Evolution of Interior and Exterior Bearing Structures of the Deep-Soft-Rock Roadway: From Theory to Field Test in the Pingdingshan Mining Area

Abstract

:1. Introduction

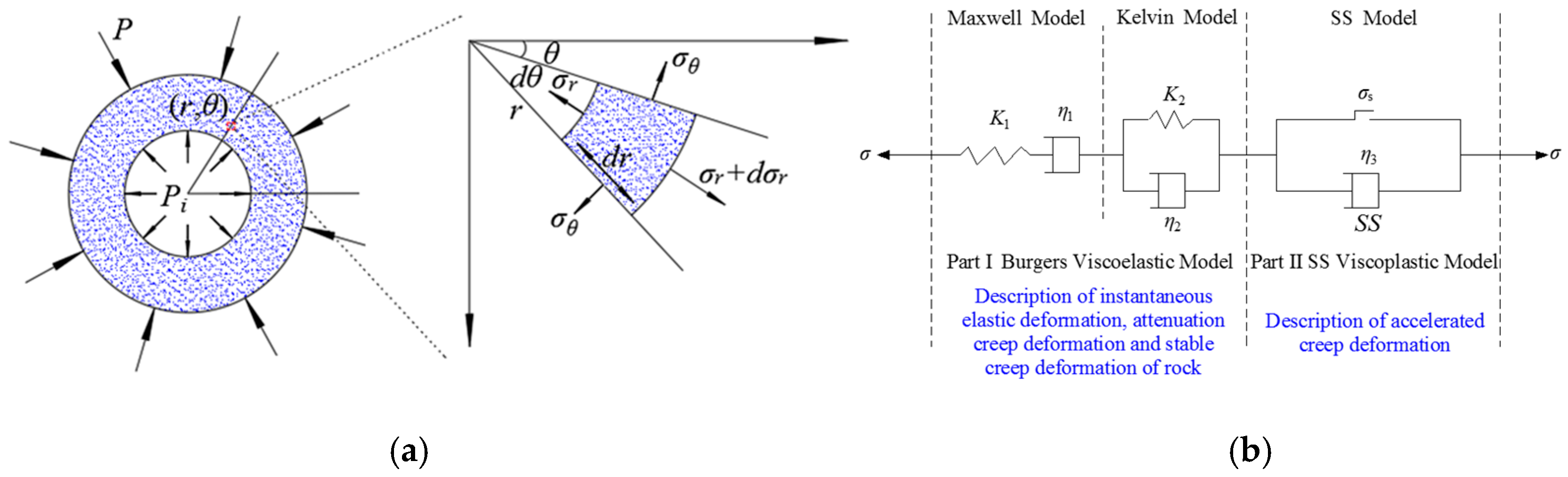

2. Characteristics of Interior and Exterior Bearing Structures of the Roadway Surrounding Rock

2.1. Interior and Exterior Bearing Structures

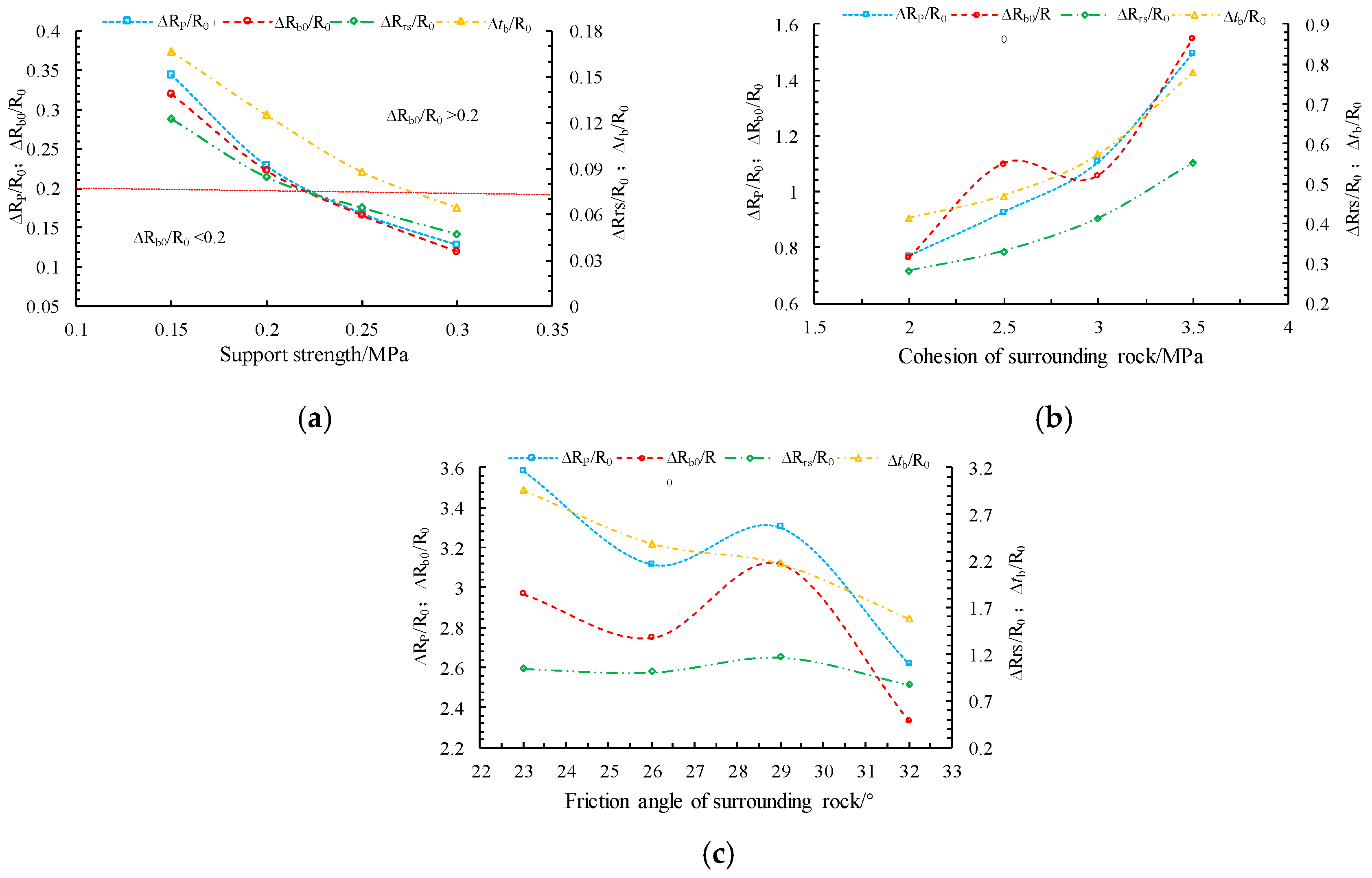

2.2. Influencing Factors and Sensitivity Analysis of the Bearing Structures

