A Review of Performance-Enhancing Innovative Modifications in Biodiesel Engines

Abstract

:1. Introduction

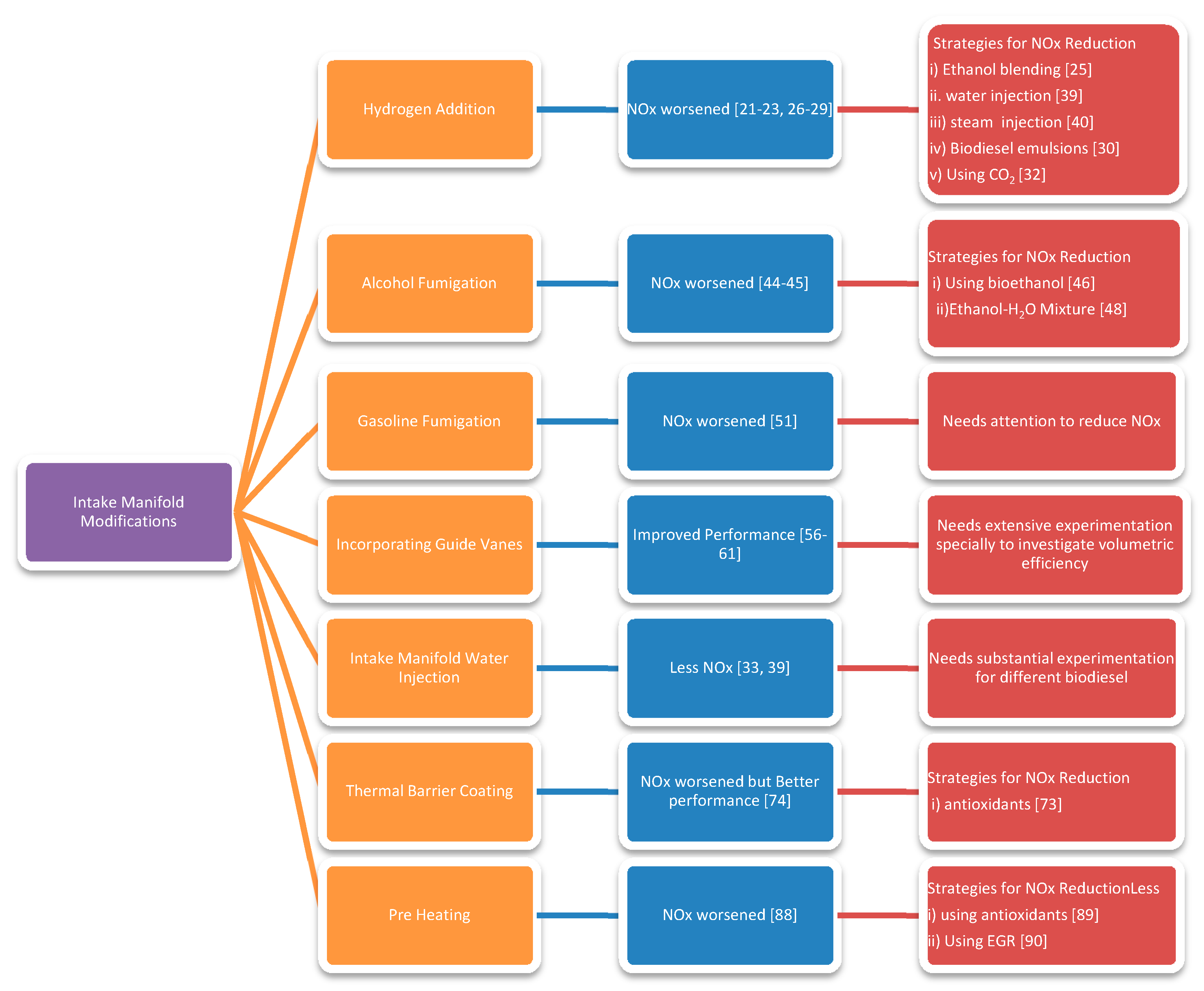

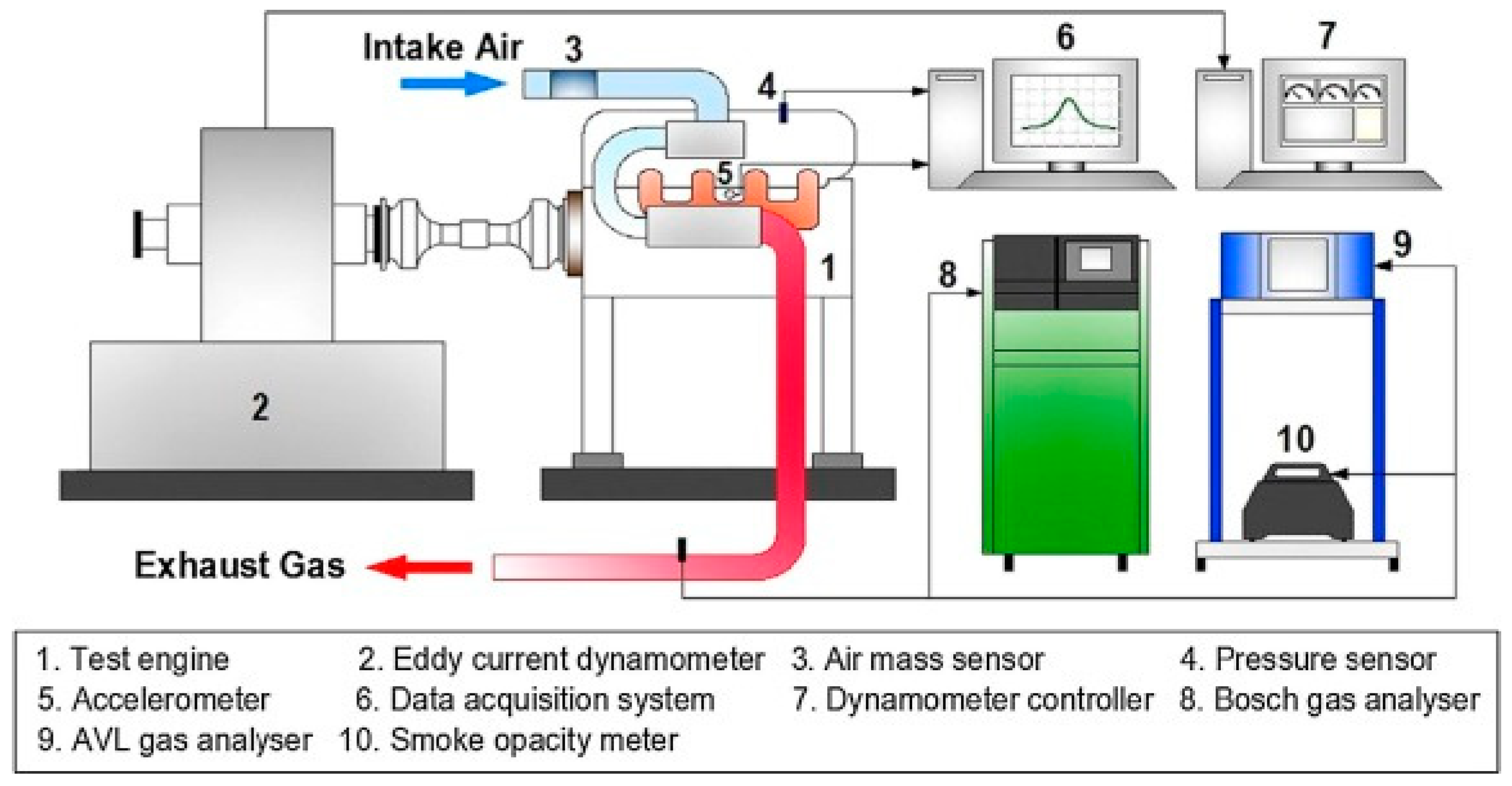

2. Intake Manifold Modifications

2.1. Hydrogen Addition

2.2. Alcohol Fumigation Modes

2.3. Gasoline Fumigation

2.4. Incorporating Guide Vanes

2.5. Intake Manifold Water Injection (IMWI)

2.6. Thermal Barrier Coating

2.7. Pre-Heating CI Biodiesel Engines

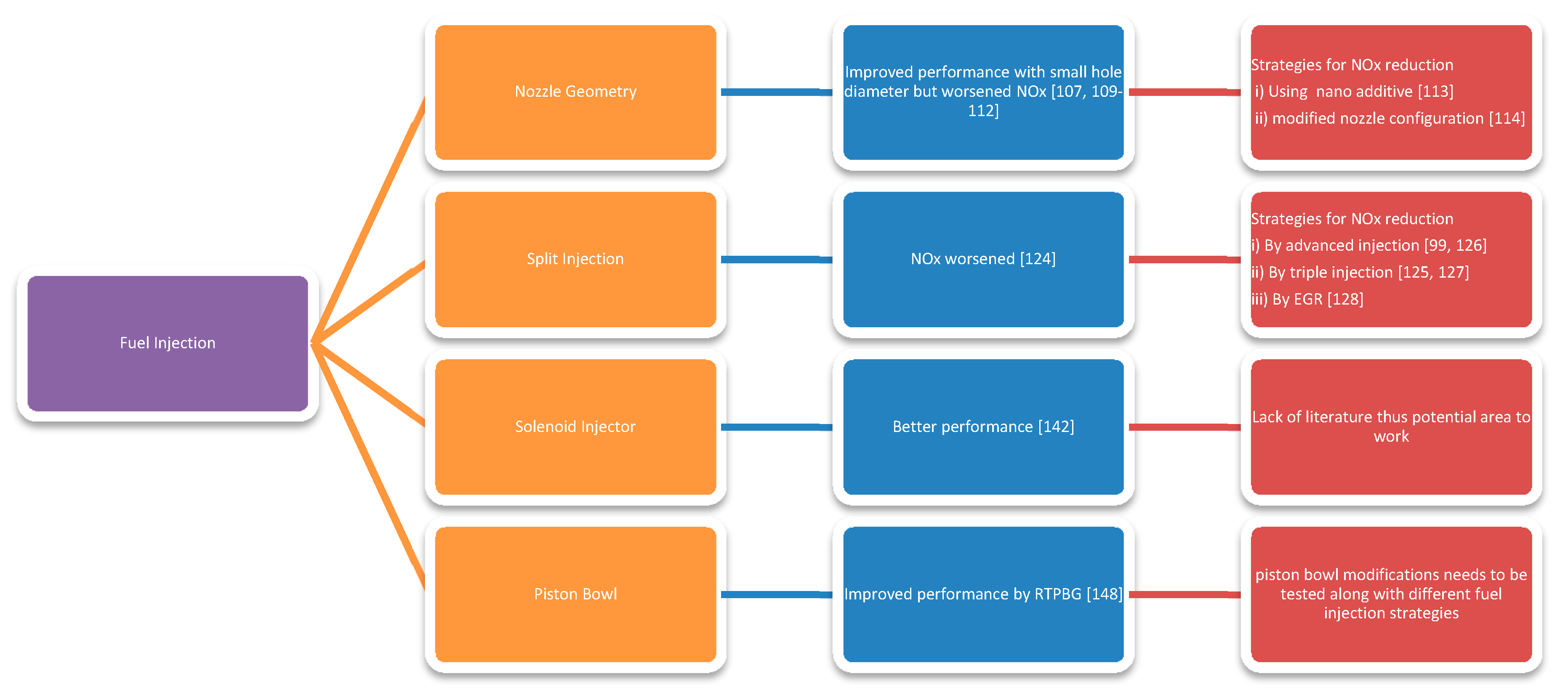

3. Fuel Injection

- Fuel must be injected at desired timing of combustion;

- The injected fuel must have correct quantity as required;

- The spray pattern should ensure rapid mixing of air with the fuel;

