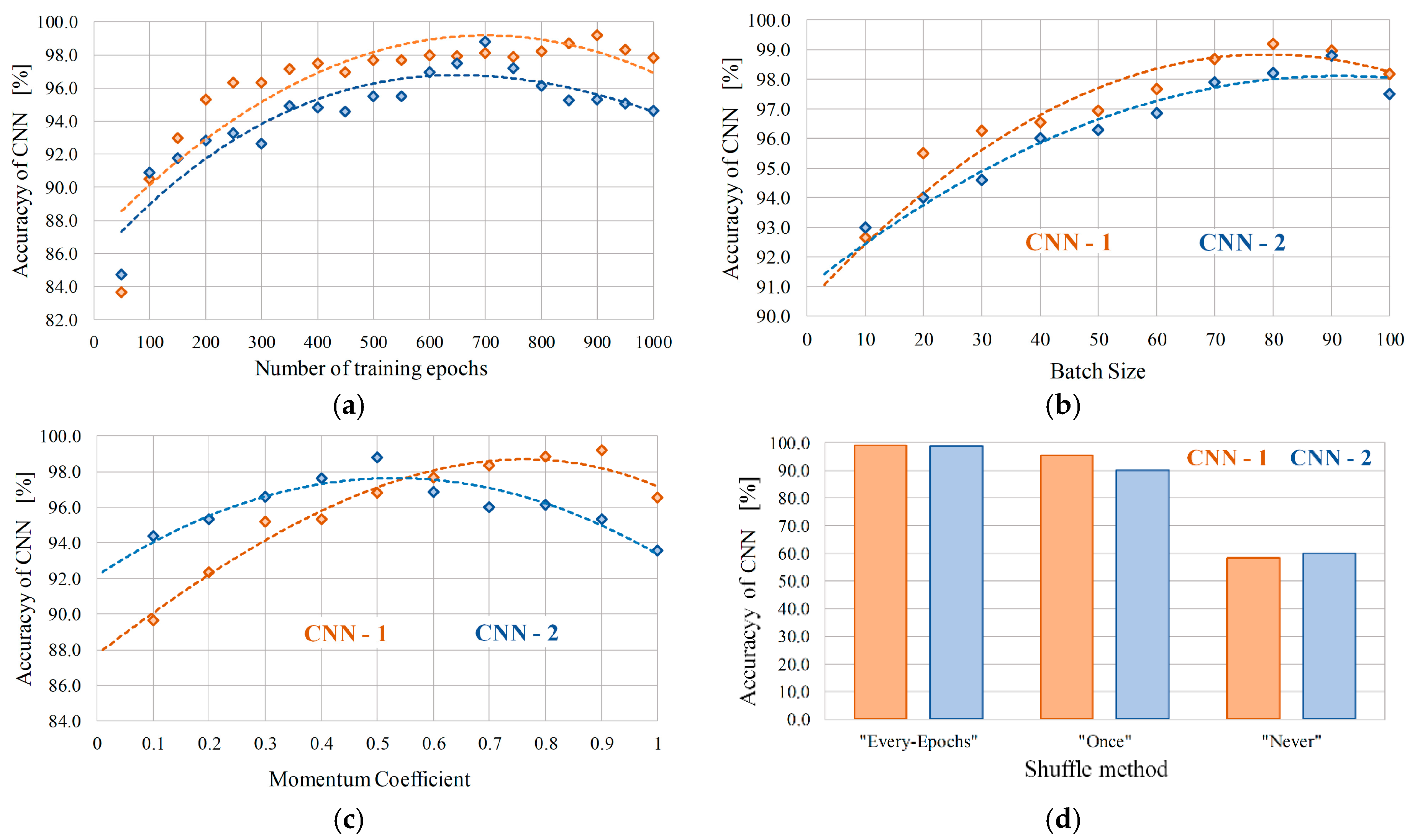

5.1. Impact of the Convolutional Network Training Parameters on the Effectiveness of IM Stator Damage Assessment

5.2. Impact of the Convolutional Network Structure on the Effectiveness of IM Stator Damage Assessment

6. Conclusions

- the use of raw measurement data as network input signals,

- no need to pre-process measurement data with analytical methods,

- high accuracy in detecting the localization of the failure (motor phase) and the fault level (number of shorted turns),

- the ability to detect even individual shorted turns (incipient faults),

- a merger of symptom extraction and damage detection in one machine learning process.