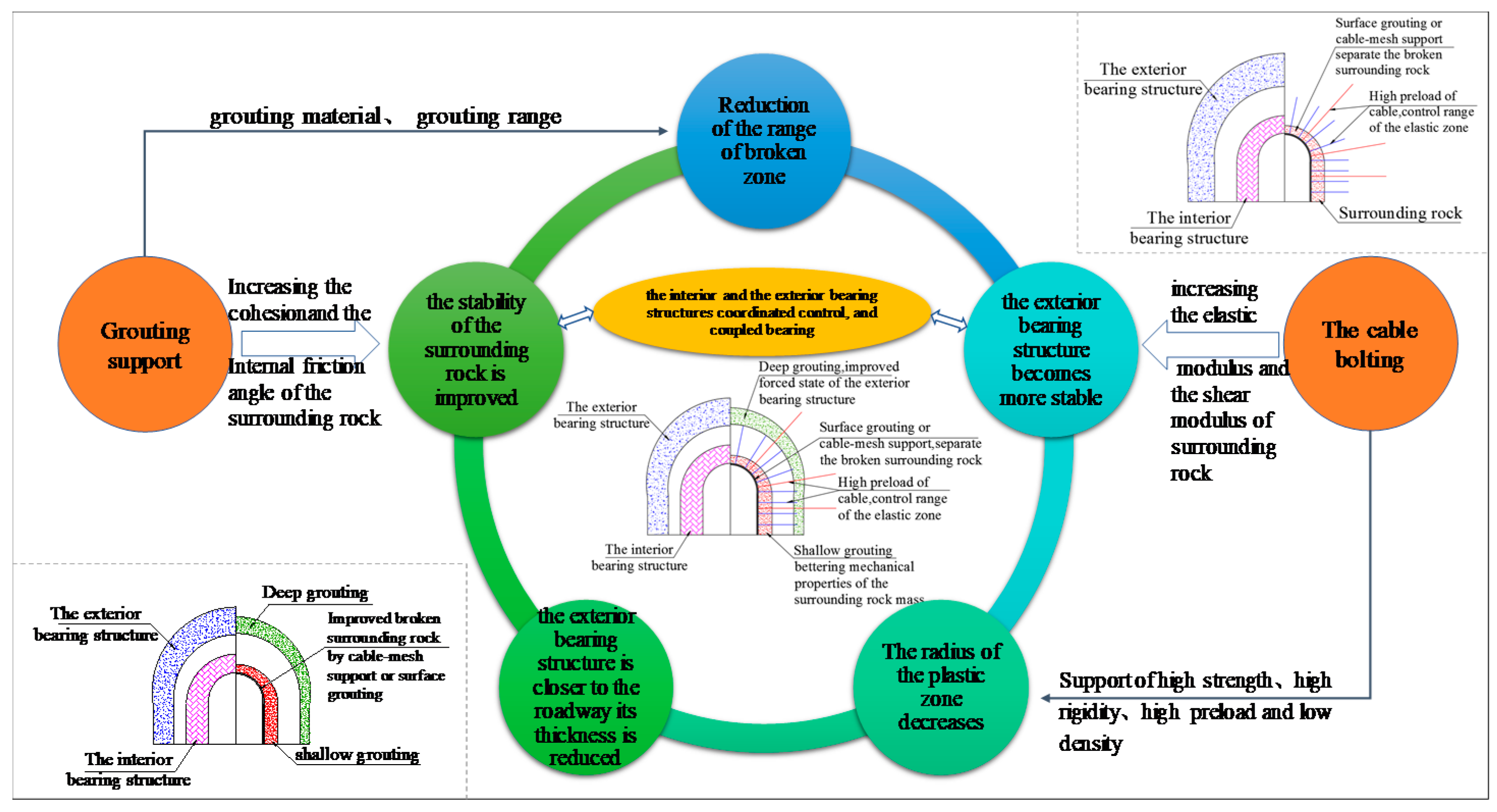

2.3. Evolution of the Bearing Structures

3. Evolution of the Interior and Exterior Bearing Structures of the Deep-Soft-Rock Roadway

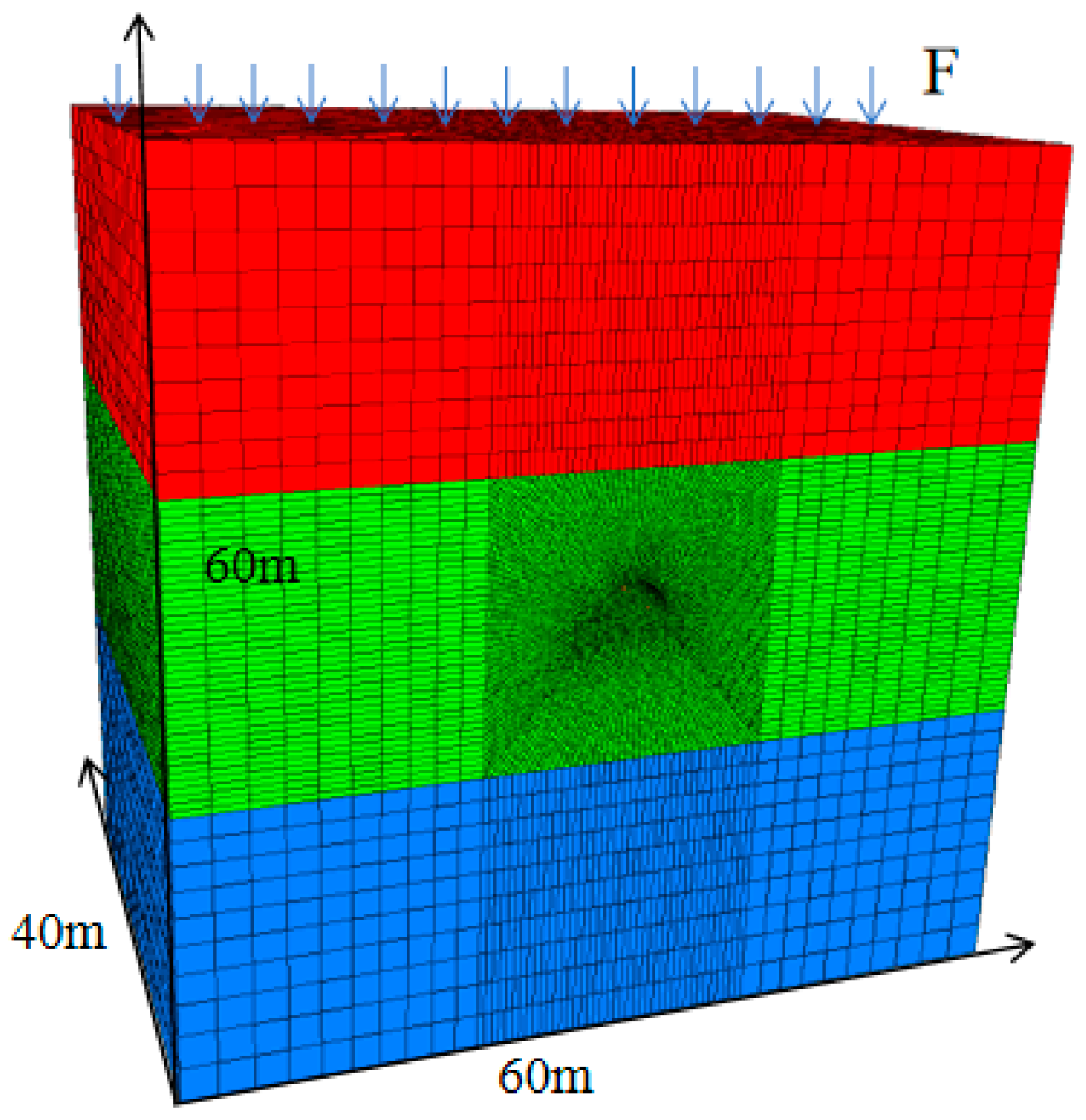

3.1. Numerical Model

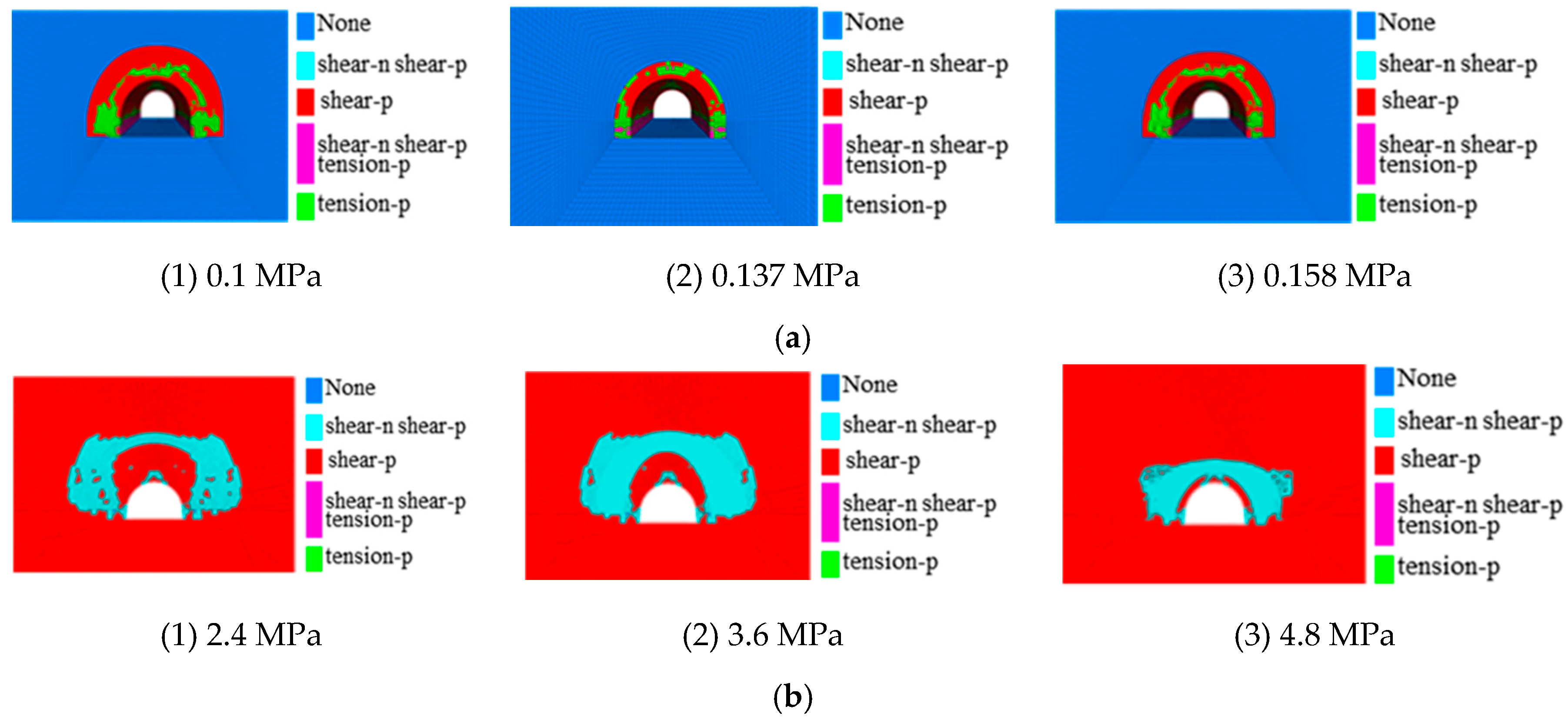

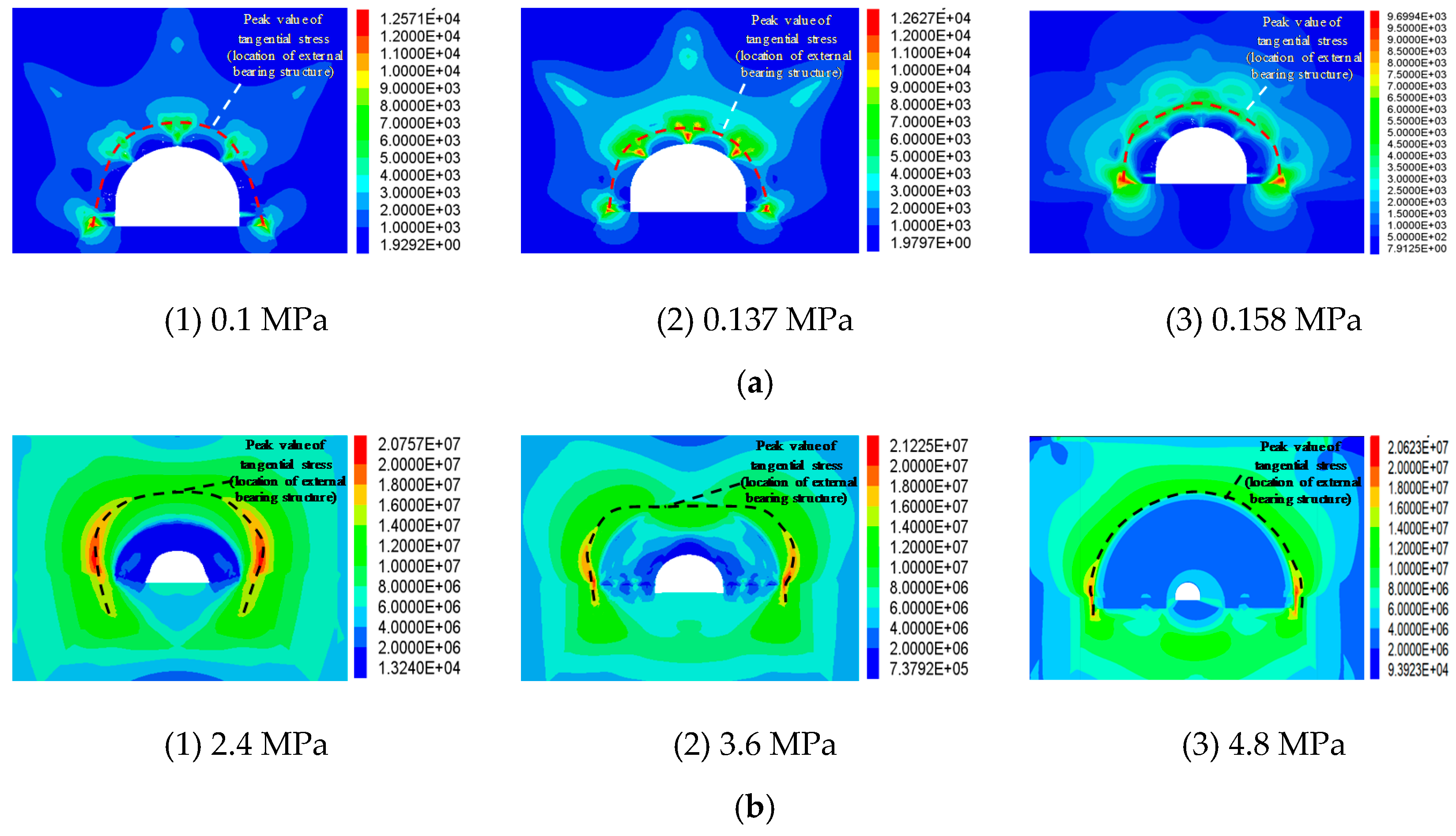

3.2. Bearing Structure Evolution

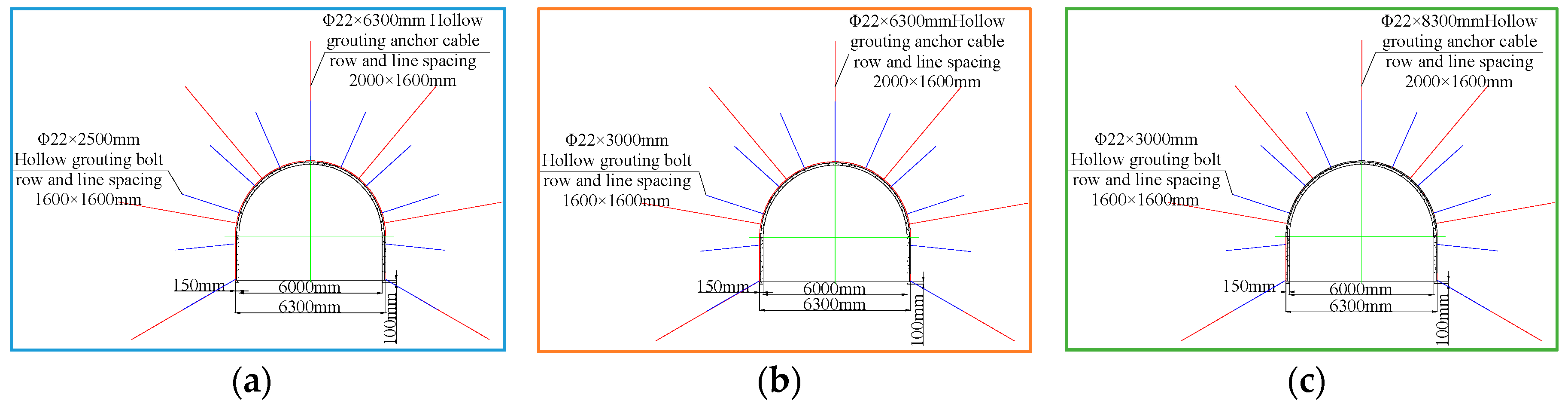

