Development of a Bio-Solar House Model for Egyptian Conditions

Abstract

:1. Introduction

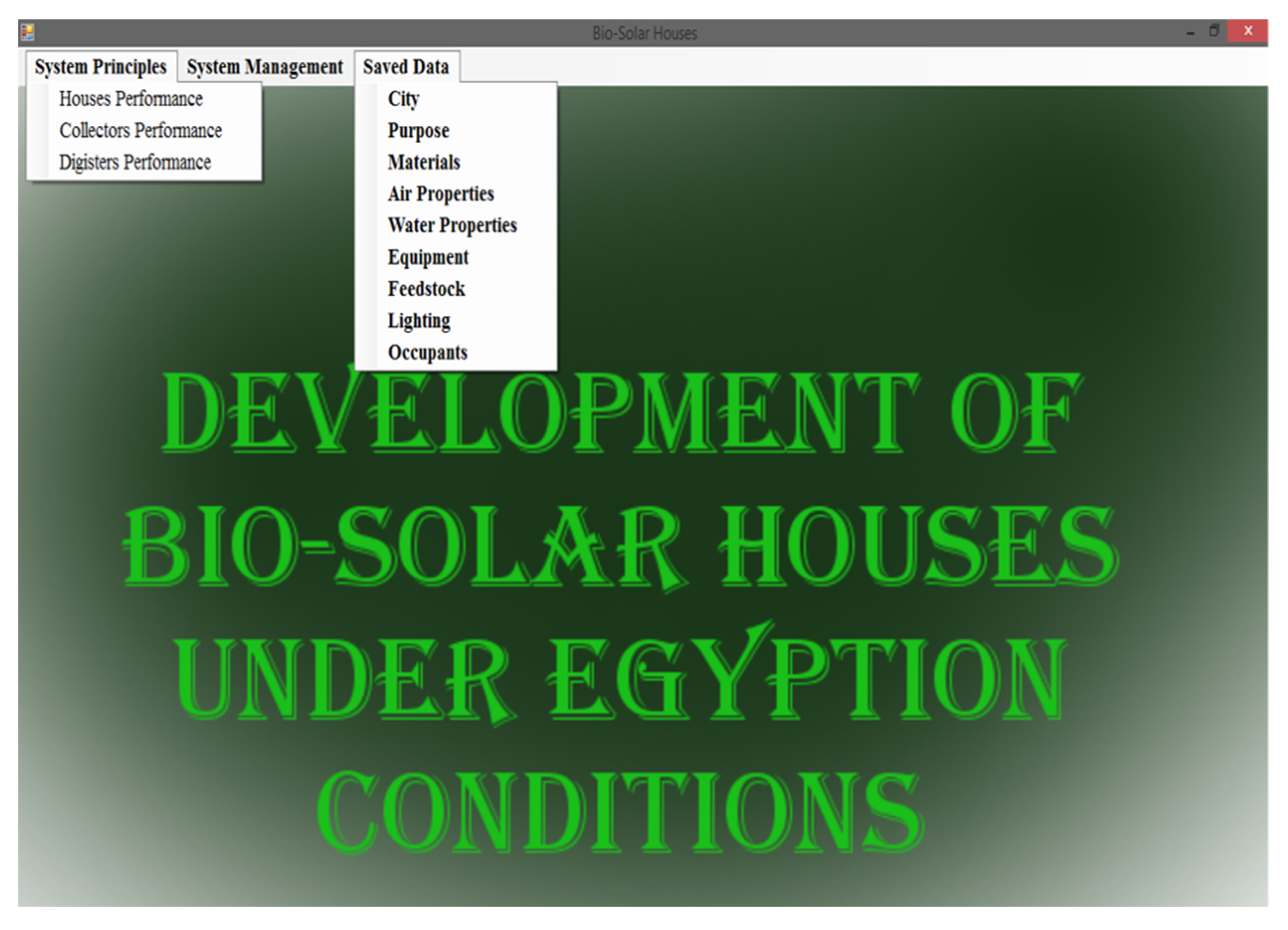

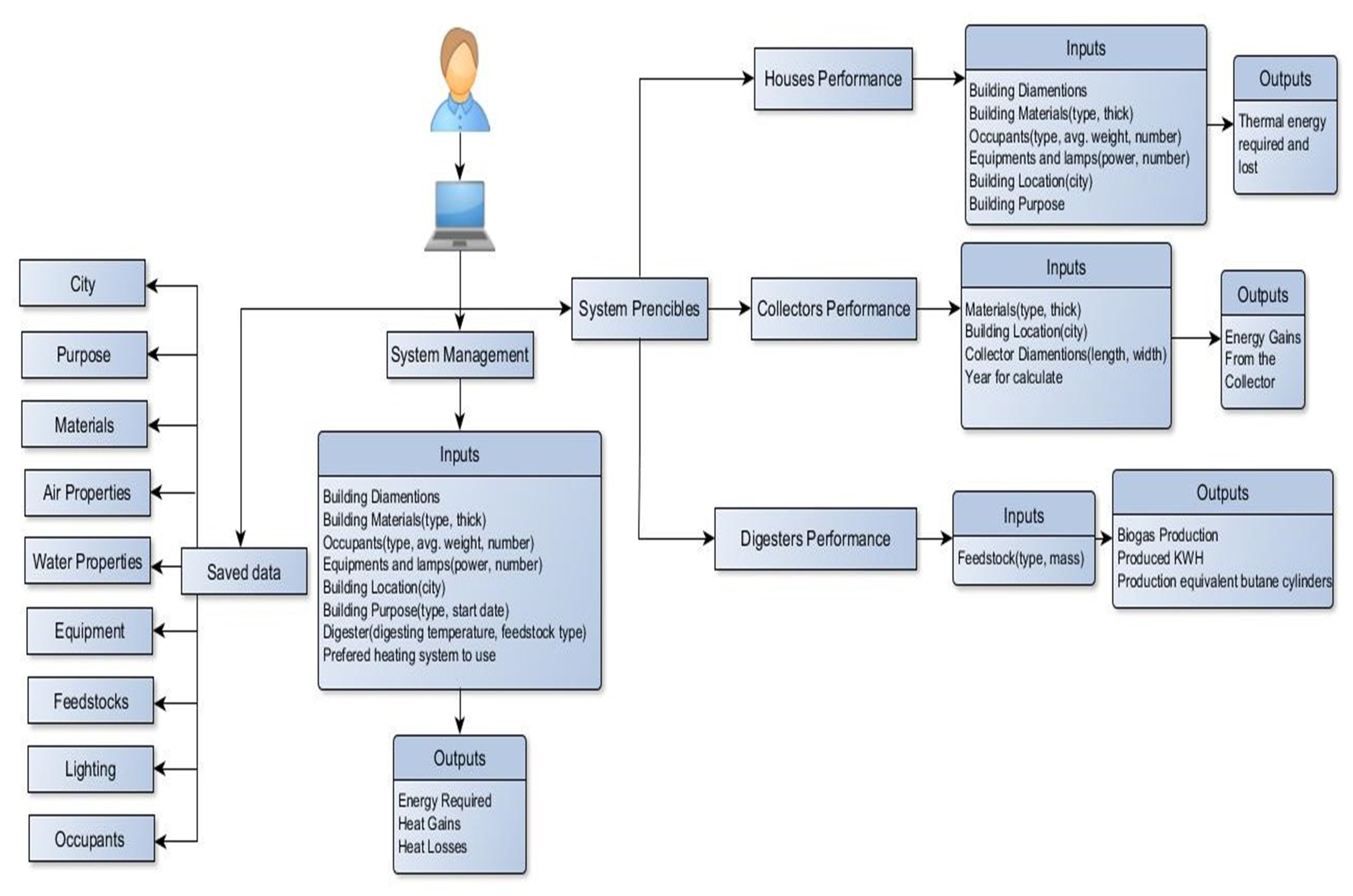

2. Model Development

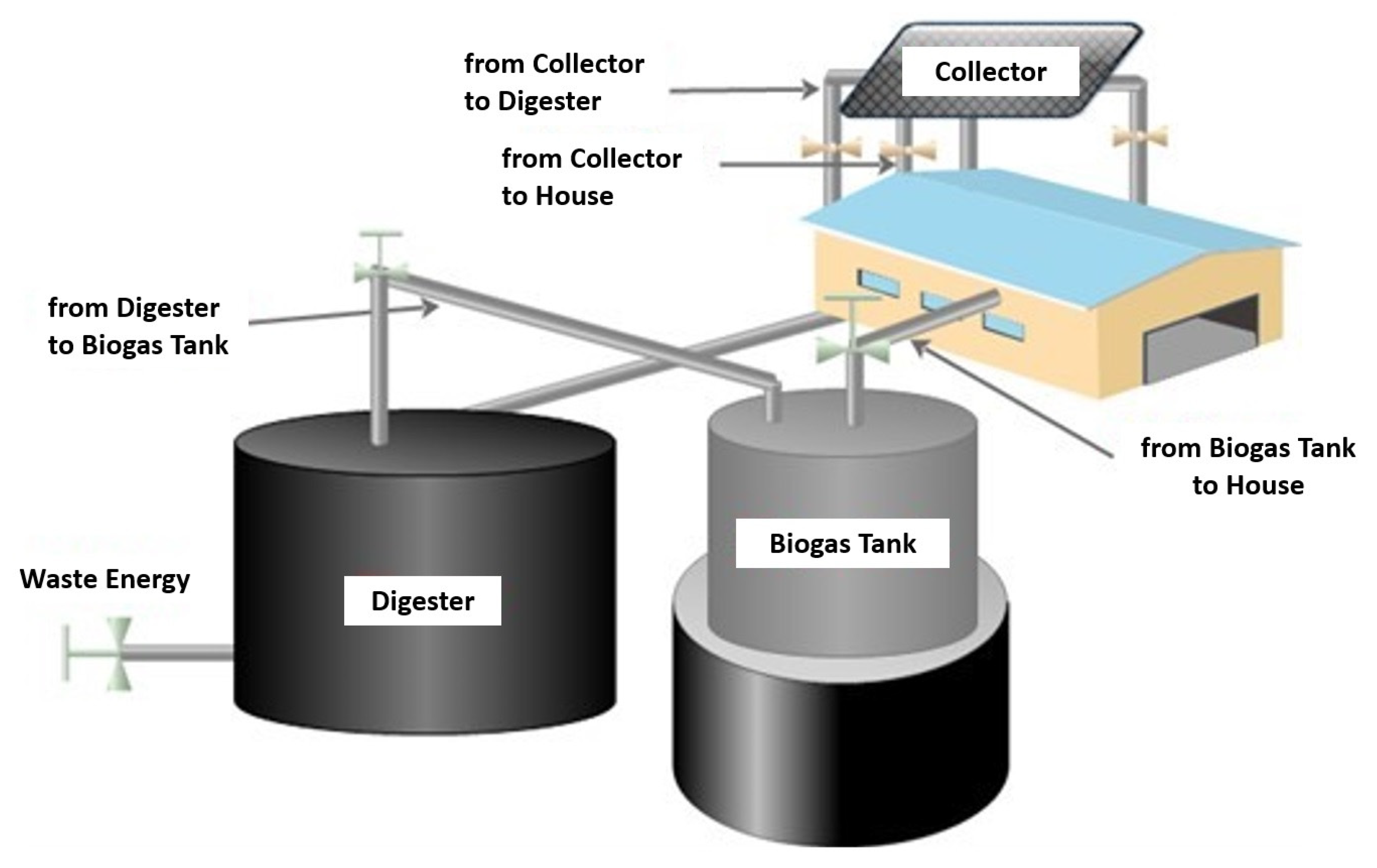

2.1. System Description

- Buildings heated by solar energy.

- Buildings heated by both solar and biogas energy (biogas digester heated by solar energy).

- Buildings heated by biogas energy that is heated by solar energy.

2.2. Mathematical Model

- The model is based on steady-state conditions.

- The temperature of air is uniform across the whole building.

- The density and heat capacity of the air are constant.

- The temperature gradients within the constructions are negligible.

- The building walls have negligible heat capacity.

- The Egyptian time zone is GMT/UTC±2, so LSM for Egypt is 30° according to Reference [17].

- The distance between absorbent plate and glass cover is assumed to be 3 mm.

- Clearness number is assumed to be 0.7 along the lines of [18].

- The absorber plate temperature is assumed to be 90 °C or 363.15 °K and the glass cover temperature is assumed to be equal to the ambient temperature.

- The internal gains in the digester are to be neglected.

- The collector tilt angle is 45°.

