1. Introduction

Famous for its unique geographic location between desert and sea, Qatar has significant desert climate and extremely hot weather conditions with a high temperature, humidity, and sand storms. The Air Conditioning (AC) systems in this region are highly mandatory for daily life through the year. The local weather has some significance of representing a unique desert and coastline climate, which attract a lot of research interests in various fields such as building efficiency, health, urban environment, and renewable energy [

1,

2,

3,

4,

5,

6,

7,

8,

9,

10,

11]. As elaborated in [

12], in GCC region such as Saudi Arab, more than 60% of the electricity consumed by local buildings goes to Air conditioning (AC). This is particularly valid for other GCC countries like Qatar, which is reliant on AC throughout the majority of the year. Due to the persistent heavy cooling load caused by high temperature weather conditions and desert climate, heating, ventilation, and Air Conditioning (HVAC) equipment degrades faster compared to HVAC facilities in other areas and also requires higher reliability while maintaining energy efficiency and adequate levels of quality and comfort.

An Air Conditioner system is made up of a compressor as key part, and other parts such as a condenser and an evaporator, where the air conditioning capacity depends on the compressor power. In space cooling scenarios, indoor temperature will oscillate at a set-point because the compressor work in switch modes of on or off [

13]. The component used to implement this control philosophy is known as an Air-Conditioner On-Off (or bang-bang) controller or thermoset. The On-Off compressor works as either being ON or OFF depending on the set-point boundary and the measured outdoor temperature. There is a dead range of 1.5

C to 2.0

C to prevent the too frequent On-Off fluctuations of the compressor that could lead to a reduced lifespan. Especially under hot weather conditions, long-term running with extra cooling load could degrade AC systems in a faster way, in particular if a very slight tracking error is imposed. Due to its simplicity, On-Off control is widely applied for temperature regulation application scenarios. However, On-Off control also have eminent drawbacks, which include temperature oscillation and non-optimal operation which negatively impacts the AC moving parts and its energy consumption [

13,

14,

15,

16,

17,

18,

19,

20,

21].

Currently, a body of research work has been reported in the literature in response to challenges around HVAC control optimization. Several research works have been proposed to optimize building HVAC system [

22,

23], and address On-Off control issues under different constraints. The related research work can be summarized as two approaches: low-complexity optimization, and dynamic optimization. In low-complexity optimization approaches, Hysteresis controllers and Pulse Width Modulation (PWM) are widely utilized [

13,

24]. A hysteresis controller has a simple structure to implement in practice, so it is widely used in HVAC applications. Because the AC systems by hysteresis control work under fixed hysteresis conditions/parameters (with a set-point temperature boundary), the hysteresis controller does not perform well if ambient parameters/working conditions change. PWM control is usually used in PWM actuated split air conditioners. The PWM controller tunes the duty ratio of the AC On-Off control signal in a continuous way to allow continuous change of the manipulated variable. It can accommodate some work conditions change based on its fast feedback control, which is similar to Proportional-Integral-Derivative (PID) control. However, PWM controller has to change under very fast switching frequency at the initial stage of the control process or scenarios of large variations in the working conditions. This fast change could degrade the AC compressor, and it has also been proven not to be optimal for all the HVAC control cases. Both of these optimized controllers treat control process time horizon as a long-term general process in one day, one week, one month or one year. Thus, the full control process needs to rely on the temperature profile of an entire period and also the controller parameters can only be set and tuned in advance. For instance, the hysteresis control parameters are pre-set with a hysteresis result under certain working conditions. The controllers cannot accommodate ambient temperature variations in an adaptive way.

As a dynamic optimization approach, Model-Predictive Control (MPC) is employed to accommodate disturbances and variations of the operating conditions such as time-variant parameters and target [

14,

24,

25,

26,

27,

28,

29,

30,

31]. The MPC’s optimization performance is subjected to the prediction horizon length. In theory, a longer prediction horizon can helps the solution be closer to the global optimum; therefore, it needs more computational power and resources. However, a proper prediction horizon is difficult to determine in practice, and MPC optimization will consume a lot of online computation loads. As such, online optimization and offline optimization need to be integrated and balanced for a trade-off between the computational load and AC control adaptiveness. In [

32], a scheme of AC On-Off control and optimization is proposed for variant ambient conditions, but the transition between off-line optimization and online control is not integrated, and the part of outdoor temperature prediction is missing because it is assumed. Moreover, demonstrations under Qatar climatic conditions for three hot seasons of a full year are missing.