4. Evolution of the Bearing Structures under Different Support Strengths

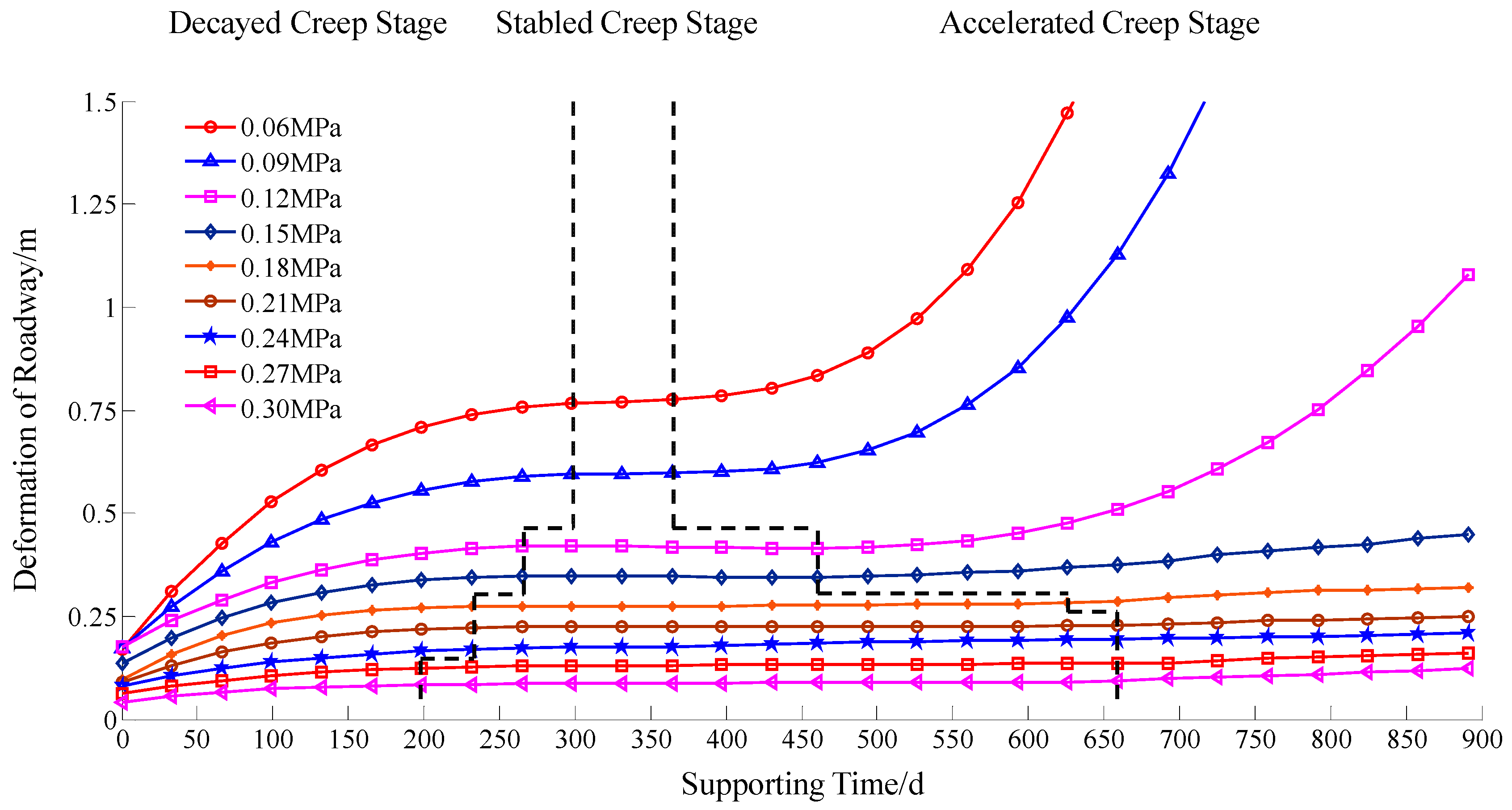

4.1. Deformation of Deep-Soft-Rock Roadway under Different Support Strengths

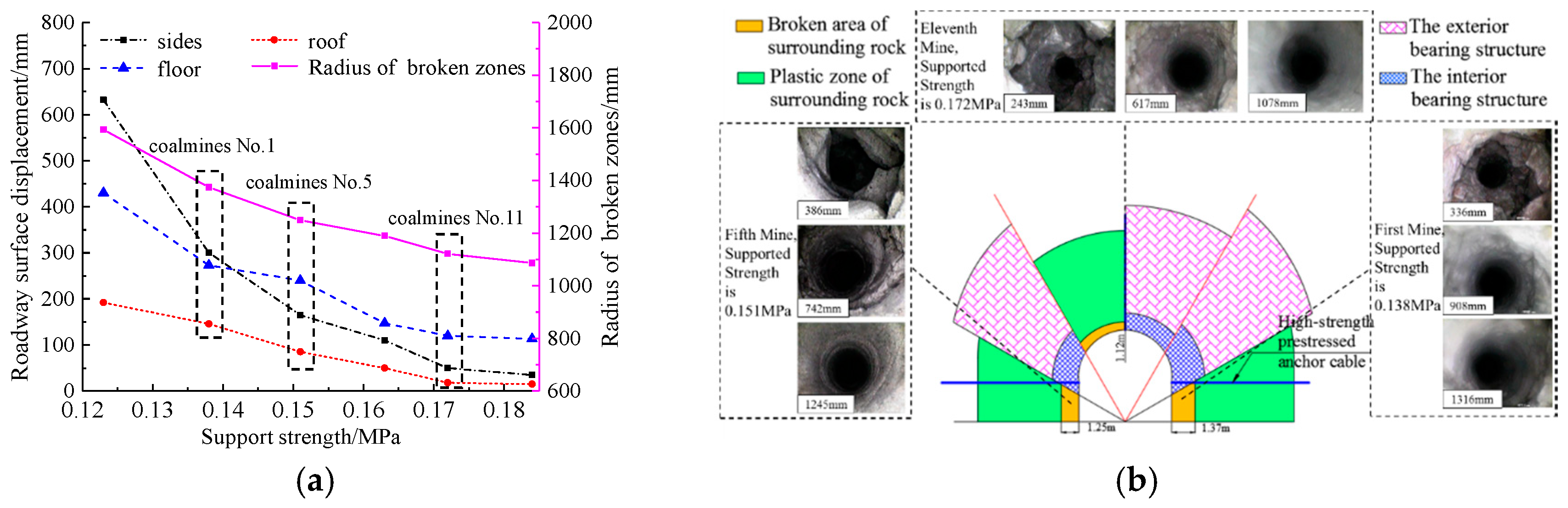

4.2. Field Test and Bearing Structure Evolution

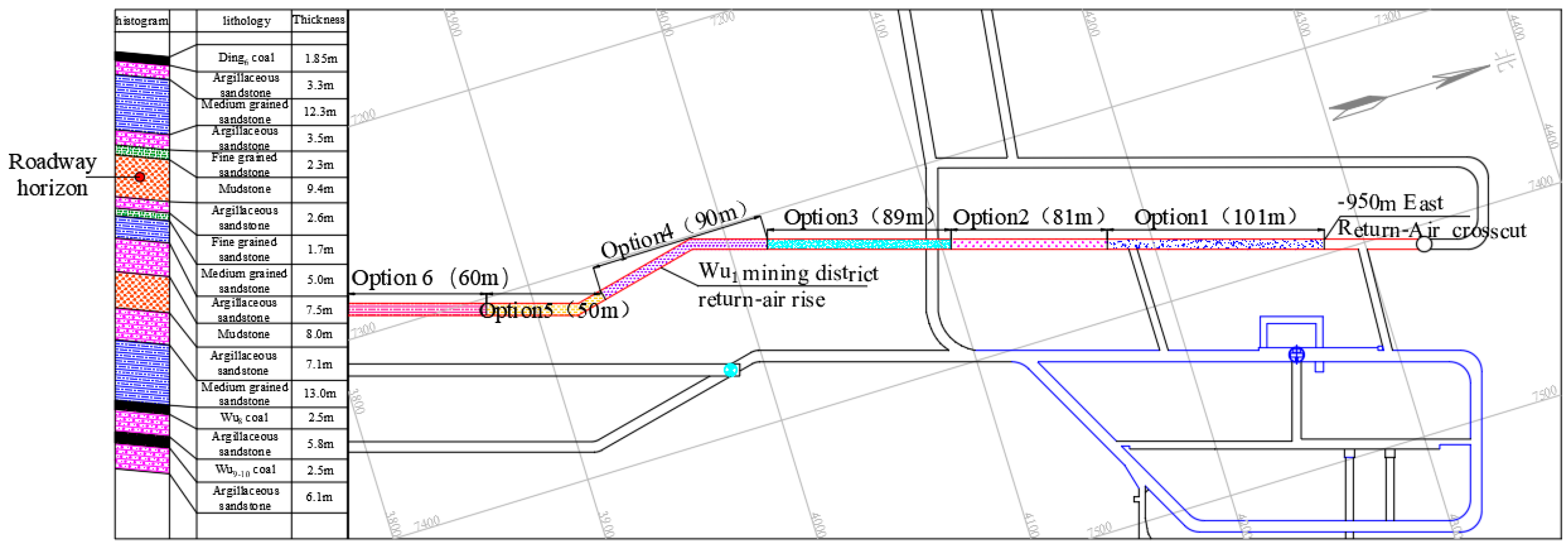

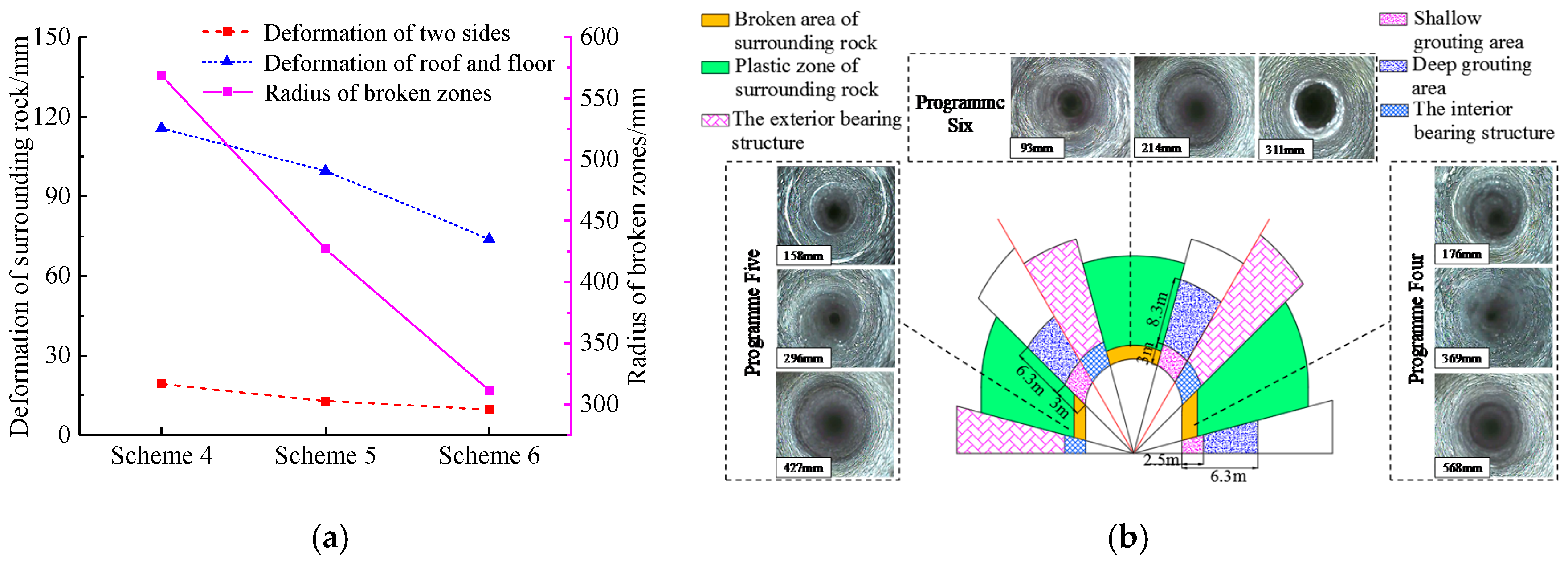

5. In-Situ Observation on the Evolution of the Bearing Structures under Different Grouting Methods