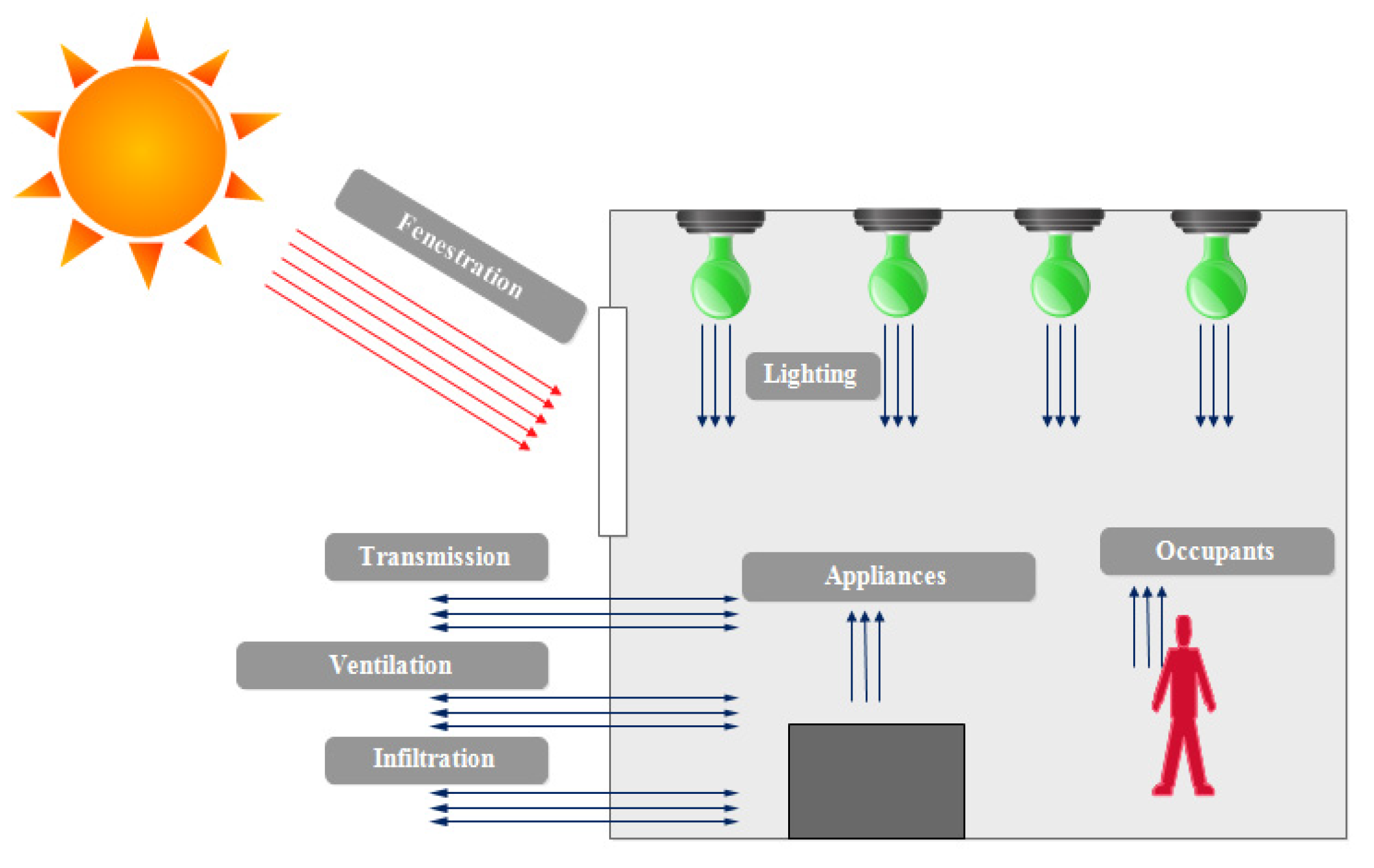

2.2.1. Houses Energy Requirements

2.2.2. Digester Energy Analysis

- Laminar flow:

- Turbulent flow:

- If the used system includes a building heated with solar energy and unheated biogas energy or a building heated with solar energy and biogas energy which is heated with solar energy, then the total energy needed from the digester on daily basis should be:= (Avg. yearly rate required for conditioning) × (24- Avg. yearly sunshine hours)/1000.

- If the used system involves a building heated with biogas energy which is heated with solar energy, then the total energy needed from the digester on a daily basis should be:= (Avg. yearly rate required for conditioning) (24)/1000.

- Biogas quantity needed (m3 day−1) = Energy needed from digester/6.5.

- Required feedstock rate (kg day−1) = Biogas daily quantity/Biogas yield.

2.2.3. Solar Collector Performance Analysis

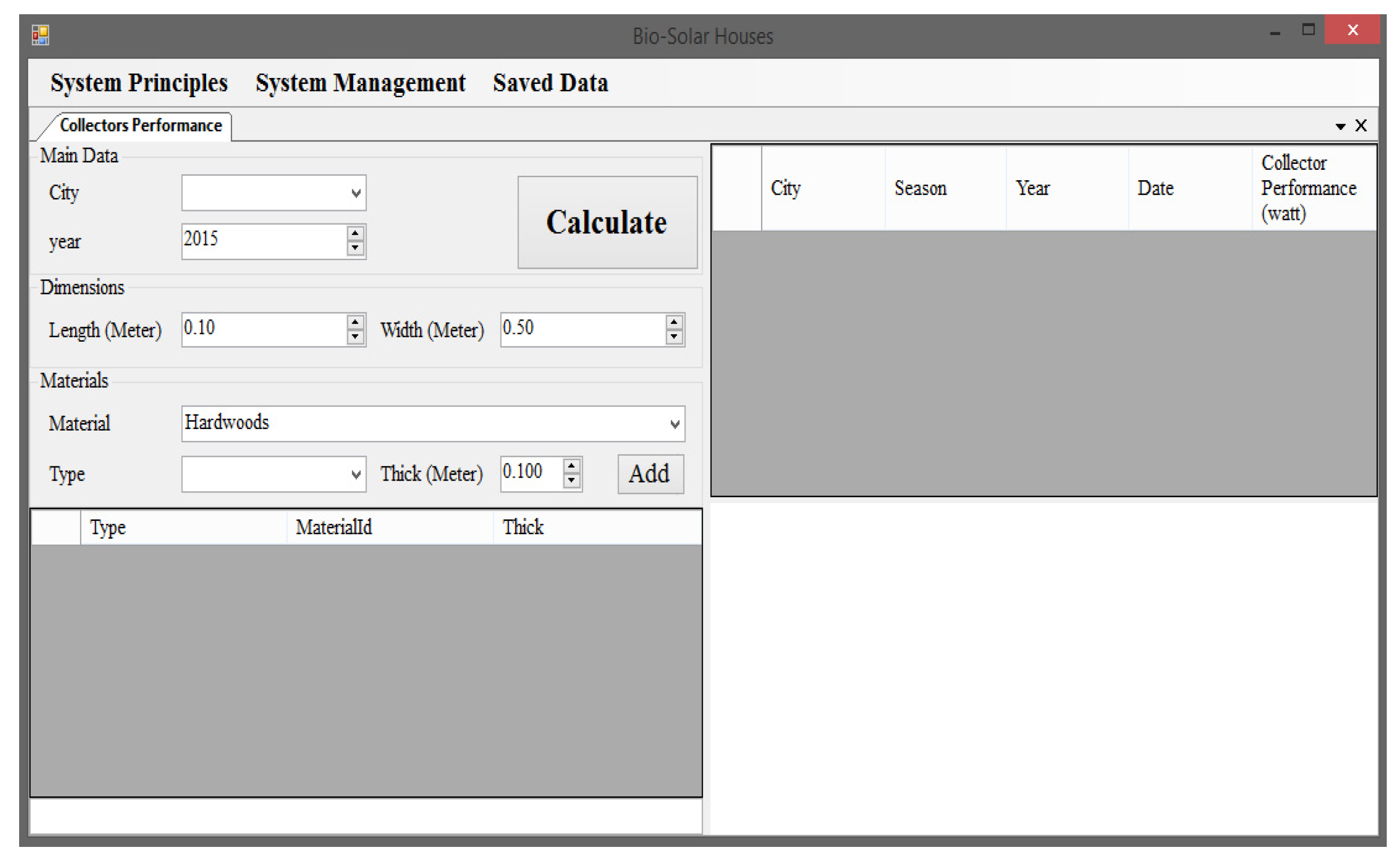

3. Model Approach

4. Procedures

4.1. Description of the Experimental Bio-Solar House

4.2. Case Studies on the Bio-Solar House

- Heating the house with solar energy.

- Heating the house and the biogas digester with solar energy during daylight and with biogas at night (temperature of the biogas digester is 309.15 K and retention time is 35 days).

- Heating the house and biogas digester with solar energy during daylight and with biogas at night (temperature of biogas digester is 322.15 K and retention time is 17.5 days).

- Heating the house with biogas while the biogas digester is heated by solar energy (temperature of biogas digester is 309.15 K and retention time is 35 days).

- Heating the house with biogas while the biogas digester is heated by solar energy (temperature of biogas digester is 322.15 K and retention time is 17.5 days).