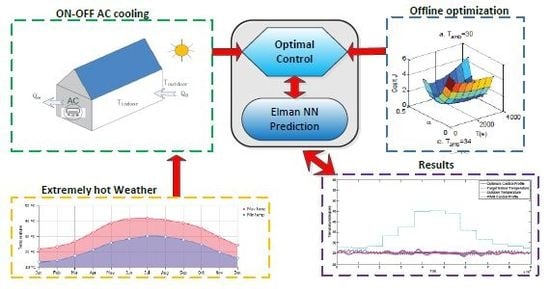

Motivated by the heavy cooling demand and its associated HVAC components wearing issues under harsh weather conditions in desert countries such as Qatar, an optimal AC On-Off Control Scheme is presented to improve cooling performance under heavy cooling load scenarios. In this scheme, optimizations are performed offline to generate the optimal solutions under certain conditions and range of outdoor temperatures, and then, a static data table of optimized parameters is generated. Based on the proposed lookup algorithm for online optimization, On-Off control parameters are tuned online to accommodate outdoor temperatures variation. As opposed to the existing AC hysteresis On-Off control schemes, the proposed On-Off control and optimization scheme can process more complex cooling scenarios such as large range and fast temperature variations. This is because the controller can adaptively accommodate the variations by tuning the parameters optimization online. Compared to the MPC control, the proposed control scheme performs optimization work offline which does not require a huge computational power in a real-time way like the online optimization technique.

This paper is structured as follows: a typical Qatar outdoor temperature profile is analyzed and the thermal model of a simple house is built in

Section 2;

Section 3 presents the proposed optimal On-Off control scheme, which includes off-line optimization and online adaptive tracking scheme. The validation results under different cooling scenarios are presented in

Section 4 and

Section 5 concludes the paper.

4. Validation Results

To validate the proposed On-Off control and optimization scheme, the studied house model parameters are referred from [

13], and the AC power is changed as 1500 W but not 300 W because It is more reasonable due to the hot climate in Qatar. Moreover, to the best of our knowledge, the HVAC facilities in Qatar is prone to easily degrading and failing and normally need a high maintenance cost. Considering the fact that the AC weariness under hot climate is more serious, the weight factors of Q in (10) are reduced to reflect the factor of cost impact. The updated parameters are shown in

Table 1.

Based on the AC parameter model list in

Table 1, the proposed control and optimization scheme is demonstrated, which includes offline optimization and online AC control performance, in different cooling scenarios.

4.1. Offline Optimization Results

To verify the offline optimization performance, a simplified AC cooling scenario is assumed for comparison in a quantitative way. In this cooling scenario, the indoor temperature is expected to be 24

C by different controller parameter settings with the outdoor temperature set as 34

C. For comparison, the temperature profiles subjected to three types of controller settings are shown in

Figure 11, and the corresponding COP values are compared.

Figure 11 shows that the COP value of the proposed optimum control is the lowest at

among optimization and non-optimization scenarios. Based on the cost value comparison, the optimum case has lower cost value, which means that it achieves better multiple-objective optimizations than other control scenarios. The cost-saving performance among the three cooling scenarios are presented in

Table 2. As shown in

Table 2, 30.16% can be saved from the case under outdoor temperature 29

C while 55.45% can be saved from the case under outdoor temperature 38

C by comparing with the optimum case.

To verify the effectiveness of offline optimization under different ambient temperature scenarios, a set of offline optimizations subjected to outdoor temperature range between 30

C and 44

C was performed. The target indoor temperature is expected to 24

C. The offline optimization parameters are shown in

Table 3, and the optimization convex surface results are shown in

Figure 12, which presents eight subfigures for eight temperature profiles with 2

C intervals. As can be seen from

Figure 12, all the optimization surfaces are convex, which means that the global optimum solution for the studied optimization case exists and only one solution exists and is unique. Due to the impact of the ambient temperature, the optimization surface shapes and cost values vary in a large range. As an input for the online adaptive control, the corresponding optimization control parameters are also generated in a list of a lookup table.