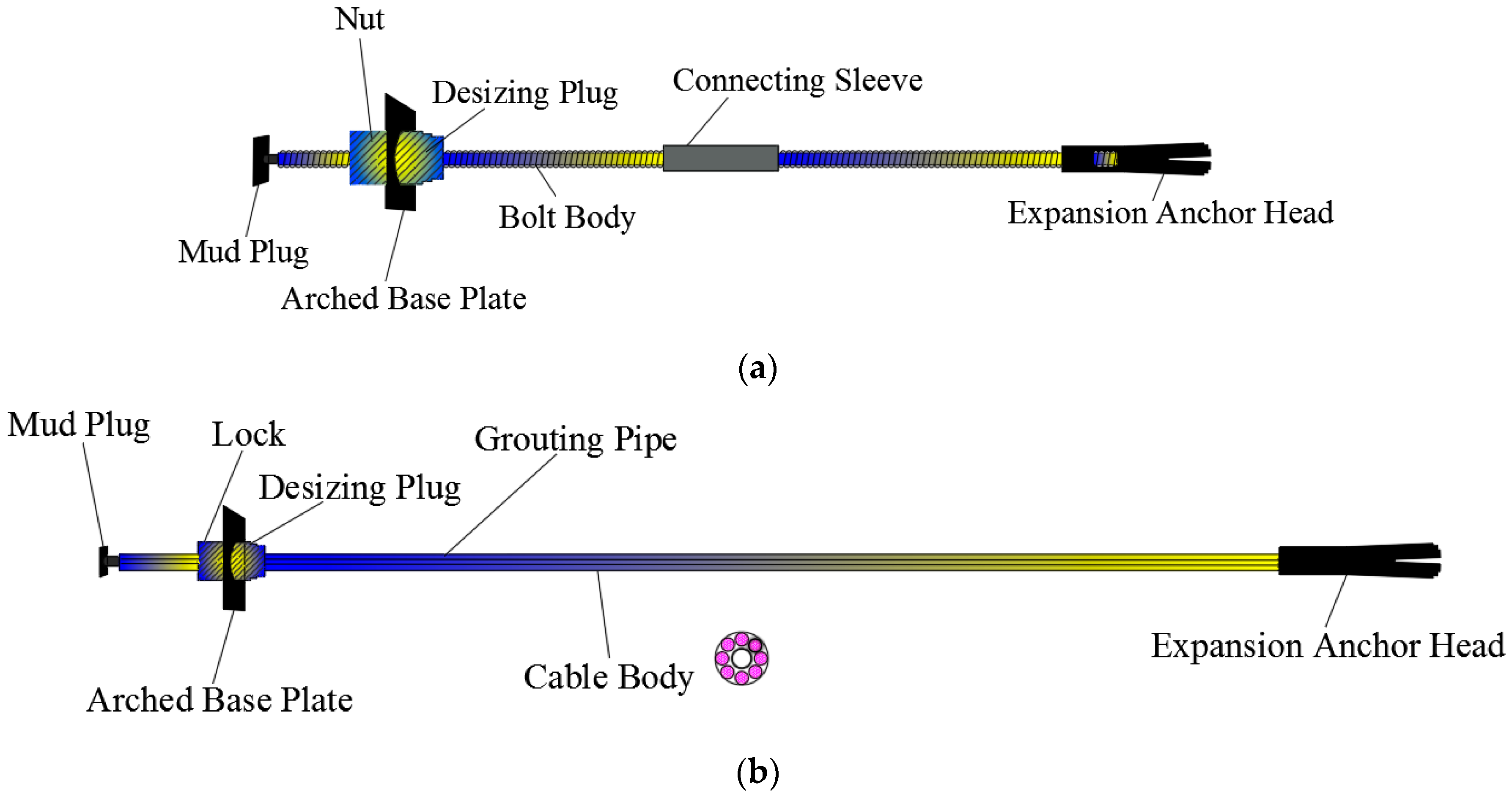

5.1. Grouting Support and Materials

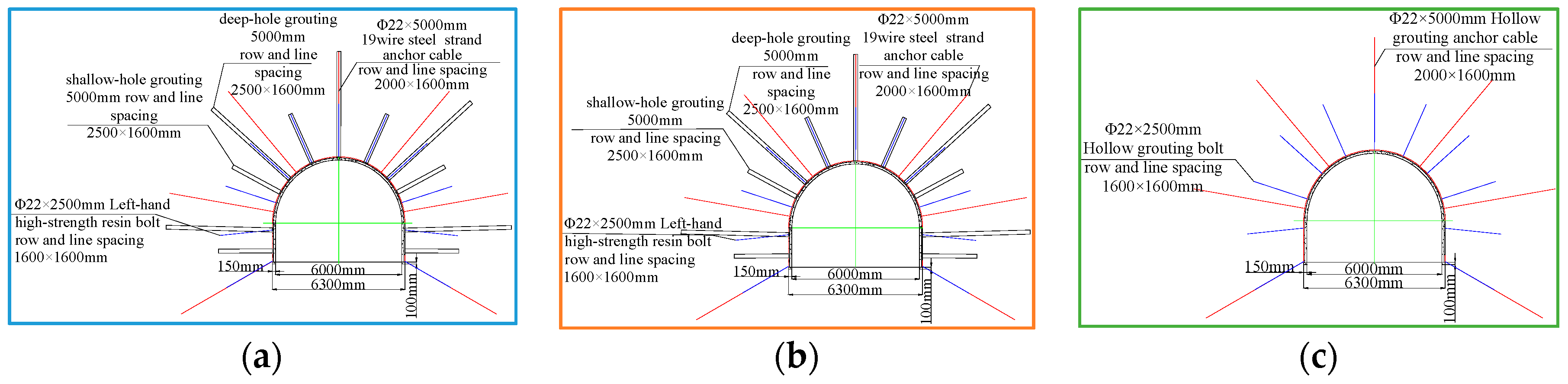

5.2. Grouting Support in the Field

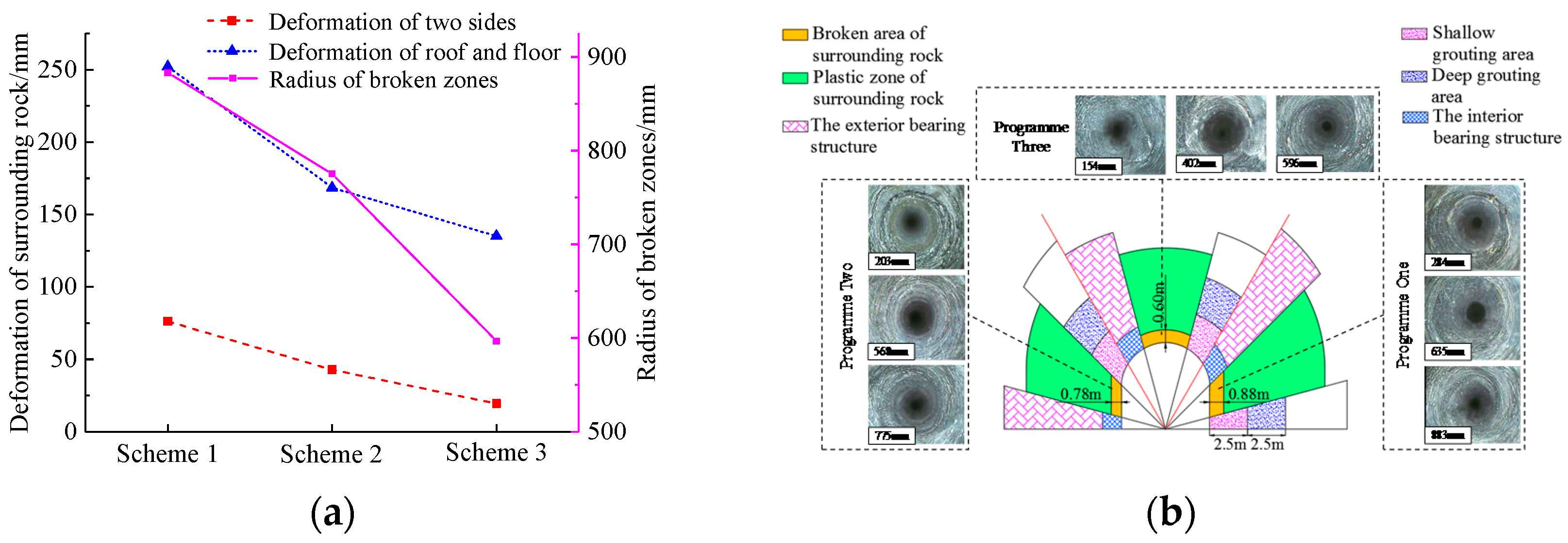

5.3. Effect of Grouting Schemes on the Bearing Structures

5.4. Influence of the Grouting Area on the Bearing Structures

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Brantut, N.; Heap, M.J.; Meredith, P.G.; Baud, P. Time-dependent