Author Contributions

Funding

Conflicts of Interest

Appendix A

| Name of the Parameter | Symbol | Units | |

|---|---|---|---|

| Power | PN | 3000 | [W] |

| Torque | TN | 19.83 | [Nm] |

| Speed | NN | 1445 | [r/min] |

| Stator phase voltage | UsN | 230 | [V] |

| Stator current | IsN | 6.8 | [A] |

| Frequency | fsN | 50 | [Hz] |

| Pole pairs number | pp | 2 | [–] |

Appendix B

References

- Stone, G.; Boutler, E.; Cubert, I.; Dhirani, H. Electrical Insulation for Rotating Machines- Design, Evaluation, Aging, Testing, and Repair, 2nd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2014. [Google Scholar]

- Benbouzid, M.E.H.; Vieira, M.; Theys, C. Induction motors faults detection and localization using stator current advanced signal processing techniques. IEEE Trans. Power Electron. 1999, 14, 14–22. [Google Scholar] [CrossRef]

- Schoen, R.R.; Habetler, T.G.; Kamran, F.; Bartfield, R.G. Motor bearing damage detection using stator current monitoring. IEEE Trans. Ind. Appl. 1995, 31, 1274–1279. [Google Scholar] [CrossRef]

- Fang, J.; Sun, Y.; Wang, Y.; Wei, B.; Hang, J. Improved ZSVC-based fault detection technique for incipient stage inter-turn fault in PMSM. IET Electric Power Appl. 2019, 13, 2015–2026. [Google Scholar] [CrossRef]

- Urresty, J.; Riba, J.; Romeral, L. A Back-emf Based Method to Detect Magnet Failures in PMSMs. IEEE Trans. Magn. 2013, 49, 591–598. [Google Scholar] [CrossRef]

- Garcia-Perez, A.; Romero-Troncoso, R.J.; Cabal-Yepez, E.; Osornio-Rios, R.A. The Application of High-Resolution Spectral Analysis for Identifying Multiple Combined Faults in Induction Motors. IEEE Trans. Ind. Electron. 2011, 58, 2002–2010. [Google Scholar] [CrossRef]

- Harmouche, J.; Delpha, C.; Diallo, D. Improved fault diagnosis of ball bearings based on the global spectrum of vibration signals. IEEE Trans. Energy Convers. 2015, 30, 376–383. [Google Scholar] [CrossRef]

- Ewert, P. Use of axial flux in the detection of electrical faults in induction motors. In Proceedings of the 2017 International Symposium on Electrical Machines (SME), Nałęczów, Poland, 18–21 June 2017. [Google Scholar] [CrossRef]

- Skowron, M.; Wolkiewicz, M.; Orlowska-Kowalska, T.; Kowalski, C.T. Effectiveness of Selected Neural Network Structures Based on Axial Flux Analysis in Stator and Rotor Winding Incipient Fault Detection of Inverter-fed Induction Motors. Energies 2019, 12, 2392. [Google Scholar] [CrossRef]

- Picazo-Ródenas, M.J.; Antonino-Daviu, J.; Climente-Alarcon, V.; Royo-Pastor, R.; Mota-Villar, A. Combination of Noninvasive Approaches for General Assessment of Induction Motors. IEEE Trans. Ind. Appl. 2015, 51, 2172–2180. [Google Scholar] [CrossRef]

- Kumar, P.S.; Xie, L.; Halick, M.S.M.; Vaiyapuri, V. Online stator end winding thermography using infrared sensor array. In Proceedings of the 2018 IEEE Applied Power Electronics Conference and Exposition (APEC), San Antonio, TX, USA, 4–8 March 2018. [Google Scholar] [CrossRef]

- Nejjari, H.; Benbouzid, M.E.H. Monitoring and diagnosis of induction motors electrical faults using a current Park’s vector pattern learning approach. IEEE Trans. Ind. Appl. 2000, 36, 730–735. [Google Scholar] [CrossRef]