- The beginning and end of the fuel injection should be sharp.

3.1. Nozzle Geometry

3.2. Split Injection

3.3. Solenoid Injector

3.4. Piston Bowl

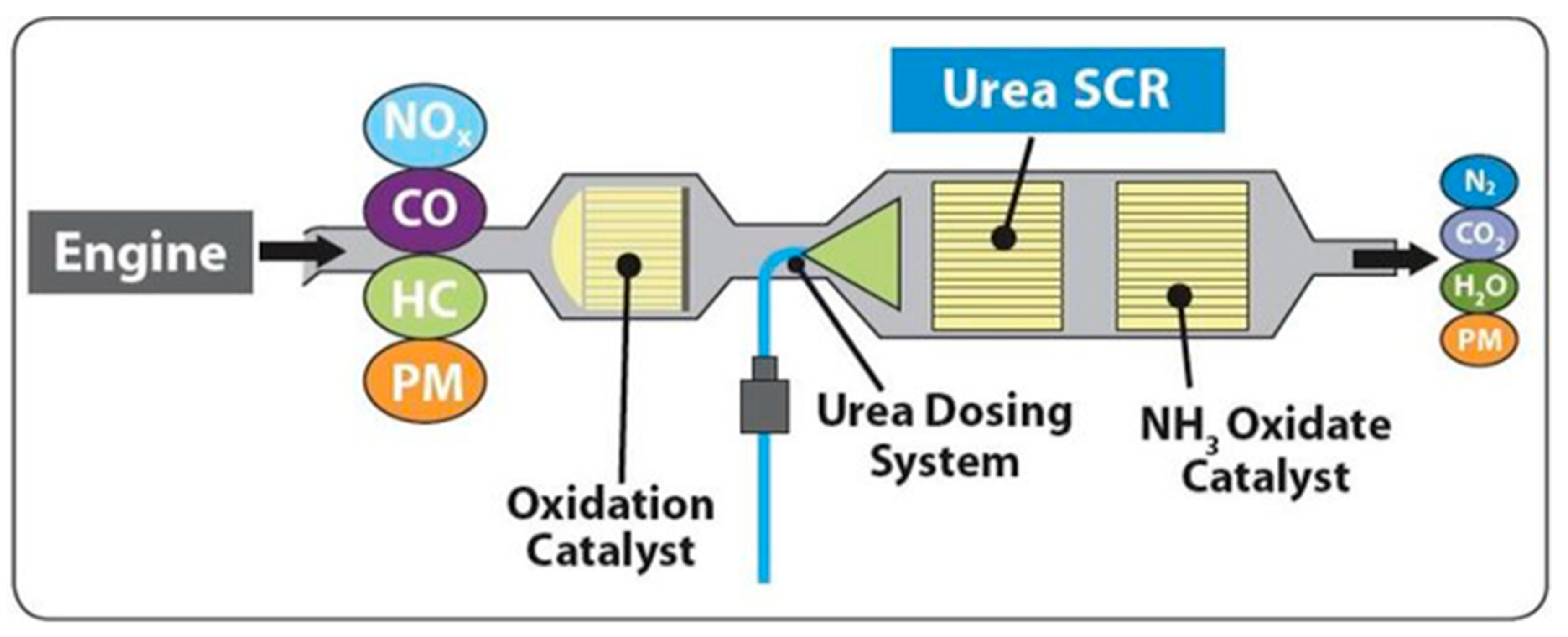

4. Exhaust Manifold

Exhaust Gas Recycle (EGR)

5. Conclusions

- Modifications in the intake manifold lead to a higher concentration of NOx but it can be minimized by using different techniques, such as water injection, steam injection, bioethanol addition, antioxidants in fuel and EGR.

- Split injection and small-hole diameter nozzle geometry give better performance with increased NOx but implementing triple injection, using an RTPBG combustion chamber, reduces NOx.

- A low rate of EGR minimizes the formation of NOx without affecting performance.