cracking and brittle creep in crustal rocks: A review. J. Struct. Geol. 2013, 52, 17–43. [Google Scholar] [CrossRef]

- Zhiliang, F.; Hua, G.; Yanfa, G. Creep Damage Characteristics of Soft Rock under Disturbance Loads. J. China Univ. Geosci. 2008, 19, 292–297. [Google Scholar] [CrossRef]

- Li, Q.; Shi, W.; Yang, R. Deformation mechanisms in a coal mine roadway in extremely swelling soft rock. Springer Plus 2016, 5, 1310. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nazimko, V.V.; Peng, S.S.; Lapteev, A.A.; Alexandrov, S.N.; Sazhnev, V.P. Damage mechanics around a tunnel due to incremental ground pressure. Int. J. Rock Mech. Min. Sci. 1997, 34, 222. [Google Scholar] [CrossRef]

- Yang, S.Q.; Chen, M.; Jing, H.W.; Chen, K.F.; Meng, B. A case study on large deformation failure mechanism of deep soft rock roadway in Xin. Eng. Geol. 2017, 217, 89–101. [Google Scholar] [CrossRef]

- Yang, X.J.; Wang, E.Y.; Wang, Y.J.; Gao, Y.; Wang, P. A Study of the Large Deformation Mechanism and Control Techniques for Deep Soft Rock Roadways. Sustainability 2018, 10, 1100. [Google Scholar] [CrossRef] [Green Version]

- Ghazvinian, A.; Sarfarazi, V.; Schubert, W.; Blumel, M. A Study of the Failure Mechanism of Planar Non-Persistent Open Joints Using PFC2D. Rock Mech. Rock Eng. 2012, 45, 677–693. [Google Scholar] [CrossRef]