- Puche-Panadero, R.; Pineda-Sanchez, M.; Riera-Guasp, M.; Roger-Folch, J.; Hurtado-Perez, E.; Perez-Cruz, J. Improved Resolution of the MCSA Method Via Hilbert Transform, Enabling the Diagnosis of Rotor Asymmetries at Very Low Slip. IEEE Trans. Energy Convers. 2009, 24, 52–59. [Google Scholar] [CrossRef]

- Arabaci, H.; Bilgin, O. The Detection of Rotor Faults By Using Short Time Fourier Transform. In Proceedings of the 2007 IEEE 15th Signal Processing and Communications Applications, Eskisehir, Turkey, 11–13 June 2007. [Google Scholar] [CrossRef]

- Jung, J.; Lee, J.; Kwon, B. Online Diagnosis of Induction Motors Using MCSA. IEEE Trans. Ind. Electron. 2006, 53, 1842–1852. [Google Scholar] [CrossRef]

- Haddad, R.Z.; Strangas, E.G. On the Accuracy of Fault Detection and Separation in Permanent Magnet Synchronous Machines Using MCSA/MVSA and LDA. IEEE Trans. Energy Convers. 2016, 31, 924–934. [Google Scholar] [CrossRef]

- Cruz, S.M.A.; Cardoso, A.J.M. Stator winding fault diagnosis in three-phase synchronous and asynchronous motors, by the extended Park’s vector approach. IEEE Trans. Ind. Appl. 2016, 37, 1227–1233. [Google Scholar] [CrossRef]

- Rosero, J.; Cusido, J.; Espinosa, A.G.; Ortega, J.A.; Romeral, L. Broken Bearings Fault Detection for a Permanent Magnet Synchronous Motor under non-constant working conditions by means of a Joint Time Frequency Analysis. In Proceedings of the 2007 IEEE International Symposium on Industrial Electronics, Vigo, Spain, 4–7 June 2007. [Google Scholar] [CrossRef]

- Espinosa, A.G.; Rosero, J.A.; Cusidó, J.; Romeral, L.; Ortega, J.A. Fault Detection by Means of Hilbert–Huang Transform of the Stator Current in a PMSM With Demagnetization. IEEE Trans. Energy Convers. 2010, 25, 312–318. [Google Scholar] [CrossRef]

- Rosero, J.; Garcia, A.; Cusido, J.; Romeral, L.; Ortega, J. Fault detection by means of Hilbert Huang Transform of the stator current in a PMSM with demagnetization. In Proceedings of the 2007 IEEE International Symposium on Intelligent Signal Processing, Alcala De Henares, Spain, 3–5 October 2007. [Google Scholar] [CrossRef][Green Version]

- Ruiz, J.R.; Rosero, J.A.; Espinosa, A.G.; Romeral, L. Detection of Demagnetization Faults in Permanent-Magnet Synchronous Motors Under Nonstationary Conditions. IEEE Trans. Magn. 2009, 45, 2961–2969. [Google Scholar] [CrossRef]

- Park, C.H.; Lee, J.; Ahn, G.; Youn, M.; Youn, B.D. Fault Detection of PMSM under Non-Stationary Conditions Based on Wavelet Transformation Combined with Distance Approach. In Proceedings of the 2019 IEEE 12th International Symposium on Diagnostics for Electrical Machines, Power Electronics and Drives (SDEMPED), Toulouse, France, 27–30 August 2019. [Google Scholar] [CrossRef]

- Riera-Guasp, M.; Antonino-Daviu, J.A.; Pineda-Sanchez, M.; Puche-Panadero, R.; Perez-Cruz, J. A General Approach for the Transient Detection of Slip-Dependent Fault Components Based on the Discrete Wavelet Transform. IEEE Trans. Ind. Electron. 2008, 55, 4167–4180. [Google Scholar] [CrossRef]