Funding

Acknowledgments

Conflicts of Interest

References

- Barreto, R.A. Fossil fuels, alternative energy and economic growth. Econ. Model. 2018, 75, 196–220. [Google Scholar] [CrossRef] [Green Version]

- Smil, V. Energy Transitions: History, Requirements, Prospects; ABC-CLIO: Santa Barbara, CA, USA, 2010. [Google Scholar]

- Kumar, N.; Varun; Chauhan, S.R. Performance and emission characteristics of biodiesel from different origins: A review. Renew. Sustain. Energy Rev. 2013, 21, 633–658. [Google Scholar] [CrossRef]

- Ong, Y.K.; Bhatia, S. The current status and perspectives of biofuel production via catalytic cracking of edible and non-edible oils. Energy 2010, 35, 111–119. [Google Scholar] [CrossRef]

- Khan, T.Y.; Atabani, A.; Badruddin, I.A.; Badarudin, A.; Khayoon, M.; Triwahyono, S. Recent scenario and technologies to utilize non-edible oils for biodiesel production. Renew. Sustain. Energy Rev. 2014, 37, 840–851. [Google Scholar] [CrossRef]

- Atabani, A.E.; Mahlia, T.M.I.; Masjuki, H.H.; Badruddin, I.A.; Yussof, H.W.; Chong, W.T.; Lee, K.T. A comparative evaluation of physical and chemical properties of biodiesel synthesized from edible and non-edible oils and study on the effect of biodiesel blending. Energy 2013, 58, 296–304. [Google Scholar] [CrossRef]

- Khan, T.Y.; Atabani, A.; Badruddin, I.A.; Ankalgi, R.; Badarudin, A. Ceiba pentandra, Nigella sativa and their blend as prospective feedstocks for biodiesel. Ind. Crop. Prod. 2015, 65, 367–373. [Google Scholar] [CrossRef] [Green Version]

- Lanjekar, R.D.; Deshmukh, D. A review of the effect of the composition of biodiesel on NOx emission, oxidative stability and cold flow properties. Renew. Sustain. Energy Rev. 2016, 54, 1401–1411. [Google Scholar] [CrossRef]

- Anwar, A.; Garforth, A. Challenges and opportunities of enhancing cold flow properties of biodiesel via heterogeneous catalysis. Fuel 2016, 173, 189–208. [Google Scholar] [CrossRef]

- Dwivedi, G.; Sharma, M. Impact of cold flow properties of biodiesel on engine performance. Renew. Sustain. Energy Rev. 2014, 31, 650–656. [Google Scholar] [CrossRef]

- Heywood, J.B. Internal Combustion Engine Fundamentals; McGraw-Hill Book Company: New York, NY, USA, 1988. [Google Scholar]

- Noor, C.M.; Noor, M.; Mamat, R. Biodiesel as alternative fuel for marine diesel engine applications: A review. Renew. Sustain. Energy Rev. 2018, 94, 127–142. [Google Scholar] [CrossRef]

- Suresh, M.; Jawahar, C.; Richard, A. A review on biodiesel production, combustion, performance, and emission characteristics of non-edible oils in variable compression ratio diesel engine using biodiesel and its blends. Renew. Sustain. Energy Rev. 2018, 92, 38–49. [Google Scholar] [CrossRef]

- Soudagar, M.E.M.; Sabri, M.F.M.; Kalam, M.; Badruddin, I.; Banapurmath, N.; Akram, N. The effect of nano-additives in diesel-biodiesel fuel blends: A comprehensive review on stability, engine performance and emission characteristics. Energy Convers. Manag. 2018, 178, 146–177. [Google Scholar] [CrossRef]

- Ramalingam, S.; Rajendran, S.; Ganesan, P.; Govindasamy, M. Effect of operating parameters and antioxidant additives with biodiesels to improve the performance and reducing the emissions in a compression ignition engine—A review. Renew. Sustain. Energy Rev. 2018, 81, 775–788. [Google Scholar] [CrossRef]

- Hosseinzadeh-Bandbafha, H.; Tabatabaei, M.; Aghbashlo, M.; Khanali, M.; Demirbas, A. A comprehensive review on the environmental impacts of diesel/biodiesel additives. Energy Convers. Manag. 2018, 174, 579–614. [Google Scholar] [CrossRef]

- Ambat, I.; Srivastava, V.; Sillanpää, M. Recent advancement in biodiesel production methodologies using various feedstock: A review. Renew. Sustain. Energy Rev. 2018, 90, 356–369. [Google Scholar] [CrossRef]

- Goel, V.; Kumar, N.; Singh, P. Impact of modified parameters on diesel engine characteristics using biodiesel: A review. Renew. Sustain. Energy Rev. 2018, 82, 2716–2729. [Google Scholar] [CrossRef]

- Khan, T.Y.; Badruddin, I.A.; Badarudin, A.; Banapurmath, N.; Ahmed, N.S.; Quadir, G.; Al-Rashed, A.A.; Khaleed, H.; Kamangar, S. Effects of engine variables and heat transfer on the performance of biodiesel fueled IC engines. Renew. Sustain. Energy Rev. 2015, 44, 682–691. [Google Scholar] [CrossRef]

- Varun; Singh, P.; Tiwari, S.K.; Singh, R.; Kumar, N. Modification in combustion chamber geometry of CI engines for suitability of biodiesel: A review. Renew. Sustain. Energy Rev. 2017, 79, 1016–1033. [Google Scholar] [CrossRef]

- Rocha, H.M.Z.; Pereira, R.D.S.; Nogueira, M.F.M.; Belchior, C.R.P.; Tostes, M.E.D.L. Experimental investigation of hydrogen addition in the intake air of compressed ignition engines running on biodiesel blend. Int. J. Hydrog. Energy 2017, 42, 4530–4539. [Google Scholar] [CrossRef]

- Aldhaidhawi, M.; Chiriac, R.; Bădescu, V.; Descombes, G.; Podevin, P. Investigation on the mixture formation, combustion characteristics and performance of a Diesel engine fueled with Diesel, Biodiesel B20 and hydrogen addition. Int. J. Hydrog. Energy 2017, 42, 16793–16807. [Google Scholar] [CrossRef] [Green Version]

- Chelladorai, P.; Varuvel, E.G.; Martin, L.J.; Bedhannan, N. Synergistic effect of hydrogen induction with biofuel obtained from winery waste (grapeseed oil) for CI engine application. Int. J. Hydrog. Energy 2018, 43, 12473–12490. [Google Scholar] [CrossRef]

- Baltacioglu, M.K.; Arat, H.T.; Özcanlı, M.; Aydin, K.; Özcanlı, M.; Aydın, K. Experimental comparison of pure hydrogen and HHO (hydroxy) enriched biodiesel (B10) fuel in a commercial diesel engine. Int. J. Hydrog. Energy 2016, 41, 8347–8353. [Google Scholar] [CrossRef]

- Parthasarathy, M.; Lalvani, J.I.J.; Dhinesh, B.; Annamalai, K.; Balasubramanian, D. Effect of hydrogen on ethanol–biodiesel blend on performance and emission characteristics of a direct injection diesel engine. Ecotoxicol. Environ. Saf. 2016, 134, 433–439. [Google Scholar] [CrossRef]

- Aydin, K.; Kenanoğlu, R. Effects of hydrogenation of fossil fuels with hydrogen and hydroxy gas on performance and emissions of internal combustion engines. Int. J. Hydrog. Energy 2018, 43, 14047–14058. [Google Scholar] [CrossRef]

- Chiriac, R.; Apostolescu, N. Emissions of a diesel engine using B20 and effects of hydrogen addition. Int. J. Hydrog. Energy 2013, 38, 13453–13462. [Google Scholar] [CrossRef]

- Sukjit, E.; Herreros, J.M.; Dearn, K.D.; Tsolakis, A.; Theinnoi, K. Effect of hydrogen on butanol–biodiesel blends in compression ignition engines. Int. J. Hydrog. Energy 2013, 38, 1624–1635. [Google Scholar] [CrossRef]

- Yaliwal, V.; Banapurmath, N.; Hosmath, R.; Khandal, S.V.; Budzianowski, W. Utilization of hydrogen in low calorific value producer gas derived from municipal solid waste and biodiesel for diesel engine power generation application. Renew. Energy 2016, 99, 1253–1261. [Google Scholar] [CrossRef]

- Korakianitis, T.; Namasivayam, A.; Crookes, R. Hydrogen dual-fuelling of compression ignition engines with emulsified biodiesel as pilot fuel. Int. J. Hydrog. Energy 2010, 35, 13329–13344. [Google Scholar] [CrossRef]