4.2. Outdoor Temperature Prediction Results

To validate the effectiveness of the proposed Elman NN based outdoor temperature prediction, the 3-day outdoor profile shown in

Figure 3 was used for Elman NN model training and test. The 3-day temperature has 72 points of hourly temperature in total. The prediction window is set as 4 so the total data point number for NN test set is

, and it is divided into two groups, 34 points each. After selecting the proper values for the Elman Training algorithm, we can get the training results in

Figure 13a,b. From

Figure 13a we can see that the Elman model output value is very close to the true value by the training procedure regression. From

Figure 13b we can see that the error is less than 0.6 degrees, which means the model regression accuracy is very high. To test the generalization ability of the proposed Elman NN model, the other group of 34 points data is used for validation, and the results are shown in

Figure 13c,d. From

Figure 13c, we can see that the estimation value is also very close to the true value. From

Figure 13d we can see that the estimation error is within the acceptable range (less than 2 degrees) although it is a little higher than training error. Based on the training regression and test validation results, we can conclude that the Elman NN model can generate an effective prediction of outdoor temperatures.

4.3. Online Adaptive Control Results

To validate the proposed online adaptive control scheme for the AC cooling under Qatar weather conditions, daily indoor temperature control scenarios are considered in the this paper. In general, the comfort indoor temperature is set as 25 C with an acceptable variation range of 2 C. Moreover, due to the slow time-variant characteristics of the outdoor temperature, a two-hour interval is a reasonable time zone to evaluate the weather temperature in existing weather measurement applications.

4.3.1. Case 1- One-Day Typical Case in Doha of Qatar

To verify the effectiveness of the proposed scheme, the second day outdoor temperature profile in

Figure 3, which is a typical day with large temperature variations, was selected for the data analysis. To compare the performance between the proposed optimal control and the PWM control mentioned in the literature review, comparative experiments are also conducted to re-implement the PWM control in the same house model as the proposed optimal control under same Qatar outdoor condition. The implemented PWM control has an adjustable pulse-width based PID control structure. In this PWM control, the PWM period is constant while the duty ratio/pulse width is adjusted as a continuous control variable to avoid the fast switching in the On-Off control. In addition, a PID module is added to make the tracking control to converge in a smooth way with acceptable oscillation error. The PWM control diagram is shown in

Figure 14, and the period time of the PWM pulse is set as 500 s, which is similar as the minimum period of the optimal control. The detailed AC control process variables such as AC consumption power, period time and duty ratio are shown in

Figure 15, and the temperature control results are presented in

Figure 16.

Figure 15 shows a modulated pulse output of the AC control power, cost value, period time, and duty ratios respectively. As can be seen from the plot of the AC power output, the AC consumption power is fixed at rated 1500 W while the pulse width is variable due to different cooling loads. The cost value plot also changes with time and shows a peak when the corresponding pulse width is the shortest. This means that a high outdoor temperature generates a heavier cooling load and more frequent AC On-Off switching actions and thus, the AC cooling overall cost is higher. From the period plot, we can see that the period time shows a valley point which it corresponds the closet pulse. From the duty ratio plot we can see that the duty ratio also reaches a peak point when the heavy load is highest. In a summary of all the plots, the results demonstrate that the control process can track the ambient temperature change and respond with appropriate control action in a real-time manner.

Figure 16 shows that the optimization AC cooling results under a typical day in summer. From the indoor temperature profile, we can see that the control scheme is effective to stabilize the indoor temperature at 25

C and be within the temperature fluctuation range although the curve is a little offset from the target curve at some instances. From the outdoor temperature profile, we can see that the outdoor temperature changes from 27

C to 46

C at a gap almost 20

C, but the control process can adaptively accommodate these variations by adjusting the control optimization parameters. Therefore, it is demonstrated that the proposed scheme applies for a typical large-variation scenario.

In addition,

Figure 16 also shows the temperature profile comparison between the PWM control and the proposed optimal control. Both the PWM control and the optimal control can stabilize the target indoor temperature at 25

C, although the outdoor temperature changes in a large daily range of 20

C. The PWM control oscillates at the transition time of the outdoor temperature’s rapid change while the proposed optimal control can accommodate this rapid transition in a smoother way. Moreover, the rapid transition causes the PWM control taking a large range of oscillation (between 23

C to 27

C) to converge into the target indoor temperature 25

C, while the optimal control can stabilize at a smaller range (between 24

C to 26

C). Through this comparison, it can be demonstrated that the optimal control has a better control performance than the PWM control in both stabilization accuracy and transition convergence speed.