- Abdellatif, S.; Aissa, C.; Hamou, A.A.; Chawki, S.; Oussama, B.S. A Deep Learning Based on Sparse Auto-Encoder with MCSA for Broken Rotor Bar Fault Detection and Diagnosis. In Proceedings of the 2018 International Conference on Electrical Sciences and Technologies in Maghreb (CISTEM), Alger, Algeria, 28–31 October 2018. [Google Scholar] [CrossRef]

- Ince, T.; Kiranyaz, S.; Eren, L.; Askar, M.; Gabbouj, M. Real-Time Motor Fault Detection by 1-D Convolutional Neural Networks. IEEE Trans. Ind. Electron. 2016, 63, 7067–7075. [Google Scholar] [CrossRef]

- Junbo, T.; Weining, L.; Juneng, A.; Xueqian, W. Fault diagnosis method study in roller bearing based on wavelet transform and stacked auto-encoder. In Proceedings of the 27th Chinese Control and Decision Conference (2015 CCDC), Qingdao, China, 23–25 May2015. [Google Scholar] [CrossRef]

- Lee, Y.O.; Jo, J.; Hwang, J. Application of deep neural network and generative adversarial network to industrial maintenance: A case study of induction motor fault detection. In Proceedings of the 2017 IEEE International Conference on Big Data (Big Data), Boston, MA, USA, 11–14 December 2017. [Google Scholar] [CrossRef]

- Hamdani, S.; Touhami, O.; Ibtiouen, R.; Fadel, M. Neural network technique for induction motor rotor faults classification-dynamic eccentricity and broken bar faults. In Proceedings of the 8th IEEE Symposium on Diagnostics for Electrical Machines, Power Electronics Drives, Bologna, Italy, 5–8 September 2011. [Google Scholar] [CrossRef]

- Ghate, V.N.; Dudul, S.V. Optimal MLP neural network classifier for fault detection of three phase induction motor. Expert Syst. Appl. 2010, 37, 3468–3481. [Google Scholar] [CrossRef]

- Taïbi, Z.M.; Hasni, M.; Hamdani, S.; Rahmani, O.; Touhami, O.; Ibtiouen, R. Optimization of the feedforward neural network for rotor cage fault diagnosis in three-phase induction motors. In Proceedings of the 2011 IEEE International Electric Machines Drives Conference (IEMDC), Niagara Falls, ON, Canada, 15–18 May 2011. [Google Scholar] [CrossRef]

- Skowron, M.; Wolkiewicz, M.; Orlowska-Kowalska, T.; Kowalski, C.T. Application of Self-Organizing Neural Networks to Electrical Fault Classification in Induction Motors. Appl. Sci. 2019, 9, 616. [Google Scholar] [CrossRef]

- Kowalski, C.T.; Orlowska-Kowalska, T. Neural networks application for induction motor faults diagnosis. Math. Comput. Simul. 2003, 63, 435–448. [Google Scholar] [CrossRef]

- Khalfaoui, N.; Salhi, M.S.; Amiri, H. The SOM tool in mechanical fault detection over an electric asynchronous drive. In Proceedings of the 2016 4th International Conference on Control Engineering Information Technology (CEIT), Hammamet, Tunisia, 16–18 December 2016. [Google Scholar] [CrossRef]

- Sid, O.; Menaa, M.; Hamdani, S.; Touhami, O.; Ibtiouen, R. Self-organizing map approach for classification of electricals rotor faults in induction motors. In Proceedings of the 2011 2nd International Conference on Electric Power and Energy Conversion Systems (EPECS), Niagara Falls, ON, Canada, 15–18 May 2011. [Google Scholar] [CrossRef]

- Afrasiabi, S.; Afrasiabi, M.; Parang, B.; Mohammadi, M. Real-Time Bearing Fault Diagnosis of Induction Motors with Accelerated Deep Learning Approach. In Proceedings of the 2019 10th International Power Electronics, Drive Systems and Technologies Conference (PEDSTC), Shiraz, Iran, 12–14 February 2019. [Google Scholar] [CrossRef]

- Shao, S.; Yan, R.; Lu, Y.; Wang, P.; Gao, R. DCNN-based Multi-signal Induction Motor Fault Diagnosis. IEEE Trans. Instrum. Meas. 2019. [Google Scholar] [CrossRef]