- Chandra, R.; Kumar, R. Fuel Properties of Some Stable Alcohol–Diesel Microemulsions for Their Use in Compression Ignition Engines. Energy Fuels 2007, 21, 3410–3414. [Google Scholar] [CrossRef]

- Attaphong, C.; Sabatini, D.A. Phase Behaviors of Vegetable Oil-Based Microemulsion Fuels: The Effects of Temperatures, Surfactants, Oils, and Water in Ethanol. Energy Fuels 2013, 27, 6773–6780. [Google Scholar] [CrossRef]

- Ashihmin, A.; Piskunov, M.V.; Roisman, I.; Yanovsky, V. Thermal stability control of the water-in-diesel microemulsion fuel produced by using a nonionic surfactant combined with aliphatic alcohols. J. Dispers. Sci. Technol. 2019, 41, 771–778. [Google Scholar] [CrossRef]

- Ashikhmin, A.; Piskunov, M.V.; Yanovsky, V.A.; Yan, W.-M. Properties and Phase Behavior of Water-in-Diesel Microemulsion Fuels Stabilized by Nonionic Surfactants in Combination with Aliphatic Alcohol. Energy Fuels 2020, 34, 2135–2142. [Google Scholar] [CrossRef]

- Heidari, S.; Najjar, R.; Burnens, G.; Awad, S.; Tazerout, M. Experimental Investigation of Emission, Combustion, and Energy Performance of a Novel Diesel/Colza Oil Fuel Microemulsion in a Direct-Injection Diesel Engine. Energy Fuels 2018, 32, 10923–10932. [Google Scholar] [CrossRef]

- Perumal, V.; Ilangkumaran, M. Water emulsified hybrid pongamia biodiesel as a modified fuel for the experimental analysis of performance, combustion and emission characteristics of a direct injection diesel engine. Renew. Energy 2018, 121, 623–631. [Google Scholar] [CrossRef]

- Cecrle, E.; Depcik, C.; Guo, J.; Peltier, E. Analysis of the effects of reformate (hydrogen/carbon monoxide) as an assistive fuel on the performance and emissions of used canola-oil biodiesel. Int. J. Hydrog. Energy 2012, 37, 3510–3527. [Google Scholar] [CrossRef]

- Ma, X.; Zhang, F.; Han, K.; Zhu, Z.; Liu, Y. Effects of Intake Manifold Water Injection on Combustion and Emissions of Diesel Engine. Energy Procedia 2014, 61, 777–781. [Google Scholar] [CrossRef] [Green Version]

- Mohapatra, D.; Swain, R.K.; Jena, S.P.; Acharya, S.K.; Patnaik, P.P. Effect of steam injection and FeCl3 as fuel additive on performance of thermal barrier coated diesel engine. Sustain. Environ. Res. 2018, 28, 247–255. [Google Scholar] [CrossRef]

- Patnaik, P.; Acharya, S.; Padhi, D.; Mohanty, U. Experimental investigation on CI engine performance using steam injection and ferric chloride as catalyst. Eng. Sci. Technol. Int. J. 2016, 19, 2073–2080. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Z.; Kang, Z.; Jiang, L.; Chao, Y.; Deng, J.; Hu, Z.; Li, L.; Wu, Z. Effect of direct water injection during compression stroke on thermal efficiency optimization of common rail diesel engine. Energy Procedia 2017, 142, 1251–1258. [Google Scholar] [CrossRef]

- Taghavifar, H.; Anvari, S.; Parvishi, A. Benchmarking of water injection in a hydrogen-fueled diesel engine to reduce emissions. Int. J. Hydrog. Energy 2017, 42, 11962–11975. [Google Scholar] [CrossRef]

- Şahin, Z.; Tuti, M.; Durgun, O. Experimental investigation of the effects of water adding to the intake air on the engine performance and exhaust emissions in a DI automotive diesel engine. Fuel 2014, 115, 884–895. [Google Scholar] [CrossRef]

- Tesfa, B.C.; Mishra, R.; Gu, F.; Ball, A.D. Water injection effects on the performance and emission characteristics of a CI engine operating with biodiesel. Renew. Energy 2012, 37, 333–344. [Google Scholar] [CrossRef] [Green Version]

- Parlak, A. A study on performance and exhaust emissions of the steam injected DI diesel engine running with different diesel- conola oil methyl ester blends. J. Energy Inst. 2019, 92, 717–729. [Google Scholar] [CrossRef]

- Mohankumar, S.; Senthilkumar, P. Particulate matter formation and its control methodologies for diesel engine: A comprehensive review. Renew. Sustain. Energy Rev. 2017, 80, 1227–1238. [Google Scholar] [CrossRef]

- Imran, A.; Varman, M.; Masjuki, H.; Kalam, M. Review on alcohol fumigation on diesel engine: A viable alternative dual fuel technology for satisfactory engine performance and reduction of environment concerning emission. Renew. Sustain. Energy Rev. 2013, 26, 739–751. [Google Scholar] [CrossRef]

- Ghadikolaei, M.A. Effect of alcohol blend and fumigation on regulated and unregulated emissions of IC engines—A review. Renew. Sustain. Energy Rev. 2016, 57, 1440–1495. [Google Scholar] [CrossRef]

- Telli, G.D.; Altafini, C.; Rosa, J.S.; Costa, C.A. Experimental investigation of a compression ignition engine operating on B7 direct injected and hydrous ethanol fumigation. Energy 2018, 165, 106–117. [Google Scholar] [CrossRef]

- Geo, V.E.; Sonthalia, A.; Nagarajan, G.; Nagalingam, B. Studies on performance, combustion and emission of a single cylinder diesel engine fuelled with rubber seed oil and its biodiesel along with ethanol as injected fuel. Fuel 2017, 209, 733–741. [Google Scholar] [CrossRef]

- Krishna, M.M.; Prakash, T.O.; Ushasri, P.; Janardhan, N.; Murthy, P. Experimental investigations on direct injection diesel engine with ceramic coated combustion chamber with carbureted alcohols and crude jatropha oil. Renew. Sustain. Energy Rev. 2016, 53, 606–628. [Google Scholar] [CrossRef]

- Hansdah, D.; Sivalingam, M. Bioethanol fumigation in a DI diesel engine. Fuel 2014, 130, 324–333. [Google Scholar] [CrossRef]

- Tutak, W. Bioethanol E85 as a fuel for dual fuel diesel engine. Energy Convers. Manag. 2014, 86, 39–48. [Google Scholar] [CrossRef]

- Goldsworthy, L. Fumigation of a heavy duty common rail marine diesel engine with ethanol–water mixtures. Exp. Therm. Fluid Sci. 2013, 47, 48–59. [Google Scholar] [CrossRef]

- Kane, R.D.; Eden, D.; Sridhar, N.; Maldonado, J.; Brongers, P.E.; Michaiel, P.H.; Agarwal, A.K.; Beavers, J.A. Stress Corrosion Cracking of Carbon Steel in Fuel Grade Ethanol: Review, Experience, Survey, Field Monitoring, and Laboratory Testing: Downstream Segment; American Petroleum Institute: Washington, DC, USA, 2007. [Google Scholar]

- Joseph, O.O. Structural Integrity of Materials in Fuel Ethanol Environments, in Alcohol Fuels-Current Technologies and Future Prospect; IntechOpen: London, UK, 2019. [Google Scholar]

- Şahin, Z.; Kurt, M.; Durgun, O. Experimental investigation of gasoline fumigation for different compression ratios in a diesel engine. Energy Procedia 2018, 147, 268–276. [Google Scholar] [CrossRef]

- Şahin, Z.; Durgun, O. Improving of diesel combustion-pollution-fuel economy and performance by gasoline fumigation. Energy Convers. Manag. 2013, 76, 620–633. [Google Scholar] [CrossRef]

- Hoseinpour, M.; Sadrnia, H.; Tabasizadeh, M.; Ghobadian, B. Evaluation of the effect of gasoline fumigation on performance and emission characteristics of a diesel engine fueled with B20 using an experimental investigation and TOPSIS method. Fuel 2018, 223, 277–285. [Google Scholar] [CrossRef]