By investigating more details about the control variables of the control approaches, the power profile for the optimal control and the PWM control is shown in

Figure 17a,b, respectively. The duty ratio profile of the PWM control is shown in

Figure 17c. By comparing

Figure 17a,b, it can be concluded that the optimal control has less pulses than the PWM control, and the cost due to switch is obviously reduced. From

Figure 17c, we can see that the duty ratio is a continuous variable which changes according to the outdoor temperature profile, which means that the PWM control can smooth the transition in a better way that the conventional On-Off control, although it is not the optimum comparing to the proposed optimum control.

Based on the fixed period value (500 s) and corresponding duty ratio sampling in each time duration, the cost in terms of COP in (10) is calculated, and the cost comparison in the corresponding time period is shown in

Table 4. From the table, we can see the proposed optimal control has less cost than the PWM control in each time duration, which means the proposed optimal control has a better control performance for multiple objectives, which consider both Coefficient of Performance, and AC compressor weariness due to On-Off switching.

4.3.2. Case 2- Cases through Three Hot Seasons in Doha of Qatar

To demonstrate the validity of the proposed scheme under three hot seasons in Qatar, complete yearly outdoor temperature data taken from our measurements, from June of 2018 to June of 2019, were used. As can been from

Figure 18, the outdoor temperature is fully or partially over 25 degrees except from December to March. In other words, spring, summer, and autumn are all hot seasons in Qatar. Thus, AC cooling is essential and the proposed optimization scheme can be applied. Considering this diversity of the Qatar desert climate, profiles of three typical days in each season, which include 2019/8/6, 2018/11/6, 2019/5/6, were selected to validate the proposed scheme for the three seasons of summer, autumn, and Spring, respectively.

As the hottest month of the year in Qatar, August is a typical for AC cooling scenarios due to its high outdoor temperature and resulting cooling load. The validation results for the selected summer day in August are presented in

Figure 19. The outdoor temperature profile shows that it varies from 32

C to 46

C in one summer day, which means that the gap between peak point and valley point is large and the AC needs to adaptively accommodate the corresponding time-variant cooling load. From the optimum temperature control profile, we can see that the oscillation period time at the peak point of the outdoor temperature is the shortest because it needs to generate the highest cooling effort. With 2-h interval time zone moving, the duty ratio and period time are both set as the best optimized value by the offline optimizations. Although the profile is not always close to the central of the target temperature of 25

C, the temperature variation range is within 1

C. This result demonstrates that the proposed AC control scheme can achieve the optimal cooling effect within the comfort level need of AC cooling.

The validation result for a typical autumn day, in November of 2018, is presented in

Figure 20. As shown in the outdoor temperature profile, it changes from 27

C to 29

C in one autumn season day. This means that the gap during the same day is very small, and also, the cooling load is lighter compared to summer days. From the optimum temperature control profile, we can see that the oscillation period time is longer than the summer case because of the lighter cooling load. The control profile is always kept to approach the target 25

C with 1

C variation range. These results demonstrate the effectiveness of the proposed scheme during autumn days in Qatar.

The validation result for a typical spring day, in May of 2019, is shown in

Figure 21. The outdoor temperature changes from 27

C to 37

C in one spring season day. This means the gap during the same day is smaller compared to summer days, and also the cooling load is changing quickly within same day. From the optimum temperature control profile, we can see that the oscillation period time is set with a very different value range because the cooling load is changing with large value range. The control profile is a little off the target 25

C due to the large variations of AC control parameter tuning, but it still satisfy the comfort level by approaching the target 25

C within 2

C variation range. These results demonstrate the effectiveness of the proposed scheme under spring season days in Qatar.

Remark 3. Because of the significance of Qatar’s extremely hot weather conditions, AC Optimization and control in this region is very different from other regions. Particular challenges such as large daily temperature peaks, heavy cooling load through the year, AC Group Consumption peaks, and local resident electricity consumption behaviours, also need to be considered. To address these challenges, effective optimization solutions are supposed to be applied for multiple objectives but not only COP and switching cost. Therefore, the needed optimization process will be more complicated, and accordingly, more advanced optimization theories such as optimization feasible zone, and tools including cloud-computing and super-computing are needed for future studies.