5. Results and Discussion

5.1. Model Experimentation

5.1.1. Solar Collector Area and Biogas Digester Volume Requirements

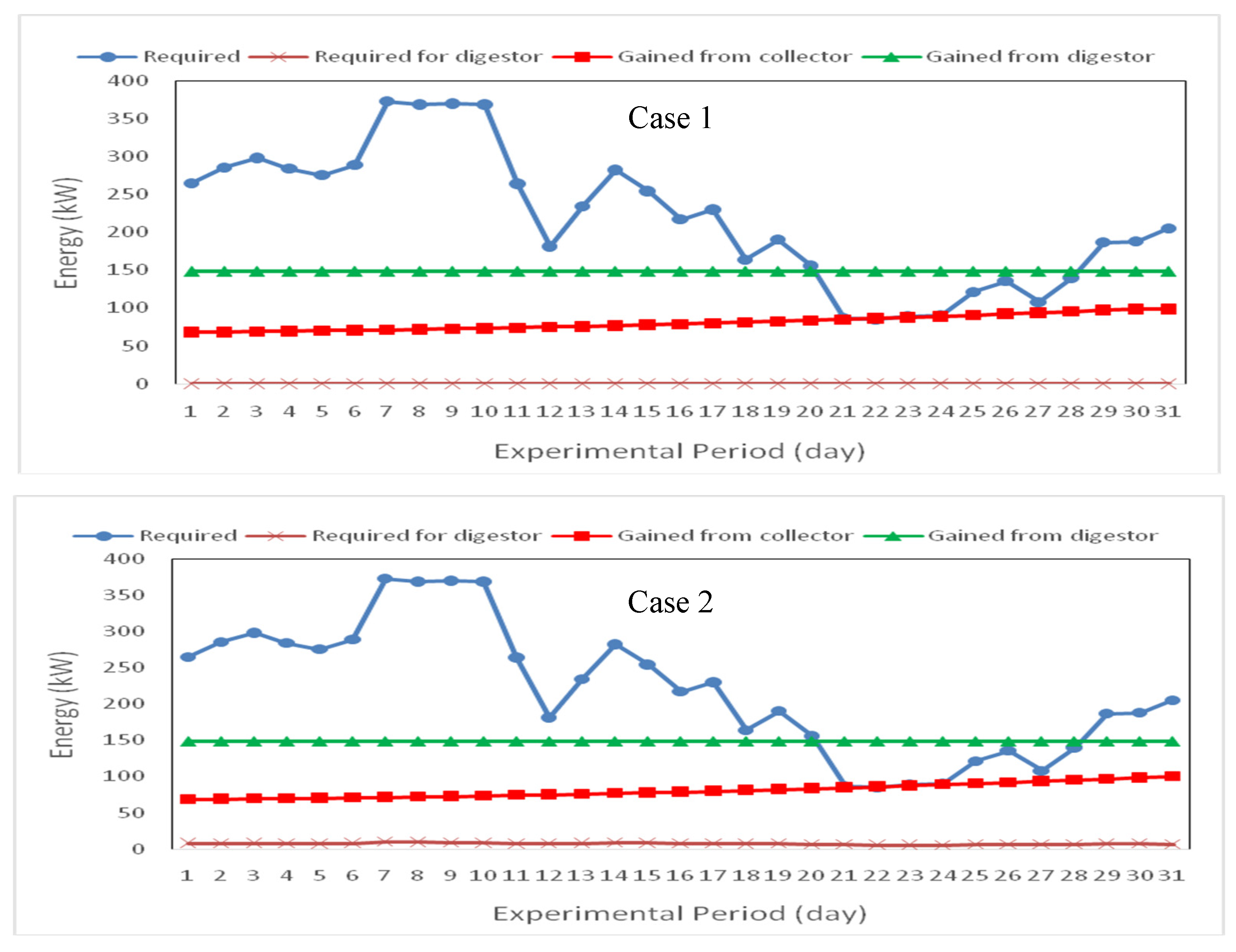

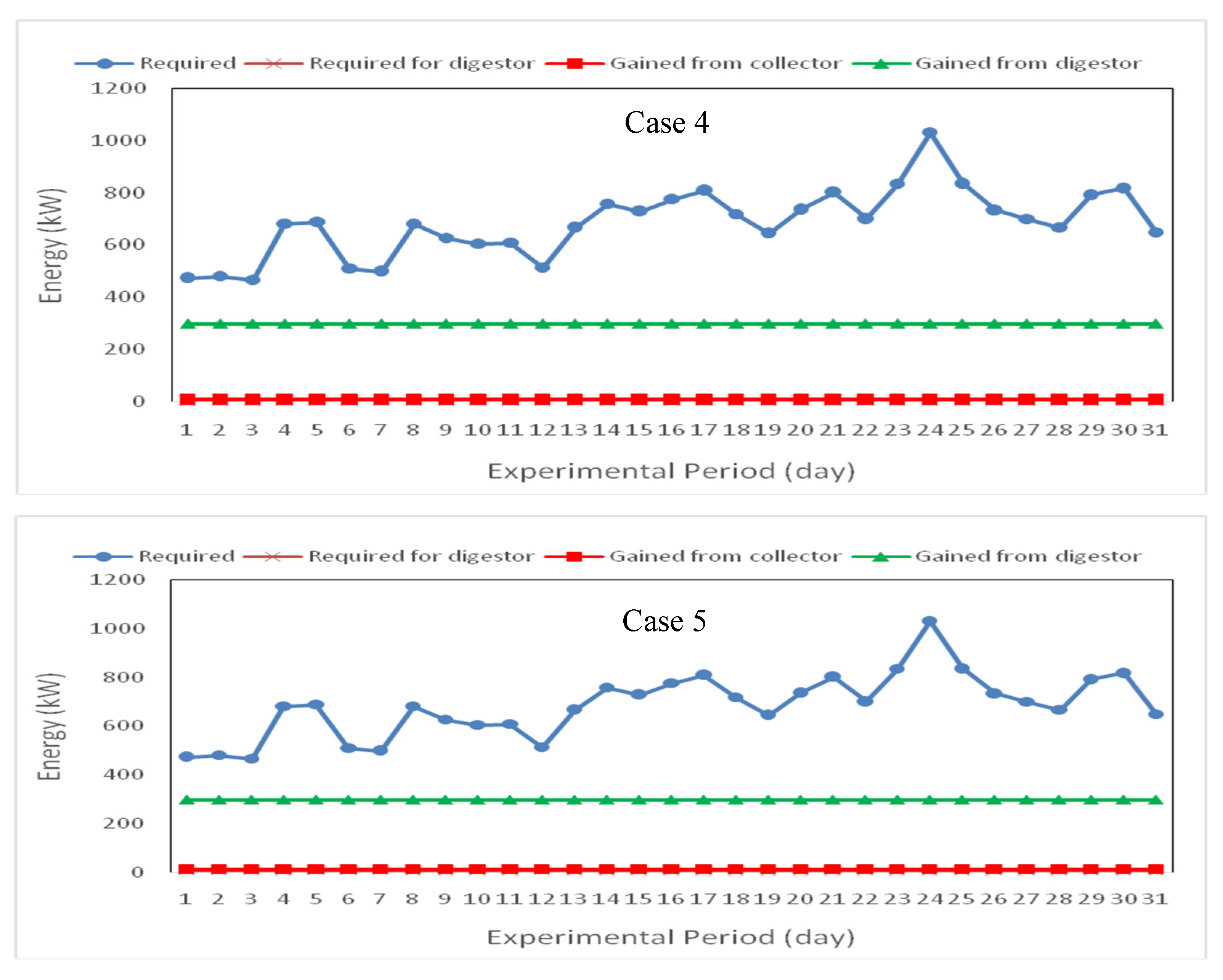

5.1.2. Results of Case Studies during Winter Season

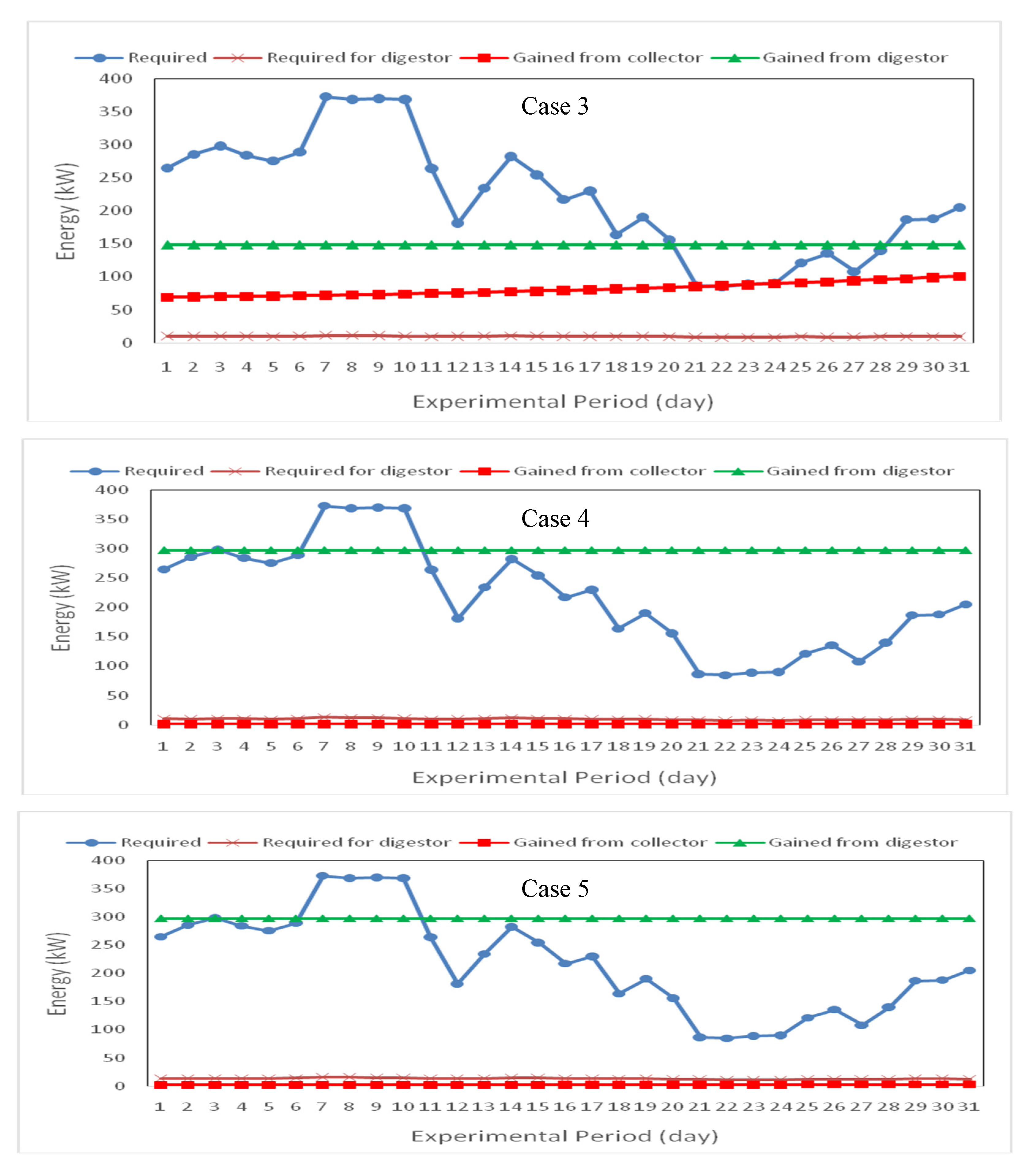

5.1.3. Results of Case Studies during Summer Season

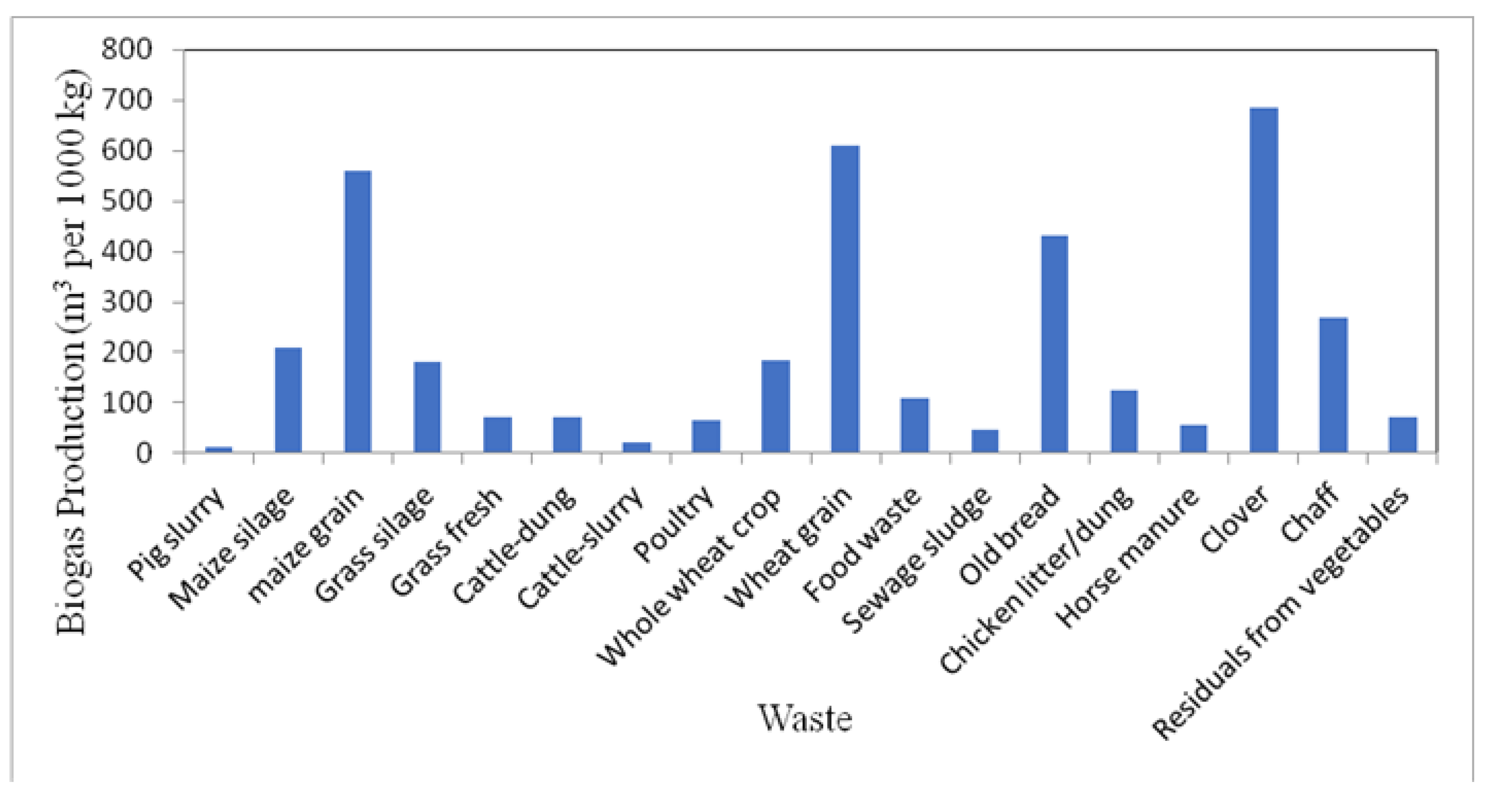

5.1.4. Digester Performance

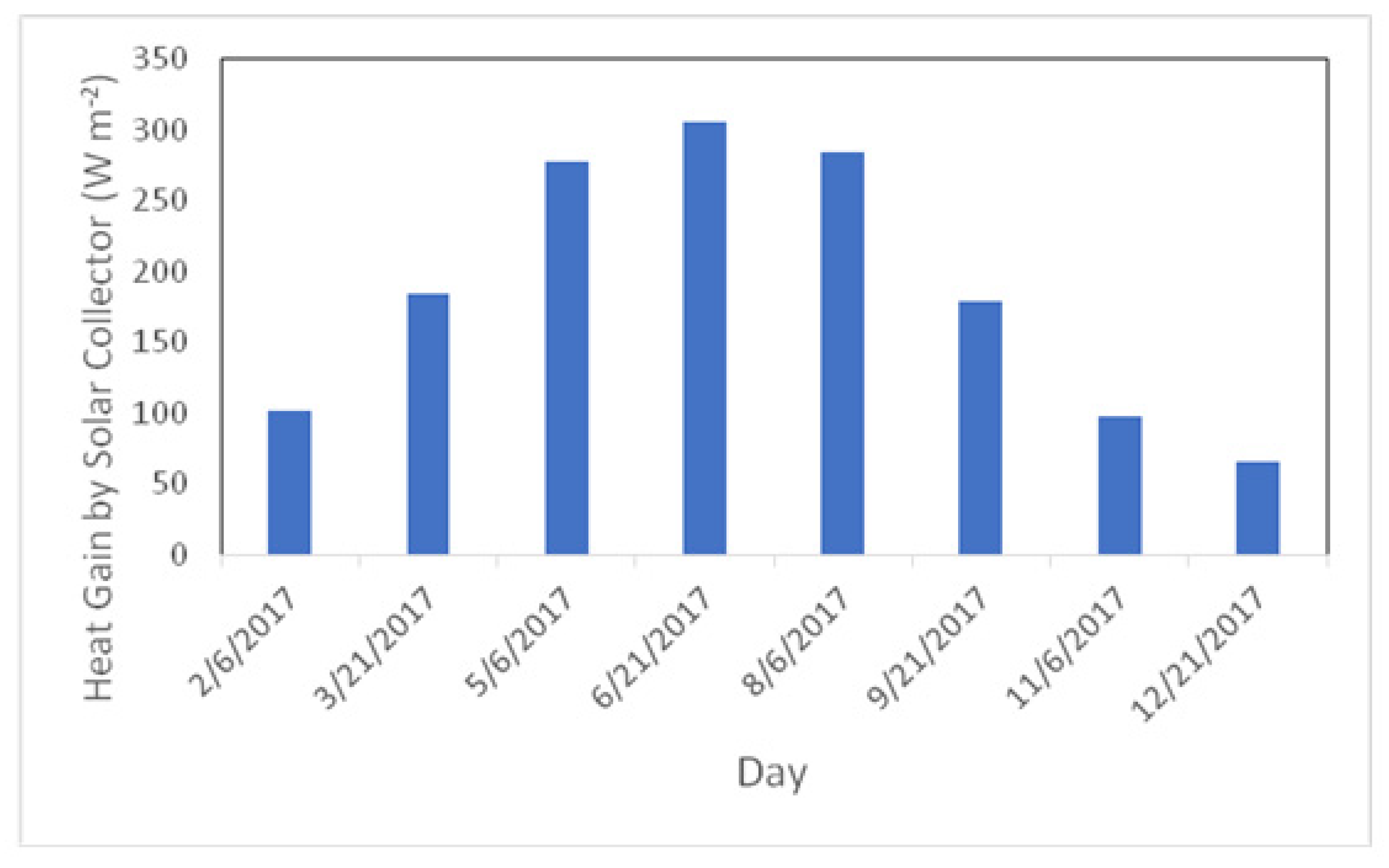

5.1.5. Solar Collector Performance

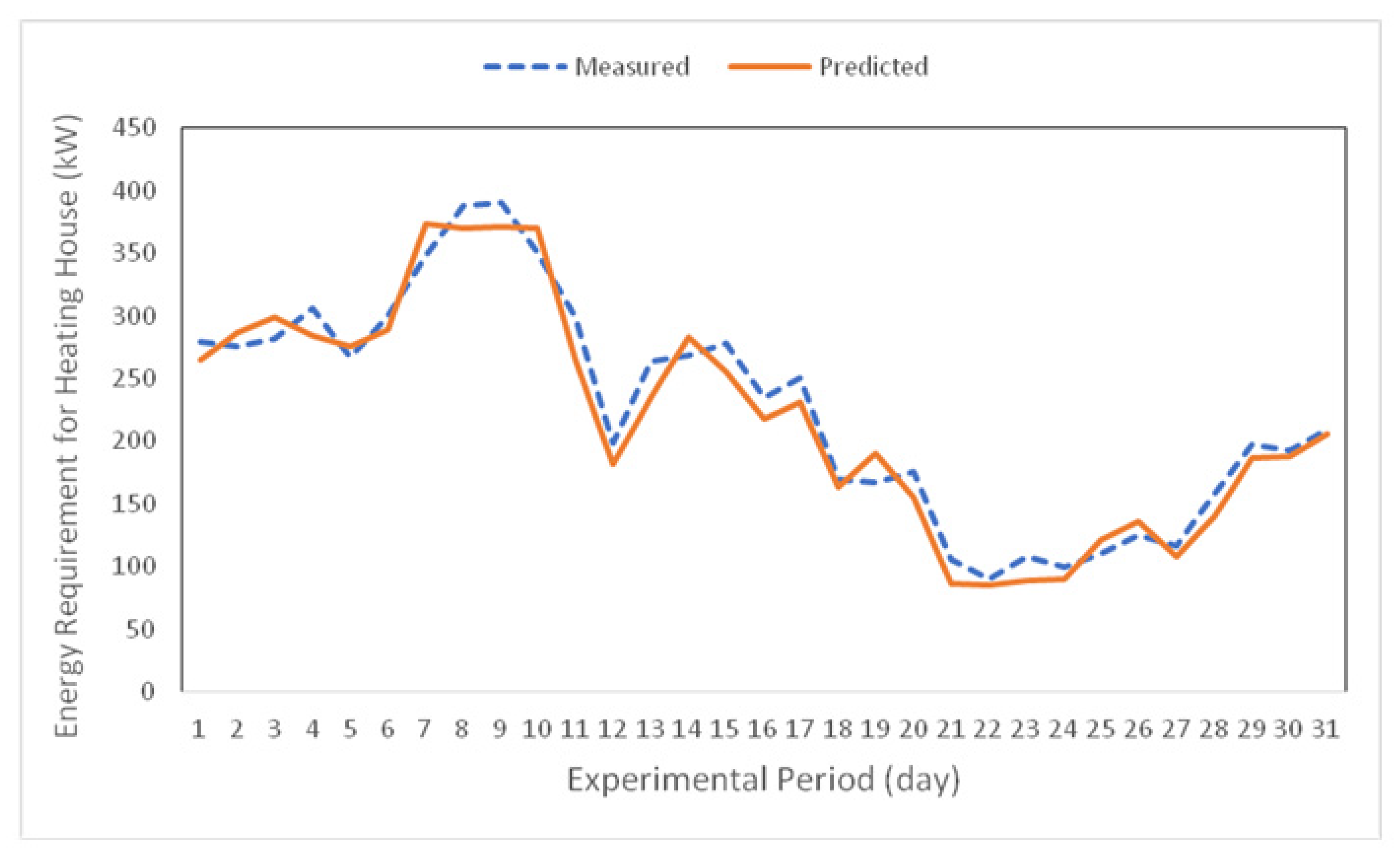

5.2. Model Validation

5.2.1. Energy Requirement for Heating the House

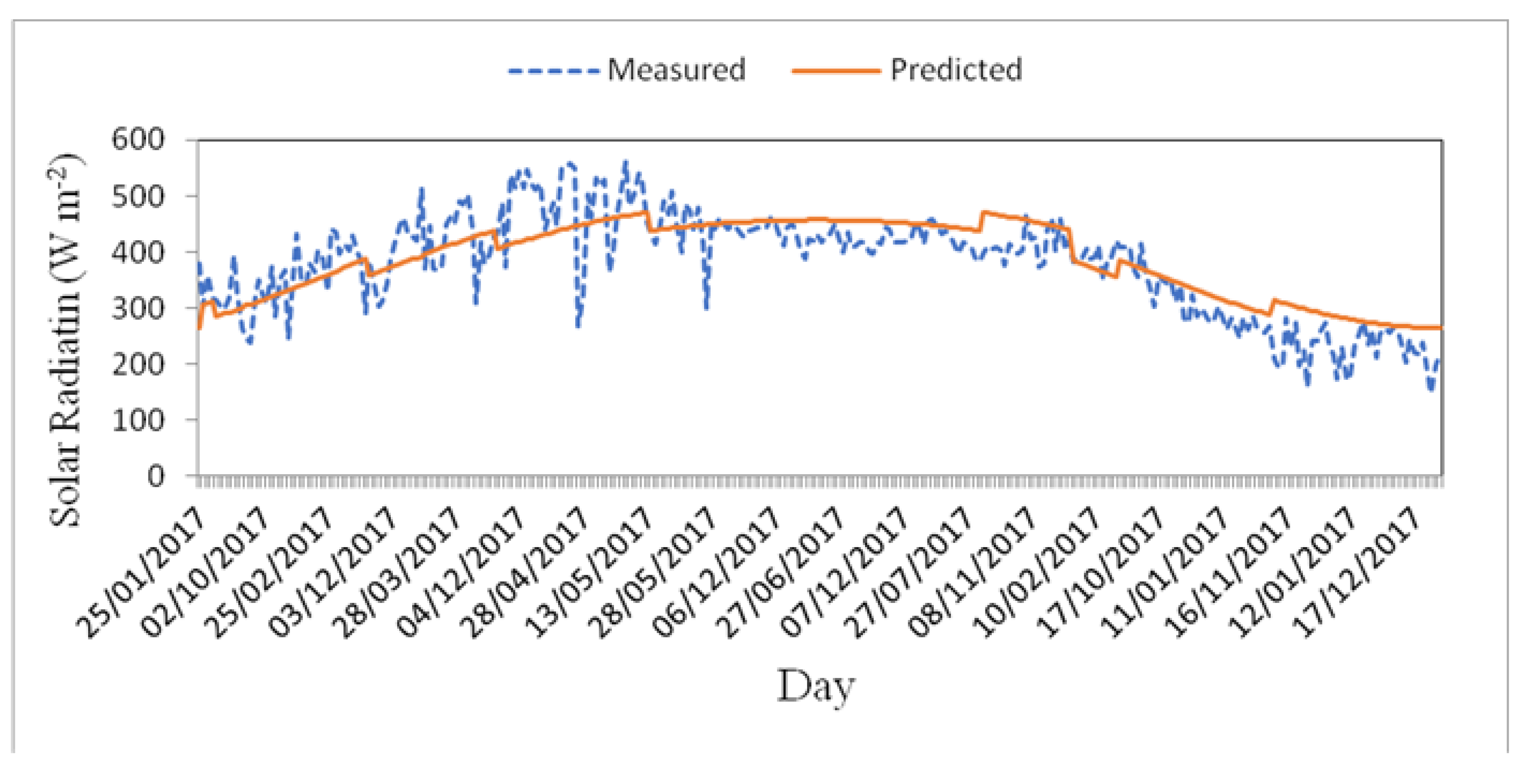

5.2.2. Solar Radiation

6. Conclusions

- The required solar collector area and the biogas digester volume for providing the bio-solar house with the required energy were 177.17, 179.06, 180.31, 4.25 and 8.50 m2 and 9.76, 4.56, 2.28, 9.15 and 4.56 m3 for first, second, third, fourth and fifth case study, respectively.