- Hoseinpour, M.; Sadrnia, H.; Tabasizadeh, M.; Ghobadian, B. Energy and exergy analyses of a diesel engine fueled with diesel, biodiesel-diesel blend and gasoline fumigation. Energy 2017, 141, 2408–2420. [Google Scholar] [CrossRef]

- Calik, A.T.; Taskiran, O.O.; Mehdiyev, R. Numerical investigation of twin swirl application in diesel engine combustion. Fuel 2018, 224, 101–110. [Google Scholar] [CrossRef]

- Rakopoulos, C.D.; Kosmadakis, G.; Pariotis, E.G. Investigation of piston bowl geometry and speed effects in a motored HSDI diesel engine using a CFD against a quasi-dimensional model. Energy Convers. Manag. 2010, 51, 470–484. [Google Scholar] [CrossRef]

- Musa, O.; Xiong, C.; ChangSheng, Z. Experimental and numerical investigation on the ignition and combustion stability in solid fuel ramjet with swirling flow. Acta Astronaut. 2017, 137, 157–167. [Google Scholar] [CrossRef]

- Bari, S.; Saad, I. Performance and emissions of a compression ignition (CI) engine run with biodiesel using guide vanes at varied vane angles. Fuel 2015, 143, 217–228. [Google Scholar] [CrossRef]

- Bari, S.; Saad, I. Effect of guide vane height on the performance and emissions of a compression ignition (CI) engine run with biodiesel through simulation and experiment. Appl. Energy 2014, 136, 431–444. [Google Scholar] [CrossRef]

- Bari, S.; Johansen, P.; Alherz, A. Simulation of Improvements to In-cylinder Mixing of Biodiesel with Air by Incorporating Guide Vanes into the Air Intake System. Procedia Eng. 2015, 105, 480–487. [Google Scholar] [CrossRef] [Green Version]

- Bari, S.; Saad, I. Optimization of vane numbers through simulation and experiment, and investigation of the effect on the performance and emissions of a CI (compression ignition) engine run with biodiesel. Energy 2015, 79, 248–263. [Google Scholar] [CrossRef]

- Bari, S.; Saad, I. CFD modelling of the effect of guide vane swirl and tumble device to generate better in-cylinder air flow in a CI engine fuelled by biodiesel. Comput. Fluids 2013, 84, 262–269. [Google Scholar] [CrossRef]

- Saad, I.; Bari, S.; Hossain, S. In-Cylinder Air Flow Characteristics Generated by Guide Vane Swirl and Tumble Device to Improve Air-Fuel Mixing in Diesel Engine Using Biodiesel. Procedia Eng. 2013, 56, 363–368. [Google Scholar] [CrossRef] [Green Version]

- Saad, I.; Bari, S. Guide Vane Swirl and Tumble Device to Improve in-cylinder Air Flow of CI Engine Using Vegetable Oil. Procedia Eng. 2014, 90, 425–430. [Google Scholar] [CrossRef] [Green Version]

- Subramanian, K. A comparison of water–diesel emulsion and timed injection of water into the intake manifold of a diesel engine for simultaneous control of NO and smoke emissions. Energy Convers. Manag. 2011, 52, 849–857. [Google Scholar] [CrossRef]

- Tauzia, X.; Maiboom, A.; Shah, S.R. Experimental study of inlet manifold water injection on combustion and emissions of an automotive direct injection Diesel engine. Energy 2010, 35, 3628–3639. [Google Scholar] [CrossRef]

- Kumarappa, S.; Prabhukumar, G.P. Improving the performance of two stroke spark ignition engine by direct electronic CNG injection. Jordan J. Mech. Ind. Eng. 2008, 2, 169–174. [Google Scholar]

- Hazar, H. Effects of biodiesel on a low heat loss diesel engine. Renew. Energy 2009, 34, 1533–1537. [Google Scholar] [CrossRef]

- Hazar, H. Cotton methyl ester usage in a diesel engine equipped with insulated combustion chamber. Appl. Energy 2010, 87, 134–140. [Google Scholar] [CrossRef]

- Hazar, H.; Öztürk, U. The effects of Al2O3–TiO2 coating in a diesel engine on performance and emission of corn oil methyl ester. Renew. Energy 2010, 35, 2211–2216. [Google Scholar] [CrossRef]

- Chan, S.H.; Khor, K.A. The Effect of Thermal Barrier Coated Piston Crown on Engine Characteristics. J. Mater. Eng. Perform. 2000, 9, 103–109. [Google Scholar] [CrossRef]

- Schulz, U.; Leyens, C.; Fritscher, K.; Peters, M.; Saruhan-Brings, B.; Lavigne, O.; Dorvaux, J.-M.; Poulain, M.; Mévrel, R.; Caliez, M. Some recent trends in research and technology of advanced thermal barrier coatings. Aerosp. Sci. Technol. 2003, 7, 73–80. [Google Scholar] [CrossRef]

- Peters, M.; Leyens, C.; Schulz, U.; Kaysser, W.A. EB-PVD Thermal Barrier Coatings for Aeroengines and Gas Turbines. Adv. Eng. Mater. 2001, 3, 193–204. [Google Scholar] [CrossRef]

- Yao, M.; Ma, T.; Wang, H.; Zheng, Z.; Liu, H.-F.; Zhang, Y. A theoretical study on the effects of thermal barrier coating on diesel engine combustion and emission characteristics. Energy 2018, 162, 744–752. [Google Scholar] [CrossRef]

- Karthickeyan, V. Effect of cetane enhancer on Moringa oleifera biodiesel in a thermal coated direct injection diesel engine. Fuel 2019, 235, 538–550. [Google Scholar] [CrossRef]

- Aydın, S.; Sayın, C. Impact of thermal barrier coating application on the combustion, performance and emissions of a diesel engine fueled with waste cooking oil biodiesel–diesel blends. Fuel 2014, 136, 334–340. [Google Scholar] [CrossRef]

- Aydin, S.; Sayin, C.; Aydin, H.; Aydin, H. Investigation of the usability of biodiesel obtained from residual frying oil in a diesel engine with thermal barrier coating. Appl. Therm. Eng. 2015, 80, 212–219. [Google Scholar] [CrossRef]

- Balat, M.; Balat, H. Progress in biodiesel processing. Appl. Energy 2010, 87, 1815–1835. [Google Scholar] [CrossRef]

- Lin, L.; Cunshan, Z.; Vittayapadung, S.; Xiangqian, S.; Dong, M. Opportunities and challenges for biodiesel fuel. Appl. Energy 2011, 88, 1020–1031. [Google Scholar] [CrossRef]

- Szabados, G.; Bereczky, Á. Experimental investigation of physicochemical properties of diesel, biodiesel and TBK-biodiesel fuels and combustion and emission analysis in CI internal combustion engine. Renew. Energy 2018, 121, 568–578. [Google Scholar] [CrossRef]

- Sani, S.; Kaisan, M.U.; Kulla, D.; Obi, A.; Jibrin, A.; Ashok, B. Determination of physico chemical properties of biodiesel from Citrullus lanatus seeds oil and diesel blends. Ind. Crop. Prod. 2018, 122, 702–708. [Google Scholar] [CrossRef]

- Aminian, A.; Zarenezhad, B. Accurate predicting the viscosity of biodiesels and blends using soft computing models. Renew. Energy 2018, 120, 488–500. [Google Scholar] [CrossRef]

- Du, E.; Cai, L.; Huang, K.; Tang, H.; Xu, X.; Tao, R. Reducing viscosity to promote biodiesel for energy security and improve combustion efficiency. Fuel 2018, 211, 194–196. [Google Scholar] [CrossRef]

- Gülüm, M.; Bilgin, A. A comprehensive study on measurement and prediction of viscosity of biodiesel-diesel-alcohol ternary blends. Energy 2018, 148, 341–361. [Google Scholar] [CrossRef]

- Gulum, M.; Bilgin, A.; Cakmak, A. Comparison of optimum reaction parameters of corn oil biodiesels produced by using sodium hydroxide (NaOH) and potassium hydroxide (KOH). J. Fac. Eng. Archit. Gazi Univ. 2015, 30, 503–511. [Google Scholar]