- Shao, S.; McAleer, S.; Yan, R.; Baldi, P. Highly Accurate Machine Fault Diagnosis Using Deep Transfer Learning. IEEE Trans. Ind. Inform. 2019, 15, 2446–2455. [Google Scholar] [CrossRef]

- Chen, Z.; Gryllias, K.; Li, W. Mechanical fault diagnosis using Convolutional Neural Networks and Extreme Learning Machine. Mech. Syst. Signal Process. 2019, 133, 106272. [Google Scholar] [CrossRef]

- Lee, J.-H.; Pack, J.-H.; Lee, I.-S. Fault Diagnosis of Induction Motor Using Convolutional Neural Network. Appl. Sci. 2019, 9, 2950. [Google Scholar] [CrossRef]

- Li, X.; Zhang, W.; Ding, Q.; Sun, J.-Q. Multi-Layer domain adaptation method for rolling bearing fault diagnosis. Signal Process. 2019, 157, 180–197. [Google Scholar] [CrossRef]

- Sun, W.; Zhao, R.; Yan, R.; Shao, S.; Chen, X. Convolutional Discriminative Feature Learning for Induction Motor Fault Diagnosis. IEEE Trans. Ind. Inform. 2017, 13, 1350–1359. [Google Scholar] [CrossRef]

- Kao, I.; Wang, W.; Lai, Y.; Perng, J. Analysis of Permanent Magnet Synchronous Motor Fault Diagnosis Based on Learning. IEEE Trans. Instrum. Meas. 2019, 68, 310–324. [Google Scholar] [CrossRef]

- Khan, T.; Alekhya, P.; Seshadrinath, J. Incipient Inter-turn Fault Diagnosis in Induction motors using CNN and LSTM based Methods. In Proceedings of the 2018 IEEE Industry Applications Society Annual Meeting (IAS), Portland, OR, USA, 23–27 September 2018. [Google Scholar] [CrossRef]

- Hoang, D.T.; Kang, H.J. A Motor Current Signal Based Bearing Fault Diagnosis Using Deep Learning And Information Fusion. IEEE Trans. Instrum. Meas. 2019. [Google Scholar] [CrossRef]

- Pandarakone, S.E.; Masuko, M.; Mizuno, Y.; Nakamura, H. Deep Neural Network Based Bearing Fault Diagnosis of Induction Motor Using Fast Fourier Transform Analysis. In Proceedings of the 2018 IEEE Energy Conversion Congress and Exposition (ECCE), Portland, OR, USA, 23–27 September 2018. [Google Scholar] [CrossRef]

- Xu, G.; Liu, M.; Jiang, Z.; Shen, W.; Huang, C. Online Fault Diagnosis Method Based on Transfer Convolutional Neural Networks. IEEE Trans. Instrum. Meas. 2020, 69, 509–520. [Google Scholar] [CrossRef]

- Xu, G.; Liu, M.; Jiang, Z.; Söffker, D.; Shen, W. Bearing Fault Diagnosis Method Based on Deep Convolutional Neural Network and Random Forest Ensemble Learning. Sensors 2019, 19, 1088. [Google Scholar] [CrossRef]

- Wen, L.; Li, X.; Gao, L.; Zhang, Y. A New Convolutional Neural Network-Based Data-Driven Fault Diagnosis Method. IEEE Trans. Ind. Electron. 2018, 65, 5990–5998. [Google Scholar] [CrossRef]

- Chattopadhyay, P.; Saha, N.; Delpha, C.; Sil, J. Deep Learning in Fault Diagnosis of Induction Motor Drives. In Proceedings of the 2018 Prognostics and System Health Management Conference (PHM-Chongqing), Chongqing, China, 26–28 October 2018. [Google Scholar] [CrossRef]

- Li, C.; Zhang, W.; Peng, G.; Liu, S. Bearing Fault Diagnosis Using Fully-Connected Winner-Take-All Autoencoder. IEEE Access 2018, 6, 6103–6115. [Google Scholar] [CrossRef]