- The highest values of energy gained by the solar collector during winter and summer seasons were 100.58 and 439.95 kW were found for third case study, respectively, while the lowest values of energy gained were 2.01 and 11.79 kW was found for fifth case study, respectively.

- The average energy gained by the biogas digester was 148.87, 148.87, 148.87, 297.75 and 297.75 kW for first, second, third, fourth and fifth bio-solar house, respectively, during winter and summer season.

- The energy requirement for heating the biogas digester during winter season ranged from 5.37 to 9.66, 8.02 to 11.56, 7.58 to 13.11 and 11.01 to 15.69 kW for second, third, fourth and fifth study case, respectively, while ranging from 1.14 to 2.27, 3.52 to 5.18, 1.54 to 3.06 and 4.75 to 7.00 kW for first, second, third, fourth and fifth bio-solar house, respectively, during summer season.

- The highest value of biogas production (686.0 m3 per 1000 kg) was reached using the clover waste, whereas the lowest value of biogas production (12 m3 per 1000 kg) was reached using pig slurry.

- The heat gained from the solar collector ranged from 66.015 to 305.735 W m2 during different days of the year in Toukh city.

- The predicted energy requirements and solar radiation were in a reasonable agreement with the measured ones. The energy requirements ranged from 89.65 to 390.12 kW experimentally, whereas theoretically the values ranged from 85.07 to 373.63 kW. The solar radiation ranged from 161.00 to 561.85 W m2 experimentally, while the theoretical values ranged from 264.88 to 470.68 W m2.

- Further studies on renewable energies utilization in heating and cooling buildings and recommend. Economical evaluation is recommended in further studies.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- International Energy Agency. Energy Efficiency Requirements in Building Codes, Energy Efficiency Policies for New Buildings; IEA Information Paper; International Energy Agency: Paris, France, 2008; pp. 1–85. [Google Scholar]

- Tungarayasub, I. A Bio-Solar House for Northern Thailand. Master’s Thesis, University of Massachusetts Lowell, Lowell, MA, USA, 2004. [Google Scholar]

- McMullan, R. Environmental Science in Buildings; Palgrave Macmillan: London, UK, 2002. [Google Scholar]

- Jekayinfa, S.O. Energetic Analysis of Poultry Processing Operations. Leonardo J. Sci. 2007, 10, 77–92. [Google Scholar]

- Alam, M.S.; Alam, M.R.; Islam, K.K. Energy Flow in Agriculture: Bangladesh. Am. J. Environ. Sci. 2005, 1, 213–220. [Google Scholar] [CrossRef]

- Grönniger, H.; Ringert, J.; Rumpe, B. System model-based definition of modeling language semantics. In Proceedings of the FMOODS/FORTE 2009, LNCS 5522, Lisbon, Portugal, 9–12 June 2009; pp. 152–166. Available online: www.se-rwth.de/publications (accessed on 9 December 2019).