- Gülüm, M.; Bilgin, A. Two-term power models for estimating kinematic viscosities of different biodiesel-diesel fuel blends. Fuel Process. Technol. 2016, 149, 121–130. [Google Scholar] [CrossRef]

- Gülüm, M.; Bilgin, A. Density, flash point and heating value variations of corn oil biodiesel–diesel fuel blends. Fuel Process. Technol. 2015, 134, 456–464. [Google Scholar] [CrossRef]

- Hazar, H.; Aydin, H. Performance and emission evaluation of a CI engine fueled with preheated raw rapeseed oil (RRO)–diesel blends. Appl. Energy 2010, 87, 786–790. [Google Scholar] [CrossRef]

- Prasad, C.M.V.; Krishna, M.V.S.M.; Reddy, C.P.; Mohan, K.R. Performance evaluation of non-edible vegetable oils as substitute fuels in low heat rejection diesel engines. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2000, 214, 181–187. [Google Scholar] [CrossRef]

- Mekonen, M.W.; Sahoo, N. Effect of fuel preheating with blended fuels and exhaust gas recirculation on diesel engine operating parameters. Renew. Energy Focus 2018, 26, 58–70. [Google Scholar] [CrossRef]

- Prabu, S.S.; Asokan, M.; Prathiba, S.; Ahmed, S.; Puthean, G. Effect of additives on performance, combustion and emission behavior of preheated palm oil/diesel blends in DI diesel engine. Renew. Energy 2018, 122, 196–205. [Google Scholar] [CrossRef]

- Yilmaz, N. Effects of intake air preheat and fuel blend ratio on a diesel engine operating on biodiesel–methanol blends. Fuel 2012, 94, 444–447. [Google Scholar] [CrossRef]

- Yehliu, K.; Boehman, A.L.; Armas, O. Emissions from different alternative diesel fuels operating with single and split fuel injection. Fuel 2010, 89, 423–437. [Google Scholar] [CrossRef]

- Agarwal, A.K.; Singh, A.P.; Maurya, R.K.; Shukla, P.C.; Dhar, A.; Srivastava, D.K. Combustion characteristics of a common rail direct injection engine using different fuel injection strategies. Int. J. Therm. Sci. 2018, 134, 475–484. [Google Scholar] [CrossRef]

- Ma, Z.; Huang, Z.; Li, C.; Wang, X.; Miao, H. Effects of Fuel Injection Timing on Combustion and Emission Characteristics of a Diesel Engine Fueled with Diesel−Propane Blends. Energy Fuels 2007, 21, 1504–1510. [Google Scholar] [CrossRef]

- Agarwal, A.K.; Dhar, A.; Srivastava, D.K.; Maurya, R.K.; Singh, A.P. Effect of fuel injection pressure on diesel particulate size and number distribution in a CRDI single cylinder research engine. Fuel 2013, 107, 84–89. [Google Scholar] [CrossRef]

- Zhao, L.; Torelli, R.; Zhu, X.; Scarcelli, R.; Som, S.; Schmidt, H.; Naber, J.; Lee, S.-Y. An Experimental and Numerical Study of Diesel Spray Impingement on a Flat Plate. SAE Int. J. Fuels Lubr. 2017, 10, 407–422. [Google Scholar] [CrossRef]

- Qianjun, S.; He, W.; Wenhua, Z.; Bo, L.; Xia, Z.; Hang, X. Study on using electronic controlled fuel injection to improve the power performance of LPG fueled engine. Chin. Intern. Combust. Engine Eng. 2002, 5, 003. [Google Scholar]

- Erkuş, B.; Surmen, A.; Karamangil, M.I. A comparative study of carburation and injection fuel supply methods in an LPG-fuelled SI engine. Fuel 2013, 107, 511–517. [Google Scholar] [CrossRef]

- Kannan, G.; Anand, R. Effect of injection pressure and injection timing on DI diesel engine fuelled with biodiesel from waste cooking oil. Biomass Bioenergy 2012, 46, 343–352. [Google Scholar] [CrossRef]

- Babu, D.; Karvembu, R.; Anand, R. Impact of split injection strategy on combustion, performance and emissions characteristics of biodiesel fuelled common rail direct injection assisted diesel engine. Energy 2018, 165, 577–592. [Google Scholar] [CrossRef]

- Yang, K.; Nishida, K.; Ogata, Y.; Yamakawa, H. Characteristics of fuel evaporation, mixture formation and combustion of 2D cavity impinging spray under high-pressure split injection. Fuel 2018, 234, 746–756. [Google Scholar] [CrossRef]

- Martínez-Martínez, S.; Sánchez-Cruz, F.; Riesco-Ávila, J.; Gallegos-Muñoz, A.; Aceves, S.M. Liquid penetration length in direct diesel fuel injection. Appl. Therm. Eng. 2008, 28, 1756–1762. [Google Scholar] [CrossRef]

- Payri, R.; Garcia, J.; Salvador, F.; Gimeno, J.; Rubio, F.J.S. Using spray momentum flux measurements to understand the influence of diesel nozzle geometry on spray characteristics. Fuel 2005, 84, 551–561. [Google Scholar] [CrossRef]

- Chen, Z.; He, Z.; Shang, W.; Duan, L.; Zhou, H.; Guo, G.; Guan, W. Experimental study on the effect of nozzle geometry on string cavitation in real-size optical diesel nozzles and spray characteristics. Fuel 2018, 232, 562–571. [Google Scholar] [CrossRef]

- Schmidt, D.P.; Corradini, M.L. The internal flow of diesel fuel injector nozzles: A review. Int. J. Engine Res. 2001, 2, 1–22. [Google Scholar] [CrossRef]

- Wei, H.; Chen, X.; Wang, G.; Zhou, L.; An, S.; Shu, G. Effect of swirl flow on spray and combustion characteristics with heavy fuel oil under two-stroke marine engine relevant conditions. Appl. Therm. Eng. 2017, 124, 302–314. [Google Scholar] [CrossRef]

- Yao, C.; Geng, P.; Yin, Z.; Hu, J.; Chen, D.; Ju, Y. Impacts of nozzle geometry on spray combustion of high pressure common rail injectors in a constant volume combustion chamber. Fuel 2016, 179, 235–245. [Google Scholar] [CrossRef]

- Kumar, M.V.; Babu, A.V.; Kumar, P.R. Experimental investigation on the effects of diesel and mahua biodiesel blended fuel in direct injection diesel engine modified by nozzle orifice diameters. Renew. Energy 2018, 119, 388–399. [Google Scholar] [CrossRef]

- Shivashimpi, M.; Alur, S.; Topannavar, S.; Dodamani, B. Combined effect of combustion chamber shapes and nozzle geometry on the performance and emission characteristics of C.I. engine operated on Pongamia. Energy 2018, 154, 17–26. [Google Scholar] [CrossRef]

- Yaliwal, V.; Banapurmath, N.; Gireesh, N.; Hosmath, R.; Donateo, T.; Tewari, P. Effect of nozzle and combustion chamber geometry on the performance of a diesel engine operated on dual fuel mode using renewable fuels. Renew. Energy 2016, 93, 483–501. [Google Scholar] [CrossRef]

- Sayin, C.; Gumus, M.; Canakci, M. Influence of injector hole number on the performance and emissions of a DI diesel engine fueled with biodiesel–diesel fuel blends. Appl. Therm. Eng. 2013, 61, 121–128. [Google Scholar] [CrossRef]

- Park, S.H.; Yoon, S.H.; Lee, C.S. Effects of multiple-injection strategies on overall spray behavior, combustion, and emissions reduction characteristics of biodiesel fuel. Appl. Energy 2011, 88, 88–98. [Google Scholar] [CrossRef]

- Tumbal, A.V.; Banapurmath, N.; Tewari, P.G. Effect of injection timing, injector opening pressure, injector nozzle geometry, and swirl on the performance of a direct injection, compression-ignition engine fuelled with honge oil methyl ester (HOME). Int. J. Automot. Technol. 2016, 17, 35–50. [Google Scholar] [CrossRef]