- Principi, E.; Rossetti, D.; Squartini, S.; Piazza, F. Unsupervised electric motor fault detection by using deep autoencoders. IEEE/CAA J. Autom. Sin. 2019, 6, 441–451. [Google Scholar] [CrossRef]

- Ding, X.; He, Q. Energy-Fluctuated Multiscale Feature Learning With Deep ConvNet for Intelligent Spindle Bearing Fault Diagnosis. IEEE Trans. Instrum. Meas. 2017, 66, 1926–1935. [Google Scholar] [CrossRef]

- Gardel, P.; Morinigo-Sotelo, D.; Duque-Perez, O.; Perez-Alonso, M.; Garcia-Escudero, L.A. Neural network broken bar detection using time domain and current spectrum data. In Proceedings of the 2012 XXth International Conference on Electrical Machines, Marseille, France, 2–5 September 2012. [Google Scholar] [CrossRef]

- Krizhevsky, A.; Sutskever, I.; Hinton, G. ImageNet classification with deep convolutional neural networks. Adv. Neural Inf. Process. Syst. 2012, 25, 1106–1114. [Google Scholar] [CrossRef]

- Kalchbrenner, N.; Grefenstette, E.; Blunsom, P. A convolutional neural network for modelling sentences. In Proceedings of the 52nd Annual Meeting of the Association for Computational Linguistics, Baltimore, MD, USA, 23–25 June 2014. [Google Scholar]

- Ioffe, S.; Szegedy, C. Batch normalization: Accelerating deep network training by reducing internal covariate shift. arXiv 2015, arXiv:1502.03167. [Google Scholar]

- Nair, V.; Hinton, G.E. Rectified linear units improve restricted Boltzmann machines. In Proceedings of the 27th International Conference on Machine Learning, Haifa, Israel, 21–24 June 2010. [Google Scholar]

- Graham, B. Fractional max-pooling. arXiv 2014, arXiv:1412.6071. [Google Scholar]

- Wang, S.; Manning, C. Fast dropout training. In Proceedings of the International Conference on Machine Learning, Atlanta, GA, USA, 16–21 June 2013. [Google Scholar] [CrossRef]

- Srivastava, N.; Hinton, G.; Krizhevsky, A.; Sutskever, I.; Salakhutdinov, R. Dropout: A Simple Way to Prevent Neural Networks from Overfitting. J. Mach. Learn. Res. 2014, 15, 1929–1958. [Google Scholar] [CrossRef]

- Yuan, B. Efficient hardware architecture of softmax layer in deep neural network. In Proceedings of the 29th IEEE International System-on-Chip Conference (SOCC), Seattle, WA, USA, 6–9 September 2016; pp. 323–326. [Google Scholar] [CrossRef]

- Dogo, E.M.; Afolabi, O.J.; Nwulu, N.I.; Twala, B.; Aigbavboa, C.O. A Comparative Analysis of Gradient Descent-Based Optimization Algorithms on Convolutional Neural Networks. In Proceedings of the 2018 Int. Conference on Computational Techniques, Electronics and Mechanical Systems (CTEMS), Belgaum, India, 21–22 December 2018; pp. 92–99. [Google Scholar] [CrossRef]

| Parameters of the Developed CNN Structures | Parameters of the Training Process of CNNs | ||||||

|---|---|---|---|---|---|---|---|

| Name of parameter | Value of parameter | Name of parameter | Value of parameter | ||||

| CNN-1 | CNN-2 | CNN-1 | CNN-2 | ||||

| Number of CONV layers | 3 | 4 | Learning method | SGDM | |||

| Numbers of filters in particular layers | 30-60-90 | 40-60-80-100 | Momentum coefficient | 0.9 | 0.5 | ||

| Filters size | (3 × 3) | (6 × 6) | Initial learning rate | 0.001 | |||

| Padding method Stride | “same” (2,2) | “same” (4,4) | Number of training epochs | 900 | 700 | ||

| Number of POOL layers | 3 | 4 | Learning rate dropping method | “piecewise” | |||

| Pooling method | Maximum | Drop period | 20 | ||||

| Pool size | (3 × 3) | (6 × 6) | L2—regularization | 0.0001 | |||

| Padding Stride | “same” (2,2) | “same” (4,4) | Gradient threshold method | L2—norm | |||