- Harel, D.; Rumpe, B. Meaningful Modeling: What’s the Semantics of “Semantics”? Computer 2004, 37, 64–72. [Google Scholar] [CrossRef]

- France, R.; Evans, A.; Lano, K.; Rumpe, B. The UML as a formal modeling notation. Comput. Stand. Interfaces 1998, 19, 325–334. [Google Scholar] [CrossRef] [Green Version]

- Breu, R.; Grosu, R.; Huber, F.; Rumpe, B.; Schwerin, W. Towards a Precise Semantics for Object-Oriented Modeling Techniques. In Proceedings of the ECOOP 1997 Workshop on Precise Semantics for Object-Oriented Modeling Techniques, Jyväskylä, Finland, 9–13 June 1997; Kilov, H., Rumpe, B., Eds.; TUM-I9725. Technische Universitat Munchen: München, Germany, 1997; pp. 53–59. [Google Scholar]

- Berger, T.; Amann, C.; Formayer, H.; Korjenic, A.; Pospischal, B.; Neururer, C.; Smutny, R. Impacts of climate change upon cooling and heating energy demand of office buildings in Vienna, Austria. Energy Build. 2014, 80, 517–530. [Google Scholar] [CrossRef]

- Negendahl, K. Building performance simulation in the early design stage: An introduction to integrated dynamic models. Autom. Constr. 2015, 54, 39–53. [Google Scholar] [CrossRef]

- Szalay, Z.; Zöld, A. Definition of nearly zero-energy building requirements based on a large building sample. Energy Policy 2014, 74, 510–521. [Google Scholar] [CrossRef]

- Nembrini, J.; Samberger, S.; Labelle, G. Parametric scripting for early design performance simulation. Energy Build. 2014, 68, 786–798. [Google Scholar] [CrossRef]

- Todorović, M.S. BPS, energy efficiency and renewable energy sources for buildings greening and zero energy cities planning: Harmony and ethics of sustainability. Energy Build. 2012, 48, 180–189. [Google Scholar] [CrossRef]

- Diakaki, C.; Grigoroudis, E.; Kolokotsa, D. Towards a multi-objective optimization approach for improving energy efficiency in buildings. Energy Build. 2008, 40, 1747–1754. [Google Scholar] [CrossRef]

- Cook, M.; Yang, T.; Cropper, P. Thermal Comfort in Naturally Ventilated Classrooms: Application of Coupled Simulation Models Building Energy Research Group; Loughborough University: Loughborough, UK; Institute of Energy and Sustainable Development, De Montfort University: Leicester, UK, 2011; pp. 14–16. [Google Scholar]

- ASHRAE. Handbook Heating, Ventilating, and Air-Conditioning Application; ASHRAE (American Society of Heating, Refrigerating and Air-Conditioning Engineers): Atlanta, GA, USA, 2009. [Google Scholar]

- Ibrahim, A.; El-Sebaii, A.A.; Ramadan, M.R.I.; El-Broullesy, S.M. Estimation of Solar Irradiance on Inclined Surfaces Facing South in Tanta, Egypt. Int. J. Renew. Energy Res. 2011, 1, 18–25. [Google Scholar]

- Crawley, D.B.; Hand, J.W.; Kummert, M.; Griffith, B.T. Contrasting the capabilities of building energy performance simulation programs. Build. Environ. 2008, 43, 661–673. [Google Scholar] [CrossRef] [Green Version]

- ASHRAE. Handbook Heating, Ventilating, and Air-Conditioning Application; ASHRAE (American Society of Heating, Refrigerating and Air-Conditioning Engineers): Atlanta, GA, USA, 2001. [Google Scholar]

- Holman, J.P. Heat Transfer; McGraw-Hill: New York, NY, USA, 1997; p. 696. [Google Scholar]

- Arora, C.P. Refrigeration and Air Conditioning, 2nd ed.; McGraw-Hill: New Dehli, India, 2006. [Google Scholar]

- Petersson, A.; Wellinger, A. Biogas Upgrading Technologies—Developements and Innovations; IEA Bioenergy: Paris, France, 2014. [Google Scholar]

- ASHRAE. Handbook Heating, Ventilating, and Air-Conditioning System and Equipement; ASHRAE (American Society of Heating, Refrigerating and Air-Conditioning Engineers): Atlanta, GA, USA, 2003. [Google Scholar]

- ASHRAE. Applications of Solar Energy for Heating and Cooling of Buildings; ASHRAE (American Society of Heating, Refrigerating and Air-Conditioning Engineers): Atlanta, GA, USA, 1997. [Google Scholar]

- Hollands, K.G.T.; Unny, T.E.; Raithby, G.D.; Konicek, L. Free Convective Heat Transfer across Inclined Air Layers. J. Heat Transf. 1976, 98, 189–193. [Google Scholar] [CrossRef]

- Duffie, J.A.; Beckman, W.A. Solar Engineering of Thermal Processes, 4th ed.; WILEY: New York, NY, USA, 2013. [Google Scholar]

- Ali, I.; Senthilkumar, R.; Mahendren, R. Modelling of Solar Still Using Granular Activated Carbon in Matlab. Bonfring Int. J. Power Syst. Integr. Circuits 2011, 1, 5–10. [Google Scholar]

- ASHRAE. Thermal Environmental Conditions for Human Occupancy; ASHRAE (American Society of Heating, Refrigerating and Air-Conditioning Engineers): Atlanta, GA, USA, 2010. [Google Scholar]

| Parameter | Units | Value | Source |

|---|---|---|---|

| V | m s−1 | 0.5 | [17] |

| F | W m−1 K−1 | 1.2 | [17] |

| LSM | Degree | 30 | |

| Ful | - | 1 | |

| Fsa | - | 1 | |

| Hardwoods (K) | W m−1 K−1 | 0.166 | [19] |

| Red brick (K) | W m−1 K−1 | 0.7 | [17] |

| Straw (K) | W m−1 K−1 | 0.042 | [17] |

| Concrete (K) | W m−1 K−1 | 0.93 | [17] |

| Glass (K) | W m−1 K−1 | 1.2 | [17] |

| SHGC | - | 0.25–0.6 | |

| Pg | - | 0.2 | |

| Cn | - | 0.665 | [29] |

| Σ | Degree | 90 |

| Type | Material | Material | Thickness (m) |

|---|---|---|---|

| House | Doors | Hardwoods | 0.05 |

| Windows | Glass | 0.006 | |

| Ground | Concrete | 0.1 | |

| Walls | Brick | 0.2 | |

| Straw bales | 0.5 | ||

| Roof | Concrete | 0.1 | |

| Straw bales | 0.5 | ||

| Solar collector | Collector Cover | Glass | 0.01 |

| Absorbent Plate | Black steel | 0.02 | |

| Insulation | Glass wool | 0.05 | |

| Collector Bottom | Black steel | 0.02 | |

| Biogas digester | Digester body | Stainless Steel | 0.02 |

| Foam | 0.05 | ||

| Feedstock | Clover | ||

| City | Toukh | |

| Year | 2017 | |

| Tilt angle | 45 | |

| Type | Flat Plate with single cover | |

| Fluid | Air | |

| Collector Dimensions | ||

| Length (m) | Width (m) | |

| 3 | 2 | |

| Collector Materials | ||

| Type | Material | Thick (m) |

| Collector Cover | Glass | 0.01 |

| Absorbent Plate | Black steel | 0.02 |

| Insulation | Glass wool | 0.05 |

| Collector Bottom | Black steel | 0.05 |

| Case | Solar Collector Area, m2 | Biogas Digester Volume, m3 |

|---|---|---|

| First | 177.17 | 9.76 |

| Second | 179.06 | 4.56 |

| Third | 180.31 | 2.28 |

| Fourth | 4.25 | 9.15 |

| Fifth | 8.50 | 4.56 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khater, E.-S.; Ashour, T.; Ali, S.; Saad, M.; Todic, J.; Hollands, J.; Korjenic, A. Development of a Bio-Solar House Model for Egyptian Conditions. Energies 2020, 13, 817. https://doi.org/10.3390/en13040817

Khater E-S, Ashour T, Ali S, Saad M, Todic J, Hollands J, Korjenic A. Development of a Bio-Solar House Model for Egyptian Conditions. Energies. 2020; 13(4):817. https://doi.org/10.3390/en13040817

Chicago/Turabian StyleKhater, El-Sayed, Taha Ashour, Samir Ali, Manar Saad, Jasna Todic, Jutta Hollands, and Azra Korjenic. 2020. "Development of a Bio-Solar House Model for Egyptian Conditions" Energies 13, no. 4: 817. https://doi.org/10.3390/en13040817