- Kang, H. Analysis on load bearing ring in surrounding rock of roadway. Rock Soil Mech. 1996, 17, 84–89. [Google Scholar]

- Kang, H. Theory of load bearing ring in surrounding rock of roadway. Mech. Eng. 1997, 19, 35–37. [Google Scholar]

- Zhao, Z.H.; Wang, W.M.; Wang, L. Response models of weakly consolidated soft rock roadway under different interior pressures considering dilatancy effect. J. Cent. South Univ. 2013, 20, 3736–3744. [Google Scholar] [CrossRef]

- Zhao, Y.; Liu, N.; Zheng, X.; Zhang, N. Mechanical model for controlling floor heave in deep roadways with U-shaped steel closed support. Int. J. Min. Sci. Technol. 2015, 25, 713–720. [Google Scholar] [CrossRef]

- Xie, G.; Li, C.; Wang, L. Mechanical characteristics and practical application on stress shell of roadway surrounding rock. J. China Coal Soc. 2016, 41, 2986–2992. [Google Scholar]

- Tan, X.J.; Chen, W.Z.; Liu, H.Y. A combined supporting system based on foamed concrete and U-shaped steel for underground coal mine roadways undergoing large deformations. Tunn. Undergr. Space Technol. 2017, 68, 196–210. [Google Scholar] [CrossRef]

- He, M.; Gong, W.; Wang, J.; Qi, P.; Tao, Z.; Du, S.; Peng, Y. Development of a novel energy-absorbing bolt with extraordinarily large elongation and constant resistance. Int. J. Rock Mech. Min. Sci. 2014, 67, 29–42. [Google Scholar] [CrossRef]

- Wang, Q.; Pan, R.; Jiang, B.; Li, S.C.; He, M.C.; Sun, H.B.; Wang, L.; Qin, Q.; Yu, H.C.; Luan, Y.C. Study on failure mechanism of roadway with soft rock in deep coal mine and confined concrete support system. Eng. Fail. Anal. 2017, 81, 155–177. [Google Scholar] [CrossRef]

- Jiao, Y.Y.; Song, L.; Wang, X.Z.; Adoko, A.C. Improvement of the U-shaped steel sets for supporting the roadways in loose thick coal seam. Int. J. Rock Mech. Min. Sci. 2013, 60, 19–25. [Google Scholar] [CrossRef]

- Kang, H.P.; Lin, J.; Fan, M.J. Investigation on support pattern of a coal mine roadway within soft rocks—A case study. Int. J. Coal Geol. 2015, 140, 31–40. [Google Scholar] [CrossRef]

- Jiang, B.; Wang, L.; Lu, Y.; Gu, S.; Sun, S. Failure mechanism analysis and support design for deep composite soft rock roadway: A case study of the Yangcheng coal mine in China. Shock Vib. 2015, 2015. [Google Scholar] [CrossRef]

- Shen, B. Coal Mine Roadway Stability in Soft Rock: A Case Study. Rock Mech. Rock Eng. 2014, 47, 2225–2238. [Google Scholar] [CrossRef]

- Qin, D.D.; Wang, X.F.; Zhang, D.S.; Chen, X.Y. Study on Surrounding Rock-Bearing Structure and Associated Control Mechanism of Deep Soft Rock Roadway Under Dynamic Pressure. Sustainability 2019, 11, 1892. [Google Scholar] [CrossRef] [Green Version]

- Hao, L.D. Study on the application of bolting and grouting technology in soft rock roadway. Hydraul. Coal Min. Pipeline Transp. 2010, 3, 12–15. [Google Scholar]

- Xu, W.Y.; Yang, S.Q.; Xie, S.Y.; Shao, J.; Wang, Y.F. Investigation on triaxial rheological mechanical properties of greenschist specimen (II): Model analysis. Yantu Lixue Rock Soil Mech. 2005, 26, 693–698. [Google Scholar]

- Wang, L.L.; Gao, M.S.; Zhang, L.S.; Cheng, J.F.; Zhao, Y. Grouting/Shotcreting/Bolting Support Technology of Gateway with Extreme Loose Coal Mass. Coal Sci. Technol. 2012, 40, 13–16. [Google Scholar]

| Location | Lithology | UCS (MPa) | Elastic Modulus (GPa) | Poisson’s Ratio | Cohesion (MPa) | Internal Friction Angle (°) |

|---|---|---|---|---|---|---|

| Roof | Sandstone | 28.36 | 21.27 | 0.31 | 5.11 | 39.69 |

| Roadway | Sandy mudstone | 12.35 | 10.76 | 0.38 | 4.69 | 18.48 |

| Floor | Sandstone | 29.64 | 20.85 | 0.28 | 5.09 | 39.59 |

| Roadway | Buried Depth (m) | Cable Bolt Support | Surface Displacement of Surrounding Rock | |||||

|---|---|---|---|---|---|---|---|---|

| Column Spacing (mm) | Row Spacing (mm) | Preload (kN) | Support Strength (MPa) | Side Convergence (mm) | Roof Convergence (mm) | Floor Heave (mm) | ||

| No. 13 F15-17-13031 Working face machine roadway | 863 | 850 | 1000 | 80 | 0.123 | 632 | 192 | 430 |

| No. 1 Level-3 transportation roadway | 876 | 700 | 800 | 70 | 0.138 | 300 | 146 | 273 |

| No. 5 F-3 downhill rail roadway | 858 | 800 | 800 | 90 | 0.151 | 165 | 85 | 240 |

| No. 1 -517 cross drift | 869 | 700 | 700 | 70 | 0.163 | 110 | 50 | 147 |

| No. 11 Level-2-D-ventilation roadway | 872 | 800 | 800 | 100 | 0.172 | 50 | 18 | 120 |

| No. 1 Level-3-F-ventilation uphill roadway | 883 | 700 | 700 | 80 | 0.184 | 35 | 15 | 113 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, Q.; Wang, X.; Chen, X.; Qin, D.; Chang, Z. Evolution of Interior and Exterior Bearing Structures of the Deep-Soft-Rock Roadway: From Theory to Field Test in the Pingdingshan Mining Area. Energies 2020, 13, 4357. https://doi.org/10.3390/en13174357

Huang Q, Wang X, Chen X, Qin D, Chang Z. Evolution of Interior and Exterior Bearing Structures of the Deep-Soft-Rock Roadway: From Theory to Field Test in the Pingdingshan Mining Area. Energies. 2020; 13(17):4357. https://doi.org/10.3390/en13174357

Chicago/Turabian StyleHuang, Qingxian, Xufeng Wang, Xuyang Chen, Dongdong Qin, and Zechao Chang. 2020. "Evolution of Interior and Exterior Bearing Structures of the Deep-Soft-Rock Roadway: From Theory to Field Test in the Pingdingshan Mining Area" Energies 13, no. 17: 4357. https://doi.org/10.3390/en13174357