| Number of ReLU layers | 3 | 4 | Training matrix size | 40 × 50 × 3 × 600 | 40 × 50 × 3 × 1600 | ||

| Number of BN layers | 3 | 4 | Testing matrix size | 40 × 50 × 3 × 600 | 40 × 50 × 3 × 1600 | ||

| Epsilon | 0.001 | 0.001 | Validation frequency | 10 | |||

| Number of DOUT layers | 1 | 1 | Shuffle method | “every-epoch” | |||

| Probability | 0.5 | 0.5 | Mini batch size | 80 | 90 | ||

| Number of FC layers | 1 | 1 | Number of categories | 6 | 16 | ||

| Number of FC neurons | 6 | 16 | |||||

| CONV—convolutional layer | BN—batch normalization layer | DOUT—dropout layer | |||||

| POOL—pooling layer | ReLU—rectified linear unit layer | FC—fully connected layer | |||||

| Number of Layers and Other Parameters | ||||||||

|---|---|---|---|---|---|---|---|---|

| Convolutional Layer | Activation Function | Pooling Layer | Batch Normalization Layer | Dropout Layer | Fully Connected Layer | Accuracy | ||

| 4 30-60-90-120 | 4 ReLU | 4 Pooling Max | 4 Epsilon = 0.0001 | 1 Probability = 0.5 | 1 Output Size = 6 | 97.0% | ||

| 3 30-60-90 | 3 ReLU | 3 Pooling Max | 3 Epsilon = 0.0001 | 1 Probability = 0.5 | 1 Output Size = 6 | 99.3% | ||

| 2 30-60-90 | 2 ReLU | 2 Pooling Max | 2 Epsilon = 0.0001 | 1 Probability = 0.5 | 1 Output Size = 6 | 98.0% | ||

| 1 30-60-90 | 1 ReLU | 1 Pooling Max | 1 Epsilon = 0.0001 | 1 Probability = 0.5 | 1 Output Size = 6 | 96.5% | ||

| Convolutional Layer | Activation Function | Pooling Layer | Batch Normalization Layer | Dropout Layer | Fully Connected Layer | Accuracy | ||

| 3 30-60-90 | 3 ReLU | 3 Pooling Max | 3 Epsilon = 0.0001 | 1 Probability = 0.5 | 1 Output Size = 6 | 99.3% | ||

| 3 30-60-90 | 3 Hyperbolic Tangent | 3 Pooling Max | 3 Epsilon = 0.0001 | 1 Probability = 0.5 | 1 Output Size = 6 | 96.8% | ||

| 3 30-60-90 | 3 Leaky ReLU | 3 Pooling Max | 3 Epsilon = 0.0001 | 1 Probability = 0.5 | 1 Output Size = 6 | 97.5% | ||

| 3 30-60-90 | 3 Clipped ReLU | 3 Pooling Max | 3 Epsilon = 0.0001 | 1 Probability = 0.5 | 1 Output Size = 6 | 98.2% | ||

| 3 30-60-90 | 3 Exp. Linear Unit | 3 Pooling Max | 3 Epsilon = 0.0001 | 1 Probability = 0.5 | 1 Output Size = 6 | 98.2% | ||

| Convolutional Layer | Activation Function | Pooling Layer | Batch Normalization Layer | Dropout Layer | Fully Connected Layer | Accuracy | ||

| 3 30-60-90 | 3 ReLU | 3 Pooling Max | 3 Epsilon = 0.0001 | 1 Probability = 0.5 | 1 Output Size = 6 | 99.3% | ||

| 3 30-60-90 | 3 ReLU | 3 Pooling Average | 3 Epsilon = 0.0001 | 1 Probability = 0.5 | 1 Output Size = 6 | 98.7% | ||

| 3 30-60-90 | 3 ReLU | 2 Pooling Max | 3 Epsilon = 0.0001 | 1 Probability = 0.5 | 1 Output Size = 6 | 98.5% | ||

| 3 30-60-90 | 3 ReLU | 2 Pooling Average | 3 Epsilon = 0.0001 | 1 Probability = 0.5 | 1 Output Size = 6 | 97.7% | ||