- Vairamuthu, G.; Sundarapandian, S.; Kailasanathan, C.; Thangagiri, B. Experimental investigation on the effects of cerium oxide nanoparticle on Calophyllum inophyllum (Punnai) biodiesel blended with diesel fuel in DI diesel engine modified by nozzle geometry. J. Energy Inst. 2016, 89, 668–682. [Google Scholar] [CrossRef]

- Lahane, S.; Subramanian, K. Impact of nozzle holes configuration on fuel spray, wall impingement and NOx emission of a diesel engine for biodiesel–diesel blend (B20). Appl. Therm. Eng. 2014, 64, 307–314. [Google Scholar] [CrossRef]

- Vasileva, T.K.; Kamburov, A.D.; Vasileva, V.D. Blended Learning in Autotronic system. In Proceedings of the ELECTRONICS’2005, Sozopol, Bulgaria, 21–23 September 2005; Volume 2, pp. 97–102. [Google Scholar]

- Khandal, S.; Banapurmath, N.; Gaitonde, V.N.; Hiremath, S. Paradigm shift from mechanical direct injection diesel engines to advanced injection strategies of diesel homogeneous charge compression ignition (HCCI) engines—A comprehensive review. Renew. Sustain. Energy Rev. 2017, 70, 369–384. [Google Scholar] [CrossRef]

- Park, S.; Kim, H.J.; Shin, D.H.; Lee, J.-T. Effects of various split injection strategies on combustion and emissions characteristics in a single-cylinder diesel engine. Appl. Therm. Eng. 2018, 140, 422–431. [Google Scholar] [CrossRef]

- Badami, M.; Mallamo, F.; Millo, F.; Rossi, E.E. Influence of Multiple Injection Strategies on Emissions, Combustion Noise and BSFC of a DI Common Rail Diesel Engine. SAE Tech. Pap. Ser. 2002, 111, 1118–1129. [Google Scholar]

- Sindhu, R.; Rao, G.A.P.; Murthy, K.M. Effective reduction of NOx emissions from diesel engine using split injections. Alex. Eng. J. 2018, 57, 1379–1392. [Google Scholar] [CrossRef]

- Li, X.; Zhou, H.; Zhao, L.M.; Su, L.; Xu, H.; Liu, F. Effect of split injections coupled with swirl on combustion performance in DI diesel engines. Energy Convers. Manag. 2016, 129, 180–188. [Google Scholar] [CrossRef]

- Sun, Y.; Yu, X.; Dong, W.; Chen, H.; Hu, Y. Effect of split injection on particle number (PN) emissions in GDI engine at fast-idle through integrated analysis of optics and mechanics. Energy 2018, 165, 55–67. [Google Scholar] [CrossRef]

- Yang, B.; Zeng, K. Effects of natural gas injection timing and split pilot fuel injection strategy on the combustion performance and emissions in a dual-fuel engine fueled with diesel and natural gas. Energy Convers. Manag. 2018, 168, 162–169. [Google Scholar] [CrossRef]

- Jeon, J.; Park, S. Effects of pilot injection strategies on the flame temperature and soot distributions in an optical CI engine fueled with biodiesel and conventional diesel. Appl. Energy 2015, 160, 581–591. [Google Scholar] [CrossRef]

- Dhar, A.; Agarwal, A.K. Experimental investigations of the effect of pilot injection on performance, emissions and combustion characteristics of Karanja biodiesel fuelled CRDI engine. Energy Convers. Manag. 2015, 93, 357–366. [Google Scholar] [CrossRef]

- Qi, D.; Leick, M.; Liu, Y.; Lee, C.-F.F. Effect of EGR and injection timing on combustion and emission characteristics of split injection strategy DI-diesel engine fueled with biodiesel. Fuel 2011, 90, 1884–1891. [Google Scholar] [CrossRef]

- Plamondon, E.; Seers, P. Parametric study of pilot–main injection strategies on the performance of a light-duty diesel engine fueled with diesel or a WCO biodiesel–diesel blend. Fuel 2019, 236, 1273–1281. [Google Scholar] [CrossRef]

- How, H.; Masjuki, H.H.; Kalam, M.; Teoh, Y. Influence of injection timing and split injection strategies on performance, emissions, and combustion characteristics of diesel engine fueled with biodiesel blended fuels. Fuel 2018, 213, 106–114. [Google Scholar] [CrossRef]

- Le, T.; Masjuki, H.H.; How, H.; Kalam, M.; Yu, K.H.; Alabdulkarem, A. Effect of two-stage injection dwell angle on engine combustion and performance characteristics of a common-rail diesel engine fueled with coconut oil methyl esters-diesel fuel blends. Fuel 2018, 234, 227–237. [Google Scholar]

- Baumgarten, C. Mixture Formation in Internal Combustion Engines; Springer Science & Business Media: New York, NY, USA, 2006. [Google Scholar]

- Pierpont, D.A.; Reitz, R.D. Effects of Injection Pressure and Nozzle Geometry on D.I. Diesel Emissions and Performance. SAE Tech. Pap. Ser. 1995, 104, 1041–1050. [Google Scholar]

- Mahr, B. Future and Potential of Diesel Injection Systems, in Thermo-and Fluid Dynamic Processes in Diesel Engines 2; Springer: Berlin/Heidelberg, Germany, 2004; pp. 3–17. [Google Scholar]

- Mulemane, A.; Han, J.-S.; Lu, P.-H.; Yoon, S.-J.; Lai, M.-C. Modeling Dynamic Behavior of Diesel Fuel Injection Systems. SAE Tech. Pap. Ser. 2004. [Google Scholar] [CrossRef]

- Bianchi, G.M.; Falfari, S.; Brusiani, F.; Pelloni, P.; Osbat, G.; Parotto, M. Numerical Investigation of Critical Issues in Multiple-Injection Strategy Operated by a New C.R. Fast-Actuation Solenoid Injector. SAE Tech. Pap. Ser. 2005. [Google Scholar] [CrossRef]

- Beierer, P.; Huhtala, K.; Lehto, E.; Vilenius, M. Study of the Impact of System Characteristics on Pressure Oscillations in a Common Rail Diesel Fuel Injection System. SAE Tech. Pap. Ser. 2005. [Google Scholar] [CrossRef]

- Payri, R.; Salvador, F.; Gimeno, J.; De La Morena, J.; Rubio, F.J.S. Influence of injector technology on injection and combustion development—Part 1: Hydraulic characterization. Appl. Energy 2011, 88, 1068–1074. [Google Scholar] [CrossRef]

- Yu, W.; Yang, W.; Mohan, B.; Tay, K.L.; Zhao, F. Macroscopic spray characteristics of wide distillation fuel (WDF). Appl. Energy 2017, 185, 1372–1382. [Google Scholar] [CrossRef]

- Payri, R.; Salvador, F.; Gimeno, J.; De La Morena, J.; Rubio, F.J.S. Influence of injector technology on injection and combustion development—Part 2: Combustion analysis. Appl. Energy 2011, 88, 1130–1139. [Google Scholar] [CrossRef]

- Jo, I.S.; Chung, M.C.; Kim, S.M.; Sung, G.S.; Lee, J.W. Experimental investigation and hydraulic simulation of dynamic effects on diesel injection characteristics in indirect acting piezo-driven injector with bypass-circuit system. Int. J. Automot. Technol. 2015, 16, 173–182. [Google Scholar] [CrossRef]

- Chung, M.; Kim, J.; Kim, S.; Sung, G.; Lee, J. Effects of hydraulic flow and spray characteristics on diesel combustion in CR direct-injection engine with indirect acting Piezo injector. J. Mech. Sci. Technol. 2015, 29, 2517–2528. [Google Scholar] [CrossRef]

- D’Ambrosio, S.; Ferrari, A. Diesel engines equipped with piezoelectric and solenoid injectors: Hydraulic performance of the injectors and comparison of the emissions, noise and fuel consumption. Appl. Energy 2018, 211, 1324–1342. [Google Scholar]