| 3 30-60-90 | 3 ReLU | 1 Pooling Max | 3 Epsilon = 0.0001 | 1 Probability = 0.5 | 1 Output Size = 6 | 97.6% | ||

| 3 30-60-90 | 3 ReLU | 1 Pooling Average | 3 Epsilon = 0.0001 | 1 Probability = 0.5 | 1 Output Size = 6 | 96.5% | ||

| Convolutional Layer | Activation Function | Pooling Layer | Batch Normalization Layer | Dropout Layer | Fully Connected Layer | Accuracy | ||

| 3 30-60-90 | 3 ReLU | 3 Pooling Max | 3 Epsilon = 0.0001 | 1 Probability = 0.5 | 1 Output Size = 6 | 99.3% | ||

| 3 30-60-90 | 3 ReLU | 3 Pooling Max | 2 Epsilon = 0.0001 | 1 Probability = 0.5 | 1 Output Size = 6 | 97.7% | ||

| 3 30-60-90 | 3 ReLU | 3 Pooling Max | 1 Epsilon = 0.0001 | 1 Probability = 0.5 | 1 Output Size = 6 | 97.8% | ||

| Convolutional Layer | Activation Function | Pooling Layer | Batch Normalization Layer | Dropout Layer and Fully Connected Layer | Accuracy | |||

| 3 30-60-90 | 3 ReLU | 3 Pooling Max | 3 Epsilon = 0.0001 | 1 Probability = 0.5 | 1 Output Size = 6 | 99.3% | ||

| 3 30-60-90 | 3 ReLU | 3 Pooling Max | 3 Epsilon = 0.0001 | 1 Probability = 0.5 | 2 Structure: 36-6 | 99.3% | ||

| 3 30-60-90 | 3 ReLU | 3 Pooling Max | 3 Epsilon = 0.0001 | 1 Probability = 0.5 | 3 Structure: 72-36-6 | 99.3% | ||

| 3 30-60-90 | 3 ReLU | 3 Pooling Max | 3 Epsilon = 0.0001 | 0 Probability = 0.5 | 1 Output Size = 6 | 94.8% | ||

| 3 30-60-90 | 3 ReLU | 3 Pooling Max | 3 Epsilon = 0.0001 | 0 Probability = 0.5 | 2 Structure: 36-6 | 95.7% | ||

| 3 30-60-90 | 3 ReLU | 3 Pooling Max | 3 Epsilon = 0.0001 | 0 Probability = 0.5 | 3 Structure: 72-36-6 | 94.7% | ||

| Used description of the convolutional layer | 3 30-60-90 | Number of convolutional layers Number of filters in 1st, 2nd, 3th layer | ||||||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Skowron, M.; Orlowska-Kowalska, T.; Wolkiewicz, M.; Kowalski, C.T. Convolutional Neural Network-Based Stator Current Data-Driven Incipient Stator Fault Diagnosis of Inverter-Fed Induction Motor. Energies 2020, 13, 1475. https://doi.org/10.3390/en13061475

Skowron M, Orlowska-Kowalska T, Wolkiewicz M, Kowalski CT. Convolutional Neural Network-Based Stator Current Data-Driven Incipient Stator Fault Diagnosis of Inverter-Fed Induction Motor. Energies. 2020; 13(6):1475. https://doi.org/10.3390/en13061475

Chicago/Turabian StyleSkowron, Maciej, Teresa Orlowska-Kowalska, Marcin Wolkiewicz, and Czeslaw T. Kowalski. 2020. "Convolutional Neural Network-Based Stator Current Data-Driven Incipient Stator Fault Diagnosis of Inverter-Fed Induction Motor" Energies 13, no. 6: 1475. https://doi.org/10.3390/en13061475

APA StyleSkowron, M., Orlowska-Kowalska, T., Wolkiewicz, M., & Kowalski, C. T. (2020). Convolutional Neural Network-Based Stator Current Data-Driven Incipient Stator Fault Diagnosis of Inverter-Fed Induction Motor. Energies, 13(6), 1475. https://doi.org/10.3390/en13061475