- Salvador, F.; Gimeno, J.; De La Morena, J.; Carreres, M.; Rubio, F.J.S. Using one-dimensional modeling to analyze the influence of the use of biodiesels on the dynamic behavior of solenoid-operated injectors in common rail systems: Results of the simulations and discussion. Energy Convers. Manag. 2012, 54, 122–132. [Google Scholar] [CrossRef] [Green Version]

- Payri, R.; Salvador, F.; Martí-Aldaraví, P.; Martínez-López, J.; Rubio, F.J.S. Using one-dimensional modeling to analyse the influence of the use of biodiesels on the dynamic behavior of solenoid-operated injectors in common rail systems: Detailed injection system model. Energy Convers. Manag. 2012, 54, 90–99. [Google Scholar] [CrossRef] [Green Version]

- Park, S.W. Optimization of combustion chamber geometry for stoichiometric diesel combustion using a micro genetic algorithm. Fuel Process. Technol. 2010, 91, 1742–1752. [Google Scholar] [CrossRef]

- Lee, S.; Park, S. Optimization of the piston bowl geometry and the operating conditions of a gasoline-diesel dual-fuel engine based on a compression ignition engine. Energy 2017, 121, 433–448. [Google Scholar] [CrossRef]

- Kakaee, A.-H.; Nasiri-Toosi, A.; Partovi, B.; Paykani, A. Effects of piston bowl geometry on combustion and emissions characteristics of a natural gas/diesel RCCI engine. Appl. Therm. Eng. 2016, 102, 1462–1472. [Google Scholar] [CrossRef]

- Gafoor, C.A.; Gupta, R. Numerical investigation of piston bowl geometry and swirl ratio on emission from diesel engines. Energy Convers. Manag. 2015, 101, 541–551. [Google Scholar] [CrossRef]

- Khan, S.; Panua, R.; Bose, P.K. Combined effects of piston bowl geometry and spray pattern on mixing, combustion and emissions of a diesel engine: A numerical approach. Fuel 2018, 225, 203–217. [Google Scholar] [CrossRef]

- Channappagoudra, M.; Ramesh, K.; Manavendra, G.; Manavendra, G. Comparative study of standard engine and modified engine with different piston bowl geometries operated with B20 fuel blend. Renew. Energy 2019, 133, 216–232. [Google Scholar] [CrossRef]

- Galloni, E.; Fontana, G.; Palmaccio, R. Effects of exhaust gas recycle in a downsized gasoline engine. Appl. Energy 2013, 105, 99–107. [Google Scholar] [CrossRef]

- Ayodhya, A.S.; Lamani, V.T.; Bedar, P.; Kumar, G.N. Effect of exhaust gas recirculation on a CRDI engine fueled with waste plastic oil blend. Fuel 2018, 227, 394–400. [Google Scholar] [CrossRef]

- Rahman, M.A.; Ruhul, A.; Aziz, M.; Ahmed, R. Experimental exploration of hydrogen enrichment in a dual fuel CI engine with exhaust gas recirculation. Int. J. Hydrog. Energy 2017, 42, 5400–5409. [Google Scholar] [CrossRef]

- Millo, F.; Giacominetto, P.F.; Bernardi, M.G. Analysis of different exhaust gas recirculation architectures for passenger car Diesel engines. Appl. Energy 2012, 98, 79–91. [Google Scholar] [CrossRef]

- Wang, H.; Zheng, Z.; Yao, M.; Reitz, R.D. An Experimental and Numerical Study on the Effects of Fuel Properties on the Combustion and Emissions of Low-Temperature Combustion Diesel Engines. Combust. Sci. Technol. 2014, 186, 1795–1815. [Google Scholar] [CrossRef]

- Lee, H.; Park, Y.; Sunwoo, M. Observer design for exhaust gas recirculation rate estimation in a variable-geometry turbocharger diesel engine using a model reference identification scheme. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2014, 228, 1688–1699. [Google Scholar] [CrossRef]

- Wang, B.; Wang, Z.; Shuai, S.; Yang, H.; Wang, J. Combustion and emission characteristics of Multiple Premixed Compression Ignition (MPCI) fuelled with naphtha and gasoline in wide load range. Energy Convers. Manag. 2014, 88, 79–87. [Google Scholar] [CrossRef]

- Li, W.; Liu, Z.; Wang, Z. Experimental and theoretical analysis of the combustion process at low loads of a diesel natural gas dual-fuel engine. Energy 2016, 94, 728–741. [Google Scholar] [CrossRef]

- Rakopoulos, C.D.; Rakopoulos, D.C.; Mavropoulos, G.C.; Kosmadakis, G. Investigating the EGR rate and temperature impact on diesel engine combustion and emissions under various injection timings and loads by comprehensive two-zone modeling. Energy 2018, 157, 990–1014. [Google Scholar] [CrossRef]

- Yasin, M.H.M.; Mamat, R.; Yusop, A.F.; Idris, D.M.N.D.; Yusaf, T.; Rasul, M.; Najafi, G. Study of a Diesel Engine Performance with Exhaust Gas Recirculation (EGR) System Fuelled with Palm Biodiesel. Energy Procedia 2017, 110, 26–31. [Google Scholar] [CrossRef] [Green Version]

- Shi, X.; Liu, B.; Zhang, C.; Hu, J.; Zeng, Q. A study on combined effect of high EGR rate and biodiesel on combustion and emission performance of a diesel engine. Appl. Therm. Eng. 2017, 125, 1272–1279. [Google Scholar] [CrossRef]

- Can, Ö.; Öztürk, E.; Solmaz, H.; Aksoy, F.; Çinar, C.; Yücesu, H.S. Combined effects of soybean biodiesel fuel addition and EGR application on the combustion and exhaust emissions in a diesel engine. Appl. Therm. Eng. 2016, 95, 115–124. [Google Scholar] [CrossRef]

- Sakhare, N.M.; Shelke, P.S.; Lahane, S. Experimental Investigation of Effect of Exhaust Gas Recirculation and Cottonseed B20 Biodiesel Fuel on Diesel Engine. Procedia Technol. 2016, 25, 869–876. [Google Scholar] [CrossRef]

- Mahla, S.K.; Dhir, A.; Gill, K.J.; Cho, H.M.; Lim, H.-C.; Chauhan, B.S.; Hee, C.L. Influence of EGR on the simultaneous reduction of NOx-smoke emissions trade-off under CNG-biodiesel dual fuel engine. Energy 2018, 152, 303–312. [Google Scholar] [CrossRef]

- Chaichan, M.T. Performance and emission characteristics of CIE using hydrogen, biodiesel, and massive EGR. Int. J. Hydrog. Energy 2018, 43, 5415–5435. [Google Scholar] [CrossRef]

- Praveen, A.; Rao, G.L.N.; Balakrishna, B. Performance and emission characteristics of a diesel engine using Calophyllum Inophyllum biodiesel blends with TiO2 nanoadditives and EGR. Egypt. J. Pet. 2018, 27, 731–738. [Google Scholar] [CrossRef]

- Solaimuthu, C.; Ganesan, V.; Senthilkumar, D.; Ramasamy, K. Emission reductions studies of a biodiesel engine using EGR and SCR for agriculture operations in developing countries. Appl. Energy 2015, 138, 91–98. [Google Scholar] [CrossRef]

- Arfaoui, J.; Boudali, L.K.; Ghorbel, A.; Delahay, G. Effect of vanadium on the behaviour of unsulfated and sulfated Ti-pillared clay catalysts in the SCR of NO by NH3. Catal. Today 2009, 142, 234–238. [Google Scholar] [CrossRef]

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khan, T.M.Y. A Review of Performance-Enhancing Innovative Modifications in Biodiesel Engines. Energies 2020, 13, 4395. https://doi.org/10.3390/en13174395

Khan TMY. A Review of Performance-Enhancing Innovative Modifications in Biodiesel Engines. Energies. 2020; 13(17):4395. https://doi.org/10.3390/en13174395

Chicago/Turabian StyleKhan, T. M. Yunus. 2020. "A Review of Performance-Enhancing Innovative Modifications in Biodiesel Engines" Energies 13, no. 17: 4395. https://doi.org/10.3390/en13174395